Abstract

Due to their cost-effectiveness, abundant resources, and suitable working potential, sodium-ion batteries are anticipated to establish themselves as a leading technology in the realm of grid energy storage. However, sodium-ion batteries still encounter challenges, including issues related to low energy density and constrained cycling performance. In this study, a self-supported electrode composed of Prussian white/KetjenBlack/MXene (TK−PW) is proposed. In the TK−PW electrode, the MXene layer is coated with Prussian white nanoparticles and KetjenBlack with high conductivity, which is conducive to rapid Na+ dynamics and effectively alleviates the expansion of the electrode. Notably, the electrode preparation method is uncomplicated and economically efficient, enabling large-scale production. Electrochemical testing demonstrates that the TK−PW electrode retains 74.9% of capacity after 200 cycles, with a discharge capacity of 69.7 mAh·g−1 at 1000 mA·g−1. Furthermore, a full cell is constructed, employing a hard carbon anode and TK−PW cathode to validate the practical application potential of the TK−PW electrode.

1. Introduction

With the growing demand for production, energy storage has become a focal point of research in today’s world [1,2]. Rechargeable batteries, known for their flexibility and high energy density, are widely regarded as pivotal components in meeting the development trends in portable electronics and renewable energy systems. In recent decades, lithium-ion batteries have garnered great attention [3,4,5]. However, the increasing cost of lithium-ion batteries, attributed to the scarcity of lithium resources, present a challenge to their widespread adoption in power grid energy storage [6,7,8]. Sodium-ion batteries, sharing similar charge and discharge mechanisms with lithium-ion batteries, benefit significantly from the abundant availability of sodium resources, resulting in a substantial cost reduction. This advantage positions them favorably for extensive applications in the realm of energy storage [9,10]. In addition, large-scale energy storage systems, such as grid storage, do not require as much energy density as portable storage devices [11]. Hence, the utilization of sodium-ion batteries holds great appeal for powering diverse applications, ranging from portable electronic devices to grid-scale energy storage solutions.

Currently, typical sodium-ion battery cathodes consists of transition metal oxides [12,13], polyanionic compounds [14,15], Prussian blue analogs [16,17], and organic compounds [18,19]. PBAs emerge as highly promising cathodes for sodium-ion batteries, characterized by their large lattice gap that can accommodate Na+ [20]. Prussian white is a sodium-rich analog of Prussian blue, which can be used to assemble full batteries because of its high sodium content [21]. But Prussian white’s poor cycling performance and electron conductivity hinder the advancements of the energy density of sodium-ion batteries [22]. At present, most research is centered around the synthesis process of Prussian white, which mainly optimizes the material structure by reducing the interstitial water content and lattice defects, thus improving the cyclic stability of the material. For example, Li et al. prepared a Prussian white nanocube with high crystallinity by simple co-precipitation with a capacity retention rate of 78% after 500 cycles [23]. However, the optimized material still needs to be mixed with a binder and coated on a metal collector to prepare the cathode. Non-active materials such as binders and current collectors pose significant obstacles to increasing the energy density of the battery and alleviating volume expansion [24].

MXenes, a kind of transition metal carbides/nitrides/carbonitrides, are currently drawing considerable attention from researchers [25,26]. The chemical formula for MXene is Mn+1XnTx (n = 1–4), and M is the transition metal (Ti, V, Nb), X represents either carbon or nitrogen, and Tx denotes the surface groups (-F, -OH, -O, and -Cl) [27]. Among them, Ti3C2Tx is the most widely studied MXene variant, known for its ability to form flexible self-supporting electrodes through the assembly of colloidal solutions [28,29]. Although the stacking phenomenon of Ti3C2Tx MXene will reduce its electrochemical performance, doping of nanoparticles has been proved to be an effective approach to prevent the stacking of Ti3C2Tx MXene nanosheets [30]. KetjenBlack(KB) is a cheap conductive agent, which can be doped into the electrode to improve its conductivity effectively [31]. Therefore, the Prussian white/KetjenBlack/MXene composite electrode will be a good choice for increasing battery energy density.

In this paper, we introduce a novel electrode manufacturing process that is simple, time-efficient, and does not necessitate demanding conditions, such as elevated temperatures and high pressure. In the TK−PW electrode, there is no binder, which reduces the pollution of organic matter in the environment. At the same time, Ti3C2Tx MXene and KetjenBlack become conductive links to the Prussian white nanoparticles. The sodium-ion battery, consisting of the TK−PW electrode, demonstrates exceptional cycle stability and rate capabilities. Notably, the TK−PW electrode achieves a discharge capacity of 69.7 mAh·g−1 at a current density of 1000 mA·g−1. Furthermore, when integrated into a full battery with a hard carbon cathode, the full battery demonstrates favorable cycle stability.

2. Results and Discussion

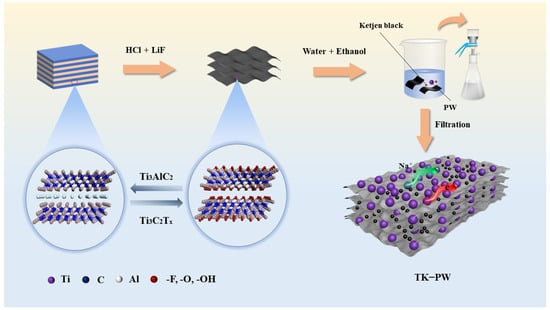

Figure 1 shows the detailed preparation process of TK−PW film. After Ti3AlC2 is etched by HCl/LiF, the strong metal bond between Ti-C layers becomes a weak van der Waals force, which makes the Ti3C2Tx MXene layers spacing expand, meaning they can easily be dispersed in aqueous solution [32]. After mixing PW with KetjenBlack and Ti3C2Tx MXene solution for a period of time, PW was dispersed into small nanoparticles mixed between the Ti3C2Tx MXene layers. Then, a large amount of anhydrous ethanol was added to the mixture for redeposition of nanoparticles [33]. The filter paper was covered with a layer of polyethylene film. Due to the hydrophilicity of MXene functional groups, which cannot interact with the hydrophobic PE film, Ti3C2Tx MXene could not adhere to the smooth polyethylene film. Therefore, during the filtration process, some PW nanoparticles were first deposited, and then, the Ti3C2Tx MXene layers and the remaining PW particles were further deposited. TK−PW can be obtained by drying the surface moisture of the filter product in a vacuum oven.

Figure 1.

Illustration of the preparation route of TK−PW film.

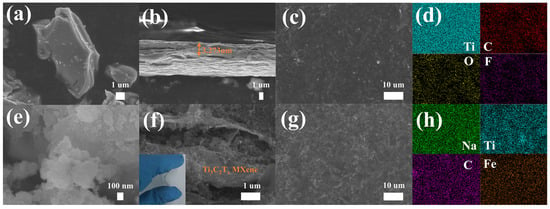

The microtopographies of Ti3AlC2 and Ti3C2Tx MXenes are shown in Figure 2a,b. Ti3AlC2 presents an obvious massive structure, while Ti3C2Tx MXenes film presents an obvious lamellar structure with a thickness of about 3.273 um. From the analysis of the EDS test results, the Ti, C, O, and F elements are uniformly distributed on the surface of Ti3C2Tx MXenes (Figure 2c,d). The SEM image and EDS image of PW are shown in Figure 2e and Figure S1a,b. The morphology of PW after grinding by a ball mill presents a large particle composed of many small nanoparticles, with the C, Na, N, and Fe elements uniformly distributed on its surface. In the TK−PW, the Ti3C2Tx MXene layers act as the skeleton of the supporting electrode to fix PW particles and the conductive agent KetjenBlack firmly in the middle of the Ti3C2Tx MXene layers (Figure 2f). At the same time, PW particles expand the distance between the Ti3C2Tx MXene layers and prevent the stacking of Ti3C2Tx MXene layers, thus ensuring the excellent electrical performance of Ti3C2Tx MXene layers [34]. When TK−PW is bent at a certain angle, no cracks appear on its surface, indicating that TK−PW has a certain flexibility. The uniform distribution of the Na, Ti, C, and Fe elements can be observed on the surface of TK−PW, which confirms the successful creation of the composite of Ti3C2Tx MXene and PW (Figure 2g,h). Figure S3a shows the XRD spectra of Ti3C2Tx MXene, PW, and TK−PW. It can be found that the diffraction peaks belonging to both Ti3C2Tx MXene and PW can be found in TK−PW, which proves that TK−PW is a good combination of Ti3C2Tx MXene and PW [35]. In the XRD pattern, the (002) peak shifts significantly to the left, indicating that the strong metal bond between the Ti3C2Tx MXene layers and the aluminum atomic layer is disrupted, resulting in an increase in the interlayer spacing of Ti3C2Tx. After PW nanoparticles are added to Ti3C2Tx MXene to form TK−PW, the (002) peak continues to shift to the left, indicating that the nanoparticles prevent Ti3C2Tx MXene stacking. From the full spectrum of the XPS, it can be observed that there is a uniform distribution of Na (belonging to PW), Ti (belonging to Ti3C2Tx MXene), and C elements on the surface of TK−PW (Figure S3b).

Figure 2.

(a) SEM image of Ti3AlC2 MAX phase. (b) SEM image of Ti3C2Tx MXene film, side section. (c) SEM image of Ti3C2Tx MXene film, front. (d) EDS of Ti3C2Tx MXene film. (e) SEM image of PW. (f) SEM image of TK−PW, side section. (g) SEM image of TK−PW, front. (h) EDS of TK−PW.

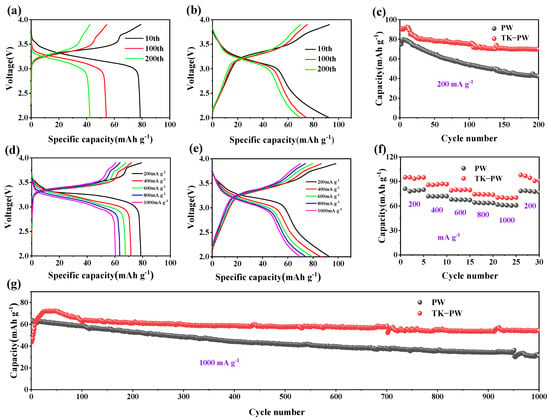

The discharge/charge voltage profiles of the PW and TK−PW cathodes at a rate of 200 mA·g−1 are shown in Figure 3a,b. The discharge capacities of the PW electrode at the 10th, 100th, and 200th cycles were found to be 78.7, 54.2, and 42.4 mAh·g−1 (Figure 3a), respectively. Similarly, the discharge capacities of the TK-PW electrode at the same cycles were 92.5, 74.8, and 69.7 mAh·g−1, respectively (Figure 3b). We can see that the electrochemical platform of the TK−PW electrode exhibited minor change with increasing cycles, indicating a lower polarization degree compared to the PW electrode. The charge and discharge curves of the TK−PW electrode appeared smoother than the PW electrode, which can be attributed to most of the PW particles being wrapped in the MXene [36]. After 200 cycles, the PW electrode’s discharge capacity decreases to 42.3 mAh·g−1, retaining 56.5% of its initial capacity (Figure 3c). The TK−PW electrode’s capacity decreases to 69.7 mAh·g−1, with a high retention rate of 74.9%, indicating that the TK−PW electrode exhibits better cyclic stability. At current densities of 200, 400, 600, 800, and 1000 mA·g−1, the discharge capacities of the PW electrode are 78.7, 71.6, 67.6, 63.5, and 60.7 mAh·g−1, respectively (Figure 3d). The specific capacities of the TK-PW electrode at the same current densities are 93.0, 86.3, 79.4, 74.1, and 69.7 mAh·g−1, respectively (Figure 3e). At a current density of 1000 mA·g−1, the PW electrode exhibits a discharge capacity that is 77.1% of the initial capacity, whereas the TK−PW electrode shows a capacity of 74.9% relative to its initial capacity. The TK−PW electrode exhibits a slightly lower capacity retention rate compared to the PW electrode, possibly due to the lack of PVDF in the TK−PW electrode, which results in less contact between the conductive agent and the active substance. Nevertheless, the specific capacity of the TK−PW electrode remains higher than that of the PW electrode at high currents. Furthermore, when the current density returns to 200 mA·g−1, the discharge capacity of the TK−PW electrode is almost the same as the initial capacity, demonstrating the good reversibility of the electrode (Figure 3f). Additionally, the long-term performance of the PW electrode and TK−PW electrode is compared at a high current density of 1000 mA·g−1. After 1000 cycles of charge and discharge, the PW electrode’s specific capacity is 31.3 mAh·g−1, while that of the TK−PW electrode is 54.1 mAh·g−1. Moreover, the cycle stability of the TK−PW electrode is significantly better than that of the PW electrode. It is worth noting that during the initial stage of the electrochemical cycle of the TK−PW electrode, there is a notable increase in capacity, which can be ascribed to the activation process resulting from the infiltration of the electrolyte into the electrode [37].

Figure 3.

Charge/discharge profiles of (a) PW and (b) TK−PW at the 10th, 100th, and 200th cycles. (c) Cycling stability at 200 mA·g−1 for PW and TK−PW. Charge/discharge profiles of (d) PW and (e) TK−PW at current densities ranging from 200 mA·g−1 to 1000 mA·g−1. (f) Rate performance at various current densities. (g) Cycling stability at 1000 mA·g−1 for PW and TK−PW.

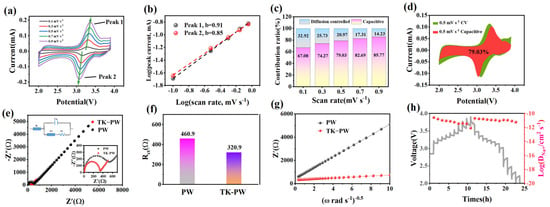

CV, EIS, and GITT tests were conducted to determine the kinetics of Na+ storage after cycling. Figure 4a shows the CV curves of the TK−PW electrode at scan rates ranging from 0.1 mV·s−1 to 0.9 mV·s−1. As the scan rate increases, due to electrode polarization, the oxidation peak moves towards higher voltage, and the reduction peak shifts towards a lower voltage. The peak current on the CV curve can be described by Equation (1):

where and are constants and is the scan rate. The value for peak 1 is 0.91, and the value for peak 2 is 0.85, both falling within the range of 0.5 to 1, especially, the value is close to 1. This suggests the occurrence of redox reactions and capacitive processes during the charge–discharge cycle, as illustrated in Figure 4b [38]. The contribution ratios of the capacitance at different scan rates is as follows: 67.08%, 74.27%, 79.03%, 82.69%, and 85.77% at scan rates of 0.1, 0.3, 0.5, 0.7, and 0.9 mV·s−1, respectively (Figure 4c). Figure 4d illustrates the calculated capacitance ratio of TK−PW at a scan rate of 0.5 mV·s−1. The cyclic voltammetry reveals that the superior performance of the TK−PW electrode is primarily attributable to the pseudocapacitance effect resulting from the nanometer-sized PW particles in the electrode [39]. EIS analysis was performed on the two electrodes after cycling. The fitted Nyquist plot of the PW electrode and TK−PW electrode after cycling is shown in Figure 4e. In the equivalent circuit in the upper left corner, Rs represents electrolyte resistance, Cdl represents a double-layer capacitor, Rct represents charge transfer resistance (area of semicircle region), and Zw is diffusion-related impedance (slope of incline line) [29]. The Rct of the PW electrode is 460.9 Ω, while the Rct of the TK−PW electrode is 320.9 Ω, according to the Nyquist plots of the high-frequency area (Figure 4e,f). Figure 4g illustrates the linear relationship between impedance at low frequencies and the inverse square root of the angular frequency on the Nyquist plot, serving to characterize the diffusion properties of ions [40]. The smaller the slope, the larger value of indicating better Na+ transfer kinetics, confirming the improved high current discharge capacity of the TK−PW electrode [41]. The GITT technique was used to further evaluate the diffusion process of Na+ in the TK−PW electrode in Figure 4h. The diffusion coefficient can be determined by the equation

where is the slope of the Warburg impedance Zw and ω−1/2, S is the contact area between the electrolyte and electrode, and F represents the Faraday constant [42]. The for the TK−PW electrode ranges between 10−12 and 10−10 cm2·s−1, better than that of the PW electrode. Therefore, it can be inferred that the MXene structure provides a larger contact area and a fast pathway for ion transfer for nanoparticles.

Figure 4.

Electrochemical kinetics and sodium storage performance of TK−PW electrode. (a) CV curves ofTK−PW at various scan rates from 0.1 to 0.9 mV s−1. (b) Analysis of values of Peak 1 and Peak2. (c) Diffusion and capacitive contribution ratios at various scan rates. (d) Pseudocapacitive fitting at 0.5 mV·s−1 for TK−PW (The red area represents theoretical pseudocapacitive capacity; the green area represents actual capacitive capacity on the CV curve). (e) Nyquist plots of PW and TK−PW (inset: the equivalent circuit modeling). (f) Charge transfer resistance of PW and TK−PW. (g) Linear relationship between ω−1/2 and Zw in the Warburg region. (h) GITT curves (Left axis: Grey curve) and Na+ diffusion coefficients (Right axis: Red curve).

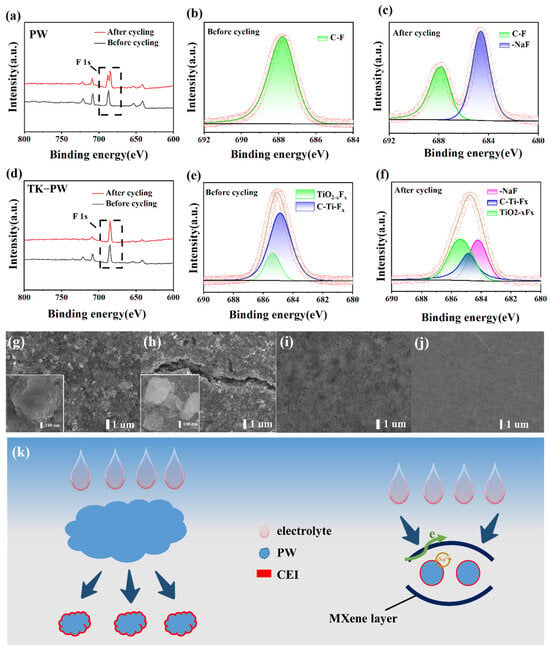

The chemical composition of the cathode/electrode interfaces (CEIs) of the PW electrode and TK−PW electrode were analyzed by XPS. As can be seen from the full spectrum of XPS of the electrodes before and after the cycle, a set of new peaks was added to F 1s of the PW electrode, while the peak height and peak width of F 1s of the TK−PW electrode changed (Figure 5a,d). Prior to the electrochemical process, there is a fitted peak in the spectrum of the PW electrode, corresponding to 687.9 eV of PVDF (Figure 5b) [43]. After the electrochemical reaction, the F 1s spectrum is divided into two peaks. In addition to the original C-F peak, a new NaF peak at 684.2 eV is added (Figure 5c) [44]. For the TK−PW electrode, before the electrochemical reaction, the F 1s spectrum can be divided into two peaks, one is the C-Ti-Fx peak at 684.9 eV, the other is the TiO2-xFx peak at 685.4 eV, both of which are derived from the Ti3C2Tx MXene (Figure 5e) [45]. After the electrochemical reaction of the TK−PW electrode, an NaF peak also appeared. NaF-containing CEIs reduce the electrolyte’s tendency to erode the active ingredient [42]. In our other work, the control electrode did not detect the appearance of an NaF peak after the electrochemical reaction, which may be attributed to the limited amount of NaF due to the short cycle charge and discharge times of the battery and the relatively thin CEI itself [44]. A small amount of NaF was detected in the experimental electrode, which was due to the high specific surface area of the nanoparticles and the full contact with the electrolyte. The change in the composition of the substance was analyzed by the peak area of the XPS peak [45]. At the early stage of the electrochemical cycle, the NaF content of the PW electrode changes very little, while at the late stage of the electrochemical cycling, the NaF content increases sharply, which indicates that as the electrochemical reaction progresses, the volume expansion of the Prussian white particles causes them to break into smaller particles, exposing the fresh PW surface to the organic electrolyte and forming a new CEI film [41,46]. For the TK−PW electrode, the content of NaF increases gently during the electrochemical reaction (Figure 5f). Ti3C2Tx MXene, distinguished by its high flexibility, partnered with nanoparticles having an elevated specific surface area, can slow the volume expansion of active substances, making it suitable for the rapid insertion and removal of Na+ [47,48]. In addition, the CEI film covered with PW nanoparticles prevents the organic electrolyte from eroding the active substance and ensures its good cycling stability [42]. The microscopic appearance of the electrode before and after the cycle can be observed by SEM. A layer of thick and elongated cracks appears on the PW electrode surface after cycling, indicating pronounced expansion of the PW electrode (Figure 5g,h). The TK−PW electrode maintains a smooth surface after circulation, with no visible cracks, indicating minimal expansion of the electrode (Figure 5i,j). Figure 5k shows the cycling mechanism of the two types of electrodes. During cycling, the PW electrode undergoes significant volume expansion, resulting in fragmentation of active particles into smaller ones and erosion by organic solvents. The TK−PW electrode, incorporating the highly flexible Ti3C2Tx MXene, effectively mitigates the volume swelling of the active substance during cycling. The CEI on the surface of the PW nanoparticles prevents electrolyte erosion and enhances the cycle stability of the active substance. Additionally, the conductive framework formed by Ti3C2Tx MXene and KetjenBlack facilitates efficient electron transfer. The close contact between the PW nanoparticles and electrolyte creates abundant Na+ migration paths, promoting rapid Na+ dynamics.

Figure 5.

(a) Full spectrum of XPS for PW cathodes before and after cycling. F 1s XPS spectra of PW (b) before cycling and (c) after cycling (red circles represents cumulative peak fitting). (d) Full spectrum of XPS for TK−PW cathodes before and after cycling. F 1s XPS spectra of TK−PW (e) before cycling and (f) after cycling. SEM image of PW (g) before cycling and (h) after cycling (inset: high resolution SEM images). SEM image of TK−PW (i) before cycling and (j) after cycling. (k) Schematic diagram of the electrochemical mechanism during the PW and TK−PW cathodes’ cycling process.

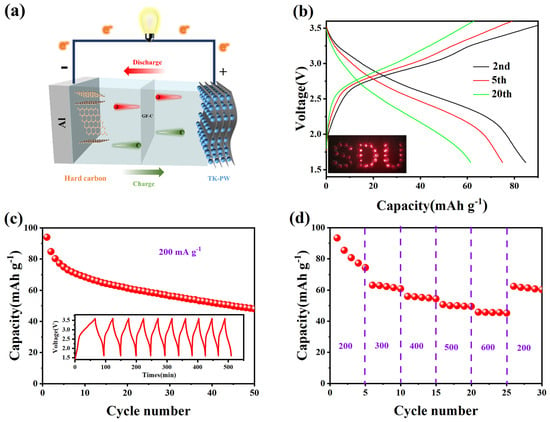

The Prussian white, which is abundant in sodium, is expected to react with the hard carbon anode to form a high-performance full battery. Figure 6a illustrates the structure of the full battery, and the experimental section provides detailed information on its preparation. The electrochemical performance of the full battery was evaluated across a voltage range of 1.6 V to 3.6 V. Prior to the charge and discharge tests of the full battery, the TK−PW cathode and hard carbon anode were pre-modified in the half battery for 3 cycles. Notably, a home-patterned “SDU” array consisting of LEDs was successfully illuminated, demonstrating its potential for various applications (inset of Figure 6b). After 50 cycles, the capacity retention rate of the full battery reached 51.6% (Figure 6c), and a charge–discharge cycle could be accomplished in approximately 46 min (inset of Figure 6c). Furthermore, the full cell exhibited excellent rate capacity, with reversible capacities of 80, 62.2, 55.3, 50.0, and 45.3 mAh·g−1 at current densities of 200, 300, 400, 500, and 600 mA·g−1, respectively (Figure 6d).

Figure 6.

Electrochemical performance of full cells based on TK−PW cathode and hard carbon anode. (a) The full battery model. (b) Charge/discharge curve at 200 mA·g-1 current density (insert: a battery-powered cluster of LEDs arranged in the shape of an “SDU”). (c) Cycling stability at 200 mA·g−1 (insert: the charge/discharge platform of the full cell). (d) Rate performance of the full battery from 200 mA·g−1 to 600 mA·g−1.

3. Conclusions

In summary, we developed a simple filtration method to prepare self-supporting electrodes without adhesives and other non-active components. This approach can alleviate the weight of the battery to some extent and improve its energy density. Given the larger interlayer spacing of Ti3C2Tx MXene, it mitigates the volume expansion caused by ion insertion and extraction during the charge and discharge process. Additionally, Prussian white nanoparticles effectively prevent MXene stacking and provide a fast Na+-transfer channel. Thus, the prepared TK−PW electrode exhibits excellent rate capability and a long cycle life. Table 1 summarizes and compares the electrochemical performance of the TK−PW and PW electrodes as well as similar electrode studies on sodium-ion batteries. Specifically, the TK−PW electrode retains 74.9% of its capacity after 200 cycles at current density of 200 mA·g−1, and its discharge capacity at a current density of 1000 mA·g−1 is 69.7 mAh·g−1. The full cell, consisting of a hard carbon anode and TK−PW cathode, retains 51.6% of its capacity after 50 cycles at a current density of 200 mA·g−1, demonstrating the practical application potential of the TK−PW.

Table 1.

Summary of electrochemical performance for TK−PW and PW electrodes as well as similar electrode studies on sodium-ion batteries.

4. Experimental Methods

4.1. Preparation of Ti3C2Tx MXene Film

Ti3C2Tx MXene film is prepared using a mild HCl/LiF etching method [55]. A volume of 20 mL of 1.2 mol/L concentrated hydrochloric acid was diluted with 4 mL of H2O, and then, reacted with 1.6 g of LiF in a Teflon reactor for 5 min. Then, the 1 g of Ti3AlC2 MAX phase was added and the reactor was stirred in a water bath at 36.5 °C for 36 h. The etched products were taken out, put into a centrifugal tube, washed until obviously expanded, and then, water was added and shaken to obtain the Ti3C2Tx MXene colloidal solution. The Ti3C2Tx MXene suspension concentrationc was about 2.2 mg/mL. The 20 mL of Ti3C2Tx MXene colloidal solution was filtered, and after the water on the surface of the filtered product evaporated, the Ti3C2Tx MXene film was formed. The preparation of thin films is based on our previous research findings [33].

4.2. Preparation of TK−PW Film

Prussian white (Na1.4Fe[Fe(CN)6]) was purchased from Sinopharm Chemical Reagent Co., Ltd., Shanghai, China. Put 16 mg of Prussian white (PW) into a ball mill and grind for 1 h. Next, mix it with 16 mg of superconducting carbon black (KetjenBlack), 4 mL of Ti3C2Tx MXene colloidal solution, and 16 mL of water. Stir the mixture for 30 min. Then, add 180 mL of anhydrous ethanol and stir for 5 min. Filter the mixture using a polyethylene diaphragm on the filter paper. Put the filter product into a 50° vacuum oven for 5 h to obtain TK−PW film.

4.3. Materials Characterization

The physical components of the composite were analyzed using XRD diffraction (XRD, MiniFlex 600, Cu-Kα radiation, Tokyo, Japan). The material’s chemical composition was examined through X-ray photoelectron spectroscopy (XPS, Axis Supra, Al-Kα source, Japan). The microscopic morphology of the substance was observed using a scanning electron microscope (SEM, JSM-7610F, Tokyo, Japan). The element distribution on the material surface was acquired using energy dispersive spectrometer (EDS, X-max, Oxford, UK).

4.4. Electrochemical Characterization

The TK−PW was cut into discs with a diameter of 10 mm, which served as the cathode of the sodium-ion battery. The electrolyte used was NaClO4 with ethylene carbonate (EC) and diethyl carbonate (DEC) (1:1 by volume), followed by the addition of 10% fluoroethylene carbonate (FEC). Each TK−PW electrode had an active material load of approximately 0.5 mg. In detail, the TK−PW electrode was assembled with a glass-fiber diaphragm (16 mm diameter), and sodium foil (14.4 mm diameter) inside an Ar-filled glove box. For the basic PW-Na batteries, the PW electrode contained 70 wt% active material, 20 wt% Super-p, and 10 wt% polyvinylidene fluoride (PVDF), which were mixed in N-methyl-2-pyrrolidone (NMP) for 24 h. The mixture was evenly coated on aluminum foil, and then, placed in a vacuum oven at 80 °C for 8 h. All electrodes were cut to small plates with a diameter of 10 mm, and each had an active material load of approximately 0.7–0.9 mg/cm2. Coin-type (CR2032) cells were assembled in an Ar-filled glove box, with the same electrolyte, diaphragm, and Na anode as the TK−PW-Na batteries. The charge/discharge performance of the battery was assessed using a battery system (CT-4008 Netware) within the potential range of 2.0 to 3.9 V. Cyclic voltammetry (CV) curves (between 2.0 and 3.9 V) and electrochemical impedance spectra (EIS) (frequency of 0.01–106 Hz) were evaluated by a CHI660E electrochemical workstation with various scan rates.

Supplementary Materials

The Supporting Information is available free of charge at https://www.mdpi.com/article/10.3390/molecules29133048/s1. Figure S1: SEM and EDS of PW. Figure S2: The XRD of Ti3C2Tx and Ti3AlC2. Figure S3: The XRD and XPS of PW and TK−PW.

Author Contributions

Conceptualization, X.D. and J.C.; methodology, X.W.; data curation, X.D. and T.X.; validation, J.C. and X.W.; investigation, C.W.; writing—original draft preparation, X.D. and J.C.; supervision. Z.W.; project administration, J.F. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Taishan Scholars Program of Shandong Province (Nos. tsqn201812002, ts20190908 and ts201511004), the Natural Science Foundation of Shandong Province (No. ZR2020JQ19), the Young Scholars Program of Shandong University (No. 2016WLJH03).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article and Supplementary Materials.

Conflicts of Interest

Author Jingyun Chun was employed by the Jiaxing Power Supply Company, State Grid Zhejiang Electric Power Co., Ltd. Author Jingyun Chun declares no conflicts of interest. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Kandari, R.; Neeraj, N.; Micallef, A. Review on recent strategies for integrating energy storage systems in microgrids. Energies 2022, 16, 317. [Google Scholar] [CrossRef]

- Hjalmarsson, J.; Thomas, K.; Boström, C. Service stacking using energy storage systems for grid applications–A review. J. Energy Storage 2023, 60, 106639. [Google Scholar] [CrossRef]

- Huang, B.; Pan, Z.; Su, X.; An, L. Recycling of lithium-ion batteries: Recent advances and perspectives. J. Power Sources 2018, 399, 274–286. [Google Scholar] [CrossRef]

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature effect and thermal impact in lithium-ion batteries: A review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666. [Google Scholar] [CrossRef]

- Yao, Y.; Zhu, M.; Zhao, Z.; Tong, B.; Fan, Y.; Hua, Z. Hydrometallurgical Processes for Recycling Spent Lithium-Ion Batteries: A Critical Review. ACS Sustain. Chem. Eng. 2018, 6, 13611–13627. [Google Scholar] [CrossRef]

- Xu, M.; Liu, M.; Yang, Z.; Wu, C.; Qian, J. Research Progress on Presodiation Strategies for High Energy Sodium-Ion Batteries. Acta Phys. Chim. Sin. 2022, 39, 2210043. [Google Scholar] [CrossRef]

- Huang, Z.-X.; Gu, Z.-Y.; Heng, Y.-L.; Huixiang Ang, E.; Geng, H.-B.; Wu, X.-L. Advanced layered oxide cathodes for sodium/potassium-ion batteries: Development, challenges and prospects. Chem. Eng. J. 2023, 452, 139438. [Google Scholar] [CrossRef]

- Lin, X.-M.; Yang, X.-T.; Chen, H.-N.; Deng, Y.-L.; Chen, W.-H.; Dong, J.-C.; Wei, Y.-M.; Li, J.-F. In situ characterizations of advanced electrode materials for sodium-ion batteries toward high electrochemical performances. J. Energy Chem. 2023, 76, 146–164. [Google Scholar] [CrossRef]

- Zhang, L.; Li, X.; Yang, M.; Chen, W. High-safety separators for lithium-ion batteries and sodium-ion batteries: Advances and perspective. Energy Storage Mater. 2021, 41, 522–545. [Google Scholar] [CrossRef]

- Lee, H.W.; Wang, R.Y.; Pasta, M.; Woo Lee, S.; Liu, N.; Cui, Y. Manganese hexacyanomanganate open framework as a high-capacity positive electrode material for sodium-ion batteries. Nat. Commun. 2014, 5, 5280. [Google Scholar] [CrossRef]

- Oz, E.; Altin, S.; Avci, S. Investigation of physical and electrochemical properties of Ni-doped Tunnel/P2 hybrid Na0.44MnO2 cathode material for sodium-ion batteries. J. Solid State Chem. 2023, 318, 123741. [Google Scholar] [CrossRef]

- Liu, Q.; Hu, Z.; Li, W.; Zou, C.; Jin, H.; Wang, S.; Chou, S.; Dou, S.-X. Sodium transition metal oxides: The preferred cathode choice for future sodium-ion batteries? Energy Environ. Sci. 2021, 14, 158–179. [Google Scholar] [CrossRef]

- Pahari, D.; Kumar, A.; Das, D.; Puravankara, S. P2-type NaxTmO2 oxides as cathodes for non-aqueous sodium-ion batteries—Structural evolution and commercial prospects. Int. J. Energy Res. 2022, 46, 21894–21927. [Google Scholar] [CrossRef]

- Lv, Z.; Ling, M.; Yue, M.; Li, X.; Song, M.; Zheng, Q.; Zhang, H. Vanadium-based polyanionic compounds as cathode materials for sodium-ion batteries: Toward high-energy and high-power applications. J. Energy Chem. 2021, 55, 361–390. [Google Scholar] [CrossRef]

- Wu, H.; Chen, Y.; Wen, T.; Chen, L.; Pu, X.; Chen, Z. Advances in Vanadium-Redoxed Polyanions for High-Voltage Sodium-Ion Batteries. Batteries 2023, 9, 56. [Google Scholar] [CrossRef]

- Lu, Y.; Wang, L.; Cheng, J.; Goodenough, J.B. Prussian blue: A new framework of electrode materials for sodium batteries. Chem. Commun. 2012, 48, 6544–6546. [Google Scholar] [CrossRef] [PubMed]

- Xie, B.; Sun, B.; Gao, T.; Ma, Y.; Yin, G.; Zuo, P. Recent progress of Prussian blue analogues as cathode materials for nonaqueous sodium-ion batteries. Coord. Chem. Rev. 2022, 460, 214478. [Google Scholar] [CrossRef]

- Wang, H.g.; Zhang, X.b. Organic carbonyl compounds for sodium-ion batteries: Recent progress and future perspectives. Chem.–A Eur. J. 2018, 24, 18235–18245. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Q.; Whittaker, A.K.; Zhao, X.S. Polymer Electrode Materials for Sodium-ion Batteries. Materials 2018, 11, 2567. [Google Scholar] [CrossRef] [PubMed]

- Fu, H.; Xia, M.; Qi, R.; Liang, X.; Zhao, M.; Zhang, Z.; Lu, X.; Cao, G. Improved rate performance of Prussian blue cathode materials for sodium ion batteries induced by ion-conductive solid-electrolyte interphase layer. J. Power Sources 2018, 399, 42–48. [Google Scholar] [CrossRef]

- Lim, C.Q.X.; Tan, Z.-K. Prussian White with Near-Maximum Specific Capacity in Sodium-Ion Batteries. ACS Appl. Energy Mater. 2021, 4, 6214–6220. [Google Scholar] [CrossRef]

- Nielsen, I.; Dzodan, D.; Ojwang, D.O.; Henry, P.F.; Ulander, A.; Ek, G.; Häggström, L.; Ericsson, T.; Boström, H.L.B.; Brant, W.R. Water driven phase transitions in Prussian white cathode materials. J. Phys. Energy 2022, 4, 044012. [Google Scholar] [CrossRef]

- Li, C.; Zang, R.; Li, P.; Man, Z.; Wang, S.; Li, X.; Wu, Y.; Liu, S.; Wang, G. High Crystalline Prussian White Nanocubes as a Promising Cathode for Sodium-ion Batteries. Chem. Asian J. 2018, 13, 342–349. [Google Scholar] [CrossRef] [PubMed]

- Song, W.-L.; Li, X.; Fan, L.-Z. Biomass derivative/graphene aerogels for binder-free supercapacitors. Energy Storage Mater. 2016, 3, 113–122. [Google Scholar] [CrossRef]

- Ma, P.; Fang, D.; Liu, Y.; Shang, Y.; Shi, Y.; Yang, H.Y. MXene-Based Materials for Electrochemical Sodium-Ion Storage. Adv. Sci. 2021, 8, e2003185. [Google Scholar] [CrossRef] [PubMed]

- Lei, Y.-J.; Yan, Z.-C.; Lai, W.-H.; Chou, S.-L.; Wang, Y.-X.; Liu, H.-K.; Dou, S.-X. Tailoring MXene-Based Materials for Sodium-Ion Storage: Synthesis, Mechanisms, and Applications. Electrochem. Energy Rev. 2020, 3, 766–792. [Google Scholar] [CrossRef]

- Xu, H.; Fan, J.; Pang, D.; Zheng, Y.; Chen, G.; Du, F.; Gogotsi, Y.; Dall’Agnese, Y.; Gao, Y. Synergy of ferric vanadate and MXene for high performance Li- and Na-ion batteries. Chem. Eng. J. 2022, 436, 135012. [Google Scholar] [CrossRef]

- Yang, J.; Wang, T.; Guo, X.; Sheng, X.; Li, J.; Wang, C.; Wang, G. Flexible sodium-ion capacitors boosted by high electrochemically-reactive and structurally-stable Sb2S3 nanowire/Ti3C2Tx MXene film anodes. Nano Res. 2021, 16, 5592–5600. [Google Scholar] [CrossRef]

- Sun, N.; Zhu, Q.; Anasori, B.; Zhang, P.; Liu, H.; Gogotsi, Y.; Xu, B. MXene-Bonded Flexible Hard Carbon Film as Anode for Stable Na/K-Ion Storage. Adv. Funct. Mater. 2019, 29, 1906282. [Google Scholar] [CrossRef]

- Xiao, S.; Zhang, X.; Zhang, J.; Wu, S.; Wang, J.; Chen, J.S.; Li, T. Enhancing the lithium storage capabilities of TiO2 nanoparticles using delaminated MXene supports. Ceram. Int. 2018, 44, 17660–17666. [Google Scholar] [CrossRef]

- Yang, C.; Wu, Q.; Cao, Y.; Gao, Y.; Li, A.; Liu, X.; Zhang, X.; Tian, Z.; Liu, R. α-MnO2/super-P with conductive carbon network for rechargeable aqueous Zinc ion batteries. Mater. Lett. 2021, 302, 130419. [Google Scholar] [CrossRef]

- Murali, G.; Reddy Modigunta, J.K.; Park, Y.H.; Lee, J.H.; Rawal, J.; Lee, S.Y.; In, I.; Park, S.J. A Review on MXene Synthesis, Stability, and Photocatalytic Applications. ACS Nano 2022, 16, 13370–13429. [Google Scholar] [CrossRef] [PubMed]

- Chun, J.; Wang, X.; Wei, C.; Wang, Z.; Zhang, Y.; Feng, J. Flexible and free-supporting Prussian blue analogs/MXene film for high-performance sodium-ion batteries. J. Power Sources 2023, 576, 233165. [Google Scholar] [CrossRef]

- Zhang, W.X.; Zhang, J.H.; Zhang, Y.K.; He, C.; Zhao, P. NiS2 nanoparticles anchored on MXene conductive frameworks with enhanced lithium and sodium storage properties. Ionics 2022, 28, 4621–4629. [Google Scholar] [CrossRef]

- Wei, C.; Xi, B.; Wang, P.; Wang, Z.; An, X.; Li, Y.; Feng, J.; Xiong, S. Rapid Growth of Bi2Se3 Nanodots on MXene Nanosheets at Room Temperature for Promoting Sulfur Redox Kinetics. Inorg. Chem. 2024, 63, 8853–8862. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhang, Y.; Jiang, H.; Wei, C.; An, Y.; Tan, L.; Xiong, S.; Feng, J. Free-standing Na2C6O6/MXene composite paper for high-performance organic sodium-ion batteries. Nano Res. 2023, 16, 458–465. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, P.; Li, S.; Zhou, C.; Guo, S.; Liu, J.; Zhou, J.; Jian, X.; Yang, Y.; Lei, Y.; et al. Nitrogen-doped carbon-wrapped porous FeMnO3 nanocages derived from etched prussian blue analogues as high-performance anode for lithium ion batteries. J. Power Sources 2020, 475, 228683. [Google Scholar] [CrossRef]

- Chen, Y.; Woo, H.J.; Syed Mohd Fadzil, S.A.F.; Tan, W.; Wang, F.; Mohd Arof, A.K. Cage-Like Porous Prussian Blue as High-Capacity Cathode for Sodium-Ion Batteries. ACS Appl. Nano Mater. 2022, 5, 4833–4840. [Google Scholar] [CrossRef]

- Cheng, F.; Liang, J.; Tao, Z.; Chen, J. Functional materials for rechargeable batteries. Adv. Mater. 2011, 23, 1695–1715. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Zheng, H.; Wang, S.; Chen, X.; Yang, S.; Feng, C. Construction of Na3V2(PO4)3/C nanoplate as cathode for stable sodium ion storage. Ionics 2022, 28, 981–988. [Google Scholar] [CrossRef]

- Xie, B.; Wang, L.; Li, H.; Huo, H.; Cui, C.; Sun, B.; Ma, Y.; Wang, J.; Yin, G.; Zuo, P. An interface-reinforced rhombohedral Prussian blue analogue in semi-solid state electrolyte for sodium-ion battery. Energy Storage Mater. 2021, 36, 99–107. [Google Scholar] [CrossRef]

- Ye, M.; You, S.; Xiong, J.; Yang, Y.; Zhang, Y.; Li, C.C. In-situ construction of a NaF-rich cathode–electrolyte interface on Prussian blue toward a 3000-cycle-life sodium-ion battery. Mater. Today Energy 2022, 23, 100898. [Google Scholar] [CrossRef]

- Chun, J.; Wang, X.; Zhang, Y.; Wei, C.; Wang, Z.; Feng, J. Ti3C2Tx film current collectors for high-performance sodium-ion batteries. Vacuum 2023, 207, 111476. [Google Scholar] [CrossRef]

- Zhang, N.; Wang, B.; Jin, F.; Chen, Y.; Jiang, Y.; Bao, C.; Tian, J.; Wang, J.; Xu, R.; Li, Y.; et al. Modified cathode-electrolyte interphase toward high-performance batteries. Cell Rep. Phys. Sci. 2022, 3, 101197. [Google Scholar] [CrossRef]

- You, Y.; He, Z. Phenol degradation in iron-based advanced oxidation processes through ferric reduction assisted by molybdenum disulfide. Chemosphere 2023, 312, 137278. [Google Scholar] [CrossRef] [PubMed]

- ur Rehman, W.; Jiang, Z.; Qu, Z.; Ahmed, S.; Ghani, A.; Xu, Y. Highly crystalline Prussian blue cubes filled with tin oxide as anode materials for lithium-ion batteries. Appl. Surf. Sci. 2022, 604, 154533. [Google Scholar] [CrossRef]

- Fu, B.; Man, H.; Zhao, J.; Wang, F.; Fang, F.; Sun, D.; Song, Y. Less Is More: High-Performance All-Solid-State Electrode Enabled by Multifunctional MXene. ACS Appl. Energy Mater. 2022, 5, 7210–7219. [Google Scholar] [CrossRef]

- Ye, W.; Yu, L.; Sun, M.; Cheng, G.; Fu, S.; Peng, S.; Han, S.; Yang, X. Yolk−shell Prussian blue analogues hierarchical microboxes: Controllably exposing active sites toward enhanced cathode performance for lithium ion batteries. Electrochim. Acta 2019, 319, 237–244. [Google Scholar] [CrossRef]

- Shen, Z.; Guo, S.; Liu, C.; Sun, Y.; Chen, Z.; Tu, J.; Liu, S.; Cheng, J.; Xie, J.; Cao, G. Na-rich Prussian white cathodes for long-life sodium-ion batteries. ACS Sustain. Chem. Eng. 2018, 6, 16121–16129. [Google Scholar] [CrossRef]

- Ren, W.; Zhu, Z.; Qin, M.; Chen, S.; Yao, X.; Li, Q.; Xu, X.; Wei, Q.; Mai, L.; Zhao, C. Prussian white hierarchical nanotubes with surface-controlled charge storage for sodium-ion batteries. Adv. Funct. Mater. 2019, 29, 1806405. [Google Scholar] [CrossRef]

- Tang, X.; Liu, H.; Su, D.; Notten, P.H.; Wang, G. Hierarchical sodium-rich Prussian blue hollow nanospheres as high-performance cathode for sodium-ion batteries. Nano Res. 2018, 11, 3979–3990. [Google Scholar] [CrossRef]

- Wang, L.; Lu, Y.; Liu, J.; Xu, M.; Cheng, J.; Zhang, D.; Goodenough, J.B. A superior low-cost cathode for a Na-ion battery. Angew. Chem. 2013, 125, 2018. [Google Scholar] [CrossRef]

- Li, W.-J.; Chou, S.-L.; Wang, J.-Z.; Kang, Y.-M.; Wang, J.-L.; Liu, Y.; Gu, Q.-F.; Liu, H.-K.; Dou, S.-X. Facile method to synthesize Na-enriched Na1+xFeFe(CN)6 frameworks as cathode with superior electrochemical performance for sodium-ion batteries. Chem. Mater. 2015, 27, 1997–2003. [Google Scholar] [CrossRef]

- Jiang, Y.; Yu, S.; Wang, B.; Li, Y.; Sun, W.; Lu, Y.; Yan, M.; Song, B.; Dou, S. Prussian blue@ C composite as an ultrahigh-rate and long-life sodium-ion battery cathode. Adv. Funct. Mater. 2016, 26, 5315–5321. [Google Scholar] [CrossRef]

- Zhang, T.; Pan, L.; Tang, H.; Du, F.; Guo, Y.; Qiu, T.; Yang, J. Synthesis of two-dimensional Ti3C2Tx MXene using HCl + LiF etchant: Enhanced exfoliation and delamination. J. Alloys Compd. 2017, 695, 818–826. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).