Effect of Koji on Flavor Compounds and Sensory Characteristics of Rice Shochu

Abstract

1. Introduction

2. Results and Discussion

2.1. Impacts of Koji on the FAAs in Rice Shochu

2.2. Volatile Flavor Compounds in Rice shochu

2.3. Analysis of the Ratio of Fusel Alcohols to Esters in Rice Shochu

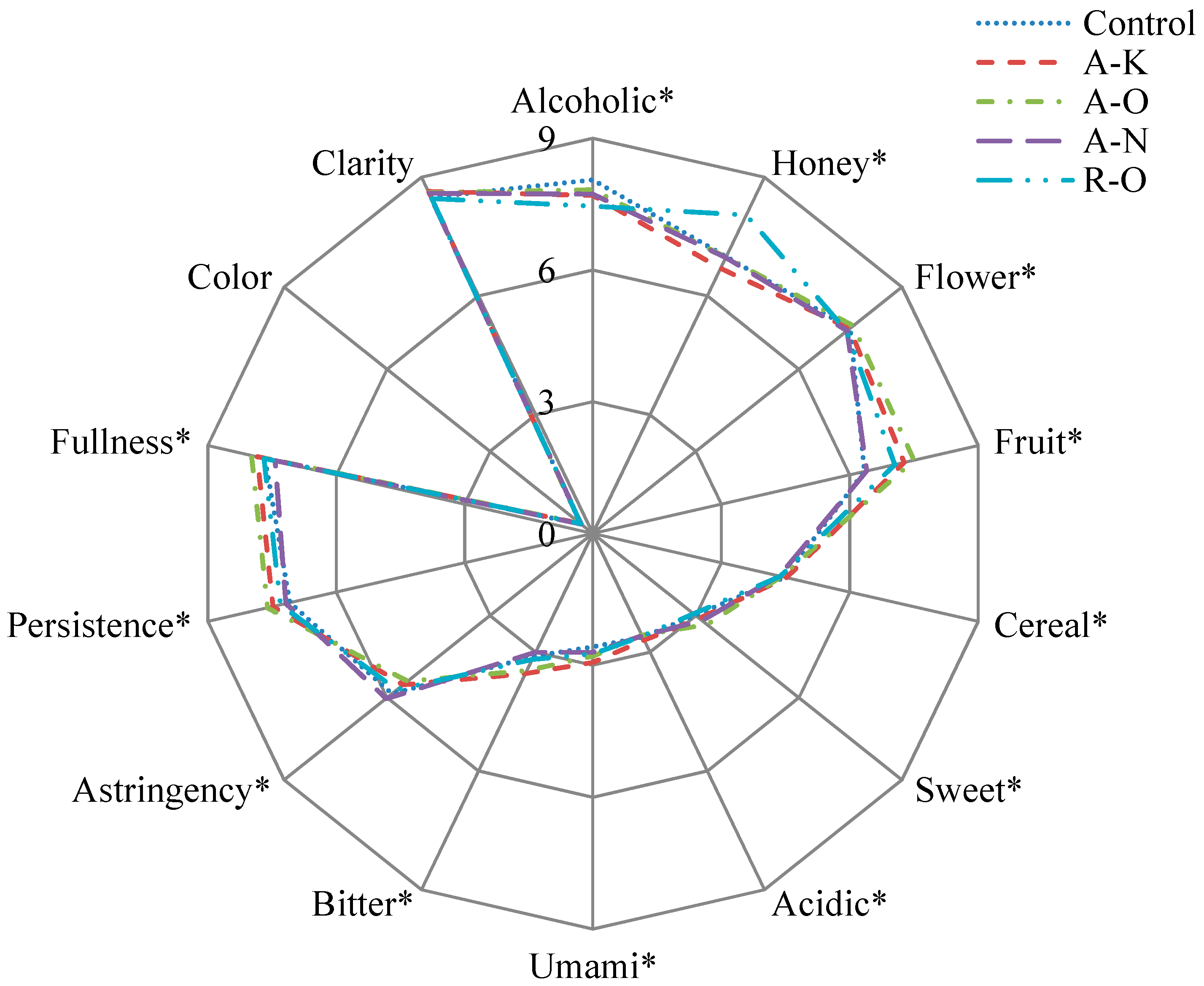

2.4. Sensory Evaluation of Rice Shochu

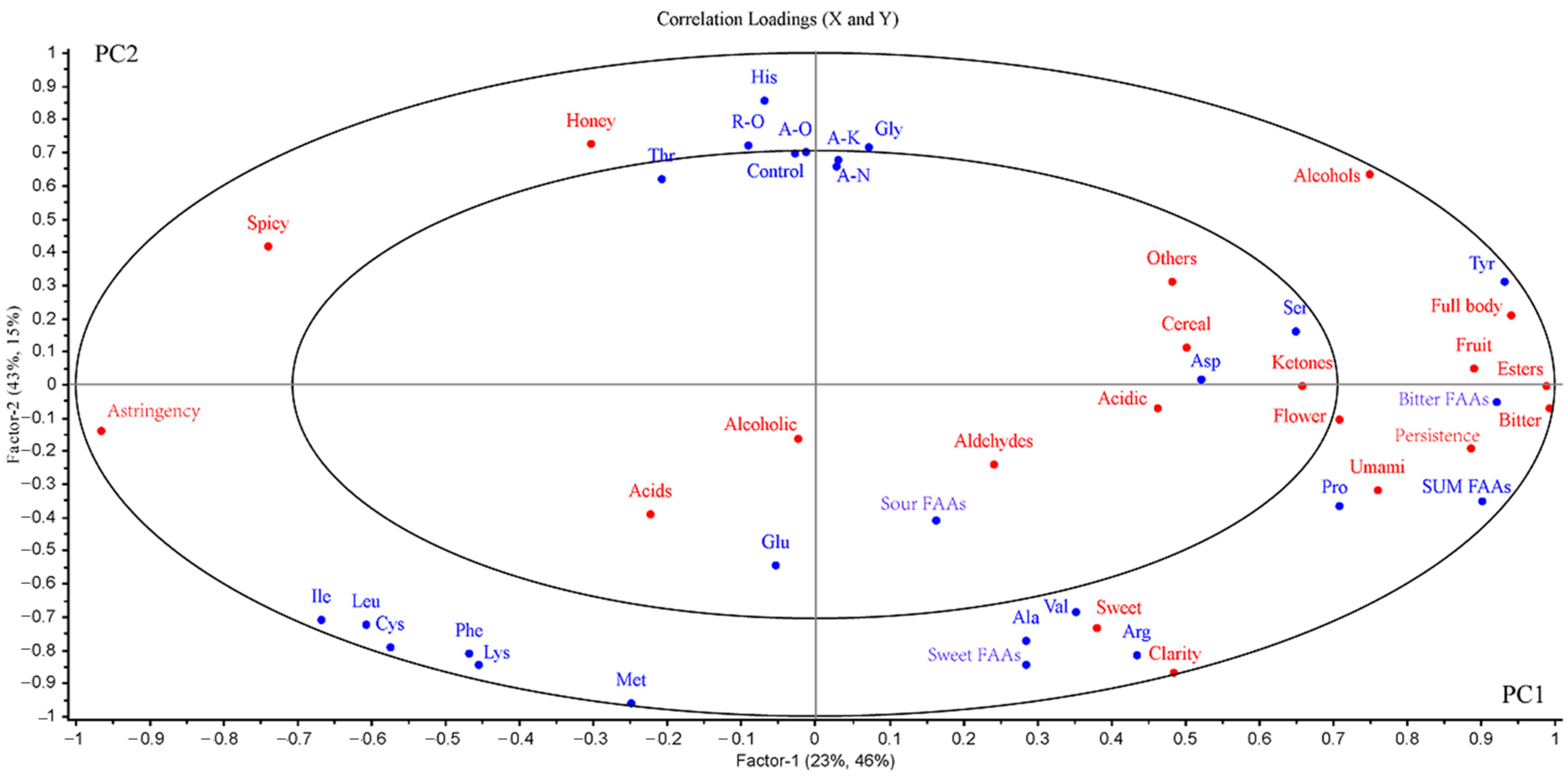

2.5. Relationships among Volatile Compounds, FAAs, as Well as Sensory Qualities in Rice Shochu Made with a Variety of koji

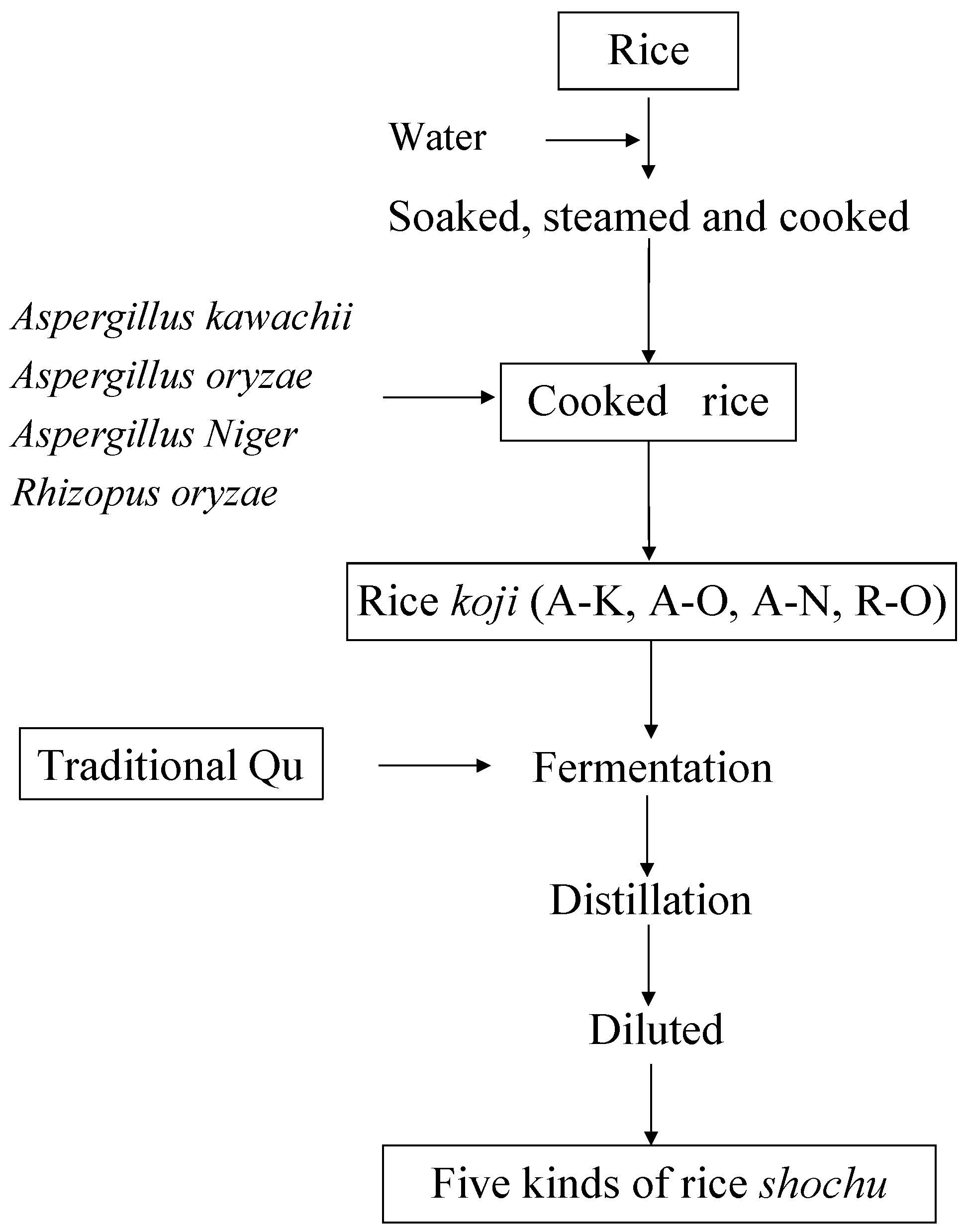

3. Materials and Methods

3.1. Rice Koji Preparation

3.2. Preparation of Yeast

3.3. Preparation of Rice Shochu

3.4. FAA Analysis

3.5. Extraction and Quantification of Volatile Flavor Compounds

3.6. Sensory Evaluation of the Rice Shochu

3.7. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yuan, H.W.; Tan, L.; Luo, S.; Chen, H.; Yi, X.; Sun, Z.Y. Development of a process for producing ethyl caproate- and ethyl lactate-rich rice shochu. J. Inst. Brew. 2015, 121, 432–439. [Google Scholar] [CrossRef]

- Sakandar, H.A.; Hussain, R.; Khan, Q.F.; Zhang, H. Functional microbiota in chinese traditional baijiu and mijiu qu (starters): A review. Food Res. Int. 2020, 138, 109830. [Google Scholar] [CrossRef]

- Xiao, C.; Wang, L.; Zhang, Y.-G.; Tu, T.-Y.; Wang, S.-T.; Shen, C.-H.; Yuan, H.-W.; Zhong, X.-Z. A comparison of microbial communities and volatile compounds in wheat Qu from different geographic locations. LWT 2021, 148, 111752. [Google Scholar] [CrossRef]

- Hayashi, K.; Kajiwara, Y.; Futagami, T.; Goto, M.; Takashita, H. Making traditional japanese distilled liquor, shochu and awamori, and the contribution of white and black koji fungi. J. Fungi 2021, 7, 517. [Google Scholar] [CrossRef]

- Fukuda, H.; Han, J.S.; Mizutani, O.; Kanai, M.; Yamada, O. Characteristics of volatile compositions and a correlation analysis of the compounds in rice shochu and barley shochu. J. Brew. Soc. Jpn. 2016, 111, 841–873. [Google Scholar] [CrossRef]

- Takamine, K.; Oyama, S.; Yoshizaki, Y.; Tamaki, H.; Sameshima, Y. Isolation of shochu yeast from soil and its application in shochu making on an industrial scale. J. Brew. Soc. Jpn. 2010, 105, 546–555. [Google Scholar] [CrossRef]

- Goto, M.; Futagami, T.; Kajiwara, Y.; Takashita, H. Study on finding the identity of white koji mold, Aspergillus kawachii. J. Brew. Soc. Jpn. 2014, 109, 219–227. [Google Scholar] [CrossRef]

- Jang, S.-W.; Kim, J.-S.; Park, J.-B.; Jung, J.-H.; Park, C.-S.; Shin, W.C.; Ha, S.-J. Characterization of the starch degradation activity from newly isolated Rhizopus oryzae WCS-1 and mixed cultures with Saccharomyces cerevisiae for efficient ethanol production from starch. Food Sci. BioTechnol. 2015, 24, 1805–1810. [Google Scholar] [CrossRef]

- Tian, S.; Zeng, W.; Fang, F.; Zhou, J.; Du, G. The microbiome of Chinese rice wine (Huangjiu). Curr. Res. Food Sci. 2022, 5, 325–335. [Google Scholar] [CrossRef]

- Shiraishi, Y.; Yoshizaki, Y.; Ono, T.; Yamato, H.; Takamine, K. Characteristic odour compounds in shochu derived from rice koji: Odour compounds in shochu from rice koji. J. Inst. Brew. 2016, 122, 381–387. [Google Scholar] [CrossRef]

- Ji, Z.; Jin, J.; Yu, G.; Mou, R.; Mao, J.; Liu, S.; Zhou, Z.; Peng, L. Characteristic of filamentous fungal diversity and dynamics associated with wheat Qu and the traditional fermentation of Chinese rice wine. Int. J. Food Sci. Technol. 2018, 53, 1611–1621. [Google Scholar] [CrossRef]

- Cai, H.; Zhang, T.; Zhang, Q.; Luo, J.; Cai, C.; Mao, J. Microbial diversity and chemical analysis of the starters used in traditional Chinese sweet rice wine. Food Microbiol. 2018, 73, 319–326. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yang, L.; Zhou, Y.; He, S.; Li, J.; Sun, H.; Yao, S.; Xu, S. Effect of mixed moulds starters on volatile flavor compounds in rice wine. LWT 2019, 112, 108215. [Google Scholar] [CrossRef]

- Ando, S.; Doi, S.; Terazono, K.; Takayama, T.; Hanai, S. The effects of manufacturing processes on flavour of rice-shochu. J. Jpn. Food Ind. 2010, 34, 48–53. [Google Scholar]

- Sakaida, H.; Nakahara, N.; Watashi, N.; Kai, T.; Nakashima, Y.; Sakakibara, Y.; Nishiyama, K.; Fukuda, N.; Suiko, M. Characteristic flavor of buckwheat Shochu and comparison of volatile compounds from variety cereal shochu. J. Jpn. Food Sci. Technol. 2003, 50, 555–562. [Google Scholar] [CrossRef]

- Taira, J.; Tsuchiya, A.; Furudate, H. Initial volatile aroma profiles of young and aged awamori shochu determined by GC/MS/Pulsed FPD. Food Sci. Technol. Res. 2012, 18, 177–181. [Google Scholar] [CrossRef]

- Kuriyama, K.; Nagatomo, M.; Yamanaka, H.; Yoshihama, Y.; Watanabe, Y. Relationships between panel preference and volatile compounds in various types of shochu. J. Brew. Soc. Jpn. 2005, 100, 817–823. [Google Scholar] [CrossRef]

- Aquino, F.W.; Boso, L.M.; Cardoso, D.R.; Franco, D.W. Amino acids profile of sugar cane spirit (cachaca), rum, and whisky. Food Chem. 2008, 108, 784–793. [Google Scholar] [CrossRef]

- Shen, F.; Niu, X.; Yang, D.; Ying, Y.; Li, B.; Zhu, G.; Wu, J. Determination of amino acids in Chinese rice wine by fourier transform near-infrared spectroscopy. J. Agric. Food Chem. 2010, 58, 9809–9816. [Google Scholar] [CrossRef]

- Yin, X.; Yoshizaki, Y.; Kurazono, S.; Sugimachi, M.; Takeuchi, H.; Han, X.-L.; Okutsu, K.; Futagami, T.; Tamaki, H.; Takamine, K. Characterization of flavor compounds in rice-flavor baijiu, a traditional Chinese distilled liquor, compared with Japanese distilled liquors, awamori and kome-shochu. Food Sci. Technol. Res. 2020, 26, 411–422. [Google Scholar] [CrossRef]

- Chen, S.; Xu, Y. The influence of yeast strains on the volatile flavour compounds of Chinese rice wine. J. Inst. Brew. 2010, 116, 190–196. [Google Scholar] [CrossRef]

- Hazelwood, L.A.; Daran, J.-M.; van Maris, A.J.; Pronk, J.T.; Dickinson, J.R. The Ehrlich pathway for fusel alcohol production: A century of research on Saccharomyces cerevisiae metabolism. Appl. Environ. Microbiol. 2008, 74, 2259–2266. [Google Scholar] [CrossRef] [PubMed]

- Procopio, S.; Qian, F.; Becker, T. Function and regulation of yeast genes involved in higher alcohol and ester metabolism during beverage fermentation. Eur. Food Res. Technol. 2011, 233, 721–729. [Google Scholar] [CrossRef]

- Huang, Y.G.; Wang, Y.X.; Xu, Y. Purification and characterisation of an acid protease from the Aspergillus hennebergii HX08 and its potential in traditional fermentation. J. Inst. Brew. 2017, 123, 432–441. [Google Scholar] [CrossRef]

- Fan, W.; Qian, M.C. Headspace solid phase microextraction and gas chromatography—Olfactometry dilution analysis of young and aged chinese ‘Yanghe Daqu’ liquors. J. Agric. Food Chem. 2005, 53, 7930–7938. [Google Scholar] [CrossRef]

- Fan, W.; Qian, M.C. Characterization of aroma compounds of Chinese‘Wuliangye’ and ‘Jiannanchun’ liquors by aroma extract dilution analysis. J. Agric. Food Chem. 2006, 54, 2695–2704. [Google Scholar] [CrossRef]

- Millati, R.; Edebo, L.; Taherzadeh, M.J. Performance of Rhizopus, Rhizomucor, and Mucorinethanol production from glucose, xylose, and wood hydrolyzates. Enzym. Microb. Technol. 2005, 36, 294–300. [Google Scholar] [CrossRef]

- Mo, X.; Fan, W.; Xu, Y. Changes in volatile compounds of Chinese rice wine wheat Qu during fermentation and storage mentation. J. Inst. Brew. 2009, 115, 300–307. [Google Scholar] [CrossRef]

- Tan, L.; Yuan, H.W.; Wang, Y.F.; Chen, H.; Sun, Z.Y.; Tang, Y.Q. Behaviour of ethyl caproate during the production and distillation of ethyl caproate-rich rice shochu. J. Inst. Brew. 2016, 122, 486–492. [Google Scholar] [CrossRef]

- Yuan, H.; Chen, W.; Chen, Y.; Wang, L.; Zhang, C.; Deng, W.; Zhang, L.; Liu, G.; Shen, C.; Lou, K.; et al. Isolation and characterization of yeast for the production of rice wine with low fusel alcohol content. PLoS ONE 2021, 16, e0260024. [Google Scholar] [CrossRef]

- Miyagawa, H.; Tang, Y.-Q.; Morimura, S.; Wasano, N.; Ota, H.; Okuno, H.; Takase, Y.; Kida, K. Development of efficient shochu production technology with long-term repetition of sashimoto and reuse of stillage for fermentation. J. Inst. Brew. 2011, 117, 91–97. [Google Scholar] [CrossRef]

- Yu, M.; He, S.; Tang, M.; Zhang, Z.; Zhu, Y.; Sun, H. Antioxidant activity and sensory characteristics of Maillard reaction products derived from different peptide fractions of soybean meal hydrolysate. Food Chem. 2018, 243, 249–257. [Google Scholar] [CrossRef]

- Zhang, W.; Cheng, Y.; Li, Y.; Du, G.; Xie, G.; Zou, H. Adaptive evolution relieves nitrogen catabolite repression and decreases urea accumulation in cultures of the Chinese rice wine strain S. cerevisiae XZ-11. J. Agric. Food Chem. 2018, 66, 9061–9069. [Google Scholar] [CrossRef]

- Wang, P.; Mao, J.; Meng, X.; Li, X.; Liu, Y.; Feng, H. Changes in flavor characteristics and bacterial diversity during the traditional fermentation of Chinese rice wines from Shaoxing region. Food Control 2014, 44, 58–63. [Google Scholar] [CrossRef]

- Luo, T.; Fan, W.L.; Xu, Y. Characterization of volatile and Semi-volatile compounds in Chinese rice wines by headspace solid phase microextraction followed by gas chromatography-mass spectrometry. J. Inst. Brew. 2012, 114, 172–179. [Google Scholar] [CrossRef]

- Yang, Y.; Xia, Y.; Wang, G.; Yu, J.; Ai, L. Effect of mixed yeast starter on volatile flavor compounds in Chinese rice wine during different brewing stages. LWT 2017, 78, 373–381. [Google Scholar] [CrossRef]

- ISO 8586-2; Sensory Analysis. General Guidance for the Selection, Training and Monitoring of Assessors. Part 2: Experts Sensory Assessors. International Organization for Standardization: Geneva, Switzerland, 2008.

- Etaio, I.; Albisu, M.; Ojeda, M.; Gil, P.; Salmerón, J.; Elortondo, F.P. Sensory quality control for food certification: A case study on wine. Panel training and qualification, method validation and monitoring. Food Control 2010, 21, 542–548. [Google Scholar] [CrossRef]

- Jung, H.; Lee, S.-J.; Lim, J.H.; Kim, B.-K.; Park, K.J. Chemical and sensory profiles of makgeolli, Korean commercial rice wine, from descriptive, chemical, and volatile compound analyses. Food Chem. 2014, 152, 624–632. [Google Scholar] [CrossRef]

- Yang, Y.J.; Xia, Y.J.; Wang, G.Q.; Zhang, H.; Xiong, Z.Q.; Yu, J.S. Comparison of oenological property, volatile profile and sensory characteristic of Chinese rice wine fermented by different starters during brewing. Int. J. Food Prop. 2017, 20, 1–17. [Google Scholar] [CrossRef]

- ISO 11035; Sensory Analysis-Identification and Selection of Descriptorsfor Establishing a Sensory Profile by a Multidimensional Approach. International Organization for Standardization: Geneva, Switzerland, 1994.

- Wang, D.; Jin, B.; Xu, Y.; Zhao, G.A. Study on flavor sensory characteristics and the construction of flavor wheel for Chinese rice wine. Food Sci. 2013, 34, 90–95. [Google Scholar]

| Control | A-K | A-O | A-N | R-O | |

|---|---|---|---|---|---|

| Sweet amino acids | |||||

| Gly | 0.930 ± 0.067 a | 0.363 ± 0.016 b | 0.986 ± 0.042 a | 0.406 ± 0.027 b | 0.907 ± 0.056 a |

| Ala | 2.282 ± 0.148 a | 2.413 ± 0.184 a | 2.408 ± 0.132 a | 2.362 ± 0.146 a | 1.686 ± 0.027 b |

| Ser | 0.364 ± 0.027 b | 0.320 ± 0.010 c | 0.446 ± 0.011 a | 0.250 ± 0.017 d | 0.290 ± 0.017 c |

| Thr | 0.496 ± 0.028 a | 0.069 ± 0.005 c | 0.497 ± 0.038 a | 0.255 ± 0.015 b | 0.473 ± 0.020 a |

| Pro | 6.364 ± 0.444 b | 7.207 ± 0.630 a | 6.480 ± 0.054 ab | 6.299 ± 0.206 b | 6.155 ± 0.418 b |

| Lys | 0.491 ± 0.024 d | 0.839 ± 0.064 b | 0.625 ± 0.040 c | 1.547 ± 0.063 a | 0.539 ± 0.035 d |

| Cys | 0.020 ± 0.001 c | 0.059 ± 0.003 b | 0.017 ± 0.002 c | 0.241 ± 0.020 a | 0.008 ± 0.001 c |

| ∑ | 10.947 ± 0.428 a | 11.271 ± 0.612 a | 11.485 ± 0.120 a | 11.360 ± 0.256 a | 10.05 8± 0.312 b |

| Bitter amino acids | |||||

| Val | 0.070 ± 0.002 d | 0.237 ± 0.009 b | 0.269 ± 0.021 a | 0.257 ± 0.009 ab | 0.181 ± 0.014 c |

| Leu | 0.233 ± 0.013 b | 0.246 ± 0.018 b | 0.226 ± 0.013 b | 0.290 ± 0.017 a | 0.234 ± 0.007 b |

| Ile | 0.112 ± 0.010 b | 0.118 ± 0.023 b | 0.108 ± 0.008 b | 0.202 ± 0.077 a | 0.113 ± 0.005 b |

| Met | 0.018 ± 0.001 c | 0.058 ± 0.006 b | 0.056 ± 0.011 b | 0.126 ± 0.007 a | 0.006 ± 0.001 d |

| Phe | 0.082 ± 0.008 d | 0.139 ± 0.016 b | 0.128 ± 0.011 bc | 0.281 ± 0.017 a | 0.113 ± 0.004 c |

| Arg | 1.159 ± 0.075 c | 2.992 ± 0.269 a | 2.905 ± 0.000 a | 2.863 ± 0.095 a | 1.734 ± 0.106 b |

| His | 1.371 ± 0.079 a | 1.013 ± 0.070 b | 0.407 ± 0.028 c | 0.372 ± 0.023 c | 1.399 ± 0.051 a |

| Tyr | 2.626 ± 0.183 c | 4.339 ± 0.047 a | 4.395 ± 0.275 a | 1.538 ± 0.076 d | 3.721 ± 0.244 b |

| ∑ | 5.669 ± 0.308 d | 9.142 ± 0.335 a | 8.495 ± 0.273 b | 5.927 ± 0.203 d | 7.501 ± 0.255 c |

| Sour amino acids | |||||

| Asp | 6.412 ± 0.053 a | 6.533 ± 0.053 a | 6.410 ± 0.009 a | 6.414 ± 0.056 a | 6.460 ± 0.105 a |

| Glu | 3.412 ± 0.144 b | 3.639 ± 0.057 a | 3.529 ± 0.065 ab | 3.6778 ± 0.085 a | 3.602 ± 0.072 a |

| ∑ | 9.824 ± 0.162 c | 10.173 ± 0.172 a | 9.939 ± 0.057 bc | 10.092 ± 0.029 ab | 10.062 ± 0.093 ab |

| SUM | 26.440 ± 0.729 b | 30.586 ± 0.944 a | 29.919 ± 0.278 a | 27.380 ± 0.469 b | 27.621 ± 0.487 b |

| Compound | Multiple of Variation | ||||

|---|---|---|---|---|---|

| Control | A-K | A-O | A-N | R-O | |

| Alcohols | |||||

| 1-Propanol | 1.0 | 2.1 | 1.9 | 0.7 | 1.7 |

| Isobutyl alcohol | 1.0 | 1.4 | 1.4 | 0.5 | 1.0 |

| 1-Butanol | 1.0 | 3.7 | 3.1 | 0.8 | 3.5 |

| Isoamyl alcohol | 1.0 | 0.9 | 1.0 | 0.4 | 0.8 |

| 1-Hexanol | 1.0 | 3.5 | 2.5 | nd | 0.5 |

| 1-Heptanol | 1.0 | 8.3 | 4.4 | 4.8 | 7.2 |

| 2,3-Butanediol | 1.0 | 3.8 | 7.9 | 1.8 | 5.6 |

| 1-Octanol | 1.0 | 25.8 | 15.8 | 3.9 | 15.6 |

| 1-Nonanol | nd | nd | + | + | + |

| 3-Methylmercapto propanol | 1.0 | 2.0 | 2.2 | 0.9 | 2.4 |

| Citronellol | 1.0 | 2.8 | nd | 0.8 | nd |

| Benzyl alcohol | 1.0 | 0.5 | 0.3 | 0.3 | 1.1 |

| Phenethyl Alcohol | 1.0 | 0.9 | 1.0 | 0.4 | 1.1 |

| 1-Dodecanol | 1.0 | 14.7 | 11.1 | 9.8 | 11.7 |

| Epicubenol | 1.0 | 1.9 | 5.7 | 0.8 | 6.8 |

| Cedrol | 1.0 | 25.1 | 24.9 | 26.0 | 63.9 |

| Ylangenol | nd | + | + | + | nd |

| 1-Hexadecanol | 1.0 | 1.4 | nd | 1.1 | nd |

| Nerolidol | 1.0 | 1.5 | 0.6 | nd | nd |

| α-Cadinol | 1.0 | 2.6 | 3.3 | 1.1 | 4.9 |

| Spathulenol | 1.0 | nd | nd | nd | 3.2 |

| α-Santalol | 1.0 | 58.1 | 2.1 | nd | 17.0 |

| α-Bisabolol | 1.0 | 2.8 | 3.0 | nd | 6.3 |

| ∑ | 1.0 | 1.0 | 17 | 0.4 | 1.0 |

| Esters | |||||

| Ethyl Acetate | 1.0 | 1.3 | 1.3 | 0.7 | 1.0 |

| Ethyl 2-methylpropionate | 1.0 | 0.8 | 1.1 | 0.9 | 0.9 |

| Ethyl caproate | 1.0 | 9.6 | 11.3 | 10.5 | 6.6 |

| Ethyl heptanoate | 1.0 | 1.1 | 0.6 | 0.5 | 0.6 |

| Ethyl lactate | 1.0 | 0.3 | 0.2 | 0.8 | 0.2 |

| Isoamyl acetate | 1.0 | 1.0 | 1.9 | 0.4 | 0.6 |

| Ethyl caprylate | 1.0 | 1.1 | 1.2 | 0.5 | 1.0 |

| Ethyl 2-hydroxy-4-methylvalerate | 1.0 | 16.4 | 16.0 | nd | 10.4 |

| Ethyl nonanoate | 1.0 | 18.7 | 16.9 | 11.6 | 13.8 |

| Butyrolactone | 1.0 | nd | 6.0 | nd | nd |

| Ethyl decanoate | nd | + | + | + | + |

| Ethyl benzoate | 1.0 | 2.1 | 1.1 | 0.2 | 1.7 |

| Diethyl succinate | 1.0 | 1.5 | 1.4 | 0.4 | 1.1 |

| Ethyl phenylacetate | 1.0 | 2.1 | 1.7 | 1.1 | 1.2 |

| Phenethyl acetate | 1.0 | 1.0 | 1.9 | 0.7 | 1.0 |

| Ethyl myristate | 1.0 | 38.1 | 37.0 | nd | 26.7 |

| Ethyl palmitate | 1.0 | 9.0 | 1.5 | nd | 1.6 |

| Methyl stearate | 1.0 | 0.6 | 0.6 | 0.2 | nd |

| Ethyl octadecanoate | 1.0 | 3.4 | 2.9 | nd | 3.3 |

| Ethyl oleate | 1.0 | 8.2 | 7.7 | 2.8 | 7.3 |

| Ethyl linoleate | 1.0 | 7.0 | 6.7 | 3.3 | 2.3 |

| ∑ | 1.0 | 1.6 | 1.5 | 0.7 | 1.1 |

| Acids | |||||

| Acetic acid | 1.0 | 0.1 | 0.0 | 0.5 | 0.1 |

| Hexanoic acid | 1.0 | 1.1 | 1.8 | 1.7 | 2.0 |

| Myristic acid | nd | nd | + | nd | nd |

| Octanoic acid | 1.0 | 69.6 | 173.4 | 140.0 | 151.0 |

| Nonanoic acid | 1.0 | nd | nd | 0.5 | nd |

| n-Decanoic acid | 1.0 | 198.0 | 15.0 | 26.7 | nd |

| n-Hexadecanoic acid | nd | nd | + | nd | + |

| ∑ | 1.0 | 1.2 | 1.4 | 1.5 | 1.4 |

| Aldehydes | |||||

| Acetaldehyde | 1.0 | 1.6 | 1.7 | 1.0 | 1.6 |

| Acetal | 1.0 | 1.0 | 1.2 | 1.0 | 1.0 |

| Hexanal | nd | nd | + | nd | nd |

| Nonanal | 1.0 | 0.7 | 0.5 | 3.1 | 0.5 |

| Furfural | 1.0 | nd | 2.1 | 1.5 | 11.8 |

| Decanal | 1.0 | 0.7 | 0.5 | 3.1 | 0.6 |

| Benzaldehyde | 1.0 | nd | nd | 0.5 | nd |

| Benzeneacetaldehyde | 1.0 | 1.4 | 1.3 | 1.3 | 1.2 |

| ∑ | 1.0 | 1.2 | 1.3 | 1.3 | 1.3 |

| Ketones | |||||

| 2,3-Butanone | nd | nd | + | nd | nd |

| 2-Octanone | 1.0 | 1.6 | 2.4 | nd | 2.0 |

| 3-Nonanone | nd | + | + | + | nd |

| Acetoin | 1.0 | nd | nd | + | + |

| ∑ | 1.0 | 10 | 8.9 | 0.6 | 2.5 |

| Others | |||||

| 2-Pentyl furan | 1.0 | 2.5 | 26.1 | nd | 18.9 |

| Naphthalene | nd | + | + | nd | nd |

| Phenol | nd | nd | nd | + | nd |

| ∑ | 1.0 | 3.2 | 27.8 | 0.6 | 18.9 |

| SUM | 1.0 | 1.2 | 1.2 | 0.5 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, H.; Tan, L.; Zhao, Y.; Wang, Y.; Li, J.; Liu, G.; Zhang, C.; Liu, K.; Wang, S.; Lou, K. Effect of Koji on Flavor Compounds and Sensory Characteristics of Rice Shochu. Molecules 2023, 28, 2708. https://doi.org/10.3390/molecules28062708

Yuan H, Tan L, Zhao Y, Wang Y, Li J, Liu G, Zhang C, Liu K, Wang S, Lou K. Effect of Koji on Flavor Compounds and Sensory Characteristics of Rice Shochu. Molecules. 2023; 28(6):2708. https://doi.org/10.3390/molecules28062708

Chicago/Turabian StyleYuan, Huawei, Li Tan, Yu Zhao, Yuting Wang, Jianlong Li, Guangqian Liu, Chao Zhang, Kunyi Liu, Songtao Wang, and Kai Lou. 2023. "Effect of Koji on Flavor Compounds and Sensory Characteristics of Rice Shochu" Molecules 28, no. 6: 2708. https://doi.org/10.3390/molecules28062708

APA StyleYuan, H., Tan, L., Zhao, Y., Wang, Y., Li, J., Liu, G., Zhang, C., Liu, K., Wang, S., & Lou, K. (2023). Effect of Koji on Flavor Compounds and Sensory Characteristics of Rice Shochu. Molecules, 28(6), 2708. https://doi.org/10.3390/molecules28062708