Effect of Metal Elements on Microstructure and Mechanical Properties of Ultrafine Cemented Carbide Prepared by SPS

Abstract

1. Introduction

2. Results

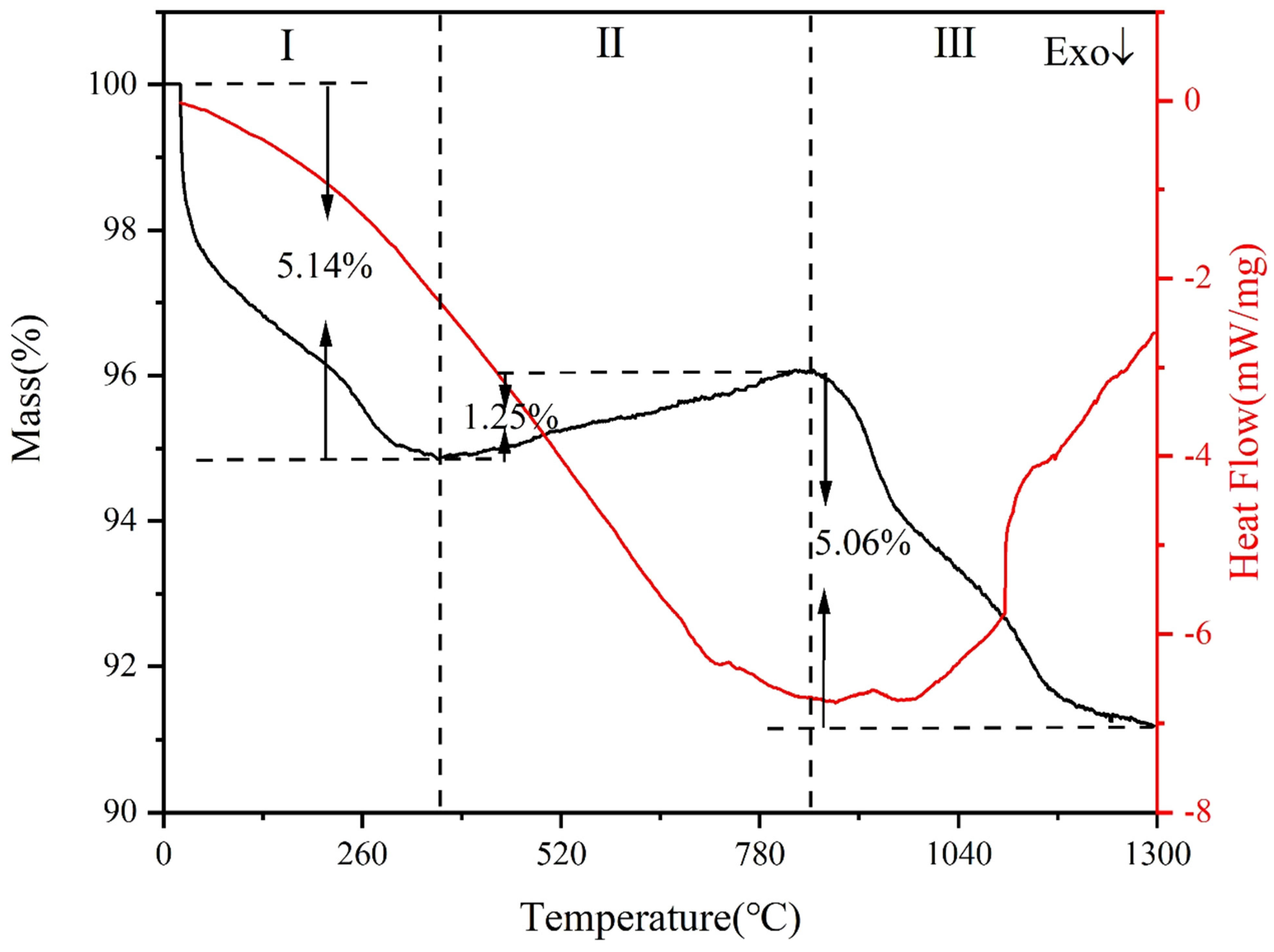

2.1. TG-DSC Analysis Results

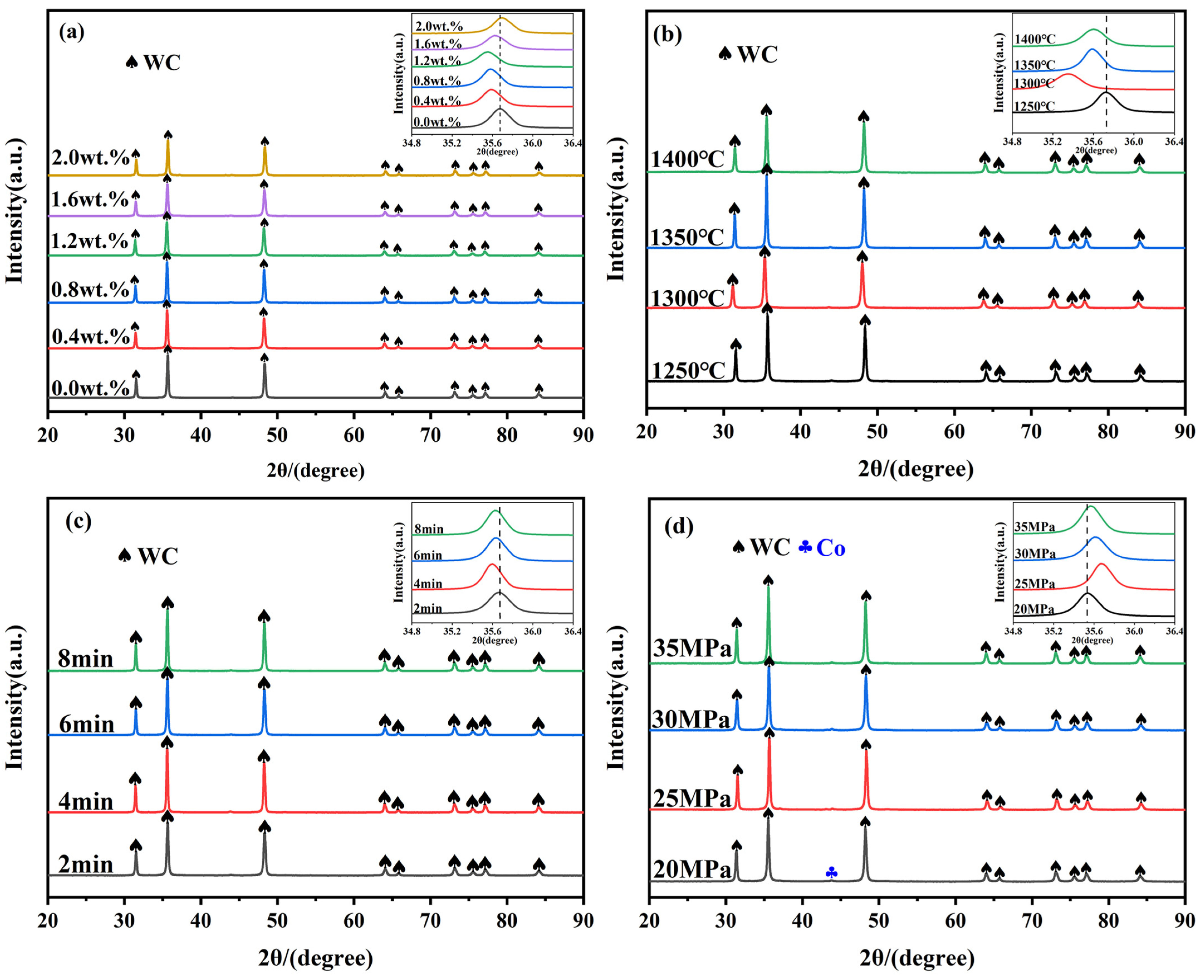

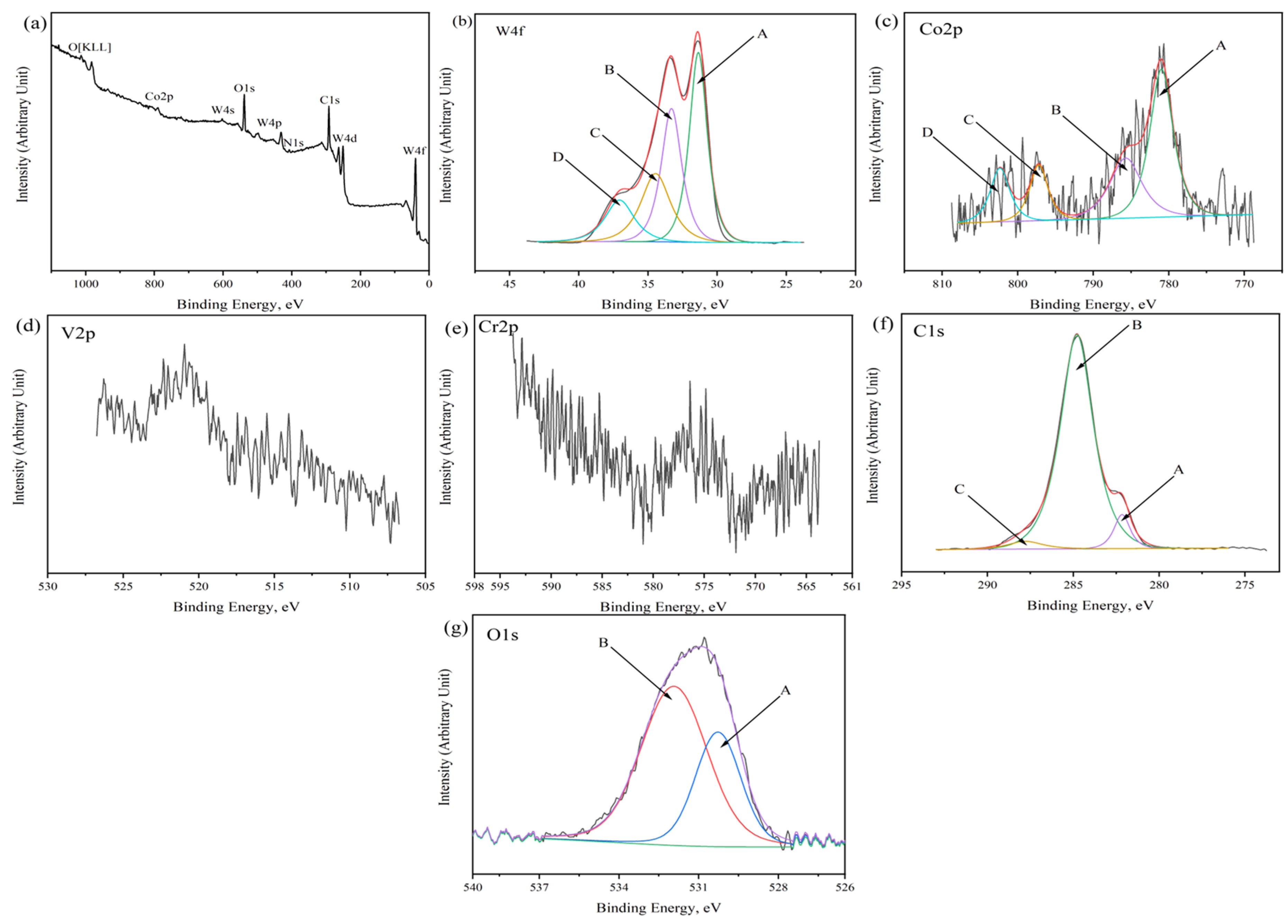

2.2. Phase Composition and Bonding State

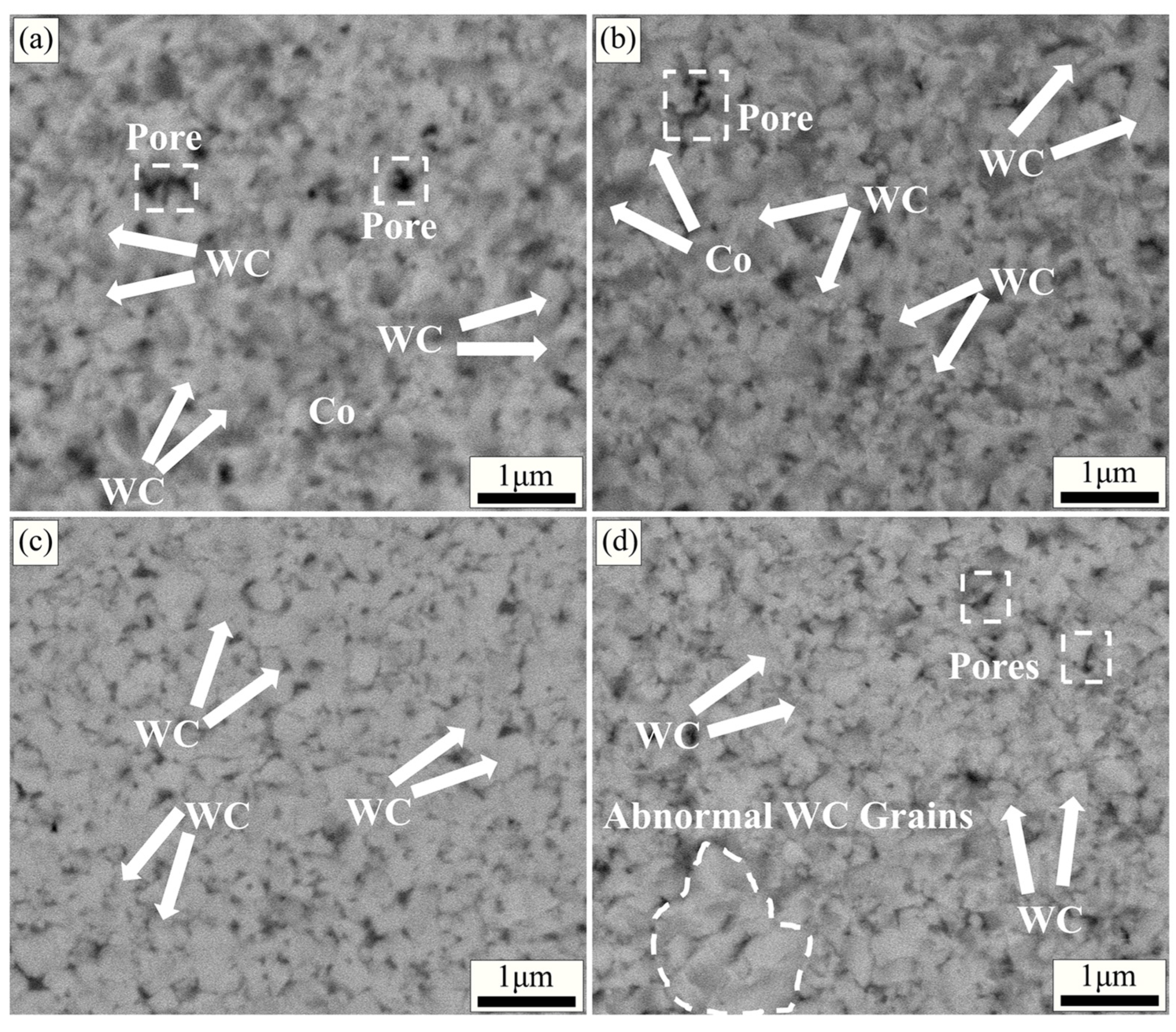

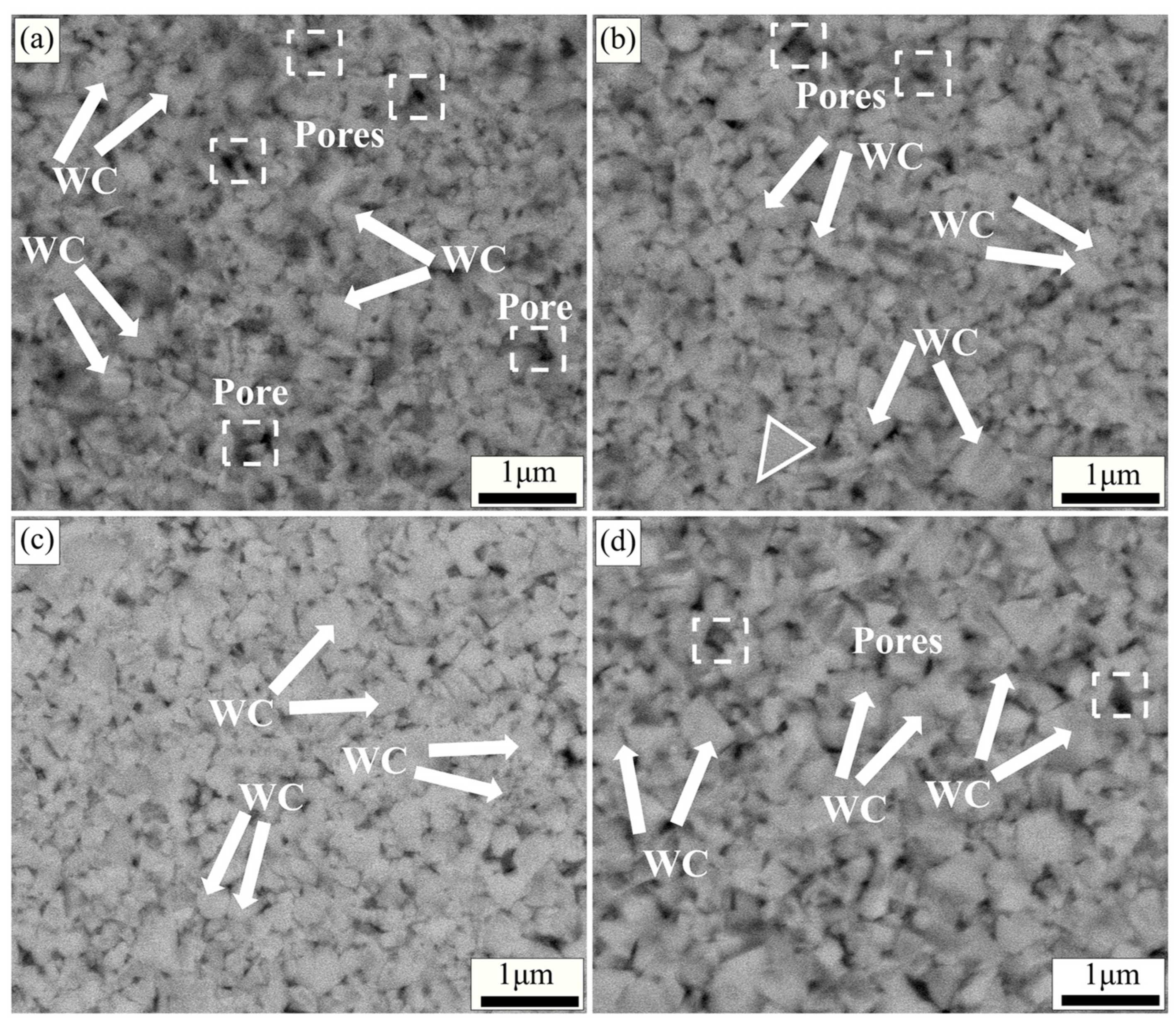

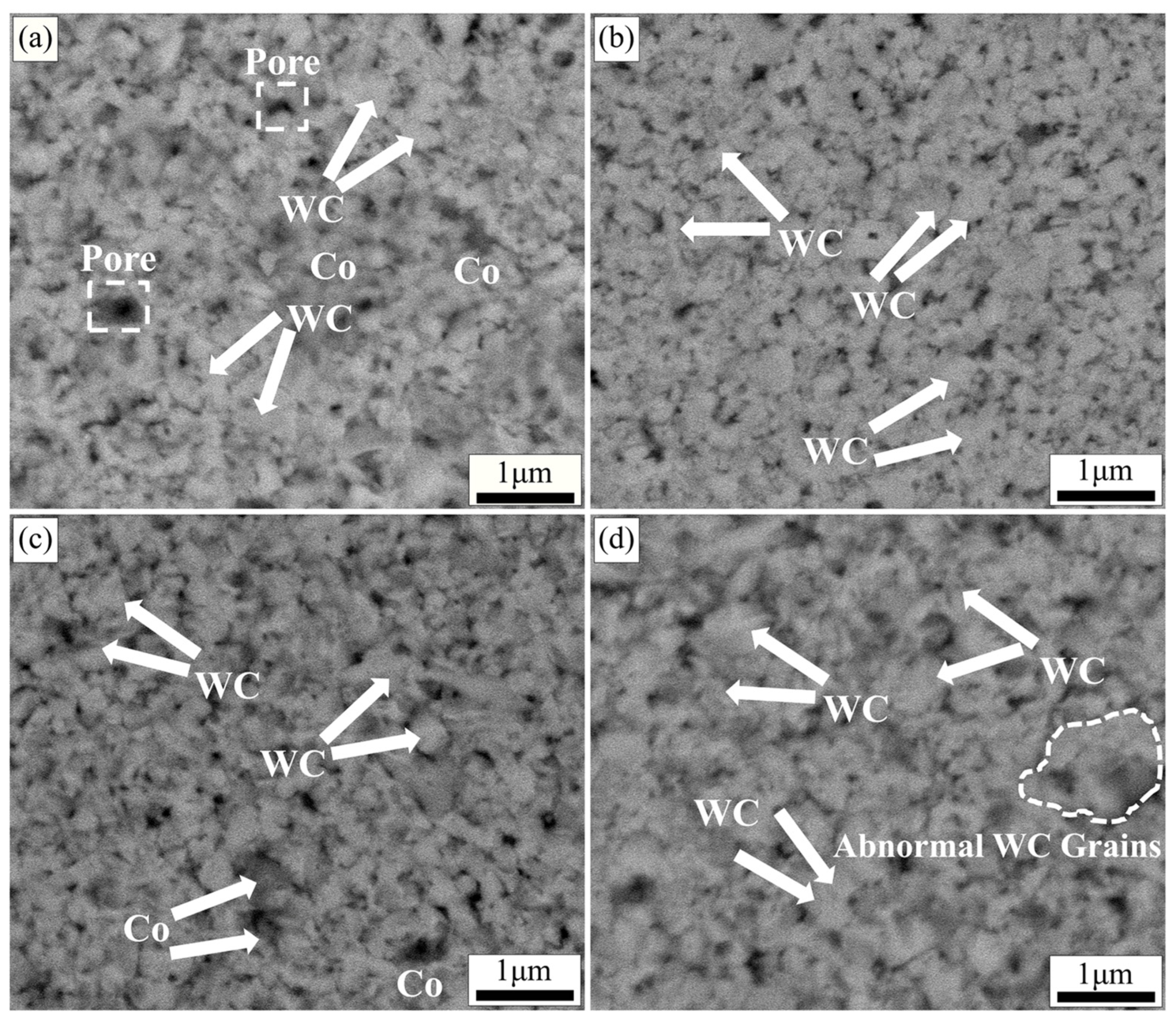

2.3. Microstructure

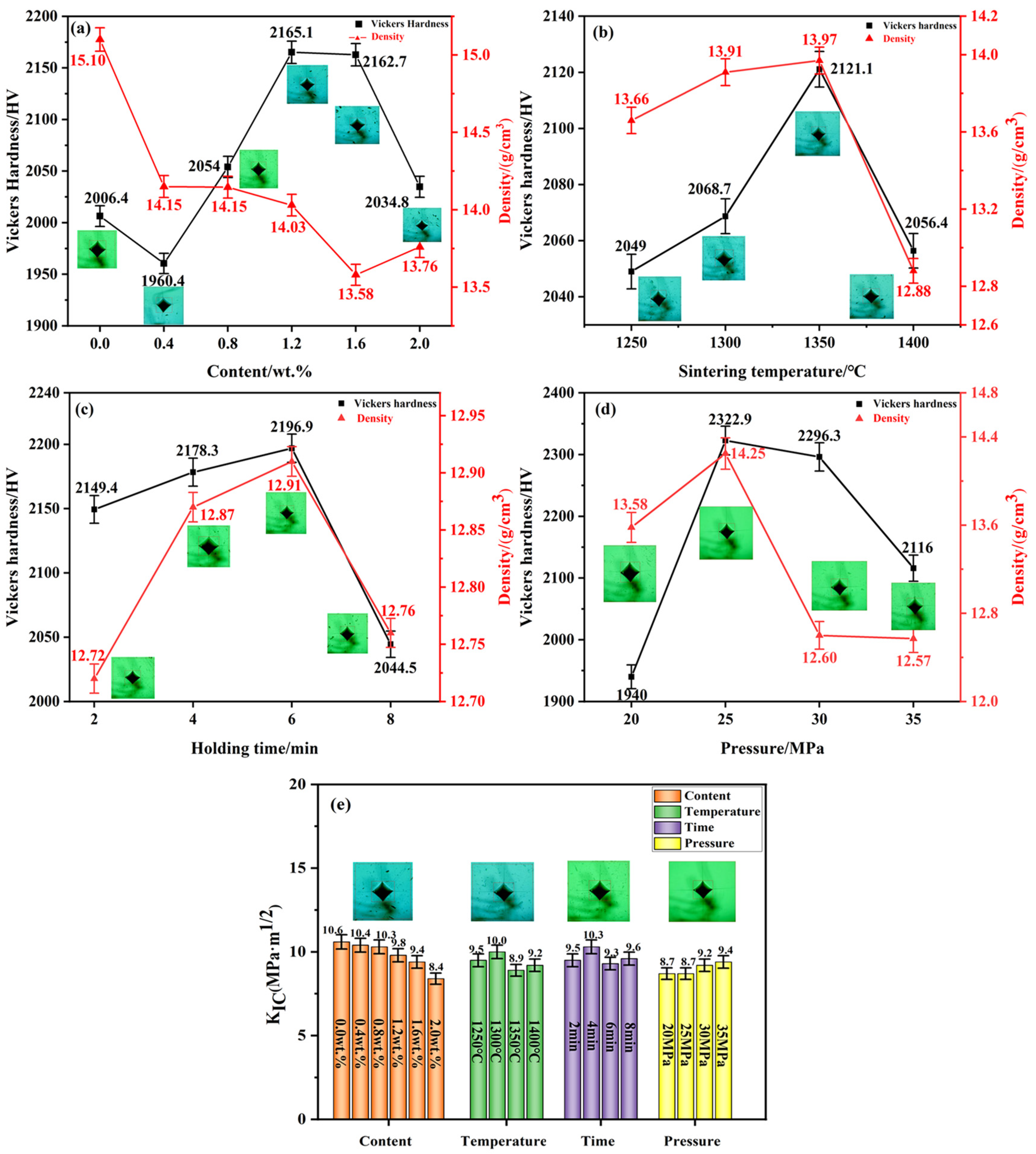

2.4. Mechanical Properties

2.5. Magnetic Properties

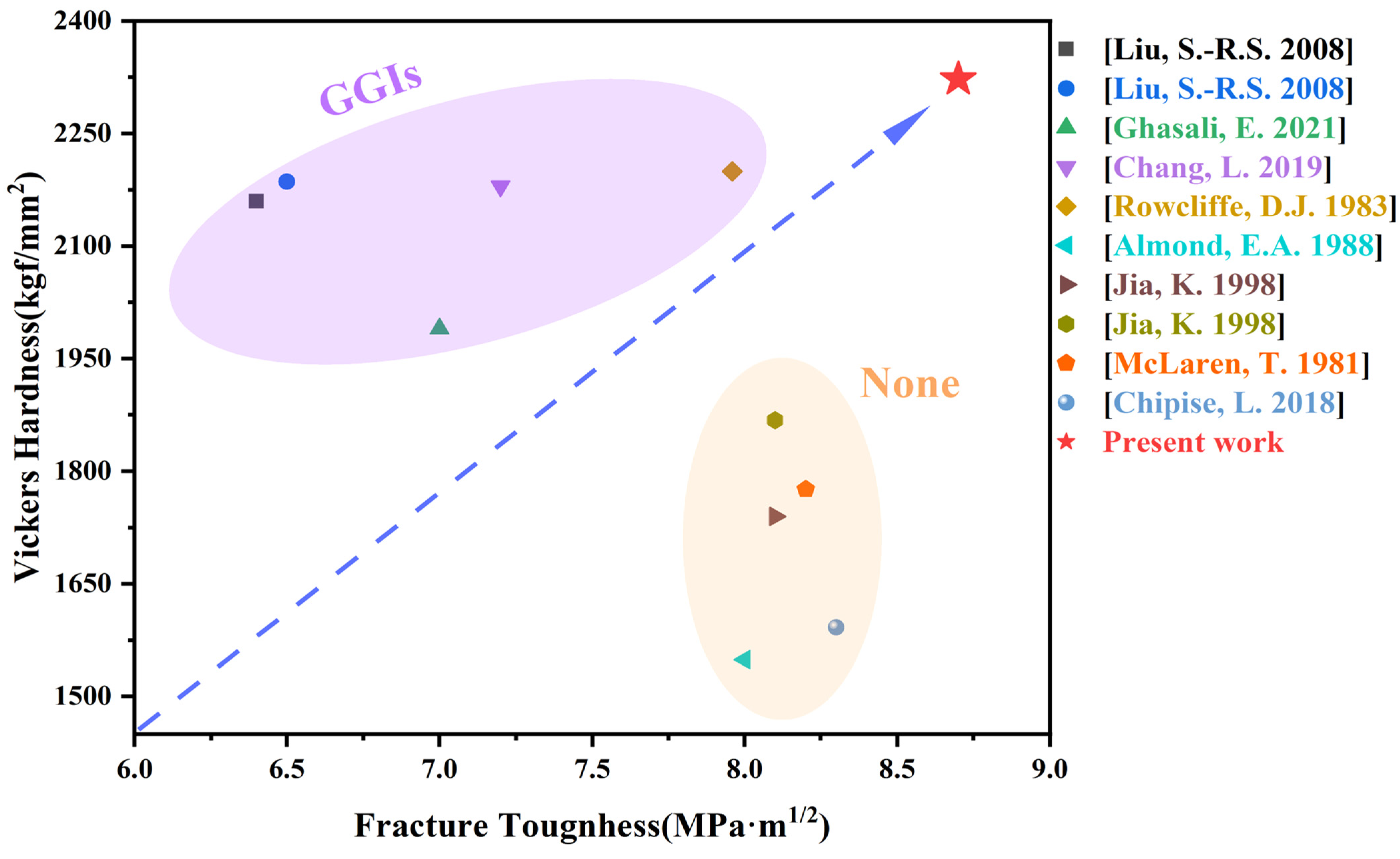

2.6. Comparison of Mechanical Properties

3. Materials and Methods

3.1. Specimen Preparation

3.2. Characterization

4. Conclusions

- (1)

- Using SPS combined with metal elements can prepare ultrafine cemented carbide alloys with fine grain size (about 300 nm) and uniform and dense microstructure;

- (2)

- Ultrafine cemented carbide with excellent mechanical properties was prepared at the metal addition of 1.2 wt.% and sintering parameters of 1350 °C, 6 min, and 25 MPa. The Vickers hardness, density, and fracture toughness were HV 2322.9, 14.25 g/cm3, and KIC 8.7 MPa·m1/2, respectively;

- (3)

- Under the optimum conditions (1.2 wt.%, 1350 °C, 6 min, and 25 MPa), the specimens have high magnetic properties, where Ms = 0.487 emu/g, Mr = 0.219 emu/g, and Hc = 283.5 Oe. This indicates that appropriate metal element additions and sintering parameters can effectively reduce the grain size and optimize the microstructure of the alloy;

- (4)

- Compared with the direct addition of grain inhibitors, the addition of the metal elements V and Cr is also able to obtain ultrafine cemented carbides with homogeneous microstructures and excellent mechanical properties, which shows the great potential of using metal elements as additives for the preparation of high-performance cemented carbides. This study provides a new way for the preparation of high performance ultrafine cemented carbide.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, T.; Zhang, J.; An, D.; Xie, Z.; Li, Y.; Sang, S.; Dai, J. Oscillatory pressure sintering: A new method for preparing WC-Co cemented carbides. J. Alloys Compd. 2020, 816, 152521–152524. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, J.; Ni, X.; Gong, F.; Li, Z. Fabrication of dense nano-laminated tungsten carbide materials doped with Cr3C2/VC through two-step sintering. J. Eur. Ceram. Soc. 2018, 38, 3096–3103. [Google Scholar] [CrossRef]

- Chang, L.; Jiang, Y.; Wang, W.; Yue, X.; Ru, H. Ultrafine WC-0.5Co-xTaC cemented carbides prepared by spark plasma sintering. Int. J. Refract. Met. Hard Mater. 2019, 84, 104994–104999. [Google Scholar] [CrossRef]

- He, M.; Wang, J.; He, R.; Yang, H.; Ruan, J. Effect of cobalt content on the microstructure and mechanical properties of coarse grained WC-Co cemented carbides fabricated from chemically coated composite powder. J. Alloys Compd. 2018, 766, 556–563. [Google Scholar] [CrossRef]

- Kornaus, K.; Raczka, M.; Gubernat, A.; Zientara, D. Pressureless sintering of binderless tungsten carbide. J. Eur. Ceram. Soc. 2017, 37, 4567–4576. [Google Scholar] [CrossRef]

- Qin, Y.Q.; Peng, Y.Q.; Tian, Y.; Luo, L.M.; Ma, Y.; Zan, X.; Zhu, X.Y.; Wu, Y.C. Effect of Y2O3 on microstructure and mechanical properties of WC-Co-cemented carbides prepared via solid-liquid doping method and spark plasma sintering. Mater. Today Commun. 2020, 24, 101096–101104. [Google Scholar] [CrossRef]

- He, R.; Li, B.; Ou, P.; Yang, C.; Yang, H.; Ruan, J. Effects of ultrafine WC on the densification behavior and microstructural evolution of coarse-grained WC-5Co cemented carbides. Ceram. Int. 2020, 46, 12852–12860. [Google Scholar] [CrossRef]

- Dvornik, M.I.; Mikhailenko, E.A. Preparation of powder by electrical discharge erosion and sintering of ultrafine WC-5TiC-10Co alloy with high hardness. Int. J. Refract. Met. Hard Mater. 2023, 112, 106154–106161. [Google Scholar] [CrossRef]

- Lu, Z.; Du, J.; Sun, Y.; Su, G.; Zhang, C.; Kong, X. Effect of ultrafine WC contents on the microstructures, mechanical properties and wear resistances of regenerated coarse grained WC-10Co cemented carbides. Int. J. Refract. Met. Hard Mater. 2021, 97, 105516–105527. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.; Yuan, J.; Yin, Z.; Huang, L.; Zheng, K. High temperature fracture mechanism of ultrafine WC-Co cemented carbides containing (Ti,W)C. Int. J. Refract. Met. Hard Mater. 2021, 95, 105428–105436. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Huang, K.; Wang, L. Effects of Cr2 (C, N) addition on microstructure and comprehensive mechanical properties of ultrafine cemented carbide. Mater. Sci. Eng. A 2023, 870, 144847–144856. [Google Scholar] [CrossRef]

- Li, D.; Liu, Y.; Ye, J.; Chen, X.; Wang, L. The enhancement of the microstructure and mechanical performances of ultrafine WC-Co cemented carbides by optimizing Cr2(C,N) addition and WC particle sizes. Int. J. Refract. Met. Hard Mater. 2021, 97, 105518–105528. [Google Scholar] [CrossRef]

- Liu, K.; Wang, Z.; Yin, Z.; Cao, L.; Yuan, J. Effect of Co content on microstructure and mechanical properties of ultrafine grained WC-Co cemented carbide sintered by spark plasma sintering. Ceram. Int. 2018, 44, 18711–18718. [Google Scholar] [CrossRef]

- Dar, Y.A.; Sheikh, N.A. A review of fabrication and properties of spark plasma sintered tungsten carbide based advanced composites. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 236, 1216–1228. [Google Scholar] [CrossRef]

- Rumman, R.; Chuan, L.C.; Quinton, J.S.; Ghomashchi, R. Understanding the potential of microwave sintering on WC-Co. Int. J. Refract. Met. Hard Mater. 2019, 81, 7–14. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhang, G.; Wang, S.; Zhao, X.; Guan, C. Preparation of ultrafine cemented carbides with uniform structure and high properties by microwave sintering. Mater. Lett. 2020, 260, 126971–126974. [Google Scholar] [CrossRef]

- Chen, J.; Huang, M.; Fang, Z.Z.; Koopman, M.; Liu, W.; Deng, X.; Zhao, Z.; Chen, S.; Wu, S.; Liu, J.; et al. Microstructure analysis of high density WC-Co composite prepared by one step selective laser melting. Int. J. Refract. Met. Hard Mater. 2019, 84, 104980–104985. [Google Scholar] [CrossRef]

- Jucan, O.D.; Gădălean, R.V.; Chicinaş, H.F.; Hering, M.; Bâlc, N.; Popa, C.O. Study on the indirect selective laser sintering (SLS) of WC-Co/PA12 powders for the manufacturing of cemented carbide parts. Int. J. Refract. Met. Hard Mater. 2021, 96, 105498. [Google Scholar] [CrossRef]

- Shon, I.J.; Jeong, I.K.; Ko, I.Y.; Doh, J.M.; Woo, K.D. Sintering behavior and mechanical properties of WC–10Co, WC–10Ni and WC–10Fe hard materials produced by high-frequency induction heated sintering. Ceram. Int. 2007, 35, 339–344. [Google Scholar] [CrossRef]

- Shon, I.J. Rapid consolidation of nanostructured WC-FeAl hard composites by high-frequency induction heating and its mechanical properties. Int. J. Refract. Met. Hard Mater. 2016, 61, 185–191. [Google Scholar] [CrossRef]

- Yao, S.; Liu, Y.; Liu, D.; Zhao, K.; Liu, J. Flash sintering of Al2O3–ZrO2 ceramics under alternating current electric field. Ceram. Int. 2022, 48, 36764–36772. [Google Scholar] [CrossRef]

- Tian, W.; Liu, Y.; Qi, B.; Wang, W. Enhanced effect of carbon nanofibers on heating efficiency of conductive cementitious composites under ohmic heating curing. Cem. Concr. Compos. 2021, 117, 103904–103914. [Google Scholar] [CrossRef]

- Tian, W.; Liu, Y.; Wang, W. Multi-structural evolution of conductive reactive powder concrete manufactured by enhanced ohmic heating curing. Cem. Concr. Compos. 2021, 123, 104199–104211. [Google Scholar] [CrossRef]

- Lee, G.; Olevsky, E.A.; Manière, C.; Maximenko, A.; Izhvanov, O.; Back, C.; McKittrick, J. Effect of electric current on densification behavior of conductive ceramic powders consolidated by spark plasma sintering. Acta Mater. 2018, 144, 524–533. [Google Scholar] [CrossRef]

- Peng, C.; Tang, H.; Liang, P.; Yuan, X.; Ke, Y.; Wang, Y.; Qiao, L.; Li, K.; Zhao, Y.; Wang, M. Spark plasma sintering of WC-VC0.5 composites with exceptional mechanical properties and high-temperature performance. Mater. Sci. Eng. A 2022, 831, 142360–142367. [Google Scholar] [CrossRef]

- Abedi, M.; Sovizi, S.; Azarniya, A.; Giuntini, D.; Seraji, M.E.; Hosseini, H.R.M.; Amutha, C.; Ramakrishna, S.; Mukasyan, A. An analytical review on Spark Plasma Sintering of metals and alloys: From processing window, phase transformation, and property perspective. Crit. Rev. Solid State Mater. Sci. 2022, 48, 169–214. [Google Scholar] [CrossRef]

- Manière, C.; Diatta, J.S.; Couder, C.; Harnois, C.; Marinel, S. Spark plasma sintering grain growth assessment by densification kinetics analysis. Scr. Mater. 2023, 228, 115346–115350. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Y.; Liu, K.; Wang, B. Mechanical properties and microstructure of spark plasma sintered WC-8wt.%Co-VC-cBN ultrafine grained cemented carbide. Ceram. Int. 2019, 45, 23658–23665. [Google Scholar] [CrossRef]

- Tian, H.; Zhang, M.; Peng, Y.; Du, Y.; Zhou, P. Sintering behavior and mechanical properties of Cr3C2 doped ultra-fine WC-Co cemented carbides: Experment guided with thermodynamic calculations. Int. J. Refract. Met. Hard Mater. 2019, 78, 240–246. [Google Scholar] [CrossRef]

- Luo, R.; Chen, N.; Xiong, H.; Li, Z. Microhomogeneous WC-TiC-Co composite powders with enhanced sinterability via a two-step carburization method. Int. J. Refract. Met. Hard Mater. 2021, 95, 105413–105424. [Google Scholar] [CrossRef]

- Zhao, C.; Lu, H.; Liu, X.; Liu, C.; Nie, Z.; Song, X. Strengthening cemented carbides by activated nano TaC. Int. J. Refract. Met. Hard Mater. 2021, 95, 105449–105456. [Google Scholar] [CrossRef]

- Lin, T.; Li, Q.; Han, Y.; Song, K.; Wang, X.; Shao, H.; Dong, J.; Wang, H.; Deng, X. Effects of Nb and NbC additives on microstructure and properties of WC-Co-Ni cemented carbides. Int. J. Refract. Met. Hard Mater. 2022, 103, 105782–105790. [Google Scholar] [CrossRef]

- Saheb, N.; Alghanim, A. Low temperature synthesis of highly pure cordierite materials by spark plasma sintering nano-oxide powders. Ceram. Int. 2020, 46, 23910–23921. [Google Scholar] [CrossRef]

- Pötschke, J.; Richter, V.; Gestrich, T.; Säuberlich, T.; Meese-Marktscheffel, J.A. Grain growth inhibition in ultrafine hardmetals. Int. J. Refract. Met. Hard Mater. 2017, 66, 95–104. [Google Scholar] [CrossRef]

- Zhao, Z.; Chen, F.; Wang, M.; Zheng, H. Synthesis of chromium carbide nanopowders via a microwave heating method. Int. J. Refract. Met. Hard Mater. 2015, 51, 212–215. [Google Scholar] [CrossRef]

- Zhao, Z. Synthesis of V8C7–Cr3C2 nanocomposite via a novel in-situ precursor method. Int. J. Refract. Met. Hard Mater. 2016, 56, 118–122. [Google Scholar] [CrossRef]

- Zhao, Z.; Hu, W. Synthesis and characterization of chromium carbide nanopowders processed by mechanical alloying assisted microwave heating route. Int. J. Refract. Met. Hard Mater. 2016, 58, 206–210. [Google Scholar] [CrossRef]

- Zhao, Z.; Zheng, H.; Liu, S.; Shen, J.; Song, W.; Chen, J. Low temperature synthesis of chromium carbide (Cr3C2) nanopowders by a novel precursor method. Int. J. Refract. Met. Hard Mater. 2015, 48, 46–50. [Google Scholar] [CrossRef]

- Yousfi, M.A.; Norgren, S.; Andrén, H.O.; Falk, L.K.L. Chromium segregation at phase boundaries in Cr-doped WC-Co cemented carbides. Mater. Charact. 2018, 144, 48–56. [Google Scholar] [CrossRef]

- Chen, H.; Yang, Q.; Yang, J.; Yang, H.; Chen, L.; Ruan, J.; Huang, Q. Effects of VC/Cr3C2 on WC grain morphologies and mechanical properties of WC-6wt.%Co cemented carbides. J. Alloys Compd. 2017, 714, 245–250. [Google Scholar] [CrossRef]

- Li, M.; Gong, M.; Cheng, Z.; Mo, D.; Wang, L.; Dusza, J.; Zhang, C. Novel WC-Co-Ti3SiC2 cemented carbide with ultrafine WC grains and improved mechanical properties. Ceram. Int. 2022, 48, 22335–22342. [Google Scholar] [CrossRef]

- Bai, T.; Xie, T. Influence of TiO2 contents and sintering temperature on the microstructure and mechanical properties of WC-Al2O3 cemented carbide reinforced by multi-wall carbon nanotubes. J. Alloys Compd. 2018, 745, 562–568. [Google Scholar] [CrossRef]

- Rezlescu, N.; Rezlescu, E.; Sachelarie, L.; Popa, P.D.; Doroftei, C. Structural and catalytic properties of mesoporous nanocrystalline mixed oxides containing magnesium. Catal. Commun. 2014, 46, 51–56. [Google Scholar] [CrossRef]

- Zhang, G.; Huang, M.; Zhao, X.; Zhang, H.; Wang, Y.; Zhang, X.; Zheng, H.; Lu, P.; Zhao, Z. Preparation and properties of Ti(C,N)-based cermets with graphene nanosheet addition by spark plasma sintering. J. Mater. Res. Technol. 2023, 24, 185–199. [Google Scholar] [CrossRef]

- Chen, Z.; Qin, M.; Chen, P.; Huang, M.; Li, R.; Zhao, S.; Qu, X. WC-Co-Cr3C2-VC nanocomposite powders fabricated by solution combustion synthesis and carbothermal reduction. Ceram. Int. 2017, 43, 9568–9572. [Google Scholar] [CrossRef]

- Xue, Z.; Ma, S.; Liu, Y.; Ma, J.; Wang, T.; Li, B.; Li, J.; Wang, R.; Hu, L. Study on the preparation mechanism of novel WC-Cr2(C, N)-Co nanocomposites. J. Alloys Compd. 2023, 943, 169036–169048. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Zhou, Z.; Wu, H.; Chen, Y.; Zhang, B.; Wang, G.; Zhou, X.; Han, G. Constructing n-type Ag2Se/CNTs composites toward synergistically enhanced thermoelectric and mechanical performance. Acta Mater. 2022, 223, 117502–117510. [Google Scholar] [CrossRef]

- Li, H.; Hu, M.; Zhang, L.; Huo, L.; Jing, P.; Liu, B.; Gao, R.; Zhang, J.; Liu, B. Hybridization of Bimetallic Molybdenum—Tungsten Carbide with Nitroge—Doped Carbon: A Rational Design of Super Active Porous Composite Nanowires with Tailored Electronic Structure for Boosting Hydrogen Evolution Catalysis. Adv. Funct. Mater. 2020, 30, 2003198–2003210. [Google Scholar] [CrossRef]

- Liu, X.; Song, X.; Wang, H.; Liu, X.; Tang, F.; Lu, H. Complexions in WC-Co cemented carbides. Acta Mater. 2018, 149, 164–178. [Google Scholar] [CrossRef]

- Rohrer, G.S. The role of grain boundary energy in grain boundary complexion transitions. Curr. Opin. Solid State Mater. Sci. 2016, 20, 231–239. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Z.; Yin, Z.; Yuan, J.; Jia, J. Preparation and properties of the VC/Cr3C2/TaC doped ultrafine WC-Co tool material by spark plasma sintering. J. Alloys Compd. 2020, 816, 152598–152608. [Google Scholar] [CrossRef]

- Buravleva, A.A.; Fedorets, A.N.; Vornovskikh, A.A.; Ognev, A.V.; Nepomnyushchaya, V.A.; Sakhnevich, V.N.; Lembikov, A.O.; Kornakova, Z.E.; Kapustina, O.V.; Tarabanova, A.E.; et al. Spark Plasma Sintering of WC-Based 10wt%Co Hard Alloy: A Study of Sintering Kinetics and Solid-Phase Processes. Materials 2022, 15, 1091. [Google Scholar] [CrossRef]

- Lee, H.R.; Kim, D.J.; Hwang, N.M. Role of Vanadium Carbide Additive during Sintering of WC-Co: Mechanism of Grain Growth Inhibition. J. Am. Ceram. Soc. 2003, 86, 152–154. [Google Scholar] [CrossRef]

- Zhang, G.; Zhao, Z.; Zheng, H.; Zhang, S.; Chen, Z.; Wang, S.; Zhao, X. Effects of the addition of multi-walled carbon nanotubes on the microstructure and properties of Ti(C,N)-based cermets prepared by spark plasma sintering. Mater. Charact. 2022, 193, 112289–112302. [Google Scholar] [CrossRef]

- Jiang, W.; Lu, H.; Chen, J.; Liu, X.; Liu, C.; Song, X. Toughening cemented carbides by phase transformation of zirconia. Mater. Des. 2021, 202, 109559–109568. [Google Scholar] [CrossRef]

- Deng, X.-C.; Lan, X.; Wang, Y.-L.; Zhang, G.-H. Effect of Mo2C on the microstructure and properties of (W, Mo)C-10Co cemented carbides. Int. J. Refract. Met. Hard Mater. 2023, 111, 106103–106111. [Google Scholar] [CrossRef]

- Yang, Q.; Yang, J.; Yang, H.; Ruan, J. The effects of fine WC contents and temperature on the microstructure and mechanical properties of inhomogeneous WC-(fine WC-Co) cemented carbides. Ceram. Int. 2016, 42, 18100–18107. [Google Scholar] [CrossRef]

- Qi, W.; Zhao, Z.; Qian, Y.; Zhang, S.; Zheng, H.; Zhao, X.; Lu, X.; Wang, S. Effect of Graphene on the Microstructure and Mechanical Properties of WC-Based Cemented Carbide. Crystals 2023, 13, 1414. [Google Scholar] [CrossRef]

- Li, S.; Yang, Q.; Xiong, W.; Wang, S.; Mao, Q.; Zhang, M. Magnetic and mechanical properties of TiC–xTiN–15MC–yNi (MC = Mo2C, WC) cermets. J. Alloys Compd. 2018, 765, 1119–1126. [Google Scholar] [CrossRef]

- Yang, Q.; Xiong, W.; Zhou, S.; Zhang, M.; Huang, B.; Chen, S. Magnetization of TiC–10TiN–xMC–yNi (MC=Mo2C, WC) cermets. Mater. Des. 2017, 115, 255–261. [Google Scholar] [CrossRef]

- Linder, D.; Hou, Z.; Xie, R.; Hedström, P.; Ström, V.; Holmström, E.; Borgenstam, A. A comparative study of microstructure and magnetic properties of a Ni-Fe cemented carbide: Influence of carbon content. Int. J. Refract. Met. Hard Mater. 2019, 80, 181–187. [Google Scholar] [CrossRef]

- Hou, Z.; Linder, D.; Hedström, P.; Ström, V.; Holmström, E.; Borgenstam, A. Evaluating magnetic properties of composites from model alloys—Application to alternative binder cemented carbides. Scr. Mater. 2019, 168, 96–99. [Google Scholar] [CrossRef]

- Liu, S.-R.S. Compositions of Hardmetal Materials with Novel Binders. U.S. Patent US20080257107A1, 8 April 2008. [Google Scholar]

- Ghasali, E.; Shahmorad, A.; Orooji, Y.; Faraji, A.; Asadian, K.; Alizadeh, M.; Ebadzadeh, T. Effects of vanadium and titanium addition on the densification, microstructure and mechanical properties of WC-Co cermets. Ceram. Int. 2021, 47, 14270–14279. [Google Scholar] [CrossRef]

- Rowcliffe, D.J. Development of a New Family of Cemented Carbides for Geothermal Drilling; Final Report. No. SAND-83-7435; SRI International: Menlo Park, CA, USA, 1983. [Google Scholar]

- Almond, E.A.; Roebuck, B. Identification of optimum binder phase compositions for improved WC hard metals. Mater. Sci. Eng. A 1988, 105–106, 237–248. [Google Scholar] [CrossRef]

- Jia, K.; Fischer, T.E.; Gallois, B. Microstructure, hardness and toughness of nanostructured and conventional WC-Co composites. Nanostruct. Mater. 1998, 10, 875–891. [Google Scholar] [CrossRef]

- McLaren, T.; Lambert, J.B. Indentation testing of a broad range of cemented carbides. In Proceedings of the International Conference on the Science of Hard Materials, Jackson, WY, USA, 23–28 August 1981. [Google Scholar]

- Chipise, L.; Jain, P.K.; Cornish, L.A. Influence of Ru on the hardness and fracture toughness of WC-VC-Co alloys. Int. J. Refract. Met. Hard Mater. 2018, 77, 54–60. [Google Scholar] [CrossRef]

- Jiang, H.; Zhao, Z.; Qian, Y.; Yan, Y.; Lei, Y.; Zhang, Z.; Zhang, S.; Chen, Z.; Wang, S.; Lu, X. Effects of nanocomposite grain growth inhibitors and multi-walled carbon nanotubes on the microstructure and mechanical properties of ultrafine cemented carbides. J. Mater. Res. Technol. 2023, 26, 3054–3069. [Google Scholar] [CrossRef]

- Shetty, D.K.; Wright, I.G.; Mincer, P.N.; Clauer, A.H. Indentation fracture of WC-Co cermets. J. Mater. Sci. 1985, 20, 1873–1882. [Google Scholar] [CrossRef]

| Reaction Equation | Tm (°C) | Tp (°C) |

|---|---|---|

| 4V(s) + 5O2(g) = 2V2O5(s)/4Cr(s) + 3O2(g) = 2Cr2O3(s) | 117.4 | 238.6 |

| Cr2O3(s) + C(s) = 2CrO(s) + Co(g)↑ | 731.5 | 740 |

| V2O3→V8C7, Cr2O3→Cr3C2 | 880.0 | 928.0 |

| V(s) + C(s) = VC(s), 3Cr(s) + 2C(S) = Cr3C2(s) | 1101.7 | 1141.1 |

| WC (wt.%) | V (wt.%) | Cr (wt.%) | Co (wt.%) |

|---|---|---|---|

| 94.0 | 0.0 | 0.0 | 6 |

| 93.2 | 0.4 | 0.4 | 6 |

| 92.4 | 0.8 | 0.8 | 6 |

| 91.6 | 1.2 | 1.2 | 6 |

| 90.8 | 1.6 | 1.6 | 6 |

| 90.0 | 2.0 | 2.0 | 6 |

| Raw Materials | WC | V | Cr | Co |

|---|---|---|---|---|

| Melting point (°C) | 2870 | 1890 | 1907 | 1495 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, H.; Fu, S.; Zhang, Z.; Wang, S.; Zhao, Z. Effect of Metal Elements on Microstructure and Mechanical Properties of Ultrafine Cemented Carbide Prepared by SPS. Molecules 2024, 29, 1678. https://doi.org/10.3390/molecules29071678

Jiang H, Fu S, Zhang Z, Wang S, Zhao Z. Effect of Metal Elements on Microstructure and Mechanical Properties of Ultrafine Cemented Carbide Prepared by SPS. Molecules. 2024; 29(7):1678. https://doi.org/10.3390/molecules29071678

Chicago/Turabian StyleJiang, Hao, Siyuan Fu, Zichang Zhang, Shun Wang, and Zhiwei Zhao. 2024. "Effect of Metal Elements on Microstructure and Mechanical Properties of Ultrafine Cemented Carbide Prepared by SPS" Molecules 29, no. 7: 1678. https://doi.org/10.3390/molecules29071678

APA StyleJiang, H., Fu, S., Zhang, Z., Wang, S., & Zhao, Z. (2024). Effect of Metal Elements on Microstructure and Mechanical Properties of Ultrafine Cemented Carbide Prepared by SPS. Molecules, 29(7), 1678. https://doi.org/10.3390/molecules29071678