1. Introduction

Ruxolitinib (RUX) is a small molecule that belongs to a class of drugs known as Janus kinase (JAK) inhibitors. It is primarily used for the treatment of certain blood disorders and inflammatory conditions (myelofibrosis, polycythemia vera, graft-versus-host disease, and vitiligo). RUX exerts its effects by targeting and inhibiting JAK enzymes, particularly JAK1 and JAK2. By inhibiting JAK1 and JAK2, RUX helps regulate the abnormal signaling associated with certain diseases. [

1]. RUX is marketed as oral tablets under the brand names of Jakafi

® (Incyte Corporation, Wilmington, DE, USA) and Jakavi

® (Novartis, Basel, Switzerland). The Jakafi

® tablet was firstly approved for the treatment of myelofibrosis, a rare bone marrow disorder, on 16 November 2011 [

2,

3]. On 24 May 2019, the FDA approved Jakafi

® for steroid-refractory acute graft-versus-host disease in adult and pediatric patients 12 years and older [

4]. On 22 September 2021, the FDA approved RUX for chronic graft-versus-host disease [

5]. On 18 July 2022, the FDA approved RUX, as Opzelura

® cream, for the treatment of acute and nonsegmental vitiligo, a chronic autoimmune condition that causes patches of skin to lose pigment and turn milky white [

6]. Opzelura

® is the first FDA-approved drug that can restore pigmentation in vitiligo patients. It is applied twice a day to affected areas, and satisfactory response may require treatment with Opzelura

® for more than 24 weeks. RUX functions by lowering an individual’s enhanced immune response [

6].

While there are effective benefits of RUX in managing these conditions, there are some associated potential side effects. The most common side effects are thrombocytopenia, anemia, hepatic toxicity, infections, and non-melanoma skin cancer. The incidence, severity, and tolerability of these effects are dose-dependent, thus accurate dosing and dose adjustment are very important for achieving a potent and safe therapy with RUX [

3,

7]. To achieve this goal, a proper analytical method is required for the quality control of RUX-containing pharmaceutical formulations (tablets and cream). Few methods exist in the literature for quantitation of RUX in its formulations [

8,

9,

10,

11,

12], and most are chromatography. These methods suffer from major drawbacks. These drawbacks include long analysis times because of the time-consuming/labor-intensive sample preparation steps, the equilibration of columns within the mobile phase before each analysis to ensure consistent and reproducible results, regular column maintenance, system suitability testing, challenges posed by the transferability of methods between different laboratories or instruments, and consumption of large volumes of costive and environmentally/health hazardous organic solvents in the mobile phase. These features limit the ability of method to meet the demands of high throughput in pharmaceutical analysis [

13,

14,

15], and cause failure of the procedures to meet the green analytical approaches in pharmaceutical analysis [

16,

17,

18,

19]. Furthermore, all these methods were developed for Jakavi

® tablets, and no method was found in the literature for the quantitation of RUX in Opzelura

® cream. For these reasons, the development of an alternative green method with high throughput for quality control of both RUX’s pharmaceutical formulations (Jakavi

® tablets and Opzelura

® cream) was important.

Microwell spectrophotometry is a prominent eco-friendly/green approach in pharmaceutical analysis [

20,

21]. An essential benefit of this methodology is its utilization of smaller sample/reagent volumes compared to conventional practices in spectrophotometric methods. This not only minimizes waste generation but also reduces expenditure on reagents. Moreover, by employing microscale techniques, the amount of hazardous chemicals/solvents used in the laboratory can be decreased, contributing to enhanced sustainability [

22,

23]. The versatility of this technique allows for various applications in the pharmaceutical industry [

24,

25,

26]. Microwell spectrophotometry lends itself well to automation using robotic systems, leading to improved efficiency, reduced errors, and time and labor savings in the laboratory. Automation also facilitates the adoption of renewable energy sources, such as solar and wind power, to decrease the carbon footprint of analytical chemical processes [

23]. These advantages have significantly increased the popularity of this technique not only within the pharmaceutical industry but also in other domains [

20,

22].

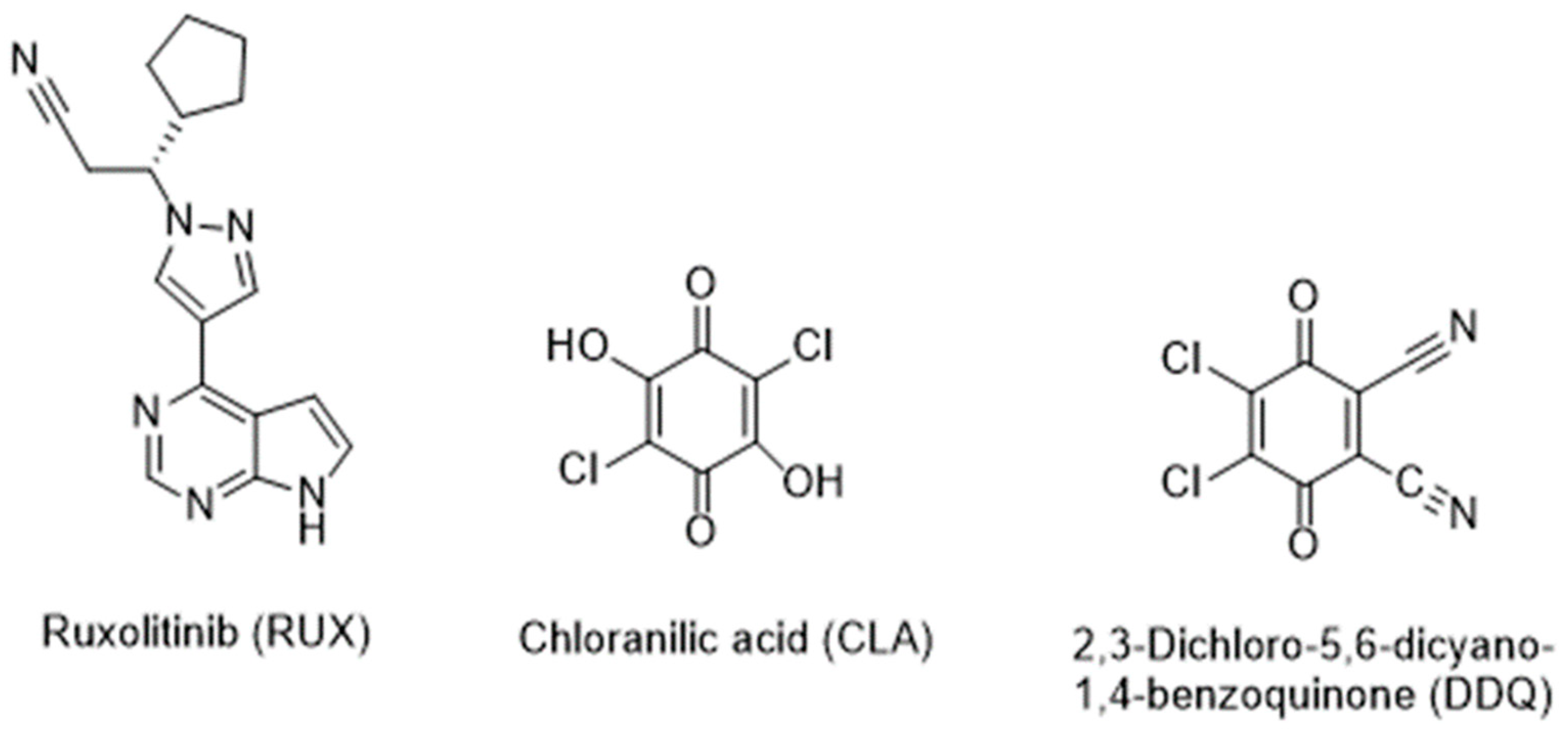

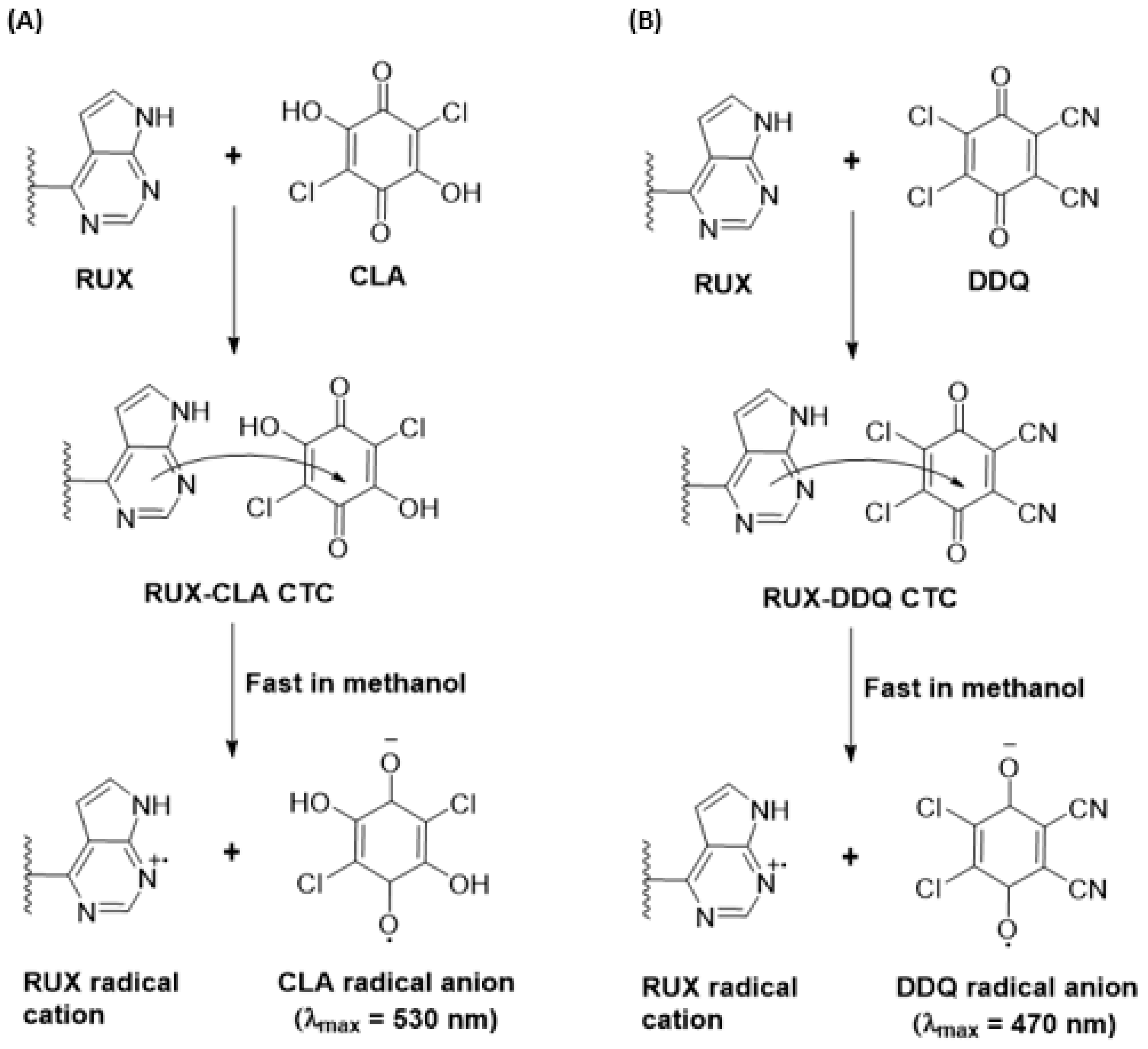

This study describes the development of a microwell-spectrophotometric method (MW-SPM) for quantitation of RUX in Jakavi® tablets and Opzelura® cream. The method involved the microscale in-microwell formation of colored charge-transfer complexes (CTCs) through reactions of RUX, an electron donor, with chloranilic acid (CLA) and 2,3-dichloro-5,6-dicyano-1,4-benzoquinone (DDQ) reagents, the electron acceptors. Both reactions were conducted in transparent 96-well plates and the absorbances of each reaction’s solutions were measured by an absorbance microplate reader at 530 and 470 nm for reactions with CLA and DDQ, respectively. The proposed MW-SPM meets the requirements of high-throughput and green analytical approaches used in the pharmaceutical industry.

3. Materials and Methods

3.1. Apparatus

The absorption spectra were recorded using a double-beam ultraviolet-visible spectrophotometer (V-530: JASCO Co. Ltd., Kyoto, Japan). For the measurement of absorbance, an absorbance microplate reader (ELx808: Bio-Tek Instruments Inc., Winooski, VT, USA) controlled with KC Junior software (version 20.0), provided with the instrument, was utilized.

3.2. Chemicals and Materials

RUX was acquired from Selleck Chemicals (Houston, TX, USA). The Jakavi® tablets (Novartis, Basel, Switzerland; Batch No. SM822) labelled as containing 15 mg RUX per tablet and Opzelura® cream (Incyte Corporation, Wilmington, DE, USA; Batch No. NDC-50881) labelled as 1.5% were generously provided by the Saudi FDA (Riyadh, Saudi Arabia). CLA and DDQ were purchased from Sigma-Aldrich Chemicals Co. (St. Louis, MO, USA). Fresh solutions of both CLA and DDQ (1%, w/v, in methanol) were prepared. Corning® 96-well transparent polystyrene assay plates were obtained from Merck & Co. (Rahway, New Jersey, NJ, USA). Adjustable single- and 8-channel pipettes, as well as reagent reservoirs with cover lids for solution dispensing, were products of Merck KGaA (Darmstadt, Germany). Other materials were obtained from Fisher Scientific (Carlsbad, CA, USA).

3.3. Preparation of Standard RUX Solutions

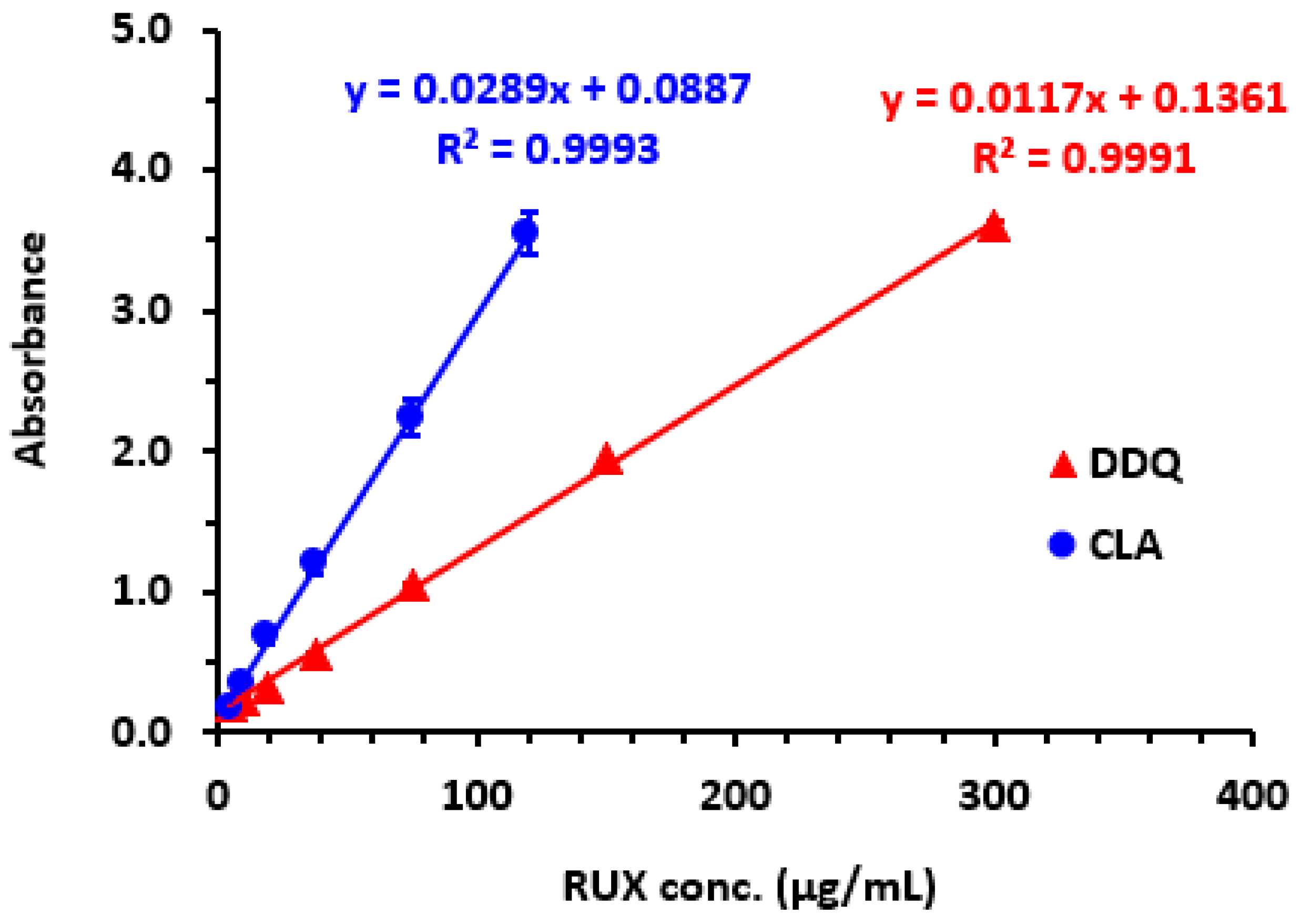

RUX stock solution (2 mg/mL) was prepared by dissolving 20 mg of RUX in 10 mL methanol. This stock solution was diluted with methanol to acquire working solutions of RUX with concentrations suitable for the corresponding experiments. These concentrations were in the ranges of 5–120 and 5–300 μg/mL for CLA and DDQ, respectively.

3.4. Preparation of Solutions of Jakavi® Tablets and Opzelura® Cream

Ten tablets of Jakavi® were pulverized into a fine powder. The precise quantity of this powder, which is equivalent to 20 mg of RUX, was transferred to a 25-mL calibrated flask. Approximately 20 mL of methanol was introduced, and the contents were thoroughly mixed to ensure complete dissolution of RUX from the tablet components. The flask’s contents were filtered, and the resulting filtrate was subsequently diluted with methanol to produce RUX solutions with concentrations ranging from 5 to 300 μg/mL. These solutions were then analyzed by the MW-SPM to determine their respective RUX concentrations.

For preparation of samples of Opzelura® cream for analysis, 1 g of cream was transferred into a 25-mL flask. Approximately 20 mL of methanol was added, and RUX was extracted from the cream base by vigorously shaking the flask contents for 5 min. The flask was allowed to settle, allowing any insoluble particles to settle to the bottom. The clear supernatant liquid was filtered, and the filtrate solution was diluted with methanol to produce RUX solutions with concentrations ranging from 5 to 300 μg/mL. These solutions were then analyzed by the MW-SPM to determine their respective RUX concentrations.

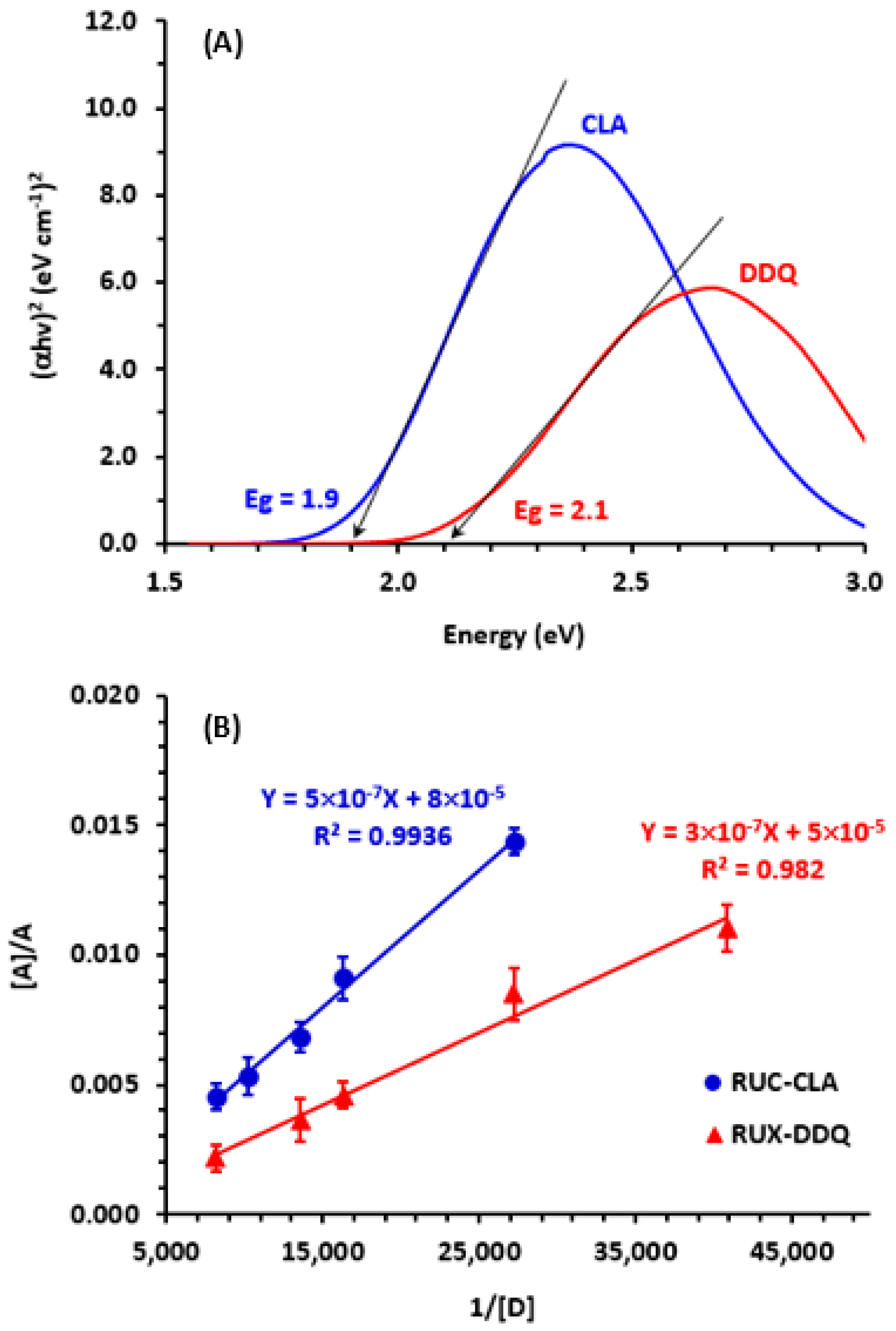

3.5. Determination of Association Constant

Two series of RUX solutions containing varying concentrations were prepared in methanol. These concentrations were in the ranges of 3.67 × 10−5–1.22 × 10−4 M and 2.45 × 10−5–1.22 × 10−4 M for reactions with CLA and DDQ, respectively. Each solution of these varying concentrations reacted with a fixed concentration of CLA (4.79 × 10−3 M) and DDQ (4.41 × 10−3 M). The reaction mixtures were equilibrated for ~5 min at room temperature (25 ± 2 °C). The absorbances of the combined solutions were measured, and these values were utilized to construct the Benesi–Hildebrand plots. The plot establishes a relationship between 1/[D] and [A]/A, where [D], [A], and A represent the molar concentration of RUX, the molar concentration of the acceptor (CLA and DDQ), and the absorbance, respectively. Regression analysis was performed on the plots, and the obtained results were employed to computationally determine the association constant of the CTCs.

3.6. Determination of Reaction Molar Ratio

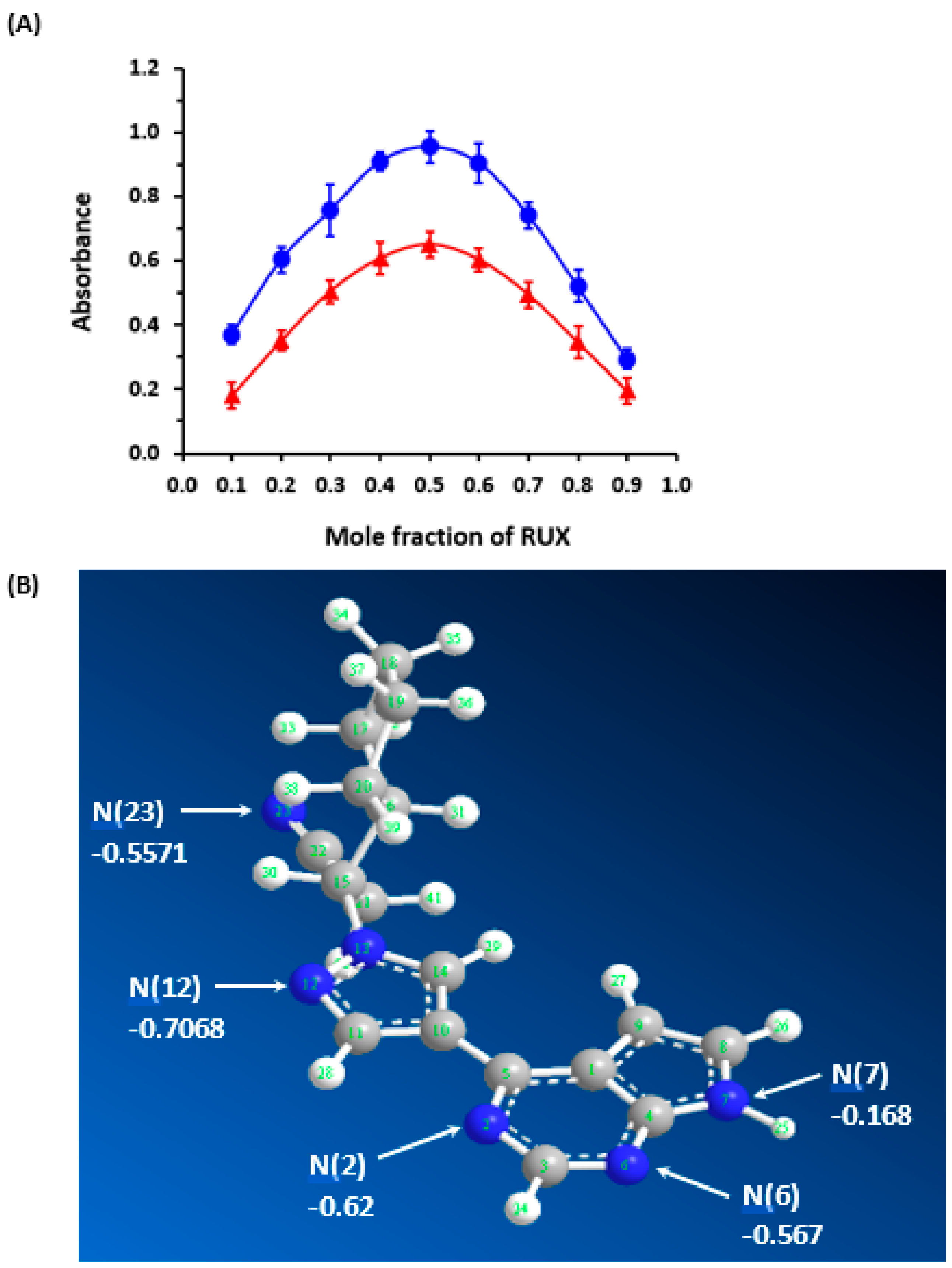

Job’s method was employed for determination of the molar ratio of RUX CTCs with both CLA and DDQ. Equimolar solutions (2 × 10−3 M) of RUX and each of CLA and DDQ were prepared. Varying volumes of RUX and the acceptor solutions were dispensed into microwells of the analysis plate used to make up different complementary volumes of RUX:acceptor (0:00, 25:175, 50:150, 100:100, 125:75, 150:50, 175:25, and 200:0). The absorbances of each well were measured and plotted as a function of the mole fraction of RUX. The generated Job’s plots were used for determining the molar ratio of the reactions between RUX and each of CLA and DDQ.

3.7. Procedures of the MW-SPM

100 µL aliquots of the RUX standard solution, Jakavi® tablets, or Opzelura® cream, which contained various concentrations of RUX ranging from 5 to 250 µg, were precisely dispensed into the wells of an analysis plate. Subsequently, 100 µL of a 1% (w/v) solution of either CLA or DDQ was added to each well, and the reaction was allowed to proceed for 5 min at room temperature (25 ± 2 °C). The absorbance of the solutions in each well was then measured using an absorbance microplate reader at 530 and 470 nm for analysis of reactions with CLA and DDQ, respectively.

) and DDQ (

) and DDQ ( ). The values are the means of 3 measurements ± SD. Panel (B) a molecule of RUX with atom numbers, and the arrows pointing to the potential atoms for participation in the formation of CTCs, along with their partial charges. Negative sign denotes negative electron density.

). The values are the means of 3 measurements ± SD. Panel (B) a molecule of RUX with atom numbers, and the arrows pointing to the potential atoms for participation in the formation of CTCs, along with their partial charges. Negative sign denotes negative electron density.

) and DDQ (

) and DDQ ( ). The values are the means of 3 measurements ± SD. Panel (B) a molecule of RUX with atom numbers, and the arrows pointing to the potential atoms for participation in the formation of CTCs, along with their partial charges. Negative sign denotes negative electron density.

). The values are the means of 3 measurements ± SD. Panel (B) a molecule of RUX with atom numbers, and the arrows pointing to the potential atoms for participation in the formation of CTCs, along with their partial charges. Negative sign denotes negative electron density.

) and DDQ (

) and DDQ ( ). The points are the means of 3 determinations ± SD.

). The points are the means of 3 determinations ± SD.

) and DDQ (

) and DDQ ( ). The points are the means of 3 determinations ± SD.

). The points are the means of 3 determinations ± SD.