Abstract

Selective catalytic reduction of nitrogen oxides (NOx) with ammonia (NH3-SCR) has been implemented in response to the regulation of NOx emissions from stationary and mobile sources above 300 °C. However, the development of NH3-SCR catalysts active at low temperatures below 200 °C is still needed to improve the energy efficiency and to cope with various fuels. In this review article, recent reports on low-temperature NH3-SCR catalysts are systematically summarized. The redox property as well as the surface acidity are two main factors that affect the catalytic activity. The strong redox property is beneficial for the low-temperature NH3-SCR activity but is responsible for N2O formation. The multiple electron transfer system is more plausible for controlling redox properties. H2O and SOx, which are often found with NOx in flue gas, have a detrimental effect on NH3-SCR activity, especially at low temperatures. The competitive adsorption of H2O can be minimized by enhancing the hydrophobic property of the catalyst. Various strategies to improve the resistance to SOx poisoning are also discussed.

1. Introduction

Anthropogenic pollutant emissions increased with human activity until a few decades ago, posing a threat to human well-being. However, over the past few decades, regulations on the emission of these pollutants and the development of technologies to control emissions have had some success in preventing significant pollution. Sulfur oxides (SOx), nitrogen oxides (NOx and N2O), CO, and volatile organic compounds (VOCs) are representative gaseous pollutants that are now strictly regulated [1]. In addition, greenhouse gases, including CO2 and methane, are currently or will be regulated in the near future, depending on the country.

NOx, such as nitrogen monoxide (NO) and nitrogen dioxide (NO2), is formed from a variety of stationary and mobile sources. Fossil fuel-based power plants and internal combustion engine-based transportation vehicles are prime examples of stationary and mobile sources of NOx emissions, respectively. In any case, thermal NOx, formed at high temperatures when nitrogen oxidizes with oxygen in the air, is the primary pathway for NOx emissions. As conventional power plants and internal combustion engine-based vehicles are replaced with renewable energy and electric vehicles, respectively, to cope with the CO2 emissions problem, the NOx emissions are expected to continue to decline. Meanwhile, with ammonia gaining much attention as a non-carbon fuel, fuel NOx, which is formed through the partial oxidation of ammonia, can be another pathway for NOx emissions in the stationary sources [2,3,4].

The selective catalytic reduction of NOx with ammonia (NH3-SCR) is the most widely adopted method for controlling NOx emissions from stationary sources among the various methods developed to date [5,6]. The following reactions occur during NH3-SCR in the absence of oxygen.

6NO + 4NH3 → 5N2 + 6H2O

6NO2 + 8NH3 → 7N2 + 12H2O

NO + NO2 + 2NH3 → 2N2 + 3H2O

In practice, because most flue gases contain varying concentrations of oxygen, the following reactions take place.

4NO + 4NH3 + O2 → 4N2 + 6H2O

2NO + 4NH3 + 2O2 →3N2 + 6H2O

2NO2 + 4NH3 + O2 → 3N2 + 6H2O

In addition, ammonia oxidations, shown below, can occur in the presence of oxygen, which is not favorable for NH3-SCR.

4NH3 + 3O2 → 2N2 + 6H2O

4NH3 + 5O2 → 4NO + 6H2O

4NH3 + 7O2 → 4NO2 + 6H2O

2NH3 + 2O2 → N2O + 3H2O

N2O can be additionally formed via the following reaction in the presence of the catalyst.

4NO + 4NH3 + 3O2 → 4N2O + 6H2O

Metal (W and/or Mo) oxides-promoted V2O5/TiO2 is a representative commercial catalyst for NH3-SCR, achieving high NOx conversion over a wide operating temperature range of 300–400 °C [7,8,9]. Because flue gas composition varies depending on the fuel (e.g., coal, biomass, organic wastes, oil, natural gas, etc.), the NH3-SCR unit is placed in different locations in the flue gas treatment process depending on the process characteristics [10]. Generally, since the flue gas contains fly ash, impurities, and SO2, the dust removal device (e.g., electrostatic precipitator) and the flue gas desulfurization device can be installed to remove the fly ash and SO2 in the flue gas, respectively [11]. After these units, additional preheaters are required to raise the flue gas temperature to the proper operating temperature of vanadia-based commercial catalysts because the flue gas temperature is reduced below 200 °C. Therefore, low-temperature NH3-SCR catalysts need to be developed to eliminate the increased operating cost and an extra capital cost due to these additional preheating units.

To date, a variety of NH3-SCR catalysts [12,13,14,15,16,17,18,19,20,21,22,23], including Cu-based [24], Ce-based [25,26,27,28], Mn-based [29,30,31], Ba-based [32], and carbon materials-supported catalysts [33,34], have been studied that are active below 200 °C. Compared with NH3-SCR catalysts operating at medium and high temperatures, low-temperature NH3-SCR catalysts are susceptible to poisoning by water vapor and SO2 in flue gas [19,21]. In particular, SO2 in flue gas can be catalytically oxidized to form SO3, which reacts with ammonia and then converts to ammonium salts (NH4HSO4 (ABS) and (NH4)2SO4 (AS)), which can block the active sites of NH3-SCR [11,35]. Furthermore, additional side reactions forming N2O have been observed over these catalysts. Low-temperature NH3-SCR catalysts capable of solving the above problems have not yet been reported. This review article summarizes recent progress on low-temperature NH3-SCR catalysis and briefly discusses research directions to address the current obstacles.

2. Low-Temperature NH3-SCR Catalysts

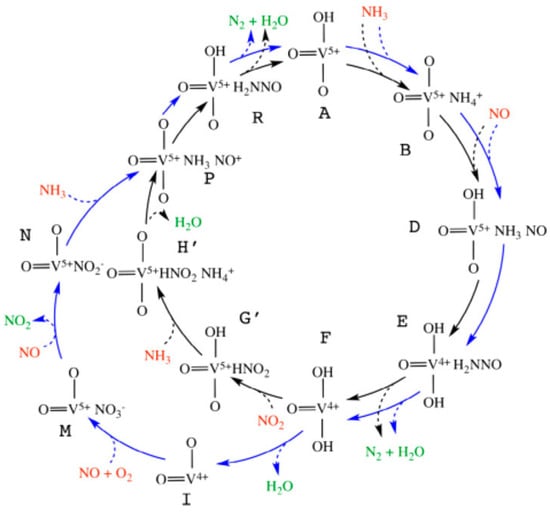

Vanadia-based catalysts active at moderate temperatures can provide meaningful information about low-temperature NH3-SCR catalysis. Arnarson et al. [36] proposed a reaction mechanism of ‘Standard NH3-SCR’ combining with ‘Fast NH3-SCR’ on a VOx/TiO2(001) catalyst model (Figure 1). The two cycles shared the same reduction part (A B D E F P R A in Figure 1) but used NO + O2 (F I M N P in Figure 1) and NO2 (F G′ H′ P in Figure 1) for the re-oxidation process, respectively. They noted that the rate of formation and desorption of H2O is a decisive factor in the ‘Standard NH3-SCR’ reaction at low temperatures and that the reaction of NO2 with the reduction sites is responsible for accelerating the ‘Fast NH3-SCR’ reaction at low temperatures [36].

Figure 1.

Proposed reaction mechanism over the VOx/TiO2(001) model. The black circle represents the ‘Fast NH3-SCR’ reaction, and the blue circle represents the NO-activation cycle; the ‘Standard NH3-SCR’ reaction is the sum of the black and blue cycles. This schematic diagram is reprinted with permission from ref [36]. Copyright 2017 Elsevier.

The reaction mechanisms [36,37,38] over V2O5/TiO2 catalyst reveal that NH3-SCR activity depends on a number of factors, including the redox property of vanadium species between V+5 and V+4, Brønsted and Lewis acid sites on the catalyst surface, dispersion of vanadium species, acidic and basic properties of the support, contribution of a support to the redox property of vanadium species, the surface hydrophobicity of the support, the hydrothermal stability of the support, and adsorption property of SOx. Therefore, these factors should also be considered when designing low-temperature NH3-SCR catalysts. First of all, the redox properties of the active metal oxides are crucial for this reaction, so Mn, Fe, Co, Cu, and Ce can be selected as promising candidates for the active metal because they have a variety of metal oxides with different oxidation states and are interconvertible under reaction conditions. However, cobalt oxide can be excluded as a promising candidate for this reaction because of its very high activity towards complete oxidation [39]. Therefore, Cu-, Fe-, Mn-, and Ce-based low-temperature NH3-SCR catalysts are covered in the following sections.

2.1. Cu-Based Catalysts

Cu-containing metal oxides and Cu-based small-pore zeolites have been reported to be active for low- and medium-temperature NH3-SCR. Various factors, including support, Cu precursor, promoter, crystal structure, preparation method, and interface engineering between Cu and support, have been considered [24]. Research on Cu-based catalysts has been motivated by their high NH3-SCR activity, especially at low temperatures, but their low SO2 tolerance is recognized as a significant barrier to field application. Moreover, due to the low hydrothermal stability of Cu-containing metal oxides, recent research has focused on Cu-based small pore zeolites, as shown in Table 1 [40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76]. Among them, low-temperature NH3-SCR activity was reported over Cu-zeolites such as Cu-LTA [41], Cu-ZSM-5 [42,43,44], Cu-SSZ-13 [47], Cu-SSZ-16 [49], Cu-SSZ-52 [51], Cu-SAPO-34 [52], Cu-UZM-35 [56], and Cu-ZJM-7 [57], metal-promoted Cu-zeolites such as Ce-Cu-SAPO-18 [59], Fe/Cu-SSZ-13 [62], CuY-SAPO-34 [63], CuNd/SAPO-34, Cu-Ce-La-SSZ-13 [65], and Cu-Ce-USY [68], and other Cu-based oxides such as Cu/ZrO2 [70] and CuAl layered double oxide (LDO) supported on carbon nanotubes (CNTs) [72].

Table 1.

NH3-SCR activity over some Cu-based catalysts.

Only a few reports can be found on Cu-containing metal oxides in the last few years. Chen et al. [69] examined the crystal-plane effects of CuO over CuO/TiO2 catalysts on NH3-SCR and reported that the proportion of Cu+ and surface-adsorbed oxygen (Oα) in CuO(111)/TiO2 catalyst was higher than that of CuO(001)/TiO2 catalyst, which could facilitate the NH3-SCR reactions. Liu et al. [71] reported that LaCuO3-x/meso-Al2O3 enriched with Cu3+ species exhibited significantly higher catalytic activity for NH3-SCR than CuO/meso-Al2O3 counterpart in the low temperature range (100–280 °C), which was attributed to the unique nature of Cu3+ species, which had more acid sites and higher redox properties to promote the adsorption and activation of ammonia and NOx.

Cu-containing zeolites have been intensively studied for NH3-SCR and/or urea-SCR for their applications to stationary and mobile sources [57,77,78]. The NH3-SCR performance of Cu-exchanged zeolite catalysts depends on the amount of isolated copper ion sites, SiO2/Al2O3 ratios, and topological structures. The isolated Cu2+ species serve as redox sources, the zeolite supplies acidic sites, and the channel structure affects the diffusion of reactants, intermediates, and products. A variety of zeolite catalysts for Fe or Cu ion exchange have been developed, all of which exhibit a wide temperature window, including ZSM-5, SAPO-18, SAPO-34, SSZ-13, SSZ-16, SSZ-39, AFX, BEA, ERI, KFI, LTA, Nu-3, PST-7, RHO, RTH, Sigma-1, UZM-35, etc. [78,79,80,81,82,83]. In terms of the hydrothermal stability, ion-exchanged small-pore zeolites such as Cu-SSZ-13, Cu-SSZ 16, Cu-SSZ-39, Cu-SAPO-18, Cu-SAPO-34, and Cu-KFI are superior to the medium-pore ZSM-5 zeolite catalysts, and finally, Cu-SSZ-13 catalysts have been commercialized for NOx control in diesel-powered vehicles owing to their outstanding NOx removal efficiency and hydrothermal stability [77,79,84]. A comparison of the NH3-SCR activity of Cu- and Fe-zeolites showed that at low temperatures (below 350 °C), the former was more active than the latter, but above 350 °C, the latter was more active than the former, which was ascribed to the fact that Cu-zeolites had higher adsorption sites for NH3 than Fe-zeolites [85].

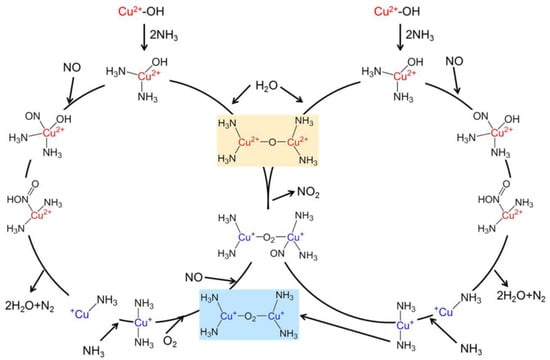

The reaction mechanism over Cu-SSZ-13 is shown in Figure 2 [86]. A mobile NH3-complex, monomeric Cu ion was identified to be active in the NOx reduction cycle in the redox mechanism. The Cu+ ion complexes thus formed subsequently migrate between the zeolite cages to form dimeric species that are important for O2 activation, which is the rate-limiting step essential for the re-oxidation of Cu+ to complete the catalytic cycle [87]. Density functional theory (DFT) calculations on a reaction mechanism for low-temperature NH3-SCR over Cu-CHA reveal that ammonia-solvated Cu cations, Cu(NH3)2+, are responsible for O2 activation as well as the formation of the key intermediates HO-NO and H2N-NO and that Brønsted acid site is related to decomposition of HO-NO and H2N-NO to N2 and H2O [88]. Oxygen activation requires pairs of Cu(NH3)2+ complexes, but HO-NO and H3N-NO coupling may occur on single complexes [88].

Figure 2.

Complete redox cycling mechanism for low-temperature standard NH3-SCR derived from DFT calculations that involves two Cu(I) centers in the initiation of the oxidation half-cycle [87]. Adapted from permission from [86]. Copyright 2017, American Chemical Society.

Catalyst deactivation in the presence of SOx in the flue gas can be classified into two categories. One is irreversible deactivation due to the formation of inactive Cu sulfate species through interaction between SOx and active Cu species [89,90,91,92,93,94,95]. The other is reversible deactivation resulting from the deposition of sulfate species (e.g., ABS and AS) [96]. SO2 poisoning inhibits the oxidation of NO to NO2, resulting in a lower NH3-SCR activity below 350 °C [79]. Above this temperature, sulfate compounds are unstable so that the available Cu sites can be sufficient for NH3-SCR activity [79]. Therefore, sulfur poisoning beyond 350 °C is insignificant. Table 2 summarizes the effects of H2O and SO2 on the NH3-SCR over some Cu-based catalysts [97,98,99,100,101,102,103,104,105,106,107,108,109]. Among them, CuO@Cu-metal organic frameworks (MOFs) core-shell catalyst [101] and Cu-doped phosphomolybdic acid catalyst [106] showed a relatively stable catalytic performance even in the presence of H2O and SO2 at low temperatures.

Table 2.

NH3-SCR activity in the presence of H2O and/or SO2 over some Cu-based catalysts.

Hammershøi et al. [89] reported that the NH3-SCR activity over Cu-SSZ-13 catalysts was significantly inhibited at 160–350 °C after exposure to SO2, but preserved above 350 °C. Jangjou et al. [110] compared SO2-induced catalyst deactivation at [CuIIOH]+ and Cu2+ sites in Cu-SSZ-13. For Cu2+ sites, the NH3-SCR activity was inhibited due to the formation of ammonium sulfate, which could be fully recovered by regeneration at >380 °C. This implies that Cu2+ sites do not adsorb sulfur during the exposure to SO2 [110]. On the other hand, [CuIIOH]+ sites could adsorb sulfur directly to form Cu bisulfite, causing the irreversible deactivation [110]. Therefore, the sulfur poisoning of [CuIIOH]+ was much more severe than that of Cu2+. H2SO4 formed in the presence of SO2 and H2O plays an important role in the formation of ammonium sulfate [111,112]. Another route to the formation of Cu bisulfate is the interaction between SO2 and CuOx nanoclusters [113].

The effect of SO2 on Cu-SAPO-34 deactivation was also investigated [91,114]. The NH3-SCR activity of sulfur-poisoned Cu-SAPO-34 was decreased significantly at 100–500 °C, though sulfur accumulation and zeolite structure collapse were not observed [114]. The deactivation was attributed to the decreased amount of isolated Cu2+ ions [91,114]. It was speculated that sulfur poisoning could hinder the copper redox transformation (between CuII and CuI) in Cu-SAPO-34, which led to the sulfation of Cu sites [115]. In addition, Cu-SAPO-34 favored the formation of stable Al2(SO4)3 species compared with Cu-SSZ-13, resulting in an irrecoverable loss in NH3-SCR activity [111].

When screening Cu-containing zeolite catalysts, hydrothermal stability has become an important selection criterion in addition to high NOx conversion over a wide range of reaction temperatures for application in transport vehicles, but this is not as important for low-temperature NH3-SCR catalysts for application in stationary sources. Rather, resistance to water and SO2 at low temperatures is an additional factor to be considered in the development of NH3-SCR catalysts. In order to improve the low-temperature NH3-SCR activity of Cu-containing zeolite catalysts, the Cu active sites can be modified by introducing the heteroatoms to facilitate the redox property of Cu and metal oxides to accelerate NO oxidation for ‘Fast NH3-SCR’ [116]. Other zeolites with different structures, including AEI and LTA, the small-pore intergrown zeolites, including AFX/CHA and CHA/AEI, and the zeolite morphology can be further examined even though they were excluded because of their poor hydrothermal stability at high temperatures [116]. Additional doping of Y [63] and lanthanides [59,60,61,62,63,64] to Cu-zeolites was reported to be effective for NH3-SCR. The composite catalysts such as MnO2-CeO2/Cu/SSZ-13 showed excellent NH3-SCR activity and N2 selectivity in the temperature ranges of 125 to 450 °C because more active monodentate nitrate was formed on the surface of the composite catalyst compared with Cu/SSZ-13 alone [99].

Chen et al. [107] synthesized a core–shell structure Cu–Ce–La/SSZ-13@ZSM-5 catalyst by a self-assembly method and applied it to NH3-SCR. They observed that Cu–Ce–La/SSZ-13@ZSM-5 with an appropriate shell thickness presented better NH3-SCR activity and hydrothermal stability than Cu–Ce–La/SSZ-13 because some metal ions were transferred and redistributed during the assembly of the ZSM-5 shell, resulting in the conversion of [Cu(OH)]+–Z to Cu2+–2Z species and the functionalization of the shell phase, which was beneficial for the adsorption and activation of NH3. Chen et al. [109] synthesized a multifunctional core-shell catalyst with Cu-SSZ-13 as the core phase and Ce-MnOx supported mesoporous silica as the shell phase via self-assembly and impregnation. The core-shell catalyst exhibited excellent low-temperature activity, SO2 tolerance, and hydrothermal stability compared with the Cu-SSZ-13 [109]. The Ce-MnOx species dispersed in the shell can rapidly activate NO and oxidize it to NO2, which allows the NH3-SCR reaction on the core-shell catalyst to be initiated in the shell phase [109]. Meanwhile, Ce-MnOx species can react preferentially with SO2 as sacrifice components, effectively avoiding the sulfur inactivation of the copper active sites [109]. This catalyst showed relatively stable NO conversion in the presence of 10% H2O and 100 ppm SO2 at 250 °C [109]. It is noteworthy that few low-temperature Cu-based catalysts with high resistance to H2O and SO2 poisoning have been reported.

2.2. Fe-Based Catalysts

Various Fe-based catalysts, including single iron oxides, Fe-containing mixed metal oxides, supported iron oxides, supported Fe-containing multicomponent metal oxides, and Fe-containing zeolites, have been reported for NH3-SCR due to their excellent redox properties and low cost. Another advantage of Fe-based catalysts is their relatively good resistance to water and SO2, although this has only been reported at temperatures above 200 °C [11].

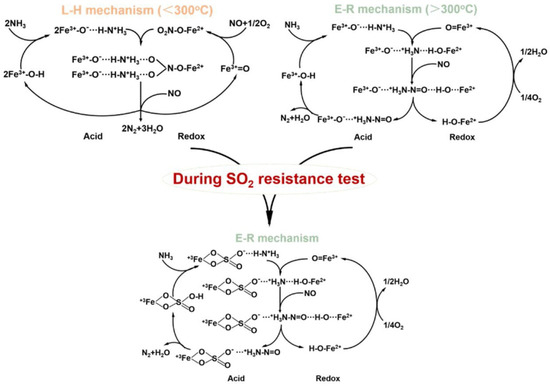

γ-Fe2O3 has been mainly reported for NH3-SCR among various single-phase Fe2O3 with different crystalline structures (e.g., α, β, γ, and ε) [11]. Yu et al. [117] proposed two different reaction mechanisms over γ-Fe2O3 (Figure 3). One is the Langmuir–Hinshelwood (L–H) mechanism in which NH3 and NO are adsorbed on the active sites, Fe3+-OH and Fe3+=O, respectively, and reacted to form N2 and H2O, which is prevalent at temperatures below 300 °C [117]. The other is the Eley–Rideal (E–R) mechanism in which NH3 is first chemisorbed on Fe3+-OH to form Fe3+-O−H-N+H3, which can be further reacted with gaseous NO to produce N2 and H2O, which is the main pathway at high temperatures above 300 °C [117]. In any case, this reaction requires the cooperation of acidic sites and redox properties. They also confirmed that the NH3-SCR activity decreased firstly and then increased slowly after the introduction of SO2 at temperatures ranging from 225 to 275 °C [117]. This was ascribed to the formation of iron sulfate species inhibiting the adsorption of NOx, thus interfering with the L–H reaction pathway [117]. On the other hand, the iron sulfate species formed enhanced the surface acidity, which promoted the E–R reaction pathway and further promoted NH3-SCR activity [117].

Figure 3.

The proposed reaction mechanism before and during the SO2 resistance test on the γ-Fe2O3 catalyst [117]. Adapted from permission from ref [117]. Copyright 2021 Elsevier.

Recent work on single Fe oxides has focused on how to increase the low-temperature NH3-SCR activity. Qin et al. [118] prepared various Fe3O4 nanostructures exposed with different crystal planes from MIL-100(Fe) as the Fe precursor and found that the catalysts with more (1 1 1) had better NH3-SCR performance than those with (1 0 0) exposure, which they attributed to the preferential exposure of the Fe3O4 (1 1 1) crystal faces leading to higher adsorbed oxygen concentration and surface acidity. Yang et al. [119] found through DFT calculations that the ‘Fast NH3-SCR’ reaction was the dominant pathway for the NH3-SCR reaction on Fe2-N6 catalysts, with the energy barrier of the rate-determining step (HONO formation) being 1.00 eV, much lower than that of other NH3-SCR catalysts, enabling excellent low-temperature activity in the temperature window of 300–500 K. Zhang et al. [120] prepared a highly defective α-Fe2O3 with enhanced acid (Lewis and Brønsted) and redox properties on homoatomic dinuclear sites comprising more positively charged Fe3+ and oxygen vacancy-coupled Fe2+ ions. The catalyst showed enhanced NH3-SCR activity at low temperatures without the addition of other acid transition metals and showed resistance to poisoning of H2O and SO2 due to the large amount of Brønsted acid [120].

Various metal oxide-promoted iron oxides have been investigated to enhance the cooperation of surface acidity and redox property to facilitate the low-temperature NH3-SCR. The positive effects of Mn [121], Nb [122], Mo [123], Ce [124], Sm [125], and W [123,126,127,128] in promoted iron oxides on the catalytic activity have been reported. Table 3 summarizes the effects of H2O and SO2 on the NH3-SCR over some Fe-based catalysts [120,121,124,125,128,129,130,131,132,133,134,135,136,137]. Among them, a relatively stable catalytic performance was observed over Mn-Fe oxides [121] even in the presence of H2O and SO2 at low temperatures.

Table 3.

NH3-SCR activity in the presence of H2O and/or SO2 over some Fe-based catalysts.

It is noteworthy that, except for catalysts containing additional Mn, few Fe-based catalysts are active for NH3-SCR at low temperatures (<200 °C) while being resistant to H2O and SO2 poisoning. Jiang et al. [138] prepared a phosphotungstic acid (HPW)-promoted Fe-based catalyst from MIL-100(Fe) as the Fe precursor by hydrothermal method and reported that active oxygen species-rich γ-Fe2O3 was the main Fe phase, which enhanced NO adsorption and activation, leading to faster NH3-SCR. The role of HPW was to increase the total acidic sites along with promoting the reactivity of NH3 adsorbed on Lewis acidic sites at low temperatures. Notably, WO3-promoted Fe2O3 was reported to have a wide temperature window and excellent water and sulfur resistance, showing relatively stable NO conversion in the presence of 100 ppm SO2 at 300 °C [128]. The roles of WO3 are known to inhibit the crystallization of the Fe2O3 phase and formation of inactive nitrate, instead increasing Lewis acid sites and appropriate redox properties [127,128]. A kind of composite catalyst, HPW-decorated ring-like Fe2O3 synthesized via mechanical-chemistry grinding of HPW and Fe2O3 nanorings prepared by a microwave-assisted hydrothermal method, showed good NH3-SCR performance over a wide temperature window of 250–500 °C [139] and an outstanding resistance against SO2, showing relatively stable NO conversion in the presence of 10% H2O and 200 ppm SO2 at 280 °C [132]. Sun et al. [125] reported that Sm modification could weaken the sulfation of active Fe sites in Sm-doped Fe2O3, which was also supported by the DFT calculation results that SO2 could be more easily adsorbed on the Sm/Fe2O3 catalyst with the adsorption sites located at the Sm atom and its neighboring Fe atoms. They observed that more reactive nitrate species were formed on the sulfated Sm/Fe2O3 catalyst due to the presence of more un-sulfated Fe sites, which they explained as making the Sm/Fe2O3 catalyst resistant to SO2 poisoning, showing relatively stable NO conversion in the presence of 5% H2O and 100 ppm SO2 at 275 °C [125]. Tan et al. [140] reported that the low-temperature (<250 °C) NH3-SCR activity of FeTiOx catalyst could be dramatically enhanced by CeO2 doping, which can be attributed to the presence of a unique Ce-O-Fe structure that contributes to the improvement of redox properties. Chen et al. [124] prepared a single-atom Ce-modified α-Fe2O3 catalyst by a citric acid-assisted sol–gel method and reported that a high NO conversion was maintained in the presence of 5% H2O and 200 ppm SO2 at 250 °C. They claimed that the atomic dispersion of the Ce species to maximize the amounts of Fe–O–Ce sites in the Ce-doped FeOx catalyst was critical because the formation of oxygen vacancies in the Fe–O–Ce sites, which could promote the oxidation of NO to NO2 and decomposition of ABS, was more favorable than that in the Fe–O–Fe sites in the Ce-free α-Fe2O3 catalyst [124]. Ma et al. [141] compared a serial of Cu0.02Fe0.2CeyTi1-yOx catalysts prepared by the sol–gel method and found that Cu0.02Fe0.2Ce0.2Ti0.8Ox exhibited superior low-temperature NH3-SCR performance in the presence and absence of water, which they attributed to the optimal distribution of surface acidity, enhanced surface oxygen content, and surface redox cycle (Ce4+ + Fe2+ Ce3+ + Fe3+). Yao et al. [133] prepared Mn-W-Sb modified siderite catalysts by impregnation method and found that the Mn-doping enhanced adsorbed NO2 formation by synergistic catalysis with Fe3+ and that the addition of Sb inhibited sulfate formation on the surface of the catalyst in the presence of SO2 and H2O, showing relatively stable NO conversion in the presence of 5% H2O and 100 ppm SO2 at 210 °C. Xu et al. [121] prepared various MnFeOx catalysts with different molar ratios and observed high low-temperature NH3-SCR activity. The Mn–Fe-0.2 (Mn/Fe = 0.2) catalyst presented excellent SO2/H2O tolerance, showing a rather stable NOx conversion even in the presence of 5% H2O and 50 ppm SO2 at 100 °C [121]. Doping Mn not only inhibited the phase transformation of iron oxide (Fe2O3) but also strengthened the interaction between MnOx and Fe2O3 due to the electron transfer between them, which led to the formation of Mn–O–Fe [121]. Bai et al. [142] prepared an amorphous metal oxide (FeOx-Mn0.1Oy) with a large surface area, sufficient oxygen vacancies, and excellent redox properties and observed high adsorption and activation capacities for O2 and NO, which further enhanced the catalytic activity at low temperatures (90–240 °C). The incorporation of Mn into the FeOx species suppressed the crystallization of hematite, further increasing the surface area and surface acid sites [142]. In addition, the incorporation of manganese increased the number of oxygen vacancies, which decreased the apparent activation energy of hematite and enhanced the redox properties of the amorphous FeOx-MnOy catalyst [142].

The mesoporous Fe-doped CeO2 catalyst after modifying organic sulfate functional groups showed excellent activity in a temperature range of 250–450 °C, which was ascribed to the strong electron interaction between Fe3+-O-Ce4+ species and sulfate groups, which modifies the acidity and redox properties of the catalyst [143]. Wang et al. [144] prepared a series of sulfated modified Fe–Ce composite oxide Fe1–xCexOδ-S catalysts and reported that the Fe0.79Ce0.21Oδ-S catalyst achieved the low-temperature NH3-SCR activity at temperatures of 175–375 °C. They claimed that sulfation formed a large amount of sulfate on the catalyst surface and provided abundant Brønsted acid sites, which enhances NH3 adsorption capacity and improves overall NOx conversion efficiency [144]. The introduction of Ce was the main determinant to control the low-temperature activity of the catalyst by modulating its redox ability, and they found that there was a strong interaction between Fe and Ce in the Fe0.79Ce0.21Oδ-S catalyst, which changed the electron density around the Fe ions, which weakened the strength of the Fe–O bond and improved the lattice oxygen mobility of the catalyst [144]. In addition, during the reaction, the Fe-Ce composite oxide catalyst showed higher surface lattice oxygen activity and a faster bulk lattice oxygen replenishment rate [144].

The support of the supported iron oxide can increase the dispersion of the iron oxide, providing high surface active sites per mass of iron oxide, provide additional surface acid sites on the support itself and at the interface between the support and the iron oxide, and improve the redox properties of the iron oxide. Different crystal planes of the support (e.g., TiO2 [145] and CeO2 [146]) of supported iron oxides were compared. Monolayer Fe2O3 supported on TiO2 nanosheets exhibited a better low-temperature NH3-SCR activity than that supported on TiO2 nanospindles because the former had more acidic sites, oxygen defects, and reactive oxygen species [145]. The iron oxides supported on CeO2 nanorods achieved higher catalytic activity for NH3-SCR than those supported on CeO2 nanopolyhedra, which was explained by the DFT calculation results that the Fe2O3/CeO2 {110} catalyst was more reactive to NO and NH3 than the Fe2O3/CeO2 {110} [146]. The Fe2O3{1 1 3}-TiO2 exhibited superior NOx removal capacity and a broader temperature operating range than Fe2O3{0 1 2}-TiO2 and Fe2O3{0 1 4}-TiO2, which can be attributed to the improved redox properties, as well as the presence of additional active oxygen species, surface acid sites, and adsorbed nitrate species on the Fe2O3{1 1 3}-TiO2 catalyst [147].

2.3. Mn-Based Catalysts

Mn-based catalysts, including MnOx, Mn-containing mixed metal oxides, supported MnOx, and supported Mn-containing multicomponent metal oxides, have been regarded as the promising low-temperature NH3-SCR catalysts [30,148,149,150]. A comparison of the low-temperature NH3-SCR activity between various transition metal oxides supported on TiO2 showed that it decreased in the following order: Mn > Cu ≥ Cr >> Co. > Fe >> V >> Ni [151]. First-principles calculations also revealed that the superior oxidative dehydrogenation performance of Mn-based catalysts to NH3 lowered the energy barrier for the activation of NH3 and reduced the formation of the key intermediate NH2NO, the rate-determining step in NH3-SCR, over Mn-, Fe-, and Ce-based oxide catalysts [152].

Among various single-phase manganese oxides, including MnO2, Mn5O8, Mn2O3, Mn3O4, and MnO, MnO2, and Mn2O3 were reported to have the highest low-temperature activity per unit surface area and N2 selectivity, respectively [153]. The crystallinity and valence state of MnOx affected by the preparation method and pretreatment conditions have been reported to influence the NH3-SCR performance [154]. Higher low-temperature NH3-SCR activity was obtained for the less crystalline MnOx [155,156]. A comparison of β-MnO2 and α-Mn2O3 showed that the former had a higher NOx conversion and N2O production rate per unit surface area than the latter, which was explained by the lower Mn–O bond energy of β-MnO2, which promoted the activation of NH3 [157]. The birnessite-type MnO2 catalyst, prepared from Mn(NO3)2·4H2O, having the fewest OH groups, was reported to exhibit the best catalytic activity and excellent SO2 resistance among the same-type catalysts prepared from different Mn precursors [158].

A novel synthetic method was applied to prepare high-surface-area manganese oxide with low crystallinity for this reaction. Mesoporous α-MnO2 nanosheets prepared by a solvent-free synthetic method had a high surface area and a mesopore size of 4 nm with large oxygen vacancies and showed 100% NOx conversion under a gas hourly space velocity (GHSV) of 700,000 h−1 at 100 °C [159]. Xu et al. [160] prepared MnOx catalysts with 3D structure by the hard-template method using KIT-6 as a template possessing high reducibility with abundant surface oxygen species and Mn4+ species and reported that more Lewis acid sites and Brønsted acid sites on the surface were beneficial for the adsorption and activation of NH3, leading to the higher NH3-SCR activity. Chen et al. [161] synthesized a novel MnOx catalyst with a large surface area, small particle size, and more crystalline defects from MOF-Mn3(BTC)2(H2O)6 using different amounts of polyvinyl pyrrolidone (PVP) and found that this catalyst had abundant acid sites, Mn4+, and surface chemical oxygen, promoting the NH3-SCR reaction. Moreover, the high SO2 tolerance was also observed because an irreversible sulfurization rate was reduced and an adsorption of active bidentate nitrates and NH4+ was promoted even in the coexistence of sulfates, showing relatively stable NO conversion in the presence of 50 ppm SO2 at 175 °C. Zhang et al. [162] also prepared various MnOx catalysts from MOF-74 under different pretreatment conditions and reported that their redox capability could be controlled by changing the ratio of Mn4+/Mnn+ and Oα/(Oα + Oβ), resulting in the promotion of the adsorption and oxidation of NO to facilitate the ‘Fast NH3-SCR’ reaction. Zhou et al. [163] prepared hydrothermally stable MnOx/Al2O3 catalysts with highly dispersed low-coordinated Mn active sites that were originally created with triethanolamine and observed excellent low-temperature NH3-SCR activity because of active low-coordinated Mn species possessing reactive redox sites and Lewis acid sites.

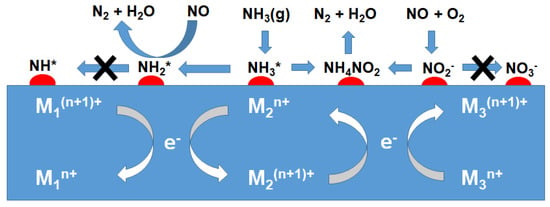

Li et al. [164] employed DFT calculations for the reaction mechanism of NH3-SCR over Mn/γ-Al2O3 catalyst. NH3 is mainly adsorbed on the Lewis acid sites and forms coordinated NH3. Subsequently, an N–H bond in the adsorbed NH3 can be dissociated to form NH2*, which can react with the gaseous NO and generate NH2NO*. NH2NO* was finally decomposed into N2* and H2O* (Figure 4). On the surface of the Mn/γ-Al2O3 catalyst, the adsorbed O2 was decomposed into the active oxygen atoms, which could oxidize NO into NO2. Among three possible routes for N2O formation, such as NO decomposition, deep dehydrogenation of NH3, and two-step dehydrogenation of NH2NO, the deep dehydrogenation of NH3 appears to be mainly responsible over the Mn/γ-Al2O3 catalyst in both the L–H and E–R reaction mechanisms.

Figure 4.

The reaction mechanism of NH3-SCR on the Mn/γ-Al2O3 catalyst calculated by Li et al. [164] Reproduced from ref [164]. Copyright 2019 American Chemical Society.

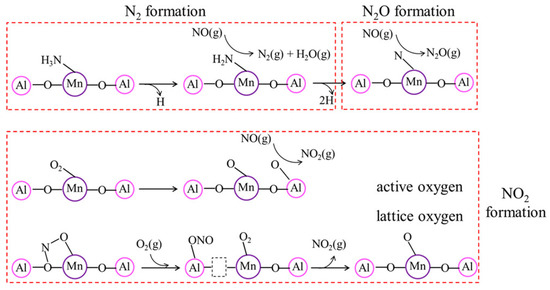

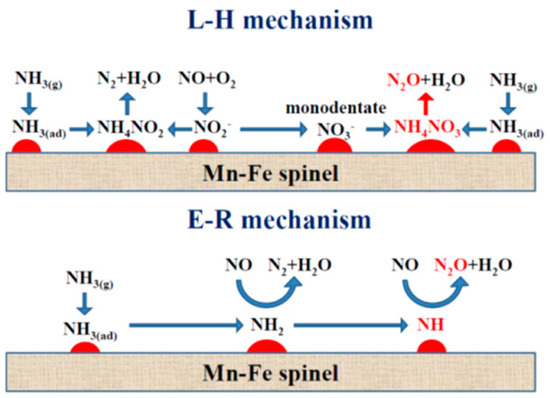

The formation of N2O over Mn-based catalysts was systematically examined over MnOx-TiO2 catalysts with different Mn/Ti ratios [165]. As the Mn/Ti ratio increased, the MnOx species layer expanded on TiO2 support, leading to an increase of redox sites but a decrease of surface acid sites, contributing to the non-selective oxidation of NH3 on MnOx species and the over-activation of NH3 at the Mn-Ti interface and resulting in the formation of N2O. Yang et al. [166] proposed the scheme for N2O formation according to the L–H and E–R mechanisms, in which monodentate –NO3− (and NH4NO3*) and –NH are key intermediates for N2O formation, respectively (Figure 5). DFT calculations and thermodynamic/kinetic analysis of NH3-SCR over α-MnO2 with specific (100), (110) and (310) exposure planes showed that the α-MnO2 catalyst exposed with the (310) plane exhibited the best NH3-SCR catalytic performance and the highest N2 selectivity due to the low energy barrier of NH3 dehydrogenation and NH2NO generation and the difficulty of NH2 dissociation [167].

Figure 5.

Proposed N2O formation mechanisms over Mn–Fe spinel. This schematic diagram is reprinted with permission from ref [166]. Copyright 2014 American Chemical Society.

Although manganese oxides exhibit high NH3-SCR activity at low temperatures, their application in practical processes is limited due to their sensitivity to SO2 and low N2 selectivity [21,168]. Therefore, Mn-containing mixed metal oxides and supported Mn-containing metal oxides have been adopted to address these issues. For Mn-containing mixed metal oxides, various second metals including Al [169], Si [170], Ti [171], V [172], Cr [173], Fe [174,175,176,177,178], Co [179,180,181,182], Ni [183], Cu [184,185], Y [186], Zr [187], Nb [188], Mo [189,190,191], Ag [192,193], Sn [194], Sb [195], La [196,197], Ce [197,198,199,200,201,202,203,204], Pr [205], Nd [206], Sm [207,208,209], Eu [210], Gd [211], Dy [212,213], Ho [214], Er [215], Tm [216], Ta [217], W [218,219], and Bi [220] have been examined. The effects of H2O and SO2 on the NH3-SCR activity over unsupported Mn-based catalysts, supported Mn-based catalysts, and core-shell Mn-based catalysts are summarized in Table 4 [161,173,194,220,221,222,223,224,225,226,227,228,229,230,231,232,233,234,235,236,237,238,239,240,241,242,243,244,245,246,247,248,249,250,251,252,253,254,255,256,257,258,259,260,261,262], Table 5 [171,187,189,195,212,215,263,264,265,266,267,268,269,270,271,272,273,274,275,276,277,278,279,280,281,282,283,284,285,286,287,288,289,290,291,292], and Table 6 [293,294,295,296,297,298,299,300,301,302,303,304,305,306,307,308], respectively. Among them, a relatively stable catalytic performance was observed over unsupported Mn-based oxides such as Mn oxides [161], Mn-Cr oxides [173,223], Mn-Fe oxides [224], Mn-Fe-Co oxides [225], Mn-Fe-Mg oxides [226], Mn-Fe-Al oxides [227], Mn-Co oxides [230,232,233,234], Mn-Co-Ce oxides [235], Mn-Co-V oxides [236], Mn-Ni oxides [235,238,239], Mn-Ni-Al oxides [240], Mn-Ni-Fe oxides [244], Mn-Ni-Ce oxides [235], Mn-Zr-Ti oxides [246], Mn-Ce oxides [248,249], Mn-Ce-Ti oxides [250,251,252], Mn-Ce-Sn oxides [248], Mn-Sm-Ti oxides [255,256], Mn-Sm-Fe oxides [257], Mn-Sm-Zr-Ti oxides [258], Mn-Sm-Ce-Ti oxides [259], Mn-Nd oxides [206], Mn-Gd oxides [261], Mn-W-Ce oxides [262], and Bi-Mn oxides [220], and supported Mn-based catalysts such as Mn/Fe-Ti spinel [263], Mn/CeO2-ZrO2 [266], Mn/CeO2-ZrO2-Al2O3 [267], TiO2-MnOx/CeO2-ZrO2 [171], Fe-Mn/TiO2 [270], Zr-Mn/attapulgite [273], Ce-Mn-V-W/TiO2 [277], Nd-Mn/TiO2 [278], Ho-Fe-Mn/TiO2 [215], Gd-MnOx/ZSM-5 [212], NiMnOx/activated coke [283], La-Mn-Fe/activated coke [284], Mn/biochar (BC) [285], Zr-Mn/BC [286], MnCe/Granular activated carbon (AC)-carbon nanotubes (CNTs) [291], and MnOx-CeO2/graphene [292], and Mn-based core-shell catalysts such as MnOx@Eu-CeOx [300], Mn-titanium nanotubes@Ce [303], and Fe2O3@MnOx@carbon nanotube (CNT) [306] even in the presence of H2O and SO2 at low temperatures.

Table 4.

NH3-SCR activity in the presence of H2O and/or SO2 over some unsupported Mn-based catalysts.

Table 5.

NH3-SCR activity in the presence of H2O and/or SO2 over some supported Mn-based catalysts.

Table 6.

NH3-SCR activity in the presence of H2O and/or SO2 over some Mn-based core-shell catalysts.

Liang et al. [221] reported that the MnOx-SiO2 mixed oxide catalyst synthesized by the co-precipitation method showed high NH3-SCR activity with high N2 selectivity and sulfur resistance because doping SiO2 increased the specific surface area of the catalyst, surface acidity, and NH3 adsorption. Doping with SiO2 inhibited the adsorption of SO2 for surface deposition of sulfate, effectively protecting the redox properties of the catalyst so that the MnOx-SiO2 catalyst showed relatively stable NO conversion in the presence of 100 ppm SO2 at 225 °C [221]. Zhu et al. [222] synthesized mesoporous Mn-TiOx with a three-dimensional structure by a solvent-free self-assembling strategy and observed an outstanding sulfur poisoning tolerance. The hierarchical cross-linked structure with a large specific surface area appeared to be favorable for enhancing the synergy between Mn and Ti, exposing more active sites, and dispersing the poisoning species [222]. Wang et al. [309] synthesized a series of MnxCeyTiz catalysts with three-dimensionally ordered macroporous (3DOM) structure by a soft template method and reported that after adding Ti, the redox capacity of the 3DOM-Mn3Ce1Ti1 catalyst decreased and the N2 selectivity was enhanced due to the strong adsorption of NH3 on the acid sites, widening the temperature window. Yao et al. [171] found that the TiO2-modified MnOx/CeO2-ZrO2 nanorod exhibited higher catalytic activity than the MnOx/CeO2-ZrO2 nanorod due to the larger amount of oxygen vacancy, the higher ratio of Mn4+ among Mn species, the higher proportion of surface adsorbed oxygen species among oxygen species, and the improvement of surface acidity. Furthermore, the TiO2 modification appropriately weakened the redox properties of the MnOx/CeO2-ZrO2 nanorods, effectively inhibiting the nonselective oxidation of NH3 to N2O [171]. Finally, TiO2-modified MnOx/CeO2-ZrO2 nanorod exhibited excellent H2O + SO2 tolerance, showing relatively stable NO conversion in the presence of 5% H2O and 100 ppm SO2 at 200 °C [171]. Xu et al. [256] reported that over a wide operating temperature range (60–225 °C), Ti-doped Sm–Mn mixed oxide showed a superior NH3-SCR performance, especially excellent SO2/H2O resistance. Stable NOx conversion was achieved even in the presence of 5% H2O and 100 ppm SO2 at 100 °C [256]. The inclusion of Ti can inhibit MnOx crystallization to increase the high specific surface area and the amount of acid sites, while Sm doping can modulate the redox properties to promote NO oxidation and inhibit NH3 nonselective oxidation [256].

Jiang et al. [282] reported that doping V2O5 to Mn-Ce/AC enhanced the NO conversion, N2 selectivity, and SO2 tolerance than Mn-Ce/AC because doping with V2O5 enhanced surface acidity and enriched surface chemisorbed oxygen. The stronger surface acidity of Mn-Ce-V/AC inhibited the competitive adsorption of SO2 and suppressed the reaction between adsorbed SO2 and NH3 species [282]. In addition, the cluster of vanadium oxide species partially prevented the dispersed Mn-Ce solid solution from being sulfated by SO2 [282]. This catalyst showed relatively stable NO conversion in the presence of 10% H2O and 100 ppm SO2 at 200 °C [282]. Li et al. [236] reported that the Mn0.50Co0.49V0.01Ox catalyst exhibited superior catalytic performance over a wide temperature window (162–508 °C) among ternary MnCoVOx catalysts and also displayed enhanced SO2 tolerance, showing relatively stable NO conversion in the presence of 5% H2O and 100 ppm SO2 at 200 °C.

Gao et al. [173] prepared Cr-Mn mixed-oxide catalysts by citric acid method and observed good low-temperature NH3-SCR performance at 100–225 °C owing to their high specific surface area, more active sites (Mn3+ and Mn4+), and effective electron transfer (Cr5+ + 2Mn3+ Cr3+ + 2Mn4+). The stronger Mn–O binding energy and weaker dehydrogenation ability in CrMn2O4 spinel were the main reasons for the lower N2O by-product than Mn3O4 [173]. The CrMn2O4 spinel showed relatively stable NO conversion in the presence of 10% H2O and 150 ppm SO2 at 200 °C [173]. The formation of Cr(III) sulfate could protect Mn active sites from sulfating. Furthermore, the transformation of -HSO3 and SO42− to (H⋯SO42−) can provide new Brønsted acid sites for ionic NH4+, enhancing the NH3-SCR activity via ‘Fast-NH3-SCR’ (NO2 + NH4+ NH4NO2 N2 + 2H2O) [173].

The DFT calculation results indicated that Fe doping promoted the adsorption of NH3 on the Mn sites over the β-MnO2 (110) surface, weakened SO2 adsorption capacity, and limited the oxidation of SO2, which promoted the decomposition of ammonium sulfate and relieved the catalytic site blockage on the catalyst surface [310]. DFT calculation demonstrated that the thermodynamically most favored structure after Fe doping was MnO2-x, and the structure remained stable as the doping amount increased [311]. The adsorption behavior of gas molecules on MnO2-x showed that NH3 and H2O preferred to adsorb on the Mn Lewis acid sites, while NO and SO2 preferred to adsorb on the O sites. MnO2-x with enhanced acidity after Fe doping showed good SO2 tolerance [311]. Wu et al. [312] prepared various Mn/TiO2 catalysts promoted with different transition metals, including Fe, Cu, Ni, and Cr, by the sol–gel method and found that more NO could be oxidized to NO2 and nitrate and then reacted with NH3, thus leading to the enhanced NH3-SCR activity at low temperatures. The promoting effect of Fe on Mn-Fe composite oxide catalysts was explained by the fact that Fe promoted NO oxidation and generated more monodentate and bidentate nitrate adsorption species on the catalyst surface [312]. It was also reported that the addition of Fe enhanced the amount and intensity of Brønsted and Lewis acid sites, which promoted the absorption of NH3 to form active intermediates, thereby improving the low-temperature NH3-SCR performance [313].

Jiang et al. [232] prepared MnO2–CoOx catalysts with different Mn/Co ratios using PVP as an assistant to control the morphology and exposed crystal faces of composite oxides. The best Mn–Co oxide showed stable NOx conversions in the presence of 5% H2O and 100 ppm SO2 at 160 °C [232]. Feng et al. [314] prepared a series of Mn-Co mixed metal oxides, MnyCo3–yOx, by an ultrasonic technology followed by a hydrothermal treatment and found that they exhibited much better NH3-SCR performance than single metal oxides (MnOx or CoOx). This can be attributed to the strong interaction between MnOx and CoOx, which reduces the crystallinity of the MnyCo3–yOx catalyst, increases the specific surface area, establishes the redox cycle of Co3+ + Mn3+ Co2+ + Mn4+, improves the reducibility, enhances the surface acid sites, and accelerates the reaction between adsorbed NOx species and coordinated NH3 bound to Lewis acid sites [314]. Chen et al. [233] prepared a MnCoOx catalyst using glucose as the forming pore agent and urea as the structural direction reagent and found that it exhibited higher low-temperature activity and SO2 resistance than pure MnOx catalysts. They revealed that the high surface area, abundant chemisorbed oxygen species, and the redox cycle (Co3+ + Mn3+ Mn4+ + Co2+) collectively account for the enhanced catalytic activity of MnCoOx catalysts [233]. The Mn(5)Co(5)Ox catalyst showed stable NOx conversions even in the presence of 5% H2O and 50 ppm SO2 at 125 °C [233]. Zhang et al. [281] prepared a highly active Ce/CoMnAl from layered double hydroxides (LDHs), which showed low-temperature NH3-SCR with good thermal stability and SO2/H2O resistance. The Ce0.5/Co1Mn0.5Al0.5Ox-layered double oxide (LDO) showed relatively stable NOx conversion at 200 °C for 10 h with 100 ppm SO2 in the feed stream [281].

Gao et al. [238] reported that the Mn-Ni spinel nanosheet (NiMn2O4) prepared by the urea hydrolysis hydrothermal synthesis exhibited excellent resistance to H2O and SO2 in the low temperature range at 150–300 °C. This catalyst showed stable NOx conversions even in the presence of 150 ppm SO2 at 175 °C [238]. Ni-doped MnOx catalysts prepared by the solvent-free doping method maintained excellent low temperature (100–200 °C) NH3-SCR activity, which was attributed to the fact that the appropriate nickel loading could effectively adjust the surface lattice oxygen activity and acidity of the catalyst, ensuring its ability to activate NH3 at low temperatures [315]. Liu et al. [316] reported that NiMn2O4 catalysts prepared via the solvothermal method exhibited excellent NH3-SCR performance in the temperature range of 85 to 285 °C due to their large specific surface area, high Mn4+/Mnn+ ratio, sufficient Oα, appropriate acidity, and redox ability. Yan et al. [240] reported that the Ni1Mn0.5Al0.5Ox showed the highest NH3-SCR activity at 100–250 °C among LDHs-derived NiMnAlOx catalysts because of more active species, abundant surface oxygen, moderate acidic sites, and redox properties. This catalyst also exhibited better resistance to SO2 with fewer sulfate species deposited on the surface, showing relatively stable NO conversion in the presence of 5% H2O and 100 ppm SO2 at 200 °C [240]. Hou et al. [241] prepared a series of highly dispersed Ni4-xMnxAlOy catalysts derived from LDHs and reported that the optimal Ni4-xMnxAlOy catalyst exhibited high NH3-SCR performance at a low temperature range of 120~210 °C but was deactivated in the presence of 5% H2O and 100 ppm SO2 at 210 °C. Yan et al. [244] prepared NiMnFeOx catalysts by the LDH-derived oxide method and reported that the optimized Ni0.5Mn0.5Fe0.5Ox catalyst had the best NH3-SCR activity, excellent N2 selectivity, a wider active temperature range (100–250 °C), higher thermal stability, and better H2O and/or SO2 resistance. This catalyst showed relatively stable NO conversion even in the presence of 5% H2O and 100 ppm SO2 at 200 °C [244]. Wang et al. [283] reported that NiMnOx supported on active coke prepared by deposition-precipitation method showed the high NH3-SCR activity because of the higher content of (Mn3+ + Mn4+), the high ratio of Mn3+/Mn4+, and Ni3+/Ni2+. This catalyst showed a stable NO conversion even in the presence of 200 ppm SO2 at 200 °C [283].

Doping MnOx and CeMnOx with Y did not improve NO conversion, but it broadened the range of high N2 selectivity compared with the undoped case [186]. The addition of Zr to Fe-Mn-Ti oxide catalysts was reported to decrease the deactivation rate in the presence of 100 ppm SO2 at 150 °C [187]. Chen et al. [285] prepared several metal (Zr, Ni, and Co) oxide-doped BC-supported Mn oxide (MnOx) catalysts by the impregnation method and found that the Zr-Mn/BC catalyst exhibited the best NH3-SCR activity among them because of the high concentration of Mn4+, more surface oxygen (Oα), excellent redox property, and more Lewis acid sites and Brønsted acid sites. Furthermore, the Zr-Mn/BC catalyst showed stable NO conversion in the presence of 5 vol% H2O and 100 ppm SO2 at 200 °C [285]. Che et al. [317] reported that the highly dispersed active MnOx species supported on the amorphous structure of ZrTiOx had a uniquely bridged Mn3+ bonded with the support through oxygen linked to Ti4+ and Zr4+, respectively, which regulated the optimal oxidizability of the MnOx species, leading to high NH3-SCR activity and N2 selectivity.

Zhou et al. [188] found that doping Nb2O5 could effectively enhance the NH3-SCR performance and N2 selectivity of the Zn-Mn-Ce/AC catalyst. Meanwhile, Nb2O5 could significantly improve the SO2 poisoning resistance of the Zn-Mn-Ce/AC catalyst, showing relatively stable NO conversion in the presence of 100 ppm SO2 at 225 °C because Nb2O5 could react with SO2 in a preferential way to restrain the sulfuration of manganese and cerium oxides on the catalyst [188]. More importantly, Nb2O5 reacted with SO2 to form Nb sulfate and then formed a new acidic site on the Zn-Mn-Ce/AC catalyst surface, which promoted the adsorption of NH3 and inhibited the adsorption of SO2, then restricted the reaction between NH3 and SO2 and hindered the formation of ammonium sulfate channels [188]. The promotional effect of Mo in Mo-MnOx catalyst was reported to be due to its higher Mn4+ content, abundant surface adsorbed oxygen (Oα), and more acid sites [189]. Li et al. [318] employed Mo and V to simultaneously fine-tune the acid and redox sites of MnOx and found that the adjusted Mn0.90Mo0.09V0.01Ox catalyst demonstrated excellent low-temperature activity and a significantly broader active temperature window.

Chang et al. [194] reported that SnO2–MnOx–CeO2 catalysts prepared by a co-precipitation method showed remarkably high activity, N2 selectivity, and SO2 resistance at temperatures in the range of 200–500 °C, which can be due to the significant enhancement of Lewis acid sites generated by surface sulfation during the SO2-containing NH3-SCR reaction. They also explained that the high SO2 tolerance can be ascribed to the inhibited formation of MnSO4 [194]. This catalyst showed stable NOx conversions in the presence of 12% H2O and 100 ppm SO2 at 110 °C [194]. Wang et al. [268] synthesized Sn-doped modified CoAl-LDH by a hydrothermal method and used it as a support for the preparation of the active hexagonal sheet structure of the MnOx(0.25)/CoSn3Al-LDO catalyst, which also showed relatively stable NO conversion at 200 °C after the introduction of 150 ppm SO2. Sn doping increased the ratios of Mn4+/Mn3+ and Co3+/Co2+ as well as the adsorbed oxygen amount on the catalyst surface, improved the redox capacity of the catalyst, and increased the number of acid sites, resulting in the excellent low-temperature NH3-SCR performance [268].

Xie et al. [195] prepared a series of xSb-4Ce-10Mn/TiO2 (x = 0, 2, 3, 4, 5, 6) catalysts by a reverse co-precipitation method and observed that the addition of Sb5+/Sb3+ slightly decreased the catalytic activity but helped improve the H2O/SO2 resistance. They found that the Sb5+/Sb3+ addition decreased the Mn4+ and Ti4+ content but increased the Ce3+, surface adsorbed oxygen content, and the surface area, which promoted the decomposition of AS and inhibited the formation of MnSO4 [195]. However, stable NOx conversion was not achieved in the presence of 5% H2O and 100 ppm SO2 at 200 °C [195].

Li et al. [319] reported that the addition of Mn to ceria greatly promotes the formation of surface oxygen vacancies that readily capture O2 from the air and form surface reactive oxygen species (superoxide and peroxide), which efficiently oxidize NO to NO2 and then promote the ‘Fast NH3-SCR’ reaction. Rong et al. [206] prepared the MnXOx catalysts (i.e., MnSmOx, MnNdOx, and MnCeOx) by the reverse co-precipitation method and found that the MnCeOx catalyst showed the best low-temperature catalytic activity and excellent H2O + SO2 resistance because of the largest amount of acid sites and the best reducibility among these MnXOx catalysts. However, stable NOx conversion was not achieved over these catalysts in the presence of 5% H2O and 100 ppm SO2 at 175 °C [206]. Fang et al. [320] reported enhanced NH3-SCR activity and SO2 tolerance of Ce-modified birnessite-MnO2 and attributed it to the preferential adsorption and oxidation of SO2 onto Ce species to form a new adsorption site for NH4+, Ce2(SO4)3, which protects the Mn active site from sulfidation and deactivation.

It is generally accepted that homogeneous metal doping into the MnOx matrix is beneficial for NH3-SCR activity. However, Cheng et al. [321] claimed that the presence of crystalline Mn3O4 and its interfacial interaction with CeO2 played a significant role in boosting the NH3-SCR performance, suggesting the great synergy between CeO2 and the crystalline phase of Mn3O4, which were responsible for NOx adsorption and the formation of NH2 species through the activation of NH3, respectively. Zhu et al. [322] prepared a series of Cex-Mn-Tiy catalysts by the co-precipitation method and found that the best NH3-SCR activity was obtained over the Ce0.1-Mn-Ti0.1 catalyst with the proper redox ability, abundant acid sites, high content of Mn4+ and Ce3+, and surface-adsorbed oxygen. Wei et al. [251] prepared Mn–Ce–Ti–O composite aerogels with large mesopore size and reported that the Mn–Ce–Ti–O catalyst calcined at 600 °C showed stable NO conversion in the presence of 5 vol% H2O and 100 ppm SO2 at 200 °C, which they attributed to its large pore size, averaging 32 nm, and abundant Lewis acid sites, as the former promoted the decomposition of ABS and the latter reduced the vapor pressure of NH3. Teng et al. [323] prepared a series of rare-earth (Ce, La, Nd, and Y) oxide-doped Mn/Al2O3 catalysts by the impregnation method and found that rare earth oxide addition significantly enhanced the NH3-SCR catalytic activity of Mn/Al2O3, with CeMn/Al2O3 obtaining the highest activity at 125–300 °C. Except for Y2O3, the rare earth oxide additives promoted the surface distribution of Mn elements and enhanced the ratio of chemisorbed oxygen and Mn4+ on the surface of Mn/Al2O3 [323]. In addition, the introduction of rare earth oxides enhanced the reducibility of MnO2 species and obtained a larger amount of weak acid sites [323]. Contrary to some reports on the promotional effect of Ce in Ce-MnOx catalysts, Gevers et al. [324] reported that the intrinsic NH3-SCR activity of the Mn active sites is not positively affected by Ce species at low temperatures based on the fact that the surface-area normalized activity did not increase by Ce addition. They concluded that Ce decreased the average oxidation state and activity of Mn active species and was just a structural promotor, increasing catalyst surface area, and that addition of Ce suppressed second-step oxidation reactions and thus N2O formation by structurally diluting MnOx [324]. The diffuse reflectance infrared Fourier transform spectroscopy (DRIFTS) analysis showed that N2O was mainly generated by the reaction between NO and excessive hydrogen abstraction of NH3 (i.e., forming NH species) and that Ca addition inhibited the formation of NH species on the catalyst surface, thereby reducing the formation of N2O [325]. Ca addition could also lead to a decreased formation of NO2, which could react with NH3 to form N2O, contributing to the promoted selectivity of N2 over Ca-modified Ce-Mn/TiO2 [325].

Wu et al. [205] reported that the Pr modification could boost the MnCeOx catalysts’ NH3-SCR activity and SO2 resistance because of the expanded specific surface area, the improved dispersion of active components, the enhanced surface acidity and redox ability, and the generated more chemisorbed oxygen (Oads) species. The MnCePrOx-0.3 catalyst exhibited stable NO conversion even in the presence of 5 vol% H2O and 100 ppm SO2 at 250 °C [205]. Wang et al. [259] reported that the MnCeSmTiOx catalyst preserved higher catalytic performance after introducing H2O and SO2 compared with the catalysts without adding Sm. They claimed that the synergistic effect of the Lewis acid sites and oxidation catalytic sites of mixed oxides was responsible for NH3-SCR by following the L–H mechanism [261]. Doping Sm into MnCeSmTiOx was reported to be able to increase oxygen vacancies and transfer electrons to Mn4+ and Ce4+, promoting the formation of active adsorbed NO2, bidentate nitrate, and bridging nitrate intermediates and suppressing SO2 poisoning by inhibiting the oxidation of SO2 by Mn4+ and Ce4+ [259]. The MnCeSmTiOx catalyst exhibited a rather stable NO conversion even in the presence of 5% H2O and 200 ppm SO2 at 200 °C [259]. Kim et al. [326] reported that the addition of Sm to MnOx/TiO2 increased the redox properties and the proportion of Mn4+ in MnOx catalysts, and the addition of Ce further improved the redox properties of Sm-MnOx/TiO2 catalysts. They also reported that when exposed to SO2/O2, Sm and Ce-modified MnOx/TiO2 not only inhibited the degradation but also increased the N2 selectivity by inhibiting the formation of N2O4 intermediate species, thereby inhibiting the formation of N2O [326].

The addition of Eu to MnOx/TiO2 was reported to be effective against the resistance of SO2 (i.e., NOx conversion gradually decreased but reached a steady-state value in the presence of 100 ppm SO2 at 150 °C) [279]. Wang et al. [210] prepared a series of MEuMnOx ternary oxides (M = Ce, Ni, Co, Sb, Sn, Mo) by one-pot co-precipitation method and observed that CeEuMnOx ternary oxide catalysts showed a high NH3-SCR activity at 100–250 °C and stable NOx conversions in the presence of 10 vol% H2O and 50 ppm SO2 at 230 °C. The facile electron transfer through the redox cycle of Mn3+ + Ce4+ Mn4+ + Ce3+ and enhanced oxygen mobility can promote the formation of more Mn species in high oxidation states and chemisorbed oxygen, accelerating oxidation of NO, and the adsorbed NO2 formed can facilitate the ‘Fast NH3-SCR’ reaction to improve low-temperature activity [210]. The addition of Ce to the EuMnOx catalyst boosts adsorption of NH3 and NOx species. NH3 species are activated as crucial intermediates (NH2) to promote the NH3-SCR reaction [210]. Guan et al. [211] synthesized a series of Gd-modified MnOx/ZSM-5 catalysts via a citric acid–ethanol dispersion method and found that the Gd-modified MnOx/ZSM-5 catalyst presented the higher catalytic activity and better SO2 resistance than MnOx/ZSM-5 in the presence of 100 ppm SO2. The high catalytic performance was mainly owing to the large surface area, enriched Mn4+ and surface chemisorbed oxygen species, strong redox properties, and the proper acidity of the catalyst [211]. The addition of Gd inhibited the reaction between the SO2 and MnOx active sites to form inactive bulk manganese sulfate, resulting in high SO2 resistance [211]. The GdMn/Z-0.3 catalyst showed a rather stable NO conversion in the presence of 10% H2O and 100 ppm SO2 at 180 °C [211]. Gao et al. [212] synthesized Dy-doped MnFe oxides with the morphology of one-dimensional nanowire by using the electrospinning method and found that the doping of Dy with an appropriate amount enhanced the surface Mn4+ concentration and surface chemical adsorption of oxygen and increased adsorption capacity for NH3 and NO. Zhuang et al. [214] investigated the effect of SO2 on the low-temperature NH3-SCR activity for Ho-modified Fe-Mn/TiO2 catalyst. The Fe0.3Ho0.1Mn0.4/TiO2 catalyst showed excellent SO2 durability at 120 °C when the concentration of SO2 was lower than 400 ppm, and the catalytic activity could recover considerably after the SO2 supply was interrupted [214]. When the concentration of SO2 was increased to 1000 ppm, the deactivation behavior was irreversible, but the deactivated catalyst could be regenerated after thermal reduction (350 °C) with 5% NH3 [214]. Zhao et al. [304] synthesized the Ho-modified titanium nanotubes (TNTs)@MnOx, where the manganese oxide active species was confined in a Ho-modified TNTs, and observed the improved SO2 resistance and N2 selectivity during NH3-SCR at low temperatures, showing NO conversion, which decreased slowly over time in the presence of 100 ppm SO2 at 180 °C. They claimed that the pore confinement effect of Ho-TNTs on Mn increased the dispersion of Mn, thereby promoting the interfacial effect between Mn and Ho, and the electron synergy between Mn and Ho inhibited the electron transfer between SO2 and Mn, thus preventing the poisoning of SO2 [302]. They also found that the interaction between Ho and Mn contributed to the proper redox ability to induce electron transfer to inhibit the generation of Mn4+, thereby achieving high N2 selectivity [302].

Zha et al. [218] found that the addition of tungsten created more Brønsted acid sites and reduced the energy barrier for NOx species adsorbed on the surface. They also claimed that the formed NH3 species and NOx species of MnCeW/m-TiO2 were more reactive due to the promotional effects of W than those of MnCe/m-TiO2 [218]. Liu et al. [327] reported the promotional effect of W-doping on the CoMn2O4/TiO2 catalyst on the resistance to H2O at low temperature. The superior performance of the CoMn2O4/W-TiO2 catalyst was ascribed to its unique spinel structure, mesoporous structure, highly dispersed tungsten species, and larger surface acidity [327]. The electron cycle among Mn, Co, W, and Ti helped to keep the Mn3+/Mn4+ and Co3+ at high concentrations and improve lattice oxygen mobility [327]. Both Lewis and Brønsted acid sites were generated by the incorporation of tungsten in the presence of H2O, which enhanced NH3 adsorption and thus promoted the E–R reaction pathway [327]. In addition, the N2 selectivity was significantly enhanced by H2O, which could be attributed to the decreased redox activity [327].

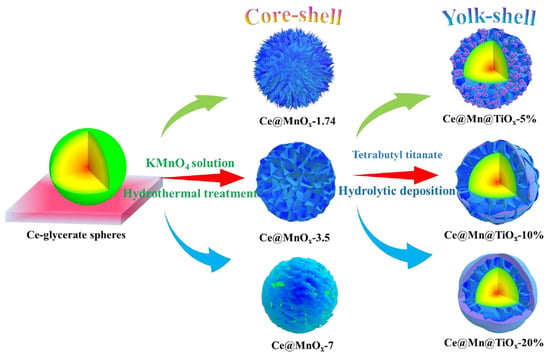

Yan et al. [305] assembled a confined MnCeOx catalyst using a mesoporous zeolite (ZSM-5) as the shell and Mn-Ce oxides as the active core (MnCeOx@ ZSM-5) with a simple one-pot method and found that the novel MnCeOx@ ZSM-5 catalyst displayed enhanced water and SO2 resistance as compared with the MnCeOx supported on ZSM-5 (MnCeOx/ZSM-5) and its precursor (MnCeOx@Al-SiO2), which was ascribed to the zeolite shell’s shielding effect and the synergy between the alumina-silica zeolite shell’s acidic properties and the mixed oxide cores’ redox properties. This catalyst showed relatively stable NO conversion in the presence of 5% H2O and 100 ppm SO2 at 300 °C [305]. Cai et al. [328] fabricated MnFe@CeOx@TiOx nanocage with a yolk-shell structure, where the CeO2 shell could effectively increase the oxygen vacancy defect sites and the TiO2 shell could remarkably improve the surface acid sites, which exhibited excellent NH3-SCR performance in the temperature range of 120–240 °C, which was ascribed to the increased proportion of active species (Mn4+, Fe3+, Ce3+, and Oads) and enhanced interaction between metal oxides. Huang et al. [304] prepared a series of yolk-shell-structured Ce@Mn@TiOx, where the TiO2 shell could provide more surface acid sites to promote the adsorption and activation of ammonia (Figure 6). The Ce@Mn@TiOx exhibited excellent NH3-SCR performance at low temperature and H2O and SO2 tolerance, showing relatively stable NO conversion in the presence of 100 ppm SO2 at 200 °C [304]. Qiao et al. [329] prepared various MnOx-ZSM-5 catalysts with different MnOx locations and found that MnOx clusters dispersed on the outside of ZSM-5 exhibited higher catalytic activity at low temperature than MnOx nanoparticles encapsulated in the channels of the support because the excellent redox ability and the dominant Mn3+ species over the former one improved the oxidation of NO to NO2 and the formation of unstable NOx intermediates, enhancing the low-temperature NH3-SCR activity. Ran et al. [330] synthesized a series of MnOx-CeOx confined in the mesopores of SBA-15 and found that they displayed enhanced resistance to SO2. Guo et al. [331] reported that the catalyst with larger mesopores exhibited much improved sulfur resistance. Zhang et al. [307] synthesized a core-shell structural catalyst, carbon nanotube (CNT)-supported MnOx and CeOx nanoparticles coated with mesoporous TiO2 sheaths (mesoTiO2@MnCe/CNTs), in which the meso–TiO2 sheaths could prevent the generation of ammonium/manganese sulfate species from blocking the active sites, resulting in a higher SO2-tolerance during NH3-SCR. The reversible deactivation was observed over this catalyst due to the presence of 200 ppm SO2 at 300 °C [307]. Yan et al. [305] prepared the core-shell MnCeOx@mesorporus ZSM-5 catalysts, in which a mesoporous zeolite (ZSM-5) covers the active core Mn-Ce oxides as the shell, and observed enhanced water and SO2 resistance during NH3-SCR owing to the zeolite shell’s shielding effect, which hinders the formation of sulfate species, and the synergy between the alumina-silica zeolite shell’s acidic properties and the mixed oxide cores’ redox properties. Zhao et al. [303] constructed a Mn-TNTs@Ce catalyst, where MnOx was confined in TNT via in situ introduction following Ce ion exchange into the skeleton of TNTs. The nanotube-confined structure improved the surface acidity to restrain SO2 adsorption, and Ce species acted as a protective site protecting Mn from SO2 attacking [303]. Furthermore, the short-range structure Ce-O-Ti promoted the electron transformation between Mn and Ce to suppress the formation of -NH and NH4NO3, resulting in inhibiting the generation of N2O [303]. It is remarkably that the Mn-TNTs@Ce catalyst showed a relatively stable NO conversion even in the presence of 5 vol% H2O and 100 ppm SO2 at 200 °C [303].

Figure 6.

The schematic illustration of the construction for yolk-shell Ce@Mn@TiOx [306]. Adapted from permission from ref [306]. Copyright 2021 Elsevier.

It is noteworthy that several promising Mn-based catalysts capable of performing NH3-SCR at low temperatures, even in the presence of H2O and SO2, have been reported; however, most of them have only been shown to be stable for short reaction times, and catalyst analysis of post-reaction samples has been limited. For previously reported promising catalysts, long-term lifetime tests should be performed at low temperatures using flue gases containing H2O and SO2 to observe deactivation phenomena, and real-time analysis should be performed to identify and validate detailed mechanisms of resistance to H2O and SO2.

2.4. Ce-Based Catalysts

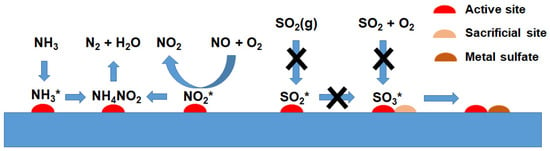

Since cerium-exchanged sodium-type mordenite (CeNa-MOR) was first reported to be active for NH3-SCR over a wide temperature range of 250–560 °C [332], unsupported and supported ceria, metal-doped ceria, and multicomponent Ce-containing mixed metal oxides [333,334,335] have been applied to NH3-SCR [336]. While NH3-SCR activity was reported to be dependent on ceria morphology (i.e., nanosphere is better than nanocube), unsupported ceria showed relatively low catalytic activity at low temperatures, even after sulfation to provide surface acidic sites [337]. Therefore, metal-doped ceria and multicomponent Ce-containing mixed metal oxide catalysts have received much attention for application in low-temperature NH3-SCR. Since Cu-, Fe-, and Mn-containing Ce-based catalysts have already been covered in the previous sections, this section mainly introduces Ce-based catalysts with other metals. The effects of H2O and SO2 on the NH3-SCR activity over Ce-based catalysts are summarized in Table 7 [338,339,340,341,342,343,344,345,346,347,348,349,350,351,352,353,354,355,356,357,358,359,360,361,362,363,364,365,366,367,368,369,370,371,372,373,374,375,376]. Among them, a relatively stable catalytic performance was observed over CO-pretreated CeO2 [338], F-Ce-Ti oxides [345], P-CeO2/TiO2 [346], Ti-Sn-Ce-Ox [352], and CeBi/TiO2 [353] even in the presence of H2O and SO2 at low temperatures.

Table 7.

NH3-SCR activity in the presence of H2O and/or SO2 over some Ce-based catalysts.

Zhou et al. [344] utilized bimetallic MOFs to prepare CeMOx (M=Ti, Cu) catalysts, allowing the homogeneous distribution of promoters. The CeTiOx catalyst with high acidity and good redox properties with abundant Ce3+ and Ti4+ showed high NH3-SCR activity from 180 to 300 °C and maintained stable performance in SO2/H2O at 225 °C [344]. Meanwhile, the aliovalent substitution of ceria by Cu2+ in CeCuOx formed oxygen vacancies and enhanced its redox properties but led to poor N2 selectivity due to NH3 over-oxidation [344]. Guo et al. [353] used Bi as the modifier to boost the performance of the Ce/TiO2 catalyst for NH3-SCR. The CeBi/TiO2 catalyst with a proper Bi content showed a rather stable NO conversion in the presence of 5% H2O and 100 ppm SO2 at 150 °C because the addition of Bi could generate more Ce3+ and chemisorbed surface oxygen species, along with enhanced redox capability and surface acidity [353].

Jin et al. [371] investigated the role of each metal component in Ce-Sn-W-Ba-Ox/TiO2 and found that TiO2 provided sufficient acid sites, CeO2 enhanced redox properties, weakened acid strength, and increased chemisorbed oxygen concentration, which helped to promote the activation and desorption of NH3. They also reported that SnO2 increased chemisorbed oxygen concentration, enhanced redox properties, and improved the activation rate of NH3, WO3 increased the amount of acid, and BaO enhanced resistance to water vapor and SO2 [371]. A rather stable NO conversion was achieved at 350 °C in the presence of 5% H2O and 200 ppm SO2 [371].

Zeng et al. [346] prepared a P-doped CeO2/TiO2 catalyst by dispersing CeO2 on strongly acidic and highly stable mesoporous P-doped TiO2. The P-doped CeO2/TiO2 catalyst exhibited much higher catalytic activity than the CeO2/TiO2 catalyst at temperatures of 200–450 °C and a rather stable NO conversion even in the presence of 5% H2O and 500 ppm SO2 at 200 °C [346]. Mu et al. [354] synthesized an ordered mesoporous CeSnOx/TiO2 catalyst through a classical evaporation-induced self-assembly (EISA) strategy and ascribed the low-temperature NH3-SCR activity to abundant reactive oxygen species (Oα), improving the surface acidity and redox capacity of the catalyst. This catalyst also showed a rather stable NO conversion even in the presence of 5% H2O and 100 ppm SO2 at 220 °C [354]. Mu et al. [356] prepared an ordered mesoporous catalyst, CeSnTiOx, modified with copper sulfate and revealed that the copper sulfate-modified one increased the reaction sites (redox site and acid site). They reported that Cu species can interfere with the electron cycle of the catalyst and reduce the strong redox performance of the Ce active site, which can effectively inhibit the adsorption of SO2, while S-species (from SO42−) can change the distribution of acid sites on the catalyst surface and the total acid content to realize a ‘Fast NH3-SCR’ reaction [356]. This catalyst also showed a rather stable NO conversion even in the presence of 5% H2O and 100 ppm SO2 at 240 °C [356]. Liu et al. [377] prepared a series of W-modified Ce-Sn catalysts by the co-precipitation method and reported that the W species regulated the structure by promoting the formation of the Ce-doped tetragonal SnO2 (t-Sn(Ce)O2) active phase while preventing the generation of the Sn-doped cubic CeO2 (c-Ce(Sn)O2) phase. In addition, the highly dispersed W species on the surface of the Ce1W0.24Sn2Ox catalyst also coupled with Ce species to form new Ce-O-W active sites [377]. The W modification also promoted the ability of the catalysts to oxidize NO to NO2 at 150–300 °C [377]. Liu et al. [378] reported the promotional effect of Ti in Ti-doped Ce– Sn mixed oxide (Ce–Sn–Ti) catalysts on the low-temperature NH3-SCR. The appropriate doping Ti formed Sn–O-Ti, Sn–O-Ce and Ti–O-Ce structures, which could increase the content of Ce3+ through electron transfer from Sn or Ti to Ce (Ce3+ + Ti4+ Ce4+ + Ti3+ and 2Ce4+ + Sn2+ 2Ce3+ + Sn4+) [378]. The solid solution structure increased specific surface areas, active sites (Ce3+), and Lewis acid sites over the Ce0.6Sn2.4Ti2 catalysts [378].

Yang et al. [379] reported that the emergence of Ce3+–O–Ce3+ structural units induced by Mo doping in Mo-doped CeO2 catalysts led to much better NH3-SCR performance by achieving low-energy barrier activation of NH3 molecules, thereby changing the dominant reaction mechanism in the catalytic reaction. They also observed the same trend in (W)-doped CeO2 catalysts, further confirming the pivotal role of Ce3+–O–Ce3+ structural units [379]. The addition of MoO3 improved the activity of the CeO2/TiO2 catalyst for NH3-SCR irrespective of the presence of H2O and SO2 because the introduction of Mo to the CeO2/TiO2 catalyst can suppress the adsorption of H2O and SO2 and the formation of surface sulfate species [365]. The MoO3-promoted CeO2/TiO2 exhibited higher activity than CeO2/TiO2 even in the co-presence of H2O and SO2, showing relatively stable NO conversion in the presence of 5% H2O and 50 ppm SO2 at 300 °C [365]. Liu et al. [380] reported the enhanced NH3-SCR performance of MoO3/CeO2 catalyst by introducing Cu to induce the generation of active Mo=O structure because the adding of Cu into MoO3/CeO2 catalyst could create unsaturated sites on CeO2 for Mo anchor, and the enhanced electron transfer from Mo to Cu would cause the formation of a new terminal Mo=O with highly distorted octahedral geometry, which is a new Lewis acid site for coordinated NH3 production. Meanwhile, the added Cu creates the adsorbed site for gaseous NO, and the formed Mo-O-Cu pair center facilitates the transformation of ionic NO2– generated from NO adsorption to NO2, which is conducive to the ‘Fast NH3-SCR reaction’ process [380]. Mo doping to CeO2-SiO2 mixed-oxide NH3-SCR catalyst exhibited high low-temperature NH3-SCR activity and superior N2 selectivity and resistance to SO2/H2O poisoning [366]. The Mo-doped CeO2-SiO2 catalyst showed a rather stable NO conversion even in the presence of 5% H2O and 200 ppm SO2 at 250 °C [366]. Two elements (Mo and Cu) could be selected for doping into CeO2 to promote the NH3 adsorption of CeO2-based materials by means of DFT calculations [381].

A comparison of NH3-SCR activity among CeOx supported on WO3 nanorods (WO3-NR) and WO3 microspheres self-assembled by nanorods (WO3-MP), and WO3 nanoparticles (WO3-NP) revealed that WO3-NP enclosed with (0 0 1) facets of the hexagonal WO3 showed the best redox ability due to the largest molar ratio of W5+/(W5+ + W6+), the highest concentration of Ce4+ on the surface of Ce/WO3-NP, the strongest surface redox properties, and the largest molar ratio of Oα/(Oα + Oβ), which was beneficial for NH3-SCR activity in the temperature range of 250–400 °C [382]. Hao et al. [103] designed a novel WOx/Cu-CeO2 oxide catalyst in which the WOx species are highly dispersed on the {111}/{100}-terminated surface of Cu-doped CeO2 nanospheres, which exhibits excellent NH3-SCR performance over a wide operating temperature window (200–400 °C), as well as good sulfur resistance and N2 selectivity. The stable NO conversion was obtained in the presence of 5% H2O and 100 ppm SO2 at 250 °C [103]. They found that the Cu introduction into the lattice of CeO2 not only increased the surface Ce3+ and oxygen vacancy concentration but also provided more sites for capture and dispersion of WOx species, thus mediating and improving the Lewis and Brønsted acid sites and reducibility of catalyst [103]. They also found that electronic interaction between WOx and Cu-doped CeO2 was enhanced due to the existence of interactions of short-range Ce-O-Cu and Ce-O-W [103]. Fang et al. [383] designed a Ce1–W1/TiO2 model catalyst by anchoring Ce1–W1 atom pairs on anatase TiO2(001) to investigate the synergy between Ce and W in NH3-SCR and found that the Ce1–W1 synergy not only shifted down the lowest unoccupied states of Ce1 near the Fermi level, thus enhancing the abilities in adsorbing and oxidizing NH3 but also makes the frontier orbital electrons of W1 delocalized, thus accelerating the activation of O2.