Effect of Fiber Loading on Mechanical and Flame-Retardant Properties of Poplar-Fiber-Reinforced Gypsum Composites

Abstract

1. Introduction

2. Experimental Study

2.1. Experimental Raw Materials

2.2. Test Equipment and Instruments

2.3. Composite Material Preparation

2.4. Performance Testing and Characterization

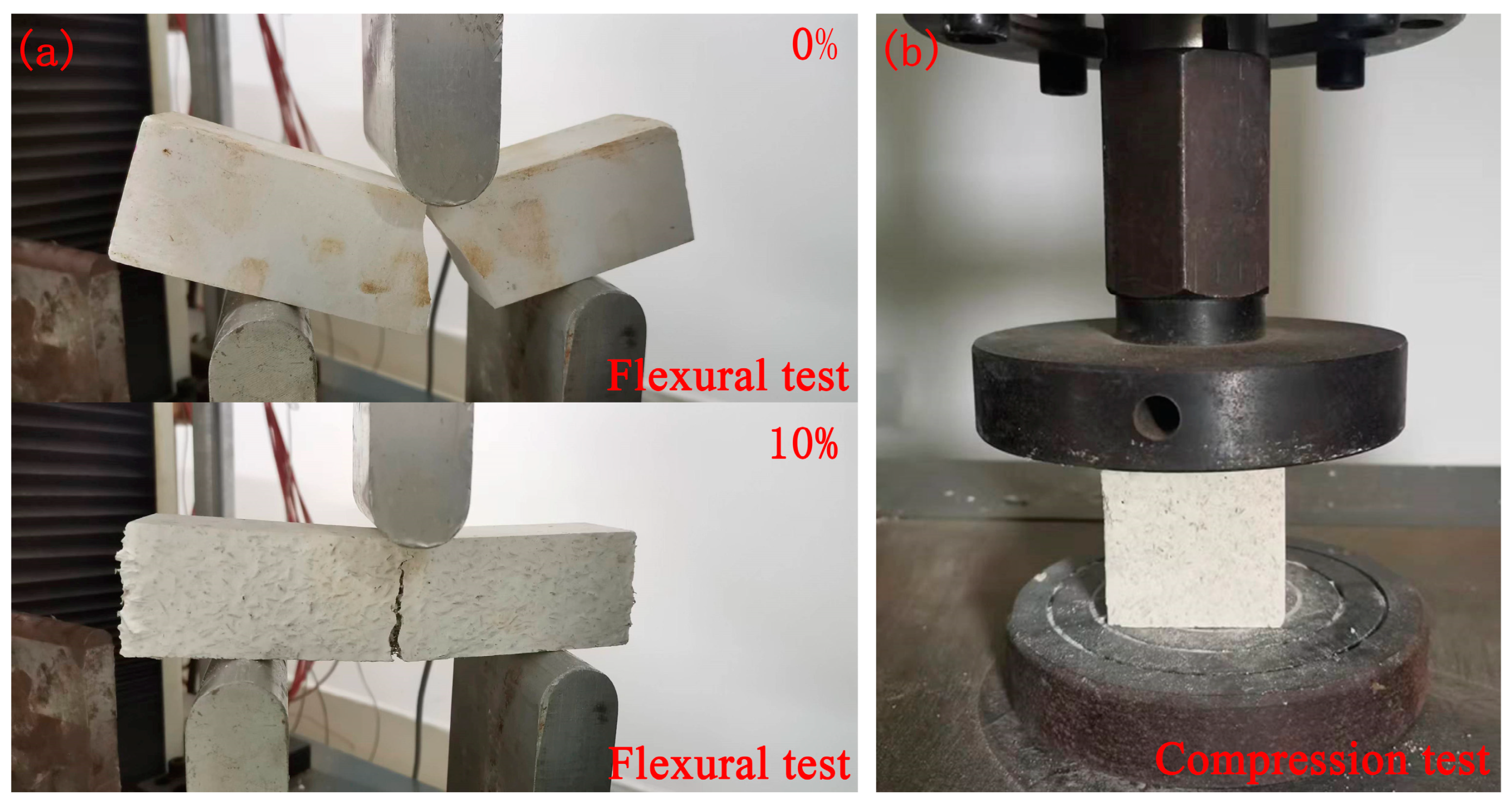

2.4.1. Mechanical Properties Testing

2.4.2. Water Resistance Test

2.4.3. X-ray Diffraction Analysis (XRD)

2.4.4. Fourier Infrared-Spectroscopy Analysis (FT-IR)

2.4.5. SEM Analysis

2.4.6. Cone Calorimetric Analysis

3. Results and Discussion

3.1. Effects of Poplar Fiber Content on Composite Mechanical Properties

3.2. Effects of Curing Time on Composite Physical and Mechanical Properties

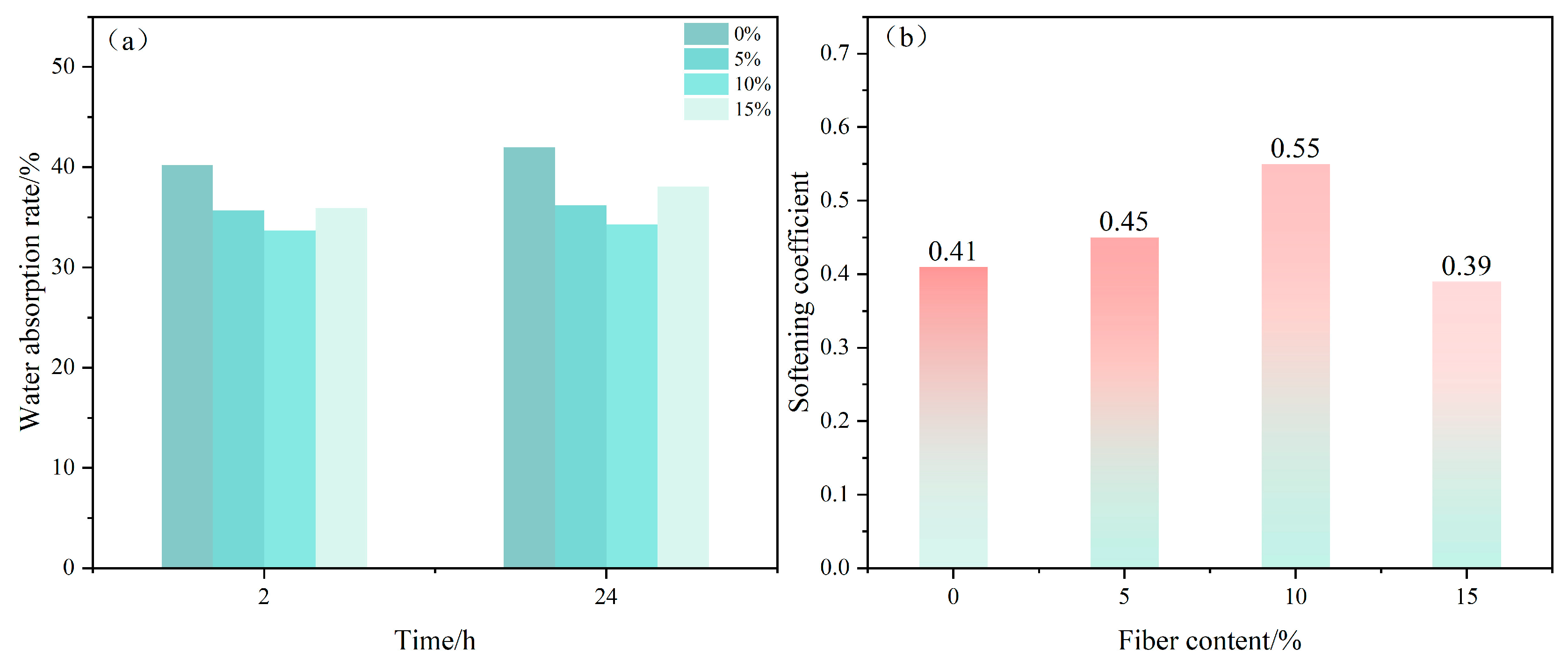

3.3. Water Resistance Test of Poplar Fiber Content on Composites

3.4. XRD Analysis of Poplar-Fiber-Reinforced Gypsum-Based Composites

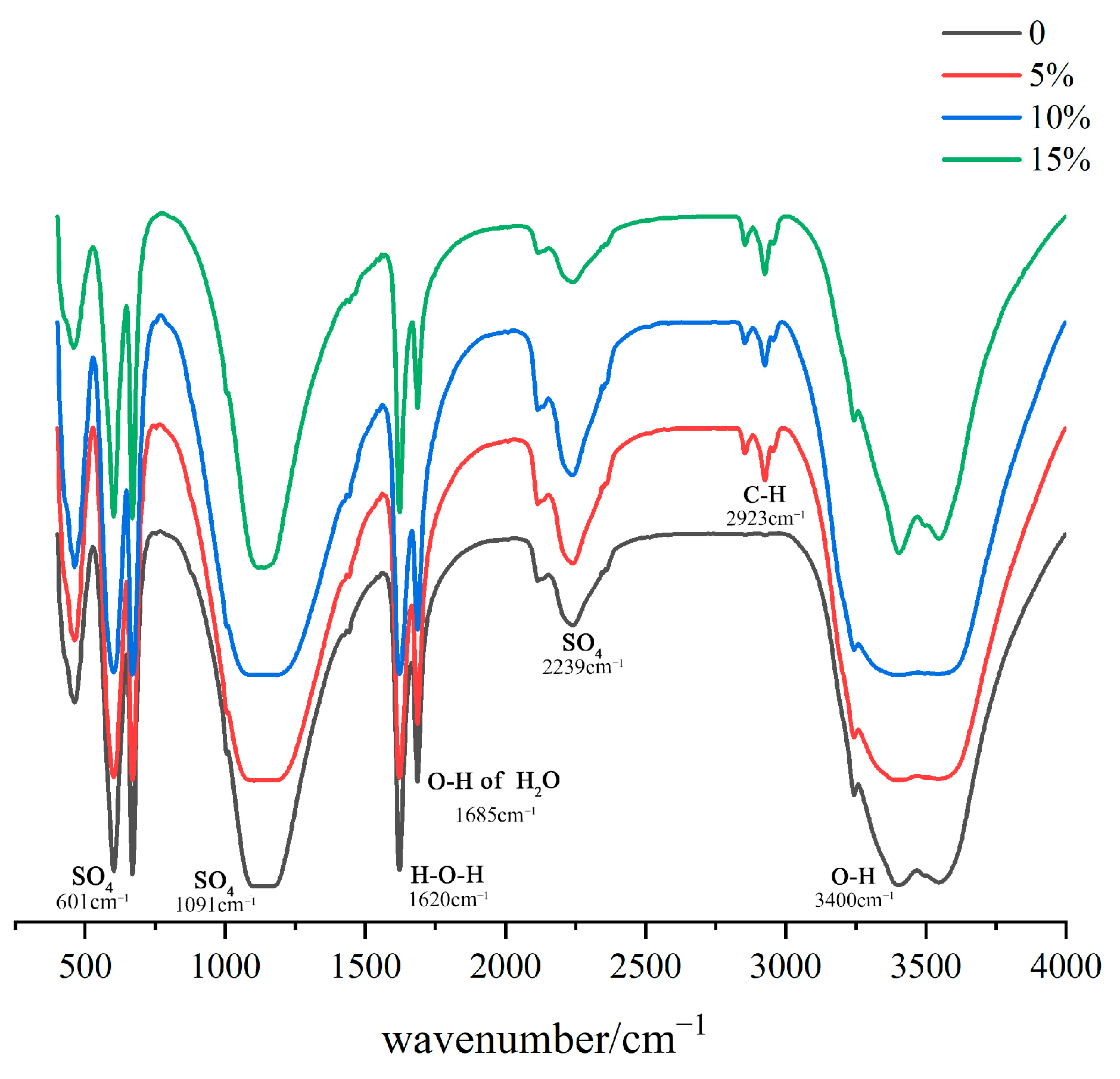

3.5. FT-IR Analysis of Poplar-Fiber-Reinforced Gypsum-Based Composites

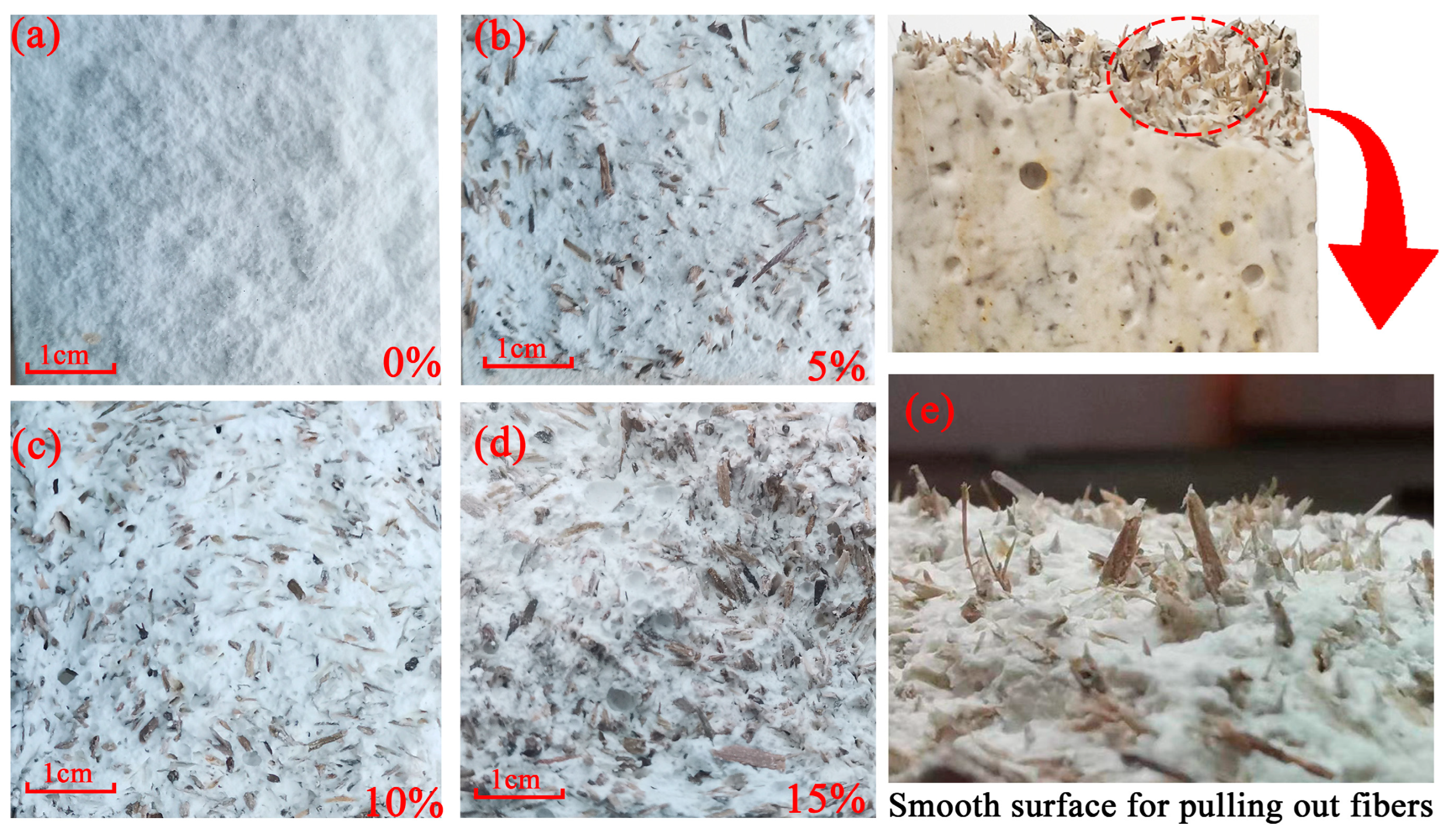

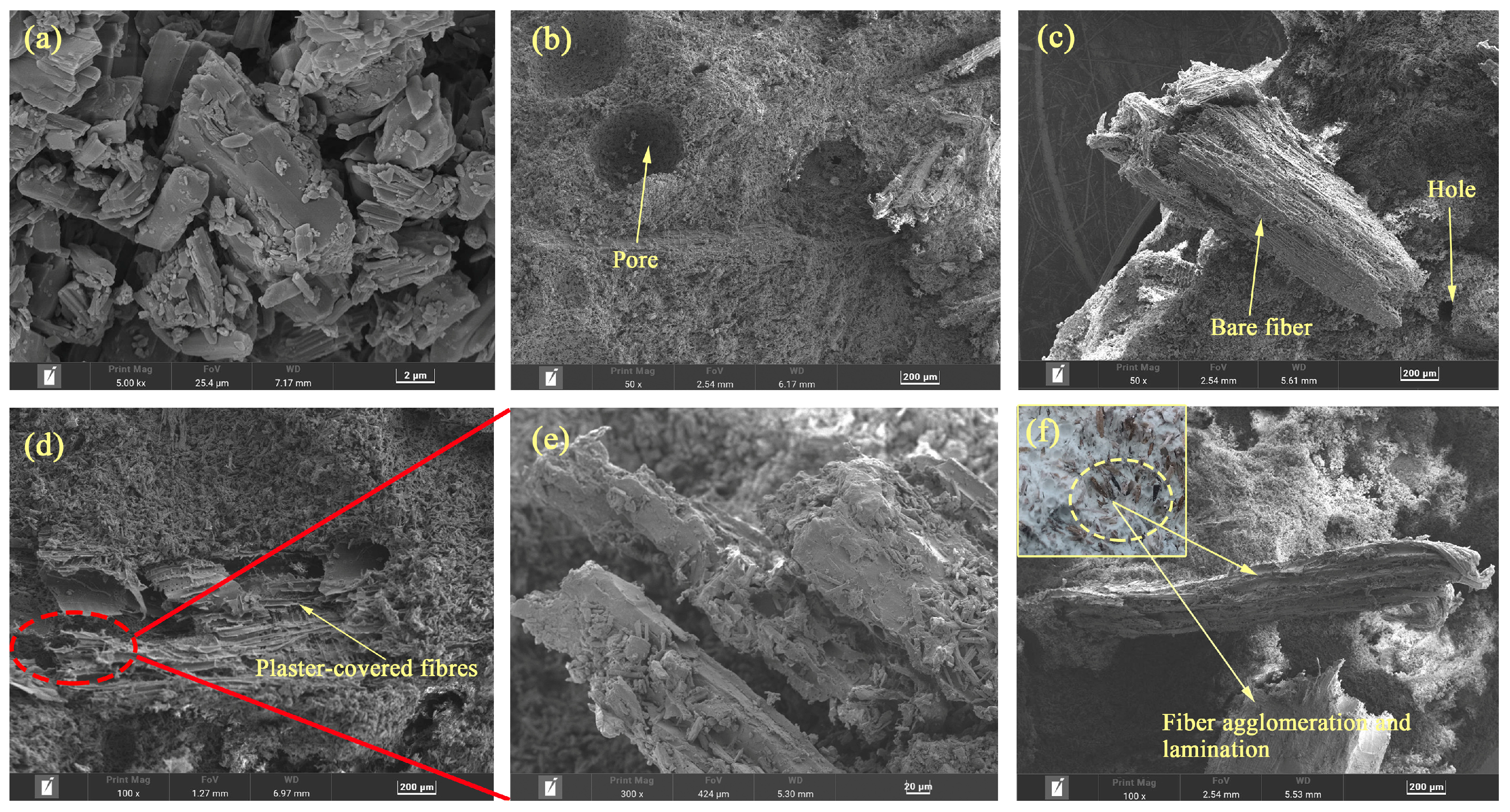

3.6. SEM Analysis of Poplar-Fiber-Reinforced Composites

3.7. Effects of Poplar Fiber Content on Flame-Retardant and Smoke Suppression Properties of Composites

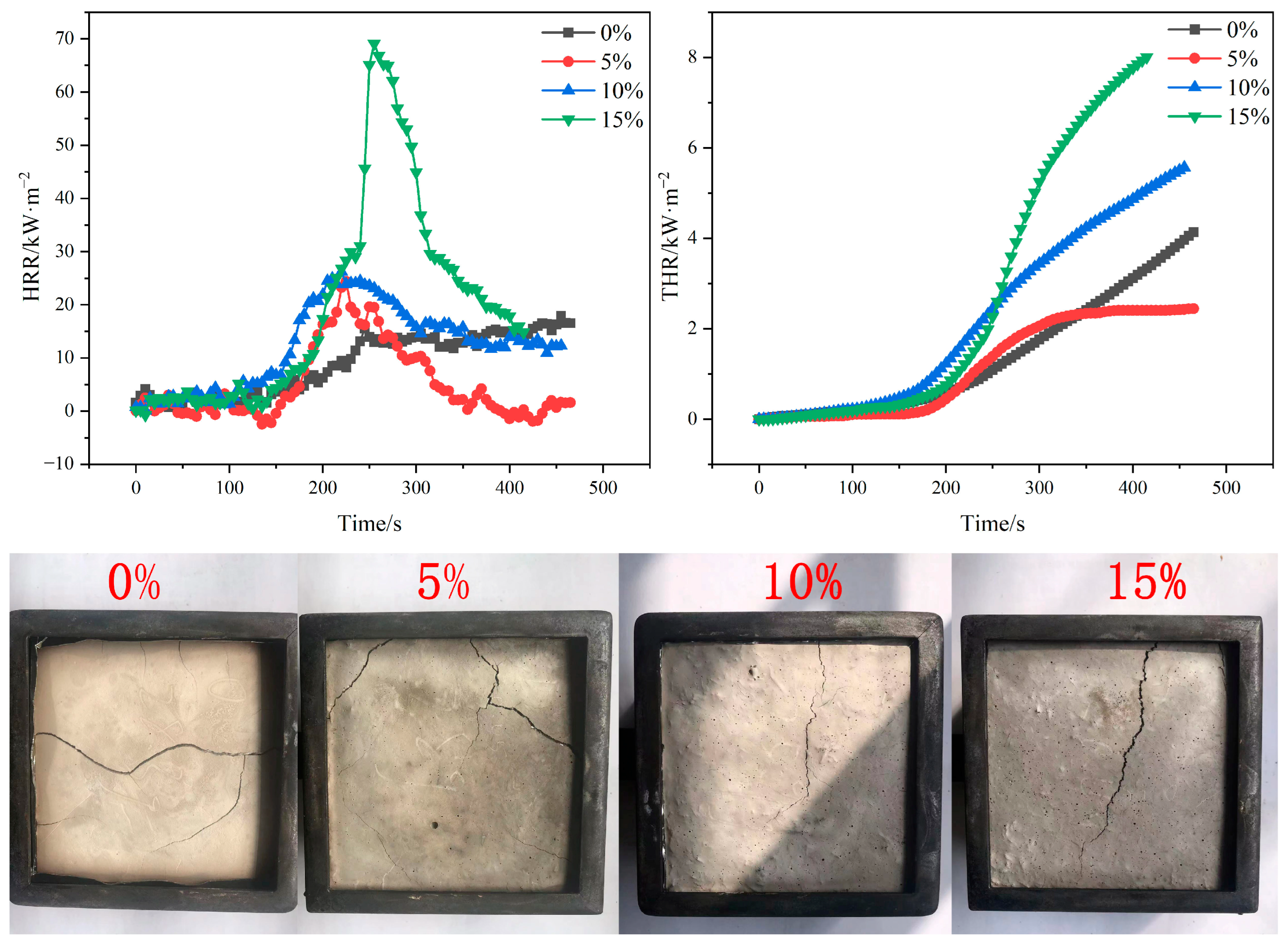

3.7.1. HRR and THR Analysis

3.7.2. Smoke Generation Rate and Total Smoke Generation

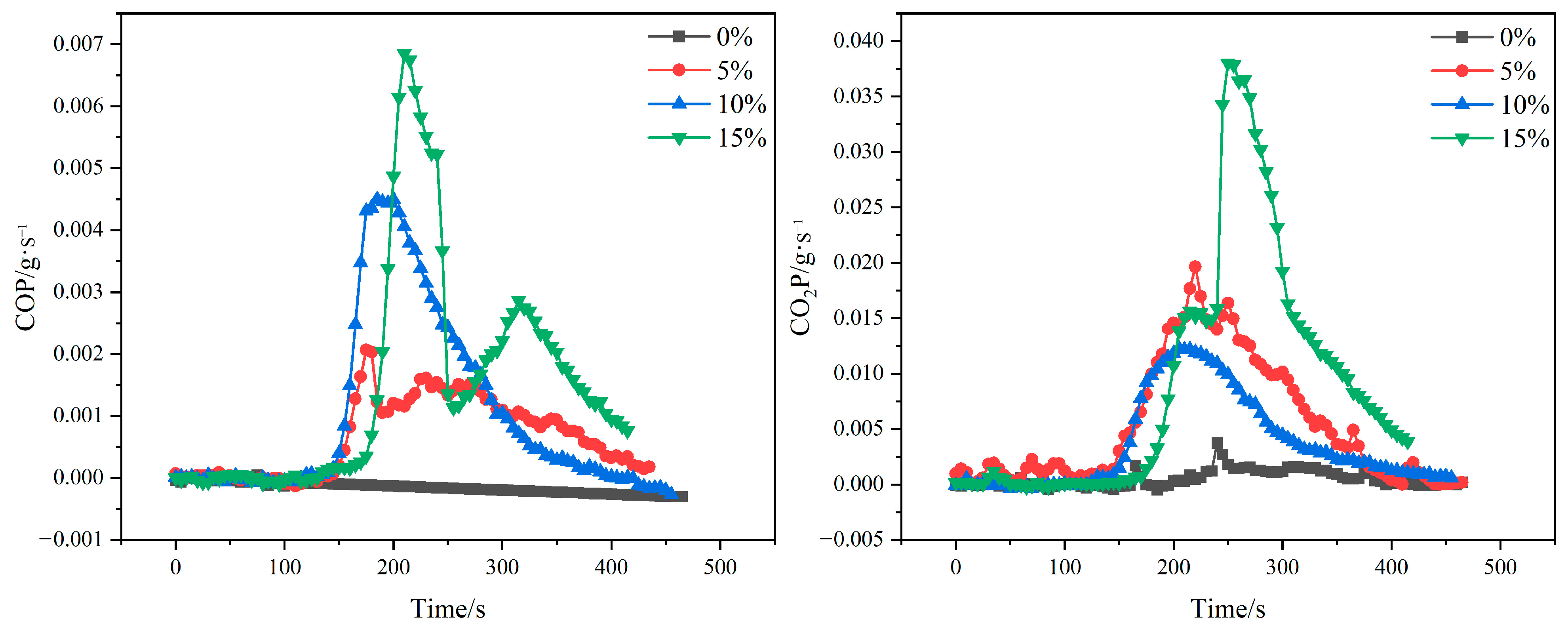

3.7.3. Carbon Monoxide Release Rate (COP) and Carbon Dioxide Release Rate (CO2P)

4. Conclusions

- The mechanical strength of gypsum-based composites increased and then decreased with increased poplar fiber content, with the mechanical strength and water resistance of the material reaching a peak with 10-wt% fiber content Among the examined composites, the 2 h flexural and compressive strengths were 2.1 and 3.48 MPa, respectively, reaching a 2.0 grade in the scale of GB/T 9776-2008 building plaster.

- The combination of poplar fibers and gypsum base was only a physical bonding, with no chemical reactions and no new material produced.

- The addition of poplar fibers reduced composite brittleness and enhanced crack resistance. Although the poplar-fiber-reinforced gypsum-based composites exhibited improved mechanical properties, it was not much.

- The bonding state of poplar fiber and gypsum surface shows a positive correlation with the mechanical strength, and the closer the internal structure of the composite material is connected, the more obvious its mechanical properties will be improved.

- The pk-HRR and THR of gypsum-based composites gradually increased with increased fiber. The appropriate amount of fiber formed a good cohesive phase with the gypsum matrix to play a flame-retardant effect and reduce TSR.

- Partial charring of poplar fibers during combustion forms a carbonized layer, which slows down the release of CO and CO2 from the composite material, and at the same time, the crystalline water in the gypsum crystals forms water vapor under the action of heat and reduces the oxygen concentration, which leads to the intensification of incomplete combustion of the composite material.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eve, S.; Gomina, M.; Gmouh, A.; Samdi, A.; Moussa, R.; Orange, G. Microstructural and mechanical behaviour of polyamide fibre-reinforced plaster composites. J. Eur. Ceram. Soc. 2002, 22, 2269–2275. [Google Scholar] [CrossRef]

- Çolak, A. Physical and mechanical properties of polymer-plaster composites. Mater. Lett. 2006, 60, 1977–1982. [Google Scholar] [CrossRef]

- Guna, V.; Yadav, C.; Maithri, B.R.; Ilangovan, M.; Touchaleaume, F.; Saulnier, B.; Grohens, Y.; Reddy, N. Wool and coir fiber reinforced gypsum ceiling tiles with enhanced stability and acoustic and thermal resistance. J. Build. Eng. 2021, 41, 102433. [Google Scholar] [CrossRef]

- Boquera, L.; Olacia, E.; Fabiani, C.; Pisello, A.L.; D’Alessandro, A.; Ubertini, F.; Cabeza, L.F. Thermo-acoustic and mechanical characterization of novel bio-based plasters: The valorisation of lignin as by-product from biomass extraction for green building applications. Constr. Build. Mater. 2021, 278, 122373. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Kazemian, M.; Shafei, B. Mechanical properties of hybrid fiber-reinforced concretes made with low dosages of synthetic fibers. Struct. Concr. 2022, 24, 1226–1243. [Google Scholar] [CrossRef]

- Muhammad Salman, N.; Ma, G.; Ijaz, N.; Wang, L. Importance and potential of cellulosic materials and derivatives in extrusion-based 3D concrete printing (3DCP): Prospects and challenges. Constr. Build. Mater. 2021, 291, 123281. [Google Scholar] [CrossRef]

- Jozwiak-Niedzwiedzka, D.; Fantilli, A.P. Wool-Reinforced Cement Based Composites. Materials 2020, 13, 3590. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, J.; Peng, J.; Cao, W.; Liu, J. Physical and mechanical properties of gypsum-based composites reinforced with PVA and PP fibers. Constr. Build. Mater. 2018, 163, 695–705. [Google Scholar] [CrossRef]

- Wang, S.; Mallick, R.B.; Rahbar, N. Toughening mechanisms in polypropylene fiber-reinforced asphalt mastic at low temperature. Constr. Build. Mater. 2020, 248, 118690. [Google Scholar] [CrossRef]

- Iucolano, F.; Boccarusso, L.; Langella, A. Hemp as eco-friendly substitute of glass fibres for gypsum reinforcement: Impact and flexural behaviour. Compos. Part B-Eng. 2019, 175, 107073. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Aprea, P.; Caputo, D. Evaluation of bio-degummed hemp fibers as reinforcement in gypsum plaster. Compos. Part B Eng. 2018, 138, 149–156. [Google Scholar] [CrossRef]

- Yldzel, S.A. Material Properties of Basalt-Fiber-Reinforced Gypsum-Based Composites Made with Metakaolin and Silica Sand. Mech. Compos. Mater. 2020, 56, 379–388. [Google Scholar] [CrossRef]

- Medina, N.F.; Barbero-Barrera, M.M. Mechanical and physical enhancement of gypsum composites through a synergic work of polypropylene fiber and recycled isostatic graphite filler. Constr. Build. Mater. 2017, 131, 165–177. [Google Scholar] [CrossRef]

- Suárez, F.; Felipe-Sesé, L.; Díaz, F.; Gálvez, J.; Alberti, M. On the fracture behaviour of fibre-reinforced gypsum using micro and macro polymer fibres. Constr. Build. Mater. 2020, 244, 118347. [Google Scholar] [CrossRef]

- Alcaraz, J.S.; Belda, I.M.; Sanchis, E.J.; Borrell, J.M.G. Mechanical properties of plaster reinforced with yute fabrics. Compos. Part B-Eng. 2019, 178, 107390. [Google Scholar] [CrossRef]

- Fatma, N.; Allegue, L.; Salem, M.; Zitoune, R.; Zidi, M. The effect of doum palm fibers on the mechanical and thermal properties of gypsum mortar. J. Compos. Mater. 2019, 53, 2641–2659. [Google Scholar] [CrossRef]

- Mendonca, R.S.; Santos, L.B.; Moura, A.E.; Vasconcelos, E.C.; Sarubbo, L.A.; Santos, V.A. Optimisation of recyclable beta plaster using plaster waste in a continuous reactor with a mobile helical element. J. Clean. Prod. 2016, 124, 370–377. [Google Scholar] [CrossRef]

- Laadila, M.A.; LeBihan, Y.; Caron, R.F.; Vaneeckhaute, C. Construction, renovation and demolition (CRD) wastes contaminated by gypsum residues: Characterization, treatment and valorization. Waste Manag. 2021, 120, 125–135. [Google Scholar] [CrossRef]

- Iucolano, F.; Caputo, D.; Leboffe, F.; Liguori, B. Mechanical behavior of plaster reinforced with abaca fibers. Constr. Build. Mater. 2015, 99, 184–191. [Google Scholar] [CrossRef]

- Xiao-Ping, L.I.; Zhang-Kang, W.U.; Zhong-Yong, X.U.; Liu, X.B. Manufacture of industrial hemp stalk based on light heat preservation materials Ⅱ-heat Insulation properties of gypsum and cement panels. Wood Process. Mach. 2014. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Jozwiak-Niedzwiedzka, D.; Denis, P. Bio-Fibres as a Reinforcement of Gypsum Composites. Materials 2021, 14, 4830. [Google Scholar] [CrossRef]

- Regulska, K.; Repelewicz, A. Properties of Gypsum Composites with Straw Fillers. IOP Conf. Ser. Mater. Sci. Eng. 2019, 585, 012105. [Google Scholar] [CrossRef]

- Hou, Z.Y. Research on Biomass Fiber Reinforced Gypsum Board Technology; Northeast Forestry University: Harbin, China, 2018. [Google Scholar]

- Li, X.D.; Kang, Y.K.; Song, Z.Y. Experimental study on the basic mechanical properties of fiber gypsum-based composite wall materials. Silic. Bull. 2019, 38, 7. [Google Scholar] [CrossRef]

- Kuqo, A.; Mai, C. Mechanical properties of lightweight gypsum composites comprised of seagrass Posidonia oceanica and pine (Pinus sylvestris) wood fibers. Constr. Build. Mater. 2021, 282, 122714. [Google Scholar] [CrossRef]

- GB/T 17669.1-1999; General Test Conditions for Gypsum in Construction: Domestic—National Standards—State Administration of Market Supervision and Administration CN-GB. National Technical Committee for Standardization of Lightweight and Decorative Building Materials: Hangzhou, China, 1999.

- Qian, X.Q. Building Engineering Materials; Zhejiang University Press: Hangzhou, China, 2009. [Google Scholar]

- ISO 5660-1; Reaction to Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method). ISO: Geneva, Switzerland, 2015.

- De Macedo, R.Q.; Ferreira, R.T.L.; Guedes, J.M.; Donadon, M.V. Intraply failure criterion for unidirectional fiber reinforced composites by means of asymptotic homogenization. Compos. Struct. 2017, 159, 335–349. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Li, G.Z.; Bai, Y. Properties of corn straw fiber/desulfurization gypsum composites. J. Compos. 2010, 6, 94–99. [Google Scholar] [CrossRef]

- Wu, Q.S.; Li, S.P.; Liu, X.J. Preparation and study of crop straw fiber reinforced desulfurization gypsum wall materials. New Constr. Mater. 2012, 1, 4. [Google Scholar]

- Guo, X.L.; Shi, H.S. Thermal treatment and utilization of flue gas desulphurization gypsum as an admixture in cement and concrete—Science Direct. Constr. Build. Mater. 2008, 22, 1471–1476. [Google Scholar] [CrossRef]

- Wang, W.H.; Hou, Z.Y.; Hao, J.X.; Dun, M.; Zhang, X. Study on the performance of wood fiber reinforced gypsum board. J. For. Eng. 2018, 3, 19–24. [Google Scholar] [CrossRef]

- Romualdi, J.P.; Batson, G.B. Mechanics of Crack Arrest in Concrete. J. Eng. Mech. Div. 1963, 89, 147–168. [Google Scholar] [CrossRef]

- He, R.; Lu, N. Unveiling the dielectric property change of concrete during hardening process by ground penetrating radar with the antenna frequency of 1.6 GHz and 2.6 GHz. Cem. Concr. Compos. 2023, 144, 105279. [Google Scholar] [CrossRef]

- He, R.; Lu, N. Air void system and freezing-thawing resistance of concrete composite with the incorporation of thermo-expansive polymeric microspheres. Constr. Build. Mater. 2024, 419, 135535. [Google Scholar] [CrossRef]

- Ac, A.; Ak, B.; Mk, A.; Mm, B.; Pm, B. The influence of cellulose derivatives on water structure in gypsum. Constr. Build. Mater. 2018, 160, 628–638. [Google Scholar] [CrossRef]

- Zhu, X.D.; Wu, Y.Q.; Tian, C.H.; Qing, Y.; Yao, C.H. Synergistic Effect of Nanosilica Aerogel with Phosphorus Flame Retardants on Improving Flame Retardancy and Leaching Resistance of Wood. J. Nanomater. 2014, 2014, 7. [Google Scholar] [CrossRef]

- Lu, J.G.; Liu, S.L.; Peng, X.Q. Study on the combustion performance of the timbers-CONE calorimeter. Fi Re Sci. Technol. 2005, 24, 414–418. (In Chinese) [Google Scholar]

| Ingredients | SiO2 | Fe2O3 | Al2O3 | MgO | SO3 | CaO |

|---|---|---|---|---|---|---|

| Content | 2.74 | 0.40 | 0.99 | 0.80 | 43.08 | 37.44 |

| Technical Specifications | 2 h Flexural Strength (MPa) | 2 h Compressive Strength (MPa) | Fineness (0.2 mm Square Hole Sieve Residue, %) | Initial Setting Time (min) | Final Setting Time (min) |

|---|---|---|---|---|---|

| Indicator value | 2.11 | 3.9 | 10.0 | 6 | 30 |

| Test Number | Poplar Fiber, g | Water, g | Gypsum, g | Sodium Citrate, g | Mesh |

|---|---|---|---|---|---|

| 1 | 0 | 3000 | 3750 | 1.88 | 10–20 |

| 2 | 187 (5-wt% gypsum) | 3000 | 3750 | 1.88 | 10–20 |

| 3 | 375 (5-wt% gypsum) | 3000 | 3750 | 1.88 | 10–20 |

| 4 | 562 (15-wt% gypsum) | 3000 | 3750 | 1.88 | 10–20 |

| Fiber Dose (wt%) | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|

| 0 | 3.26 ± 0.32 | 8.03 ± 0.25 |

| 5 | 3.2 ± 0.07 | 7.97 ± 0.14 |

| 10 | 3.59 ± 0.17 | 8.06 ± 0.66 |

| 15 | 3.49 ± 0.20 | 6.75 ± 0.25 |

| Fiber Dose | 7 d Strength/MPa | 14 d Strength/MPa | 28 d Strength/MPa | |||

|---|---|---|---|---|---|---|

| Flexural Strength | Compressive Strength | Flexural Strength | Compressive Strength | Flexural Strength | Compressive Strength | |

| 0 | 1.92 ± 0.2 | 3.65 ± 0.2 | 2.82 ± 0.05 | 5.98 ± 0.15 | 2.94 ± 0.03 | 6.19 ± 0.03 |

| 5 | 2.7 ± 0.23 | 5.72 ± 0.18 | 2.79 ± 0.07 | 5.76 ± 0.3 | 3.34 ± 0.11 | 6.15 ± 0.06 |

| 10 | 3.48 ± 0.04 | 5.76 ± 0.2 | 3.57 ± 0.01 | 6.16 ± 0.19 | 3.59 ± 0.1 | 6.42 ± 0.24 |

| 15 | 2.97 ± 0.11 | 5.46 ± 0.18 | 2.99 ± 0.05 | 5.28 ± 0.12 | 3.19 ± 0.03 | 5.58 ± 0.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, Y.; Huang, Q.; Li, X. Effect of Fiber Loading on Mechanical and Flame-Retardant Properties of Poplar-Fiber-Reinforced Gypsum Composites. Molecules 2024, 29, 2674. https://doi.org/10.3390/molecules29112674

Ye Y, Huang Q, Li X. Effect of Fiber Loading on Mechanical and Flame-Retardant Properties of Poplar-Fiber-Reinforced Gypsum Composites. Molecules. 2024; 29(11):2674. https://doi.org/10.3390/molecules29112674

Chicago/Turabian StyleYe, Yunpeng, Qinqin Huang, and Xingong Li. 2024. "Effect of Fiber Loading on Mechanical and Flame-Retardant Properties of Poplar-Fiber-Reinforced Gypsum Composites" Molecules 29, no. 11: 2674. https://doi.org/10.3390/molecules29112674

APA StyleYe, Y., Huang, Q., & Li, X. (2024). Effect of Fiber Loading on Mechanical and Flame-Retardant Properties of Poplar-Fiber-Reinforced Gypsum Composites. Molecules, 29(11), 2674. https://doi.org/10.3390/molecules29112674