Effect of Wet–Dry Cycling on Properties of Natural-Cellulose-Fiber-Reinforced Geopolymers: A Short Review

Abstract

1. Introduction

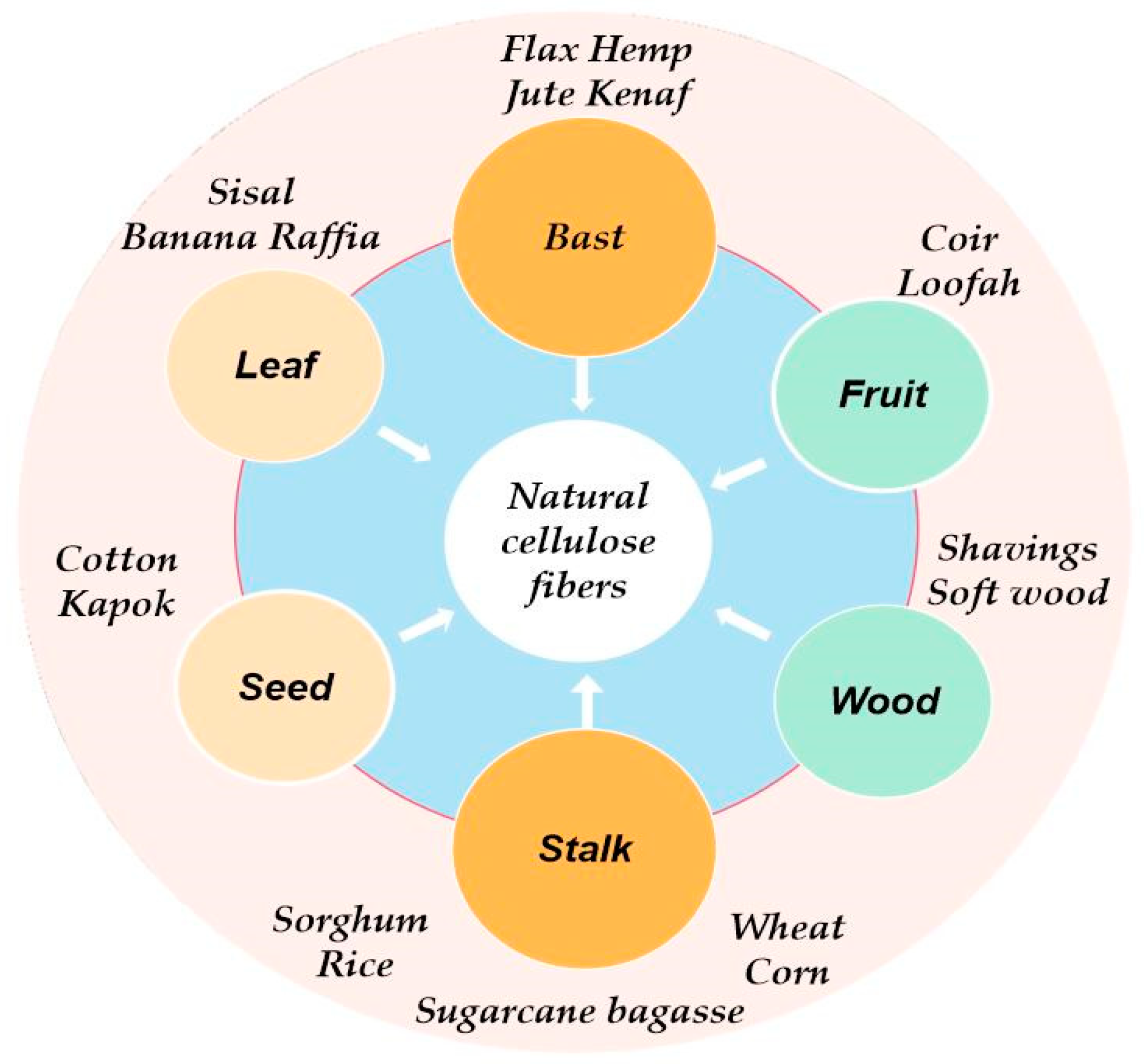

2. Classification and Properties of NCFs

3. Properties of NCFRG Composite

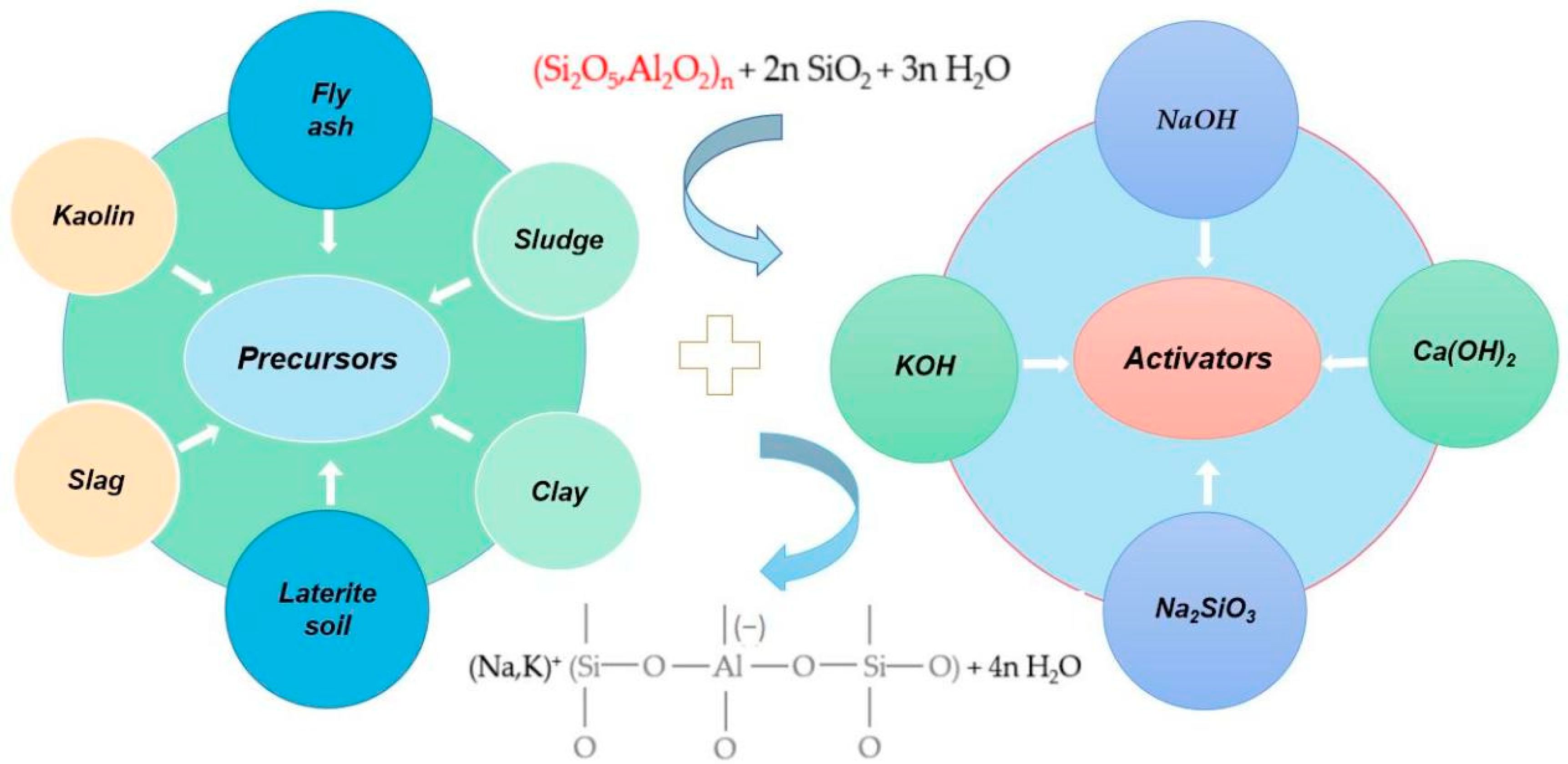

3.1. Types of Geopolymers

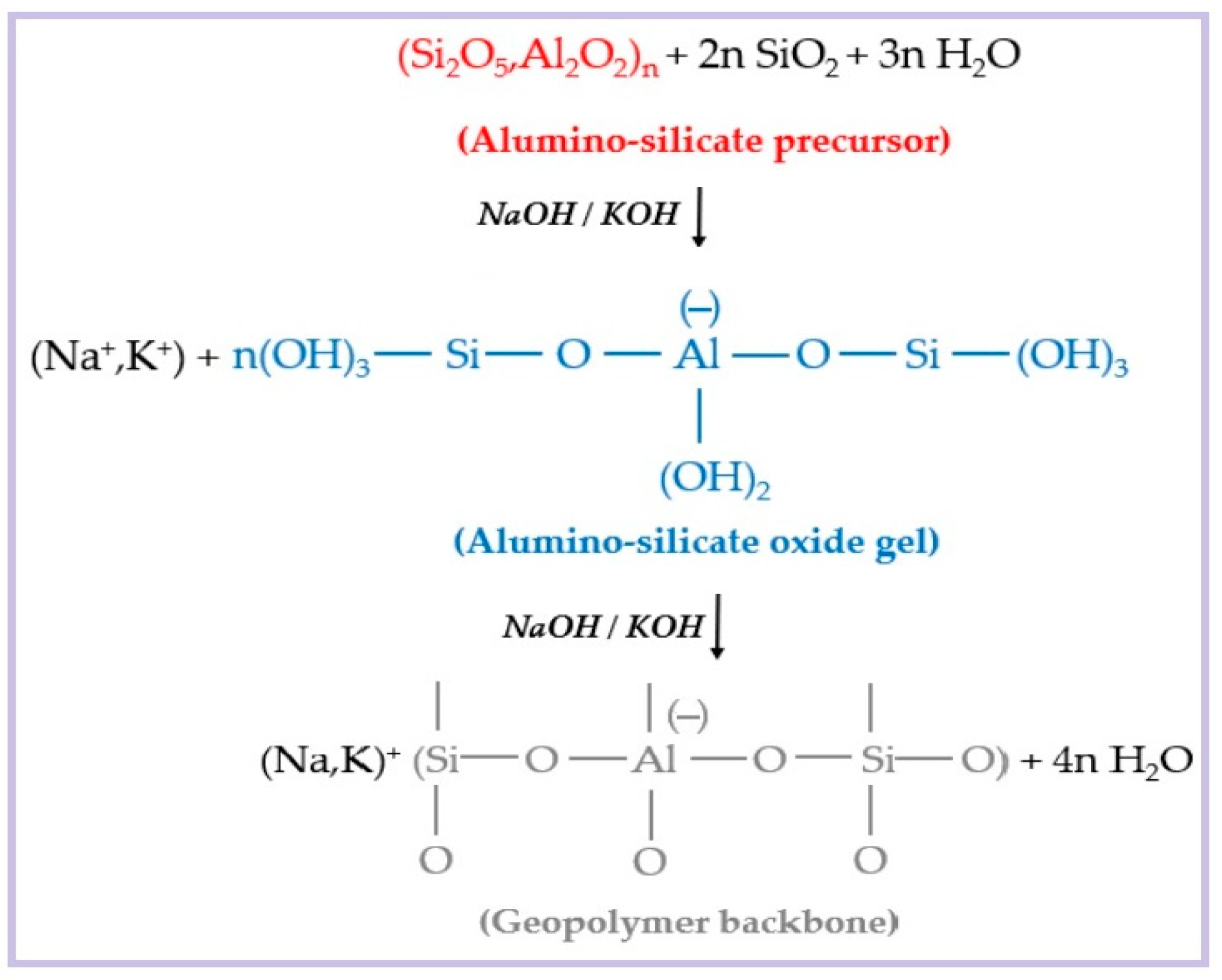

3.2. Polymerization Mechanism of Geopolymers

3.3. Bonding Properties of NCF and Geopolymers

3.4. Water Absorption Properties of NCFRG

4. Mechanical Properties of NCFRG under Non-Wet–Dry Cycle Conditions

4.1. Influence of Different Kinds of Fibers on the Mechanical Properties of Geopolymers

4.2. Effect of Fiber Modification on Composite Materials

5. Effect of Wet–Dry Cycles on Properties of Fiber-Reinforced Geopolymers

5.1. Wet–Dry Cycle Test Method

5.2. Effect of Wet–Dry Cycling on Geopolymer Matrix

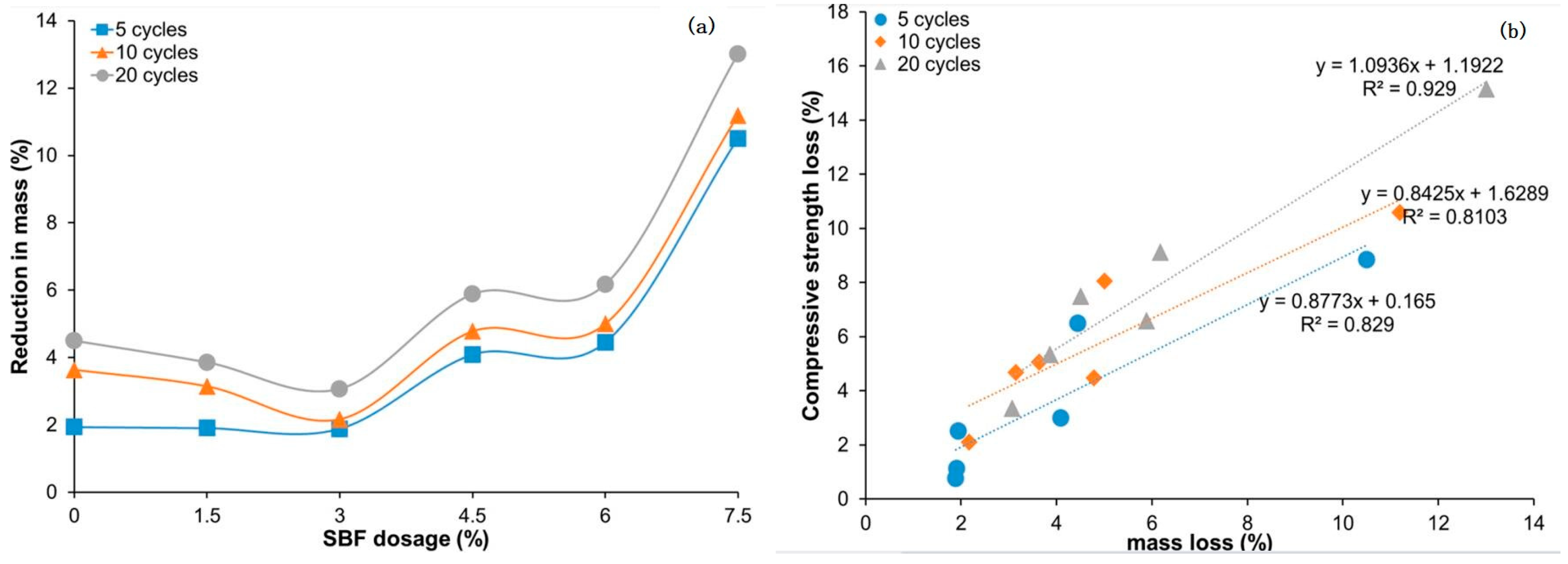

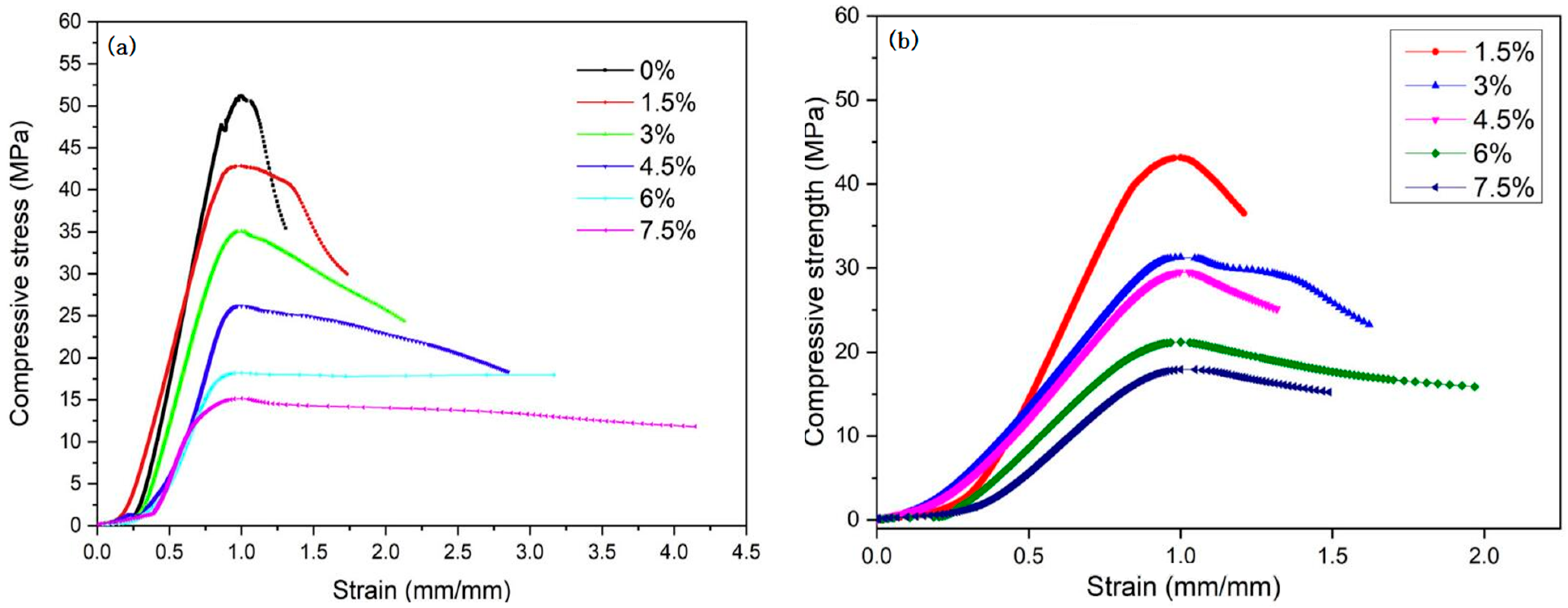

5.2.1. Influence of Wet–Dry Cycle on Compressive Strength of Composites

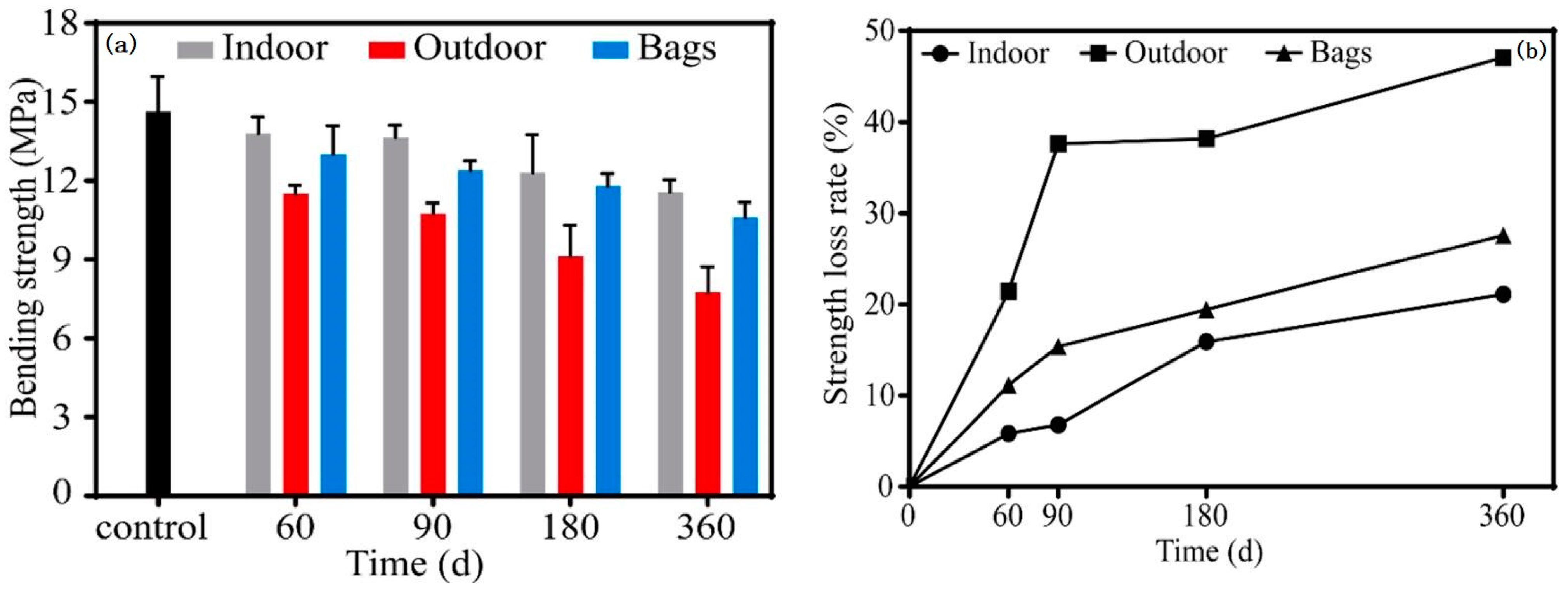

5.2.2. Influence of Bending Strength

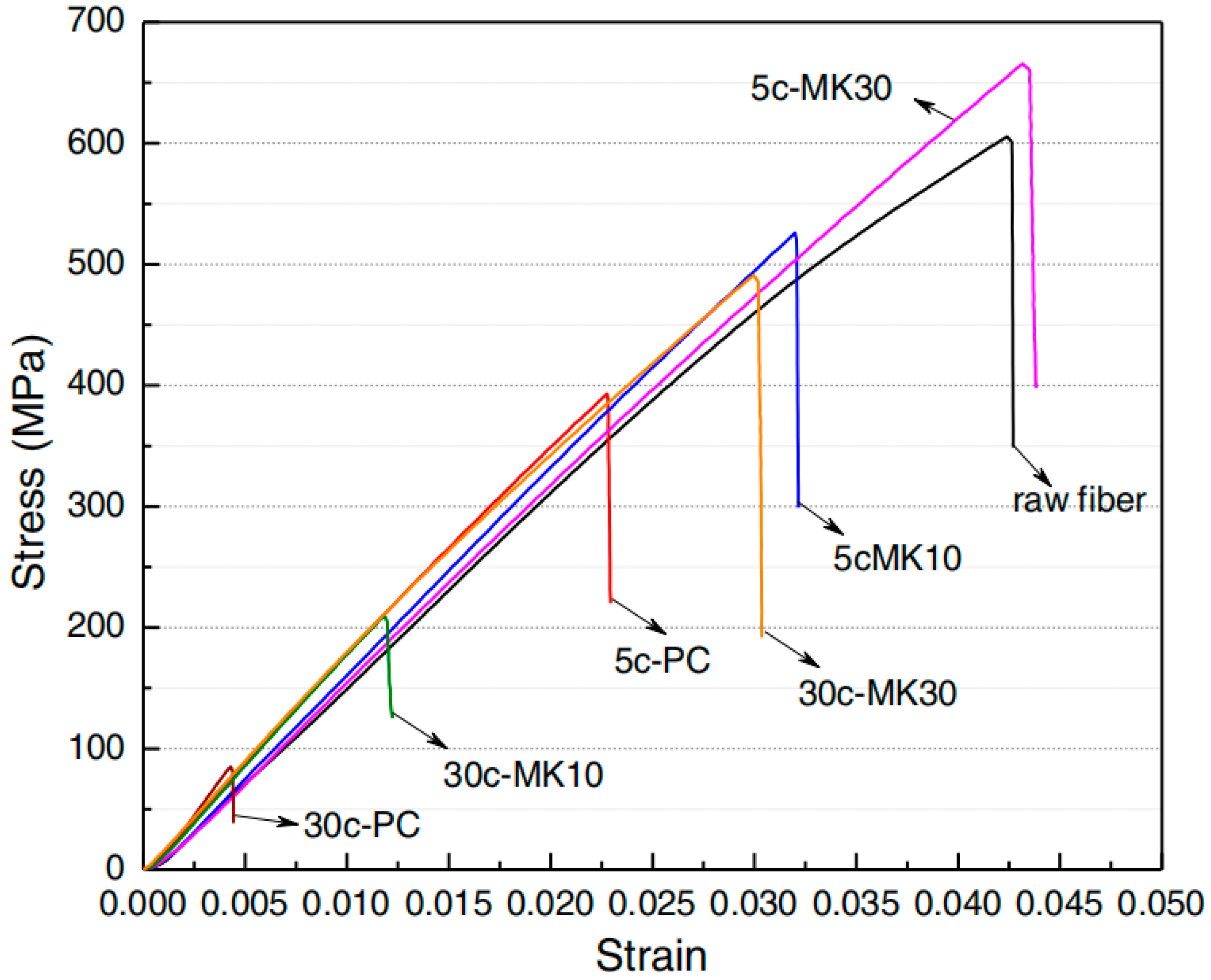

5.2.3. Influence of Wet–Dry Cycle on Fiber

- Keratinization mechanism of NCFs under wet–dry cycle

- Degradation behavior under wet–dry cycle conditions

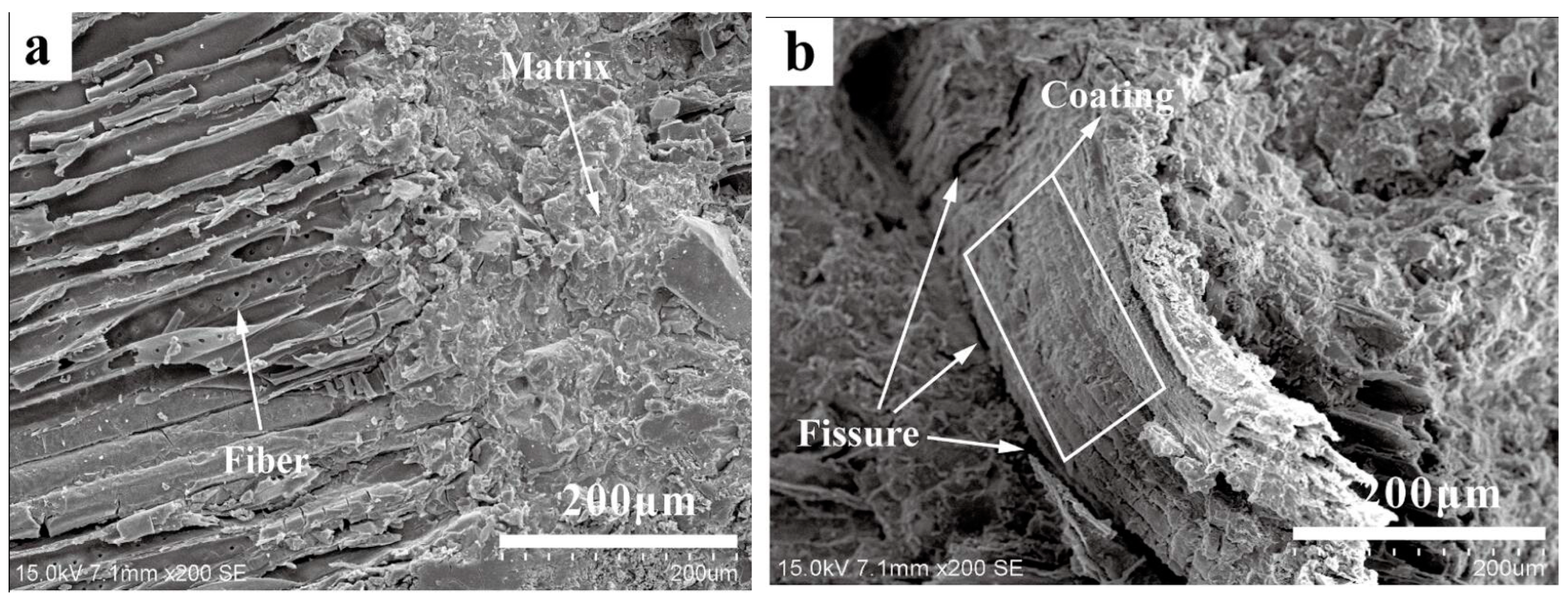

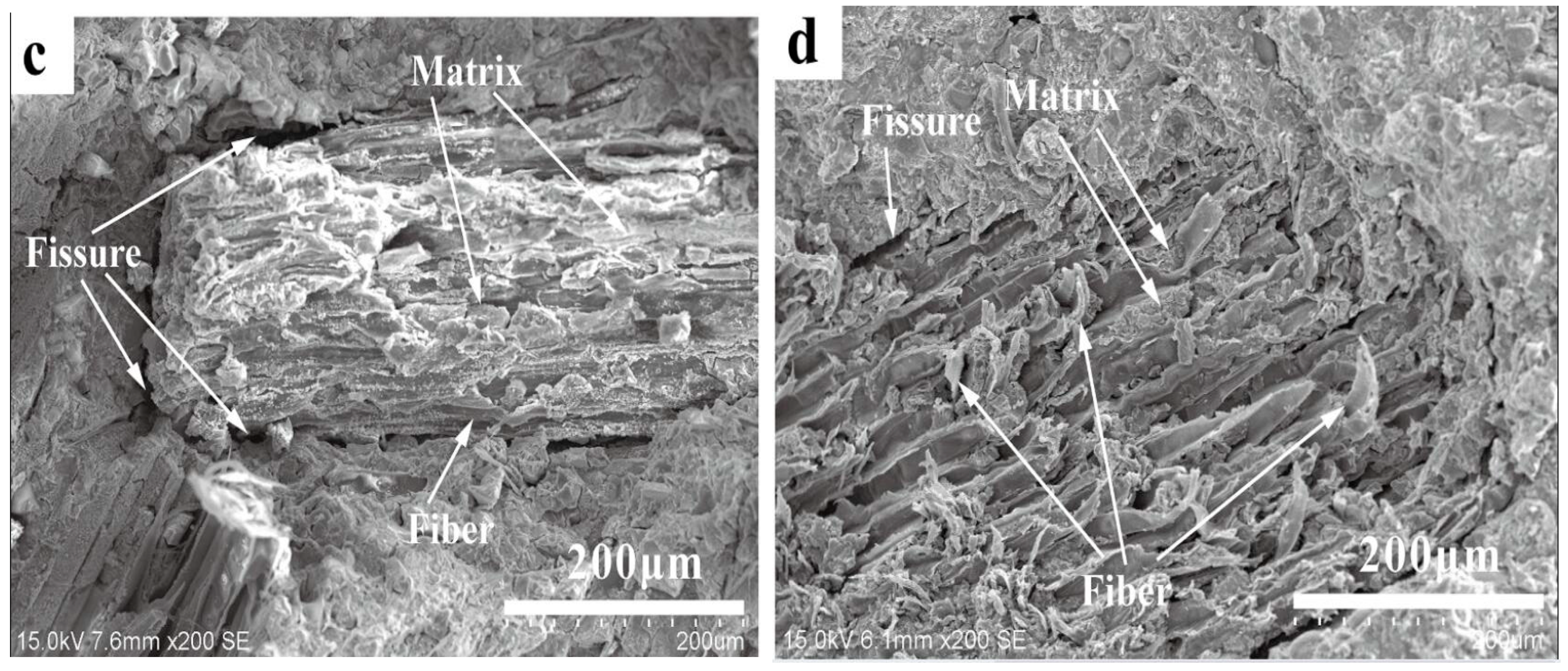

6. Influence of Wet–Dry Cycle on the Microstructure of Composites

7. Future Directions and Limitations

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, N.B.; Middendorf, B. Geopolymers as an alternative to Portland cement: An overview. Constr. Build. Mater. 2020, 237, 117455. [Google Scholar] [CrossRef]

- Nguyen, Q.D.; Castel, A. Developing Geopolymer Concrete by Using Ferronickel Slag and Ground-Granulated Blast-Furnace Slag. Ceramics 2023, 6, 1861–1878. [Google Scholar] [CrossRef]

- Xiong, L.; Fan, B.; Wan, Z.; Zhang, Z.; Zhang, Y.; Shi, P. Study on the Mechanical Properties of Fly-Ash-Based Light-Weighted Porous Geopolymer and Its Utilization in Roof-Adaptive End Filling Technology. Molecules 2021, 26, 4450. [Google Scholar] [CrossRef] [PubMed]

- Provis, J.L.; Bernal, S.A. Geopolymers and related alkali-activated materials. Annu. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Toniolo, N.; Boccaccini, A.R. Fly ash-based geopolymers containing added silicate waste. A review. Ceram. Int. 2017, 43, 14545–14551. [Google Scholar] [CrossRef]

- Detphan, S.; Chindaprasirt, P. Preparation of fly ash and rice husk ash geopolymer. Int. J. Miner. Metall. Mater. 2009, 16, 720–726. [Google Scholar]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M. A comprehensive review on the ground granulated blast furnace slag (GGBS) in concrete production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Wang, S.; Jin, H.; Deng, Y.; Xiao, Y. Comprehensive utilization status of red mud in China: A critical review. J. Clean. Prod. 2021, 289, 125136. [Google Scholar] [CrossRef]

- He, J.; Jie, Y.; Zhang, J.; Yu, Y.; Zhang, G. Synthesis and characterization of red mud and rice husk ash-based geopolymer composites. Cem. Concr. Compos. 2013, 37, 108–118. [Google Scholar] [CrossRef]

- Opiso, E.M.; Tabelin, C.B.; Maestre, C.V.; Aseniero, J.P.J.; Arima, T.; Villacorte-Tabelin, M. Utilization of Palm Oil Fuel Ash (POFA) as an Admixture for the Synthesis of a Gold Mine Tailings-Based Geopolymer Composite. Minerals 2023, 13, 232. [Google Scholar] [CrossRef]

- Lv, C.; Wu, D.; Guo, G.; Zhang, Y.; Liu, S.; Qu, E.; Liu, J. Effect of Plant Fiber on Early Properties of Geopolymer. Molecules 2023, 28, 4710. [Google Scholar] [CrossRef] [PubMed]

- Santos, S.F.; Tonoli, G.H.D.; Mejia, J.E.B.; Fiorelli, J.; Savastano, H., Jr. Non-conventional cement-based composites reinforced with vegetable fibers: A review of strategies to improve durability. Mater. Construcción 2015, 65, 41. [Google Scholar]

- Liu, J.; Lv, C. Research Progress on Durability of Cellulose Fiber-Reinforced Cement-Based Composites. Int. J. Polym. Sci. 2021, 2021, 1014531. [Google Scholar] [CrossRef]

- Liu, J.; Lv, C. Properties of 3D-Printed Polymer Fiber-Reinforced Mortars: A Review. Polymers 2022, 14, 1315. [Google Scholar] [CrossRef] [PubMed]

- Neupane, K. Evaluation of environmental sustainability of one-part geopolymer binder concrete. Clean. Mater. 2022, 6, 100138. [Google Scholar] [CrossRef]

- Singh, N.B. Fly ash-based geopolymer binder: A future construction material. Minerals 2018, 8, 299. [Google Scholar] [CrossRef]

- de Oliveira, L.B.; de Azevedo, A.R.G.; Marvila, M.T.; Pereira, E.C.; Fediuk, R.; Vieira, C.M.F. Durability of geopolymers with industrial waste. Case Stud. Constr. Mater. 2022, 16, e00839. [Google Scholar] [CrossRef]

- Farooq, F.; Jin, X.; Faisal Javed, M.; Akbar, A.; Izhar Shah, M.; Aslam, F.; Alyousef, R. Geopolymer concrete as sustainable material: A state of the art review. Constr. Build. Mater. 2021, 306, 124762. [Google Scholar] [CrossRef]

- Huang, G.; Ji, Y.; Li, J.; Hou, Z.; Jin, C. Use of slaked lime and Portland cement to improve the resistance of MSWI bottom ash-GBFS geopolymer concrete against carbonation. Constr. Build. Mater. 2018, 166, 290–300. [Google Scholar] [CrossRef]

- Pacewska, B.; Wilińska, I. Usage of supplementary cementitious materials: Advantages and limitations. J. Therm. Anal. Calorim. 2020, 142, 371–393. [Google Scholar] [CrossRef]

- Aygormez, Y.; Canpolat, O.; Al-Mashhadani, M.; Uysal, M. Elevated temperature, freezing-thawing and wetting-drying effects on polypropylene fiber reinforced metakaolin based geopolymer composites, Construct. Build. Mater. 2020, 235, 117502. [Google Scholar] [CrossRef]

- Horpibulsuk, S.; Suksiripattanapong, C.; Samingthong, W.; Rachan, R.; Arulrajah, A. Durability against wetting-drying cycles of water treatment sludge-fly ash geopolymer and water treatment sludge-cement and silty clay-cement systems. J. Mater. Civ. Eng. 2015, 28, 04015078. [Google Scholar] [CrossRef]

- Sodoke, F.K.; Toubal, L.; Laperrière, L. Wetting/drying cyclic effects on mechanical and physicochemical properties of quasiisotopic flax/epoxy composites. Polym. Degrad. Stab. 2019, 161, 121–130. [Google Scholar] [CrossRef]

- Wei, M.; Xie, J.; Zhang, H.; Li, J. Bond-slip behaviors of BFRP-to-concrete interfaces exposed to wet/dry cycles in chloride environment. Compos. Struct. 2019, 219, 185–193. [Google Scholar] [CrossRef]

- Liu, J.; Lv, C. Durability of Cellulosic-Fiber-Reinforced Geopolymers: A Review. Molecules 2022, 27, 796. [Google Scholar] [CrossRef]

- Lv, C.; Shen, H.; Liu, J.; Wu, D.; Qu, E.; Liu, S. Properties of 3D Printing Fiber-Reinforced Geopolymers Based on Interlayer Bonding and Anisotropy. Materials 2022, 15, 8032. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Kruglikov, A.; Mischinenk, V.; Yavna, V. Sustainable geopolymer composites reinforced with flax tows. Ceram. Int. 2020, 46, 12870–12875. [Google Scholar] [CrossRef]

- Bos, H.L.; Oever, M.; Peters, O. Tensile and compressive properties of flax fibres for natural fibre reinforced composites. J. Mater. Sci. 2002, 37, 1683–1692. [Google Scholar] [CrossRef]

- Pickering, K.L.; Beckermann, G.W.; Alam, S.N.; Foreman, N.J. Optimising industrial hemp fibre for composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 461. [Google Scholar] [CrossRef]

- Mustafa, A.; Abdollah, M.; Shuhimi, F.F.; Ismail, N.; Amiruddin, H.; Umehara, N. Selection and verification of kenaf fibres as an alternative friction material using weighted decision matrix method. Mater. Des. 2015, 67, 577–582. [Google Scholar] [CrossRef]

- Kumar, R.; Obrai, S.; Sharma, A. Chemical modifications of natural fiber for composite material. Chem. Sin. 2011, 2, 219–228. [Google Scholar]

- Santos, G.; Oliveira, D.; Filho, J.; Silva, N. Sustainable geopolymer composite reinforced with sisal fiber: Durability to wetting and drying cycles. J. Build. Eng. 2021, 43, 102568. [Google Scholar] [CrossRef]

- Kamaruddin, F.A.; Anggraini, V.; Kim Huat, B.; Nahazanan, H. Wetting/Drying Behavior of Lime and Alkaline Activation Stabilized Marine Clay Reinforced with Modified Coir Fiber. Materials 2020, 13, 2753. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Chopped glass and recycled newspaper as reinforcement fibers in injection molded poly (lactic acid) (pla) composites: A comparative study. Compos. Sci. Technol. 2015, 66, 1813–1824. [Google Scholar] [CrossRef]

- Korniejenko, K.; Fraczek, M.; Pytlak, E.; Adamski, M. Mechanical properties of geopolymer composites reinforced with natural fibers. Procedia Eng. 2016, 151, 388–393. [Google Scholar] [CrossRef]

- Ranjbar, N.; Zhang, M. Fiber reinforced geopolymer composites: A review. Cem. Concr. Comp. 2020, 107, 103498. [Google Scholar] [CrossRef]

- Guo, G.; Lv, C.; Liu, J.; Wang, L. Properties of Fiber-Reinforced One-Part Geopolymers: A Review. Polymers 2022, 14, 3333. [Google Scholar] [CrossRef]

- Nkwaju, R.Y.; Djobo, J.N.Y.; Nouping, J.N.F.; Huisken, P.W.M.; Deutou, J.G.N.; Courard, L. Iron-rich laterite-bagasse fibers based geopolymer composite: Mechanical, durability and insulating properties. Appl. Clay Sci. 2019, 183, 105333. [Google Scholar] [CrossRef]

- Lv, C.; Liu, J.; Guo, G.; Zhang, Y. The Mechanical Properties of Plant Fiber-Reinforced Geopolymers: A Review. Polymers 2022, 14, 4134. [Google Scholar] [CrossRef]

- Trindade, A.; Silva, F.; Alcamand, H.; Borges, P. On the durability behavior of natural fiber reinforced geopolymer. Ceram. Eng. Sci. Proc. 2018, 38, 215–228. [Google Scholar]

- Filho, J.; Silva, F.; Filho, R. Degradation kinetics and aging mechanisms on sisal fiber cement composite systems. Cem. Concr. Compos. 2013, 40, 30–39. [Google Scholar] [CrossRef]

- Wei, J.; Gencturk, B. Degradation of Natural Fiber in Cement Composites Containing Diatomaceous Earth. J. Mater. Civ. Eng. 2018, 30, 04018282. [Google Scholar] [CrossRef]

- Asante, B.; Schmidt, G.; Teixeira, R.; Krause, A.; Junior, H.S. Influence of wood pretreatment and fly ash particle size on the performance of geopolymer wood composite. Eur. J. Wood Prod. 2021, 79, 597–609. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: Strength and permeability properties. J. Clean. Prod. 2018, 205, 49–57. [Google Scholar] [CrossRef]

- Tian, Q.; Bai, Y.; Pan, Y.; Chen, C.; Yao, S.; Sasaki, K.; Zhang, H. Application of Geopolymer in Stabilization/Solidification of Hazardous Pollutants: A Review. Molecules 2022, 27, 4570. [Google Scholar] [CrossRef]

- Venkatesan, R.P.; Pazhani, K.C. Strength and durability properties of geopolymer concrete made with Ground Granulated Blast Furnace Slag and Black Rice Husk Ash. KSCE J. Civ. Eng. 2016, 20, 2384–2391. [Google Scholar] [CrossRef]

- Bukhary, A.; Azam, S. A Review of Physicochemical Stabilization for Improved Engineering Properties of Clays. Geotechnics 2023, 3, 744–759. [Google Scholar] [CrossRef]

- Han, R.; Guo, X.; Guan, J.; Yao, X.; Hao, Y. Activation Mechanism of Coal Gangue and Its Impact on the Properties of Geopolymers: A Review. Polymers 2022, 14, 3861. [Google Scholar] [CrossRef]

- Arioza, E.; Ariozb, O.; Mete Kockar, O. An Experimental Study on the Mechanical and Microstructural Properties of Geopolymers. Procedia Eng. 2012, 42, 100–105. [Google Scholar] [CrossRef][Green Version]

- Sambucci, M.; Sibai, A.; Valente, M. Recent advances in geopolymer technology. A potential eco-friendly solution in the construction materials industry: A review. J. Compos. Sci. 2021, 5, 109. [Google Scholar] [CrossRef]

- Duxson, P.; Lukey, G.C.; Separovic, F.; van Deventer, J.S.J. Effect of alkali cations on aluminum incorporation in geopolymeric gels. Ind. Eng. Chem. Res. 2005, 44, 832–839. [Google Scholar] [CrossRef]

- Rao, J.; Zhou, Y.; Fan, M. Revealing the Interface Structure and Bonding Mechanism of Coupling Agent Treated WPC. Polymers 2018, 10, 266. [Google Scholar] [CrossRef] [PubMed]

- Awoyera, P.; Odutuga, O.; Effiong, J.; De Jesus Silvera Sarmiento, A.; Mortazavi, S.; Hu, J. Development of Fibre-Reinforced Cementitious Mortar with Mineral Wool and Coconut Fibre. Materials 2022, 15, 4520. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Li, S. Effects of wetting and drying on alkalinity and strength of fly ash/slag-activated materials. Constr. Build. Mater. 2020, 254, 119069. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.; Low, I. Synthesis and mechanical properties of cotton fabric reinforced geopolymer composites. Compos. Part B 2014, 60, 36–42. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Shaikh, F.; Low, I.M. Characterisation of mechanical and thermal properties in flax fabric reinforced geopolymer composites. J. Adv. Ceram. 2015, 4, 272–281. [Google Scholar] [CrossRef]

- Assarar, M.; Scida, D.; EL Mahi, A.; Poilâne, C.; Ayad, R. Influence of water ageing on mechanical properties and damage events of two reinforced composite materials: Flax-fibres and glass-fibres. Mater. Des. 2011, 32, 788–795. [Google Scholar] [CrossRef]

- Ali, A.; Mucteba, U.; Arın, Y.; Al-mashhadani Mukhallad, M.; Orhan, C.; Furkan, S.; Yurdakul, A. Influence of wetting-drying curing system on the performance of fiber reinforced metakaolin-based geopolymer composites. Constr. Build. Mater. 2019, 225, 909–926. [Google Scholar]

- Mourak, A.; Hajjaji, M.; Alagui, A. Cured alkali-activated heated clay-cellulose composites: Microstructure, effect of glass addition and performances. Boletín Soc. Española Cerámica Vidr. 2021, 20, 62–72. [Google Scholar] [CrossRef]

- More, F.; Subramanian, S. Impact of Fibres on the Mechanical and Durable Behaviour of Fibre-Reinforced Concrete. Buildings 2022, 12, 1436. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation mechanisms of natural fiber in the matrix of cement composites. Cem. Concr. Res. 2015, 73, 1–16. [Google Scholar] [CrossRef]

- Addis, L.; Sendekie, Z.; Satheesh, N. Degradation Kinetics and Durability Enhancement Strategies of Cellulosic Fiber-Reinforced Geopolymers and Cement Composites. Adv. Mater. Sci. Eng. 2022, 2022, 1981755. [Google Scholar] [CrossRef]

- Azwa, Z.N.; Yousif, B.F.; Manalo, A.C.; Karunasena, W. A review on the degradability of polymeric composites based on natural fibres. Mater. Des. 2013, 47, 424–442. [Google Scholar] [CrossRef]

- Vaisanen, T.; Das, O.; Tomppo, L. A review on new biobased constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Methacanon, P.; Weerawatsophon, U.; Sumransin, N.; Prahsarn, C.; Bergado, D. Properties and potential application of the selected natural fibers as limited life geotextiles. Carbohyd. Polym. 2010, 82, 1090–1096. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sulfuric acid resistance of fly ash based geopolymer concrete. Constr. Build. Mater. 2017, 146, 136–143. [Google Scholar] [CrossRef]

- Zabihi, S.M.; Tavakoli, H.; Mohseni, E. Engineering and microstructural properties of fiber-reinforced rice husk-ash based geopolymer concrete. J. Mater. Civ. Eng. 2018, 30, 04018183. [Google Scholar] [CrossRef]

- Lv, C.; Liu, J. Alkaline Degradation of Plant Fiber Reinforcements in Geopolymer: A Review. Molecules 2023, 28, 1868. [Google Scholar] [CrossRef]

- Eyerusalem, A.; Judith, A.; Dirk, W.; Daniel, T.; Aldo, R. Hemp fiber reinforced red mud/fly ash geopolymer composite materials: Effect of fiber content on mechanical strength. Materials 2021, 14, 14030511. [Google Scholar]

- Sáez-Pérez, M.; Brümmer, M.; Durán-Suárez, A. Effect of the state of conservation of the hemp used in geopolymer and hydraulic lime concretes. Constr. Build. Mater. 2021, 285, 122853. [Google Scholar] [CrossRef]

- Poletanovic, B.; Dragas, J.; Ignjatovic, I.; Komljenovic, M.; Merta, I. Physical and mechanical properties of hemp fibre reinforced alkali-activated fly ash and fly ash/slag mortars. Constr. Build. Mater. 2020, 259, 119677. [Google Scholar] [CrossRef]

- Trindade, A.C.; Arêas, I.O.; Almeida, D.C.; Alcamand, H.A.; Borges, P.H.; Silva, F.A. Mechanical behavior of geopolymeric composites reinforced with natural fibers. In International Conference on Strain-Hardening Cement-Based Composites; Mechtcherine, V., Slowik, V., Kabele, P., Eds.; RILEM Bookseries; Springer: Berlin/Heidelberg, Germany, 2017; Volume 15. [Google Scholar]

- Na, Z.; Hya, B.; Dpa, B.; Yang, Z. Effects of alkali-treated kenaf fiber on environmentally friendly geopolymer-kenaf composites: Black liquid as the regenerated activator of the geopolymer. Constr. Build. Mater. 2021, 297, 123787. [Google Scholar]

- Kornejenko, K.; Ach, M.; Salamtmur, N.D.; Furtos, G.; Mkua, J. The overview of mechanical properties of short natural fiber reinforced geopolymer composites. Environ. Res. Technol. 2020, 3, 21–32. [Google Scholar] [CrossRef]

- Ampol, W.; Ronnakrit, K.; Sakchai, N.; Vanchai, S.; Prinya, C. Natural fiber reinforced high calcium fly ash geopolymer mortar. Constr. Build. Mater. 2020, 241, 118143. [Google Scholar]

- Haque, M.; Rahman, R.; Islam, N.; Huque, M.; Hasan, M. Mechanical properties of polypropylene composites reinforced with chemically treated coir and abaca fiber. J. Reinf. Plast. Compos. 2010, 29, 2253–2261. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.U.A.; Low, I.M. Effect of fabric orientation on mechanical properties of cotton fabric reinforced geopolymer composites. Mater. Des. 2014, 57, 360–365. [Google Scholar] [CrossRef]

- Zulfiati, R.; Saloma; Idris, Y. Mechanical properties of fly ash-based geopolymer with natural fiber. J. Phys. Conf. Ser. 2019, 1198, 082021. [Google Scholar] [CrossRef]

- Kroehong, W.; Chai, J.; Pothisiri, T.; Chindaprasirt, P. Effect of oil palm fiber content on the physical and mechanical properties and microstructure of high-calcium fly ash geopolymer paste. Arab. J. Sci. Eng. 2018, 11, 5215–5224. [Google Scholar] [CrossRef]

- Mazen, A.; Abu, M.; Juma, A.; Yasair, A.; Tarek, F.; Abderrazek, K.; Fernando, R. Fabrication, microstructural and mechanical characterization of Luffa Cylindrical Fibre-Reinforced geopolymer composite. Appl. Clay Sci. 2017, 143, 125–133. [Google Scholar]

- Su, Z.; Guo, L.; Zhang, Z.; Duan, P. Influence of different fibers on properties of thermal insulation composites based on geopolymer blended with glazed hollow bead. Constr. Build. Mater. 2019, 203, 525–540. [Google Scholar] [CrossRef]

- Gabriel, F.; Laura, S.; Petru, P.; Codruta, S.; Kinga, K. Mechanical properties of wood fiber reinforced geopolymer composites with sand addition. J. Nat. Fibers 2021, 18, 285–296. [Google Scholar]

- Chen, R.; Ahmari, S.; Zhang, L. Utilization of sweet sorghum fiber to reinforce fly ash-based geopolymer. J. Mater. Sci. 2014, 49, 2548–2558. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites-A review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Kundu, S.; Chakraborty, S.; Majumder, S.; Adhikari, B. Effectiveness of the mild alkali and dilute polymer modification in controlling the durability of jute fibre in alkaline cement medium. Constr. Build. Mater. 2018, 174, 330–342. [Google Scholar] [CrossRef]

- Filho, K.S.R.D.T.; Ghavami, K.; England, G.L. Development of vegetable fibre–mortar composites of improved durability. Cem. Concr. Compos. 2003, 25, 186–196. [Google Scholar]

- Lazorenko, G.; Kasprzhitskii, A.; Yavna, V. Effect of pre-treatment of flax tows on mechanical properties and microstructure of natural fiber reinforced geopolymer composites. Environ. Technol. Innov. 2020, 20, 101105. [Google Scholar] [CrossRef]

- Bogard, F.; Bach, T.; Bogard, V.; Beaumont, F.; Murer, S.; Bliard, C.; Polidori, G. Mechanical Properties of a PLA/Nettle Agro-Composite with 10% Oriented Fibers. Appl. Sci. 2022, 12, 9835. [Google Scholar] [CrossRef]

- Huang, Y.; Tan, J.; Xuan, X.; Liu, L.; Xie, M.; Liu, H.; Yu, S.; Zheng, G. Study on untreated and alkali treated rice straw reinforced geopolymer composites. Mater. Chem. Phys. 2021, 262, 124304. [Google Scholar] [CrossRef]

- Workiye, A.; Woldsenbet, E. Development of maize stalk cellulose fiber reinforced calcined kaolinite clay geopolymer composite. Proc. Eng. Technol. Innov. 2020, 16, 30–38. [Google Scholar] [CrossRef]

- Ribeiro, R.A.S.; Ribeiro, M.G.S.; Sankar, K.; Kriven, W.M. Geopolymer-bamboo composite—A novel sustainable construction material. Constr. Build. Mater. 2016, 123, 501–507. [Google Scholar] [CrossRef]

- Malenab, R.A.J.; Ngo, J.P.S.; Promentilla, M.A.B. Chemical treatment of waste abaca for natural fiber-reinforced geopolymer composite. Materials 2017, 10, 579. [Google Scholar] [CrossRef] [PubMed]

- Maichin, P.; Suwan, T.; Jitsangiam, P. Hemp fiber reinforced geopolymer composites: Effects of NaOH concentration on fiber pre-treatment process. Key Eng. Mater. 2020, 841, 166–170. [Google Scholar] [CrossRef]

- Maichin, P.; Suwan, T.; Jitsangiam, P. Effect of self-treatment process on properties of natural fiber-reinforced geopolymer composites. Mater. Manuf. Process. 2020, 35, 1120–1128. [Google Scholar] [CrossRef]

- Nkwaju, R.; Kaze, C.; Adesina, A.; Djobo, J.N. Performance of laterite-based geopolymers reinforced with sugarcane bagasse fibers. Case Stud. Constr. Mater. 2021, 15, e00762. [Google Scholar]

- Huang, Y.; Tan, J.; Xuan, X.; Wei, S.; Liu, L.; Yu, S.; Zheng, G. Durability of plant fiber reinforced alkali activated composites. Constr. Build. Mater. 2022, 314, 125501. [Google Scholar] [CrossRef]

- Vu, M.; Satomi, T.; Takahashi, H.; Le, A. Study on Weak Soil Improvement by Using Geopolymer and Paper Fragments. Int. J. Soc. Mater. Eng. Resour. 2018, 23, 203–208. [Google Scholar] [CrossRef][Green Version]

- Kamei, T.; Ahmed, A.; Ugai, K. Durability of soft clay stabilized with recycled bassanite and furnace cement mixtures. Jpn. Geotech. Soc. Soils Found. 2013, 53, 155–165. [Google Scholar] [CrossRef]

- Muntohar, A.; Hartono, E.; Widianti, A. Engineering properties of silty soil stabilized with lime and rice husk ash and reinforced with waste plastic fiber. J. Mater. Civ. Eng. 2013, 25, 1260–1270. [Google Scholar] [CrossRef]

- Du, Y.J.; Bo, Y.L.; Jin, F.; Liu, C.Y. Durability of reactive magnesia-activated slag stabilized low plasticity clay subjected to drying-wetting cycle. Eur. J. Environ. Civ. Eng. 2016, 20, 215–230. [Google Scholar] [CrossRef]

- Hoy, M.; Rachan, R.; Horpibulsuk, S.; Arulrajah, A.; Mirzababaei, M. Effect of wetting-drying cycles on compressive strength and microstructure of recycled asphalt pavement—Fly ash geopolymer. Constr. Build. Mater. 2017, 144, 624–634. [Google Scholar] [CrossRef]

- Yin, S.; Jing, L.; Yin, M.; Wang, B. Mechanical properties of textile reinforced concrete under chloride wet-dry and freeze-thaw cycle environments. Cem. Concr. Compos. 2018, 96, 118–127. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Degradation rate of natural fiber in cement composites exposed to various accelerated aging environment conditions. Corros. Sci. 2014, 88, 118–132. [Google Scholar] [CrossRef]

- Bui, H.; Levacher, D.; Boutouil, M.; Sebaibi, N. Effects of Wetting and Drying Cycles on Microstructure Change and Mechanical Properties of Coconut Fibre-Reinforced Mortar. J. Compos. Sci. 2022, 6, 102. [Google Scholar] [CrossRef]

- Marvila, M.; Azevedo, A.; Delaqua, G.; Mendes, B.; Pedroti, L.; Vieira, C. Performance of geopolymer tiles in high temperature and saturation conditions. Constr. Build. Mater. 2021, 286, 122994. [Google Scholar] [CrossRef]

- Puertas, F.; Amat, T.; Fernández-Jiménez, A.; Vázquez, T. Mechanical and durable behaviour of alkaline cement mortars reinforced with polypropylene fibres. Cem. Concr. Res. 2003, 33, 2031–2036. [Google Scholar] [CrossRef]

- Sanvezzo, P.B.; Negreiros, F.P.d.C.; Branciforti, M.C. Degradation of Polypropylene and Jute Fiber-Reinforced Composites Exposed to Natural and Accelerated Aging: Mechanical Properties and Wettability. Chemistry 2021, 3, 1392–1400. [Google Scholar] [CrossRef]

- Alomayri, T.; Shaikh, F.; Low, I. Thermal and mechanical properties of cotton fabric-reinforced geopolymer composites. J. Mater. Sci. 2013, 48, 6746–6752. [Google Scholar] [CrossRef]

- Zhang, P.; Zhang, X.; Zhang, Y.; Zheng, Y.; Wang, T. Gray correlation analysis of factors influencing compressive strength and durability of nano-SiO2 and PVA fiber reinforced geopolymer mortar. Nanotechnol. Rev. 2022, 11, 3195–3206. [Google Scholar] [CrossRef]

- Assaedi, H.; Alomayri, T.; Shaikh, F.; Low, I. Influence of nano silica particles on durability of flax fabric reinforced geopolymer composites. Materials 2019, 12, 1459. [Google Scholar] [CrossRef]

- Ardanuy, M.; Clarmunt, J.; Filho, R. Evaluation of durability to wet/dry cycling of cement mortar composites reinforced with nanofibrillated cellulose. Brittle Matrix Compos. 2012, 10, 33–41. [Google Scholar]

- Diniz, J.M.B.F.; Gil, M.H.; Castro, J.A.A.M. Hornification—Its origin and interpretation in wood pulps. Wood Sci. Technol. 2004, 37, 489–494. [Google Scholar] [CrossRef]

- Ballesteros, J.E.M.; Dos Santos, S.F.; Mármol, G.; Savastano, H., Jr.; Fiorelli, J. Evaluation of cellulosic pulps treated by hornification as reinforcement of cementitious composites. Constr. Build. Mater. 2015, 100, 83–90. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curauá fiber cement basedcomposite systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Lima, P.R.L.; Silva, F.A.; Filho, R.D.T. Effect of Sisal Fiber Hornification on the Fiber-Matrix Bonding Characteristics and Bending Behavior of Cement Based Composites. Key Eng. Mater. 2014, 600, 421–432. [Google Scholar] [CrossRef]

- Claramunt, J.; Ardanuy, M.; Garcia-Hortal, J.A.; Filho, R.D.T. The hornification of vegetable fibers to improve the durability of cement mortar composites. Cem. Concr. Compos. 2011, 33, 586–595. [Google Scholar] [CrossRef]

- Ballesteros, J.E.M.; Santos, V.; Mármol, G.; Frías, M.; Fiorelli, J. Potential of the hornification treatment on eucalyptus and pine fibers for fiber-cement applications. Cellulose 2017, 42, 49–2286. [Google Scholar] [CrossRef]

- Ferreira, S.R.; Silva, F.D.A.; Lima, P.R.L.; Filho, R.D.T. Effect of Natural Fiber Hornification on the Fiber Matrix Interface in Cement Based Composite Systems. Key Eng. Mater. 2015, 668, 118–125. [Google Scholar] [CrossRef]

- Olayiwola, H.O.; Amiandamhen, S.O.; Meincken, M.; Tyhoda, L. Investigating the suitability of fly ash/metakaolin-based geopolymers reinforced with south african alien invasive wood and sugarcane bagasse residues for use in outdoor conditions. Eur. J. Wood Prod. 2021, 79, 611–627. [Google Scholar] [CrossRef]

- Wei, J.; Meyer, C. Improving degradation resistance of sisal fiber in concrete through fiber surface treatment. Appl. Surf. Sci. 2014, 289, 511–523. [Google Scholar] [CrossRef]

- Mohr, B.; Nanko, H.; Kurtis, K. Durability of thermomechanical pulp fiber-cement composites to wet/dry cycling. Cem. Concr. Res. 2005, 35, 1646–1649. [Google Scholar] [CrossRef]

- Ye, H.; Zhang, Y.; Yu, Z. Effects of cellulose, hemicellulose, and lignin on the morphology and mechanical properties of metakaolin-based geopolymer. Constr. Build. Mater. 2018, 173, 10–16. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Effect of UV and water spraying on the mechanical properties of flax fabric reinforced polymer composites used for civil engineering applications. Mater. Des. 2015, 71, 17–25. [Google Scholar] [CrossRef]

- Correia, V.D.C.; Ardanuy, M.; Claramunt, J.; Savastano, H. Assessment of chemical and mechanical behavior of bamboo pulp and nanofibrillated cellulose exposed to alkaline environments. Cellulose 2019, 26, 9269–9285. [Google Scholar] [CrossRef]

- Chen, H.; Miao, M.; Ding, X. Influence of moisture absorption on the interfacial strength of bamboo/vinyl ester composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 2013–2019. [Google Scholar] [CrossRef]

- Mohr, B.; Nanko, H.; Kurtis, K. Durability of kraft pulp fiber-cement composites to wet/dry cycling. Cem. Concr. Compos. 2005, 27, 435–448. [Google Scholar] [CrossRef]

- Mohr, B.; Biernacki, J.; Kurtis, K. Supplementary cementitious materials for mitigating degradation of kraft pulp fiber-cement composites. Cem. Concr. Res. 2007, 37, 1531–1543. [Google Scholar] [CrossRef]

- Mohr, B.; Biernacki, J.; Kurtis, K. Microstructural and chemical effects of wet/dry cycling on pulp fiber-cement composites. Cem. Concr. Res. 2006, 36, 1240–1251. [Google Scholar] [CrossRef]

- Cheng, S.; Shui, Z.; Gao, X.; Yu, R.; Sun, T.; Guo, C.; Huang, Y. Degradation mechanisms of Portland cement mortar under seawater attack and drying-wetting cycles. Constr. Build. Mater. 2019, 230, 116934. [Google Scholar] [CrossRef]

| Fiber | Density /(g·cm−3) | Tensile Strength/MPa | Modulus /GPa | Elongation /% | Ref. |

|---|---|---|---|---|---|

| Flax | 1.40–1.50 | 2200 | 27.6–80.0 | 3.7 | [27,28] |

| Hemp | 1.48 | 550–900 | 70.0 | 2.0–4.0 | [29] |

| kenaf | 1.45 | 930 | 53.0 | 1.6 | [30] |

| Sisal | 0.90 | 577 | 19.0 | 3.0–7.0 | [31,32] |

| Banana | 1.35 | 600 | 17.9 | 3.4 | [31] |

| Coir | 1.20 | 60–130 | 4.0–6.0 | 30.0 | [31,33] |

| Cotton | 1.60 | 400 | 4.8 | 7.0–8.0 | [34,35] |

| Bagass | 1.30 | 222–290 | 17.0–27.0 | 1.1 | [36] |

| Fiber | Cellulose/% | Hemicellulose/% | Lignin/% | Others/% | Ref. |

|---|---|---|---|---|---|

| Sisal | 54.0–66.0 | 12.0–17.0 | 7.0–14.0 | 2.0–8.0 | [40] |

| Jute | 72.0 | 12.8 | 8.1 | 7.1 | [41] |

| Coir | 9.5–71.5 | 17.0–17.8 | 4.4–4.7 | 4.0–4.5 | [42] |

| Precursor | Activator | Fiber | Fiber Content/% | Ref. |

|---|---|---|---|---|

| Sludge and Portland cement | Potassium hydroxide solution | Sisal | 2 | [32] |

| Soil, hydrated lime, and fly ash | Potassium hydroxide solution | Coir | 1.0 | [33] |

| Iron-rich laterite | Sodium hydroxide and Sodium silicate solution | Sugarcane bagasse | 1.5, 3.0, 4.5, 6.0 and 7.5 * | [38] |

| Fly ash | Sodium hydroxide and Sodium silicate solution | Wood particle | 20 * | [92] |

| Metakaolin and cement | Polycarboxylate and Superplasticizer | Sisal | 2 | [58] |

| Metakaolin, silica fume, and blast furnace slag | Sodium hydroxide and Sodium silicate solution | Jute | 10 | [40] |

| Metakaolin and cement | Superplasticizer | Sisal | 6 | [41] |

| Diatomaceous earth and Portland cement | Limestone | Sisal | 2 | [42] |

| Laterite soil | Sodium hydroxide and Sodium silicate solution | Sugarcane bagasse | 1.5, 3.0, 4.5, 6.0 and 7.5 * | [95] |

| Slag | Sodium hydroxide and Sodium silicate solution | Shaving | 13 * | [96] |

| Silt, clay, and fly ash | Sodium hydroxide and Sodium silicate solution | Wastepaper | 10, 20 and 30 | [97] |

| Author | Specimen Shape | Specimen Size/mm | Curing Condition | Curing Time/d | Cyclic Mode | Duration of A Cycle/h | Cycle Number |

|---|---|---|---|---|---|---|---|

| Kamaruddin et al. [33] | Cylinder | Diameter 50, Height 100 | Standard curing chamber | 7, 28 and 90 | Air dry for 24 h, then soak for 24 h | 48 | 1, 3 and 5 |

| Nkwaju et al. [38] | Cube; Cylinder: | 50 × 50 × 50; Diameter 100, Height 50 | Room condition | 28 | Soak in water for 24 h, then dry in the open air for 24 h | 48 | 5, 10 and 20 |

| Batista dos Santos et al. [32] | Plate | 195 × 50 × 6 | 27 °C and 80% RH | 180 | Soak in water at 22 ± 2 °C for 1 d, dry in an oven at 40 ± 2 °C for 2 d | 72 | 10 |

| Huang et al. [96] | Plate | 220 × 50 × 10 | Constant temperature drying oven, 40 °C, 28 d | 28, 60, 90, 180 and 360 | Indoor, outdoor, and bagged (indoor 11–32 °C) | - | Random |

| Filho et al. [41] | Plate | 400 × 100 × 12 | Curing chamber with 100% RH and 23 ± 1 °C | 28 to 5 years | Soak in water 1 d, 2 d in a forced air chamber | 72 | 5, 10, 15, 20 and 25 |

| Wei et al. [42] | Plate | 200 × 50 × 12 | Lime water at 23.2 °C | 28 | Soak in a stainless steel container for 25 h and dry in a ventilated oven at 70 °C for 35 h | 60 | 5, 10 and 20 |

| Nkwaju et al. [95] | Prism; cylinder | 40 × 40 × 160; Diameter 50, Height 150 | 20 ± 2 °C, store in plastic bag | 28 | Dry at 60 °C for 24 h, then soak in water for 24 h | 48 | 5, 10 and 20 |

| Wei et al. [61] | Beam; Cube | 200 × 50 × 12; 50 × 50 × 50 | Soaked in saturated water at 23 ± 2 °C | 28 | Soak in 70 °C water for 15 h and dry in 70 °C oven for 25 h. | 42 | 5, 15 and 30 |

| Trindade et al. [40] | Plate | 450 × 60 × 12, and 270 × 60 × 12 | Room temperature (25 ± 2 °C) | 7 | 24 h of wetting and 48 h of drying | 72 | 15 |

| VU et al. [97] | Cylinder | Diameter 50, Height 100 | Wrapped in vinyl sheet, 20 ± 3 °C | 28 and 42 | 2 d in 40 °C electric furnace, 1 d in 20 °C water | 72 | 10 |

| Asante et al. [43] | Prism | 25 × 30 × 50 | Stored at 20 °C, 65% RH | 7 | Soak in water at 20 ± 5 °C for 170 min, in a ventilated oven at 70 ± 5 °C for 170 min | 6 | 200 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, C.; He, P.; Pang, G.; Liu, J. Effect of Wet–Dry Cycling on Properties of Natural-Cellulose-Fiber-Reinforced Geopolymers: A Short Review. Molecules 2023, 28, 7189. https://doi.org/10.3390/molecules28207189

Lv C, He P, Pang G, Liu J. Effect of Wet–Dry Cycling on Properties of Natural-Cellulose-Fiber-Reinforced Geopolymers: A Short Review. Molecules. 2023; 28(20):7189. https://doi.org/10.3390/molecules28207189

Chicago/Turabian StyleLv, Chun, Pengyi He, Guowei Pang, and Jie Liu. 2023. "Effect of Wet–Dry Cycling on Properties of Natural-Cellulose-Fiber-Reinforced Geopolymers: A Short Review" Molecules 28, no. 20: 7189. https://doi.org/10.3390/molecules28207189

APA StyleLv, C., He, P., Pang, G., & Liu, J. (2023). Effect of Wet–Dry Cycling on Properties of Natural-Cellulose-Fiber-Reinforced Geopolymers: A Short Review. Molecules, 28(20), 7189. https://doi.org/10.3390/molecules28207189