The Preparation and Dust Suppression Performance Evaluation of Iron Ore Tailing-Based Cementitious Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Proportions and Sample Preparation

2.3. Test Methods

3. Results and Discussion

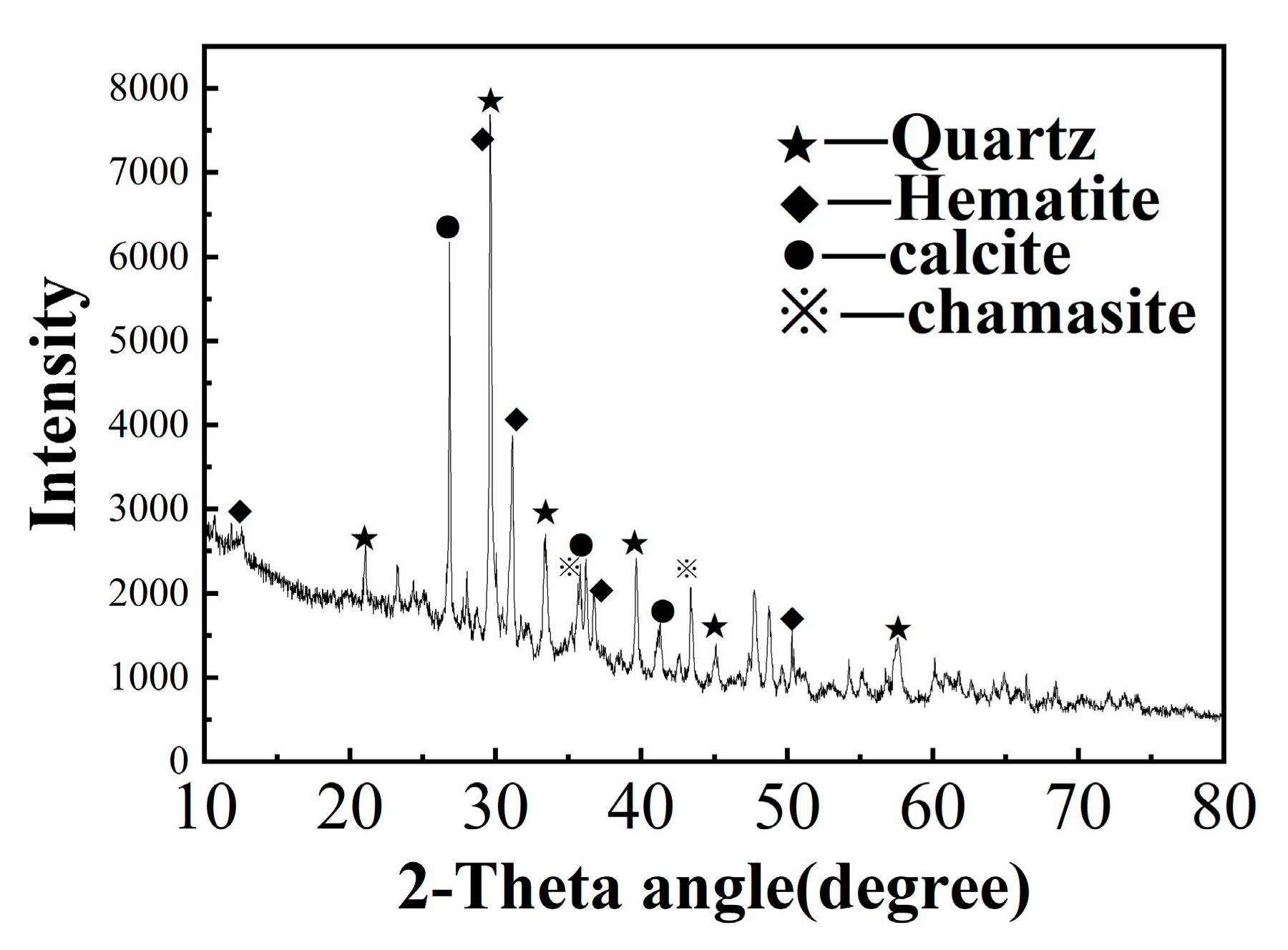

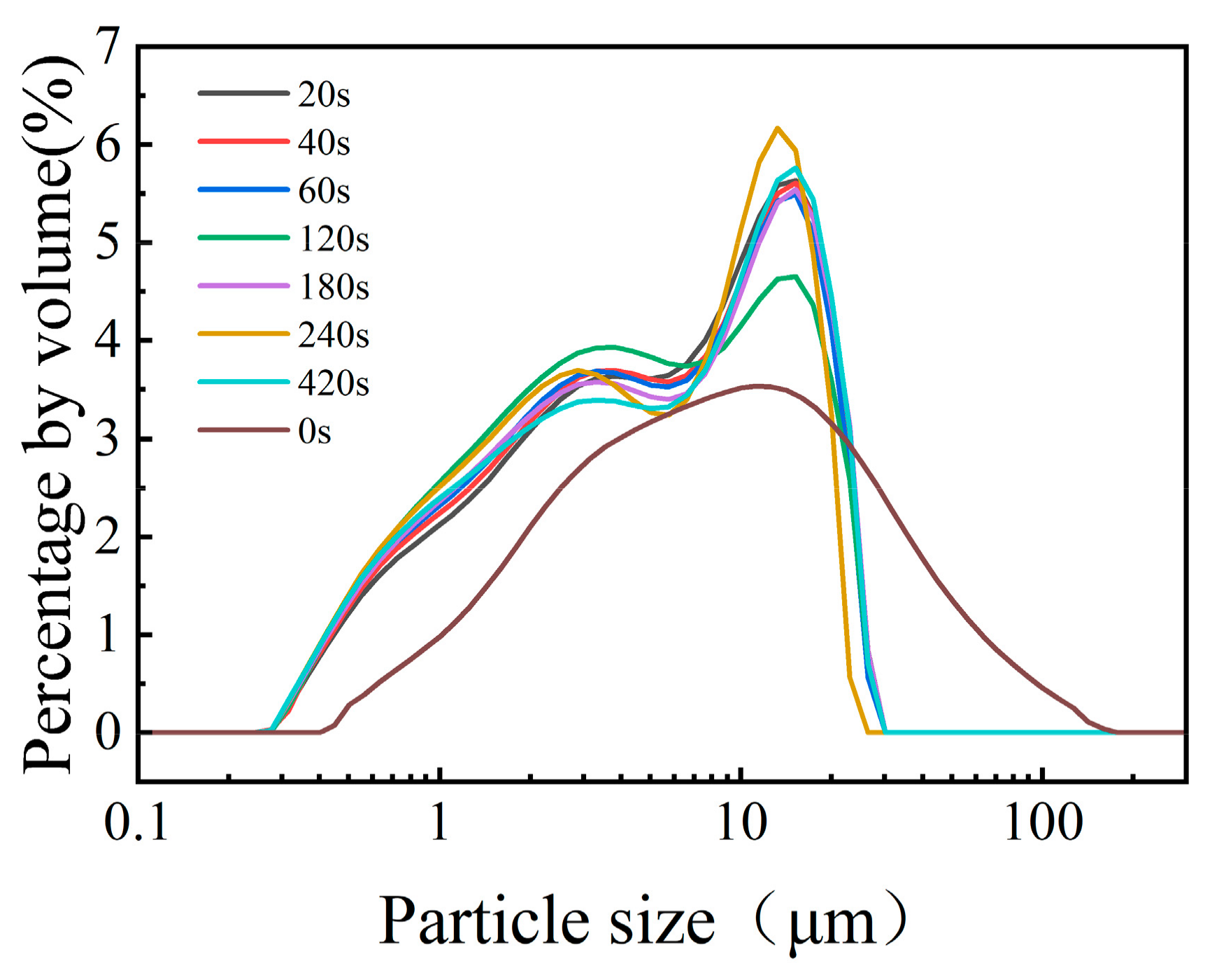

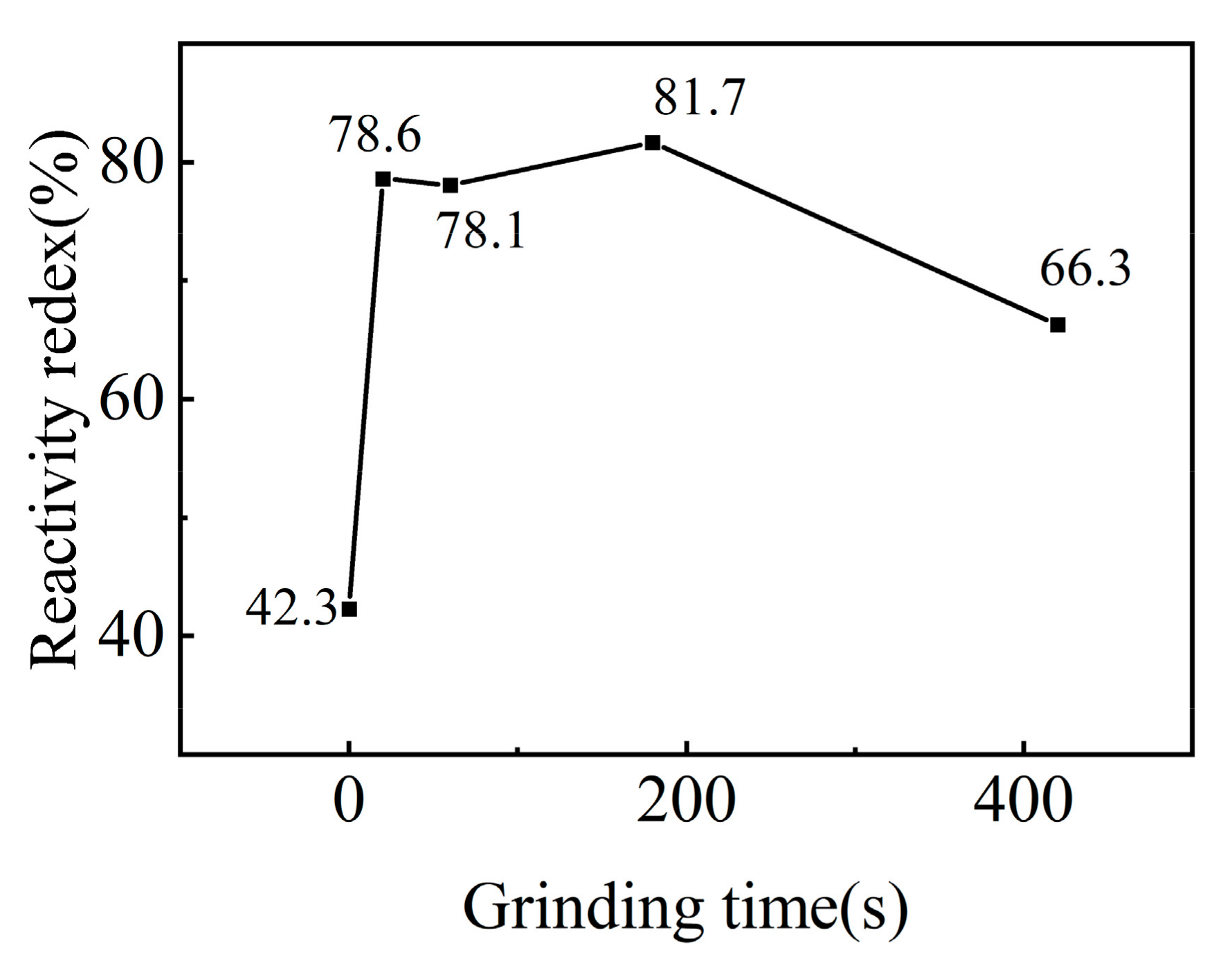

3.1. Mechanical Activation of Iron Ore Tailings

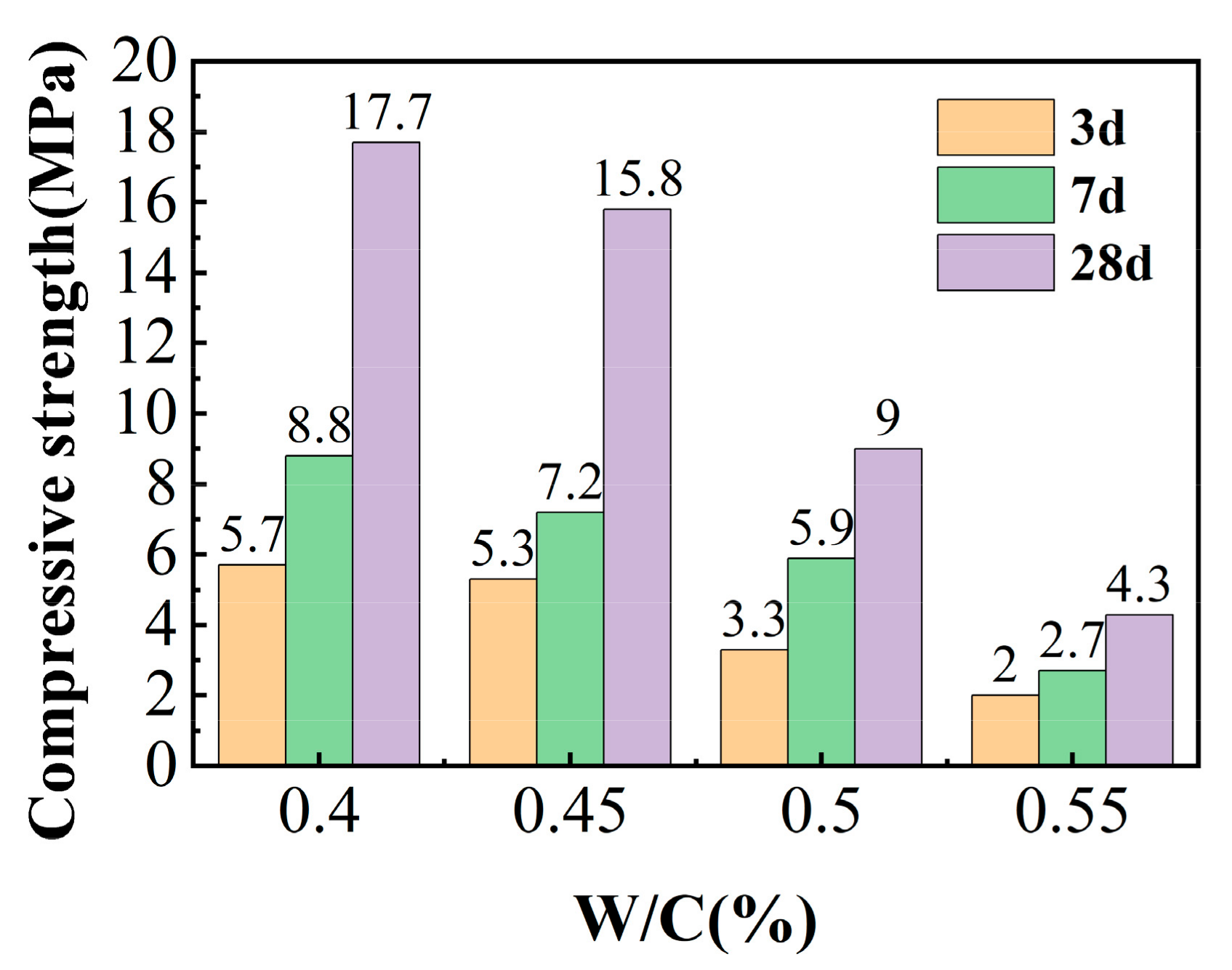

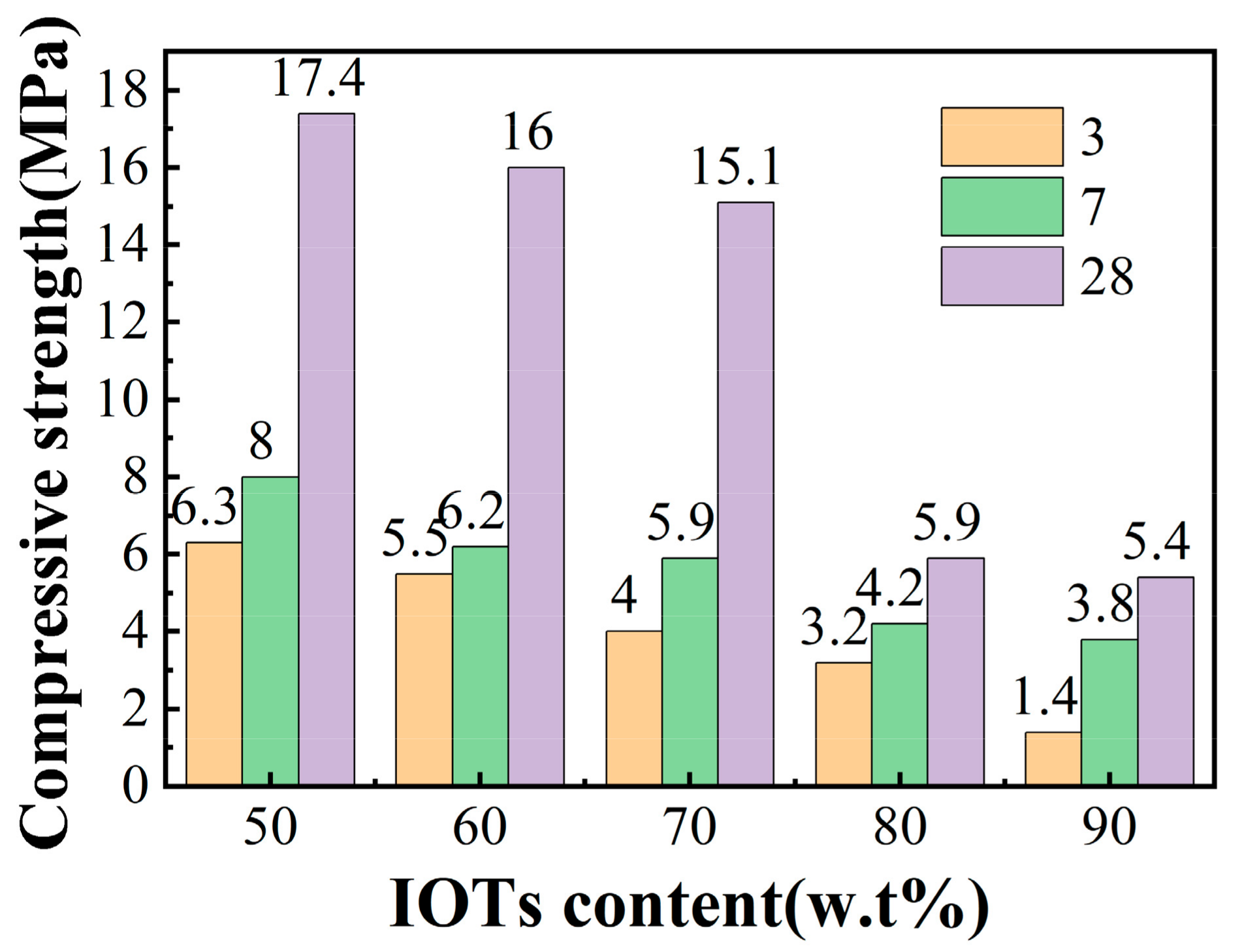

3.2. Mechanical and Physical Properties of IOT-Based Cementitious Composites

3.3. XRD Analysis of IOT-Based Cementitious Composites

3.4. FTIR Analysis of IOT-Based Cementitious Composites

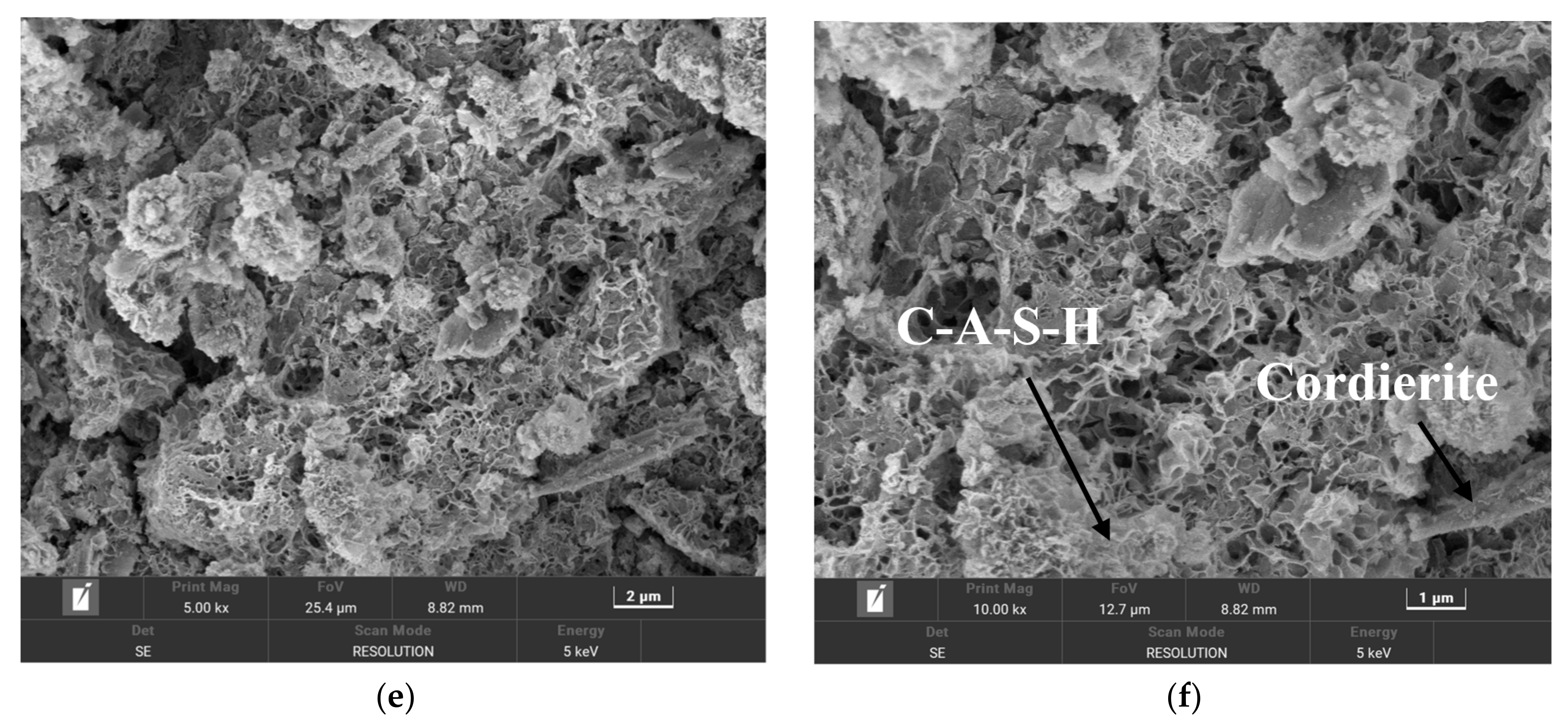

3.5. SEM Analysis of IOT-Based Cementitious Composites

3.6. Analysis of Wind Erosion Resistance Performance

3.7. Water Requirement of Normal Consistency and Setting Time of the Crust Layer

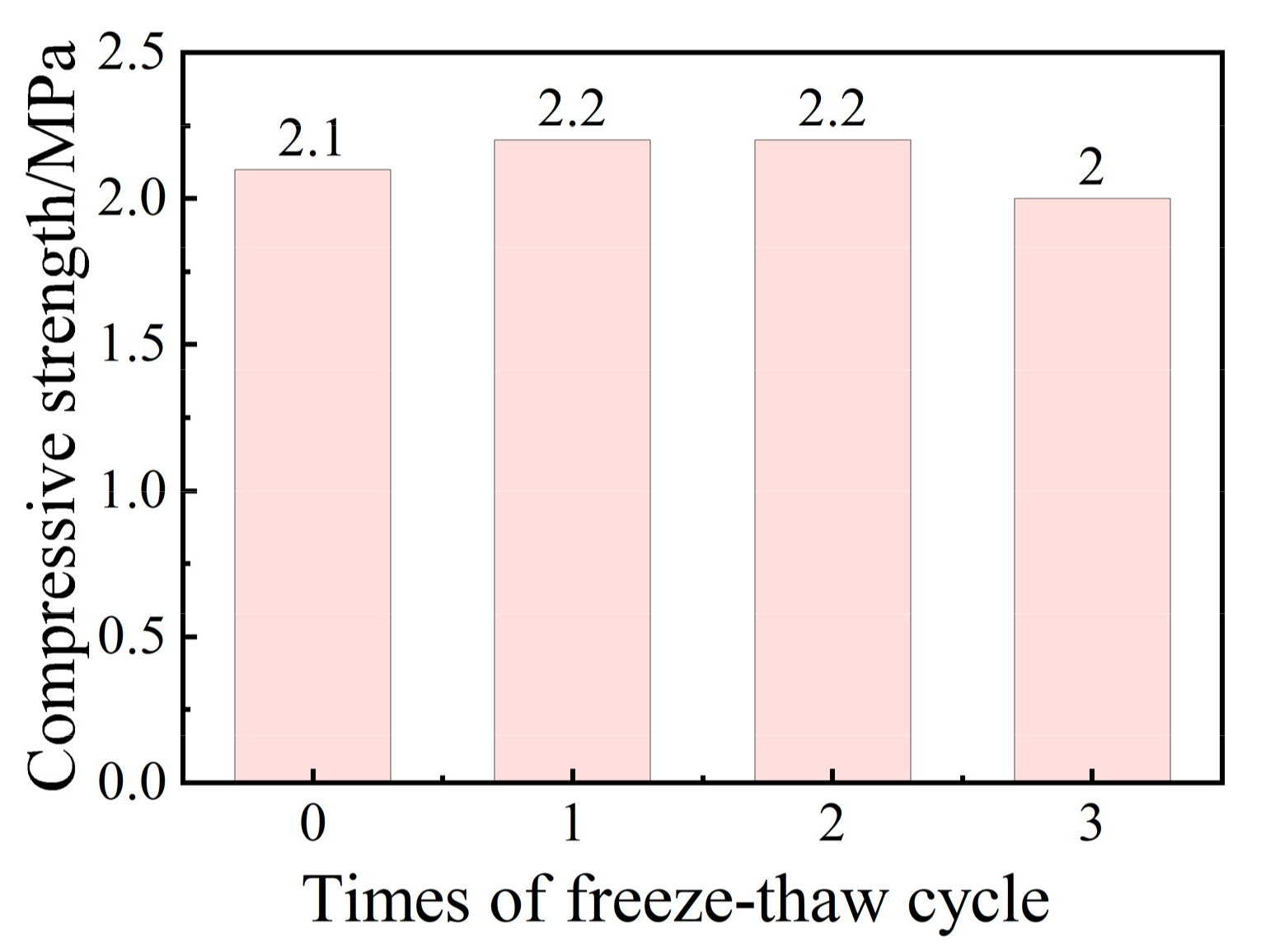

3.8. Analysis of Freeze–Thaw Cycle Resistance

4. Conclusions

- (1)

- With prolonged grinding times, the structural degradation of IOTs occurred, especially for the clay minerals stilpnomelane and muscovite in the IOTs. Mechanical activation could induce the amorphization of IOT powders, which was beneficial in improving the pozzolanic activity of IOTs. The D50 values of IOT powders were 5.143 μm and 4.346 μm; the D90 values of IOT powers after grinding for 20 s were obtained. The activity index of iron tailings increased from 42.3% (unground) to 78.6%;

- (2)

- In the IOT–calcium oxide–anhydrite system, fiber-like ettringite and amorphous C-S-H gel were the major hydration products. The IOTCC was prepared by blending 86% IOT, 10% GGBS, and 4% cement clinker. When the water–cement ratio was 0.4, the compressive strength after curing for 7 days and 28 days was 8.8 MPa and 17.7 MPa, respectively;

- (3)

- The initial setting time of the iron tailing dust suppression material was 48 min, and the final setting time was 91 min. When the material is sprayed on the tailings at a dry beach or other similar sites, it can condense and harden within more appropriate time periods to achieve the effect of dust suppression;

- (4)

- The dust suppression material of the iron tailings’ foundation layer exhibited good stability. It exhibited good effects in conditions of wind erosion, rainfall, and freezing and thawing, and its dust suppression performance exhibited a wind erosion resistance rate of over 99.5%, with an effective period of more than 8 months. Durability, frost resistance, and high-temperature resistance were good.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Liu, K.; Wang, S.; Quan, X.; Jing, W.; Xu, J.; Zhao, N.; Liu, B.; Ying, H. Industrial byproduct Iron ore tailings as ecofriendly materials in the utilization of cementitious composites. Constr. Build. Mater. 2023, 372, 130813. [Google Scholar] [CrossRef]

- Liu, J.; Ge, X.; Liu, P.; Song, G.; Hu, Z. Experimental study on the preparation of cementitious materials from iron ore tailings by activation. Constr. Build. Mater. 2023, 385, 131409. [Google Scholar] [CrossRef]

- Gou, M.; Zhou, L.; Then, N.W.Y. Utilization of tailings in cement and concrete: A review. Sci. Eng. Compos. Mater. 2019, 26, 449–464. [Google Scholar] [CrossRef]

- Yang, M.; Sun, J.; Dun, C.; Duan, Y.; Meng, Z. Cementitious activity optimization studies of iron tailings powder as a concrete admixture. Constr. Build. Mater. 2020, 265, 120760. [Google Scholar] [CrossRef]

- de Magalhaes, L.F.; França, S.; dos Santos Oliveira, M.; Peixoto, R.A.F.; Bessa, S.A.L.; da Silva Bezerra, A.C. Iron ore tailings as a supplementary cementitious material in the production of pigmented cements. J. Clean. Prod. 2020, 274, 123260. [Google Scholar] [CrossRef]

- Yun-hong, C.; Si-hui, Y.; Jing-yu, Z.; Xiao-hui, S. Test research on hydration process of cement-iron tailings powder composite cementitious materials. Powder Technol. 2022, 399, 117215. [Google Scholar] [CrossRef]

- Kiventerä, J.; Perumal, P.; Yliniemi, J.; Illikainen, M. Mine tailings as a raw material in alkali activation: A review. Int. J. Miner. Metall. Mater. 2020, 27, 1009–1020. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Shaikh, F.; Krishna, R.; Mishra, J. Utilization potential of mine tailings in geopolymers: Physicochemical and environmental aspects. Process Saf. Environ. Prot. 2021, 147, 559–577. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlíková, M.; Keppert, M.; Lauermannová, A.-M.; Jankovský, O.; Lojka, M.; Jiříčková, A.; Łagód, G.; Pavlík, Z. Thermally treated coal mining waste as a supplementary cementitious material—Case study from Bogdanka mine, Poland. J. Build. Eng. 2023, 68, 106036. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.; Song, J. Study on the grinding kinetics of copper tailing powder. Powder Technol. 2018, 330, 105–113. [Google Scholar] [CrossRef]

- Hu, H.; Chen, Q.; Yin, Z.; Zhang, P.; Wang, G. Effect of grinding atmosphere on the leaching of mechanically activated pyrite and sphalerite. Hydrometallurgy 2004, 72, 79–86. [Google Scholar] [CrossRef]

- Wang, H.; Ju, C.; Zhou, M.; Dong, Y.; Hou, H.; Liu, S. Grinding kinetics of lead–zinc tailing powders and its optimal particle size as a pozzolanic admixture in cement mortar. Adv. Powder Technol. 2022, 33, 103730. [Google Scholar] [CrossRef]

- Duarte, M.S.; Almada, B.S.; dos Santos, W.J.; Bessa, S.A.L.; da Silva Bezerra, A.C.; Aguilar, M.T.P. Influence of mechanical treatment and magnetic separation on the performance of iron ore tailings as supplementary cementitious material. J. Build. Eng. 2022, 59, 105099. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, B.; Gu, X.; Nehdi, M.L.; Zhang, L.V. Mechanochemical activation of iron ore tailing-based ternary supplementary cementitious materials. Constr. Build. Mater. 2022, 346, 128420. [Google Scholar] [CrossRef]

- Thejas, H.K.; Hossiney, N. Alkali-activated bricks made with mining waste iron ore tailings. Case Stud. Constr. Mater. 2022, 16, e973. [Google Scholar]

- Shi, C.; Qian, J. High performance cementing materials from industrial slags—A review. Resour. Conserv. Recycl. 2000, 29, 195–207. [Google Scholar] [CrossRef]

- Nodehi, M.; Taghvaee, V.M. Alkali-Activated Materials and Geopolymer: A Review of Common Precursors and Activators Addressing Circular Economy. Circ. Econ. Sustain. 2022, 2, 165–196. [Google Scholar] [CrossRef]

- Perumal, P.; Kiventerä, J.; Illikainen, M. Influence of alkali source on properties of alkali activated silicate tailings. Mater. Chem. Phys. 2021, 271, 124932. [Google Scholar] [CrossRef]

- Yi, Z.-L.; Sun, H.-H.; Wei, X.-Q.; Li, C. Iron ore tailings used for the preparation of cementitious material by compound thermal activation. Int. J. Miner. Metall. Mater. 2009, 16, 355–358. [Google Scholar] [CrossRef]

- Bao, S.; Luo, Y.; Zhang, Y. Fabrication of green one-part geopolymer from silica-rich vanadium tailing via thermal activation and modification. Int. J. Miner. Metall. Mater. 2022, 29, 177–184. [Google Scholar] [CrossRef]

- Karthikeyan, B.; Kathyayini, R.; Aravindh Kumar, V.; Uthra, V.; Kumaran, S.S. Effect of dumped iron ore tailing waste as fine aggregate with steel and basalt fibre in improving the performance of concrete. Mater. Today Proc. 2021, 46, 7624–7632. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, S.; Zhou, Y.; Zhang, C.; Meng, T.; Jiang, S.; Liu, L.; Hu, G. Effect of incorporation of rice husk ash and iron ore tailings on properties of concrete. Constr. Build. Mater. 2022, 338, 127584. [Google Scholar] [CrossRef]

- Saedi, A.; Jamshidi-Zanjani, A.; Darban, A.K.; Mohseni, M.; Nejati, H. Utilization of lead–zinc mine tailings as cement substitutes in concrete-construction: Effect of sulfide content. J. Build. Eng. 2022, 57, 104865. [Google Scholar] [CrossRef]

- GB 175-2007; Common Portland Cement. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2007.

- GB/T 17671-1999; Method of Testing Cements—Determination of Strength. The State Bureau of Quality and Technical Supervision: Beijing, China, 1999.

- GB/T 12957-2005; Test method for Activity of Industrial Waste Slag Used as Addition to Cement. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2005.

- GB/T 1346-2001; Test methods for Water Requirement of Normal Consistency Setting Time and Soundness of the Portland Cements. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2001.

- Zhao, J.; Ni, K.; Su, Y.; Shi, Y. An evaluation of iron ore tailings characteristics and iron ore tailings concrete properties. Constr. Build. Mater. 2021, 286, 122968. [Google Scholar] [CrossRef]

- Jiang, W.; Zhu, H.; Haruna, S.I.; Shao, J.; Yu, Y.; Wu, K. Mechanical properties and freeze–thaw resistance of polyurethane-based polymer mortar with crumb rubber powder. Constr. Build. Mater. 2022, 352, 129040. [Google Scholar] [CrossRef]

- Krishna, R.; Shaikh, F.; Mishra, J.; Lazorenko, G.; Kasprzhitskii, A. Mine tailings-based geopolymers: Properties, applications and industrial prospects. Ceram. Int. 2021, 47, 17826–17843. [Google Scholar] [CrossRef]

- Wu, C.-R.; Hong, Z.-Q.; Yin, Y.-H.; Kou, S.-C. Mechanical activated waste magnetite tailing as pozzolanic material substitute for cement in the preparation of cement products. Constr. Build. Mater. 2020, 252, 119129. [Google Scholar] [CrossRef]

- Li, H.W.; Wang, R.; Wei, M.W.; Lei, N.Z.; Sun, H.X.; Fan, J.J. Mechanical properties and hydration mechanism of high-volume ultra-fine iron ore tailings cementitious materials. Constr. Build. Mater. 2022, 353, 129100. [Google Scholar] [CrossRef]

- Chen, Y.; Zhang, Y.; Chen, T.; Zhao, Y.; Bao, S. Preparation of eco-friendly construction bricks from hematite tailings. Constr. Build. Mater. 2011, 25, 2107–2111. [Google Scholar] [CrossRef]

- Vilela, A.P.; Eugênio, T.M.C.; de Oliveira, F.F.; Mendes, J.F.; Ribeiro, A.G.C.; Brandão, L.E.V.D.S.; Mendes, R.F. Technological properties of soil-cement bricks produced with iron ore mining waste. Constr. Build. Mater. 2020, 262, 120883. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, D.; Gu, X.; Chen, H.; Li, Z. Application of Iron Tailings-Based Composite Supplementary Cementitious Materials (SCMs) in Green Concrete. Materials 2022, 15, 3866. [Google Scholar] [CrossRef] [PubMed]

- Han, G.; Zhang, J.; Sun, H.; Shen, D.; Wu, Z.; An, X.; Meye, S.M.; Huang, Y. Application of Iron Ore Tailings and Phosphogypsum to Create Artificial Rockfills Used in Rock-Filled Concrete. Buildings 2022, 12, 555. [Google Scholar] [CrossRef]

- Saedi, A.; Jamshidi-Zanjani, A.; Darban, A.K. A review on different methods of activating tailings to improve their cementitious property as cemented paste and reusability. J. Environ. Manag. 2020, 270, 110881. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Chen, H.; Wei, M.; Wang, R.; Lei, N.; Wang, Q. Design and preparation of double-layer iron ore tailings cement-based electromagnetic wave absorbing materials containing carbon black and steel fiber. Constr. Build. Mater. 2023, 364, 129972. [Google Scholar] [CrossRef]

- Lee, N.K.; Lee, H.K. Reactivity and reaction products of alkali-activated, fly ash/slag paste. Constr. Build. Mater. 2015, 81, 303–312. [Google Scholar] [CrossRef]

- Nikvar-Hassani, A.; Hodges, R.; Zhang, L. Production of green bricks from low-reactive copper mine tailings: Durability and environmental aspects. Constr. Build. Mater. 2022, 337, 127571. [Google Scholar] [CrossRef]

- Moukannaa, S.; Loutou, M.; Benzaazoua, M.; Vitola, L.; Alami, J.; Hakkou, R. Recycling of phosphate mine tailings for the production of geopolymers. J. Clean. Prod. 2018, 185, 891–903. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. Geopolymerisation of multiple minerals. Miner. Eng. 2002, 15, 1131–1139. [Google Scholar] [CrossRef]

- Gitari, M.W.; Akinyemi, S.A.; Thobakgale, R.; Ngoejana, P.C.; Ramugondo, L.; Matidza, M.; Mhlongo, S.E.; Dacosta, F.A. and Nemapate, N. Physicochemical and mineralogical characterization of Musina Mine copper and New Union gold mine tailings; implications for fabrication of beneficial geopolymeric construction materials. J. Afr. Earth Sci. 2018, 137, 218–228. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Puertas, F.; Sobrados, I.; Sanz, J. Structure of Calcium Silicate Hydrates Formed in Alkaline-Activated Slag: Influence of the Type of Alkaline Activator. J. Am. Ceram. Soc. 2003, 86, 1389–1394. [Google Scholar] [CrossRef]

| Chemical Composition | IOT | GGBS | Clinker |

|---|---|---|---|

| Fe2O3 | 19.510 | 0.466 | 5.957 |

| SiO2 | 26.113 | 27.070 | 24.765 |

| Al2O3 | 7.201 | 19.958 | 14.159 |

| CaO | 23.978 | 31.559 | 43.092 |

| MgO | 18.447 | 14.055 | 3.915 |

| TiO2 | 0.212 | 1.763 | 0.821 |

| SO3 | 1.782 | 2.833 | 4.353 |

| K2O | 1.081 | 0.487 | 1.645 |

| P2O5 | 0.087 | 0.021 | 0.105 |

| No. | GGBS/g | Clinker/g | NaOH/g | Na2SiO3/g | IOT/wt% | W/C |

|---|---|---|---|---|---|---|

| 1 | 24 | 4 | 16 | 8 | 92 | 0.45 |

| 2 | 24 | 12 | 24 | 16 | 90 | 0.45 |

| 3 | 24 | 20 | 32 | 24 | 88 | 0.45 |

| 4 | 32 | 4 | 24 | 24 | 90 | 0.45 |

| 5 | 32 | 12 | 32 | 8 | 88 | 0.45 |

| 6 | 32 | 20 | 16 | 16 | 86 | 0.45 |

| 7 | 40 | 4 | 32 | 16 | 88 | 0.45 |

| 8 | 40 | 12 | 16 | 24 | 86 | 0.45 |

| 9 | 40 | 20 | 24 | 8 | 83 | 0.45 |

| No. | W/C | W/mL | NaOH/g | Na2SiO3/g | IOT/g | GGBS/g | Clinker/g |

|---|---|---|---|---|---|---|---|

| F1 | 0.40 | 144 | 16 | 24 | 288 | 48 | 24 |

| F2 | 0.45 | 162 | 16 | 24 | 288 | 48 | 24 |

| F3 | 0.50 | 180 | 16 | 24 | 288 | 48 | 24 |

| F4 | 0.55 | 198 | 16 | 24 | 288 | 48 | 24 |

| Milling Time (s) | 0 | 20 | 40 | 60 | 120 | 180 | 240 | 300 | 360 | 420 |

|---|---|---|---|---|---|---|---|---|---|---|

| D50 (μm) | 9.107 | 5.143 | 4.844 | 4.817 | 4.089 | 4.346 | 4.728 | 5.734 | 6.271 | 6.596 |

| D90 (μm) | 38.547 | 16.588 | 16.347 | 16.644 | 15.720 | 14.667 | 16.600 | 17.477 | 20.012 | 20.612 |

| No. | IOT/wt% | W/C/% | Compressive Strength/MPa | |

|---|---|---|---|---|

| 7 d | 28 d | |||

| 1 | 92 | 0.45 | 0.2 | 0.8 |

| 2 | 90 | 0.45 | 0.7 | 2.3 |

| 3 | 88 | 0.45 | 0.7 | 2.4 |

| 4 | 90 | 0.45 | 1.3 | 3.1 |

| 5 | 88 | 0.45 | 0.5 | 2.1 |

| 6 | 86 | 0.45 | 1.7 | 4.0 |

| 7 | 88 | 0.45 | 1.5 | 3.2 |

| 8 | 86 | 0.45 | 2.5 | 5.4 |

| 9 | 83 | 0.45 | 2.0 | 3.4 |

| NO. | G1/g | G2/g | υ/% | L/% |

|---|---|---|---|---|

| 1 | 292.6 | 292.0 | 0.2 | 99.8 |

| 2 | 278.8 | 277.9 | 0.3 | 99.7 |

| 3 | 283.4 | 282.1 | 0.5 | 99.5 |

| Dust Suppressant | L% | Dust Suppression Period | Cracking Situation |

|---|---|---|---|

| A | 99.5 | >8 months | No |

| B | 92.3 | >6 months | Yes |

| C | 90.7 | >2 months | Yes |

| Material | Water Requirement for Standard Consistency (%) | Initial Setting Time (min) | Final Setting Time (min) |

|---|---|---|---|

| Iron tailing-based cement | 41 | 48 | 91 |

| P.O42.5 cement | 25.4 | >45 | <390 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, M.; Li, S.; Li, X.; Bao, S.; Chen, P.; Zhang, Y.; Ding, S.; Li, J. The Preparation and Dust Suppression Performance Evaluation of Iron Ore Tailing-Based Cementitious Composites. Molecules 2024, 29, 2056. https://doi.org/10.3390/molecules29092056

Nie M, Li S, Li X, Bao S, Chen P, Zhang Y, Ding S, Li J. The Preparation and Dust Suppression Performance Evaluation of Iron Ore Tailing-Based Cementitious Composites. Molecules. 2024; 29(9):2056. https://doi.org/10.3390/molecules29092056

Chicago/Turabian StyleNie, Miaomiao, Shefeng Li, Xuli Li, Shenxu Bao, Pei Chen, Yong Zhang, Siyu Ding, and Jiale Li. 2024. "The Preparation and Dust Suppression Performance Evaluation of Iron Ore Tailing-Based Cementitious Composites" Molecules 29, no. 9: 2056. https://doi.org/10.3390/molecules29092056

APA StyleNie, M., Li, S., Li, X., Bao, S., Chen, P., Zhang, Y., Ding, S., & Li, J. (2024). The Preparation and Dust Suppression Performance Evaluation of Iron Ore Tailing-Based Cementitious Composites. Molecules, 29(9), 2056. https://doi.org/10.3390/molecules29092056