The Role of Water Content of Deep Eutectic Solvent Ethaline in the Anodic Process of Gold Electrode

Abstract

1. Introduction

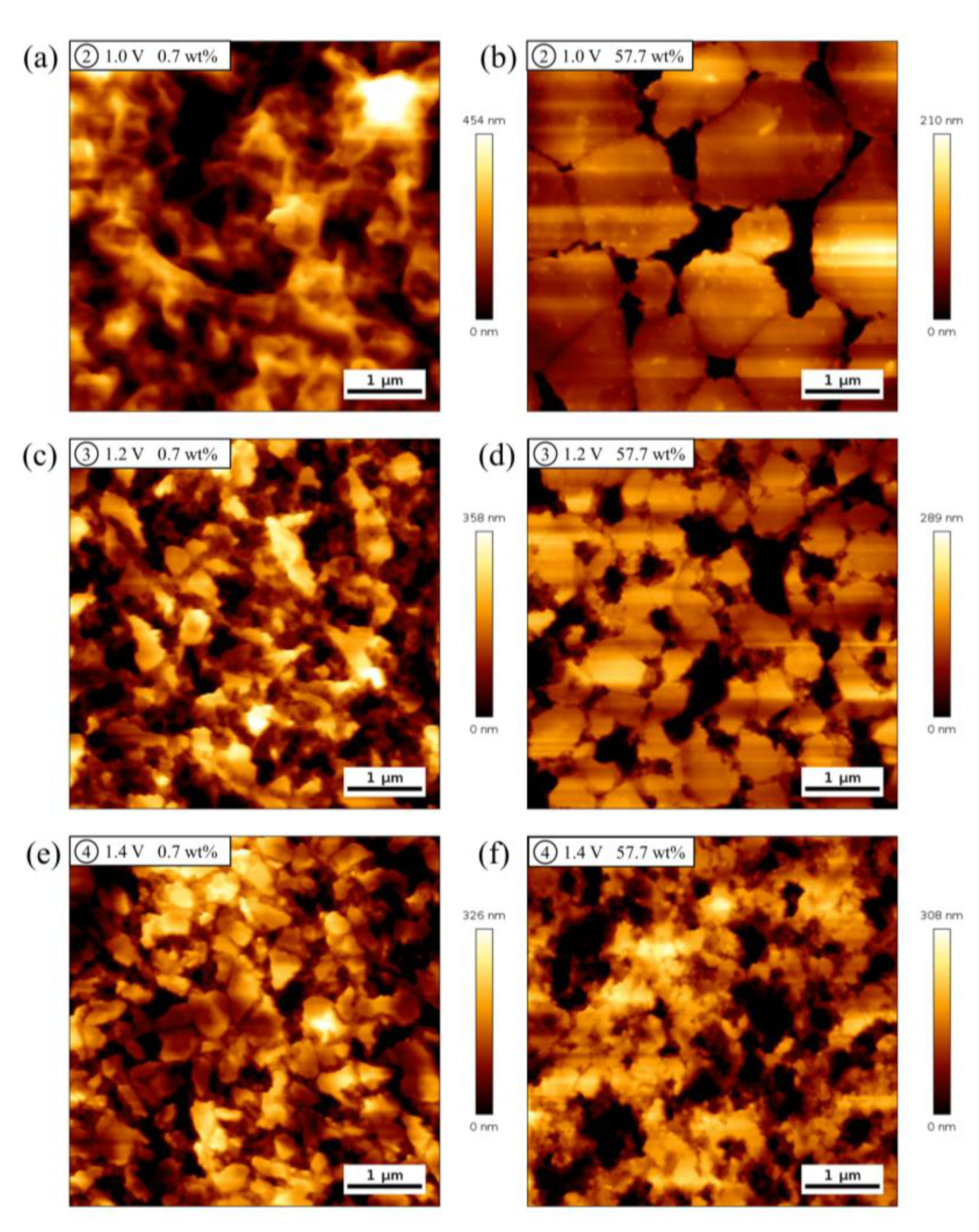

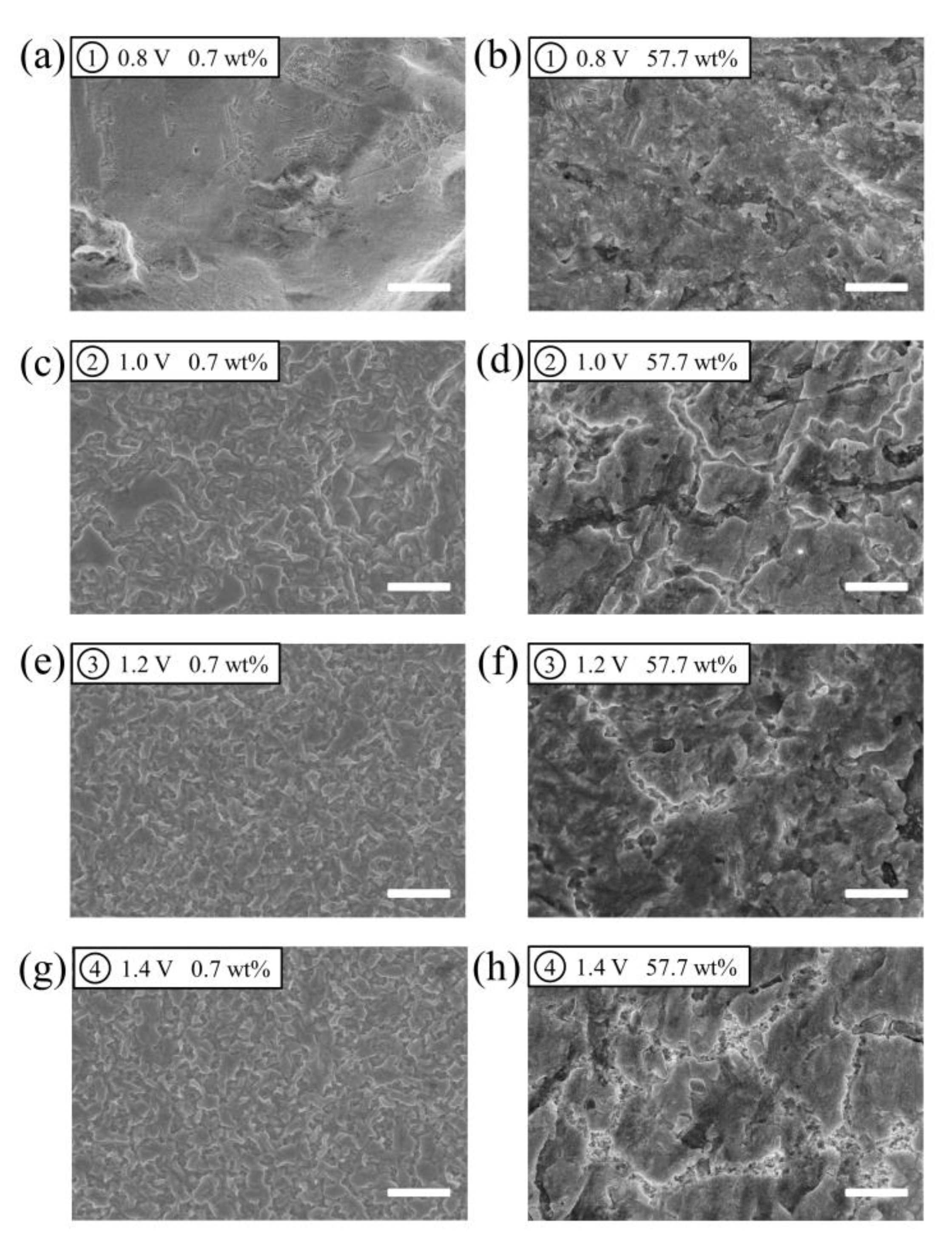

2. Results and Discussion

3. Materials and Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Green, T.A. Gold etching for microfabrication. Gold Bull. 2014, 47, 205–216. [Google Scholar] [CrossRef]

- Shao, J.; Josephs, E.A.; Lee, C.; Lopez, A.; Ye, T. Electrochemical Etching of Gold within Nanoshaved Self-Assembled Monolayers. ACS Nano 2013, 7, 5421–5429. [Google Scholar] [CrossRef]

- Liu, S.; Yuan, T.; Wei, W.; Su, H.; Wang, W. Photoassisted Electrochemical Micropatterning of Gold Film. Anal. Chem. 2019, 91, 9413–9418. [Google Scholar] [CrossRef]

- Jiang, J. Copper-Assisted Etching of Gold through Electrochemical Deposition and Dissolution of Copper in Ionic Liquids. J. Electrochem. Soc. 2019, 166, D940–D945. [Google Scholar] [CrossRef]

- Philipsen, H.; Mouwen, N.; Teck, S.; Monnens, W.; Quoc Toan, L.; Holsteyns, F.; Struyf, H. Wet-chemical etching of metals for advanced semiconductor technology nodes: Ru etching in acidic Ce4+ solutions. Electrochim. Acta 2019, 306, 285–298. [Google Scholar] [CrossRef]

- Shifrin, N.S.; Beck, B.D.; Gauthier, T.D.; Chapnick, S.D.; Goodman, G. Chemistry, toxicology, and human health risk of cyanide compounds in soils at former manufactured gas plant sites. Regul. Toxicol. Pharmacol. 1996, 23, 106–116. [Google Scholar] [CrossRef] [PubMed]

- Donato, D.B.; Nichols, O.; Possingham, H.P.; Moore, M.; Ricci, P.F.; Noller, B.N. A critical review of the effects of gold cyanide-bearing tailings solutions on wildlife. Environ. Int. 2007, 33, 974–984. [Google Scholar] [CrossRef]

- Lee, S.; Nam, Y.-S.; Choi, S.-H.; Lee, Y.; Lee, K.-B. Highly sensitive photometric determination of cyanide based on selective etching of gold nanorods. Microchim. Acta 2016, 183, 3035–3041. [Google Scholar] [CrossRef]

- Sun, S.; Gao, M.; Lei, G.; Zou, H.; Ma, J.; Huang, C. Visually monitoring the etching process of gold nanoparticles by KI/I-2 at single-nanoparticle level using scattered-light dark-field microscopic imaging. Nano Res. 2016, 9, 1125–1134. [Google Scholar] [CrossRef]

- Birich, A.; Stopic, S.; Friedrich, B. Kinetic Investigation and Dissolution Behavior of Cyanide Alternative Gold Leaching Reagents. Sci. Rep. 2019, 9, 7191. [Google Scholar] [CrossRef] [PubMed]

- Luo, Y.; Kawashima, A.; Ishido, Y.; Yoshihara, A.; Oda, K.; Hiroi, N.; Ito, T.; Ishii, N.; Suzuki, K. Iodine Excess as an Environmental Risk Factor for Autoimmune Thyroid Disease. Int. J. Mol. Sci. 2014, 15, 12895–12912. [Google Scholar] [CrossRef]

- Farebrother, J.; Zimmermann, M.B.; Andersson, M. Excess iodine intake: Sources, assessment, and effects on thyroid function. Ann. N. Y. Acad. Sci. 2019, 1446, 44–65. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; De Oliveira Vigier, K.; Royer, S.; Jerome, F. Deep eutectic solvents: Syntheses, properties and applications. Chem. Soc. Rev. 2012, 41, 7108–7146. [Google Scholar] [CrossRef]

- Smith, E.L.; Abbott, A.P.; Ryder, K.S. Deep eutectic solvents (DESs) and their applications. Chem. Rev. 2014, 114, 11060–11082. [Google Scholar] [CrossRef]

- Hansen, B.B.; Spittle, S.; Chen, B.; Poe, D.; Zhang, Y.; Klein, J.M.; Horton, A.; Adhikari, L.; Zelovich, T.; Doherty, B.W.; et al. Deep Eutectic Solvents: A Review of Fundamentals and Applications. Chem. Rev. 2021, 121, 1232–1285. [Google Scholar] [CrossRef]

- Wu, J.X.; Liang, Q.H.; Yu, X.L.; Lu, Q.F.; Ma, L.B.; Qin, X.Y.; Chen, G.H.; Li, B.H. Deep Eutectic Solvents for Boosting Electrochemical Energy Storage and Conversion: A Review and Perspective. Adv. Funct. Mater. 2021, 31. [Google Scholar] [CrossRef]

- Ma, C.; Laaksonen, A.; Liu, C.; Lu, X.; Ji, X. The peculiar effect of water on ionic liquids and deep eutectic solvents. Chem. Soc. Rev. 2018, 47, 8685–8720. [Google Scholar] [CrossRef] [PubMed]

- Kaur, S.; Malik, A.; Kashyap, H.K. Anatomy of Microscopic Structure of Ethaline Deep Eutectic Solvent Decoded through Molecular Dynamics Simulations. J. Phys. Chem. B 2019, 123, 8291–8299. [Google Scholar] [CrossRef] [PubMed]

- Stefanovic, R.; Ludwig, M.; Webber, G.B.; Atkin, R.; Page, A.J. Nanostructure, hydrogen bonding and rheology in choline chloride deep eutectic solvents as a function of the hydrogen bond donor. Phys. Chem. Chem. Phys. 2017, 19, 3297–3306. [Google Scholar] [CrossRef]

- Kaur, S.; Kumari, M.; Kashyap, H.K. Microstructure of Deep Eutectic Solvents: Current Understanding and Challenges. J. Phys. Chem. B 2020, 124, 10601–10616. [Google Scholar] [CrossRef]

- Abbott, A.P. Deep eutectic solvents and their application in electrochemistry. Curr. Opin. Green Sustain. Chem. 2022, 36. [Google Scholar] [CrossRef]

- Fuchs, D.; Bayer, B.C.; Gupta, T.; Szabo, G.L.; Wilhelm, R.A.; Eder, D.; Meyer, J.C.; Steiner, S.; Gollas, B. Electrochemical Behavior of Graphene in a Deep Eutectic Solvent. ACS Appl. Mater. Interfaces 2020, 12, 40937–40948. [Google Scholar] [CrossRef]

- Tan, Z.; Liu, S.; Wu, J.; Nan, Z.; Yang, F.; Zhan, D.; Yan, J.; Mao, B. Copper Deposition on Au(111) in a Deep Eutectic Solvent: An In Situ STM Study**. Chemelectrochem 2022. [Google Scholar] [CrossRef]

- Brett, C.M.A. Deep eutectic solvents and applications in electrochemical sensing. Curr. Opin. Electrochem. 2018, 10, 143–148. [Google Scholar] [CrossRef]

- Toniolo, R.; Dossi, N.; Giannilivigni, E.; Fattori, A.; Svigelj, R.; Bontempelli, G.; Giacomino, A.; Daniele, S. Modified Screen Printed Electrode Suitable for Electrochemical Measurements in Gas Phase. Anal. Chem. 2020, 92, 3689–3696. [Google Scholar] [CrossRef]

- Liang, X.; Zhou, Y.; Brett, C.M.A. Electropolymerisation of brilliant cresyl blue and neutral red on carbon-nanotube modified electrodes in binary and ternary deep eutectic solvents. J. Electroanal. Chem. 2022, 919, 116557. [Google Scholar] [CrossRef]

- Paiva, A.; Craveiro, R.; Aroso, I.; Martins, M.; Reis, R.L.; Duarte, A.R.C. Natural Deep Eutectic Solvents - Solvents for the 21st Century. ACS Sustain. Chem. Eng. 2014, 2, 1063–1071. [Google Scholar] [CrossRef]

- Yang, X.; Zou, Q.; Zhao, T.; Chen, P.; Liu, Z.; Liu, F.; Lin, Q. Deep Eutectic Solvents as Efficient Catalysts for Fixation of CO2 to Cyclic Carbonates at Ambient Temperature and Pressure through Synergetic Catalysis. ACS Sustain. Chem. Eng. 2021, 9, 10437–10443. [Google Scholar] [CrossRef]

- Amoroso, R.; Hollmann, F.; Maccallini, C. Choline Chloride-Based DES as Solvents/Catalysts/Chemical Donors in Pharmaceutical Synthesis. Molecules 2021, 26, 6286. [Google Scholar] [CrossRef]

- Kalhor, P.; Ghandi, K. Deep Eutectic Solvents for Pretreatment, Extraction, and Catalysis of Biomass and Food Waste. Molecules 2019, 24, 4012. [Google Scholar] [CrossRef]

- Juneidi, I.; Hayyan, M.; Hashim, M.A. Intensification of biotransformations using deep eutectic solvents: Overview and outlook. Process Biochem. 2018, 66, 33–60. [Google Scholar] [CrossRef]

- Abbott, A.P.; Frisch, G.; Hartley, J.; Karim, W.O.; Ryder, K.S. Anodic dissolution of metals in ionic liquids. Prog. Nat. Sci. -Mater. Int. 2015, 25, 595–602. [Google Scholar] [CrossRef]

- Wu, J.; Liu, S.; Tan, Z.; Guo, Y.; Zhou, J.; Mao, B.; Yan, J. Effect of hydrogen bond donor molecules ethylene glycerol and lactic acid on electrochemical interfaces in choline chloride based-deep eutectic solvents. J. Chem. Phys. 2021, 155, 244702. [Google Scholar] [CrossRef]

- Chen, Y.; Yu, D.; Chen, W.; Fu, L.; Mu, T. Water absorption by deep eutectic solvents. Phys. Chem. Chem. Phys. 2019, 21, 2601–2610. [Google Scholar] [CrossRef]

- Meng, X.; Ballerat-Busserolles, K.; Husson, P.; Andanson, J.-M. Impact of water on the melting temperature of urea + choline chloride deep eutectic solvent. New J. Chem. 2016, 40, 4492–4499. [Google Scholar] [CrossRef]

- Shah, D.; Mjalli, F.S. Effect of water on the thermo-physical properties of Reline: An experimental and molecular simulation based approach. Phys. Chem. Chem. Phys. 2014, 16, 23900–23907. [Google Scholar] [CrossRef]

- Alizadeh, V.; Malberg, F.; Padua, A.A.H.; Kirchner, B. Are There Magic Compositions in Deep Eutectic Solvents? Effects of Composition and Water Content in Choline Chloride/Ethylene Glycol from Ab Initio Molecular Dynamics. J. Phys. Chem. B 2020, 124, 7433–7443. [Google Scholar] [CrossRef]

- Hammond, O.S.; Li, H.; Westermann, C.; Al-Murshedi, A.Y.M.; Endres, F.; Abbott, A.P.; Warr, G.G.; Edler, K.J.; Atkin, R. Nanostructure of the deep eutectic solvent/platinum electrode interface as a function of potential and water content. Nanoscale Horiz. 2019, 4, 158–168. [Google Scholar] [CrossRef]

- Elbourne, A.; Besford, Q.A.; Meftahi, N.; Crawford, R.J.; Daeneke, T.; Greaves, T.L.; McConville, C.F.; Bryant, G.; Bryant, S.J.; Christofferson, A.J. The Impact of Water on the Lateral Nanostructure of a Deep Eutectic Solvent-Solid Interface. Aust. J. Chem. 2021. [Google Scholar] [CrossRef]

- Zec, N.; Mangiapia, G.; Zheludkevich, M.L.; Busch, S.; Moulin, J.F. Revealing the interfacial nanostructure of a deep eutectic solvent at a solid electrode. Phys. Chem. Chem. Phys. 2020, 22, 12104–12112. [Google Scholar] [CrossRef]

- Kaur, S.; Gupta, A.; Kashyap, H.K. How Hydration Affects the Microscopic Structural Morphology in a Deep Eutectic Solvent. J. Phys. Chem. B 2020, 124, 2230–2237. [Google Scholar] [CrossRef]

- Hammond, O.S.; Bowron, D.T.; Edler, K.J. The Effect of Water upon Deep Eutectic Solvent Nanostructure: An Unusual Transition from Ionic Mixture to Aqueous Solution. Angew. Chem. Int. Ed. 2017, 56, 9782–9785. [Google Scholar] [CrossRef] [PubMed]

- Mamme, M.H.; Moors, S.L.C.; Mernissi Cherigui, E.A.; Terryn, H.; Deconinck, J.; Ustarroz, J.; De Proft, F. Water distribution at the electrified interface of deep eutectic solvents. Nanoscale Adv. 2019, 1, 2847–2856. [Google Scholar] [CrossRef] [PubMed]

- Al-Murshedi, A.Y.M.; Hartley, J.M.; Abbott, A.P.; Ryder, K.S. Effect of water on the electrodeposition of copper on nickel in deep eutectic solvents. Trans. Inst. Met. Finish. 2019, 97, 321–329. [Google Scholar] [CrossRef]

- Zhen, F.; Hapiot, P. Electron Transfer Kinetics in Ethaline/Water Mixtures: An Apparent Non-Marcus Behavior in a Deep Eutectic Solvent. Chemelectrochem 2022, 9, e202200351. [Google Scholar] [CrossRef]

- Valverde, P.E.; Green, T.A.; Roy, S. Effect of water on the electrodeposition of copper from a deep eutectic solvent. J. Appl. Electrochem. 2020, 50, 699–712. [Google Scholar] [CrossRef]

- Lukaczynska-Anderson, M.; Mamme, M.H.; Ceglia, A.; Van den Bergh, K.; De Strycker, J.; De Proft, F.; Terryn, H.; Ustarroz, J. The role of hydrogen bond donor and water content on the electrochemical reduction of Ni(2+) from solvents–an experimental and modelling study. Phys. Chem. Chem. Phys. 2020, 22, 16125–16135. [Google Scholar] [CrossRef]

- Sebastian, P.; Gomez, E.; Climent, V.; Feliu, J.M. Copper underpotential deposition at gold surfaces in contact with a deep eutectic solvent: New insights. Electrochem. Commun. 2017, 78, 51–55. [Google Scholar] [CrossRef]

- Sebastian, P.; Gomez, E.; Climent, V.; Feliu, J.M. Investigating the M(hkl)broken vertical bar ionic liquid interface by using laser induced temperature jump technique. Electrochim. Acta 2019, 311, 30–40. [Google Scholar] [CrossRef]

- Dean, W.; Klein, J.; Gurkan, B. Do Deep Eutectic Solvents Behave Like Ionic Liquid Electrolytes? A Perspective from the Electrode-Electrolyte Interface. J. Electrochem. Soc. 2021, 168. [Google Scholar] [CrossRef]

- Wu, J.D.; Zhou, R.Y.; Radjenovic, P.M.; Liu, S.; Wu, D.Y.; Li, J.F.; Mao, B.W.; Yan, J.W. Electrochemical impedance spectroscopy and Raman spectroscopy studies on electrochemical interface between Au(111) electrode and ethaline deep eutectic solvent. Electrochim. Acta 2021, 390, 138859. [Google Scholar] [CrossRef]

- Tan, Z.; Peng, Y.; Liu, J.L.; Yang, Y.; Zhang, Z.S.; Chen, Z.B.; Mao, B.W.; Yan, J.W. An In Situ Scanning Tunneling Microscopy Study on the Electrochemical Interface between Au(111) and Ethaline Deep Eutectic Solvent. Chemelectrochem 2020, 7, 4601–4605. [Google Scholar] [CrossRef]

- Xiang Li, Q.-A.H.; Li, W.-H.; Bai, Y.-X.; Wang, J.; Liu, Y.; Zhao, Y.-F.; Wang, J.; Zhang, J.-J. Fundamentals of Electrochemical Impedance Spectroscopy for Macrohomogeneous Porous Electrodes. J. Electrochem. 2021, 27, 467–497. [Google Scholar] [CrossRef]

- Vivier, V.; Orazem, M.E. Impedance Analysis of Electrochemical Systems. Chem. Rev. 2022, 122. [Google Scholar] [CrossRef]

- Yue, D.; Jia, Y.; Yao, Y.; Sun, J.; Jing, Y. Structure and electrochemical behavior of ionic liquid analogue based on choline chloride and urea. Electrochim. Acta 2012, 65, 30–36. [Google Scholar] [CrossRef]

- Hammons, J.A.; Besford, Q.A.; Ilavsky, J.; Christofferson, A.J. Manipulating meso-scale solvent structure from Pd nanoparticle deposits in deep eutectic solvents. J. Chem. Phys. 2021, 155. [Google Scholar] [CrossRef]

- Panic, M.; Radovic, M.; Cvjetko Bubalo, M.; Radosevic, K.; Rogosic, M.; Coutinho, J.A.P.; Radojcic Redovnikovic, I.; Jurinjak Tusek, A. Prediction of pH Value of Aqueous Acidic and Basic Deep Eutectic Solvent Using COSMO-RS sigma Profiles’ Molecular Descriptors. Molecules 2022, 27, 4489. [Google Scholar] [CrossRef]

- Alfurayj, I.; Fraenza, C.C.; Zhang, Y.; Pandian, R.; Spittle, S.; Hansen, B.; Dean, W.; Gurkan, B.; Savinell, R.; Greenbaum, S.; et al. Solvation Dynamics of Wet Ethaline: Water is the Magic Component. J. Phys. Chem. B 2021, 125, 8888–8901. [Google Scholar] [CrossRef]

- Rozas, S.; Benito, C.; Alcalde, R.; Atilhan, M.; Aparicio, S. Insights on the water effect on deep eutectic solvents properties and structuring: The archetypical case of choline chloride + ethylene glycol. J. Mol. Liq. 2021, 344, 117717. [Google Scholar] [CrossRef]

- Kityk, A.A.; Rublova, Y.D.; Kelm, A.; Malyshev, V.V.; Bannyk, N.G.; Flis-Kabulska, I. Kinetics and mechanism of corrosion of mild steel in new types of ionic liquids. J. Electroanal. Chem. 2018, 823, 234–244. [Google Scholar] [CrossRef]

- Ye, S.; Ishibashi, C.; Uosaki, K. Anisotropic dissolution of an Au(111) electrode in perchloric acid solution containing chloride anion investigated by in situ STM–The important role of adsorbed chloride anion. Langmuir 1999, 15, 807–812. [Google Scholar] [CrossRef]

- Ueda, H.; Nishimori, K.; Hisatomi, T.; Shiraishi, Y.; Yoshimoto, S. Iodine adlayer mediated gold electrooxidation in bis(trifluoromethylsulfonyl)amide-based ionic liquids. Electrochim. Acta 2021, 371, 137811. [Google Scholar] [CrossRef]

- Zheng, J.F.; Huang, W.; Chen, S.; Niu, Z.J.; Li, Z.L. New oscillatory phenomena during gold electrodissolution in sulfuric acid containing Br- or in concentrated HCl. Electrochem. Commun. 2006, 8, 600–604. [Google Scholar] [CrossRef]

- Kasian, O.; Kulyk, N.; Mingers, A.; Zeradjanin, A.R.; Mayrhofer, K.J.J.; Cherevko, S. Electrochemical dissolution of gold in presence of chloride and bromide traces studied by on-line electrochemical inductively coupled plasma mass spectrometry. Electrochim. Acta 2016, 222, 1056–1063. [Google Scholar] [CrossRef]

- Salvador Ramirez-Rico, D.; Roxana Larios-Duran, E. Electrochemical Study on Electrodissolution of Gold in Acidic Medium Using Chlorides as Ligands. J. Electrochem. Soc. 2017, 164, H994–H1002. [Google Scholar] [CrossRef]

- Tian, M.; Pell, W.G.; Conway, B.E. EQCN study of anodic dissolution and surface oxide film formation at Au in the presence of Cl- or Br- ions: A model process for corrosion studies. Corros. Sci. 2008, 50, 2682–2690. [Google Scholar] [CrossRef]

- Han, L.-H.; He, Q.-F.; Zhan, D.-P. Sailing to the Ocean of Electrochemistry: The First Step of Experiment. J. Electrochem. 2021, 27, 311–315. [Google Scholar] [CrossRef]

- Chen, J.-Q.; Ye, X.X.; Liao, L.-W.; Wei, Z.; Xu, M.-L.; Chen, Y.-X. Ohmic Drop Compensation in Electrochemical Measurement. J. Electrochem. 2021, 27, 291–300. [Google Scholar] [CrossRef]

- Clavilier, J.; Faure, R.; Guinet, G.; Durand, R. Preparation of monocrystalline Pt microelectrodes and electrochemical study of the plane surfaces cut in the direction of the {111} and {110} planes. J. Electroanal. Chem. Interfacial Electrochem. 1980, 107, 205–209. [Google Scholar] [CrossRef]

- Clavilier, J.; Armand, D.; Sun, S.G.; Petit, M. Electrochemical adsorption behaviour of platinum stepped surfaces in sulphuric acid solutions. J. Electroanal. Chem. Interfacial Electrochem. 1986, 205, 267–277. [Google Scholar] [CrossRef]

- Rodes, A.; Herrero, E.; Feliu, J.M.; Aldaz, A. Structure sensitivity of irreversibly adsorbed tin on gold single-crystal electrodes in acid media. J. Chem. Soc. -Faraday Trans. 1996, 92, 3769–3776. [Google Scholar] [CrossRef]

| Water Weight Percentage | Water Mole Percentage | Molar Ratio of Water:Ethaline |

|---|---|---|

| 0.7 wt% | 3.4 mol% | 0.1:1 |

| 25.5 wt% | 62.5 mol% | 5:1 |

| 57.7 wt% | 87.0 mol% | 20:1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.-D.; Ding, Y.; Zhu, F.; Gu, Y.; Wang, W.-W.; Sun, L.; Mao, B.-W.; Yan, J.-W. The Role of Water Content of Deep Eutectic Solvent Ethaline in the Anodic Process of Gold Electrode. Molecules 2023, 28, 2300. https://doi.org/10.3390/molecules28052300

Wu J-D, Ding Y, Zhu F, Gu Y, Wang W-W, Sun L, Mao B-W, Yan J-W. The Role of Water Content of Deep Eutectic Solvent Ethaline in the Anodic Process of Gold Electrode. Molecules. 2023; 28(5):2300. https://doi.org/10.3390/molecules28052300

Chicago/Turabian StyleWu, Jie-Du, Yu Ding, Feng Zhu, Yu Gu, Wei-Wei Wang, Lan Sun, Bing-Wei Mao, and Jia-Wei Yan. 2023. "The Role of Water Content of Deep Eutectic Solvent Ethaline in the Anodic Process of Gold Electrode" Molecules 28, no. 5: 2300. https://doi.org/10.3390/molecules28052300

APA StyleWu, J.-D., Ding, Y., Zhu, F., Gu, Y., Wang, W.-W., Sun, L., Mao, B.-W., & Yan, J.-W. (2023). The Role of Water Content of Deep Eutectic Solvent Ethaline in the Anodic Process of Gold Electrode. Molecules, 28(5), 2300. https://doi.org/10.3390/molecules28052300