Abstract

Multifunctional thermal regulation materials with good thermal properties, efficient magnetic performance, and satisfactory interface bonding on fabrics are highly desirable for protective fabrics, building winter protection materials, medical thermal regulation materials, and special-environment work clothing. Herein, a new class of magnetic phase-change PW@CaCO3@Fe3O4 microcapsules was successfully produced by controlling the content of magnetic Fe3O4 through a self-assembly method. The microstructure, chemical composition, phase-change behavior, and magnetic properties of the products were sequentially characterized and analyzed. The findings revealed that the obtained microcapsules possessed regular spherical structure with uniform size and excellent thermal properties. Furthermore, PW@CaCO3 with Fe3O4 (i.e., 8% mass fraction) showed the highest thermal regulation and magnetic properties and reached an enthalpy value of 94.25 J·g−1, which is clearly superior to the value of 77.51 J·g−1 for PW@CaCO3 microcapsules. At the same time, the encapsulation efficiency of 38.7% and saturation magnetization of 2.50 emu·g−1 were the best among the four given samples. Therefore, the good paramagnetic feature had a significant synergistic effect on the thermal properties of the PW@CaCO3 microcapsules under study. More importantly, multifunctional fabrics loaded with PW@CaCO3@Fe3O4 microcapsules still showed an enthalpy value of 25.81 J·g−1 after several washes and have the potential to be used widely in the field of temperature control. The thermal regulation fabrics in this study exhibited excellent thermal properties and fastness, which contribute to their practical applications in advancing multifunctional textiles and high-technology modern fabrics.

1. Introduction

With the continuous development of science and technology, multifunctional, intelligent textiles have gradually attracted widespread attention in recent decades in response to many studies of aspects such as heat, electricity, and mechanical forces; these textiles are achieving more diversified applications in the textile, building decoration, and medical protection fields [1,2,3]. In particularly, multifunctional, intelligent textiles are applied in magnetic thermal regulation fabrics due to the contribution of magnetic materials and phase-change microcapsule (PCM) materials. Magnetic PCM materials not only have the ability to regulate temperature but also possess characteristics such as magnetic responsiveness, energy efficiency, and multifunctionality. Consequently, magnetic PCMs have become one of the hotspots in intelligent textile research. The core of thermal regulation fabrics lies in their inclusion of PCMs, which are functional materials capable of storing and releasing thermal energy [4,5]. PCMs can regulate the surrounding environment’s temperature by absorbing or releasing heat within a specific temperature range. Their high thermal storage density permits a considerable amount of heat to be contained within a confined space. Moreover, the phase change occurs independently, without requiring any external energy input, resulting in substantial energy savings. Therefore, PCMs have been widely applied in various fields, including solar energy utilization, building insulation, functional textiles, medical devices, electronic products, and food refrigeration.

Conventional PCMs typically exhibit low thermal conductivity and are prone to leakage during phase transition [6]. Consequently, these drawbacks have restricted their practical applications in scope and depth. To overcome these challenges, researchers have recently enhanced the thermal conductivity and stability of PCMs by either coating them with inorganic shell materials or incorporating high-thermal-conductivity nanoparticles into PCMs. Zhao and his team members selected n-octadecane as the phase-change core material and crosslinked polystyrene as the shell material to prepare PCMs through suspension polymerization. Moreover, silicon carbide nanoparticles were used to modify the shell material of the microcapsules to improve their thermal conductivity and photothermal conversion efficiency [7,8,9,10]. The results indicated that compared with the undoped microcapsule samples, the samples with added silicon carbide nanoparticles exhibited enhanced thermal performance, conductivity, and photothermal conversion efficiency. Especially, the photothermal conversion efficiency reached up to 54.91% in the study. Yu et al. [11] selected solar salt (a binary eutectic salt with a mass ratio of NaNO3:KNO3 of 3:2) as the PCM and silicon dioxide (SiO2) as the shell material. However, their study did not focus on the effect of magnetic ferrite on phase-change microcapsules. By introducing high thermal conductivity and superparamagnetic carbon nanotube and iron oxide nanoparticles (CNTs-Fe3O4) composite material as the enhancement phase, they prepared multifunctional magnetic PCMs. The results indicated that the encapsulation of SiO2 and the introduction of CNTs-Fe3O4 increased the thermal conductivity of the microcapsules by approximately 53.4%. Furthermore, the microcapsules exhibited superparamagnetic properties and photothermal conversion characteristics, suggesting remarkable potential for applications in energy collection, conversion, and storage. Cai et al. [12] used paraffin was (PW) as the phase-change core material and Fe3O4 nanoparticles modified with melamine–formaldehyde resin as the shell material to prepare multifunctional microcapsules. Although the addition of magnetic Fe3O4 nanoparticles can generate a significant synergistic effect on the thermal properties of the microcapsules, but their research did not explore its application in the textile protective field. Analysis revealed that these PCMs possess not only infrared stealth and microwave absorption effects but also temperature regulation and electromagnetic radiation absorption properties. Therefore, we will continue to explore the synergistic function of Fe3O4 with PW@CaCO3 microcapsules’ thermal properties and their wide application prospects in the fields of fabric production for national defense and civilian construction.

CaCO3 is highly favored due to its widespread availability, low cost, high mechanical strength, stable performance, and environmental friendliness. As the shell material, CaCO3 is easy to process into a microcapsule structure with controllable size and wide compatibility, making it excellent for exploratory work on phase-change microcapsules. Meanwhile, Fe3O4 nanoparticles are extensively used in the study of modified PCMs because of their high thermal conductivity and size effect advantages [13]. Therefore, in this paper, PW was first selected as the core material, and CaCO3 doped with Fe3O4 nanoparticles was used as the hybrid shell material. Using the self-assembly method, magnetic phase-change microcapsules with different quantities of Fe3O4 nanoparticles were prepared. Subsequently, the dipping method was employed for the post-treatment of pure cotton fabrics, ensuring that their surfaces were uniformly covered with microcapsules, thereby endowing them with excellent temperature-regulating properties. Finally, the microstructure, chemical composition, phase-change behavior, and magnetic properties of the microcapsules and the surface morphology and temperature-regulating properties of the treated fabrics were systematically characterized and analyzed. Through these studies, new inspirations and ideas for the development of multifunctional thermal regulation fabrics are provided.

2. Results

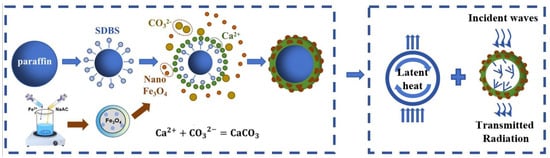

2.1. Illustration of the Preparation Process

Figure 1 presents the preparation mechanism of PW@CaCO3@Fe3O4 PCMs, including the preprocessing of Fe3O4 nanoparticles and the self-assembly of PCMs. First, magnetic Fe3O4 nanoparticles were successfully prepared by our previous research [14]. Second, PW was dissolved with 15% mass percentage of sodium dodecyl benzene sulfonate (SDBS), which was extended toward the PW particles as follows. Subsequently, some CaCl2 solution was slowly added, reacting with the hydrophilic groups to form a uniform complex. Next, Na2CO3 solution and prefinished Fe3O4 nanoparticles were gradually introduced. The Ca2+ then reacted with CO32− to encapsulate the PW particles uniformly, forming the hybrid shell material [15,16]. Ultimately, the PW@CaCO3@Fe3O4 PCMs were prepared for fine shaping, together with predesign thermal regulation and electromagnetic radiation protection, as shown in Figure 1.

Figure 1.

Schematic representation of the preparation of PW@CaCO3@Fe3O4 PCMs.

2.2. Surface Morphology Analysis of Microcapsules

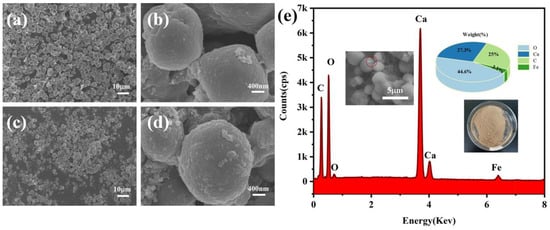

The surface morphology of the microcapsules is depicted in Figure 2. Figure 2a,b display the shape of the PW@CaCO3 PCMs, which appear as regular spheroids with clear outlines and even distribution. It can be seen that the particle size of the microcapsules ranges from approximately 2 μm to 4 μm. Furthermore, Figure 2c,d reveals the scanning electron microscopy (SEM) images of the microcapsules containing 0.8 g of Fe3O4 nanoparticles. No obvious Fe3O4 nanoparticles are present on the surface of the microcapsules, suggesting that the incorporation of Fe3O4 nanoparticles does not affect the original morphology of the PW@CaCO3 phase microcapsules [17,18]. The obtained PW@CaCO3@Fe3O4 microcapsules have a larger particle size than the pure microcapsules. Figure 2e illustrates the energy-dispersive spectroscopy (EDS) results of the red-marked field of PW@CaCO3@Fe3O4 (8%) PCMs. As observed, the surface of the microcapsule is mostly made of the elements O, Ca, C, and Fe, illustrating that the test capsule’s shell material is composed of CaCO3 and Fe3O4 through the characteristic peak [19].

Figure 2.

SEM images: (a,b) PW@CaCO3 and (c,d) PW@CaCO3@Fe3O4 PCMs at different magnifications; (e) EDS energy spectrum of PW@CaCO3@Fe3O4 PCMs.

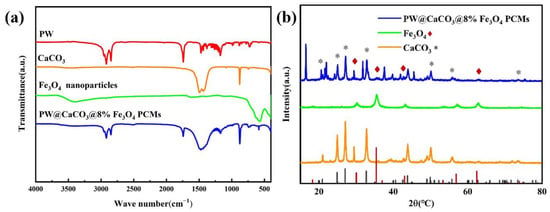

2.3. Analysis of the Chemical Structure of the Microcapsules

Fourier transform infrared (FTIR) spectroscopy analysis was performed to assess the chemical structure of PW, CaCO3, Fe3O4 nanoparticles, and composite microcapsules. In Figure 3a, the diffraction curve of pure PW shows characteristic peaks at 2915 and 2848 cm−1, corresponding to the C-H stretching vibrations of the -CH3 and -CH2 groups, respectively. The distinctive peaks for CaCO3 appear at 708 and 875 cm−1, associated with the in-plane and out-of-plane bending vibrations of CO32−, respectively. However, the peak at 1475 cm−1 is attributed to the asymmetric stretching vibrations of CO32− in CaCO3 [20]. The absorption peak at 575 cm−1 is linked to the Fe-O group obtained from the Fe3O4 crystal structure. The PW@CaCO3@Fe3O4 PCM curve exhibits the characteristic absorption peaks without the appearance of any new peak. The C-H stretching vibration peaks of PW, and the characteristic peaks of CaCO3 are still presented, together with the Fe-O absorption peak of Fe3O4. The characteristic absorption peaks of PW, CaCO3, and Fe3O4 can be simultaneously observed in the spectrum of PW@CaCO3@Fe3O4 PCM, indicating that these individual components have been successfully embedded into the microcapsule structure while retaining their respective chemical characteristics [21]. This observation confirms the successful synthesis of the microcapsules through a self-assembly method. This observation also suggests that the three components physically combine without any unnecessary chemical reaction in the preparation. Furthermore, Figure 3b shows the crystal structures of CaCO3, Fe3O4 nanoparticles, and the magnetic PW@CaCO3@Fe3O4 PCMs. The diffraction peaks of the obtained microcapsules at 2θ angles of 20.91°, 24.87°, 27.03°, 32.71°, 49.92°, 55.73°, and 73.45°, correspond to the diffraction peaks of CaCO3’s crystal planes (002), (100), (101), (102), (104), (202), and (212), respectively [22]. Additionally, the 2θ angles of 30.35°, 35.39°, 43.01°, and 62.46° are consistent with the characteristic diffraction peaks of the Fe3O4 nanoparticles, aligning with the crystal planes (220), (311), (400), and (440), respectively [23]. Consequently, the diffraction pattern of the PW@CaCO3@Fe3O4 PCMs exhibits the characteristic crystal planes of both CaCO3 and Fe3O4 sections, which is highly consistent with the primary study [14].

Figure 3.

(a) FTIR patterns of PW, CaCO3, Fe3O4, and PW@CaCO3@Fe3O4 PCMs and (b) XRD patterns of CaCO3, Fe3O4, and PW@CaCO3@Fe3O4 PCMs.

2.4. Analysis of the Thermal Properties of the Microcapsules

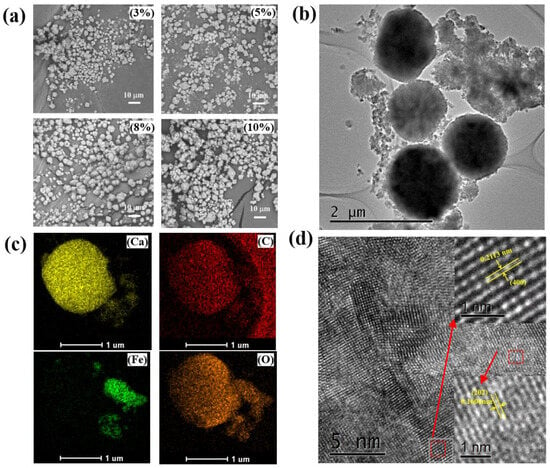

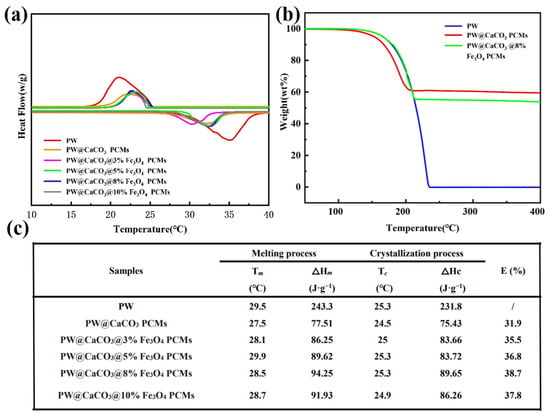

The morphology of the PW@CaCO3 magnetic PCMs with different mass fractions of Fe3O4 is illustrated in Figure 4a. The incorporation of Fe3O4 nanoparticles does not affect the original spherical structure of the PW@CaCO3 PCMs, showing the spherical shape and fine distribution. Notably, microcapsules containing 8% Fe3O4 in Figure 4b show the optimum state with uniform dispersion, with an average particle size around 2 μm. Furthermore, the core-shell structure of the obtained capsules are obvious, with a number of tiny particles around the shell edge. The combination of the PW@CaCO3 microcapsules and Fe3O4@ nanoparticles shows higher binding action in the process of self-assembly. However, the visual element mapping is described as Figure 4c. There are uniformly dispersed Ca, C, and O elements in two-dimensional composites, containing bit Fe elements evenly distributed on the surface and more concentrated on the edge of the sphere microcapsule, illustrating the test capsule’s shell material is composed of CaCO3 and Fe3O4 through the characteristic. We can see that the lattice spacing of 0.2132 nm corresponds to CaCO3’s crystal plane (202), and 0.1606 nm corresponds to Fe3O4’s crystal plane (400), respectively. As observed, the results further illustrate the role of the co-existence of CaCO3 and Fe3O4 in the forming process of shell [24,25]. However, the differential scanning calorimetry (DSC) curves and data of the samples are shown in Figure 5a,c, which provides detailed information on the enthalpy values, phase-change temperatures, and encapsulation rates of the microcapsule samples. The enthalpy value of the PW@CaCO3 PCMs is 77.51 J·g−1. With the addition of Fe3O4 nanoparticles, the curves of enthalpy initially increase to 94.25 J·g−1 of 0.8 g Fe3O4 and then decrease to 91.93 J·g−1 with the constantly increasing addition [26]. Li have successfully prepared Fe3O4 nanocomposites with flower-like and chain-like shapes. They showed higher coercive force values than our samples’, which is not suitable for soft magnetic properties required low coercivity for protective fields [27]. Shao’s team prepared PCMs with equivalent Fe3O4 nanoparticles exhibited an enthalpy value of 85 J·g−1 as measured by the seed microsuspension polymerization method; this value is lower than our sample’s 91.93 J·g−1 [28]. The result shows that the heat storage performance of our study is better, leading to a broader application prospect. Figure 5b illustrates the thermal degradation behaviors of PW, PW@CaCO3, and PW@CaCO3@Fe3O4 PCMs. According to the thermal gravimetric (TG) curves, PW starts to decompose at around 120 °C, and its maximum mass loss occurs near 230 °C. Similarly, PW@CaCO3 and PW@CaCO3@Fe3O4 PCMs begin to decompose at 120 °C. The PW@CaCO3 PCMs experiences a 62% weight loss at 210 °C, whereas the PW@CaCO3@Fe3O4 PCMs encounters a 55% weight loss at 220 °C. As the temperature reaches 400 °C, no further weight changes are observed. At this stage, the core material PW has completely vaporized, leaving only the Fe3O4 nanoparticles and the CaCO3 shell material [29].

Figure 4.

(a) SEM images of PW@CaCO3 microcapsules with Fe3O4 content of 3%, 5%, 8%, and 10%; (b) TEM, (c) mapping, and (d) HRTEM of PW@CaCO3 microcapsules with 8% Fe3O4.

Figure 5.

(a) DSC and (b) TG curves of PW and microcapsules; (c) DSC data of microcapsules.

2.5. Analysis of the Magnetic Properties of the PCMs

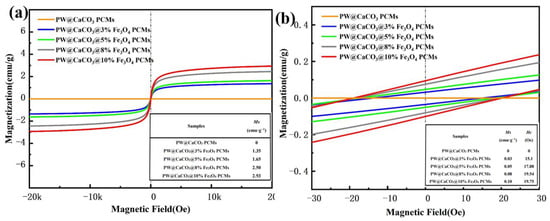

The magnetic properties of the PW@CaCO3 PCMs with varying Fe3O4 mass fractions are analyzed using a vibrating sample magnetometer (VSM), as illustrated by the hysteresis loops in Figure 6a,b. The magnetization curve is also called the hysteresis curve, which reflects the relationship between the magnetic induction intensity of the magnetic material and the magnetic field intensity. We can see that each sample exhibits an S-shaped hysteresis loop, indicating low coercivity and remanent magnetization under an external magnetic field with fine ferromagnetism [30,31,32,33]. Specifically, with a 3% mass fraction of Fe3O4 nanoparticles, the magnetic microcapsules achieve a magnetization saturation strength of just 1.35 emu·g−1. This value rises to 2.93 emu·g−1 when the Fe3O4 nanoparticles mass fraction is increased to 10%. However, the coercivity values are similar and low than 20 Oe, illustrating the soft magnetic properties are close and stable among the four samples, which are shown in the interior tables as follows [34]. With the rise of the soft magnetic materials, it may be used to develop smart wearable textiles with specific functions, for example, magnetic shielding clothing to protect the wearer from electromagnetic radiation or functional magnetic therapy textiles to improve the wearer’s blood circulation and relieve pain [35].

Figure 6.

Hysteresis loops (a) and magnified hysteresis loops (b) of the PW@CaCO3@Fe3O4 PCMs.

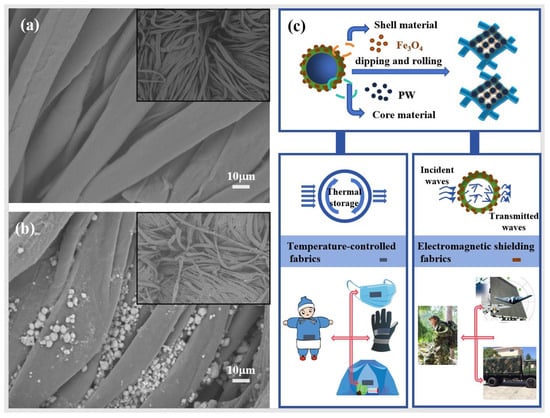

2.6. Performance Analysis of the Thermal Regulation Fabrics

Figure 7 shows the surface morphology of the fabrics as well as the preparation principle and application scenario schematic diagram. Figure 7a,b show the SEM images of pure cotton fabric and thermal regulation fabric, respectively. The PCMs are evenly distributed on the fiber surface and inside the fibrous septum, confirming that the microcapsules have been successfully loaded on the fabrics through the dip coating method [36,37,38,39]. In the process, the finishing liquid enters the structural gap of the fabric through the pressure of the counter-rotating rolling mills [40,41]. Consequently, the microcapsules are spread unevenly across the fabric surface, leading to low concentrations in certain regions. Figure 7c describes the preparation principle and application scenario of the functional fabrics, including thermal regulation products and electromagnetic shielding fabrics.

Figure 7.

(a) SEM image of cotton fabric, (b) SEM image of thermal regulation fabric, and (c) scenario diagram of the preparation and application of thermal regulation fabric.

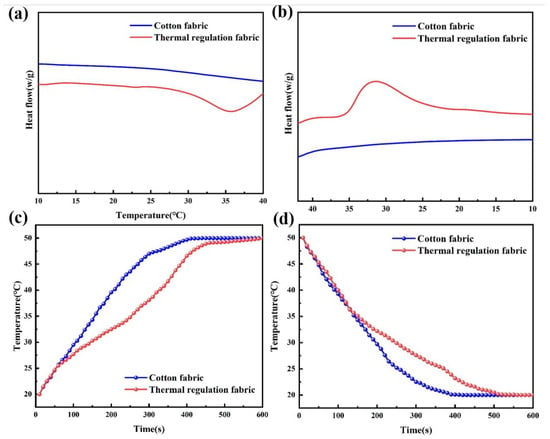

Figure 8a,b illustrate the DSC curves of the above fabrics. Pure cotton fabric shows very low thermal properties. Following the dipping treatment, the enthalpy values of the thermal regulation fabric for melting and crystallization are 25.81 J·g−1 and 25.79 J·g−1, respectively. Additionally, the phase transition temperature spans from 15 °C to 39 °C. Figure 8c illustrates the time–temperature curve for pure cotton fabric and thermal regulation fabric at temperature rise. Initially, both fabrics are heated from room temperature to 50 °C. Notably, as the regulation fabric approaches its phase transition temperature, its heating rate diminishes, demonstrating its ability to regulate temperature [42,43,44]. By the 9-min mark, both fabrics have exceeded 38 °C, indicating that the thermal regulation fabric can maintain its phase-change performance for approximately 8 min during heating. Figure 8d illustrates the time–temperature curve of the pure cotton fabric and the thermal regulation fabric at temperature drop. Both fabrics cool from 50 °C to approximately 20 °C simultaneously. In the initial 2 min, the cooling rates of both fabrics are nearly identical, and both drop below 37 °C at 2 min. Subsequently, the cooling rate of the fabric gradually decelerates until 9 min, at which point the temperatures of both fabrics decrease to about 20 °C, indicating that the thermal regulation fabric exhibits certain phase transition performance during cooling and can maintain this state for approximately 7 min.

Figure 8.

DSC curves of the fabrics during a temperature rise (a) and drop (b); time–temperature point plots of the fabrics during a temperature rise (c) and drop (d).

The softness of the fabrics was evaluated using a fabric stiffness tester, measuring bending length and flexural rigidity to assess its soft property. The bending rigidity substantially increases from 57.696 mg·cm to 75.307 mg·cm, illustrating the decline in softness of the dip-rolled fabric in Table 1. However, the bending lengths are similar due to the finishing solution with the microcapsules and appropriate additives, which establishes fine linking at the interface of the functional fabrics [45,46]. Consequently, the mechanical properties of the fabric have been notably enhanced after the dipping treatment.

Table 1.

Mechanical properties of fabrics.

Table 2 shows the melting and crystallization temperatures along with the enthalpy changes of the fabrics after several wash cycles [47]. While the phase transition temperatures remain consistent, the enthalpy changes considerably. Specifically, the thermal enthalpy of the thermal regulation fabric decreases after several times of washing. The decline is due to the partial removal of microcapsules from the fabric. After three and five times of washing, the fabric retains 88.11% and 82.06% of its melting enthalpy, respectively. However, the decline degree is remarkably slow when the number of washes is increased from three to five. Hence, the stability of the dipping fabrics is gradually achieved when it is washed five times. However, Chen have studied the effect of ten times washing on the fastness and heat storage properties of the microcapsules. The residue rate was higher than our samples, but the thermal performance is not as good as our samples’ enthalpy value of 21.18 J·g−1 [48].

Table 2.

Phase-change characteristics of fabrics after different wash cycled.

3. Materials and Methods

3.1. Materials

PW (melting point: 28 °C) was purchased from Dongguan Donglin New Materials Co., Ltd. (Dongguan, China). Anhydrous calcium chloride (CaCl2), SDBS, and polyethylene glycol 400 (PEG-400) were obtained from Shanghai Macklin Biochemical Technology Co., Ltd. (Shanghai, China). Sodium carbonate (Na2CO3) and anhydrous ethanol were acquired from Xilong Scientific Co., Ltd. (Guangzhou, China). Water-based polyurethane adhesive was purchased from Anhui Dawei Huatai Technology New Material Co., Ltd. (Hefei, China). Deionized water was used during the experiments.

3.2. Preparation of PW@CaCO3@Fe3O4 PCMs

First, spherical Fe3O4 nanoparticles with uniform structures were prepared using a repeated synthesis method similar to that described in our previous study. Then, 1.5 g of SDBS was dissolved into 100 mL of deionized water and stirred magnetically for 20 min to ensure a homogeneous mixture. At the same time, 10 g of PW was poured into a three-neck flask and heated at 40 °C water bath until completely melted. Subsequently, the mixed SDBS solution was dropwise added to the three-neck flask and stir mechanically at 1000 RPM for 30 min to obtain the oil phase solution. Second, 10 g of CaCl2 was dissolved in 100 mL of deionized water and magnetically stirred for 20 min. Simultaneously, Na2CO3 powder was conducted to 100 mL of deionized water with varying mass fractions of Fe3O4 nanoparticles at 50 °C for 3 h. Third, the CaCl2 solution was gradually introduced into the three-neck flask while stirring at 1000 RPM for 3 h. Then, the Na2CO3 solution was introduced slowly at 800 RPM for another 3 h. Finally, the PW@CaCO3@Fe3O4 PCMs were washed thoroughly with deionized water, followed by drainage and drying in the following experiments.

3.3. Preparation of Thermal Regulation Fabrics

First, the prepared cotton fabric was immersed in a sodium hydroxide (NaOH) solution at 70 °C for 60 min for alkali treatment and then dried. Second, the previously mentioned microcapsules were measured while adding deionized water and stirred mechanically for 30 min to achieve a uniformly mixed impregnation finishing solution. Third, the fabric was placed into the above solution, and a liquor ratio of 1:50 was maintained for 3 h of ultrasonic assistance. Then, a rolling mill of double dipping and double rolling was conducted to produce the finished fabric. Finally, all the fabric samples were prebaked at 80 °C for 10 min, baked at 120 °C for 3 min, and allowed to dry naturally to obtain the thermal regulation fabrics for further study.

3.4. Characterizations

The surface morphology of the microcapsules and fabrics was examined using field emission SEM. Elemental analysis of the magnetic phase-change microcapsules was performed using X-ray spectroscopy (EDS). The crystal structures of CaCO3, Fe3O4 nanoparticles, and the microcapsules were analyzed by X-ray diffraction (XRD) within a 2θ scan range of 10° to 80° at 40 kV and 40 mA. FTIR Spectroscopy was utilized to investigate the chemical functional group composition of PW, CaCO3, Fe3O4, and the microcapsules, covering a range from 4000 cm−1 to 400 cm−1. The melting and crystallization temperatures, along with the enthalpies of PW, microcapsules, and fabrics were determined using DSC. These measurements were conducted from 0 °C to 50 °C at a heating rate of 10 °C/min under a nitrogen atmosphere. The thermal stability of PW and the microcapsules was assessed via TG analysis by heating the samples from room temperature to 400 °C in an aluminum crucible at a rate of 10 °C/min. The magnetic properties of the PW@CaCO3@Fe3O4 PCMs were characterized with a VSM over a range of −20 KOe to 20 KOe at room temperature. The thermal regulation performance of the fabrics was evaluated using a flat temperature-retaining instrument, and data were recorded through an infrared thermographic camera to generate heating and cooling time–temperature curves. Finally, the softness of the obtained fabrics was tested using a fabric stiffness tester.

4. Conclusions

In this comprehensive study, magnetic PCMs of PW@CaCO3@Fe3O4 were produced from varying Fe3O4 fractions serving as hybrid shell materials through a self-assembly method. The main findings of the study regarding the synergistic function of Fe3O4 with PW@CaCO3 microcapsules’ thermal properties and the broader application prospects of thermal regulation fabrics are as follows.

- (1)

- The appearance, phase transformation, and magnetic properties of the obtained microcapsules were assessed to determine their thermal performance. The XRD and FTIR results confirmed the successful preparation of the target magnetic microcapsules. The SEM and TEM images showed that the microcapsules were spherical and uniformly distributed, measuring approximately 2 μm in diameter. When the Fe3O4 nanoparticle mass fraction was 8%, the microcapsules exhibited a melting enthalpy of 94.25 J·g−1 and a saturation magnetization of 2.50 emu·g−1 according to DSC and VSM analyses.

- (2)

- Cotton fabric, serving as the base material, was impregnated and finished with a solution comprising an adhesive and microcapsules to create functional thermal regulation fabrics. The structure and properties of the obtained fabrics were measured and analyzed in succession. The impregnated fabrics demonstrated good appearance and softness properties, together with thermal performance.

- (3)

- Under optimal processing conditions, the tempering fabric’s phase-change enthalpy reached 25.81 J·g−1, maintaining phase-change behavior for 8 min during heating. Additionally, the enthalpy retention rate was 82.06% after five washing cycles.

Author Contributions

X.S. and Y.L. conceived and designed the study idea and experiments. C.X. and R.S. Managed activities of Data curation. R.S., C.W. and J.D. performed the related experiments. X.S. and H.W. studied the data results. X.S. and X.F. wrote and revised the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Research Project of the Fashu Foundation of Minjiang University (No. MFK23004), the Major Science and Technology Project of Nanping (No. N2021A004), Science and technology projects of Fujian Province (No. 2022I0045), and the Science and Technology Projects of Fujian Province (No. 2023J011404).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

Author Hong Wei was employed by the company Hangzhou Jingsha Information Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Yan, S.; Zhu, S.; Newton, M.A.; Cai, J.; Feng, H.; Xin, B.; Xing, W. Ultra-light, ultra-resilient and ultra-flexible, multifunctional composite carbon nanofiber aerogel for physiological signal monitoring and hazard warning in extreme environments. Chem. Eng. J. 2024, 495, 153017. [Google Scholar] [CrossRef]

- Dong, X.X.; Cao, Y.M.; Wang, C.; Wu, B.; Zheng, M.; Xue, Y.B.; Li, W.; Han, B.; Zheng, M.; Wang, Z.S.; et al. MXene-decorated smart textiles with the desired mid-infrared emissivity for passive personal thermal management. ACS Appl. Mater. Interfaces 2023, 9, 12032–12040. [Google Scholar] [CrossRef] [PubMed]

- Ye, C.; Yang, S.; Ren, J.S. Electroassisted core-spun triboelectric nanogenerator fabrics for intelligence and artificial intelligence perception. ACS Nano 2022, 16, 4415–4425. [Google Scholar] [CrossRef]

- Hossain, M.M.; Lubna, M.M.; Bradford, P.D. Multifunctional and washable carbon nanotube-wrapped textile yarns for wearable E-textiles. ACS Appl. Mater. Interfaces 2023, 2, 3365–3376. [Google Scholar] [CrossRef] [PubMed]

- Alicja, N.; Ewa, G.; Irena, K.; Malgorzata, C. Assessment of thermal performance of textile materials modified with PCM microcapsules using combination of DSC and infrared thermography methods. Molecules 2020, 25, 122. [Google Scholar]

- Abebe, M.G.; Rosolen, G.; Odent, J.; Raquez, J.M.; Maes, B. A dynamic passive thermoregulation fabric using metallic microparticles. Nanoscale 2022, 14, 1421–1431. [Google Scholar] [CrossRef]

- Wang, Z.; Bo, Y.; Bai, P.; Zhang, S.; Li, G.; Wan, X.; Chen, Y. Self-sustaining personal all-day thermoregulatory clothing using only sunlight. Science 2023, 382, 1291–1296. [Google Scholar] [CrossRef]

- Lei, L.; Shi, S.; Wang, D.; Meng, S.; Dai, J.G.; Fu, S.; Hu, J. Recent advances in thermoregulatory clothing: Materials, mechanisms, and perspectives. ACS Nano 2023, 17, 1803–1830. [Google Scholar] [CrossRef]

- Liu, X.-Y.; Wang, J.-F.; Xie, H.-Q.; Guo, Z.-X. Concurrent magnetic and thermal energy storage using a novel phase-change microencapsulated-nanoparticles fluid. J. Energy Storage 2022, 56, 105973. [Google Scholar] [CrossRef]

- Kumar, S.S.A.; Ramesh, K.; Ramesh, S.; Bang, L.T. A study on hybrid composite coatings: The significance of its surface wettability, dispersibility and thermal degradation performances. Prog. Org. Coat. 2024, 189, 108351. [Google Scholar] [CrossRef]

- Yu, S.; Zhang, Q.; Liu, L.; Ma, R. Thermochromic conductive fibers with modifiable solar absorption for personal thermal management and temperature visualization. ACS Nano 2023, 17, 20299–20307. [Google Scholar] [CrossRef] [PubMed]

- Cai, X.; Gao, L.; Wang, J.; Li, D. MOF-integrated hierarchical composite fiber for efficient daytime radiative cooling and antibacterial protective textiles. ACS Appl. Mater. Interfaces 2023, 15, 8537–8545. [Google Scholar] [CrossRef] [PubMed]

- He, H.; Guo, Z. Fabric-based superhydrophobic MXene@polypyrrole heater with superior dual-driving energy conversion. J. Colloid Interface Sci. 2023, 629, 508–521. [Google Scholar] [CrossRef] [PubMed]

- Song, X.L.; Xu, C.Z.; Yao, W.D.; Wen, J.Y.; Wei, Q.f.; Li, Y.G.; Feng, X.Q. Study on the controllable preparation of Nd3+ doped in Fe3O4 nanoparticles for magnetic protective fabrics. Molecules 2023, 28, 3175. [Google Scholar] [CrossRef] [PubMed]

- Rathore, P.K.S.; Shukla, S.K. Potential of macroencapsulated PCM for thermal energy storage in buildings: A comprehensive review. Constr. Build. Mater. 2019, 225, 723–744. [Google Scholar] [CrossRef]

- Wang, M.; Jeon, S.; Su, C.; Yu, T.; Tan, L.S.; Chiang, L.Y. Synthesis of photoswitchable magnetic Au-fullerosome hybrid nanomaterials for permittivity enhancement applications. Molecules 2015, 20, 14746–14760. [Google Scholar] [CrossRef]

- Zhang, G.; Sun, Y.; Wu, C.; Yan, X.; Zhao, W.; Peng, C. Low-cost and highly thermally conductive lauric acid–paraffin–expanded graphite multifunctional composite phase change materials for quenching thermal runaway of lithium-ion battery. Energy Rep. 2023, 9, 2538–2547. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, X.; Wu, D. Silica encapsulation of n-octadecane via sol–gel process: A novel microencapsulated phase-change material with enhanced thermal conductivity and performance. J. Colloid Interface Sci. 2010, 343, 246–255. [Google Scholar] [CrossRef]

- Li, C.; Fu, J.F.; Zhu, H.Z.; Si, T. Controlled latent heat phase-change microcapsules for temperature regulation. ACS Appl. Mater. Interfaces 2023, 15, 30383–30393. [Google Scholar] [CrossRef]

- Wang, T.; Lu, W.; He, Z.; Liang, Y.; Sun, Y.; Song, S.; Sun, W.; Wang, L. Tetradecyl octadecanoate phase change microcapsules incorporated with hydroxylated boron nitrides for reliable and durable heat energy storage. Solar Energy 2022, 245, 127–135. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, H. Liu, and X. Wang. Highly efficient, antibacterial, and salt-resistant strategy based on carbon black/chitosan-decorated phase-change microcapsules for solar-powered seawater desalination. ACS Appl. Mater. Interfaces 2023, 15, 16640–16653. [Google Scholar] [CrossRef] [PubMed]

- Zhao, L.; Wu, X.; Hu, X.; Zheng, S.; Cao, Z. Enhanced thermal conductivity of phase change microcapsules based on boron nitride/graphene oxide composite sheets. ACS Appl. Polym. Mater. 2023, 5, 3835–3847. [Google Scholar] [CrossRef]

- Soares, S.F.; Fernandes, T.; Trindade, T.; Daniel-da-Silva, A.L. Trimethyl Chitosan/Siloxane-hybrid coated Fe3O4 nanoparticles for the uptake of sulfamethoxazole from water. Molecules 2019, 24, 1958. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.; Park, S.; Park, M.; Kim, Y.; Lee, K.M.; Lee, O.M.; Son, H.J. Characterization of a novel CaCO3-forming alkali-tolerant rhodococcus erythreus S26 as a filling agent for repairing concrete cracks. Molecules 2021, 26, 2967. [Google Scholar] [CrossRef]

- Li, A.Q. Morphology-controlled synthesis of Cu2O encapsulated phase change materials: Photo thermal conversion and storage performance in visible light regime. Chem. Eng. J. 2023, 454, 140089. [Google Scholar]

- Shao, J.Y. Study on Absorption-Phase Change Microcapsules Infrared Microwave Compatible Stealth Composites. Master’s Thesis, Lanzhou University of Technology, Lanzhou, China, 2017. [Google Scholar]

- Wei, H.; He, F.; Li, Y.; Zhang, Q.; Zhou, Y.; Yan, H.; He, R.; Fan, J.; Yang, W. Bifunctional paraffin@CaCO3: Ce3+ phase change microcapsules for thermal energy storage and photoluminescence. ACS Sustain. Chem. Eng. 2019, 7, 18854–18862. [Google Scholar] [CrossRef]

- Liu, H.; Tian, X.; Ouyang, M.; Wang, X.; Wu, D.; Wang, X. Microencapsulating n-docosane phase change material into CaCO3/Fe3O4 composites for high-efficient utilization of solar photothermal energy. Renew. Energy 2021, 179, 47–64. [Google Scholar] [CrossRef]

- Jiang, Z.N.; Yang, W.B.; He, F.F.; Xie, C.Q.; Fan, J.H.; Wu, J.Y.; Zhang, K. Modified phase change microcapsules with calcium carbonate and graphene oxide shells for enhanced energy storage and leakage prevention. ACS Sustain. Chem. Eng. 2018, 6, 5182–5191. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, X.; Wu, D. Fabrication of microencapsulated phase change materials with TiO2/Fe3O4 hybrid shell as thermoregulatory enzyme carriers: A novel design of applied energy microsystem for bioapplications. Appl. Energy 2017, 201, 20–33. [Google Scholar] [CrossRef]

- Wang, L.; Huang, Y.; Li, L.; Li, Y.; Cheng, X. Binary nitrate molten salt magnetic microcapsules modified with Fe3O4-functionalized carbon nanotubes for accelerating thermal energy storage. J. Energy Storage 2023, 74, 109394. [Google Scholar] [CrossRef]

- Wang, X.; Lei, W.; Zou, F.; Zhang, C.; Zhu, J. Synthesis and characterization of nano-Fe3O4 hybrid phase change microcapsules for infrared stealth and microwave absorption. J. Mater. Res. 2022, 37, 2335–2346. [Google Scholar] [CrossRef]

- Nguyen, G.T.; Truong, T.A.N.; Dat, N.D.; Phan, T.A.D.; Bui, T.H. Polyethylene glycol confined in SiO2–modified expanded graphite as novel form–stable phase change materials for thermal energy storage. ACS Omega 2023, 8, 38160–38169. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.W.; Yuan, T.; Wang, F.; Hu, J.Q.; Tu, W.P. Magnetically separable Fe3O4@TiO2 nanospheres: Preparation and photocatalytic activity. J. Mater. Sci. Mater. Electron. 2016, 27, 9983–9988. [Google Scholar] [CrossRef]

- Jiang, Z.; Shu, J.; Ge, Z.; Jiang, Z.; Wang, M.; Ge, X. Preparation and performance of magnetic phase change microcapsules with organic-inorganic double shell. Sol. Energy Mater. Sol. Cells 2022, 240, 111716. [Google Scholar] [CrossRef]

- Alvaro Javier Gómez Rodríguez, D.; Oyola Lozano, J. Trujillo Hernández. Production and characterization of nanostructured powders of Nd2Fe14B and Fe90Al10 by mechanical alloying. Molecules 2022, 27, 7190. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, W.; Liu, H.; Wang, X. Sustainable interfacial evaporation system based on hierarchical MXene/polydopamine/magnetic phase-change microcapsule composites for solar-driven seawater desalination. ACS Appl. Mater. Interfaces 2022, 14, 50966–50981. [Google Scholar] [CrossRef]

- Liu, X.; Wang, J.; Xie, H. Self-assembled synthesis of microencapsulated paraffin wax phase change materials with excellent thermal properties of calcium carbonate shell. J. Enhanc. Heat Transf. 2023, 30, 1–18. [Google Scholar] [CrossRef]

- Shi, J.; Wu, X.; Sun, R. Synthesis and performance evaluation of paraffin microcapsules with calcium carbonate shell modulated by different anionic surfactants for thermal energy storage. Colloids Surf. A 2019, 571, 36–43. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, T.; Guo, C.; Jiao, S.; Rao, Z. Photo-thermal conversion and heat storage characteristics of multi-walled carbon nanotubes dispersed magnetic phase change microcapsules slurry. Int. J. Energy Res. 2020, 44, 6873–6884. [Google Scholar] [CrossRef]

- Wei, Y.; Li, X.; Wang, Y.; Hirtz, T.; Guo, Z.; Qiao, Y.; Cui, T.; Tian, H.; Yang, Y.; Ren, T.L. Graphene-based multifunctional textile for sensing and actuating. ACS Nano 2021, 15, 17738–17747. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, Z.; Mao, X.; Chen, X.L.; Li, H.H.; Wang, Y.Y. Multifunctional textiles/metal−organic frameworks composites for efficient ultraviolet radiation blocking and noise reduction. ACS Appl. Mater. Interfaces 2020, 12, 55316–55323. [Google Scholar] [CrossRef] [PubMed]

- Yi, P.; Zou, H.; Yu, Y.; Li, X.; Li, Z.; Deng, G.; Chen, C.; Fang, M.; He, J.; Sun, X.; et al. MXene-reinforced liquid metal/polymer fibers via interface engineering for wearable multifunctional textiles. ACS Nano 2022, 16, 14490–14502. [Google Scholar] [CrossRef]

- Zheng, G.; Cui, Y.; Jiang, Z.; Zhou, M.; Wang, P.; Yu, Y.; Wang, Q. Multifunctional composite coatings with hydrophobic, UV-resistant, anti-oxidative, and photothermal performance for healthcare. Colloids Surf. A 2023, 667, 131367. [Google Scholar] [CrossRef] [PubMed]

- Ibili, H.; Daşdemir, M. AgCl-TiO2;/dendrimer-based nanoparticles for superhydrophobic and antibacterial multifunctional textiles. J. Text. Inst. 2023, 114, 861–873. [Google Scholar] [CrossRef]

- Lu, B.; Zhang, Y.; Zhang, J.; Zhao, H.; Wang, Z. Preparation, optimization and thermal characterization of paraffin/nano-Fe3O4 composite phase change material for solar thermal energy storage. J. Energy Storage 2022, 46, 103928. [Google Scholar] [CrossRef]

- Hu, E.; Shang, S.; Chiu, K.L. Removal of reactive dyes in textile effluents by catalytic ozonation pursuing on-site effluent recycling. Molecules 2019, 24, 2755. [Google Scholar] [CrossRef]

- Bie, Y.F.; Liu, Y.H.; Xu, H.Y.; Tian, Y.F.; Wang, X.; Qian, J. Conductive ink based on GNSs/MWCNTs for fabricating wearable wash-resistant electrothermal devices. ACS Appl. Electron. Mater. 2024, 6, 276–291. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).