1. Introduction

Additive manufacturing, often called 3D printing, is a transformative process in producing three-dimensional products. 3D printing is a technique that involves creating physical objects from a CAD (Computer-Aided Design) model. There are various processes in which material is deposited layer by layer, allowing the individual layers to join together to form a final 3D object. Additive manufacturing encompasses a range of advanced rapid prototyping techniques, including but not limited to material jetting, binder jetting, extrusion, vat photopolymerization, powder fusion, sheet lamination, and energy deposition [

1,

2]. 3D printing technology has applications across various industries, including food processing, which is referred to as Food Layered Manufacturing (FLM). The convergence of digital gastronomy and 3D printing technology has facilitated the advancement of FLM techniques [

1,

3].

Among the different methods for additive manufacturing, the extrusion-based technique is recognised as the most appropriate for 3D food printing applications [

4]. This fundamental technique is used in 3D printing, where food material is extruded through a nozzle and layered to create a three-dimensional object [

5]. The process consists of four essential steps: preparing materials, extruding ink, depositing it, and forming a 3D structure [

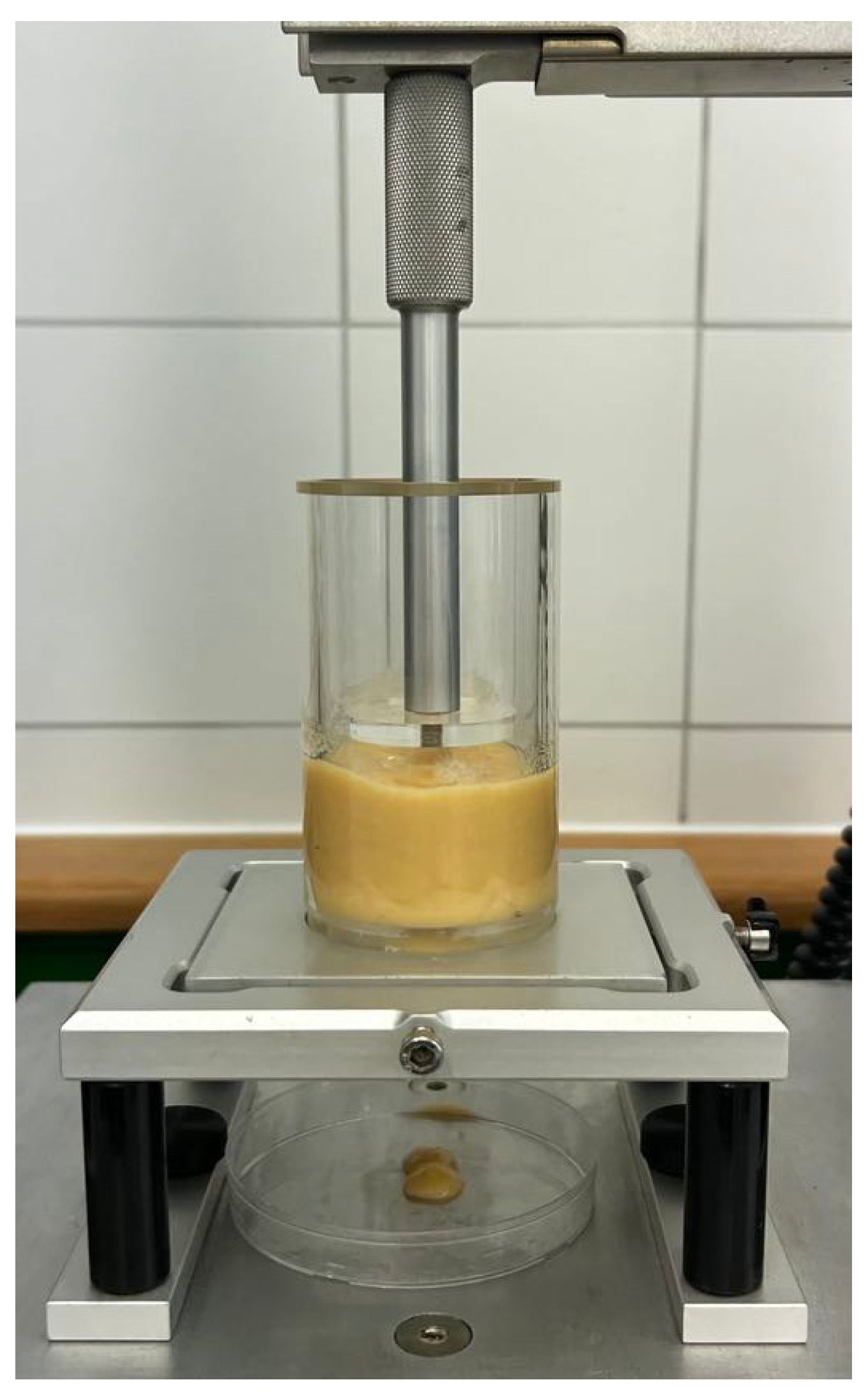

6]. In the domain of three-dimensional extrusion printing, the delivery of edible ink is facilitated through a nozzle employing various mechanisms. These mechanisms may include pneumatic pressure, a piston-driven system, or a screw extruder [

7]. The predominance of extrusion-based 3D printing can be attributed to its inherent simplicity, cost-effectiveness and versatility in accommodating a diverse range of food materials. The primary raw materials utilised in three-dimensional printing processes include purées, sols, gels, doughs, and emulsions. The formulation of these materials is carefully engineered to optimise their rheological properties, thereby ensuring a consistent and controlled flow through the printer nozzle. This meticulous design is essential for achieving precision in layer deposition and overall structural integrity in the printed object [

8].

The materials utilised in the printing process, frequently referred to as “food inks,” comprise a diverse array of ingredients. These ingredients include dairy products, eggs, cheese, chocolate, various oils, plant materials, and meats. This range of components facilitates a broad spectrum of culinary applications and enhances the versatility of food ink formulations [

9]. The ink must exhibit sufficient plasticity to flow through the nozzle. Also, it must possess adequate structural stability post-printing to maintain its integrity [

7]. The rheological properties of the inks are crucial, as they significantly influence both extrudability and stability of the material during the printing process [

10].

Food 3D printing enables the precise tailoring of nutritional profiles to meet the specific dietary needs of individual consumers, but also allows for extensive customisation in terms of dimensions, shape, colour, texture, and flavour [

11,

12]. The technique can potentially enhance the consumption of fruits and vegetables, particularly among vulnerable populations such as children and seniors, who frequently experience challenges related to swallowing and chewing.

Fruit and vegetables are essential to the human diet, supplying crucial vitamins, carbohydrates, minerals, and bioactive compounds [

13]. The regular consumption of fruit and vegetables has been demonstrated to play a pivotal role in the primary prevention of chronic diseases. This phenomenon can be attributed to the bioactive compounds present in these foods and their substantial antioxidant properties [

14].

Fruit and vegetables can be used in the 3D printing process. However, they are classified as non-printable raw materials due to their high water content, low protein and fat content, and the possibility of phase segregation [

9]. Water, as the primary component of fruit and vegetables, plays a significant role in influencing the viscosity of the ink. This viscosity depends on the specific vegetable raw material used in the formulation. The incorporation of hydrocolloids into non-printable raw materials, including fruits, vegetables, rice, and meat, has been demonstrated to enhance their extrusion capacity [

13]. Gelling and binding agents such as xanthan gum, guar gum, locust bean gum, agar or carrageenan can be added to achieve the appropriate structure and stability of inks [

9].

Hydrocolloids possess a variety of functional properties, including gelling, thickening, stabilising, and emulsifying. Group of hydrocolloids include, i.a., guar gum, alginate, agar, carrageenan, gellan gum, xanthan gum, gelatine, and modified starches [

15]. In food production, using hydrocolloids has become a common practice, primarily aimed at enhancing the final product’s rheological, sensory, and textural characteristics [

16]. The composite gels based on peach, gum polysaccharide, and gelatine showed moderate viscosity, good print quality, and structural stability [

17]. A comparative study investigated the impact of xanthan gum, konjac gum, and locust bean gum on the rheological properties, textural attributes, moisture content, printability, and sensory characteristics of pea protein-based inks. The experimental concentrations of these hydrocolloids ranged from 0.3 to 0.7% (

w/

w). The addition of xanthan gum resulted in a reduction of the melt limit and the viscosity. Conversely, incorporating konjac gum and locust bean gum increased viscosity [

18]. Polysaccharide hydrocolloids can form gel structures and be subjected to extrusion moulding under optimal conditions, rendering them viable materials for three-dimensional printing applications. Incorporating an optimal amount of these hydrocolloids can significantly improve the mechanical strength of printed structures and increase the models’ shape stability. This advancement facilitates the production of more complex and precise food gels using 3D printing technology [

14,

17].

In this study, two selected hydrocolloids were utilised: xanthan gum and carrageenan. These were selected on the basis of their functional properties, plant and microbiological origin, wide range of applications in food technology, and proven effectiveness in food 3D printing applications in numerous studies [

19,

20,

21].

κ-Carrageenan, extracted from red algae, is a sulphated polysaccharide with thermo-reversible properties that forms brittle gels [

19,

22]. κ-Carrageenan exhibits high water-binding capacity, which is crucial for its applications in food [

23]. The viscosity and elasticity of κ-carrageenan are influenced by concentration, pH, and the presence of salts. At higher concentrations, κ-carrageenan transitions from a disordered coil to an ordered helical conformation, forming gels [

24]. This hydrocolloid helps in maintaining intestinal homeostasis by positively influencing gut microbiota composition [

25]. The advantages of this additive are numerous, encompassing its cost-effectiveness, widespread availability, and biodegradability [

26]. However, the acceptable daily intake (ADI) for κ-Carrageenan is 75 mg/kg body weight per day [

27].

Xanthan gum, produced by

Xanthomonas campestris, exhibits significant pseudoplastic behaviour, characterised by its ability to decrease in viscosity under applied shear forces and subsequently recover its viscosity rapidly upon the cessation of such forces [

19,

22]. The utilisation of xanthan gum in diets for individuals afflicted with dysphagia is of particular significance, given its extensive application in this context due to its efficacious rheological properties, stability against salivary enzymes, and considerable resistance to both acidic and alkaline conditions [

28]. This biopolymer has a wide and varied range of applications due to its remarkable physicochemical properties, biodegradability, and non-toxicity [

29].

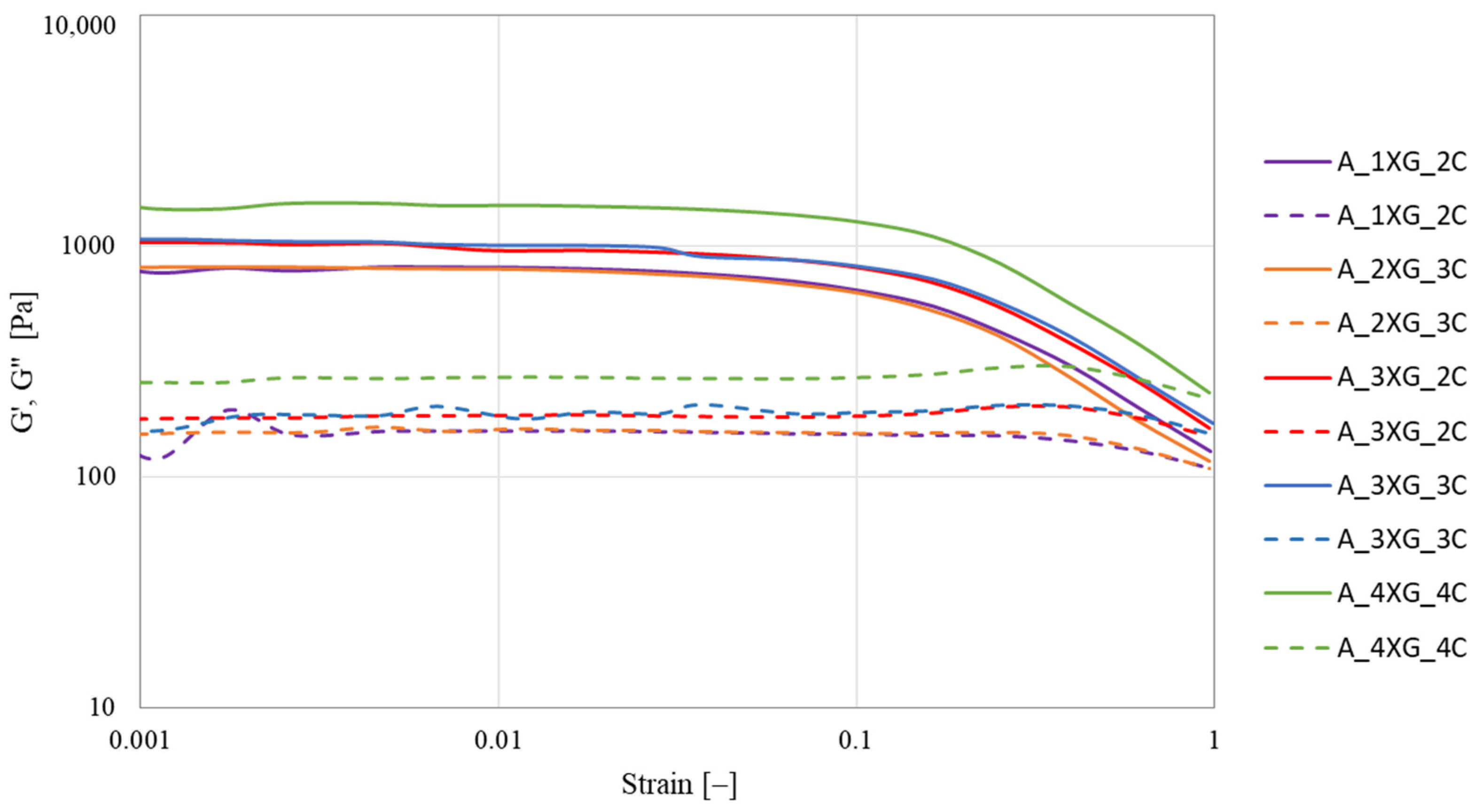

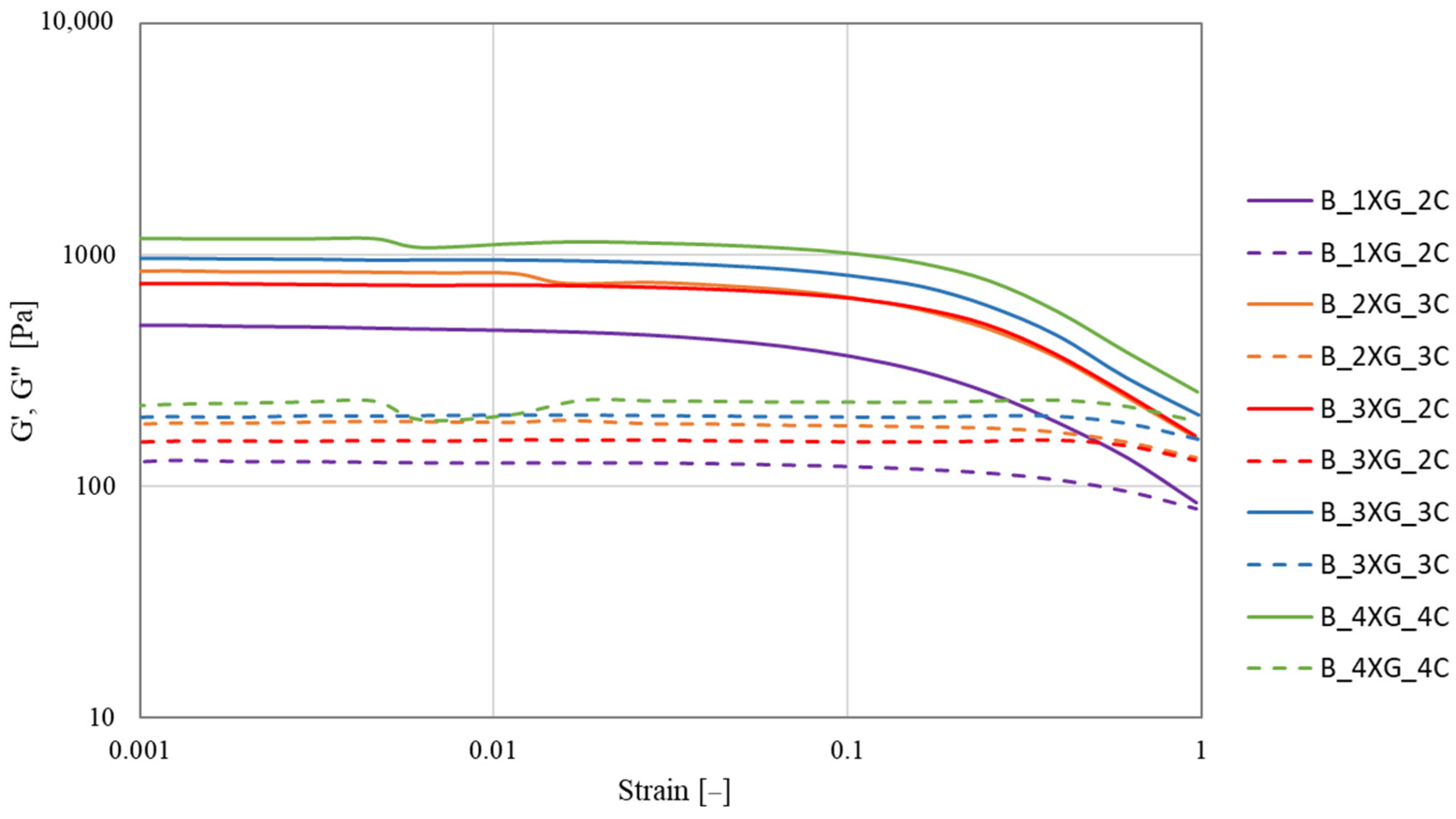

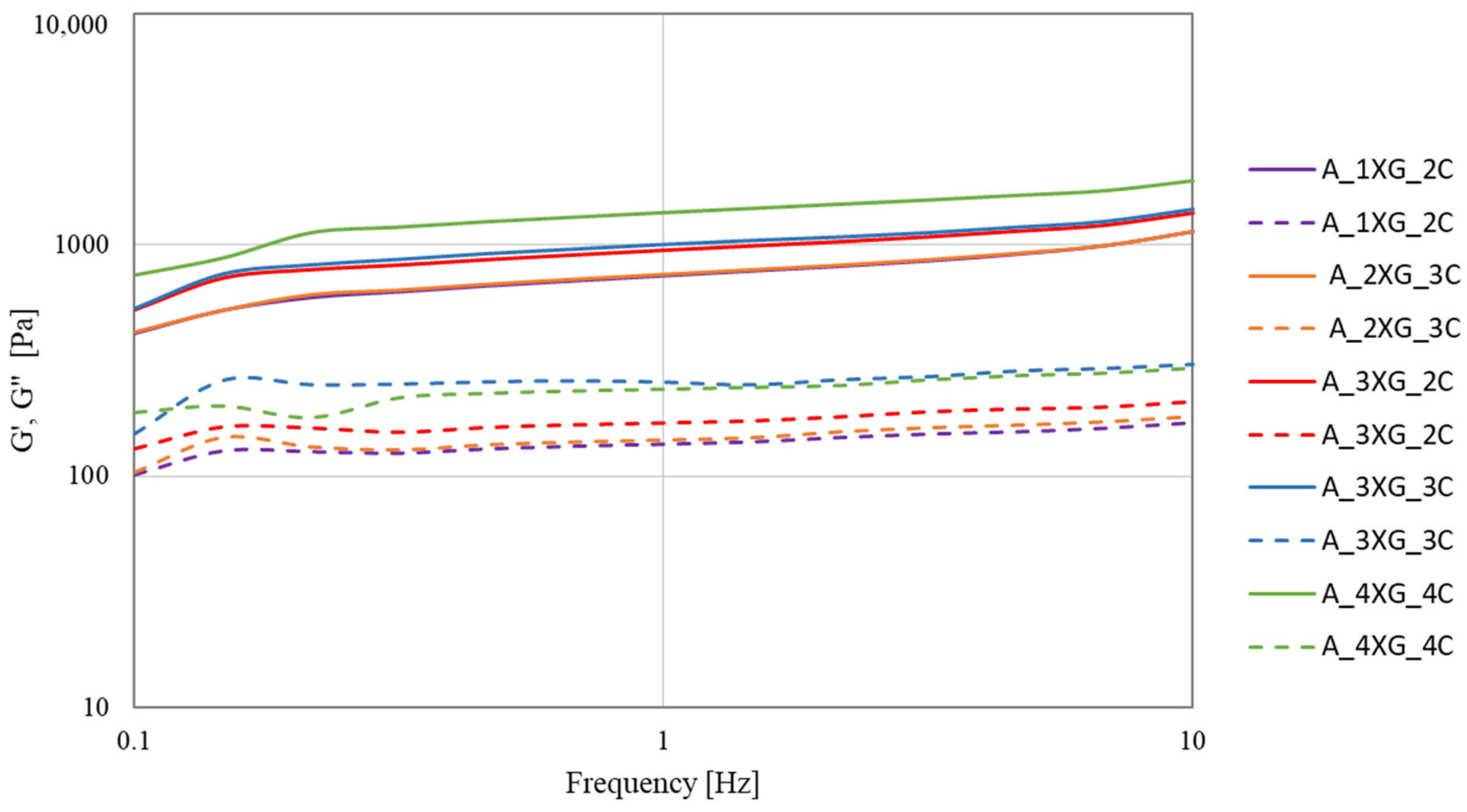

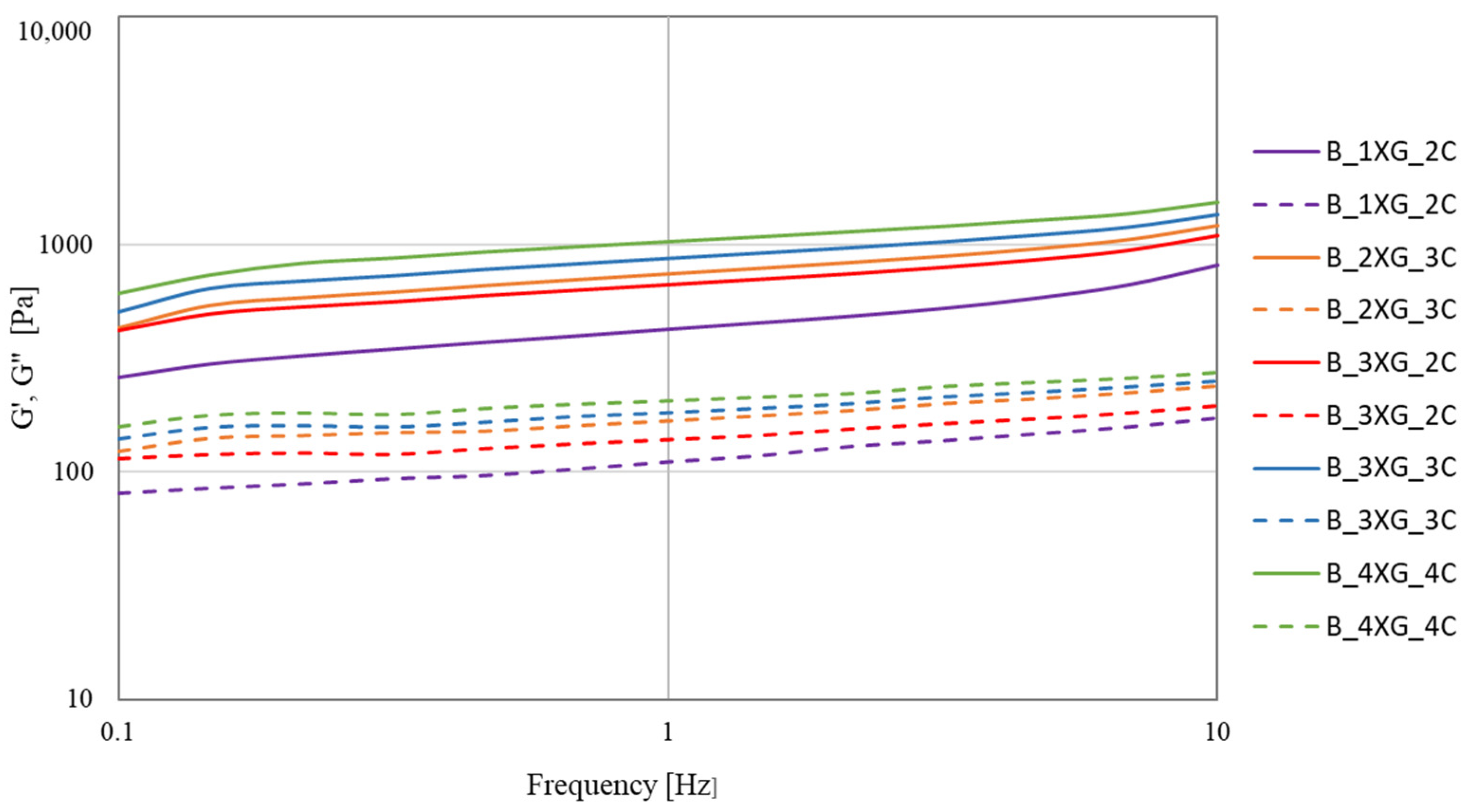

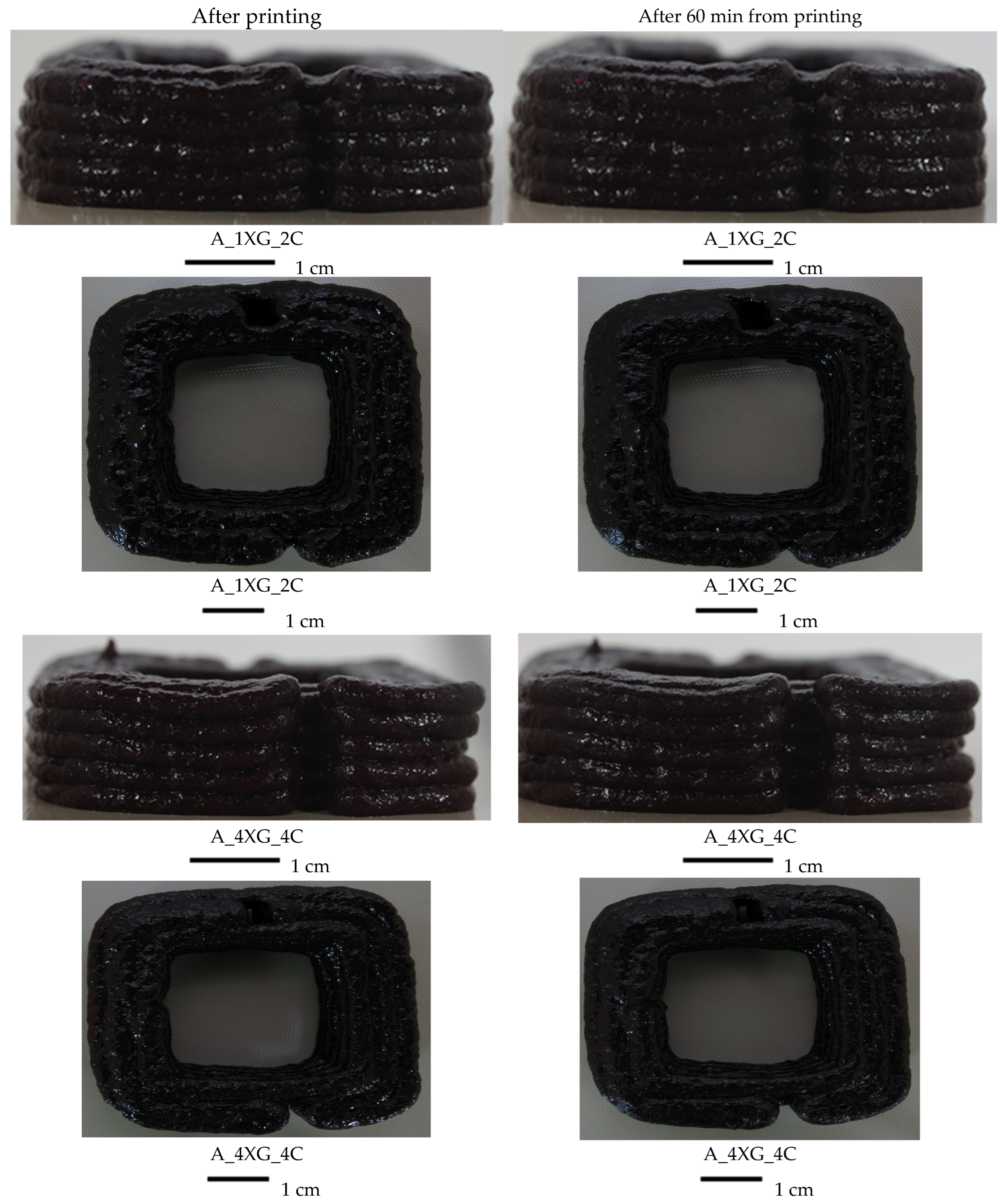

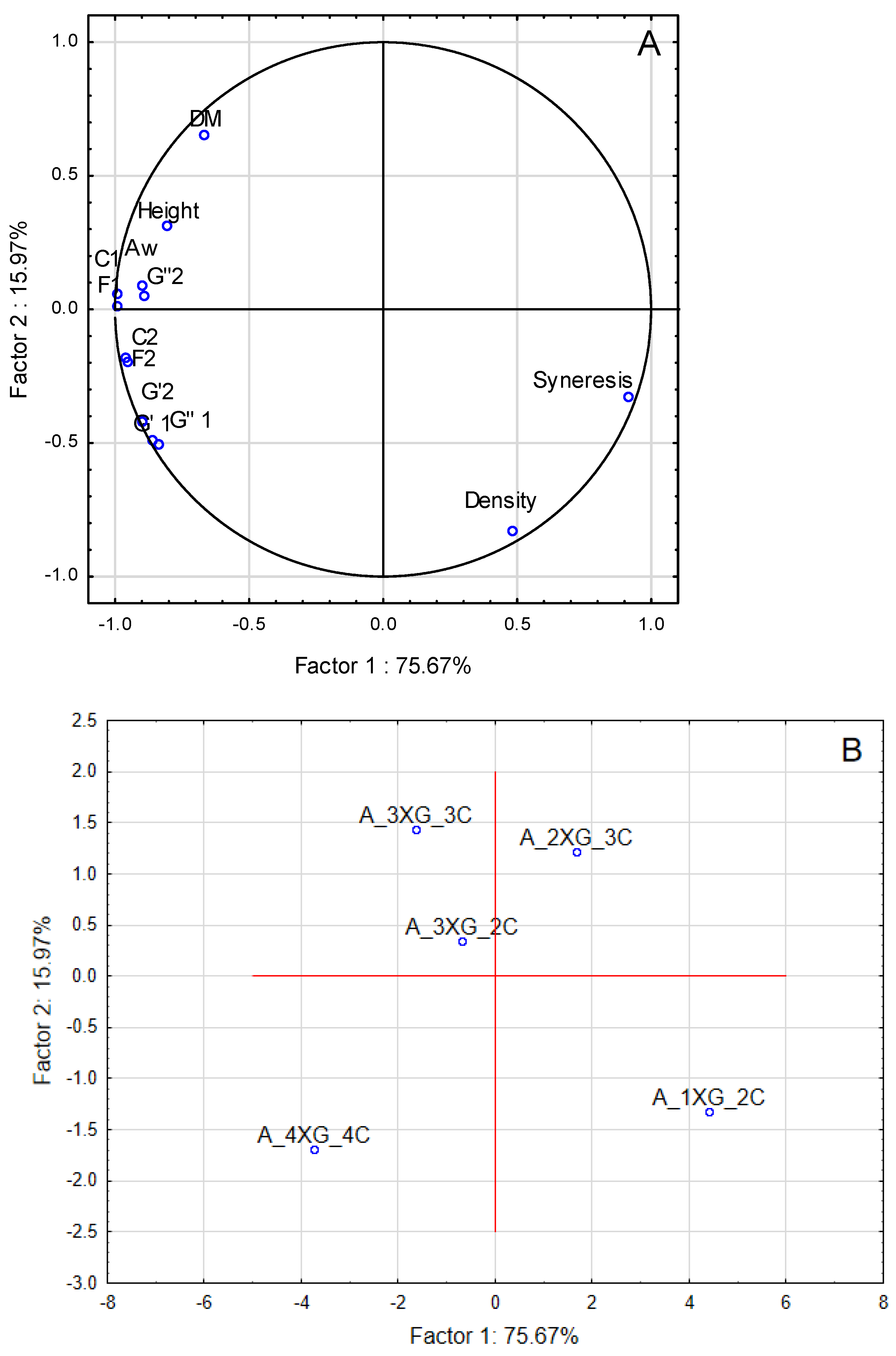

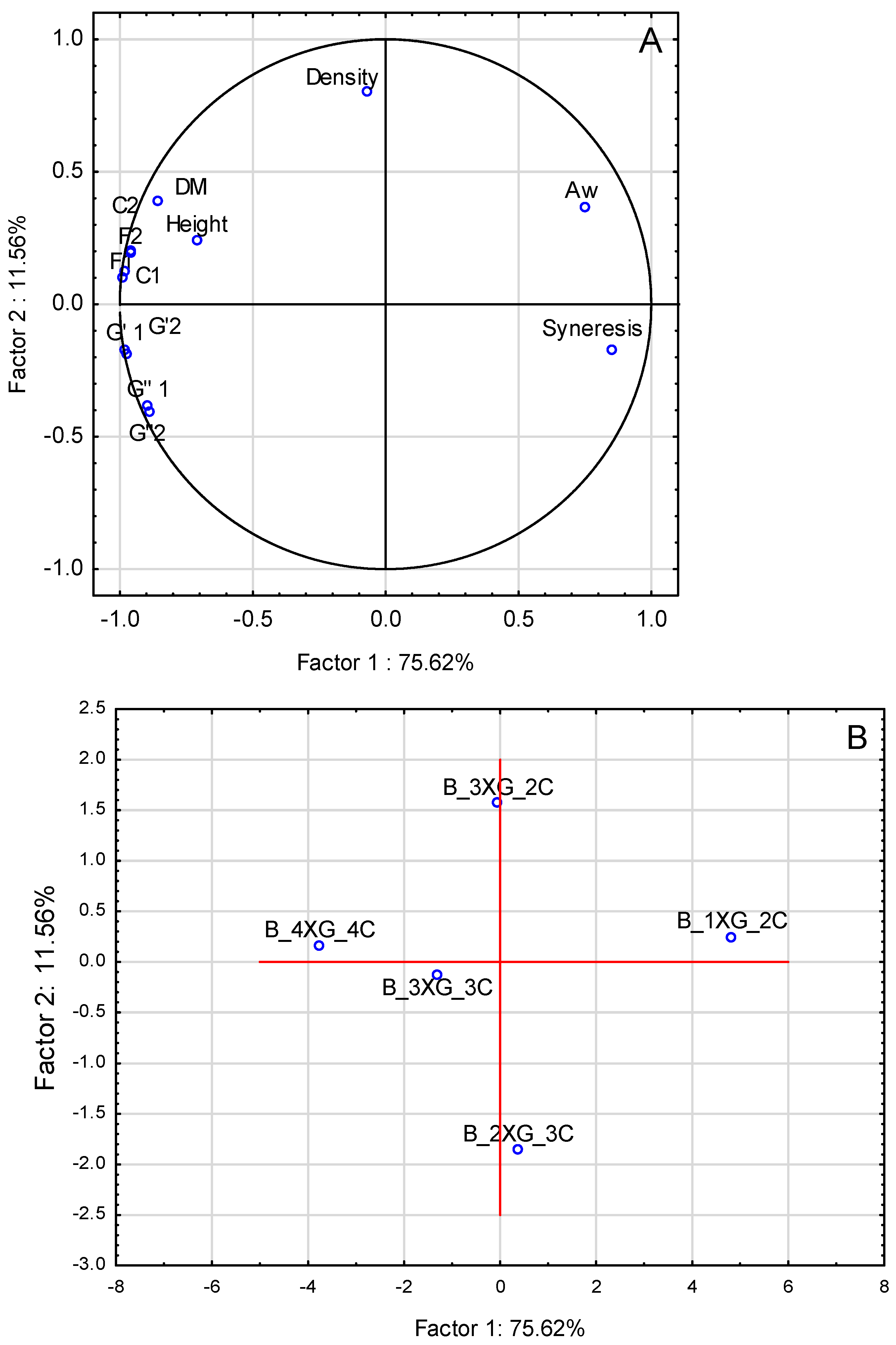

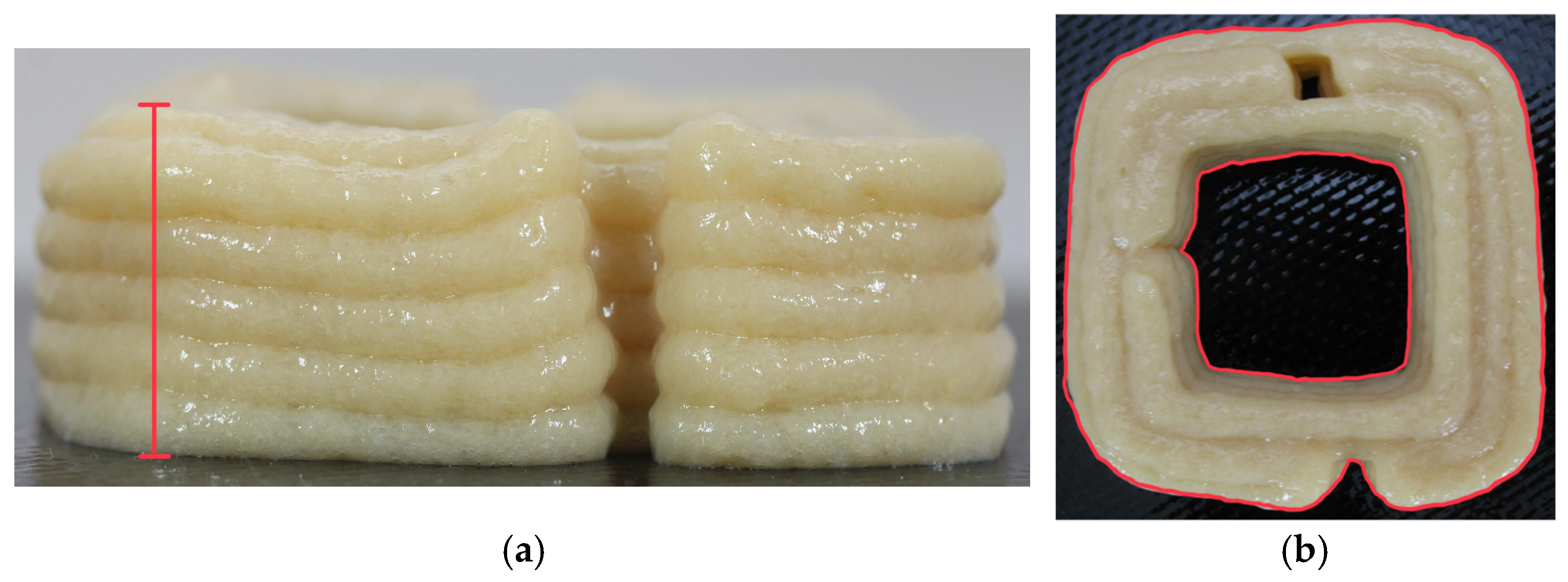

In this study, printing inks were developed based on banana and blueberry purées, with the addition of hydrocolloid mixtures, specifically xanthan gum and carrageenan, in concentrations ranging from 1 to 4%. The ink prepared in this manner was subsequently printed by means of extrusion-based 3D printing. The objective of the present study was to ascertain the impact of ink composition and physical properties on the texture and shape retention of objects printed using 3D technology. The impact of the materials was assessed in terms of physical properties such as dry weight, water activity, density, syneresis, rheological properties (i.e., elasticity and viscosity modulus), and textural properties (i.e., strength and deformation work), as well as dimensional stability of the structures after printing. The printed models were analysed immediately after production and after 60 min of storage in order to assess their durability and compliance with the intended geometric model. The 3D printing of fruit purées, including banana and blueberry, represents a pioneering technique for the fabrication of foodstuffs with customised consistency and form. This technology is particularly useful in the provision of sustenance for individuals suffering from dysphagia, children, and the elderly, for whom conventional products may be difficult to accept due to their texture or appearance. Through the implementation of suitable rheological modifications, it is possible to preserve the nutritional value of fruit while simultaneously enhancing the sensory and functional appeal of food products.

4. Conclusions

The results showed that adding hydrocolloids in the concentration range of 1 to 4%, including xanthan gum and carrageenan, to fruit purée-based inks affected the material’s rheological properties, texture, and stability. Increasing the hydrocolloid content had no significant effect on water activity or dry matter content, due to the high-water content of the fruit purée. The density of the inks was found to be similar across all treatments, irrespective of the type of fruit purée and hydrocolloid content. This finding suggests that the ink’s composition exerted a negligible influence on this particular parameter. The viscoelasticity modules for all the inks that were tested, both blueberry and banana purée-based, were characterised by a clear predominance of the elasticity module over the viscosity modules. The predominance of the elastic modulus may have contributed to the ink’s enhanced extrudability and shape retention after printing, thereby enabling the creation of stable shapes. The examination of fidelity and stability in 3D-printed objects incorporating blueberry and banana purée revealed that increased concentrations of hydrocolloids significantly enhanced the conformity of the printed shapes to their intended models. Ink syneresis studies showed that increasing the concentration of hydrocolloid particles reduced leakage during storage, which was crucial for maintaining the stability of printed objects. Increasing the concentration of hydrocolloids can enhance the mechanical strength of inks; however, an excessive amount may impede the 3D printing process by increasing extrusion resistance. Increasing the concentration of xanthan gum and carrageenan improved the mechanical properties of the inks, with xanthan gum having a more substantial effect on texture than carrageenan. It can be concluded that variants based on blueberry puree, as well as banana purée with 4% xanthan gum and 4% carrageenan addition, are suitable for 3D printing applications, as they show optimal rheological and textural properties, minimal syneresis, and well-defined structural parameters. These characteristics, upon completion of the printing process, were found to be consistent with the predetermined model. However, printing ink compositions were used with the lowest possible level of additives necessary to achieve the desired technological properties. Hydrocolloid mixtures containing 3% xanthan gum and 3% carrageenan, as well as 3% xanthan gum and 2% carrageenan, proved to be optimal for 3D printing and suitable for consumption. This product is particularly suitable for individuals with difficulties in consuming solid foods, such as children, the elderly, or patients with dysphagia and, due to the use of plant-based hydrocolloids, is also appropriate for vegetarian and vegan diets. The effectiveness of hydrocolloids depends on the composition of the fruit, which highlights the need to adjust formulations based on the type of raw material used.