Characterization of Key Aroma Compounds in Aged Chinese Nongxiangxing Baijiu Based on Sensory and Quantitative Analysis: Emphasis on the Contribution of Trace Compounds

Abstract

1. Introduction

2. Results and Discussion

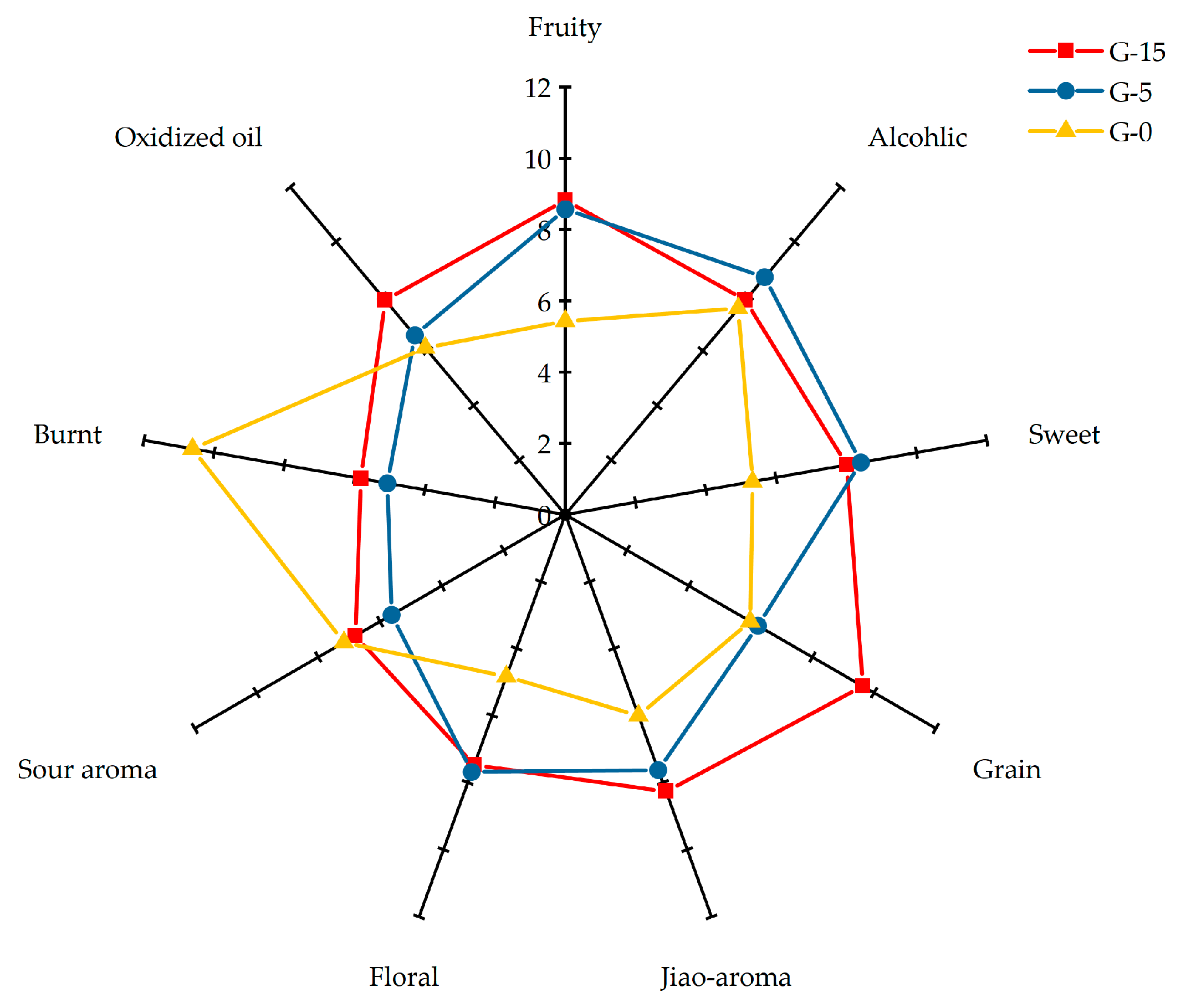

2.1. Aroma Profile of Different Aging Years of Baijiu Samples

2.2. Identification of Aroma Compounds in Young and Aged Nongxiangxing Baijiu by GC-O/MS

2.3. Quantification of Aroma Compounds in Baijiu Samples and Trace Compounds OAV Analysis

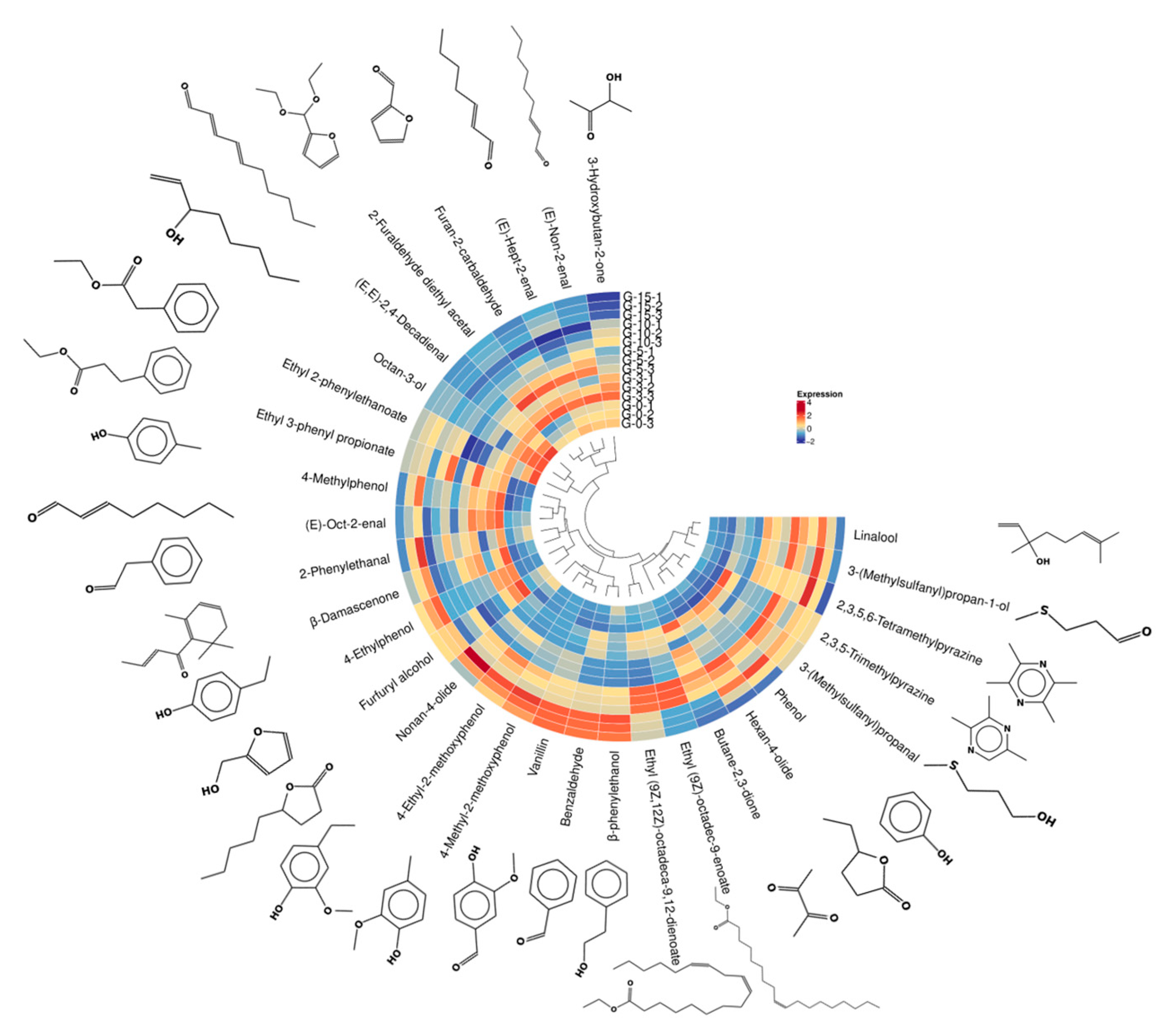

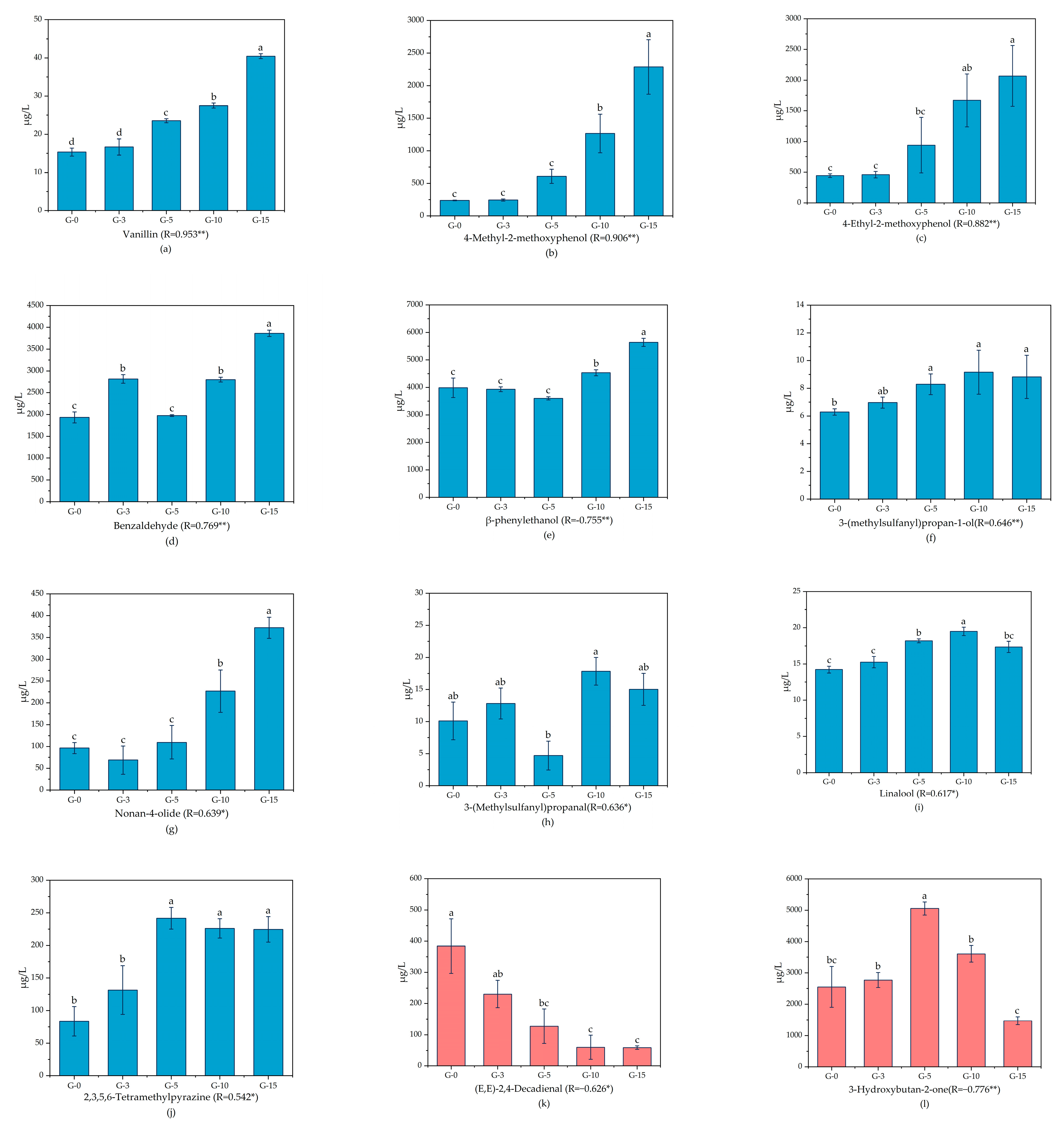

2.4. Variation Pattern of Trace Aroma Compound Concentration During Aging of Nongxiangxing Baijiu

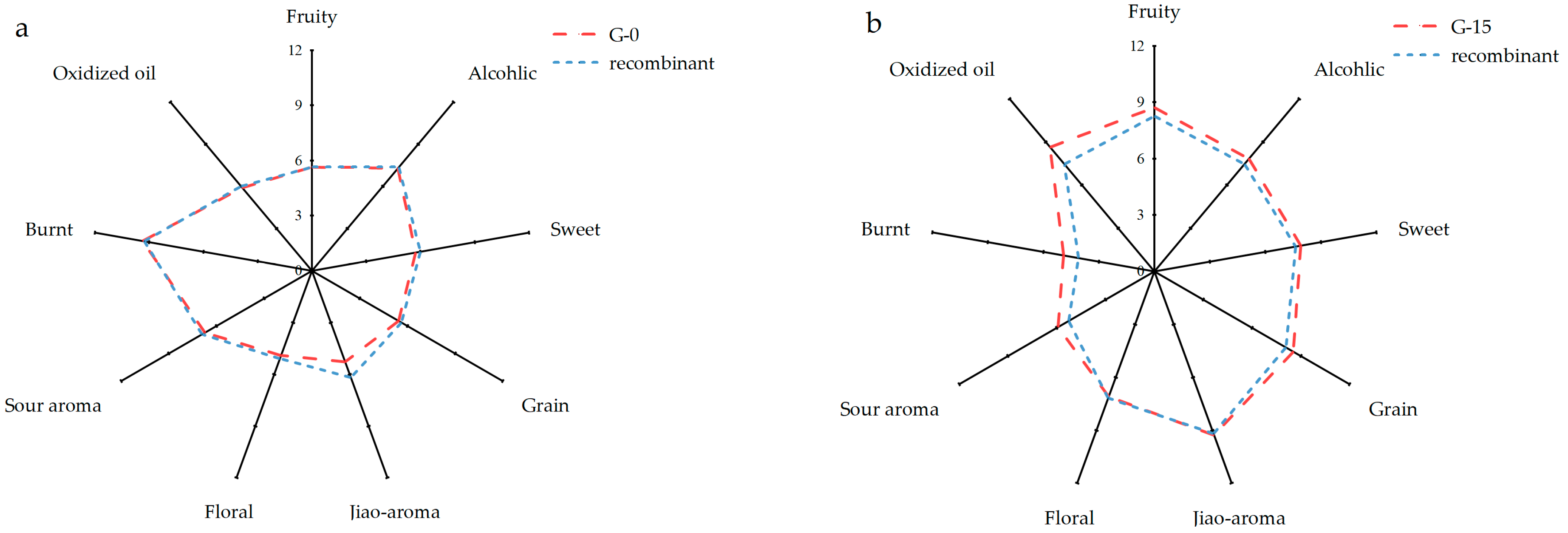

2.5. Aroma Recombination and Omission

3. Material and Methods

3.1. Baijiu Samples

3.2. Reagents and Chemicals

3.3. Sensory Analysis

3.4. Baijiu Analysis

3.4.1. Extraction of Volatile Compounds by Liquid–Liquid Extraction (LLE)

3.4.2. Aroma Extraction by Headspace Solid-Phase Microextraction Arrow (HS-SPME-Arrow)

3.4.3. GC-O Analysis

3.4.4. cAEDA Test

3.5. Quantitative Analysis of Aroma Compounds

3.5.1. Quantification by Gas Chromatography Using a Flame Ionization Detector (GC-FID)

3.5.2. Gas Chromatography-Mass Spectrometry (GC–MS) Analysis

3.5.3. Quantification by Liquid–Liquid Microextraction–Gas Chromatography-Mass Spectrometry (LLME-GC–MS)

3.6. Aroma Recombination and Omission Tests

3.7. Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- GB/T 15109-2021; Terminology of Baijiu Industry. China Food and Fermentation Industry Research Institute Co., Ltd.: Beijing, China, 2021.

- Qin, D.; Duan, J.; Li, Y.; He, F.; Li, H.; Sun, B. A Review of Changes of Flavor Compounds during Baijiu Aging and Recent Progress in Artificial Aging Techniques. Food Sci. 2021, 42, 260–267. [Google Scholar]

- China Alcoholic Drinks Association Market Specialized Committee. Mid-Term-Research-Report-on-the-Chinese-Baijiu-Market-2025. Available online: https://kpmg.com/cn/zh/home/insights/2025/06/mid-term-research-report-on-the-chinese-baijiu-market-2025.html (accessed on 8 July 2025).

- Ou, X. Revenue of Chinese Baijiu Industry in China from 2017 to 2021 with Estimates Until 2026, by Type of Aroma. Available online: https://www.statista.com/statistics/1332565/china-revenue-of-baijiu-by-flavor/ (accessed on 8 February 2024).

- Zhao, D.; Shi, D.; Sun, J.; Li, A.; Sun, B.; Zhao, M.; Chen, F.; Sun, X.; Li, H.; Huang, M.; et al. Characterization of key aroma compounds in Gujinggong Chinese Baijiu by gas chromatography–olfactometry, quantitative measurements, and sensory evaluation. Food Res. Int. 2018, 105, 616–627. [Google Scholar] [CrossRef] [PubMed]

- Li, W.Q. Study on the Increase of Ehyl hexanoate and Decrease of Ethyl lactate of Nongxiangxing Baijiu. Liquor.-Mak. Sci. Technol. 2000, 6, 51–52. [Google Scholar] [CrossRef]

- Fan, W.L.; Qian, M.C. Headspace solid phase microextraction and gas chromatography-olfactometry dilution analysis of young and aged Chinese “Yanghe Daqu” liquors. J. Agric. Food Chem. 2005, 53, 7931–7938. [Google Scholar] [CrossRef]

- Gong, L.L. Analytical Study on Volatile Aroma Compounds of Gujinggong Baijiu Vintage Original Syrup Series. Master’s Thesis, Beijing Technology and Business University, Beijing, China, 2017. [Google Scholar]

- Wang, L.L.; Wu, L.; Xiang, D.H.; Huang, H.; Han, Y.; Zhen, P.; Shi, B.B.; Chen, S.; Xu, Y. Characterization of key aroma compounds in aged Qingxiangxing Baijiu by comparative aroma extract dilution analysis, quantitative measurements, aroma recombination, and omission studies. Food Chem. 2023, 419, 136027. [Google Scholar] [CrossRef]

- Wang, L.L.; Gao, Y.C.; Wu, L.; Chen, S.; Xu, Y. Characterization of Key Aging Aroma Compounds in Aged Jiangxiangxing Baijiu and Their Formation Influencing Factors during the Storge Process. J. Agric. Food Chem. 2024, 72, 1695–1707. [Google Scholar] [CrossRef]

- Niu, Y.W.; Kong, J.L.; Xiao, Z.B.; Chen, F.; Ma, N.; Zhu, J.C. Characterization of odor-active compounds of various Chinese “Wuliangye” liquors by gas chromatography-olfactometry, gas chromatography-mass spectrometry and sensory evaluation. Int. J. Food Prop. 2017, 20, S735–S745. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, J.; Liu, X.; Zhang, C.; Zhao, Z.; Li, X.; Sun, B. Flavor mystery of Chinese traditional fermented Baijiu: The great contribution of ester compounds. Food Chem. 2022, 369, 130920. [Google Scholar] [CrossRef]

- Yang, C.; Wei, K.K.; Xu, M.H.; Wang, Z.J.; Cui, C.J.; Dai, Q.Y.; Chen, G.J.; Hou, R.Y. Sensory wheel construction and key flavor compounds characterization of black tea milk tea beverages. Food Chem. 2025, 481, 143931. [Google Scholar] [CrossRef]

- Plutowska, B.; Wardencki, W. Application of gas chromatography-olfactometry (GC-O) in analysis and quality assessment of alcoholic beverages—A review. Food Chem. 2008, 107, 449–463. [Google Scholar] [CrossRef]

- van Gemert, L.J. Compilation of Odour Threshold Values in Air, Water and Other Media, 2nd ed.; Oliemans Punter & Partners: Zeist, The Netherlands, 2011. [Google Scholar]

- Wang, L.; Hu, G.Y.; Lei, L.B.; Lin, L.; Wang, D.Q.; Wu, J.X. Identification and Aroma Impact of Volatile Terpenes in Moutai Liquor. Int. J. Food Prop. 2016, 19, 1335–1352. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, X.; Chen, S.; Xu, Y. Characterization of key aroma compounds contributing to oxidized oil-like off-odor in Jiangxiangxing Baijiu. Food Chem. 2025, 483, 144250. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Dai, Y.F.; Qiu, S.Y.; Sun, B.G.; Zeng, X.Y. Distribution and Quantification of 1,2-Propylene Glycol Enantiomers in Baijiu. Foods 2021, 10, 3039. [Google Scholar] [CrossRef] [PubMed]

- Willner, B.; Granvogl, M.; Schieberle, P. Characterization of the Key Aroma Compounds in Bartlett Pear Brandies by Means of the Sensomics Concept. J. Agric. Food Chem. 2013, 61, 9583–9593. [Google Scholar] [CrossRef]

- Li, N.; Li, G.Y.; Guan, X.; Li, A.H.; Tao, Y.S. Volatile aroma compound-based decoding and prediction of sweet berry aromas in dry red wine. Food Chem. 2025, 463, 141248. [Google Scholar] [CrossRef]

- Lin, L.Y.; Fan, W.L.; Xu, Y.; Zhu, D.C.; Yang, T.; Li, J. Characterization of Key Odorants in Chinese Texiang Aroma and Flavor Type Baijiu (Chinese Liquor) by Means of a Molecular Sensory Science Approach. J. Agric. Food Chem. 2024, 72, 1256–1265. [Google Scholar] [CrossRef]

- Han, B.L.; Zhou, W.T.; Chen, R.F.; Tian, S.L.; Gong, H.C.; Wang, Y.; Xu, Q.; Bian, M.H. Multi-factor analysis of the quality of cellar mud of Luzhou-flavor liquor in Yibin production area. Food Sci. Nutr. 2024, 12, 5231–5249. [Google Scholar] [CrossRef]

- Dugelay, I.; Baumes, R.; Gunata, Z.; Razungles, A.; Bayonove, C. Aroma Evolution During Wine Aging—Formation of 4-(1-Ethoxyethyl)-Phenol and 4-(1-Ethoxyethyl)-Gaiacol. Sci. Aliment. 1995, 15, 423–433. [Google Scholar]

- Vanbeneden, N.; Saison, D.; Delvaux, F.; Delvaux, F.R. Decrease of 4-Vinylguaiacol during Beer Aging and Formation of Apocynol and Vanillin in Beer. J. Agric. Food Chem. 2008, 56, 11983–11988. [Google Scholar] [CrossRef]

- Chen, S.; Wang, C.C.; Qian, M.; Li, Z.; Xu, Y. Characterization of the Key Aroma Compounds in Aged Chinese Rice Wine by Comparative Aroma Extract Dilution Analysis, Quantitative Measurements, Aroma Recombination, and Omission Studies. J. Agric. Food Chem. 2019, 67, 4876–4884. [Google Scholar] [CrossRef]

- Cardinal, M.; Cornet, J.; Sérot, T.; Baron, R. Effects of the smoking process on odour characteristics of smoked herring (Clupea harengus) and relationships with phenolic compound content. Food Chem. 2006, 96, 137–146. [Google Scholar] [CrossRef]

- Lustre, A.O.; Issenberg, P. Volatile components of hardwood sawdust smoke. Components of phenolic fraction. J. Agric. Food Chem. 1969, 17, 1387–1393. [Google Scholar] [CrossRef]

- Pino, J.A. Characterisation of volatile compounds in a smoke flavouring from rice husk. Food Chem. 2014, 153, 81–86. [Google Scholar] [CrossRef]

- Rayne, S.; Eggers, N.J. Quantitative determination of 4-ethylphenol and 4-ethyl-2-methoxyphenol in wines by a stable isotope dilution assay. J. Chromatogr. A 2007, 1167, 195–201. [Google Scholar] [CrossRef]

- Hernández-Orte, P.; Lapeña, A.C.; Escudero, A.; Astrain, J.; Baron, C.; Pardo, I.; Polo, L.; Ferrer, S.; Cacho, J.; Ferreira, V. Effect of micro-oxygenation on the evolution of aromatic compounds in wines: Malolactic fermentation and ageing in wood. LWT-Food Sci. Technol. 2009, 42, 391–401. [Google Scholar] [CrossRef]

- Deed, R.C.; Hou, R.Y.; Kinzurik, M.I.; Gardner, R.C.; Fedrizzi, B. The role of yeast ARO8, ARO9 and ARO1O genes in the biosynthesis of 3-(methylthio)-1-propanol from L-methionine during fermentation in synthetic grape medium. FEMS Yeast Res. 2019, 19, foy109. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Z.; Sun, B. Low Quantity but Critical Contribution to Flavor: Review of The Current Understanding of Volatile Sulfur-containing Compounds in Baijiu. J. Food Compos. Anal. 2021, 103, 104079. [Google Scholar] [CrossRef]

- Slaghenaufi, D.; Ugliano, M. Norisoprenoids, Sesquiterpenes and Terpenoids Content of Valpolicella Wines During Aging: Investigating Aroma Potential in Relationship to Evolution of Tobacco and Balsamic Aroma in Aged Wine. Front. Chem. 2018, 6, 66. [Google Scholar] [CrossRef]

- Ma, Y.; Tang, K.; Xu, Y.; Li, J.M. Characterization of the Key Aroma Compounds in Chinese Vidal Icewine by Gas Chromatography-Olfactometry, Quantitative Measurements, Aroma Recombination, and Omission Tests. J. Agric. Food Chem. 2017, 65, 394–401. [Google Scholar] [CrossRef]

- ISO 8586:2012; Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 4120:2021; Sensory Analysis—Methodology—Triangle Test. International Organization for Standardization: Geneva, Switzerland, 2021.

| No | Compound | RI a | RIL b | Odor Descriptor | FD c | Identification d | ||

|---|---|---|---|---|---|---|---|---|

| 15 years | 5 years | 0 years | ||||||

| Esters | ||||||||

| 1 | Ethyl ethanoate | 893 | 902 | Fruity | 1024 | 1024 | 2048 | RI, MS, Std, Aroma |

| 2 | Methyl hexanoate | 1108 | 1183 | Fruity | 32 | 4 | 4 | RI, MS, Aroma |

| 3 | Ethyl hexanoate | 1183 | 1235 | Fruity | 2048 | 1024 | 1024 | RI, MS, Std, Aroma |

| 4 | Pentyl butanoate | 1199 | 1326 | Banana | 8 | 4 | 4 | RI, MS, Aroma |

| 5 | Propyl hexanoate | 1253 | 1293 | Pineapple | 64 | 16 | 16 | RI, MS, Std, Aroma |

| 6 | Ethyl heptanoate | 1271 | 1342 | Pineapple | 32 | 16 | 16 | RI, MS, Std, Aroma |

| 7 | 2-Methylpropyl hexanoate | 1286 | 1362 | Fruity | 8 | 4 | 4 | RI, MS, Std, Aroma |

| 8 | Butyl hexanoate | 1352 | 1384 | Fruity | 8 | 4 | 4 | RI, MS, Std, Aroma |

| 9 | Hexyl butanoate | 1355 | 1388 | Soapy, fruity | 4 | 4 | 4 | RI, MS, Aroma |

| 10 | Ethyl octanoate | 1379 | 1434 | Fruity, waxy | 4 | 4 | 4 | RI, MS, Std, Aroma |

| 11 | 3-Methylbutyl butanoate | 1402 | 1459 | Banana | 64 | 32 | 64 | RI, MS, Std, Aroma |

| 12 | Ethyl nonanoate | 1486 | 1533 | Fruity | 8 | 8 | 16 | RI, MS, Std, Aroma |

| 13 | Hexyl hexanoate | 1571 | 1609 | Herbal, grass | 4 | 4 | 8 | RI, MS, Std, Aroma |

| 14 | Ethyl decanoate | 1606 | 1634 | Waxy, fruity | 4 | 2 | 16 | RI, MS, Std, Aroma |

| 15 | Diethyl butanedioate | 1659 | 1677 | Fruity | 16 | 4 | 4 | RI, MS, Std, Aroma |

| 16 | Ethyl dodecanoate | 1803 | 1860 | Waxy, soapy | 4 | 8 | 8 | RI, MS, Std, Aroma |

| 17 | Ethyl butanoate | 1023 | 1025 | Fruity | 1024 | 1024 | 512 | RI, MS, Std, Aroma |

| 18 | 3-Methylbutyl ethanoate | 1128 | 1131 | Sweet, fruity | 4 | 16 | 16 | RI, MS, Std, Aroma |

| 19 | Ethyl pentanoate | 1122 | 1159 | Fruity | 32 | 16 | 8 | RI, MS, Std, Aroma |

| 20 | Ethyl hexadecanoate | 2255 | 2265 | Waxy, fruity | 2 | 4 | 4 | RI, MS, Std, Aroma |

| 21 | Ethyl (9Z)-octadec-9-enoate | 2479 | 2476 | Fatty, oily | 2 | 2 | 2 | RI, MS, Std, Aroma |

| 22 | Ethyl (9Z,12Z)-octadeca-9,12-dienoate | 2521 | 2521 | Fatty, oily | 4 | 2 | 2 | RI, MS, Std, Aroma |

| 23 | Ethyl 2-methyl butanoate | 1040 | 1053 | Fruity | 256 | 64 | 32 | RI, MS, Std, Aroma |

| 24 | Ethyl 3-methylbutanoate | 1055 | 1060 | Sweet, apple | 128 | 64 | 64 | RI, MS, Aroma |

| 25 | Ethyl 4-methylpentanoate | 1189 | 1197 | Fruity | 64 | 32 | 16 | RI, MS, Std, Aroma |

| 26 | Ethyl 2-hydroxy-4-methylpentanoate | 1508 | 1516 | Blackberry | 4 | 8 | 16 | RI, MS, Aroma |

| 27 | Ethyl cyclohexanecarboxylate | 1414 | 1424 | Fruity | 32 | 64 | 32 | RI, MS, Std, Aroma |

| Alcohols | ||||||||

| 28 | Butan-2-ol | 938 | 1020 | Sweet | 512 | 256 | 256 | RI, MS, Aroma |

| 29 | Propan-1-ol | 972 | 1035 | Alcoholic | 64 | 32 | 16 | RI, MS, Std, Aroma |

| 30 | 2-Methylpropan-1-ol | 1049 | 1078 | Winey | 4 | 4 | 4 | RI, MS, Aroma |

| 31 | Pentan-2-ol | 1078 | 1114 | Oily, fermented | 256 | 128 | 256 | RI, MS, Std, Aroma |

| 32 | Butan-1-ol | 1092 | 1137 | Fusel, sweet | 128 | 64 | 16 | RI, MS, Aroma |

| 33 | 3-Methylbutan-1-ol | 1135 | 1201 | Fermented | 128 | 64 | 64 | RI, MS, Aroma |

| 34 | Hexan-2-ol | 1190 | 1210 | Winey | 16 | 8 | 8 | RI, MS, Aroma |

| 35 | 3-Methylbutan-2-ol | 1220 | 1256 | Fermented, Fruity | 4 | 4 | 4 | RI, MS, Aroma |

| 36 | 3-Methylbut-3-en-1-ol | 1225 | 1246 | Sweet, fruity | 4 | 4 | 4 | RI, MS, Aroma |

| 37 | Heptan-2-ol | 1274 | 1306 | Citrus, herbal | 4 | 8 | 4 | RI, MS, Std, Aroma |

| 38 | Hexan-1-ol | 1313 | 1341 | Herbal | 64 | 32 | 4 | RI, MS, Aroma |

| 39 | Octan-3-ol | 1430 | 1462 | Mushroom | 32 | 32 | 64 | RI, MS, Std, Aroma |

| 40 | Heptan-1-ol | 1410 | 1442 | Green, herbal | 16 | 16 | 32 | RI, MS, Std, Aroma |

| 41 | Octan-1-ol | 1514 | 1554 | Waxy | 16 | 4 | 4 | RI, MS, Std, Aroma |

| 42 | 2-Methylbutan-1-ol | 1204 | 1197 | Fusel, alcoholic | 8 | 8 | 8 | RI, MS, Std, Aroma |

| 43 | (±)-Butane-2,3-diol | 1594 | 1604 | Fruity, creamy | 4 | 4 | 16 | RI, MS, Aroma |

| Acids | ||||||||

| 44 | Ethanoic acid | 1415 | 1424 | Sour | 32 | 32 | 32 | RI, MS, Std, Aroma |

| 45 | 2-Methylpropanoic acid | 1532 | 1555 | Sour | 4 | 8 | 64 | RI, MS, Aroma |

| 46 | Butanoic acid | 1591 | 1602 | Cheese | 64 | 32 | 32 | RI, MS, Std, Aroma |

| 47 | 3-Methylbutanoic acid | 1637 | 1655 | Sour, cheesy | 2 | 8 | 16 | RI, MS, Aroma |

| 48 | Pentanoic acid | 1708 | 1733 | Sweaty, sour | 2048 | 1024 | 256 | RI, MS, Std, Aroma |

| 49 | 4-Methylpentanoic acid | 1773 | 1800 | Pungent, Cheesy | 8 | 4 | 4 | RI, MS, Std, Aroma |

| 50 | Hexanoic acid | 1818 | 1857 | Sour, fatty | 16 | 16 | 2 | RI, MS, Std, Aroma |

| 51 | Heptanoic acid | 1928 | 1960 | Sour, cheesy | 8 | 4 | 2 | RI, MS, Std, Aroma |

| 52 | Octanoic acid | 2035 | 2070 | Sweaty, cheesy | 4 | 4 | 2 | RI, MS, Std, Aroma |

| 53 | Propanoic acid | 1530 | 1535 | Cheesy | 16 | 8 | 2 | RI, MS, Std, Aroma |

| 54 | Nonanoic acid | 2162 | 2169 | Waxy, cheesy | 16 | 16 | 64 | RI, MS, Std, Aroma |

| Aldehydes and ketones | ||||||||

| 55 | Oct-1-en-3-one | 1309 | 1306 | Mushroom, herbal | 16 | 32 | 64 | RI, MS, Std, Aroma |

| 56 | Oct-3-en-2-one | 1388 | 1408 | Earthy, herbal | 8 | 8 | 16 | RI, MS, Aroma |

| 57 | 1,1-Diethoxyethane | 892 | 892 | Green, nutty | 512 | 64 | 64 | RI, MS, Std, Aroma |

| 58 | 3-Methylbutanal | 928 | 952 | Aldehydic, fatty | 32 | 16 | 4 | RI, MS, Std, Aroma |

| 59 | Pentan-2-one | 1009 | 1003 | Fruity | 16 | 16 | 4 | RI, MS, Std, Aroma |

| 60 | 3-Hydroxybutan-2-one | 1280 | 1305 | Buttery, creamy | 32 | 8 | 4 | RI, MS, Std, Aroma |

| 61 | Butane-2,3-dione | 1005 | 977 | Buttery, sweet | 8 | 8 | 4 | RI, MS, Std, Aroma |

| 62 | (E)-Oct-2-enal | 1430 | 1433 | Green, cucumber | 128 | 32 | 16 | RI, MS, Std, Aroma |

| 63 | (E)-Non-2-enal | 1542 | 1551 | Cucumber, green | 64 | 32 | 32 | RI, MS, Std, Aroma |

| 64 | (E,Z)-Nona-2,6-dienal | 1572 | 1591 | Cucumber, green | 32 | 8 | 4 | RI, MS, Std, Aroma |

| 65 | (E,E)-Nona-2,4-dienal | 1696 | 1686 | Fatty, green | 16 | 16 | 4 | RI, MS, Std, Aroma |

| 66 | (E,E)-Deca-2,4-dienal | 1819 | 1802 | Citrus, green | 64 | 64 | 4 | RI, MS, Aroma |

| 67 | (E)-Hept-2-enal | 1309 | 1314 | Green, fatty | 4 | 4 | 2 | RI, MS, Std, Aroma |

| Terpenoids | ||||||||

| 68 | β-damascenone | 1818 | 1827 | Floral | 512 | 64 | 32 | RI, MS, Std, Aroma |

| 69 | β-Ionone | 1947 | 1958 | Floral | 64 | 32 | 32 | RI, MS, Aroma |

| 70 | Linalool | 1552 | 1579 | Floral, citrus | 32 | 4 | 2 | RI, MS, Aroma |

| 71 | Nerol | 1806 | 1821 | Floral | 16 | 4 | 4 | RI, MS, Aroma |

| Lactones | ||||||||

| 72 | Butan-4-olide | 1611 | 1626 | Creamy, oily | 64 | 32 | 32 | RI, MS, Std, Aroma |

| 73 | Hexan-4-olide | 1695 | 1703 | Herbal | 4 | 2 | 2 | RI, MS, Std, Aroma |

| 74 | Nonan-4-olide | 2031 | 2024 | Coconut | 128 | 64 | 128 | RI, MS, Std, Aroma |

| Aromatics | ||||||||

| 75 | β-phenylethanol | 1923 | 1906 | Floral | 256 | 128 | 16 | RI, MS, Std, Aroma |

| 76 | 2-Phenylethanal | 1634 | 1642 | Green, sweet | 128 | 16 | 8 | RI, MS, Std, Aroma |

| 77 | Benzaldehyde | 1508 | 1534 | Fruity | 8 | 4 | 2 | RI, MS, Std, Aroma |

| 78 | Ethyl 3-phenylpropionate | 1870 | 1880 | Floral, honey | 2048 | 256 | 256 | RI, MS, Std, Aroma |

| 79 | Ethyl 2-phenylethanoate | 1764 | 1797 | Floral | 128 | 128 | 16 | RI, MS, Std, Aroma |

| Furans | ||||||||

| 80 | 2-(Diethoxymethyl)furan | 1442 | 1432 | Mushroom | 16 | 16 | 64 | RI, Aroma |

| 81 | Furan-2-carbaldehyde | 1458 | 1466 | Baked bread | 16 | 32 | 64 | RI, MS, Std, Aroma |

| 82 | 1-(Furan-2-yl)pentan-1-one | 1737 | 1747 | Sweet, caramel | 2 | 4 | 64 | RI, Aroma, Aroma |

| 83 | (Furan-2-yl)methanol | 1666 | 1647 | Bready | 4 | 4 | 8 | RI, MS, Std, Aroma |

| Sulfur-containing compounds | ||||||||

| 84 | 2-(Methylsulfanyl)ethan-1-ol | 1515 | 1486 | Sulfurous, meaty | 256 | 32 | 32 | RI, MS, Aroma |

| 85 | 3-(Methylsulfanyl)propanal | 1455 | 1458 | Musty tomato | 2048 | 128 | 16 | RI, MS, Std, Aroma |

| 86 | 3-(Methylsulfanyl)propan-1-ol | 1719 | 1719 | Meaty, onion | 8 | 16 | 8 | RI, MS, Std, Aroma |

| Pyrazines | ||||||||

| 87 | 2,3,5-Trimethylpyrazine | 1397 | 1392 | Nutty, earthy | 32 | 4 | 4 | RI, MS, Std, Aroma |

| 88 | 2,3,5,6-Tetramethylpyrazine | 1472 | 1477 | Nutty | 64 | 8 | 16 | RI, MS, Std, Aroma |

| Phenolic compounds | ||||||||

| 89 | 4-Methyl-2-methoxyphenol | 1945 | 1953 | Woody | 64 | 16 | 16 | RI, MS, Std, Aroma |

| 90 | Phenol | 1987 | 2030 | Plastic, rubber | 4 | 4 | 8 | RI, MS, Std, Aroma |

| 91 | 4-Ethyl-2-methoxyphenol | 2022 | 2048 | Smoky, clove | 32 | 32 | 16 | RI, MS, Std, Aroma |

| 92 | 4-Methylphenol | 2078 | 2089 | Phenolic | 256 | 128 | 128 | RI, MS, Std, Aroma |

| 93 | 4-Ethylphenol | 2195 | 2195 | Smoky | 256 | 64 | 64 | RI, MS, Std, Aroma |

| 94 | Vanillin | 2599 | 2600 | Vanilla | 256 | 128 | 128 | RI, MS, Std, Aroma |

| No | Compound | Odor Threshold (μg/L) | OAV | G-15/G-0 Ratio j | |

|---|---|---|---|---|---|

| G-15 | G-0 | ||||

| 1 | 4-Methyl-2-methoxyphenol | 314.56 b | 7.3 | 0.8 | 9.59 |

| 2 | Heptan-1-ol | 26,600 c | 0.1 | <0.1 | 6.48 |

| 3 | 4-Ethyl-2-methoxyphenol | 122.74 b | 16.8 | 3.6 | 4.67 |

| 4 | Heptanoic acid | 13,821.32 b | 2.6 | 0.6 | 4.44 |

| 5 | β-damascenone | 5.38 a | 3.0 | 0.8 | 3.95 |

| 6 | Nonan-4-olide | 90.66 b | 4.1 | 1.1 | 3.86 |

| 7 | Octanoic acid | 2701.23 b | 16.8 | 4.8 | 3.50 |

| 8 | 3-(Methylsulfanyl)propanal | 7.1 b | 2.1 | 0.7 | 3.20 |

| 9 | Hexan-4-olide | 12500 e | 0.1 | <0.1 | 2.89 |

| 10 | 2,3,5,6-Tetramethylpyrazine | 80,073.16 b | <0.1 | <0.1 | 2.69 |

| 11 | Vanillin | 438.52 b | 0.1 | <0.1 | 2.64 |

| 12 | Diethyl butanedioate | 353,193.25 b | <0.1 | <0.1 | 2.39 |

| 13 | Pentanoic acid | 389.11 b | 108.6 | 45.9 | 2.37 |

| 14 | 4-Ethylphenol | 617.68 b | 2.1 | 0.9 | 2.35 |

| 15 | Butan-2-ol | 50,000 c | 1.8 | 0.8 | 2.15 |

| 16 | 2,3,5-Trimethylpyrazine | 729.86 b | 0.6 | 0.3 | 2.12 |

| 17 | Phenol | 18,909.34 b | <0.1 | <0.1 | 2.02 |

| 18 | Benzaldehyde | 4203.1 b | 0.9 | 0.5 | 2.00 |

| 19 | 4-Methylphenol | 166.97 b | 18.7 | 11.1 | 1.68 |

| 20 | Propyl hexanoate | 12,783.77 b | 0.7 | 0.4 | 1.64 |

| 21 | Octan-1-ol | 1100 c | 0.9 | 0.6 | 1.62 |

| 22 | Nonanoic acid | 3560 b | 0.4 | 0.3 | 1.51 |

| 23 | 2-Phenylethanal | 262 b | 2.5 | 1.6 | 1.50 |

| 24 | 1,2-Propanediol | 4660 f | 0.8 | 0.5 | 1.45 |

| 25 | Ethyl heptanoate | 13,153.17 b | 5.1 | 3.6 | 1.44 |

| 26 | Ethyl 3-phenyl propionate | 125.21 b | 79.1 | 55.4 | 1.43 |

| 27 | β-phenylethanol | 28,900 c | 0.2 | 0.1 | 1.41 |

| 28 | 3-(Methylsulfanyl)propan-1-ol | 2110.41 b | <0.1 | <0.1 | 1.40 |

| 29 | 4-Methyl pentanoic acid | 144 b | 43.0 | 31.5 | 1.37 |

| 30 | Propanoic acid | 18,200 b | 1.4 | 1.0 | 1.34 |

| 31 | Ethyl 2-methylbutanoate | 248.6 a | 0.7 | 0.5 | 1.30 |

| 32 | (E)-Oct-2-enal | 15.1 b | 22.9 | 18.5 | 1.24 |

| 33 | Linalool | 13.1 d | 1.3 | 1.1 | 1.22 |

| 34 | Ethyl cyclohexanecarboxylate | 21.37 a | 0.5 | 0.4 | 1.19 |

| 35 | Furfuryl alcohol | 54,700 c | 0.1 | 0.1 | 1.16 |

| 36 | Pentan-2-ol | 194,000 c | 0.1 | 0.1 | 1.16 |

| 37 | Ethyl (9Z,12Z)-octadeca-9,12-dienoate | 32,298.23 e | 0.6 | 0.6 | 1.10 |

| 38 | 2-methylpropyl hexanoate | 5350.3 b | 14.1 | 13.7 | 1.03 |

| 39 | 3-Methylbutan-1-ol | 37,400 c | 0.6 | 0.6 | 1.03 |

| 40 | Ethyl palmitate | 58,362.49 e | 0.7 | 0.7 | 0.97 |

| 41 | Ethyl (9Z)-octadec-9-enoate | 65,139.73 e | 0.1 | 0.2 | 0.94 |

| 42 | Ethyl 2-phenylethanoate | 406.83 b | 7.7 | 8.6 | 0.89 |

| 43 | Butane-2,3-dione | 100 c | 0.2 | 0.2 | 0.89 |

| 44 | 3-Methylbutyl butanoate | 1400 b | 13.7 | 15.5 | 0.88 |

| 45 | Ethyl 4-methylpentanoate | 188.32 a | 0.6 | 0.7 | 0.84 |

| 46 | Decanoic acid | 2800 g | 1.1 | 1.4 | 0.81 |

| 47 | 3-Methylbutanoic acid | 1045.47 b | 20.9 | 26.0 | 0.80 |

| 48 | (±)-Butane-2,3-diol | 50,000 h | 0.3 | 0.4 | 0.77 |

| 49 | Butyl hexanoate | 678 b | 17.0 | 23.9 | 0.71 |

| 50 | 2-Furaldehyde diethyl acetal | 6172 i | <0.1 | <0.1 | 0.69 |

| 51 | (E)-Hept-2-enal | 2112.01 e | 0.1 | 0.1 | 0.66 |

| 52 | Ethyl dodecanoate | 640 c | 1.9 | 2.9 | 0.65 |

| 53 | Ethyl decanoate | 1122.3 b | 3.5 | 6.3 | 0.56 |

| 54 | Hexyl hexanoate | 1890 c | 5.8 | 11.0 | 0.53 |

| 55 | 3-Hydroxybutan-2-one | 259 c | 5.7 | 11.8 | 0.48 |

| 56 | 2-Methylpropanoic acid | 1580 b | 7.9 | 16.5 | 0.48 |

| 57 | Furan-2-carbaldehyde | 44,029.73 b | 0.1 | 0.2 | 0.45 |

| 58 | (E)-Non-2-enal | 50.5 b | 59.4 | 133.1 | 0.45 |

| 59 | 3-Methylbutyl ethanoate | 93.93 b | 53.1 | 131.1 | 0.40 |

| 60 | Heptan-2-ol | 1433.94 b | 1.4 | 5.2 | 0.27 |

| 61 | Octan-3-ol | 6.12 b | 2.6 | 12.2 | 0.21 |

| 62 | (E,E)-2,4-Decadienal | 7.71 b | 7.7 | 38.5 | 0.20 |

| 63 | Ethyl nonanoate | 3150.61 b | <0.1 | 0.6 | 0.04 |

| No | Compounds | Odor Descriptor | N/20 | Significance a |

|---|---|---|---|---|

| 1 | Vanillin | Vanilla, sweet | 3 | - |

| 2 | 4-Methyl-2-methoxyphenol | Smoky | 18 | *** |

| 3 | 4-Ethyl-2-methoxyphenol | Smoky | 6 | - |

| 4 | Benzaldehyde | Almond | 11 | ** |

| 5 | β-phenylethanol | Rose, floral | 13 | ** |

| 6 | 3-(Methylsulfanyl)propan-1-ol | Roasted meat | 16 | *** |

| 7 | Nonan-4-olide | Coconut | 4 | - |

| 8 | 3-(Methylsulfanyl)propanal | Musty tomato | 18 | *** |

| 9 | Linalool | Floral, citrus | 11 | ** |

| 10 | 2,3,5,6-Tetramethylpyrazine | Nut | 1 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, P.; Ling, Y.; Shen, X.; Liang, C.; Tang, Y.; Chen, S.; Wang, L.Z.; Chen, S.; Li, A.; Xu, Y. Characterization of Key Aroma Compounds in Aged Chinese Nongxiangxing Baijiu Based on Sensory and Quantitative Analysis: Emphasis on the Contribution of Trace Compounds. Molecules 2025, 30, 2963. https://doi.org/10.3390/molecules30142963

Li P, Ling Y, Shen X, Liang C, Tang Y, Chen S, Wang LZ, Chen S, Li A, Xu Y. Characterization of Key Aroma Compounds in Aged Chinese Nongxiangxing Baijiu Based on Sensory and Quantitative Analysis: Emphasis on the Contribution of Trace Compounds. Molecules. 2025; 30(14):2963. https://doi.org/10.3390/molecules30142963

Chicago/Turabian StyleLi, Peiqi, Yuting Ling, Xiaomei Shen, Chengcheng Liang, Youhong Tang, Shan Chen, Lisa Zhou Wang, Shuang Chen, Anjun Li, and Yan Xu. 2025. "Characterization of Key Aroma Compounds in Aged Chinese Nongxiangxing Baijiu Based on Sensory and Quantitative Analysis: Emphasis on the Contribution of Trace Compounds" Molecules 30, no. 14: 2963. https://doi.org/10.3390/molecules30142963

APA StyleLi, P., Ling, Y., Shen, X., Liang, C., Tang, Y., Chen, S., Wang, L. Z., Chen, S., Li, A., & Xu, Y. (2025). Characterization of Key Aroma Compounds in Aged Chinese Nongxiangxing Baijiu Based on Sensory and Quantitative Analysis: Emphasis on the Contribution of Trace Compounds. Molecules, 30(14), 2963. https://doi.org/10.3390/molecules30142963