Facile Synthesis of PdO.TiO2 Nanocomposite for Photoelectrochemical Oxygen Evolution Reaction

Abstract

1. Introduction

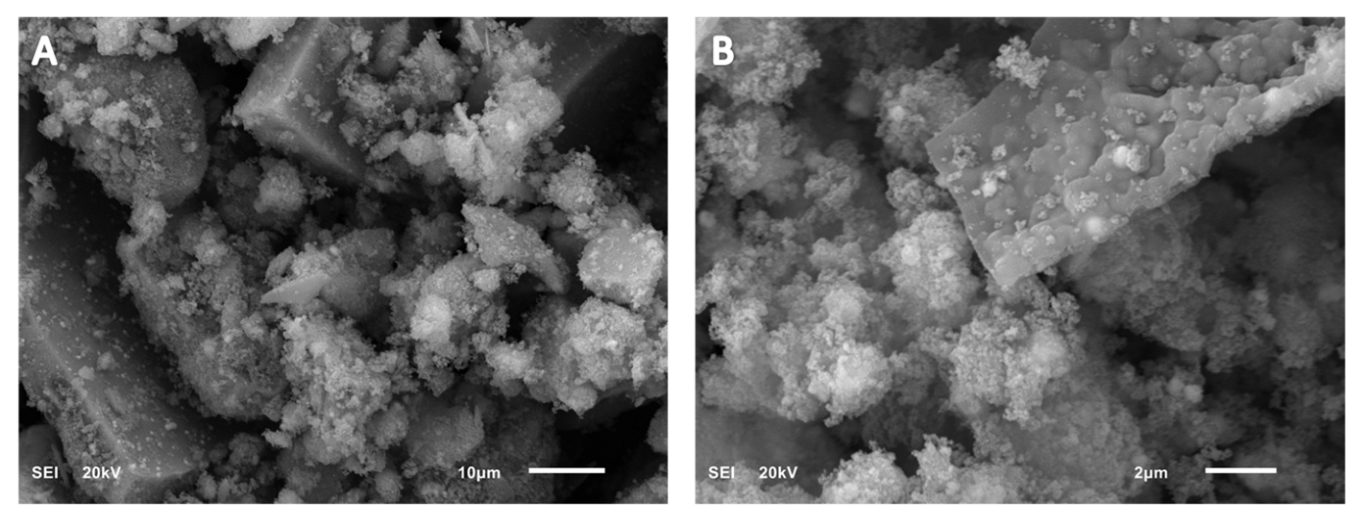

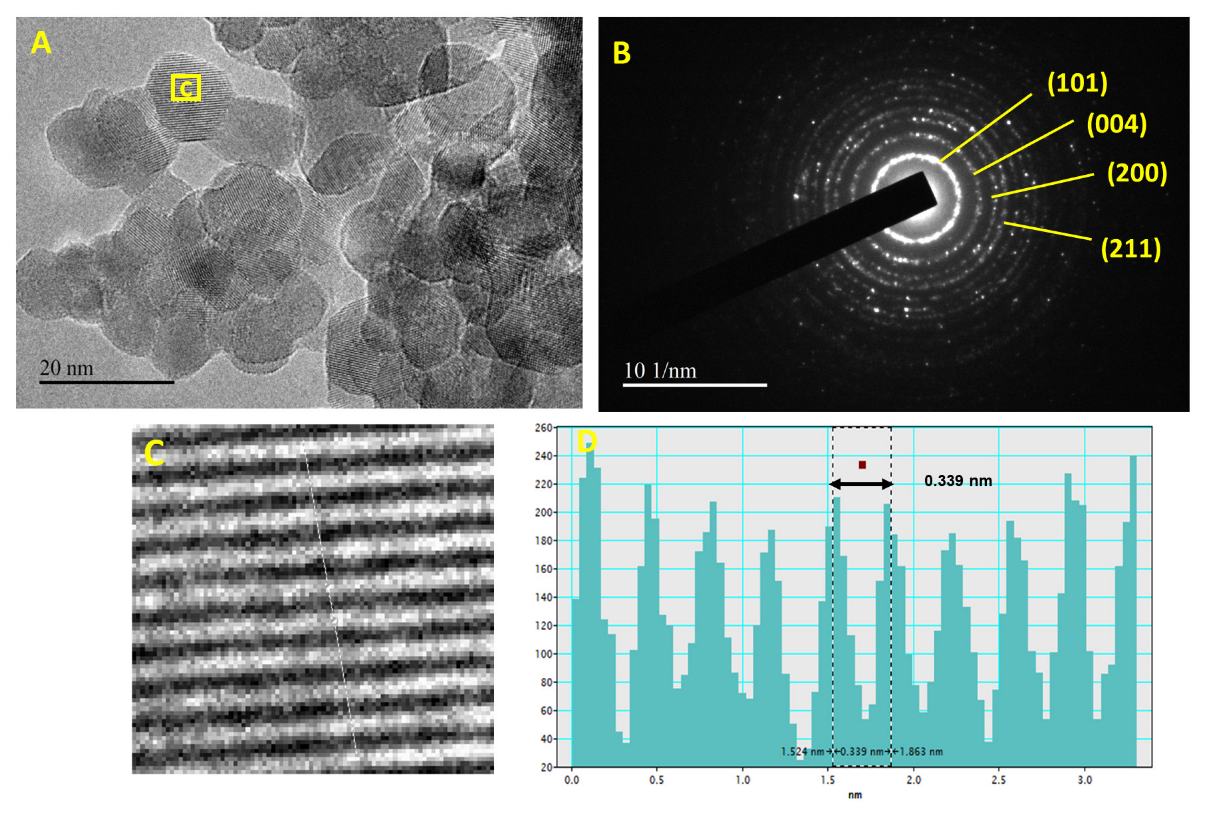

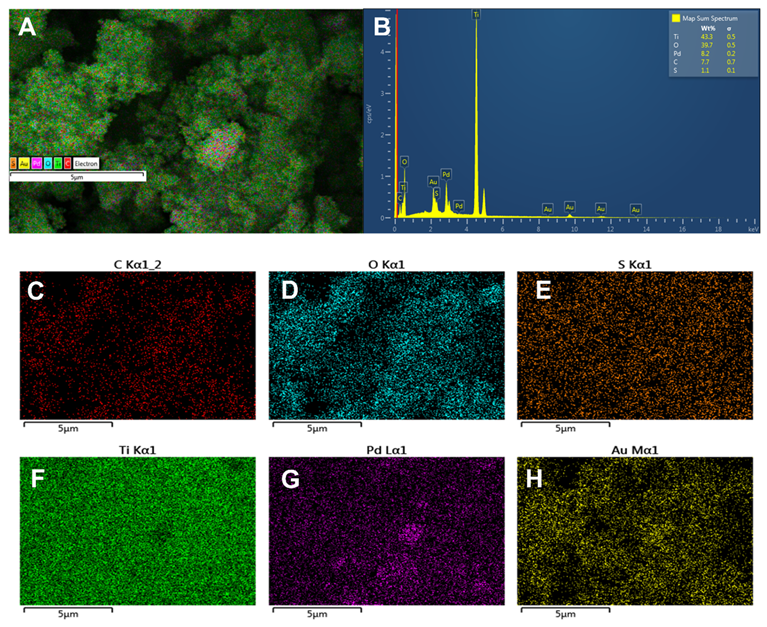

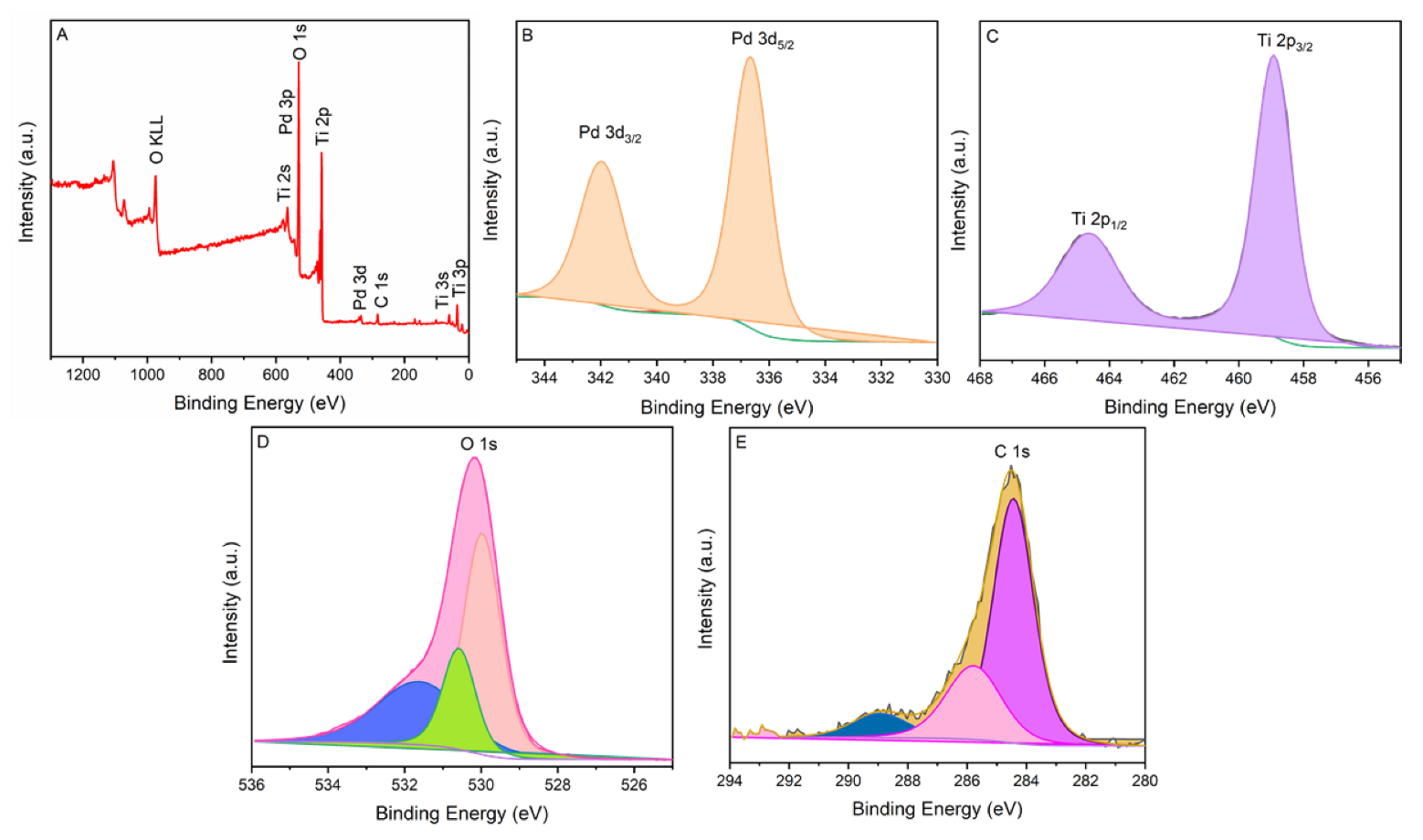

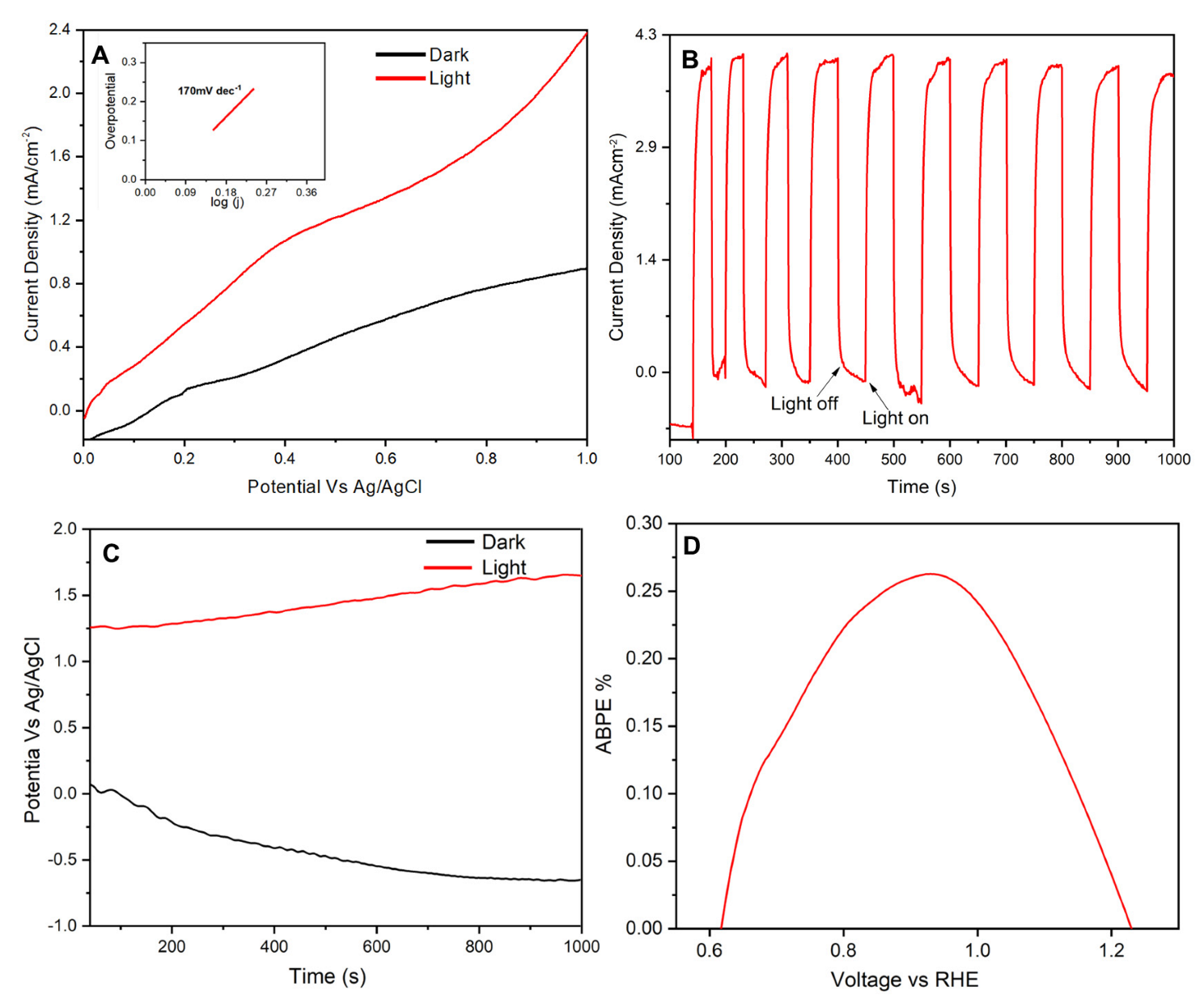

2. Results

3. Materials and Methods

3.1. Chemicals

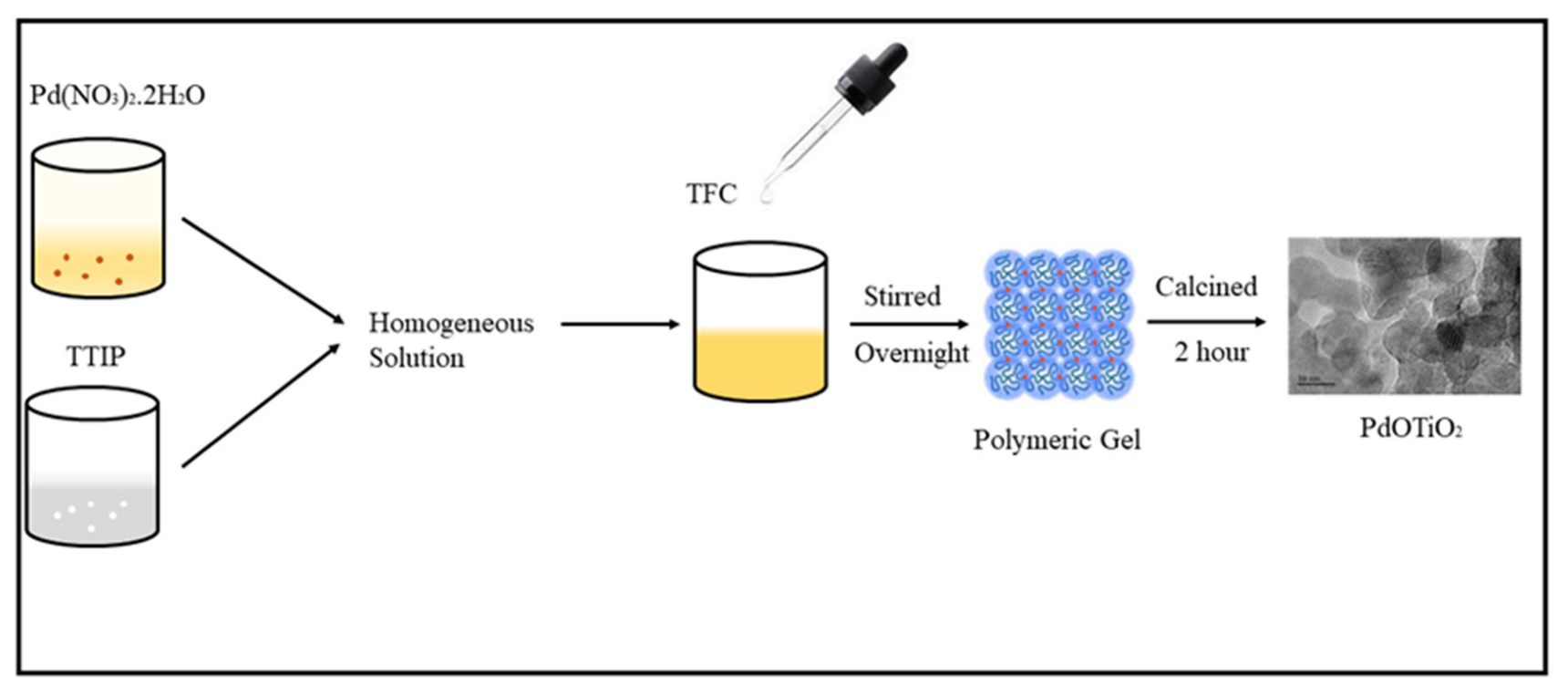

3.2. Synthesis of Palladium Titanate

3.3. Fabrication of Electrode

3.4. PEC Measurement

3.5. Characterizations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shi, J.; Guo, L. ABO3-based photocatalysts for water splitting. Prog. Nat. Sci. Mater. Int. 2012, 22, 592–615. [Google Scholar] [CrossRef]

- Esmaili, H.; Kowsari, E.; Ramakrishna, S.; Motamedisade, A.; Andersson, G. Sensitization of TiO2 nanoarrays by a novel palladium decorated naphthalene diimide functionalized graphene nanoribbons for enhanced photoelectrochemical water splitting. Mater. Today Chem. 2022, 24, 100900. [Google Scholar] [CrossRef]

- Najam, T.; Shah, S.S.A.; Ding, W.; Ling, Z.; Li, L.; Wei, Z. Electron penetration from metal core to metal species attached skin in nitrogen-doped core-shell catalyst for enhancing oxygen evolution reaction. Electrochim. Acta 2019, 327, 134939. [Google Scholar] [CrossRef]

- Najam, T.; Shah, S.S.A.; Javed, M.S.; Chen, P.-T.; Chuang, C.; Saad, A.; Song, Z.; Liu, W.; Cai, X. Modulating the electronic structure of zinc single atom catalyst by P/N coordination and Co2P supports for efficient oxygen reduction in Zn-Air battery. Chem. Eng. J. 2022, 440, 135928. [Google Scholar] [CrossRef]

- Shah, S.S.A.; Jiao, L.; Jiang, H.-L. Optimizing MOF electrocatalysis by metal sequence coding. Chem. Catal. 2022, 2, 3–5. [Google Scholar] [CrossRef]

- Zeb, W.; Altaf, A.; Aamir, M.; Baig, N.; Baig, I.; Nafady, A.; Sharif, M.; Sher, M.; Sohail, M. Enhanced photoelectrochemical performance of P-doped g-C3N4/Zn0. 5Cd0. 5S heterojunction photocathode for water splitting. J. Saudi Chem. Soc. 2022, 26, 101542. [Google Scholar] [CrossRef]

- Bilal, M.; Rashid; Altaf, A.; Baig, N.; Chotana, G.A.; Ashraf, R.S.; Rasul, S.; Nafady, A.; Ul-Hamid, A.; Sohail, M. Crystalline and porous CoSe dendrimeric architectures for efficient oxygen evolution reaction. Fuel 2022, 323, 124324. [Google Scholar] [CrossRef]

- Wu, B.; Kempt, R.; Kovalska, E.; Luxa, J.; Kuc, A.; Heine, T.; Sofer, Z. Lithium-Assisted Exfoliation of Palladium Thiophosphate Nanosheets for Photoelectrocatalytic Water Splitting. ACS Appl. Nano Mater. 2021, 4, 441–448. [Google Scholar] [CrossRef]

- You, Y.; Tong, X.; Channa, A.I.; Li, X.; Liu, C.; Ye, H.; Wang, Z. Engineering interfacial structure in “Giant” PbS/CdS quantum dots for photoelectrochemical solar energy conversion. EcoMat 2016, 30, 531–541. [Google Scholar]

- Khan, I.; Qurashi, A.; Berdiyorov, G.; Iqbal, N.; Fuji, K.; Yamani, Z.H. Single-step strategy for the fabrication of GaON/ZnO nanoarchitectured photoanode their experimental and computational photoelectrochemical water splitting. Nano Energy 2018, 44, 23–33. [Google Scholar] [CrossRef]

- Ning, X.; Yin, D.; Fan, Y.; Zhang, Q.; Du, P.; Zhang, D.; Chen, J.; Lu, X. Plasmon-Enhanced Charge Separation and Surface Reactions Based on Ag-Loaded Transition-Metal Hydroxide for Photoelectrochemical Water Oxidation. Adv. Energy Mater. 2021, 11, 2100405. [Google Scholar] [CrossRef]

- Kausar, F.; Varghese, A.; Pinheiro, D.; Sunaja Devi, K.R. Recent trends in photocatalytic water splitting using titania based ternary photocatalysts—A review. Int. J. Hydrogen Energy 2022, 47, 22371–22402. [Google Scholar] [CrossRef]

- Liu, R.; Fang, S.Y.; Dong, C.D.; Tsai, K.C.; Yang, W.D. Enhancing hydrogen evolution of water splitting under solar spectra using Au/TiO2 heterojunction photo-catalysts. Int. J. Hydrogen Energy 2021, 46, 28462–28473. [Google Scholar] [CrossRef]

- Ye, M.; Gong, J.; Lai, Y.; Lin, C.; Lin, Z. High-Efficiency Photoelectrocatalytic Hydrogen Generation Enabled by Palladium Quantum Dots-Sensitized TiO2 Nanotube Arrays. J. Am. Chem. Soc. 2012, 134, 15720–15723. [Google Scholar] [CrossRef] [PubMed]

- Antolini, E.J.E.; Science, E. Science, Palladium in fuel cell catalysis. Energy Environ. Sci. 2009, 2, 915–931. [Google Scholar] [CrossRef]

- Rice, C.; Ha, S.; Masel, R.; Wieckowski, A. Catalysts for direct formic acid fuel cells. J. Power Sources 2003, 115, 229–235. [Google Scholar] [CrossRef]

- Najafi, B.; Mamaghani, A.H.; Rinaldi, F.; Casalegno, A. Fuel partialization and power/heat shifting strategies applied to a 30 kWel high temperature PEM fuel cell based residential micro cogeneration plant. Int. J. Hydrogen Energy 2015, 40, 14224–14234. [Google Scholar] [CrossRef]

- Kim, J.H.; Jang, J.W.; Kang, H.J.; Magesh, G.; Kim, J.Y.; Kim, J.H.; Kim, J.H.; Lee, J.; Lee, J.S. Palladium oxide as a novel oxygen evolution catalyst on BiVO4 photoanode for photoelectrochemical water splitting. J. Catal. 2014, 317, 126–134. [Google Scholar] [CrossRef]

- Sohail, M.; Tahir, N.; Rubab, A.; Beller, M.; Sharif, M. Facile Synthesis of Iron-Titanate Nanocomposite as a Sustainable Material for Selective Amination of Substitued Nitro-Arenes. Catalysts 2020, 10, 871. [Google Scholar] [CrossRef]

- Bharti, B.; Kumar, S.; Lee, H.-N.; Kumar, R. Formation of oxygen vacancies and Ti3+ state in TiO2 thin film and enhanced optical properties by air plasma treatment. Sci. Rep. 2016, 6, srep32355. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Altaf, A.; Sohail, M.; Nafady, A.; Siddique, R.G.; Shah, S.S.A.; Najam, T. Facile Synthesis of PdO.TiO2 Nanocomposite for Photoelectrochemical Oxygen Evolution Reaction. Molecules 2023, 28, 572. https://doi.org/10.3390/molecules28020572

Altaf A, Sohail M, Nafady A, Siddique RG, Shah SSA, Najam T. Facile Synthesis of PdO.TiO2 Nanocomposite for Photoelectrochemical Oxygen Evolution Reaction. Molecules. 2023; 28(2):572. https://doi.org/10.3390/molecules28020572

Chicago/Turabian StyleAltaf, Amna, Manzar Sohail, Ayman Nafady, Rashid G. Siddique, Syed Shoaib Ahmad Shah, and Tayyaba Najam. 2023. "Facile Synthesis of PdO.TiO2 Nanocomposite for Photoelectrochemical Oxygen Evolution Reaction" Molecules 28, no. 2: 572. https://doi.org/10.3390/molecules28020572

APA StyleAltaf, A., Sohail, M., Nafady, A., Siddique, R. G., Shah, S. S. A., & Najam, T. (2023). Facile Synthesis of PdO.TiO2 Nanocomposite for Photoelectrochemical Oxygen Evolution Reaction. Molecules, 28(2), 572. https://doi.org/10.3390/molecules28020572