Enhancement and Compatibilization of Waste-Sourced Biocomposites Through Elastomer Blending and Matrix Grafting Modification

Abstract

1. Introduction

2. Results and Discussion

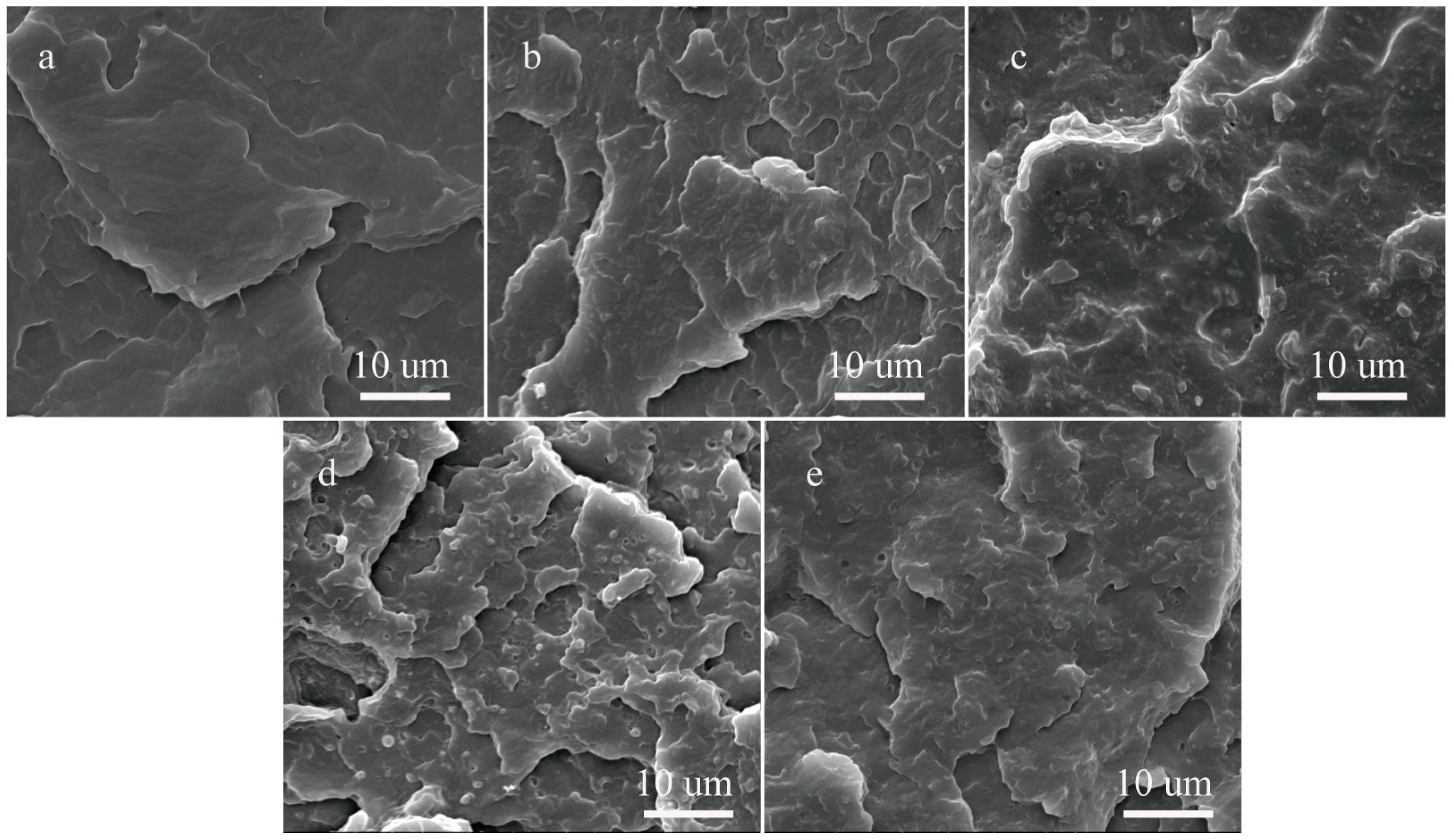

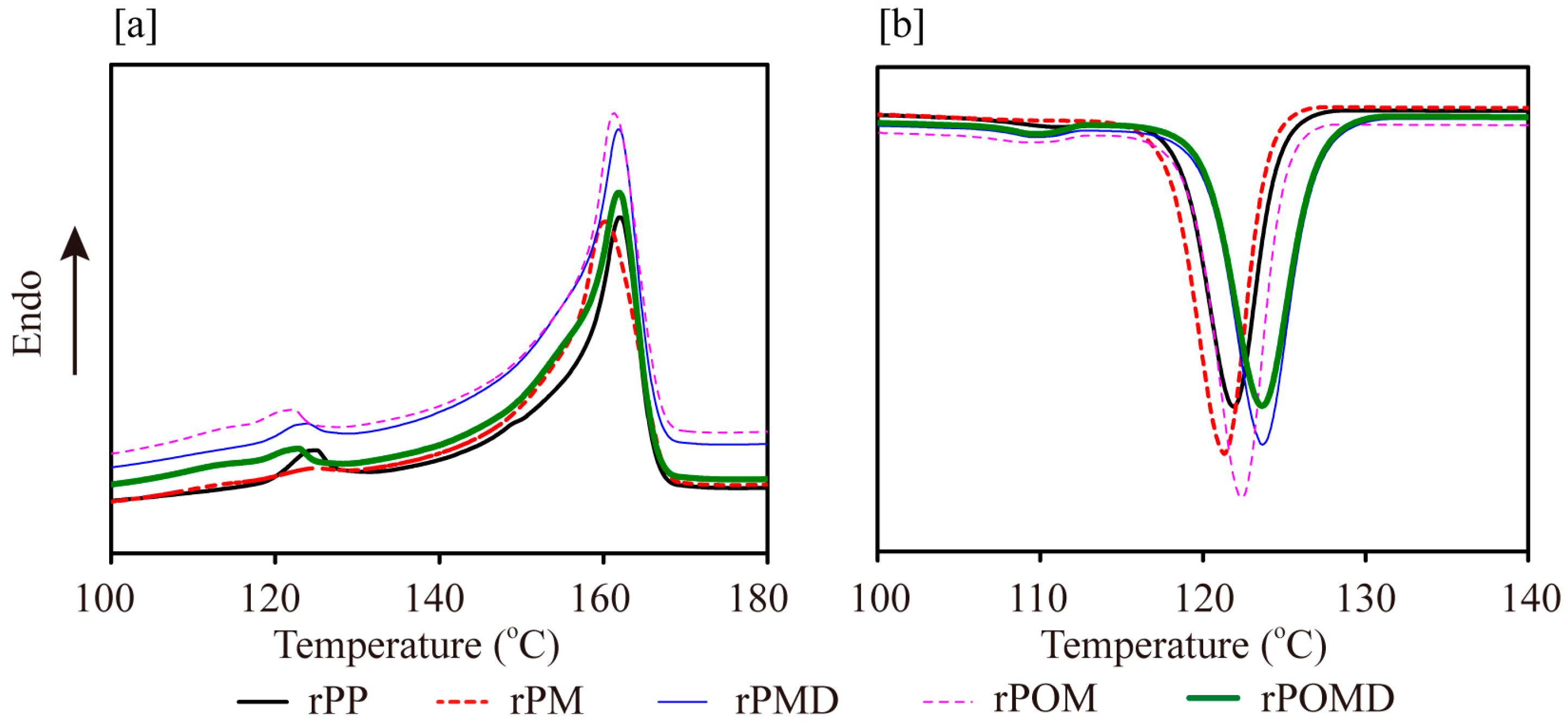

2.1. Study on the Structure and Properties of Modified Polymer Matrix

2.2. Properties of Composites

2.2.1. Morphological Analysis

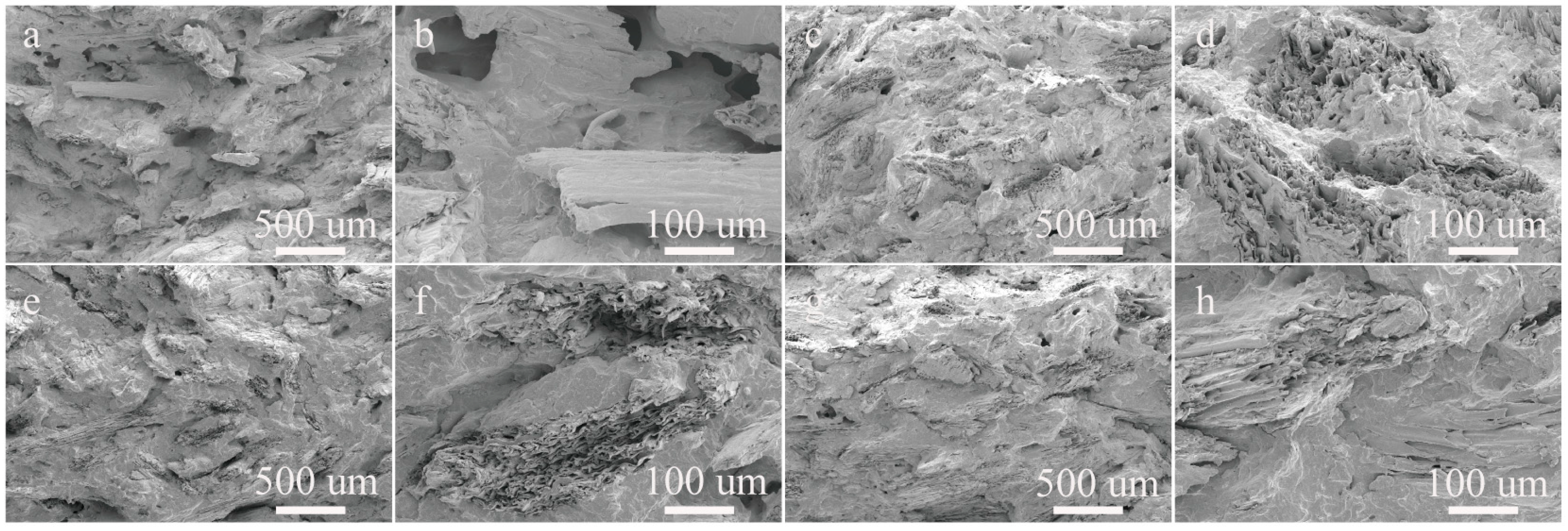

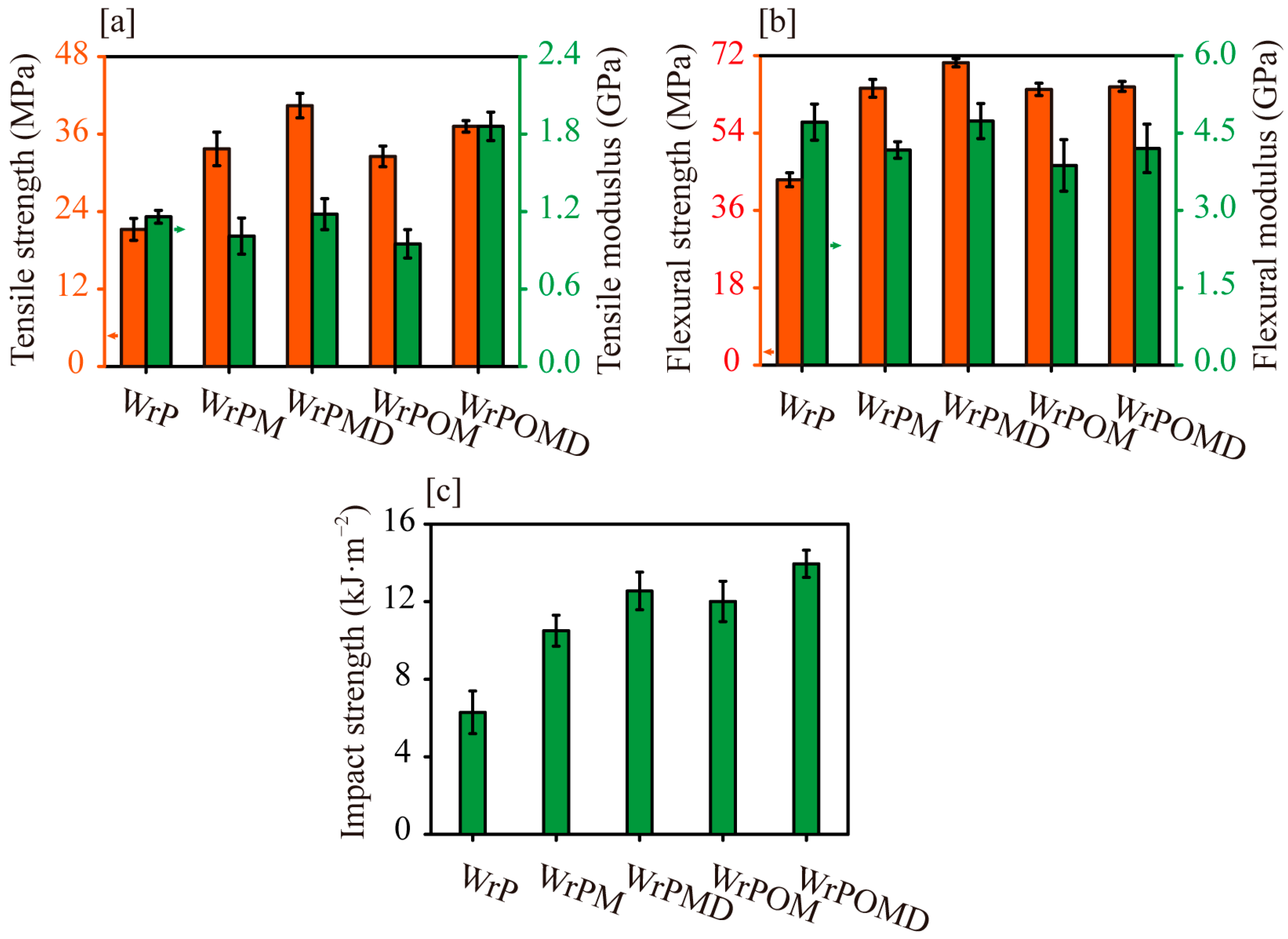

2.2.2. Analysis of Mechanical Properties and Fracture Mechanism

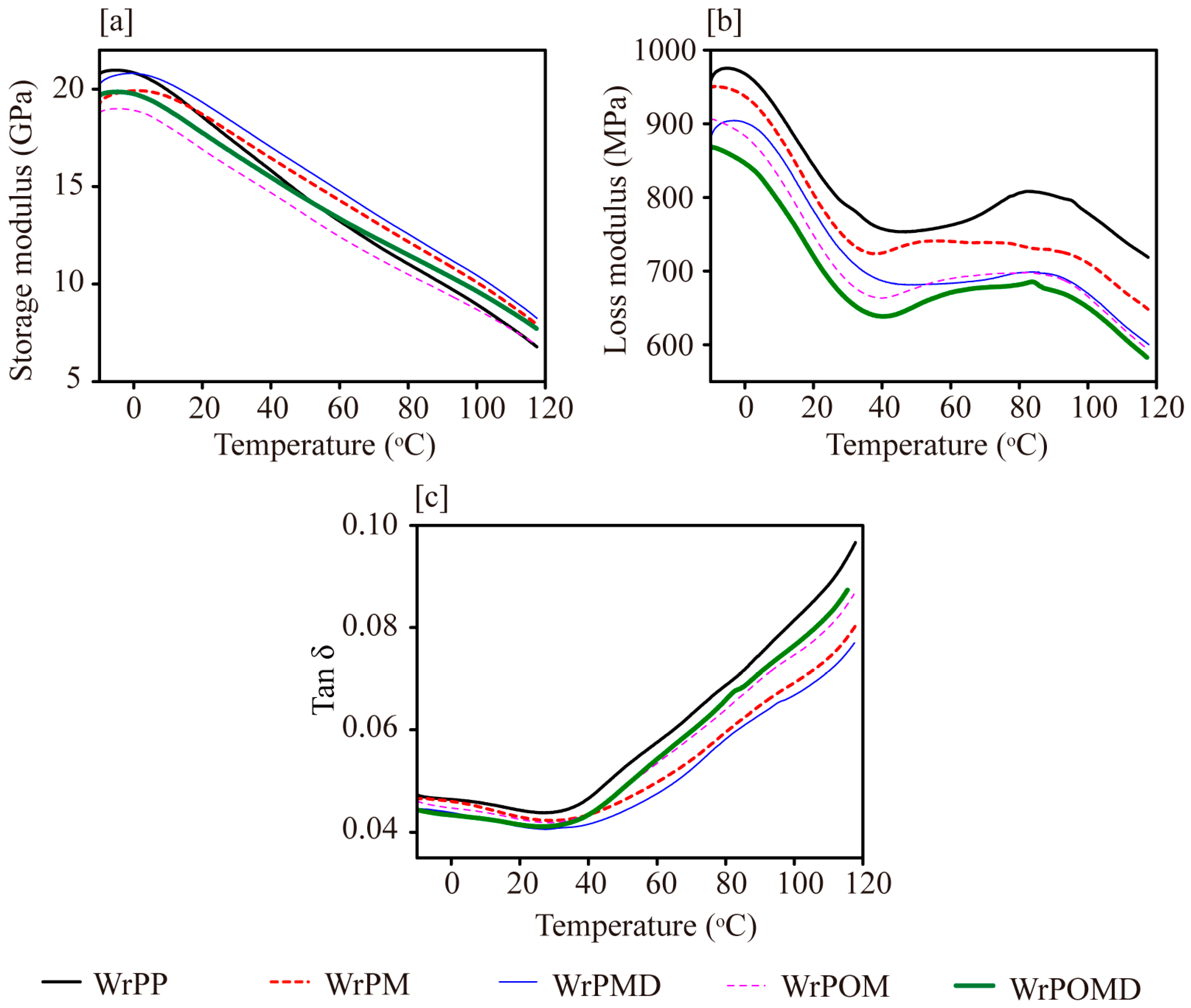

2.2.3. Analysis of Dynamic Mechanical and Deformation Mechanism

3. Experimental

3.1. Materials

3.2. Grafting of Polymer Matrix

3.3. Preparation of Waste-Sourced Biocomposites Sample

3.4. Characterization and Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with nature fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ayana, K.D.; Ha, C.S.; Ali, A.Y. Comprehensive overview of wood polymer composite: Formulation and technology, properties, interphase modification, and characterization. Sustain. Mater. Technol. 2024, 40, e00983. [Google Scholar] [CrossRef]

- Shan, Z.Q.; Jia, X.H.; Qiu, Y.; Yang, J.; Wang, Z.F.; Song, H.J. High-strength, flexible and self-lubricating wood-plastic composites based on synergistic reinforcement of “hard-soft” units. Tribol. Int. 2024, 199, 110016. [Google Scholar] [CrossRef]

- Serra-Parareda, F.; Julián, F.; Espinosa, E.; Rodríguez, A.; Espinach, F.X.; Vilaseca, F. Feasibility of Barley Straw Fibers as Reinforcement in Fully Biobased Polyethylene Composites: Macro and Micro Mechanics of the Flexural Strength. Molecules 2020, 25, 2242. [Google Scholar] [CrossRef]

- Cui, Y.; Lee, S.; Noruziaan, B.; Cheung, M.; Tao, J. Fabrication and interfacial modification of wood/recycled plastic composites materials. Compos. Part A 2008, 39, 655–661. [Google Scholar] [CrossRef]

- Yu, W.W.; Li, M.Q.; Lei, W.; Pu, Y.Z.; Sun, K.J.; Ma, Y.L. Effects of Wood Flour (WF) Pretreatment and the Addition of a Toughening Agent on the Properties of FDM 3D-Printed WF/Poly(lactic acid) Biocomposites. Molecules 2022, 27, 2985. [Google Scholar] [CrossRef]

- Yu, W.W.; Qiu, R.; Li, M.Y.; Lei, W. Effects of Wood Content and Modification on Properties of Wood Flour/Polybutylene Adipate Terephthalate Biocomposites. Molecules 2023, 28, 8057. [Google Scholar] [CrossRef]

- Gupta, M.K.; Srivastava, R.K. Mechanical Properties of Hybrid Fibers-Reinforced Polymer Composite: A Review. Polym.-Plast. Technol. 2016, 55, 626–642. [Google Scholar] [CrossRef]

- Xie, Y.J.; Hill, C.A.S.; Xiao, Z.F.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Pracella, M.; Chionna, D.; Anguillesi, I.; Kulinski, Z.; Piorkowska, E. Functionalization, compatibilization and properties of polypropylene composites with Hemp fibres. Compos. Sci. Technol. 2006, 66, 2218–2230. [Google Scholar] [CrossRef]

- Elamin, M.A.M.; Li, S.X.; Osman, Z.A.; Otitoju, T.A. Preparation and characterization of wood-plastic composite by utilizing a hybrid compatibilizer system. Ind. Crop. Prod. 2020, 154, 112659. [Google Scholar] [CrossRef]

- Fang, X.Y.; Li, Y.C.; Zhao, J.Q.; Xu, J.N.; Li, C.C.; Liu, J.X.; Liu, Y.; Guo, H.W. Improved interfacial performance of bamboo fibers/polylactic acid composites enabled by a self-supplied bio-coupling agent strategy. J. Clean. Prod. 2022, 380, 134719. [Google Scholar] [CrossRef]

- Xu, J.J.; Chen, C.F.; Li, Y.Y.; Zhou, H.Y.; Hao, X.L.; Ou, R.X.; Wang, Q.W. Optimizing the rheological and mechanical properties of ultra-highly filled wood fiber/polyethylene composites through binary alloy matrix strategy. Compos. Sci. Technol. 2024, 256, 110740. [Google Scholar] [CrossRef]

- Xie, Y.J.; Xiao, Z.F.; Grüneberg, T.; Militz, H.; Hill, C.A.S.; Steuernagel, L.; Mai, C. Effects of chemical modification of wood particles with glutaraldehyde and 1,3-dimethylol-4,5-dihydroxyethyleneurea on properties of the resulting polypropylene composites. Compos. Sci. Technol. 2010, 70, 2003–2011. [Google Scholar] [CrossRef]

- Wambua, P.; Ivens, J.; Verpoest, I. Natural fibres: Can they replace glass in fibre reinforced plastics? Compos. Sci. Technol. 2003, 63, 1259–1264. [Google Scholar] [CrossRef]

- Ou, R.X.; Zhao, H.; Sui, S.J.; Song, Y.M.; Wang, Q.W. Reinforcing effects of Kevlar fiber on the mechanical properties of wood-flour/high-density-polyethylene composites. Compos. Part A 2010, 41, 1272–1278. [Google Scholar] [CrossRef]

- Wang, K.; Xu, X.Y.; Huo, R.L.; Fang, H.; Chen, X.X. Flexural reinforcement of wood plastic composite panels by bonding glass fiber reinforced polymer sheets and embedding bars. Polym. Compos. 2024; in press. [Google Scholar] [CrossRef]

- Karagöz, I.; Büyükkaya, K.; Demirer, H.; Mudu, M.; Kartal, I. Mechanical and thermal characterization of elastomer modified polypropylene hybrid composites reinforced with hazdlnut shell and wollastonite fillers. J. Appl. Polym. Sci. 2024, 141, e55710. [Google Scholar] [CrossRef]

- Homkhiew, C.; Rawangwong, S.; Boonchouytan, W.; Suchaiya, V. Morphological, mechanical, and physical properties of ground rubber tire thermoplastic elastomer/rubberwood sawdust composites: Effects of composition contents and rubber types. J. Thermoplast. Compos. 2023, 36, 1952–1977. [Google Scholar] [CrossRef]

- Hao, J.X.; Wang, H.G.; Song, Y.M.; Wang, W.H. Simultaneously improving the toughness and stiffness of wood flour/polypropylene composites using elastomer A669/talcum blends. Polym. Compos. 2019, 40, 1335–1341. [Google Scholar] [CrossRef]

- Clemons, C. Elastomer modified polypropylene–polyethylene blends as matrices for wood flour–plastic composites. Compos. Part A 2020, 41, 1559–1569. [Google Scholar] [CrossRef]

- Liu, H.; Wu, Q.; Han, G.; Yao, F.; Kojima, Y.; Suzuki, S. Compatibilizing and toughening bamboo flour-filled HDPE composites: Mechanical properties and morphologies. Compos. Part A 2008, 39, 1891–1900. [Google Scholar] [CrossRef]

- Li, T.Q.; Yan, N. Mechanical properties of wood flour/HDPE/ionomer composites. Compos. Part A 2007, 38, 1–12. [Google Scholar] [CrossRef]

- Kolárík, J.; Jancár, J. Ternary composites of polypropylene/elastomer/calcium carbonate: Effect of functionalized components on phase structure and mechanical properties. Polymer 1992, 23, 4961–4967. [Google Scholar] [CrossRef]

- Sudár, A.; Burgstaller, C.; Renner, K.; Móczó, J.; Pukánszky, B. Wood fiber reinforced multicomponent, multiphase PP composites: Structure, properties, failure mechanism. Compos. Sci. Technol. 2014, 103, 106–112. [Google Scholar] [CrossRef]

- Sudár, A.; Renner, K.; Móczó, J.; Lummerstorfer, T.; Burgstaller, C.; Jerabek, M.; Gahleitner, M.; Doshev, P.; Pukánszky, B. Fracture resistance of hybrid PP/elastomer/wood composites. Compos. Struct. 2016, 141, 143–154. [Google Scholar] [CrossRef]

- Molnár, S.; Pukánszky, B.; Hammer, C.o.; Maurer, F.H.J. Impact fracture study of multicomponent polypropylene composites. Polymer 2000, 41, 1529–1539. [Google Scholar] [CrossRef]

- Jin, X.B.; Li, J.P.; Zhang, R.; Jiang, Z.H.; Qin, D.C. Fabrication of High-Performance Bamboo–Plastic Composites Reinforced by Natural Halloysite Nanotubes. Molecules 2020, 25, 2259. [Google Scholar] [CrossRef]

- Ben Hamou, K.; Kaddami, H.; Elisabete, F.; Erchiqui, F. Synergistic association of wood/hemp fibers reinforcements on mechanical, physical and thermal properties of polypropylene-based hybrid composites. Ind. Crop. Prod. 2023, 192, 116052. [Google Scholar] [CrossRef]

- Arya, S.; Kumar, R.; Chauhan, S.; Kelkar, B.U. Development of natural fiber reinforced thermoplastic bonded hybrid wood veneer composite. Constr. Build. Mater. 2023, 368, 130459. [Google Scholar] [CrossRef]

- Yi, S.M.; Xu, S.H.; Li, Y.; Gan, W.T.; Yi, X.; Liu, W.Y.; Wang, Q.W.; Wang, H.G.; Ou, R.X. synergistic toughening effects of grafting modification and elastomer olefin block copolymer addition on the fracture resistance of wood particle/polypropylene/elastomer composites. Mater. Des. 2019, 181, 107918. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernández, B.; Cantero, G.; Llano-Ponte, R.; Valea, A.; Mondragon, I. Mechanical properties of flax fibre/polypropylene composites. Influence of fibre/matrix modification and glass fibre hybridization. Compos. Part A 2005, 36, 1637–1644. [Google Scholar] [CrossRef]

- Yi, S.M.; Xu, S.H.; Fang, Y.Q.; Wang, H.G.; Wang, Q.W. Effects of Matrix Modification on the Mechanical Properties of Wood–Polypropylene Composites. Polymers 2017, 9, 712. [Google Scholar] [CrossRef]

- Li, Y.; Xie, X.M.; Guo, B.H. Study on styrene-assisted melt free-radical grafting of maleic anhydride onto polypropylene. Polymer 2001, 42, 3419–3425. [Google Scholar] [CrossRef]

- Al-Malaika, S.; Eddiyanto, E. Reactive processing of polymers: Effect of bifunctional and tri-functional comonomers on melt grafting of glycidyl methacrylate onto polypropylene. Polym. Degrad. Stab. 2010, 95, 353–362. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Wan, D.; Xing, H.P.; Zhang, Z.J.; Tan, H.Y.; Wang, L.; Zheng, J.; An, Y.J.; Tang, T. A new grafting monomer for synthesizing long chain branched polypropylene through melt radical reaction. Polymer 2012, 53, 121–129. [Google Scholar] [CrossRef]

- Zhao, W.Y.; Huang, Y.J.; Liao, X.; Yang, Q. The molecular structure characteristics of long chain branched polypropylene and its effects on non-isothermal crystallization and mechanical properties. Polymer 2013, 54, 1455–1462. [Google Scholar] [CrossRef]

- Lin, Y.J.; Marchand, G.R.; Hiltner, A.; Baer, E. Adhesion of olefin block copolymers to polypropylene and high density polyethylene and their effectiveness as compatibilizers in blends. Polymer 2011, 52, 1635–1644. [Google Scholar] [CrossRef]

- Gao, H.; Xie, Y.J.; Ou, R.X.; Wang, Q.W. Grafting effects of polypropylene/polyethylene blends with maleic anhydride on the properties of the resulting wood-plastic composites. Compos. Part A 2012, 43, 150–157. [Google Scholar] [CrossRef]

- Etaati, A.; Pather, S.; Fang, Z.P.; Wang, H. The study of fibre/matrix bond strength in short hemp polypropylene composites from dynamic mechanical analysis. Compos. Part B 2014, 62, 19–28. [Google Scholar] [CrossRef]

- Sclavons, M.; Carlier, V.; Verfaillie, G.; Fallais, I.; Legras, R.; Laurent, M.; Fc, T.; Franquinet, P. Quantification of the maleic anhydride grafted onto polypropylene by chemical and viscosimetric titrations, and FTIR spectroscopy. Polymer 2000, 41, 1989–1999. [Google Scholar] [CrossRef]

- GB/T 3682-2000; Determination of the Melt Mass-Flow Rate (MFR) and the Melt Volume-Flow Rate (MVR) of Thermoplastics. Standards Press of China: Beijing, China, 2000.

- ASTM D638-10; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D790-10; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D256-10; Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D4812-06; Standard Test Method for Unnotched Cantilever Beam Impact Resistance of Plastics. ASTM International: West Conshohocken, PA, USA, 2012.

| Samples | Xc (%) | Tm (°C) | Tc (°C) |

|---|---|---|---|

| rPP | 37.1 | 162 | 122.0 |

| rPM | 45.2 | 160.1 | 121.4 |

| rPMD | 46.4 | 161.8 | 123.8 |

| rPOM | 42.6 | 161.3 | 122.4 |

| rPOMD | 42.0 | 161.8 | 123.7 |

| Samples | rPP (wt.%) | OBC (wt.%) | MAH ※ (wt.%) | DVB ※ (wt.%) | DCP ※ (wt.%) |

|---|---|---|---|---|---|

| rPP | 100 | 0 | 0 | 0 | 0 |

| rPM | 100 | 0 | 0.6 | 0 | 0.09 |

| rPMD | 100 | 0 | 0.6 | 0.3 | 0.09 |

| rPOM | 90 | 10 | 0.6 | 0 | 0.09 |

| rPOMD | 90 | 10 | 0.6 | 0.3 | 0.09 |

| Sample | WF (wt.%) | Polymer Matrix (wt.%) | Lubricant ※ (wt.%) |

|---|---|---|---|

| WrP | 60 | rPP(40) | 2 |

| WrPM | 60 | rPM(40) | 2 |

| WrPMD | 60 | rPMD(40) | 2 |

| WrPOM | 60 | rPOM(40) | 2 |

| WrPOMD | 60 | rPOMD (40) | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, S.; Liu, W.; Xu, S.; Hu, R.; Li, Q.; Wu, M.; Wang, Q.; Huang, Z. Enhancement and Compatibilization of Waste-Sourced Biocomposites Through Elastomer Blending and Matrix Grafting Modification. Molecules 2024, 29, 4905. https://doi.org/10.3390/molecules29204905

Yi S, Liu W, Xu S, Hu R, Li Q, Wu M, Wang Q, Huang Z. Enhancement and Compatibilization of Waste-Sourced Biocomposites Through Elastomer Blending and Matrix Grafting Modification. Molecules. 2024; 29(20):4905. https://doi.org/10.3390/molecules29204905

Chicago/Turabian StyleYi, Shunmin, Wanyu Liu, Shihua Xu, Ruijia Hu, Qing Li, Meijia Wu, Qingwen Wang, and Zhimin Huang. 2024. "Enhancement and Compatibilization of Waste-Sourced Biocomposites Through Elastomer Blending and Matrix Grafting Modification" Molecules 29, no. 20: 4905. https://doi.org/10.3390/molecules29204905

APA StyleYi, S., Liu, W., Xu, S., Hu, R., Li, Q., Wu, M., Wang, Q., & Huang, Z. (2024). Enhancement and Compatibilization of Waste-Sourced Biocomposites Through Elastomer Blending and Matrix Grafting Modification. Molecules, 29(20), 4905. https://doi.org/10.3390/molecules29204905