Mimicking Polymer Processing Conditions on the Meso-Scale: Relaxation and Crystallization in Polyethylene Systems after Uni- and Biaxial Stretching

Abstract

1. Introduction

2. Results

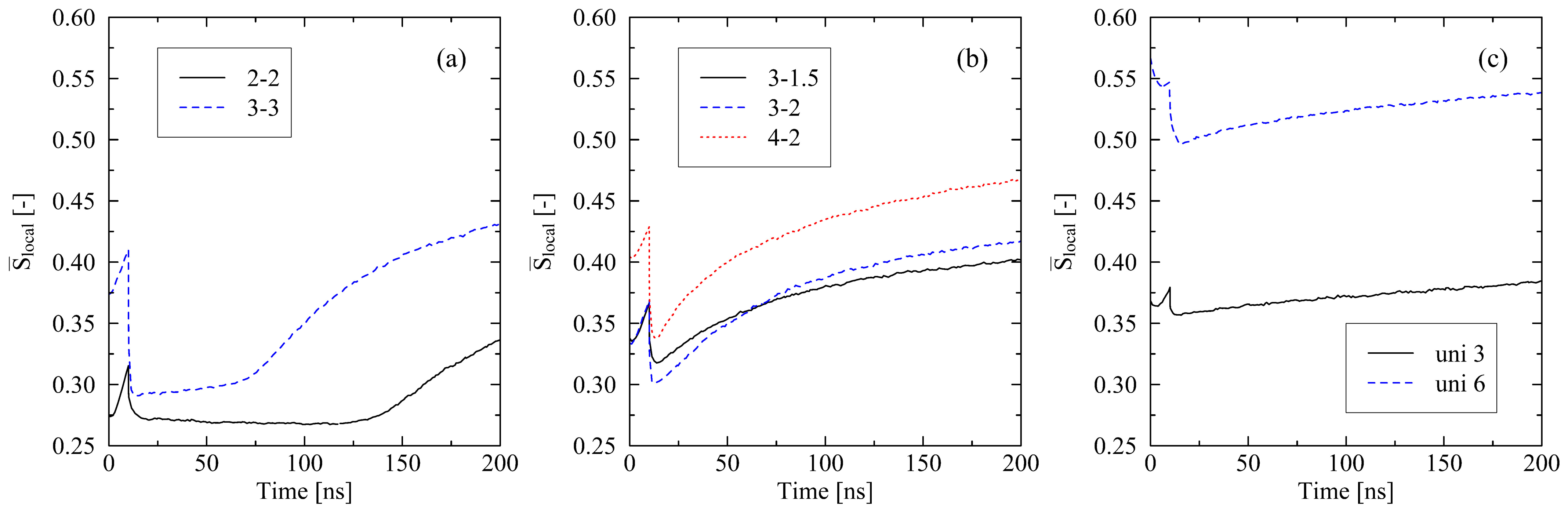

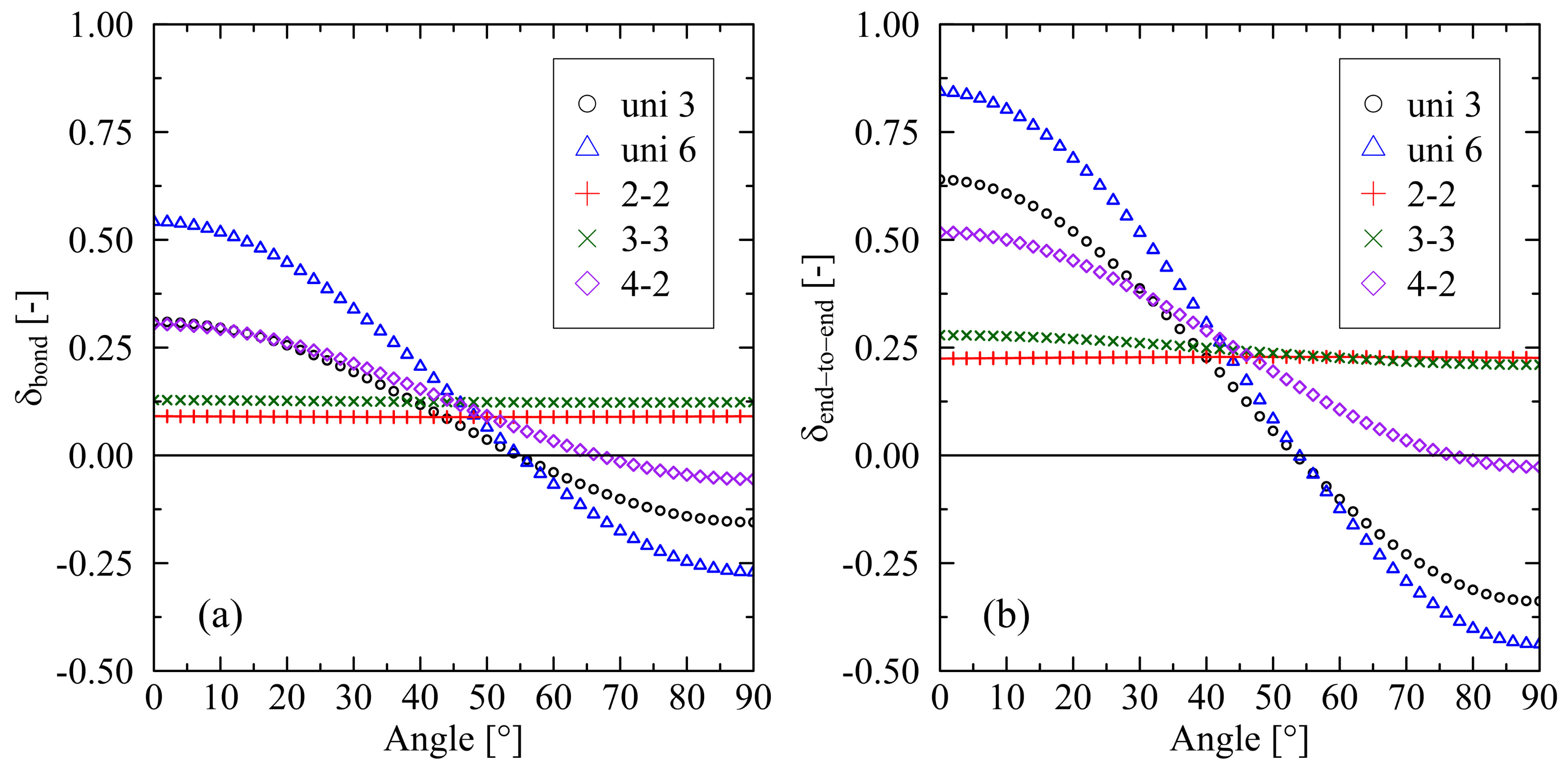

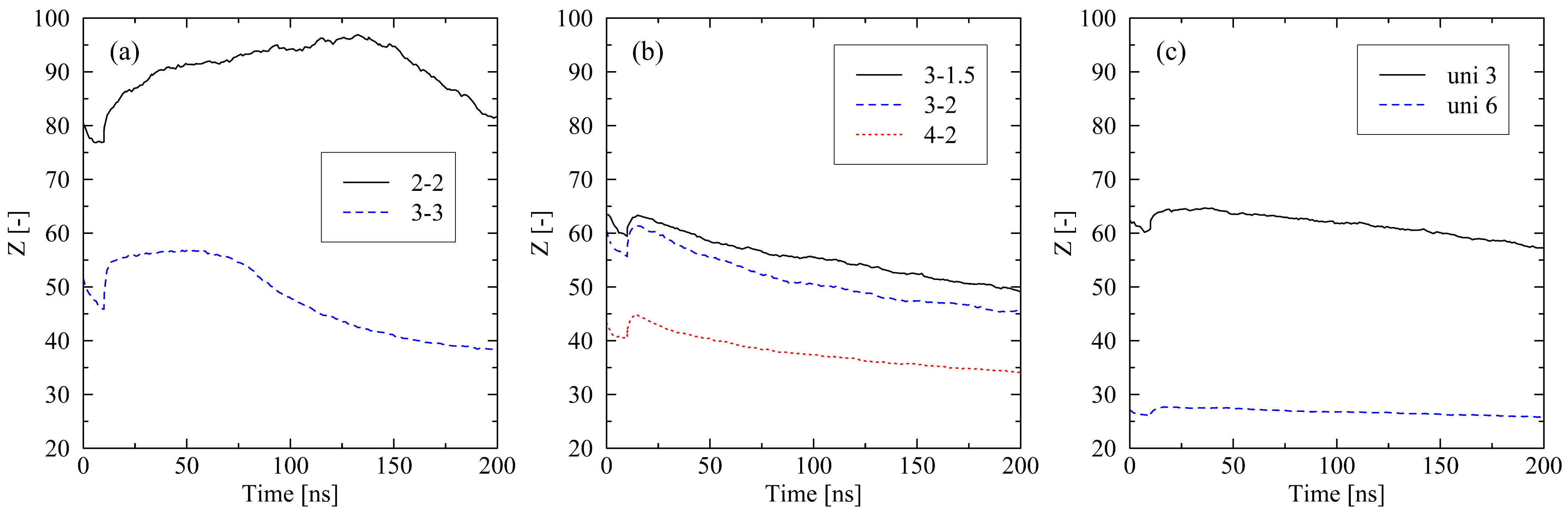

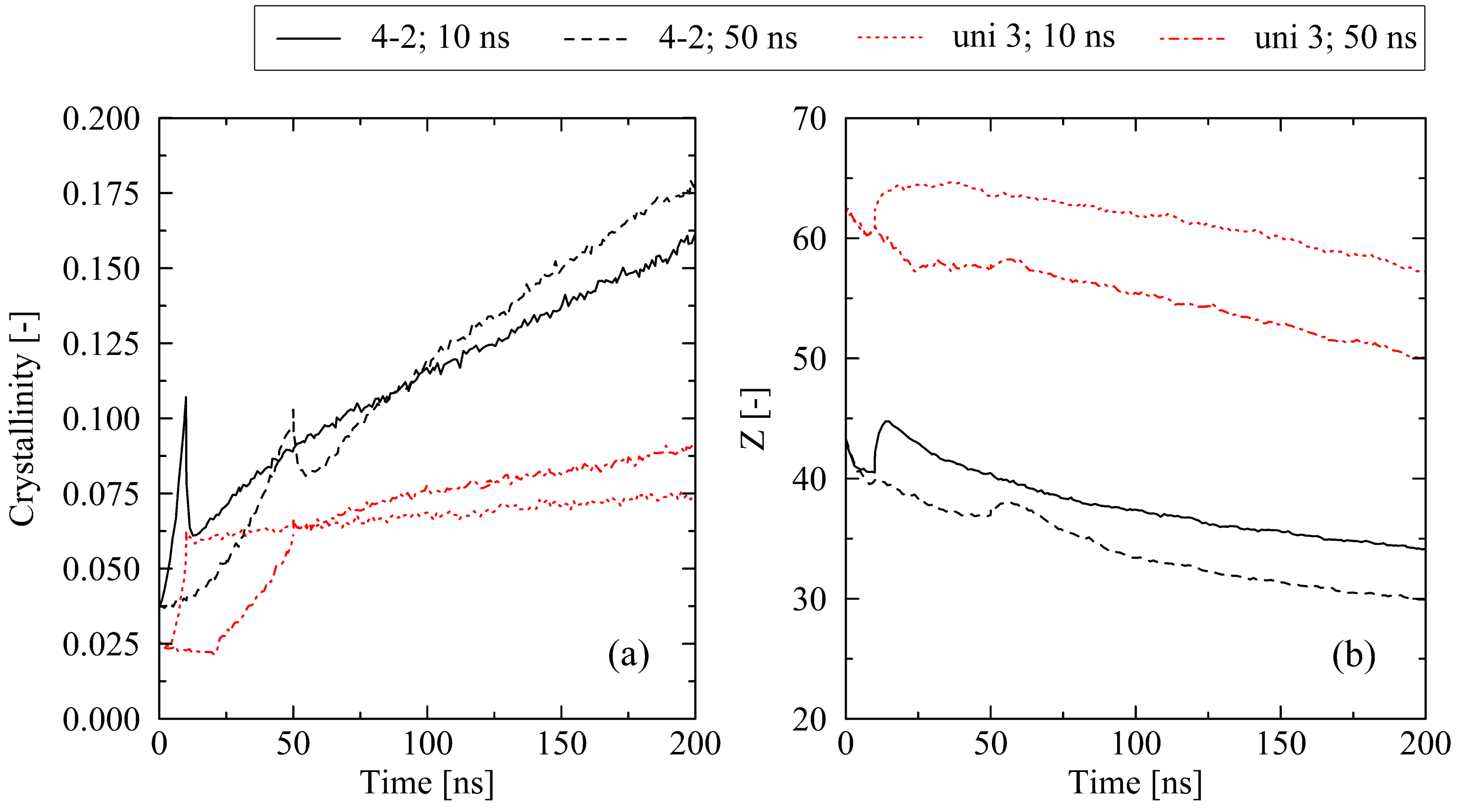

2.1. General Crystallization and Relaxation Behavior

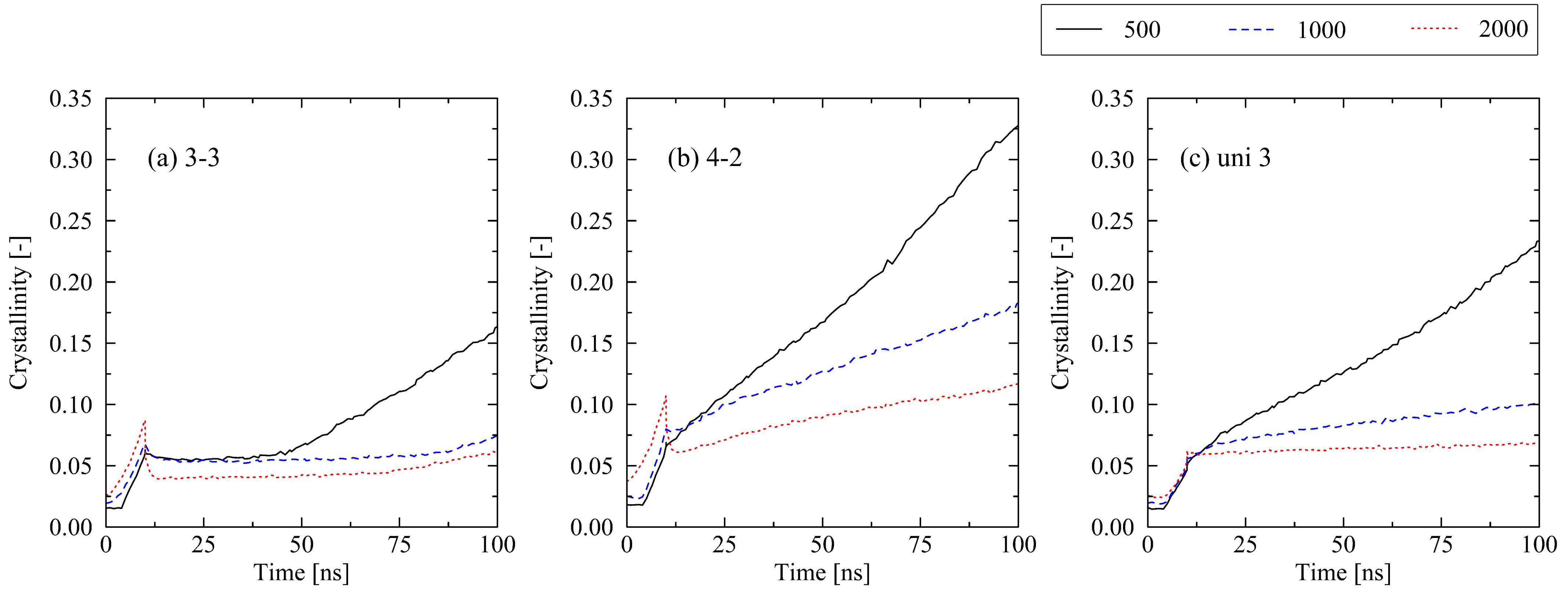

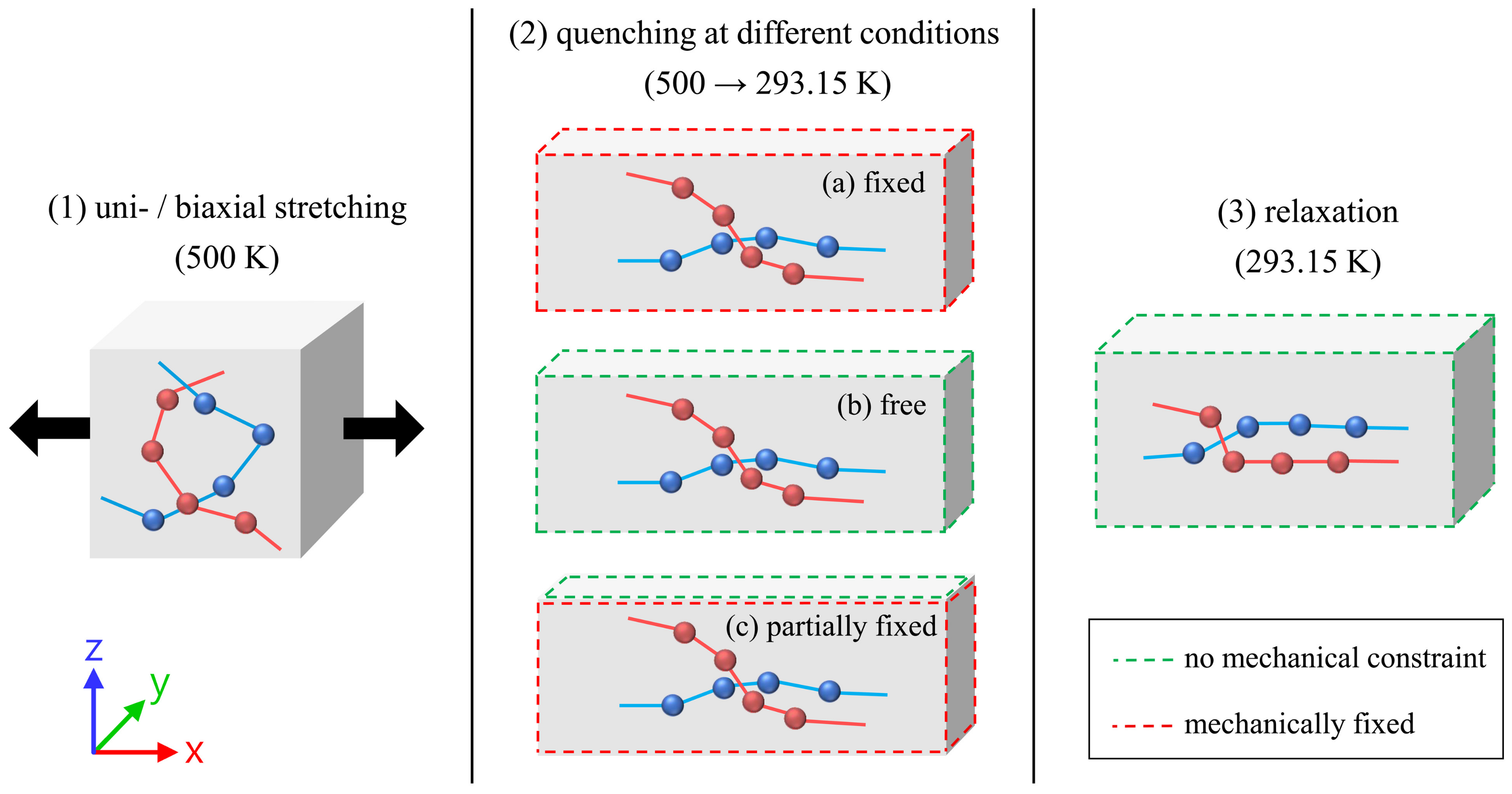

2.2. Influence of Varying Conditions at Cooling Stage

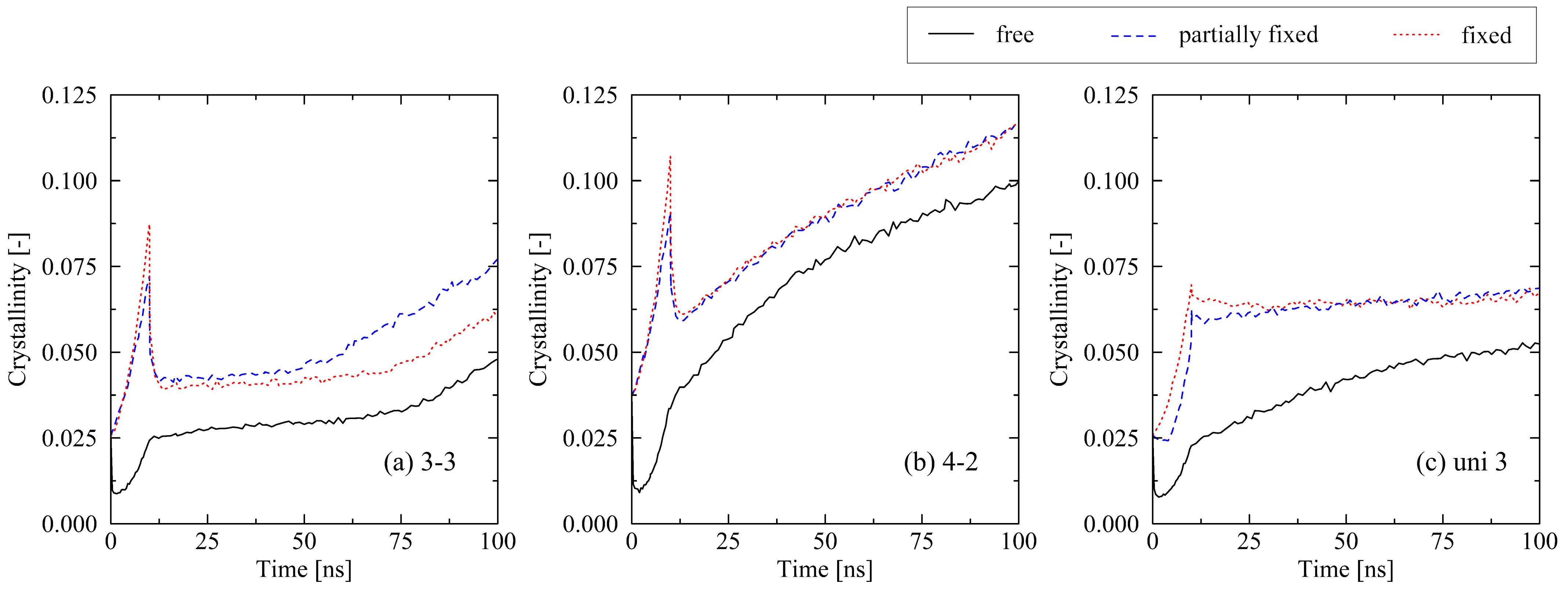

2.2.1. Mechanical Boundary Conditions

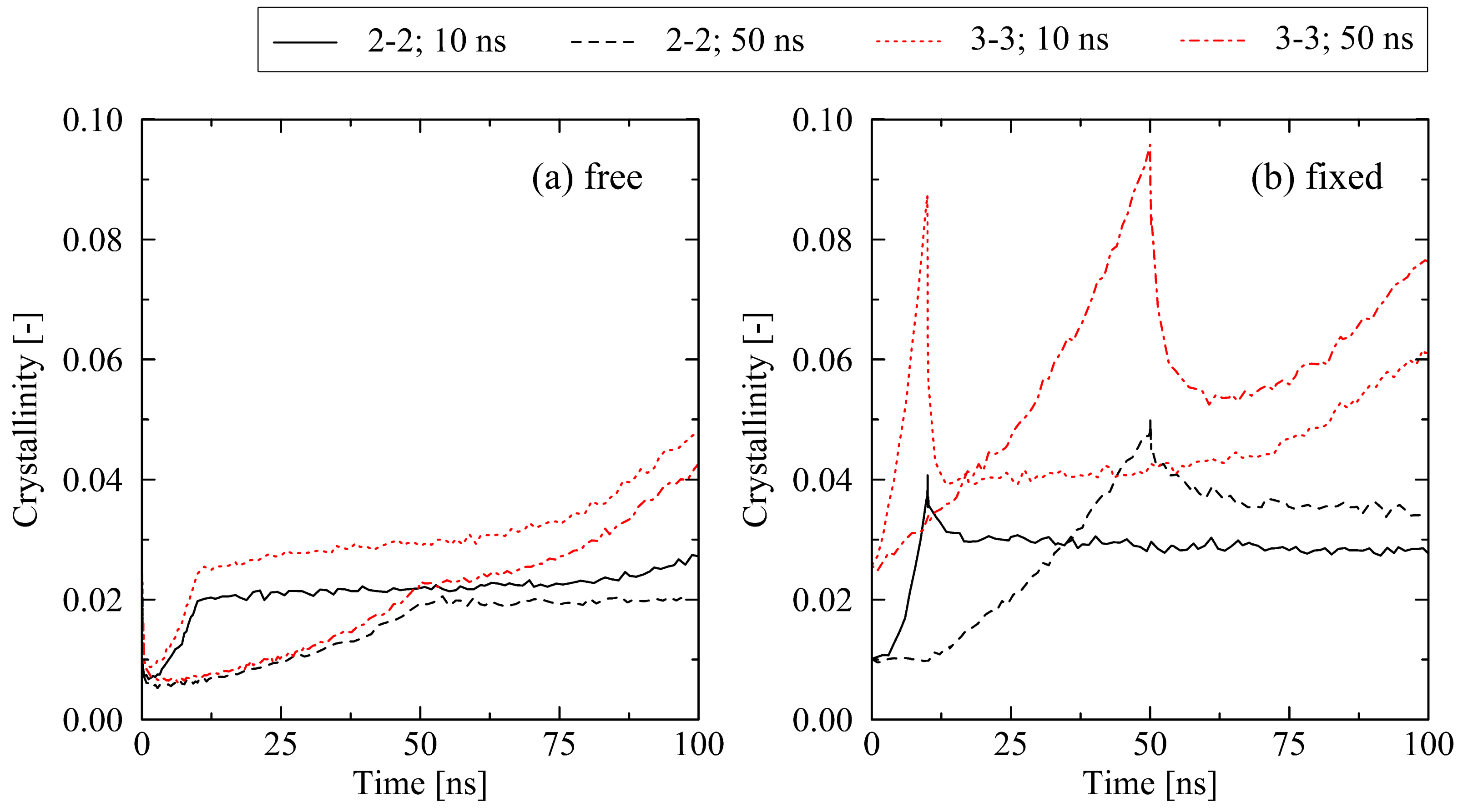

2.2.2. Cooling Time

3. Discussion

4. Simulation Methodology

4.1. Force Field

4.2. Simulation Procedure

4.3. Evaluation of the Microscopic Structure

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Grosso, G.; Troisi, E.M.; Jaensson, N.O.; Peters, G.W.; Anderson, P.D. Modelling flow induced crystallization of IPP: Multiple crystal phases and morphologies. Polymer 2019, 182, 121806. [Google Scholar] [CrossRef]

- Ma, Z.; Balzano, L.; Peters, G.W.M. Dissolution and re-emergence of flow-induced shish in polyethylene with a broad molecular weight distribution. Macromolecules 2016, 49, 2724–2730. [Google Scholar] [CrossRef]

- Wang, Z.; Ma, Z.; Li, L. Flow-induced crystallization of polymers: Molecular and thermodynamic considerations. Macromolecules 2016, 49, 1505–1517. [Google Scholar] [CrossRef]

- Matsuura, T.; Murakami, M.; Inoue, R.; Nishida, K.; Ogawa, H.; Ohta, N.; Kanaya, T. Microbeam wide-angle X-ray scattering study on precursor of shish kebab. Effects of shear rate and annealing on inner structure. Macromolecules 2015, 48, 3337–3343. [Google Scholar] [CrossRef]

- Kalyon, D. Extrusion Blow Molding—Process Dynamics and Product Properties. Ph.D. Thesis, McGill University Montreal, Montréal, QC, Canada, 1980. [Google Scholar]

- Grünwald, J. Entwicklung und Erprobung Neuer Werkzeugkonzepte zur Radialen Wanddickenbeeinflussung beim Extrusionsblasformen. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2004. [Google Scholar]

- Ohlendorf, F. Vorhersage der Mechanischen Eigenschaften bei der Schlauchfolienextrusion. Ph.D. Thesis, RWTH Aachen, Aachen, Germany, 2004. [Google Scholar]

- Ramakers-van Dorp, E.; Eger, B.; Raschen, C.; Urbanek, M.; Möginger, B.; Hausnerova, B. Local process-dependent structural and mechanical properties of extrusion blow molded high-density polyethylene hollow parts. Polym. Test. 2019, 82, 106314. [Google Scholar] [CrossRef]

- Ramakers-van Dorp, E.; Möginger, B.; Hausnerova, B. Thermal expansion of semi-crystalline polymers: Anisotropic thermal strain and crystallite orientation. Polymer 2020, 191, 122249. [Google Scholar] [CrossRef]

- Zhou, H. Structure-Property Relationships: Model Studies on Melt-Extruded Uniaxially-Oriented High Density Polyethylene Films Having Well Defined Morphologies. Ph.D. Thesis, Virginia Polytechnic Institute and State University, Blacksburg, VA, USA, 1997. [Google Scholar]

- Hopmann, C.; Rasche, S.; Leopold, T. Strukturmechanisches Verhalten gefüllter PET-Flaschen. Kunststoffe 2012, 102, 70–74. [Google Scholar]

- Kamal, M.R.; Kalyon, D.; Tan, V. Anisotropy and dimensions of blow-molded polyethylene bottles. Polym. Eng. Sci. 1982, 22, 287–291. [Google Scholar] [CrossRef]

- Kamal, M.R.; Kalyon, D. Heat transfer and microstructure in extrusion blowmolding. Polym. Eng. Sci. 1983, 23, 503–509. [Google Scholar] [CrossRef]

- Choi, K.J.; Spruiell, J.E.; White, J.L. Orientation and crystalline morphology of blow molded polyethylene bottles. Polym. Eng. Sci. 1989, 29, 463–470. [Google Scholar] [CrossRef]

- Anwar, M.; Turci, F.; Schilling, T. Crystallization mechanism in melts of short n-alkane chains. J. Chem. Phys. 2013, 139, 214904. [Google Scholar] [CrossRef]

- Lavine, M.S.; Waheed, N.; Rutledge, G.C. Molecular dynamics simulation of orientation and crystallization of polyethylene during uniaxial extension. Polymer 2003, 44, 1771–1779. [Google Scholar] [CrossRef]

- Ko, M.J.; Waheed, N.; Lavine, M.S.; Rutledge, G.C. Characterization of polyethylene crystallization from an oriented melt by molecular dynamics simulation. J. Chem. Phys. 2004, 121, 2823–2832. [Google Scholar] [CrossRef]

- Sliozberg, Y.R.; Yeh, I.C.; Kroeger, M.; Masser, K.A.; Lenhart, J.L.; Andzelm, J.W. Ordering and crystallization of entangled polyethylene melt under uniaxial tension: A molecular dynamics study. Macromolecules 2018, 51, 9635–9648. [Google Scholar] [CrossRef]

- Yamamoto, T. Molecular dynamics simulation of stretch-induced crystallization in polyethylene: Emergence of fiber structure and molecular network. Macromolecules 2019, 52, 1695–1706. [Google Scholar] [CrossRef]

- Anwar, M.; Graham, R.S. Molecular dynamics simulations of crystal nucleation in entangled polymer melts under start-up shear conditions. J. Chem. Phys. 2019, 150, 084905. [Google Scholar] [CrossRef]

- Zhang, W.; Larson, R.G. Effect of flow-induced nematic order on polyethylene crystal nucleation. Macromolecules 2020, 53, 7650–7657. [Google Scholar] [CrossRef]

- Grommes, D.; Schenk, M.R.; Bruch, O.; Reith, D. Investigation of crystallization and relaxation effects in coarse-grained polyethylene systems after uniaxial stretching. Polymers 2021, 13, 4466. [Google Scholar] [CrossRef]

- Romanos, N.; Megariotis, G.; Theodorou, D.N. Molecular dynamics simulations of stretch-induced crystallization in layered polyethylene. Polym. Cryst. 2021, 4, e10172. [Google Scholar] [CrossRef]

- Nie, C.; Peng, F.; Xu, T.; Ding, Y.; Sheng, J.; Chen, W.; Li, L. Biaxial stretch-induced crystallization of polymers: A molecular dynamics simulation study. Macromolecules 2021, 54, 9794–9803. [Google Scholar] [CrossRef]

- Zhang, Y.; Qiao, L.; Fan, J.; Xue, S.; Jar, P.B. Molecular dynamics simulation of plastic deformation in polyethylene under uniaxial and biaxial tension. Proc. Inst. Mech. Eng. Part J. Mater. Des. Appl. 2022, 236, 389–403. [Google Scholar] [CrossRef]

- Hall, K.W.; Sirk, T.W.; Klein, M.L.; Shinoda, W. A coarse-grain model for entangled polyethylene melts and polyethylene crystallization. J. Chem. Phys. 2019, 150, 244901. [Google Scholar] [CrossRef] [PubMed]

- Zou, L.; Zhang, W. Molecular dynamics simulations of the effects of entanglement on polymer crystal nucleation. Macromolecules 2022, 55, 4899–4906. [Google Scholar] [CrossRef]

- Zhu, C.; Zhao, J. Nucleation and crystallization of polymer melts under cyclic stretching: Entanglement effect. Macromolecules 2023, 56, 5490–5501. [Google Scholar] [CrossRef]

- Hagita, K.; Fujiwara, S.; Iwaoka, N. Structure formation of a quenched single polyethylene chain with different force fields in united atom molecular dynamics simulations. AIP Adv. 2018, 8, 115108. [Google Scholar] [CrossRef]

- Flory, P.J. Thermodynamics of crystallization in high polymers. I. Crystallization induced by stretching. J. Chem. Phys. 1947, 15, 397–408. [Google Scholar] [CrossRef]

- Grommes, D.; Schenk, M.R.; Bruch, O.; Reith, D. Initial crystallization effects in coarse-grained polyethylene systems after uni- and biaxial stretching in blow-molding cooling scenarios. Polymers 2022, 14, 5144. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the open visualization tool. Model. Simul. Mater. Sci. Eng. 2010, 18, 015012. [Google Scholar] [CrossRef]

- Eichenberger, A.P. Molecular Dynamics Simulation of Alkanes and Proteins: Methodology, Prediction of Properties and Comparison to Experimental Data. Ph.D. Thesis, ETH Zürich, Zürich, Switzerland, 2013. [Google Scholar]

- Grommes, D.; Reith, D. Determination of relevant mechanical properties for the production process of polyethylene by using mesoscale molecular simulation techniques. Soft Mater. 2020, 18, 242–261. [Google Scholar] [CrossRef]

- Auhl, R.; Everaers, R.; Grest, G.S.; Kremer, K.; Plimpton, S.J. Equilibration of long chain polymer melts in computer simulations. J. Chem. Phys. 2003, 119, 12718–12728. [Google Scholar] [CrossRef]

- Moreira, L.; Zhang, G.; Müller, F.; Stuehn, T.; Kremer, K. Direct equilibration and characterization of polymer melts for computer simulations. Macromol. Theory Simulations 2015, 24, 419–431. [Google Scholar] [CrossRef]

- Halverson, J.D.; Brandes, T.; Lenz, O.; Arnold, A.; Bevc, S.; Starchenko, V.; Kremer, K.; Stuehn, T.; Reith, D. ESPResSo++: A modern multiscale simulation package for soft matter systems. Comput. Phys. Commun. 2013, 184, 1129–1149. [Google Scholar] [CrossRef]

- Guzman, H.V.; Tretyakov, N.; Kobayashi, H.; Fogarty, A.C.; Kreis, K.; Krajniak, J.; Junghans, C.; Kremer, K.; Stuehn, T. ESPResSo++ 2.0: Advanced methods for multiscale molecular simulation. Comput. Phys. Commun. 2019, 238, 66–76. [Google Scholar] [CrossRef]

- Rosato, D.V. Blow Molding Handbook, 2nd ed.; Hanser: Munich, Germany, 2003. [Google Scholar]

- Moyassari, A.; Gkourmpis, T.; Hedenqvist, M.S.; Gedde, U.W. Molecular dynamics simulation of linear polyethylene blends: Effect of molar mass bimodality on topological characteristics and mechanical behavior. Polymer 2019, 161, 139–150. [Google Scholar] [CrossRef]

- Ramasubramani, V.; Dice, B.D.; Harper, E.S.; Spellings, M.P.; Anderson, J.A.; Glotzer, S.C. freud: A software suite for high throughput analysis of particle simulation data. Comput. Phys. Commun. 2020, 254, 107275. [Google Scholar] [CrossRef]

- Everaers, R.; Sukumaran, S.K.; Grest, G.S.; Svaneborg, C.; Sivasubramanian, A.; Kremer, K. Rheology and microscopic topology of entangled polymeric liquids. Science 2004, 303, 823–826. [Google Scholar] [CrossRef]

- Yashiro, K.; Ito, T.; Tomita, Y. Molecular dynamics simulation of deformation behavior in amorphous polymer: Nucleation of chain entanglements and network structure under uniaxial tension. Int. J. Mech. Sci. 2003, 45, 1863–1876. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grommes, D.; Bruch, O.; Reith, D. Mimicking Polymer Processing Conditions on the Meso-Scale: Relaxation and Crystallization in Polyethylene Systems after Uni- and Biaxial Stretching. Molecules 2024, 29, 3391. https://doi.org/10.3390/molecules29143391

Grommes D, Bruch O, Reith D. Mimicking Polymer Processing Conditions on the Meso-Scale: Relaxation and Crystallization in Polyethylene Systems after Uni- and Biaxial Stretching. Molecules. 2024; 29(14):3391. https://doi.org/10.3390/molecules29143391

Chicago/Turabian StyleGrommes, Dirk, Olaf Bruch, and Dirk Reith. 2024. "Mimicking Polymer Processing Conditions on the Meso-Scale: Relaxation and Crystallization in Polyethylene Systems after Uni- and Biaxial Stretching" Molecules 29, no. 14: 3391. https://doi.org/10.3390/molecules29143391

APA StyleGrommes, D., Bruch, O., & Reith, D. (2024). Mimicking Polymer Processing Conditions on the Meso-Scale: Relaxation and Crystallization in Polyethylene Systems after Uni- and Biaxial Stretching. Molecules, 29(14), 3391. https://doi.org/10.3390/molecules29143391