Wood-Based Panels and Volatile Organic Compounds (VOCs): An Overview on Production, Emission Sources and Analysis

Abstract

1. Contextualization

- Contextualization: Presents the objectives and structure of the work;

- Wood-based panels: Contains an overview of the wood and WBP industry, the different WBPs and their manufacturing processes, the adhesives employed, and the legal restrictions the production of WBPs must abide by;

- Volatile Organic Compounds Emitted from WBPs: Focuses on VOCs, specifically, the identification of possible sources within WBPs, followed by an in-depth discussion of the most prominent groups of compounds emitted;

- Methodologies Used for the Analysis of VOCs in WBPs: Presents both the standard methods used for the determination of VOCs in WBPs and alternative analytical methods;

- Comparison of Emission Results Found in the Literature: Provides a summary and discussion of the determined values for terpenes, carbonyl compounds, and others for different types of wood and WBPs.

2. Wood-Based Panels

2.1. Wood

2.2. Production of Wood-Based Panels

2.2.1. Plywood

2.2.2. Oriented Strand Board

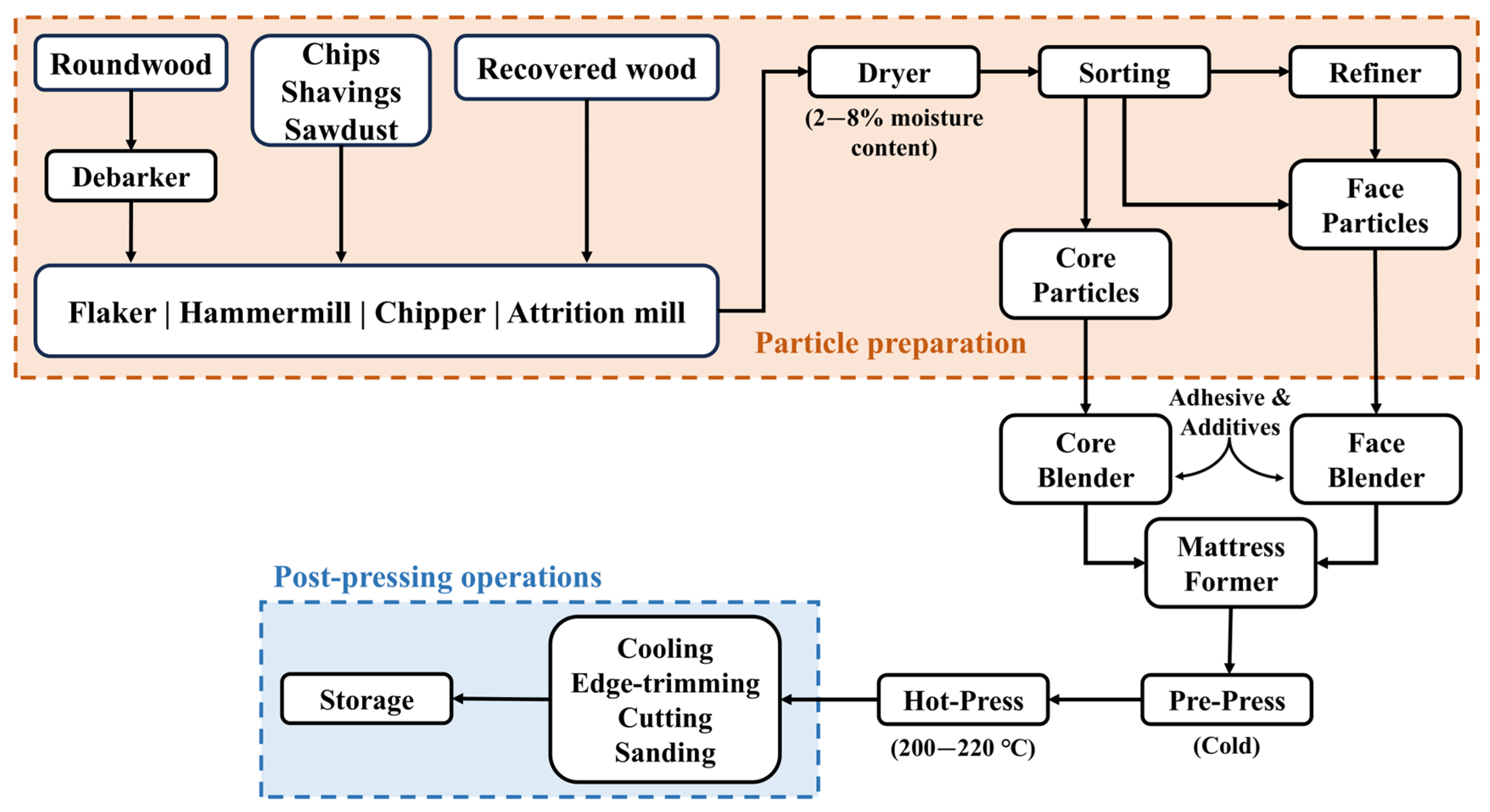

2.2.3. Particleboard

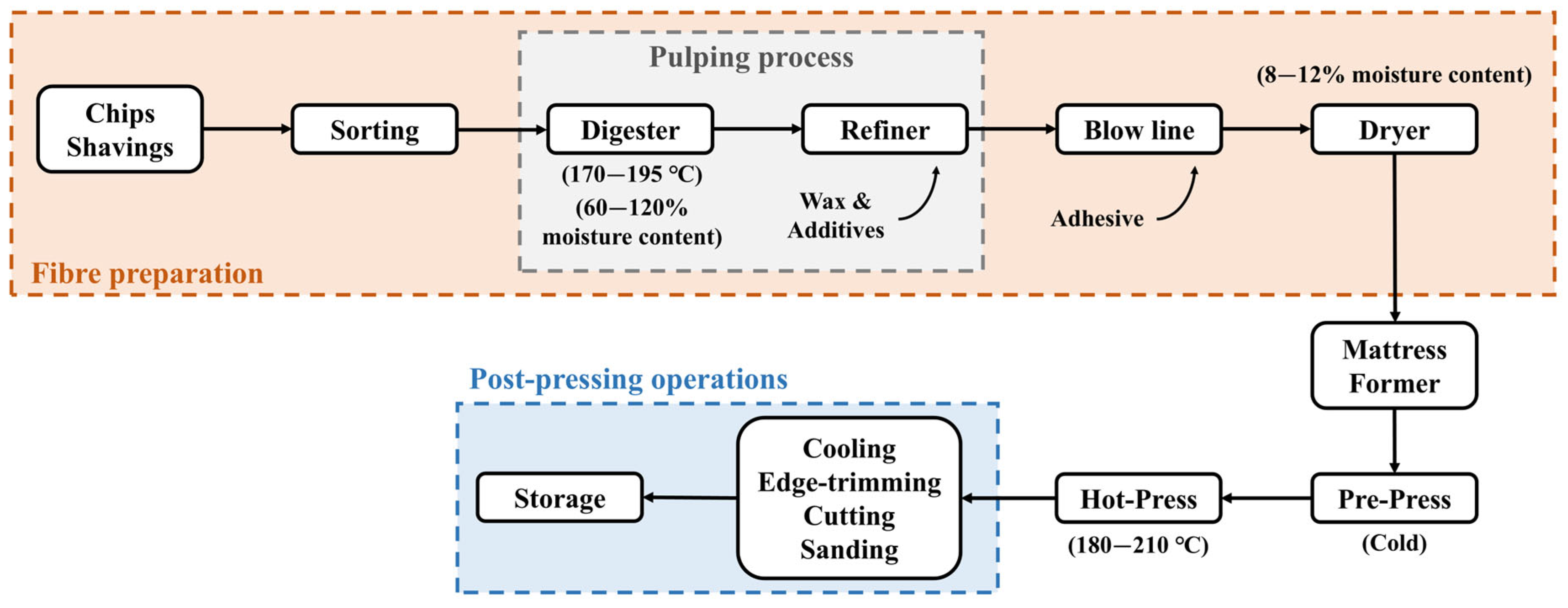

2.2.4. Medium-Density Fiberboard

2.3. Adhesives in WBP Production

2.4. Emission Issues and Legislation

3. Volatile Organic Compounds Emitted from WBPs

3.1. Terpenes and Terpenoids

3.2. Aldehydes, Carboxylic Acids, and Ketones

3.3. Other Compounds

4. Methodologies Used for the Analysis of VOCs in WBPs

4.1. International Standards

4.2. Other Methods

5. Comparison of Emission Results Found in the Literature

6. Final Remarks

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Salthammer, T.; Mentese, S.; Marutzky, R. Formaldehyde in the Indoor Environment. Chem. Rev. 2010, 110, 2536–2572. [Google Scholar] [CrossRef]

- Salem, M.; Böhm, M. Understanding of Formaldehyde Emissions from Solid Wood: An Overview. BioResources 2013, 8, 4775–4790. [Google Scholar] [CrossRef]

- Salthammer, T. Formaldehyde in the Ambient Atmosphere: From an Indoor Pollutant to an Outdoor Pollutant? Angew. Chem. Int. Ed. 2013, 52, 3320–3327. [Google Scholar] [CrossRef]

- Salthammer, T. The formaldehyde dilemma. Int. J. Hyg. Environ. Health 2015, 218, 433–436. [Google Scholar] [CrossRef] [PubMed]

- Carvalho, L.; Magalhães, F.; João, F. Formaldehyde Emissions from Wood-Based Panel-Testing Methods and Industrial Perspectives. In Formaldehyde: Chemistry, Applications and Role in Polymerization; Cheng, C.B., Lin, F.H., Eds.; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2012; pp. 73–107. [Google Scholar]

- Yuan, Q.; Liu, Z.; Zheng, K.; Ma, C. Wood. In Civil Engineering Materials; Yuan, Q., Liu, Z., Zheng, K., Ma, C., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; pp. 239–259. [Google Scholar]

- Hassegawa, M.; Van Brusselen, J.; Cramm, M.; Verkerk, P.J. Wood-Based Products in the Circular Bioeconomy: Status and Opportunities towards Environmental Sustainability. Land 2022, 11, 2131. [Google Scholar] [CrossRef]

- Leon, M.; Cornejo, G.; Calderón, M.; González-Carrión, E.; Florez, H. Effect of Deforestation on Climate Change: A Co-Integration and Causality Approach with Time Series. Sustainability 2022, 14, 11303. [Google Scholar] [CrossRef]

- Bais-Moleman, A.L.; Sikkema, R.; Vis, M.; Reumerman, P.; Theurl, M.C.; Erb, K.H. Assessing wood use efficiency and greenhouse gas emissions of wood product cascading in the European Union. J. Clean. Prod. 2018, 172, 3942–3954. [Google Scholar] [CrossRef]

- Irle, M.; Barbu, M.; Niemz, P.; Carvalho, L.; Martins, J.; Costa, C.; Muszyski, L.; Launey, M.; Sernek, M.; Dunky, M.; et al. Wood-Based Panels: An Introduction for Specialists; Brunel University Press: London, UK, 2010. [Google Scholar]

- Members. Available online: https://wood4bauhaus.eu/members/ (accessed on 25 July 2025).

- Norhazaedawati, B.; SaifulAzry, S.O.A.; Lee, S.H.; Ilyas, R.A. Wood-based panel industries. In Oil Palm Biomass for Composite Panels; Elsevier: Amsterdam, The Netherlands, 2022; pp. 69–86. [Google Scholar]

- O’Halloran, M.R. Wood: Structural Panels. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 9740–9744. [Google Scholar]

- Adcock, T.; Wolcott, M.P. Wood: Nonstructural Panels. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2001; pp. 9678–9683. [Google Scholar]

- EN 13986:2004+A1:2015; Wood-Based Panels for Use in Construction—Characteristics, Evaluation of Conformity and Marking. European Committee for Standardisation: Brussels, Belgium, 2015.

- Boehner, A.W. Wood: Structural Panel Processes. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 9736–9740. [Google Scholar]

- Stubdrup, K.R.; Karlis, P.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Wood-based Panels; Publications Office of the EU: Luxembourg, 2016. [Google Scholar]

- Kamke, F.A. Wood: Nonstructural Panel Processes. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 9673–9678. [Google Scholar]

- EN 313-2:2010; Plywood—Classification and Terminology—Part 2: Terminology. European Committee for Standardisation: Brussels, Belgium, 2010.

- EN 316:2009; Wood Fibre Boards—Definition, Classification and Symbols. European Committee for Standardisation: Brussels, Belgium, 2009.

- Plywood. Available online: https://europanels.org/the-wood-based-panel-industry/types-of-wood-based-panels-economic-impact/plywood/ (accessed on 11 April 2024).

- Stark, N.M.; Cai, Z.; Carll, C. Wood-Based Composite Materials: Panel Products, Glued-Laminated Timber, Structural Composite Lumber, and Wood-Nonwood Composite Materials. In Wood Handbook: Wood as an Engineering Material; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010. [Google Scholar]

- Feraboli, P. Notched response of OSB wood composites. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1355–1361. [Google Scholar] [CrossRef]

- EN 300:2006; Oriented Strand Boards (OSB)—Definitions, Classification and Specifications. European Committee for Standardisation: Brussels, Belgium, 2006.

- Oriented Strand Board. Available online: https://europanels.org/the-wood-based-panel-industry/types-of-wood-based-panels-economic-impact/oriented-strand-board/ (accessed on 26 June 2023).

- EN 309:2005; Particleboards—Definition and Classification. European Committee for Standardisation: Brussels, Belgium, 2005.

- Particleboard. Available online: https://europanels.org/the-wood-based-panel-industry/types-of-wood-based-panels-economic-impact/particleboard/ (accessed on 5 April 2024).

- Conner, A.H. Wood: Adhesives. In Encyclopedia of Materials: Science and Technology; Elsevier: Amsterdam, The Netherlands, 2001; pp. 9583–9599. [Google Scholar]

- Chrobak, J.; Iłowska, J.; Chrobok, A. Formaldehyde-Free Resins for the Wood-Based Panel Industry: Alternatives to Formaldehyde and Novel Hardeners. Molecules 2022, 27, 4862. [Google Scholar] [CrossRef]

- Dunky, M. Urea–formaldehyde (UF) adhesive resins for wood. Int. J. Adhes. Adhes. 1998, 18, 95–107. [Google Scholar] [CrossRef]

- Ormondroyd, G.A. Adhesives for wood composites. In Wood Composites; Ansell, M.P., Ed.; Woodhead Publishing: Sawston, UK, 2015; pp. 47–66. [Google Scholar]

- Substance Information—European Chemicals Agency. Available online: https://echa.europa.eu/substance-information/-/substanceinfo/100.043.361 (accessed on 11 July 2023).

- ISO 12460-5:2015; Wood-Based Panels—Determination of Formaldehyde Release—Part 5: Extraction Method (Called the Perforator Method). International Organization for Standardization: Geneva, Switzerland, 2015.

- EN 717-1:2004; Wood-Based Panels—Determination of Formaldehyde Release—Part 1: Formaldehyde Emission by the Chamber Method. European Committee for Standardisation: Brussels, Belgium, 2004.

- Commission Regulation (EU) 2023/1464 of 14 July 2023 Amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council as Regards Formaldehyde and Formaldehyde Releasers. Off. J. Eur. Union 2023, 66, 12–20.

- ASTM E1333; Standard Test Method for Determining Formaldehyde Concentrations in Air and Emission Rates from Wood Products Using a Large Chamber. American Society for Testing and Materials: West Conshohocken, PA, USA, 2022.

- Environmental Protection Agency. 81 FR 89674—Formaldehyde Emission Standards for Composite Wood Products; Office of the Federal Register, National Archives and Records Administration: College Park, MD, USA, 2016; Volume 81, pp. 89674–89743.

- GB/T 39600-2021:2021; Formaldehyde Emission Grading for Wood-Based Panel and Finishing Products. Standardization Administration of China: Beijing, China, 2021.

- GB/T 39600-2021; New National Standard that Legalize E0 Plywood in China—Yalong Wood. Available online: https://www.yalongwood.com/gbt39600-2021/ (accessed on 6 January 2025).

- JIS A 5908:2003; Particleboards. Japanese Standards Association: Tokyo, Japan, 2003.

- JIS A 1460:2015; Determination of the Emission of Formaldehyde from Building Boards—Desiccator Method. Japanese Standards Association: Tokyo, Japan, 2015.

- EN 16516:2017+A1:2020; Construction Products: Assessment of Release of Dangerous Substances—Determination of Emissions into Indoor Air. European Committee for Standardisation: Brussels, Belgium, 2020.

- Bulian, F.; Fragassa, C. VOC Emissions From Wood Products and Furniture: A Survey About Legislation, Standards and Measures Referred to Different Materials. FME Trans. 2016, 44, 358–364. [Google Scholar] [CrossRef]

- Legal Requirements on VOC Emissions—Eurofins. Available online: https://www.eurofins.com/consumer-product-testing/services/certifications-international-approvals/voc/legal-requirements/ (accessed on 4 August 2023).

- Fengel, D.; Wegener, G. Wood: Chemistry, Ultrastructure, Reactions; Walter de Gruyter: Berlin, Germany, 1989. [Google Scholar]

- Wiemann, M.C. Characteristics and Availability of Commercially Important Woods. In Wood Handbook: Wood as an Engineering Material; Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2010. [Google Scholar]

- Bajer, T.; Šulc, J.; Ventura, K.; Bajerová, P. Volatile compounds fingerprinting of larch tree samples for Siberian and European larch distinction. Eur. J. Wood Wood Prod. 2020, 78, 393–402. [Google Scholar] [CrossRef]

- Risholm-Sundman, M.; Lundgren, M.; Vestin, E.; Herder, P. Emissions of acetic acid and other volatile organic compounds from different species of solid wood. Holz Als Roh-Werkst. 1998, 56, 125–129. [Google Scholar] [CrossRef]

- Hafizoglu, H.; Holmbom, B. Chemical composition of extractives from Abies nordmanniana. Holz Als Roh-Und Werkst. 1995, 53, 273–275. [Google Scholar] [CrossRef]

- Roffael, E. Volatile organic compounds and formaldehyde in nature, wood and wood based panels. Holz Als Roh-Werkst. 2006, 64, 144–149. [Google Scholar] [CrossRef]

- Roffael, E.; Schneider, T.; Dix, B. Effect of oxidising and reducing agents on the release of volatile organic compounds (VOCs) from strands made of Scots pine (Pinus sylvestris L.). Wood Sci. Technol. 2015, 49, 957–967. [Google Scholar] [CrossRef]

- Wajs, A.; Pranovich, A.; Reunanen, M.; Willför, S.; Holmbom, B. Headspace-SPME Analysis of the Sapwood and Heartwood of Picea abies, Pinus sylvestris and Larix decidua. J. Essent. Oil Res. 2007, 19, 125–133. [Google Scholar] [CrossRef]

- Wajs, A.; Pranovich, A.; Reunanen, M.; Willför, S.; Holmbom, B. Characterisation of volatile organic compounds in stemwood using solid-phase microextraction. Phytochem. Anal. 2006, 17, 91–101. [Google Scholar] [CrossRef]

- Adamová, T.; Hradecký, J.; Pánek, M. Volatile Organic Compounds (VOCs) from Wood and Wood-Based Panels: Methods for Evaluation, Potential Health Risks, and Mitigation. Polymers 2020, 12, 2289. [Google Scholar] [CrossRef] [PubMed]

- Ashour, M.; Wink, M.; Gershenzon, J. Biochemistry of Terpenoids: Monoterpenes, Sesquiterpenes and Diterpenes. In Annual Plant Reviews Volume 40: Biochemistry of Plant Secondary Metabolism; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2010; pp. 258–303. [Google Scholar]

- Antonelli, M.; Donelli, D.; Barbieri, G.; Valussi, M.; Maggini, V.; Firenzuoli, F. Forest volatile organic compounds and their effects on human health: A state-of-the-art review. Int. J. Environ. Res. Public Health 2020, 17, 6506. [Google Scholar] [CrossRef]

- Kessler, A.; Heil, M. The multiple faces of indirect defences and their agents of natural selection. Funct. Ecol. 2011, 25, 348–357. [Google Scholar] [CrossRef]

- Ninkuu, V.; Zhang, L.; Yan, J.; Fu, Z.; Yang, T.; Zeng, H. Biochemistry of Terpenes and Recent Advances in Plant Protection. Int. J. Mol. Sci. 2021, 22, 5710. [Google Scholar] [CrossRef]

- Pohleven, J.; Burnard, M.; Kutnar, A. Volatile organic compounds emitted from untreated and thermally modified wood—A review. Wood Fiber Sci. 2019, 51, 231–254. [Google Scholar] [CrossRef]

- Loreto, F.; Pollastri, S.; Fineschi, S.; Velikova, V. Volatile isoprenoids and their importance for protection against environmental constraints in the Mediterranean area. Environ. Exp. Bot. 2014, 103, 99–106. [Google Scholar] [CrossRef]

- Englund, F.; Nussbaum, R.M. Monoterpenes in Scots Pine and Norway Spruce and their Emission during Kiln Drying. Holzforschung 2000, 54, 449–456. [Google Scholar] [CrossRef]

- Sivrikaya, H.; Tesařová, D.; Jeřábková, E.; Can, A. Color change and emission of volatile organic compounds from Scots pine exposed to heat and vacuum-heat treatment. J. Build. Eng. 2019, 26, 100918. [Google Scholar] [CrossRef]

- Manninen, A.M.; Utriainen, J.; Holopainen, T.; Kainulainen, P. Terpenoids in the wood of Scots pine and Norway spruce seedlings exposed to ozone at different nitrogen availability. Can. J. For. Res. 2002, 32, 2140–2145. [Google Scholar] [CrossRef]

- Czajka, M.; Fabisiak, B.; Fabisiak, E. Emission of Volatile Organic Compounds from Heartwood and Sapwood of Selected Coniferous Species. Forests 2020, 11, 92. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Z.; Qin, Y.; Yin, X.; Huang, A. Released Volatile Organic Compounds in Southern Yellow Pine before and after Heat Treatment. Int. J. Environ. Res. Public Health 2018, 15, 2579. [Google Scholar] [CrossRef]

- Hyttinen, M.; Masalin-Weijo, M.; Kalliokoski, P.; Pasanen, P. Comparison of VOC emissions between air-dried and heat-treated Norway spruce (Picea abies), Scots pine (Pinus sylvesteris) and European aspen (Populus tremula) wood. Atmos. Environ. 2010, 44, 5028–5033. [Google Scholar] [CrossRef]

- Ruuskanen, T.; Hakola, H.; Kajos, M.; Hellén, H.; Tarvainen, V.; Rinne, J. Volatile organic compound emissions from Siberian larch. Atmos. Environ. 2007, 41, 5807–5812. [Google Scholar] [CrossRef]

- Waliszewska, B.; Zborowska, M.; Dukiewicz, H.; Wojciechowski, T.; Cofta, G. Identification of volatile organic compounds emitted from meranti and larch wood. Ann. Wars. Univ. Life Sci.—SGGW. For. Wood Technol. 2013, 84, 262–268. [Google Scholar]

- Liu, Y.; Shen, J.; Zhu, X.D. Headspace Solid-phase Microextraction for the Determination of Volatile Organic Compounds in Larix Gmelini Particles. Phys. Procedia 2012, 32, 605–613. [Google Scholar] [CrossRef]

- Kačík, F.; Veľková, V.; Šmíra, P.; Nasswettrová, A.; Kačíková, D.; Reinprecht, L. Release of terpenes from fir wood during its long-term use and in thermal treatment. Molecules 2012, 17, 9990–9999. [Google Scholar] [CrossRef]

- Velic, A.; Soldán, M.; Haz, A.; Surina, I.; Jablonsky, M. Determination of volatile compounds’ emissions from wood processing. Wood Res. 2019, 46, 461–470. [Google Scholar]

- Que, Z.-L.; Wang, F.-B.; Li, J.-Z.; Furuno, T. Assessment on emission of volatile organic compounds and formaldehyde from building materials. Compos. Part B Eng. 2013, 49, 36–42. [Google Scholar] [CrossRef]

- Son, Y.S.; Lim, B.A.; Park, H.J.; Kim, J.C. Characteristics of volatile organic compounds (VOCs) emitted from building materials to improve indoor air quality: Focused on natural VOCs. Air Qual. Atmos. Health 2013, 6, 737–746. [Google Scholar] [CrossRef]

- Baumann, M.G.D.; Batterman, S.A.; Zhang, G.Z. Terpene emissions from particleboard and medium-density fiberboard products. For. Prod. J. 1999, 49, 49–56. [Google Scholar]

- Simon, V.; Uitterhaegen, E.; Robillard, A.; Ballas, S.; Véronèse, T.; Vilarem, G.; Merah, O.; Talou, T.; Evon, P. VOC and carbonyl compound emissions of a fiberboard resulting from a coriander biorefinery: Comparison with two commercial wood-based building materials. Environ. Sci. Pollut. Res. 2020, 27, 16121–16133. [Google Scholar] [CrossRef]

- Schumann, A.; Lenth, C.; Hasener, J.; Steckel, V. Detection of volatile organic compounds from wood-based panels by gas chromatography-field asymmetric ion mobility spectrometry (GC-FAIMS). Int. J. Ion Mobil. Spectrom. 2012, 15, 157–168. [Google Scholar] [CrossRef]

- Liu, Y.; Zhu, X.; Qin, X.; Wang, W.; Hu, Y.; Yuan, D. Identification and characterization of odorous volatile organic compounds emitted from wood-based panels. Environ. Monit. Assess. 2020, 192, 348. [Google Scholar] [CrossRef]

- Straumfors, A.; Olsen, R.; Daae, H.L.; Afanou, A.; McLean, D.; Corbin, M.; Mannetje, A.; Ulvestad, B.; Bakke, B.; Johnsen, H.L.; et al. Exposure to Wood Dust, Microbial Components, and Terpenes in the Norwegian Sawmill Industry. Ann. Work Expo. Health 2018, 62, 674–688. [Google Scholar] [CrossRef] [PubMed]

- Falk, A.; Löf, A.; Hagberg, M.; Wigaeus Hjelm, E.; Wang, Z. Human exposure to 3-carene by inhalation: Toxicokinetics, effects on pulmonary function and occurrence of irritative and CNS symptoms. Toxicol. Appl. Pharmacol. 1991, 110, 198–205. [Google Scholar] [CrossRef]

- Roffael, E. Significance of wood extractives for wood bonding. Appl. Microbiol. Biotechnol. 2016, 100, 1589–1596. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Little, J.C. Materials Responsible for Formaldehyde and Volatile Organic Compound (VOC) Emissions; Woodhead Publishing: Cambridgeshire, UK, 2012; pp. 76–121. [Google Scholar]

- Roffael, E.; Uhde, M. Influence of storage on the emission of volatile acids from wood chips. Eur. J. Wood Wood Prod. 2012, 70, 763–765. [Google Scholar] [CrossRef][Green Version]

- Tshabalala, M.A.; McSweeny, J.D.; Rowell, R.M. Heat treatment of wet wood fiber: A study of the effect of reaction conditions on the formation of furfurals. Wood Mater. Sci. Eng. 2012, 7, 202–208. [Google Scholar] [CrossRef]

- Fernández de Simón, B.; Esteruelas, E.; Muñoz, Á.M.; Cadahía, E.; Sanz, M. Volatile Compounds in Acacia, Chestnut, Cherry, Ash, and Oak Woods, with a View to Their Use in Cooperage. J. Agric. Food Chem. 2009, 57, 3217–3227. [Google Scholar] [CrossRef]

- Tjeerdsma, B.F.; Boonstra, M.; Pizzi, A.; Tekely, P.; Militz, H. Characterisation of thermally modified wood: Molecular reasons for wood performance improvement. Holz Als Roh-Und Werkst. 1998, 56, 149–153. [Google Scholar] [CrossRef]

- Schäfer, M.; Roffael, E. On the formaldehyde release of wood. Holz Als Roh-Und Werkst. 2000, 58, 259–264. [Google Scholar] [CrossRef]

- Manninen, A.-M.; Pasanen, P.; Holopainen, J.K. Comparing the VOC emissions between air-dried and heat-treated Scots pine wood. Atmos. Environ. 2002, 36, 1763–1768. [Google Scholar] [CrossRef]

- Shao, M.; Wildt, J. Quantification of acetone emission from pine plants. Sci. China Ser. B Chem. 2002, 45, 532–540. [Google Scholar] [CrossRef]

- Desai, R.L.; Shields, J.A. Photochemical degradation of cellulose material. Die Makromol. Chem. 1969, 122, 134–144. [Google Scholar] [CrossRef]

- Jensen, L.K.; Larsen, A.; M⊘lhave, L.; Hansen, M.K.; Knudsen, B. Health Evaluation of Volatile Organic Compound (VOC) Emissions from Wood and Wood-Based Materials. Arch. Environ. Health Int. J. 2001, 56, 419–432. [Google Scholar] [CrossRef]

- Schieweck, A. Very volatile organic compounds (VVOC) as emissions from wooden materials and in indoor air of new prefabricated wooden houses. Build. Environ. 2021, 190, 107537. [Google Scholar] [CrossRef]

- Englund, F. Emissions of Volatile Organic Compounds (VOC) from Wood; Trätek—Institutet för Träteknisk Forskning: Stockholm, Sweeden, 1999. [Google Scholar]

- Peters, J.; Pfriem, A.; Horbens, M.; Fischer, S.; Wagenführ, A. Emissions from thermally modified beech wood, their reduction by solvent extraction and fungicidal effect of the organic solvent extracts. Wood Mater. Sci. Eng. 2009, 4, 61–66. [Google Scholar] [CrossRef]

- Baumann, M.G.D.; Lorenz, L.; Batterman, S.; Zhang, G.Z. Aldehyde emissions from particleboard and medium density fiberboard products. For. Prod. J. 2000, 50, 75–82. [Google Scholar]

- Fuczek, D.; Czajka, M.; Szuta, J.; Szutkowski, K.; Kwaśniewska-Sip, P. VOC Emission from Lightweight Wood Fiber Insulation Board. Forests 2023, 14, 1300. [Google Scholar] [CrossRef]

- Trojanová, K.; Veľková, V.; Kačík, F. Volatile Organic Compounds Arising from Wood Polymers on Thermal Loading of Spruce Wood. Polymers 2025, 17, 875. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, F.D.; Almeida, M.L.; Martins, J.M.; Carvalho, L.H.; Rodrigues, J.A.; Ramos, R.M. Gas-diffusion microextraction combined with HPLC-DAD for the comprehensive analysis of volatile carbonyl compounds in wood-based panels. Talanta 2024, 272, 125818. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, F.D.; Martins, J.M.; Carvalho, L.H.; Rodrigues, J.A.; Ramos, R.M. Volatile Carbonyl Compounds Emission in Dry-Process Fibreboard: Identification through a Selective GDME-HPLC-DAD-MS/MS Method. Separations 2024, 11, 92. [Google Scholar] [CrossRef]

- Formaldehyde. In Monographs on the Evaluation of Carcinogenic Risks to Humans—Formaldehyde, 2-Butoxyethanol and 1-terc-Butoxypropan-2-ol; International Agency for Research on Cancer: Lyon, France, 2006; Volume 88, pp. 39–325.

- Khoshakhlagh, A.H.; Mohammadzadeh, M.; Manafi, S.S.; Yousefian, F.; Gruszecka-Kosowska, A. Inhalational exposure to formaldehyde, carcinogenic, and non-carcinogenic risk assessment: A systematic review. Environ. Pollut. 2023, 331, 121854. [Google Scholar] [CrossRef]

- Medical Management Guidelines for Formaldehyde. Available online: https://wwwn.cdc.gov/TSP/MMG/MMGDetails.aspx?mmgid=216&toxid=39 (accessed on 16 July 2024).

- Fischer, M.H. The Toxic Effects of Formaldehyde and Formalin. J. Exp. Med. 1905, 6, 487–518. [Google Scholar] [CrossRef]

- Acetaldehyde. In Monographs on the Evaluation of Carcinogenic Risks to Humans—Re-Evaluation of Some Organic Chemicals, Hydrazine and Hydrogen Peroxide; International Agency for Research on Cancer: Lyon, France, 1999; Volume 77, pp. 319–335.

- Acetaldehyde. In Emergency and Continuous Exposure Guidance Levels for Selected Submarine Contaminants; National Academies Press: Washington, DC, USA, 2009; Volume 3.

- Ernstgård, L.; Iregren, A.; Sjögren, B.; Johanson, G. Acute effects of exposure to vapours of acetic acid in humans. Toxicol. Lett. 2006, 165, 22–30. [Google Scholar] [CrossRef]

- McGraw, G.W.; Hemingway, R.W.; Ingram, L.L., Jr.; Canady, C.S.; McGraw, W.B. Thermal degradation of terpenes: Camphene, Δ-carene, limonene, and α-terpinene. Environ. Sci. Technol. 1999, 33, 4029–4433. [Google Scholar] [CrossRef]

- Elaieb, M.T.; Candelier, K.; Petrissans, A.; Dumarçay, S.; Gérardin, P.; Pétrissans, M. Heat treatment of Tunisian soft wood species: Effect on the durability, chemical modifications and mechanical properties. Maderas Cienc. Y Tecnol. 2015, 17, 699–710. [Google Scholar] [CrossRef]

- Stachowiak-Wencek, A.; Prądzyński, W. Emission of volatile organic compounds from wood of exotic species. For. Wood Technol. 2014, 86, 215–219. [Google Scholar]

- Roffael, E. Release of acetic acid and formaldehyde from particleboards bonded with phenolic resins. Eur. J. Wood Wood Prod. 2017, 75, 1025–1026. [Google Scholar] [CrossRef]

- ISO 16000-3:2022; Indoor Air—Part 3: Determination of Formaldehyde and Other Carbonyl Compounds in Indoor Air and Test Chamber Air—Active Sampling Method. International Organization for Standardization: Geneva, Switzerland, 2022.

- ISO 16000-6:2021; Indoor Air—Part 6: Determination of Volatile Carbonyl Compounds in Indoor Air and Test Chamber Air by Active Sampling on Tenax TA® Sorbent, Thermal Desorption and Gas Chromatography Using MS or MS-FID. International Organization for Standardization: Geneva, Switzerland, 2021.

- ISO 16000-9:2006; Indoor Air—Part 9: Determination of the Emission of Volatile Organic Compounds from Building Products and Furnishing—Emission Test Chamber Method. International Organization for Standardization: Geneva, Switzerland, 2006.

- Santos, M.B.; Sillero, L.; Gatto, D.A.; Labidi, J. Bioactive molecules in wood extractives: Methods of extraction and separation, a review. Ind. Crops Prod. 2022, 186, 115231. [Google Scholar] [CrossRef]

- Vichi, S.; Santini, C.; Natali, N.; Riponi, C.; López-Tamames, E.; Buxaderas, S. Volatile and semi-volatile components of oak wood chips analysed by Accelerated Solvent Extraction (ASE) coupled to gas chromatography–mass spectrometry (GC–MS). Food Chem. 2007, 102, 1260–1269. [Google Scholar] [CrossRef]

- Bukhanko, N.; Attard, T.; Arshadi, M.; Eriksson, D.; Budarin, V.; Hunt, A.J.; Geladi, P.; Bergsten, U.; Clark, J. Extraction of cones, branches, needles and bark from Norway spruce (Picea abies) by supercritical carbon dioxide and soxhlet extractions techniques. Ind. Crops Prod. 2020, 145, 112096. [Google Scholar] [CrossRef]

- Bertaud, F.; Crampon, C.; Badens, E. Volatile terpene extraction of spruce, fir and maritime pine wood: Supercritical CO2 extraction compared to classical solvent extractions and steam distillation. Holzforschung 2017, 71, 667–673. [Google Scholar] [CrossRef]

- Pawliszyn, J.; Pawliszyn, B.; Pawliszyn, M. Solid Phase Microextraction (SPME). Chem. Educ. 1997, 2, 1–7. [Google Scholar] [CrossRef]

- Pati, S.; Tufariello, M.; Crupi, P.; Coletta, A.; Grieco, F.; Losito, I. Quantification of Volatile Compounds in Wines by HS-SPME-GC/MS: Critical Issues and Use of Multivariate Statistics in Method Optimization. Processes 2021, 9, 662. [Google Scholar] [CrossRef]

- Rossi, L.; Foschi, M.; Biancolillo, A.; Maggi, M.A.; D’Archivio, A.A. Optimization of HS-SPME-GC/MS Analysis of Wine Volatiles Supported by Chemometrics for the Aroma Profiling of Trebbiano d’Abruzzo and Pecorino White Wines Produced in Abruzzo (Italy). Molecules 2023, 28, 1534. [Google Scholar]

- Kaikiti, K.; Omirou, M.; Savvides, S.; Ioannides, I.M.; Agapiou, A. HS-SPME-GC-MS analysis of Cyprus vineyard soil for VOCs determination. Sustain. Chem. Environ. 2023, 2, 100021. [Google Scholar] [CrossRef]

- Wypych, J.; Manko, T. Determination of Volatile Organic Compounds (VOCs) in Water and Soil Using Solid Phase Microextraction. Chem. Anal. 2002, 47, 507. [Google Scholar]

- Higashikawa, F.S.; Cayuela, M.L.; Roig, A.; Silva, C.A.; Sánchez-Monedero, M.A. Matrix effect on the performance of headspace solid phase microextraction method for the analysis of target volatile organic compounds (VOCs) in environmental samples. Chemosphere 2013, 93, 2311–2318. [Google Scholar] [CrossRef]

- Yu, M.-Y.; Yang, X.-Q.; Fan, R.; Zheng, Y.-K.; Shi, J.-B.; Zheng, Q. Non-target Screening Analysis of Volatile Organic Compounds in Drinking Water by Headspace-solid Phase Microextraction Gas Chromatography-Mass Spectrometry. Chin. J. Anal. Chem. 2020, 48, 1228–1235. [Google Scholar] [CrossRef]

- Whang, C.W.; Jen, J.F.; Kumar, P.V. Recent Advances in Solid-Phase Microextraction for Environmental Applications. In Comprehensive Sampling and Sample Preparation; Pawliszyn, J., Ed.; Academic Press: Cambridge, MA, USA, 2012; Volume 3, pp. 629–656. [Google Scholar]

- Stalikas, C.D.; Fiamegos, Y.C. Microextraction combined with derivatization. TrAC Trends Anal. Chem. 2008, 27, 533–542. [Google Scholar] [CrossRef]

- Jordão, A.M.; Ricardo-da-Silva, J.M.; Laureano, O.; Adams, A.; Demyttenaere, J.; Verhé, R.; De Kimpe, N. Volatile composition analysis by solid-phase microextraction applied to oak wood used in cooperage (Quercus pyrenaica and Quercus petraea): Effect of botanical species and toasting process. J. Wood Sci. 2006, 52, 514–521. [Google Scholar] [CrossRef]

- Bajer, T.; Šulc, J.; Ventura, K.; Bajerová, P. Design of the Extraction Process for Characterization of Volatile Profile of Stem Wood by Solid-Phase Microextraction. Nat. Prod. Commun. 2019, 14. [Google Scholar] [CrossRef]

- Ewen, R.J.; Jones, P.R.; Ratcliffe, N.M.; Spencer-Phillips, P.T. Identification by gas chromatography-mass spectrometry of the volatile organic compounds emitted from the wood-rotting fungi Serpula lacrymans and Coniophora puteana, and from Pinus sylvestris timber. Mycol. Res. 2004, 108, 806–814. [Google Scholar] [CrossRef] [PubMed]

- Pacheco, J.G.; Valente, I.M.; Gonçalves, L.M.; Rodrigues, J.A.; Barros, A.A. Gas-diffusion microextraction. J. Sep. Sci. 2010, 33, 3207–3212. [Google Scholar] [CrossRef]

- Brandão, P.F.; Ramos, R.M.; Valente, I.M.; Almeida, P.J.; Carro, A.M.; Lorenzo, R.A.; Rodrigues, J.A. Gas-diffusion microextraction coupled with spectrophotometry for the determination of formaldehyde in cork agglomerates. Anal. Bioanal. Chem. 2017, 409, 2885–2892. [Google Scholar] [CrossRef]

- Brandão, P.F.; Ramos, R.M.; Rodrigues, J.A. GDME-based methodology for the determination of free formaldehyde in cosmetics and hygiene products containing formaldehyde releasers. Anal. Bioanal. Chem. 2018, 410, 6873–6880. [Google Scholar] [CrossRef]

- Ferreira, R.C.; Ramos, R.M.; Gonçalves, L.M.; Almeida, P.J.; Rodrigues, J.A. Application of gas-diffusion microextraction to solid samples using the chromatographic determination of α-diketones in bread as a case study. Analyst 2015, 140, 3648–3653. [Google Scholar] [CrossRef]

- Dvořák, P.; Ramos, R.M.; Vyskočil, V.; Rodrigues, J.A. A new electroanalytical methodology for the determination of formaldehyde in wood-based products. Talanta 2020, 217, 121068. [Google Scholar] [CrossRef]

- Ge, M.; Zheng, Y.; Zhu, Y.; Ge, J.; Zhang, Q. Effects of Air Exchange Rate on VOCs and Odor Emission from PVC Veneered Plywood Used in Indoor Built Environment. Coatings 2023, 13, 1608. [Google Scholar] [CrossRef]

- Jia, L.; Chu, J.; Li, J.; Ren, J.; Huang, P.; Li, D. Formaldehyde and VOC emissions from plywood panels bonded with bio-oil phenolic resins. Environ. Pollut. 2020, 264, 114819. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Meile, K.; Godina, D.; Rizhikovs, J.; Syrpas, M.; Venskutonis, P.R. Qualitative Differences and Emission Persistence of Volatile Organic Compounds from Bio-Based Particleboards. Materials 2022, 15, 5278. [Google Scholar] [CrossRef] [PubMed]

- Chizzola, R.; Müllner, K. Variability of volatiles in Pinus cembra L. within and between trees from a stand in the Salzburg Alps (Austria) as assessed by essential oil and SPME analysis. Genet. Resour. Crop. Evol. 2021, 68, 567–579. [Google Scholar] [CrossRef]

- ASTM D 5116-90; Standard Guide for Small-Scale Environmental Chamber Determinations of Organic Emissions from Indoor Materials/Products. American Society for Testing and Materials: West Conshohocken, PA, USA, 1990.

- ISO 16000-10:2006; Indoor Air—Part 10: Determination of the Emission of Volatile Organic Compounds from Building Products and Furnishing—Emission Test Cell Method. International Organization for Standardization: Geneva, Switzerland, 2006.

- VDI 4301-7:2017; Measurement of Indoor Air Pollution—Measurement of Carboxylic Acids. Verlag des Vereins Deutscher Ingenieure: Düsseldorf, Germany, 2017.

- Schieweck, A.; Gunschera, J.; Varol, D.; Salthammer, T. Analytical procedure for the determination of very volatile organic compounds (C3–C6) in indoor air. Anal. Bioanal. Chem. 2018, 410, 3171–3183. [Google Scholar] [CrossRef] [PubMed]

- Bertheau, E.; Simon, V.; Delgado Raynaud, C. Microchamber Extraction and Analytical Pyrolysis to Explore Volatile Organic Compounds from Compression-Cooking Wood Materials Obtained under Different Conditions. Molecules 2022, 27, 8260. [Google Scholar] [CrossRef] [PubMed]

| Resin System | Applications | Advantages | Disadvantages |

|---|---|---|---|

| UF | PB MDF Plywood | Inexpensive; Fast curing; Adaptable to curing conditions; Water soluble; Hardness; Colorless when cured. | Low resistance to water; Emission of formaldehyde at slow rates. |

| MF & MUF | Exterior or semi-exterior plywood PB | Moisture tolerant; Durable; Less susceptible to release formaldehyde. | Expensive; Slow curing. |

| PF | Construction plywood OSB | Resistant to water; Durable; Fast curing; Low formaldehyde release. | Expensive; Dark colored when cured; Reduced mechanical properties. |

| pMDI | PB OSB MDF | Moisture tolerant; Fast curing; Durable; VOCs and formaldehyde-free. | Expensive; Adheres to metal; Potentially carcinogenic (when uncured). |

| Country | Substance | Limits (mg·m−3) | References |

|---|---|---|---|

| Germany | Carcinogenic compounds (3 days) | 0.01 | [43,44] |

| TVOCs (3 days) | 10 | ||

| Carcinogenic compounds (28 days) | 0.001 | ||

| TVOCs (28 days) | 1 | ||

| Belgium | Formaldehyde (28 days) | 0.1 | [43,44] |

| Acetaldehyde (28 days) | 0.2 | ||

| Toluene (28 days) | 0.3 | ||

| TVOCs (28 days) | 1 | ||

| Carcinogenic compounds (28 days) | 0.001 | ||

| Italy | Formaldehyde (28 days) | 0.06 | [44] |

| Acetaldehyde, Xylene (28 days) | 0.3 | ||

| Benzene (28 days) | 0.001 | ||

| Toluene (28 days) | 0.45 | ||

| TVOCs (28 days) | 1.5 |

| Substance | Limits (mg·m−3) After 28 Days of Emission Testing | |||

|---|---|---|---|---|

| Class C | Class B | Class A | Class A+ | |

| Formaldehyde | >0.12 | 0.06–0.12 | 0.01–0.06 | <0.01 |

| Acetaldehyde, Xylene | >0.4 | 0.3–0.4 | 0.2–0.3 | <0.2 |

| Toluene | >0.6 | 0.45–0.6 | 0.3–0.45 | <0.3 |

| TVOCs | >2 | 1.5–2 | 1–1.5 | <1 |

| Wood | Volatile Terpenes Emitted * | References |

|---|---|---|

| Pine (Pinus sylvestris, Pinus spp.) | α-pinene, β-pinene, limonene, Δ3-carene, α-terpineol, camphene, β-phellandrene, terpinolene, verbenol, p-cymene, β-myrcene, and γ-terpinene | [50,51,61,62,63,64,65,66] |

| Spruce (Picea abies) | α-pinene, β-pinene, limonene, Δ3-carene, β-phellandrene, β-myrcene and camphene | [61,63,64,66] |

| Larch (Larix decidua, Larix sibirica, Larix gmelinii) | α-pinene, β-pinene, limonene, Δ3-carene, β-phellandrene, camphene, terpinolene, sabinene, tricyclene, α-phellandrene, linalool, τ-elemene, α-farnesene, β-caryophyllene, longifolene, β-cubinene, σ/τ-cadinene, α-caryophyllene, β-bourbonene and isolongifolene | [64,67,68,69] |

| Fir (Abies alba) | α-pinene, β-pinene, limonene, Δ3-carene, camphene, β-phellandrene and myrcene | [70] |

| Wood-Based Panel | Volatile Terpenes Emitted * | References |

|---|---|---|

| Particleboard (undisclosed pine species) | α-pinene, β-pinene, limonene, Δ3-carene, camphene, fenchone, fenchol, camphor, p-cymene, borneol | [74] |

| Particleboard (Douglas fir) | α-pinene, β-pinene, limonene, Δ3-carene, p-cymene, borneol | [74] |

| Particleboard (undisclosed hardwood species) | α-pinene, β-pinene, Δ3-carene | [74] |

| Particleboard (undisclosed wood species) | α-pinene, β-pinene, limonene, Δ3-carene, camphene, camphor, linalool, longifolene, m-cymene, p-cymene, trans-calamenene, α-muurolene, β-copaene, borneol, α-thujene | [75,76] |

| Particleboard and laminated particleboard (60% Dahurian larch, softwood, and hardwood mix) | α-pinene, limonene, Δ3-carene | [77] |

| MDF (undisclosed pine species) | limonene, Δ3-carene, borneol, p-cymene, fenchone, fenchol, camphor | [74] |

| MDF (undisclosed hardwood species) | limonene, p-cymene, borneol | [74] |

| MDF (undisclosed wood species) | α-pinene, β-pinene, limonene, Δ3-carene, camphene, camphor, linalool, longifolene, p-cymene, trans-calamenene, α-muurolene, β-copaene, borneol | [75] |

| Wood | Volatile Carbonyl Compounds Emitted * | References | |

|---|---|---|---|

| Softwood | Pine (Pinus sylvestris, Pinus spp.) | formaldehyde, acetaldehyde, propanal, butanal, pentanal, hexanal, octanal, nonanal, decanal, oct-2-enal, furfural, benzaldehyde, acetone, 6-methyl-5-hepten-2-one, acetophenone, formic acid, acetic acid, octanoic acid, nonanoic acid | [48,64,65,87,90,91] |

| Spruce (Picea abies) | formaldehyde, acetaldehyde, propanal, butanal, pentanal, hexanal, octanal, nonanal, furfural, benzaldehyde, acetone, acetophenone, formic acid, acetic acid | [48,64,90,91] | |

| Larch (Larix decidua, Larix sibirica, Larix gmelinii) | formaldehyde, acetaldehyde, octanal, nonanal, decanal, benzaldehyde, formic acid, acetic acid, acetone, acetophenone | [64,69,91] | |

| Hardwood | Oak (Quercus robur) | formaldehyde, acetaldehyde, propanal, butanal, hexanal, furfural formic acid, acetic acid, hexanoic acid, methylacetate | [48,90,91,92] |

| Beech (Fagus sylvatica) | formaldehyde, acetaldehyde, propanal, butanal, pentanal, hexanal, furfural, acetone, formic acid, acetic acid, hexanoic acid | [48,90,91,93] | |

| Ash (Franxinus excelsior) | formaldehyde, acetaldehyde, propanal, butanal, hexanal, acetic acid | [48] | |

| Wood-Based Panel | Volatile Carbonyl Compounds Emitted * | References |

|---|---|---|

| Particleboard (undisclosed pine species) | formaldehyde, acetaldehyde, propanal, butanal, pentanal, hexanal, heptanal, octanal, nonanal, furfural, benzaldehyde, oct-2-enal | [94,97] |

| Particleboard (Douglas fir) | Pentanal, hexanal, octanal, nonanal, benzaldehyde, oct-2-enal | [94] |

| Particleboard (undisclosed hardwood species) | Pentanal, hexanal, heptanal, octanal, nonanal, benzaldehyde, oct-2-enal | [94] |

| Particleboard (undisclosed wood species) | formaldehyde, acetaldehyde, propanal, butanal, pentanal, hexanal, octanal, nonanal, decanal, furfural, benzaldehyde, propenal, oct-2-enal, acetone, butan-2-one | [75,90,94] |

| Particleboard and laminated particleboard (60% Dahurian larch, softwood, and hardwood mix) | Acetaldehyde, hexanal, heptanal, octanal, nonanal, decanal, undecanal, acetone, (5E)-6,10-Dimethylundeca-5,9-dien-2-one (geranylacetone) | [77] |

| MDF (undisclosed pine species) | Pentanal, hexanal, heptanal, octanal, nonanal, benzaldehyde, oct-2-enal | [94] |

| MDF (undisclosed hardwood species) | Pentanal, hexanal, octanal, nonanal, benzaldehyde, oct-2-enal | [94] |

| MDF (undisclosed wood species) | formaldehyde, acetaldehyde, propanal, butanal, pentanal, hexanal, heptanal, octanal, nonanal, decanal, benzaldehyde, oxaldehyde (glyoxal), 4-hydroxybenzaldehyde, prop-2-enal, but-2-enal, hept-2-enal, oct-2-enal, dec-2-enal, acetone, butan-2-one, 1-hydroxypropan-2-one (acetol), butane-2,3-dione, pentane-2,3-dione | [75,90,94,98] |

| Wood | Other Volatile Compounds Emitted * | References | |

|---|---|---|---|

| Softwood | Pine (Pinus sylvestris, Pinus spp.) | ethanol, pentan-1-ol, tridecane, toluene, o/m/p-xylene | [64,65,87,91] |

| Spruce (Picea abies) | ethanol, propan-2-ol, 2-ethylhexanol, o/m/p-xylene | [64,91] | |

| Larch (Larix decidua, Larix sibirica, Larix gmelinii) | ethanol, propan-2-ol, 2-ethylhexanol, 1-propene, octadecane, o/m/p-xylene | [64,69,91] | |

| Hardwood | Oak (Quercus robur) | methanol, ethanol, propan-2-ol, 2-penthylfuran | [48,91] |

| Beech (Fagus sylvatica) | methanol, ethanol, propan-2-ol, 2-penthylfuran | [48,91,92] | |

| Ash (Franxinus excelsior) | methanol, ethanol, 2-penthylfuran | [48,92] | |

| Wood | Conditions | Compounds | Value | Compounds | Value | Unit | Method | References |

|---|---|---|---|---|---|---|---|---|

| Douglas Fir | ||||||||

| Particleboard | Conditioned (23 °C, 45% RH) 4 days of sampling period | α-Pinene | 11 | Limonene | 9 | µg·m−2·h−1 | GC-MSD | [74] |

| β-Pinene | 1 | Borneol | 4 | |||||

| Δ3-Carene | 2 | p-Cymene | 4 | |||||

| α-Pinene/Δ3-Carene | 8 | Borneol | 4 | ASTM D 5116-90 [138] | ||||

| β-Pinene/Limonene | 38 | p-Cymene | 8 | |||||

| Fir | ||||||||

| Solid Wood | Untreated Age of wood: 1 year | α-Pinene | 115 ± 1 | Cymene | 6.16 ± 0.05 | mg·kg−1 | Hexane extraction and GC-MS | [70] |

| β-Pinene | 20.99 ± 0.09 | Borneol | 3.34 ± 0.08 | |||||

| Limonene | 6.2 ± 0.1 | Fenchol | 2.4 ± 0. 2 | |||||

| Camphene | 12.3 ± 0.3 | Thymol | 4.3 ± 0.1 | |||||

| α-Phellandrene | 1.65 ± 0.04 | Myrtenal | 6.1 ± 0.2 | |||||

| Verbenone | 7.6 ± 0.1 | |||||||

| Heat treatment (120 °C) Age of wood: 1 year | α-Pinene | 0.175 ± 0.003 | Cymene | 0.0252 ± 0.0009 | ||||

| β-Pinene | 0.067 ± 0.001 | Borneol | 0.0163 ± 0.0002 | |||||

| Limonene | 0.0413 ± 0.0004 | Fenchol | 0.0077 ± 0.0001 | |||||

| Camphene | 0.0059 ± 0.0002 | Thymol | 0.040 ± 0.002 | |||||

| α-Phellandrene | 0.169 ± 0.003 | Myrtenal | 0.0459 ± 0.0009 | |||||

| Verbenone | 0.455 ± 0.009 | |||||||

| Untreated | α-Pinene | 4.33 ± 0.03 | Verbenone | 0.80 ± 0.02 | ||||

| Age of wood: 146 years | β-Pinene | 0.192 ± 0.003 | Thymol | 0.52 ± 0.01 | ||||

| Limonene | 1.0672 ± 0.013 | Myrtenal | 1.2875 ± 0.004 | |||||

| Camphene | 0.387 ± 0.004 | |||||||

| Heat treatment (120 °C) Age of wood: 146 years | Limonene | 0.337 ± 0.006 | Borneol | 0.6303 ± 0.006 | ||||

| Pine | ||||||||

| Solid wood | Air-dried Conditioned (23 °C, 50% RH) 28 days of sampling period | α-Pinene | 410 | Camphene | 9 | µg·m−2·h−1 | ISO 16000-6 and GC-MS | [66] |

| β-Pinene | 17 | β-Phellandrene | 11 | |||||

| Δ3-Carene | 340 | β-Myrsene | 17 | |||||

| Limonene | 13 | |||||||

| Heat treatment (212 °C) Conditioned (23 °C, 50% RH) 28 days of sampling period | α-Pinene | 2 | Limonene/Δ3-Carene | 3 | ||||

| Heartwood/ Sapwood | Fresh wood Conditioned (23 °C, 45% RH) 28 days of sampling period | α-Pinene | 459/294 | Limonene | 5/<1 | µg·m−3 | ISO 16000-6 and ISO 16000-9 | [64] |

| β-Pinene | 13/15 | Camphene | 23/10 | |||||

| Δ3-Carene | 108/40 | Terpinolene | 8/- | |||||

| Air-dried Conditioned (20–25 °C, 50% RH) 3 h of sampling period | β-Pinene | 7.95/2.82 | Camphene | 8.61/1.73 | mg·m−2·h−1 | ISO 16000-6, ISO 16000-10 [139] and GC-MS | [62] | |

| Limonene | 5.26/1.22 | γ-Terpinene | -/0.02 | |||||

| Heat treatment (200 °C) Conditioned (23 °C, 45% RH) 3 h of sampling period | β-Pinene | 3.59/4.73 | γ-Terpinene | 0.17/0.06 | ||||

| Limonene | 5.62/2.41 | α-Phellandrene | 0.125/0.05 | |||||

| Particleboard | Conditioned (23 °C, 45% RH) 4 days of sampling period | α-Pinene | 42 | Camphene | 3 | µg·m−2·h−1 | GC-MSD | [74] |

| β-Pinene | 72 | Borneol | 11 | |||||

| Δ3-Carene | 78 | p-Cymene | 28 | |||||

| Limonene | 50 | |||||||

| α-Pinene | 23 | Camphene | 2 | ASTM D 5116-90 | ||||

| β-Pinene | 26 | Borneol | 12 | |||||

| Δ3-Carene | 48 | p-Cymene | 24 | |||||

| Limonene | 31 | |||||||

| MDF | Conditioned (23 °C, 45% RH) 4 days of sampling period | Δ3-Carene | 2 | Borneol | 7 | ASTM D 5116-90 | ||

| Limonene | 2 | p-Cymene | 0.2 | |||||

| Spruce | [66] | |||||||

| Solid wood | Air-dried Conditioned (23 °C, 50% RH) 28 days of sampling period | α-Pinene | 54 | Camphene/β-Myrsene | 4 | µg·m−2·h−1 | ISO 16000-6 and GC-MS | |

| β-Pinene | 38 | Limonene | 53 | |||||

| Δ3-Carene | 6 | β-Fellandrene | 5 | |||||

| Heat treatment (190 °C) Conditioned (23 °C, 50% RH) 28 days of sampling period | α-Pinene | 3 | Limonene | 1 |

| Wood | Conditions | Compounds | Value | Compounds | Value | Unit | Method | References |

|---|---|---|---|---|---|---|---|---|

| Aspen | ||||||||

| Solid wood | Air-dried Conditioned (23 °C, 50% RH) 28 days of sampling period | Acetic acid | 51 | Propanoic acid | 5 | µg·m−2·h−1 | ISO 16000-6 and GC-MS | [66] |

| Hexanoic acid | 9 | Benzoic acid | 1 | |||||

| Pentanal | 29 | Hexanal | 180 | |||||

| Pent-2-enal | 4 | |||||||

| Heat treatment (190 °C) | Acetic acid | 170 | Propanoic acid | 7 | ||||

| Conditioned (23 °C, 50% RH) | Benzoic acid | 2 | Furfural | 37 | ||||

| 28 days of sampling period | Pentanal/Hexanal | 1 | Octanal | 1 | ||||

| Nonanal/Decanal | 2 | |||||||

| Beech | ||||||||

| Solid wood (Veneer) | Conditioned (23 °C, 50% RH) 2.5 h of sampling period | Formic acid | 252–366 | Acetic acid | 1104–1166 | µg·m−3 | VDI 4301-7 [140] and ISO 16000-9 | [91] |

| Formaldehyde | 6–12 | Propanal | <3 | ISO 16000-3 and ISO 16000-9 | ||||

| Acetaldehyde | 13–17 | Acetone | 4–98 | |||||

| Prop-2-enal | <1 | ISO 16000-9 and according to [141] | ||||||

| Solid wood (Slat) | Conditioned (23 °C, 50% RH) 2.5 h of sampling period | Formic acid | 132–193 | Acetic acid | 1277–1720 | µg·m−3 | VDI 4301-7 and ISO 16000-9 | |

| Formaldehyde | <2 | Propanal | 7–13 | ISO 16000-3 and ISO 16000-9 | ||||

| Acetaldehyde | 16–48 | Acetone | 95–168 | |||||

| Prop-2-enal | <1 | ISO 16000-9 and according to [141] | ||||||

| Laminated veneer lumber | Conditioned (23 °C, 50% RH) 2.5 h of sampling period Resin: MUF | Formic acid | 156–400 | Acetic acid | 1302–1409 | µg·m−3 | VDI 4301-7 and ISO 16000-9 | |

| Formaldehyde | 16–23 | Acetaldehyde | 16–80 | ISO 16000-3 and ISO 16000-9 | ||||

| Propanal | <3 | Acetone | 3–120 | |||||

| Prop-2-enal | <1 | ISO 16000-9 and according to [141] | ||||||

| Conditioned (23 °C, 50% RH) 2.5 h of sampling period Resin: Phenol-Formaldehyde | Formic acid | 217–276 | Acetic acid | 1268–1624 | µg·m−3 | VDI 4301-7 and ISO 16000-9 | ||

| Formaldehyde | 2–6 | Acetaldehyde | 36–161 | ISO 16000-3 and ISO 16000-9 | ||||

| Propanal | <3 | Acetone | 5–24 | |||||

| Prop-2-enal | <1 | ISO 16000-9 and according to [141] | ||||||

| Douglas fir | ||||||||

| Solid wood | Conditioned (23 °C, 50% RH) 2.5 h of sampling period | Formic acid | 28–106 | Acetic acid | 458–782 | µg·m−3 | VDI 4301-7 and ISO 16000-9 | [91] |

| Formaldehyde | 11–23 | Propanal | <3 | ISO 16000-3 and ISO 16000-9 | ||||

| Acetaldehyde | 20–70 | Acetone | 32–68 | |||||

| Prop-2-enal | 1–4 | ISO 16000-9 and according to [141] | ||||||

| Larch | ||||||||

| Solid wood | Conditioned (23 °C, 50% RH) 2.5 h of sampling period | Formic acid | 36–58 | Acetic acid | 286–352 | µg·m−3 | VDI 4301-7 and ISO 16000-9 | [91] |

| Formaldehyde | 10–28 | Propanal | <4 | ISO 16000-3 and ISO 16000-9 | ||||

| Acetaldehyde | 21–23 | Acetone | 9–27 | |||||

| Prop-2-enal | 1–4 | ISO 16000-9 and according to [141] | ||||||

| Oak | ||||||||

| Solid wood | Conditioned (23 °C, 50% RH) 2.5 h of sampling period | Formic acid | 68–172 | Acetic acid | 172–2876 | µg·m−3 | VDI 4301-7 and ISO 16000-9 | [91] |

| Formaldehyde | 7–29 | Propanal | <4–6 | ISO 16000-3 and ISO 16000-9 | ||||

| Acetaldehyde | 6–18 | Acetone | <3–31 | |||||

| Prop-2-enal | <1 | ISO 16000-9 and according to [141] | ||||||

| Heartwood | Raw byproduct of wine barrels production (12% moisture content) Conditioned (23 °C, 50% RH) 18 h of sampling period | Acetic acid | (106 ± 15)·104 | Acetone | <0.4 | µg·m−2·h−1 | ISO 16000-9 and HPLC-DAD | [142] |

| Formaldehyde | 186.9 ± 9.0 | Propenal | 1080 ± 330 | |||||

| Acetaldehyde | 313 ± 73 | Furfural | (360 ± 50)·102 | |||||

| Propanal | 13.4 ± 1.1 | Benzaldehyde | <1.5 | |||||

| Butanal | 5.1 ± 4.0 | |||||||

| Binderless board | Heartwood Pressing conditions (170 °C, 30 MPa, 6 min) Conditioned (23 °C, 50% RH) 18 h of sampling period | Acetic acid | 387 ± 68 | Acetone | 6.5 ± 1.2 | |||

| Formaldehyde | 60.5 ± 9.4 | Propenal | 187 ± 57 | |||||

| Acetaldehyde | 782 ± 97 | Furfural | 337 ± 58 | |||||

| Propanal | 11.0 ± 2.7 | Benzaldehyde | <0.3 | |||||

| Butanal | 13.8 ± 3.8 | |||||||

| Pine | ||||||||

| Solid wood | Air-dried Conditioned (23 °C, 50% RH) 28 days of sampling period | Acetic acid | 3 | 1- Pentanol | 12 | µg·m−2·h−1 | ISO 16000-6 and GC-MS | [66] |

| Hexanal | 34 | Furfural | 1 | |||||

| Heat treatment (212 °C) Conditioned (23 °C, 50% RH) 28 days of sampling period | Acetic acid | 27 | Benzoic acid | 12 | ||||

| Pentanal | 2 | Benzaldehyde | 6 | |||||

| Hexanal | 11 | Furfural | 18 | |||||

| Nonanal | 3 | |||||||

| Heartwood/ Sapwood | Fresh wood Conditioned (23 °C, 45% RH) 28 days of sampling period | Hexanal | 4/152 | Decanal | 1/11 | µg·m−3 | ISO 16000-6 and ISO 16000-9 | [64] |

| Octanal | 1/7 | Benzaldehyde | <1/6 | |||||

| Nonanal | 14/12 | Acetophenone | 1/11 | |||||

| Particleboard | Conditioned (23 °C, 45% RH) 3 days of sampling period Average values | Pentanal | 82 | Nonanal | 32 | µg·m−2· h−1 | ASTM D 5116-90 | [94] |

| Hexanal | 851 | trans-2-octenal | 41 | |||||

| Heptanal | 21 | Benzaldehyde | 55 | |||||

| Octanal | 34 | |||||||

| MDF | Conditioned (23 °C, 45% RH) 3 days of sampling period | Pentanal | 26 | Nonanal | 12 | |||

| Hexanal | 285 | trans-2-octenal | 4 | |||||

| Heptanal | 7 | Benzaldehyde | 17 | |||||

| Octanal | 9 | |||||||

| Poplar | ||||||||

| Laminated veneer lumber | Conditioned (23 °C, 50% RH) 2.5 h of sampling period Resin: MUF | Formic acid | 19–44 | Acetic acid | 949–1486 | µg·m−3 | VDI 4301-7 and ISO 16000-9 | [91] |

| Formaldehyde | 20–30 | Acetaldehyde | 10–34 | ISO 16000-3 and ISO 16000-9 | ||||

| Propanal | <3 | Acetone | 3–120 | |||||

| Prop-2-enal | <1 | ISO 16000-9 and according to [141] | ||||||

| Spruce | ||||||||

| Solid wood | Air-dried Conditioned (23 °C, 50% RH) 28 days of sampling period | Acetic acid | 12 | Hexanal | 8 | µg·m−2·h−1 | ISO 16000-6 and GC-MS | [66] |

| Heat treatment (190 °C) | Acetic acid | 28 | Decanal | 5 | ||||

| Conditioned (23 °C, 50% RH) | Hexanal | 1 | Furfural | 23 | ||||

| 28 days of sampling period | Nonanal | 4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonçalves, F.D.; Carvalho, L.H.; Rodrigues, J.A.; Ramos, R.M. Wood-Based Panels and Volatile Organic Compounds (VOCs): An Overview on Production, Emission Sources and Analysis. Molecules 2025, 30, 3195. https://doi.org/10.3390/molecules30153195

Gonçalves FD, Carvalho LH, Rodrigues JA, Ramos RM. Wood-Based Panels and Volatile Organic Compounds (VOCs): An Overview on Production, Emission Sources and Analysis. Molecules. 2025; 30(15):3195. https://doi.org/10.3390/molecules30153195

Chicago/Turabian StyleGonçalves, Fátima Daniela, Luísa Hora Carvalho, José António Rodrigues, and Rui Miguel Ramos. 2025. "Wood-Based Panels and Volatile Organic Compounds (VOCs): An Overview on Production, Emission Sources and Analysis" Molecules 30, no. 15: 3195. https://doi.org/10.3390/molecules30153195

APA StyleGonçalves, F. D., Carvalho, L. H., Rodrigues, J. A., & Ramos, R. M. (2025). Wood-Based Panels and Volatile Organic Compounds (VOCs): An Overview on Production, Emission Sources and Analysis. Molecules, 30(15), 3195. https://doi.org/10.3390/molecules30153195