Advances in Ablation or Oxidation Mechanisms and Behaviors of Carbon Fiber-Reinforced Si-Based Composites

Abstract

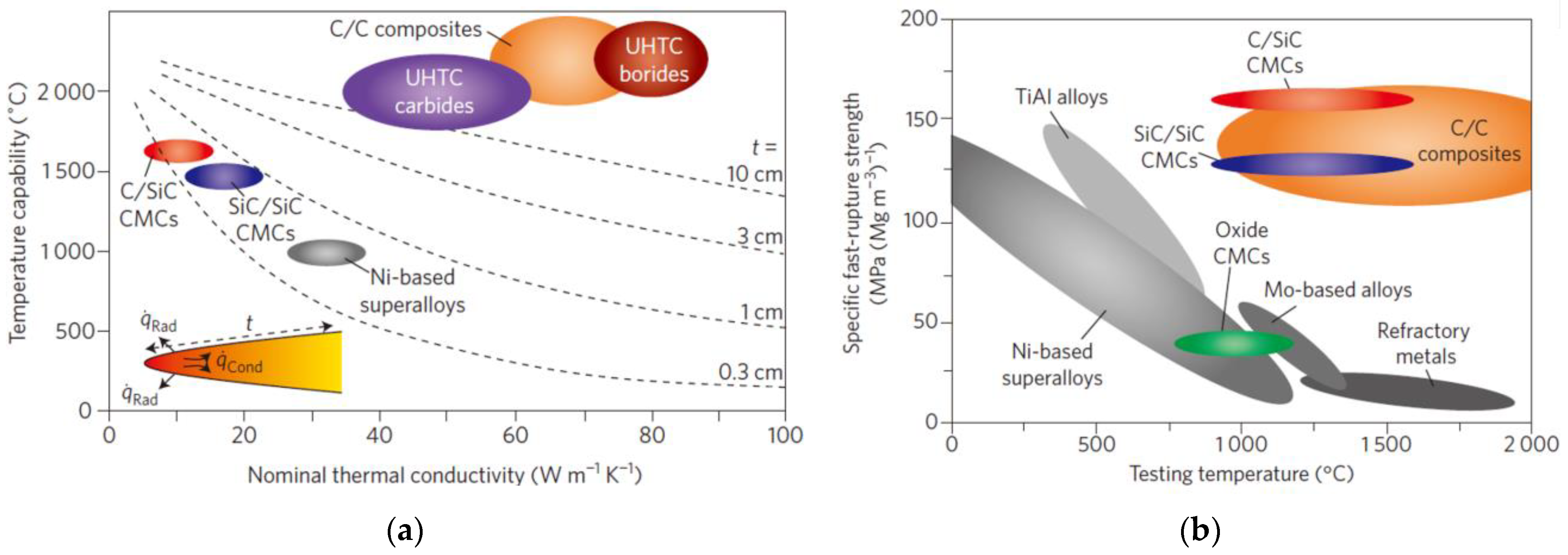

1. Introduction

2. Preparation of C/Si-Based Composites

3. Ablation Behaviors and Mechanisms of Pure C/SiM Composites

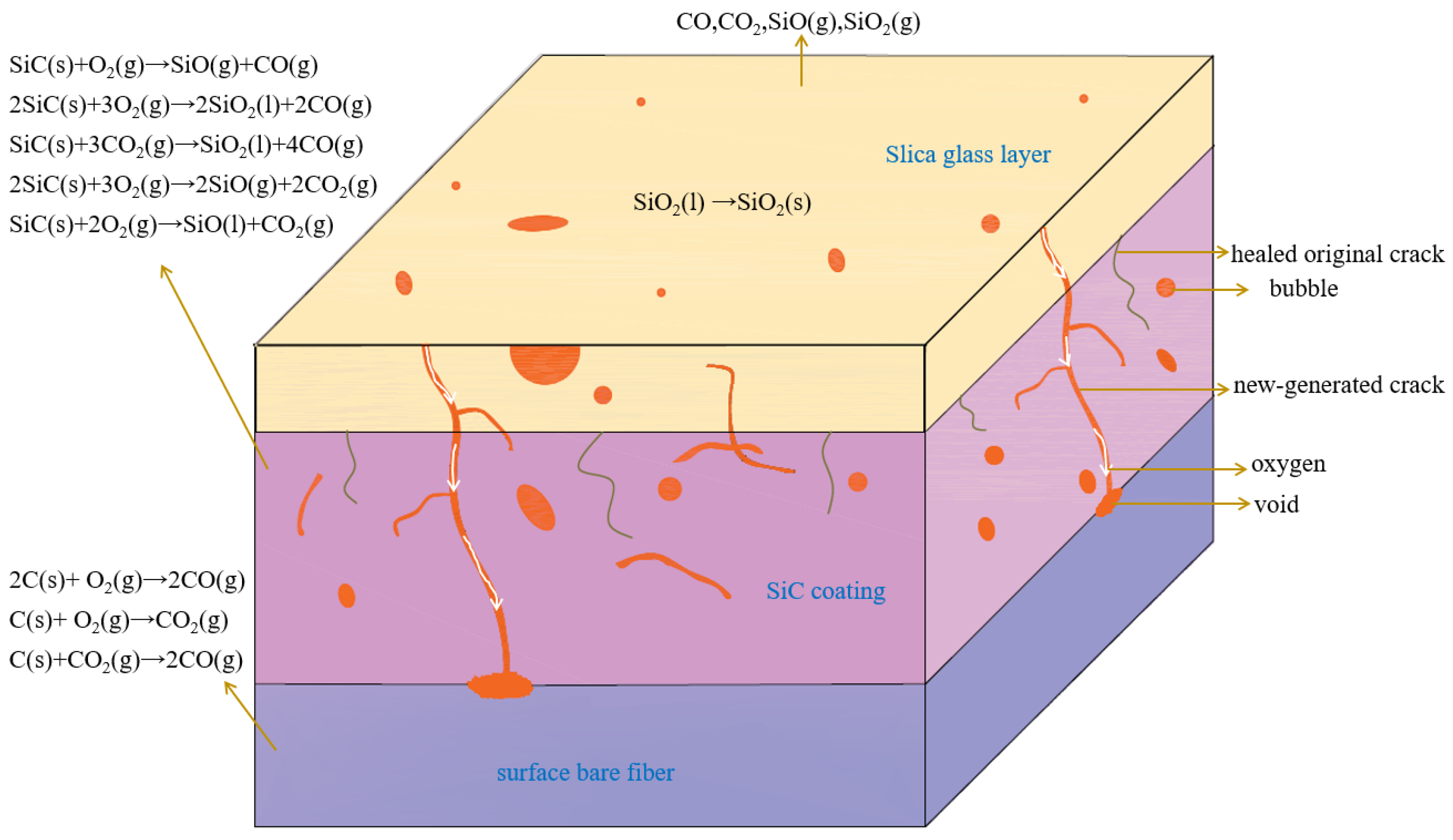

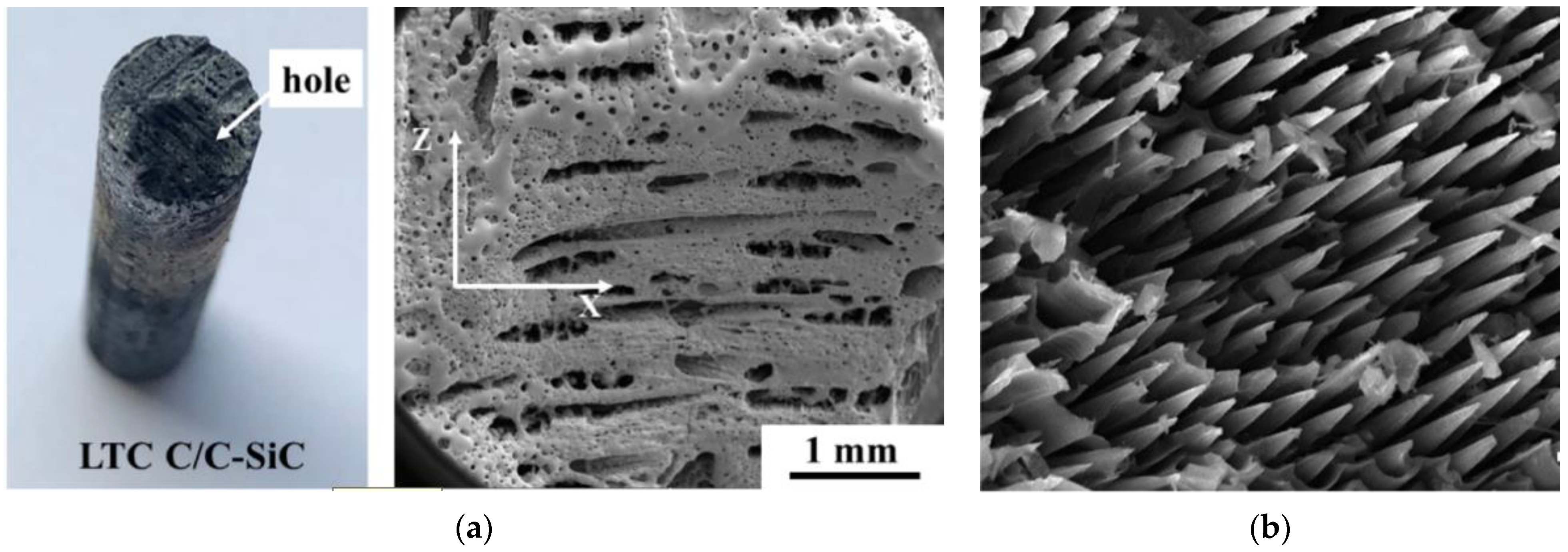

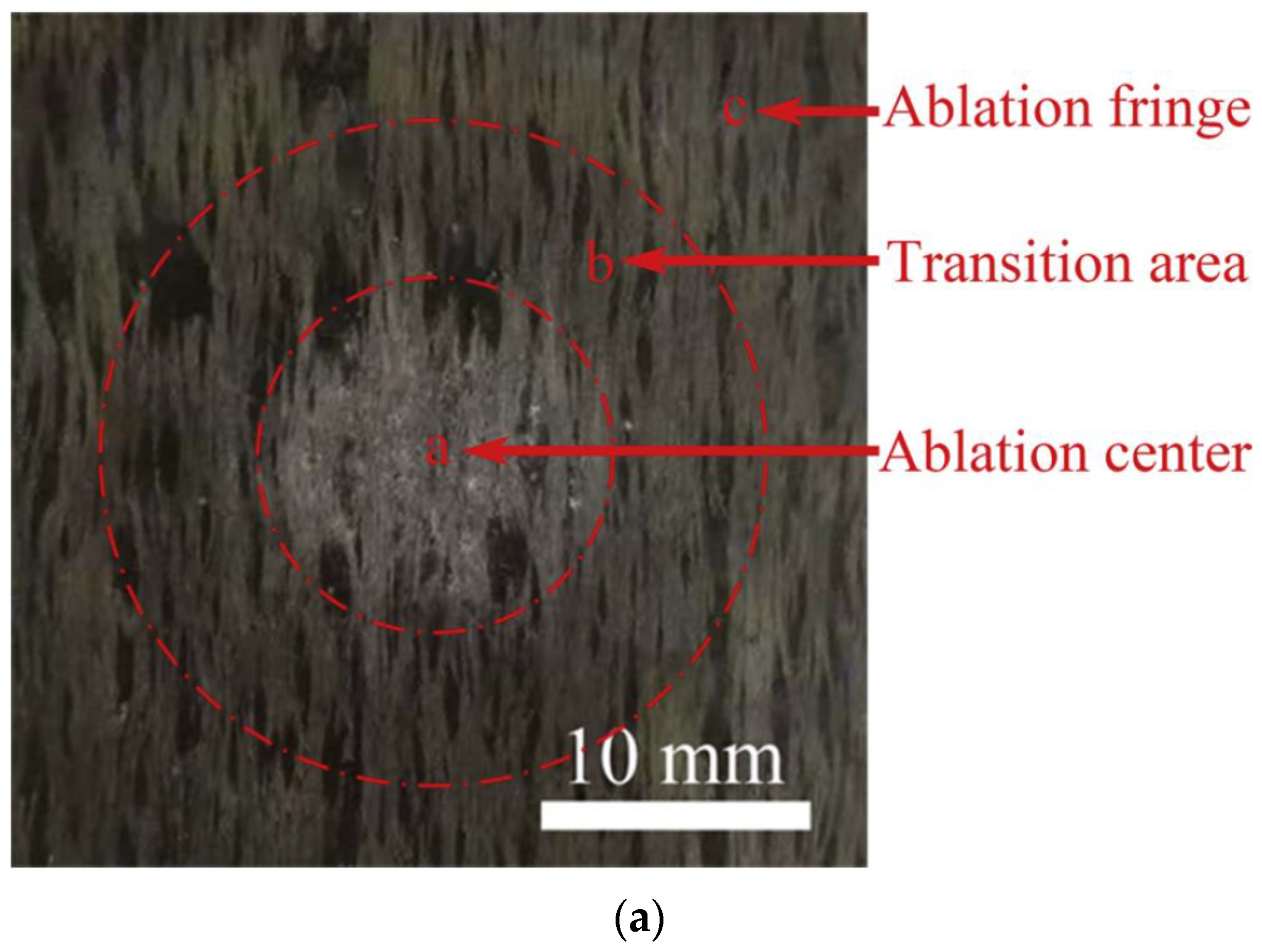

3.1. Ablation Behaviors and Mechanisms of C/SiC Composites

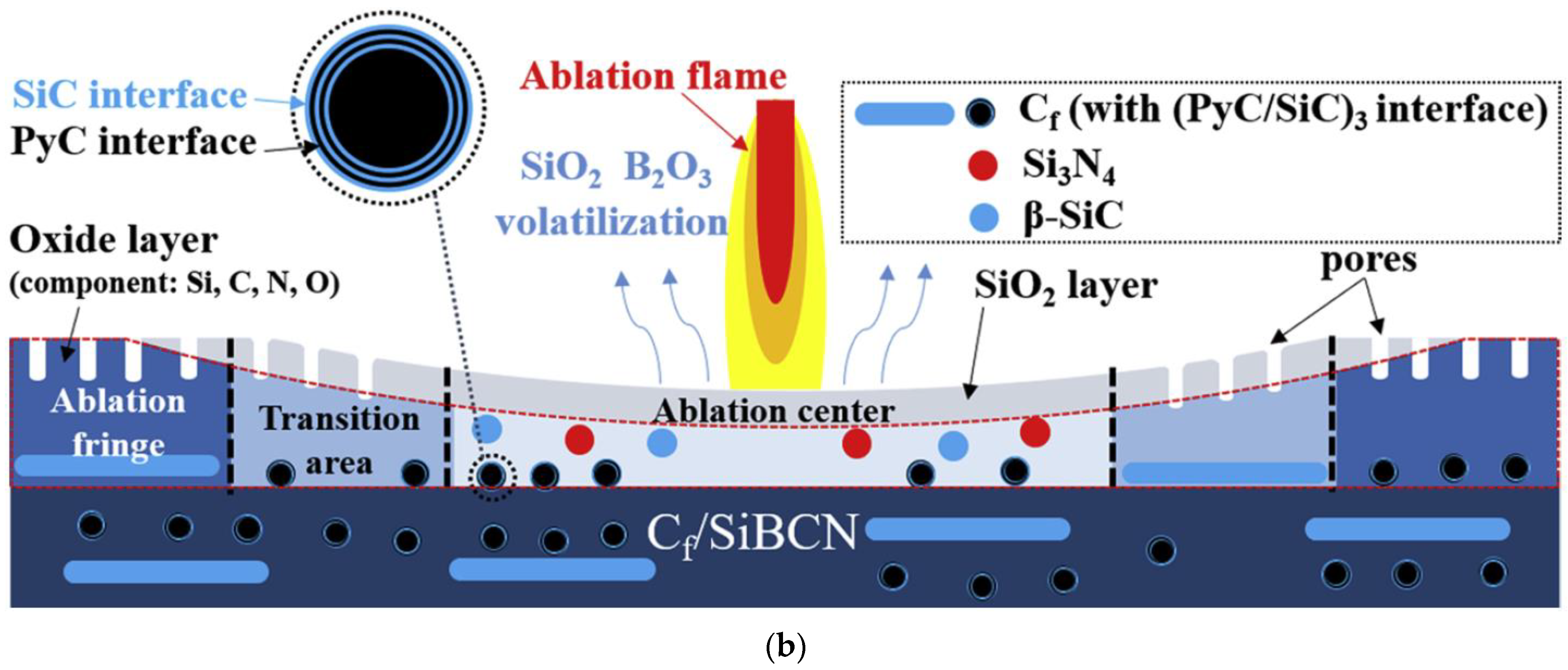

3.2. Ablation Behaviors and Mechanisms of C/SiBCN Composites

4. Ablation of C/SiZrM Composites

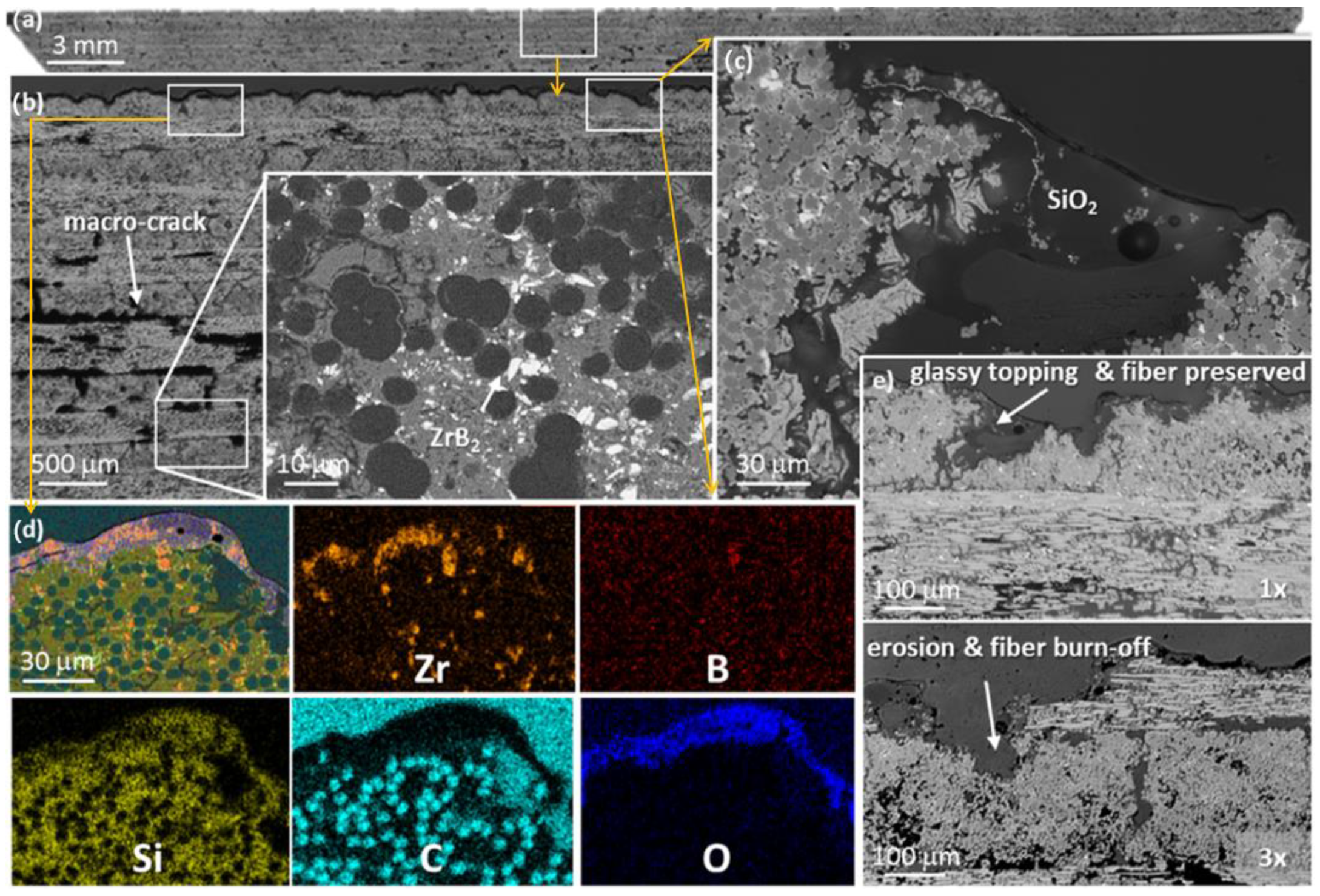

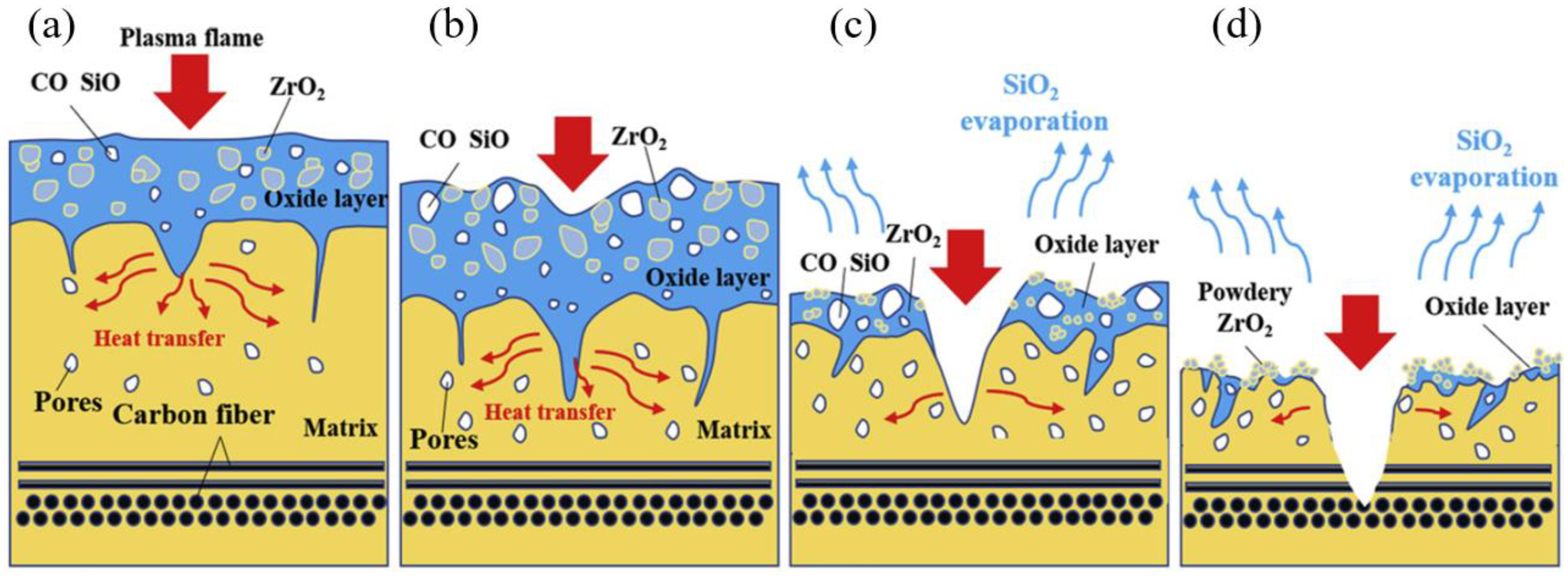

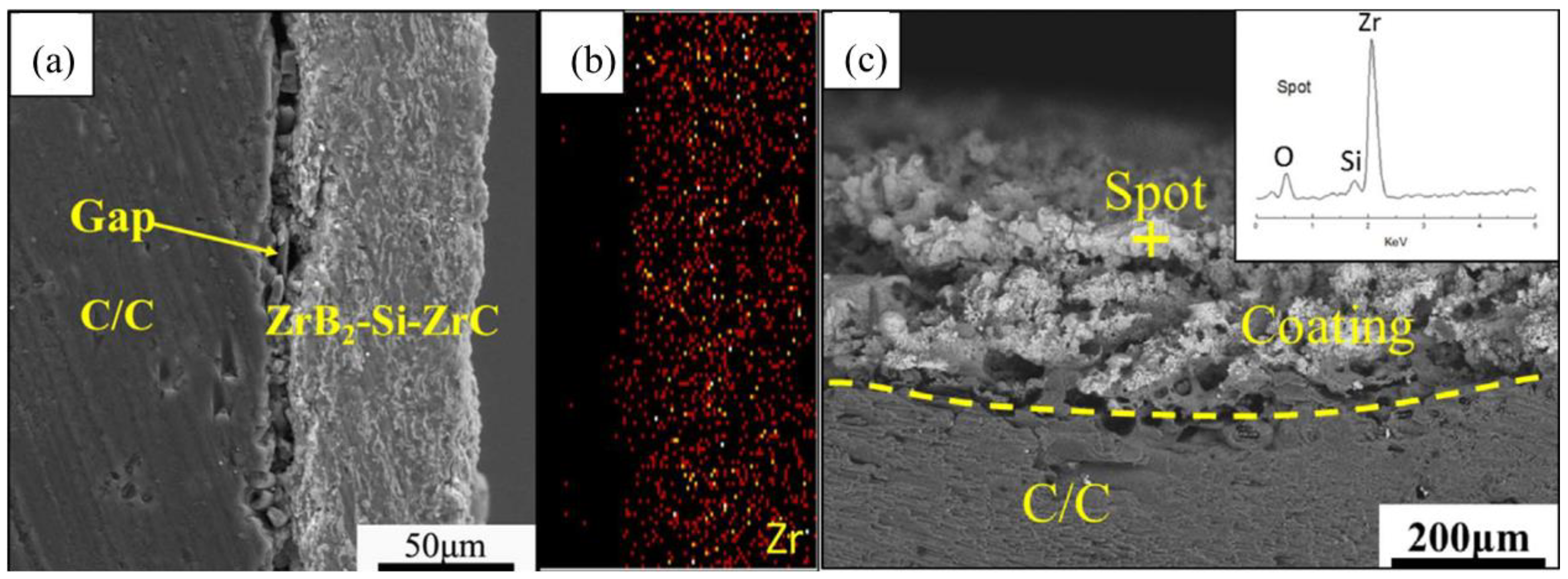

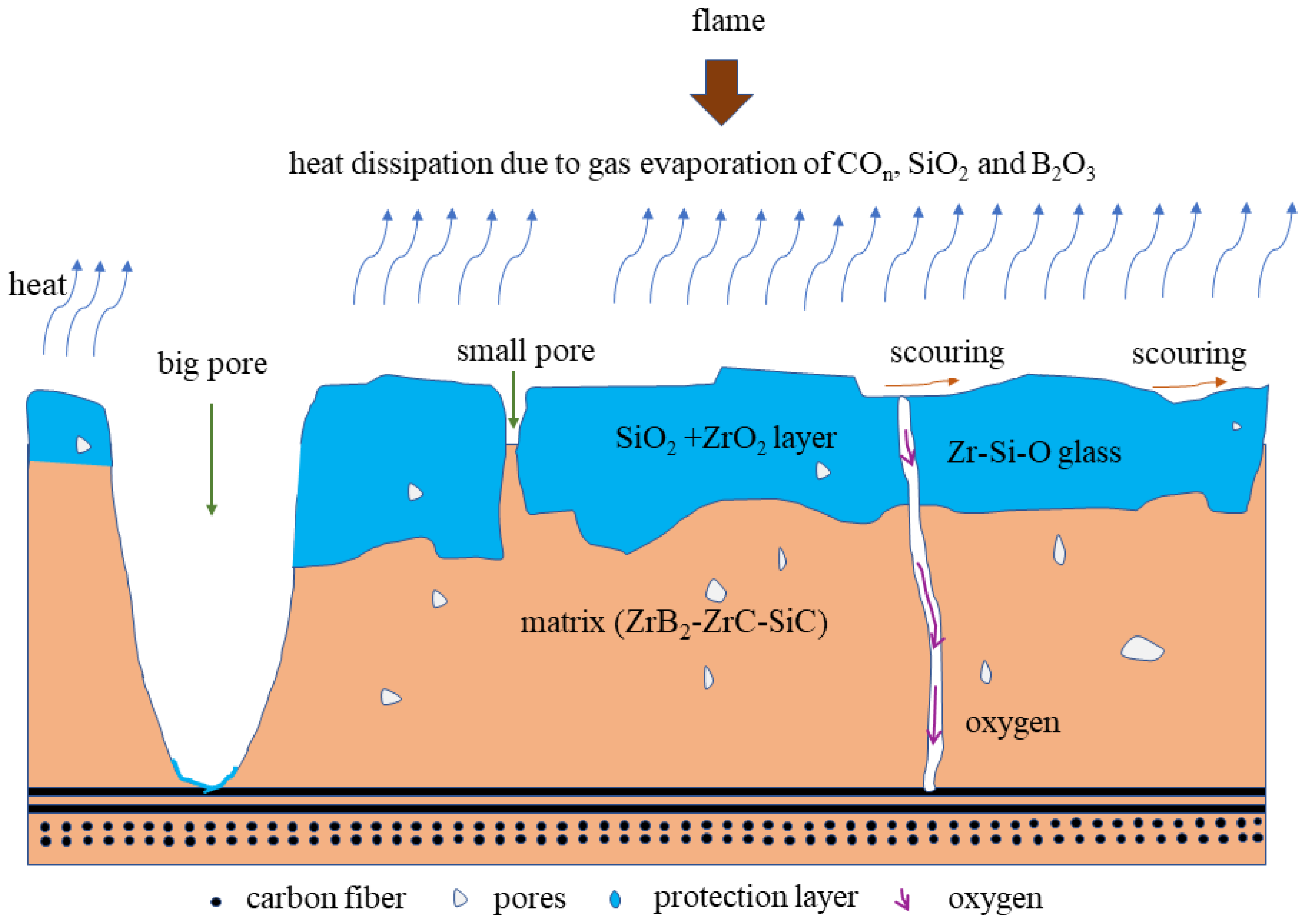

4.1. Ablation Behaviors and Mechanisms of C/ZrB2-SiC Composites

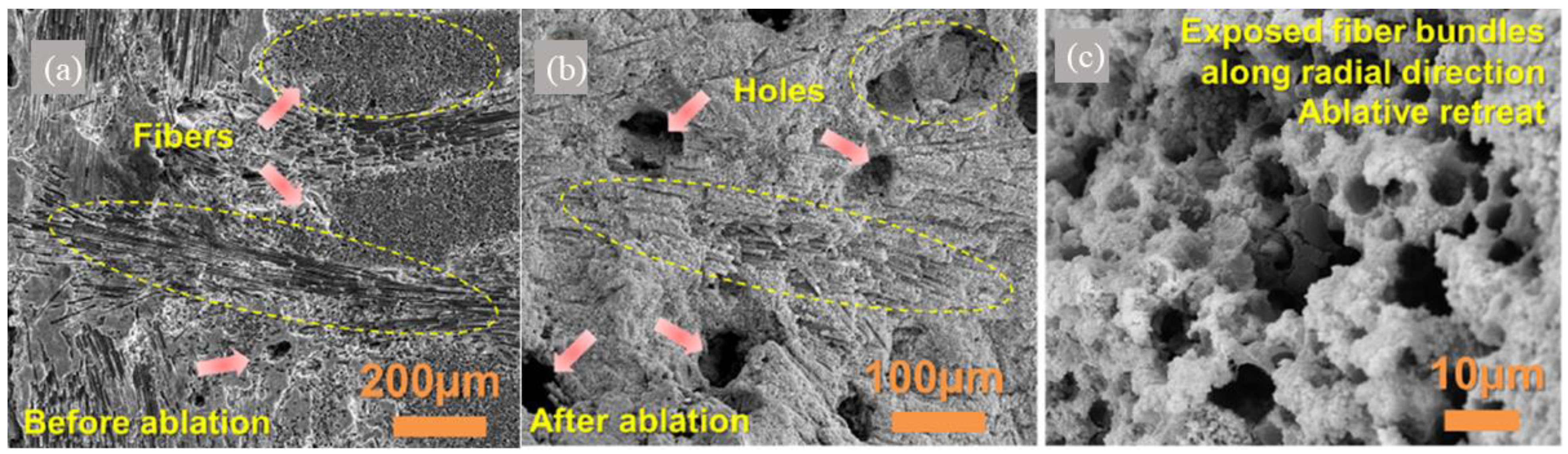

4.2. Ablation Behaviors and Mechanisms of C/ZrC-SiC Composites

4.3. Ablation Behaviors and Mechanisms of C/ZrB2-ZrC-SiC Composite

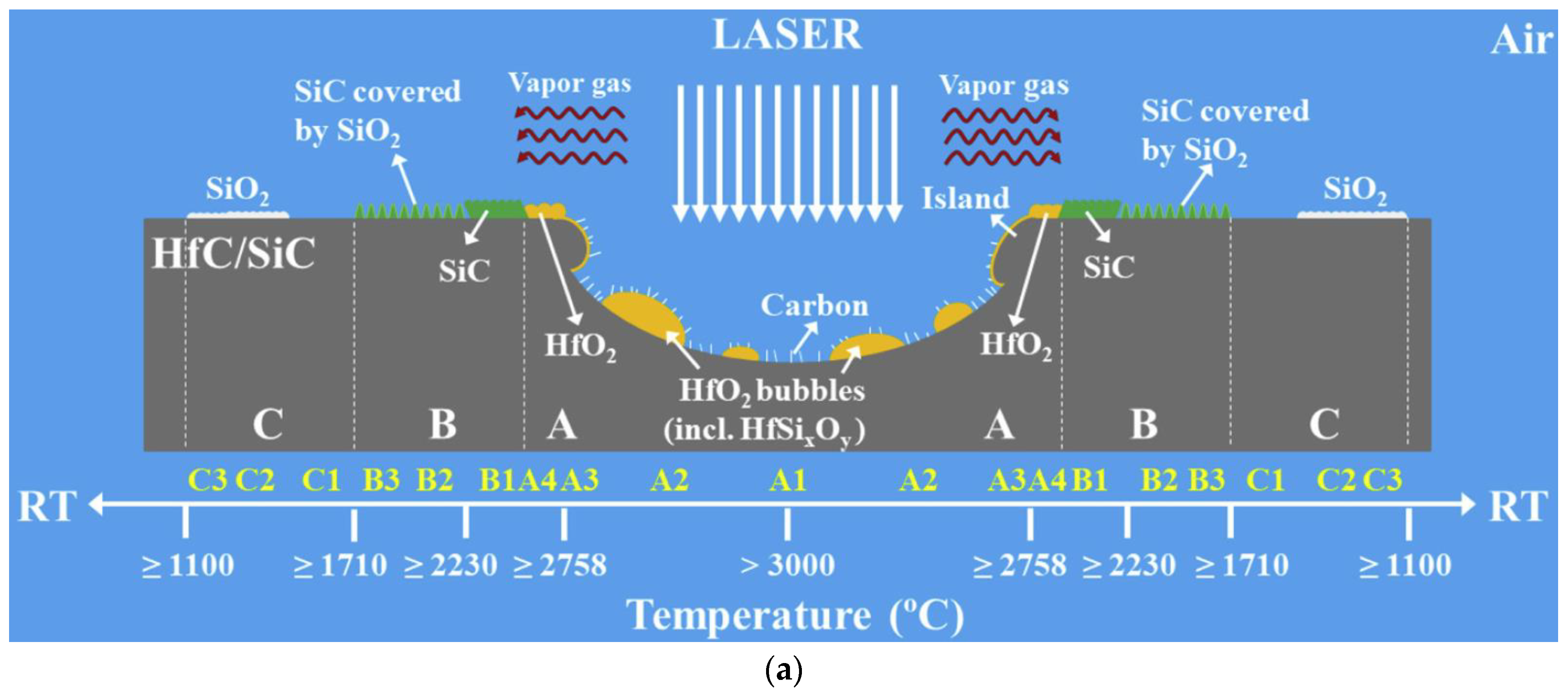

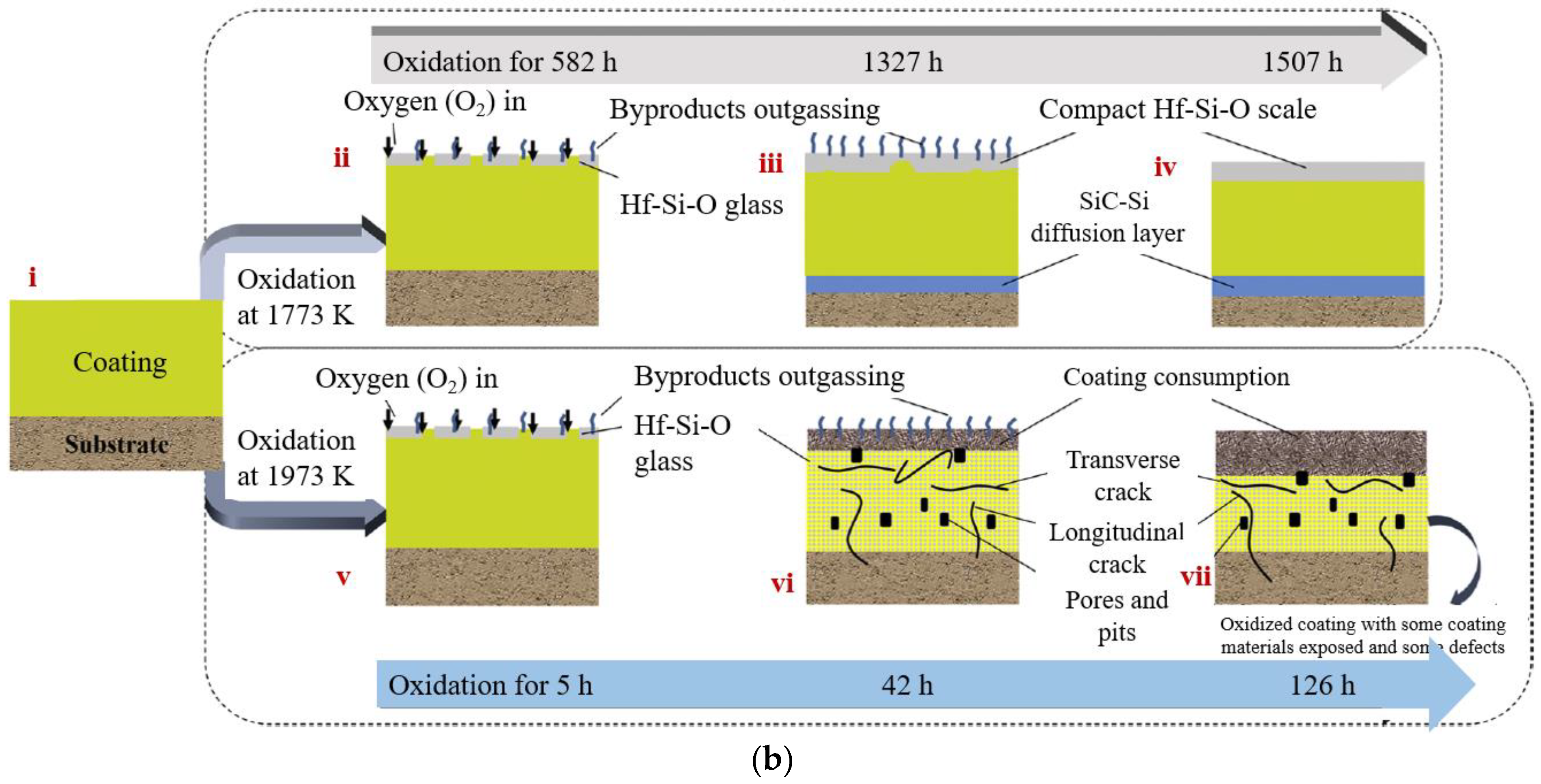

5. Ablation of the C/SiZM Composites

6. Conclusions and Future Perspectives

- (1)

- The mechanical properties

- (2)

- Selection of reinforcement

- (3)

- Matrix modification

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Wu, J.; Wang, H.; Wang, C.; Zhang, Z.; Tang, Y.; Hou, Z.; Wan, S.; Wu, D.; Tan, Z.; Ouyang, X. High-Pressure synthesis of Al2O3-cBN-hBN Self-lubricating ceramic. Mater. Des. 2022, 217, 110638. [Google Scholar] [CrossRef]

- Liu, R.; Yang, L.; Miao, H.; Jiang, M.; Wang, Y.; Liu, X.; Wan, F. Influence of the SiC matrix introduction time on the microstructure and mechanical properties of Cf/Hf0.5Zr0.5C-SiC ultra-high temperature composites. Ceram. Int. 2022, 48, 3762–3770. [Google Scholar] [CrossRef]

- Gao, H.; Luo, F.; Wen, Q.; Duan, S.; Zhou, W.; Zhu, D. Influence of different matrices on the mechanical and microwave absorption properties of SiC fiber-reinforced oxide matrix composites. Ceram. Int. 2018, 44, 6010–6015. [Google Scholar] [CrossRef]

- Glass, D.E.; Splinter, S.C. Active oxidation of a uhtc-based cmc. In Proceedings of the International Astronautical Congress, Cape Town, South Africa, 3–7 October 2011. [Google Scholar]

- Galizia, P.; Sciti, D. Disclosing residual thermal stresses in UHT fibre-reinforced ceramic composites and their effect on mechanical behaviour and damage evolution. Compos. Part B Eng. 2023, 248, 110369. [Google Scholar] [CrossRef]

- Nisar, A.; Ariharan, S.; Venkateswaran, T.; Sreenivas, N.; Balani, K. Effect of carbon nanotube on processing, microstructural, mechanical and ablation behavior of ZrB2-20SiC based ultra-high temperature ceramic composites. Carbon 2017, 111, 269–282. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, P.; Xiong, X. Research progress of continuous fiber reinforced ceramic matrix composites. Powder Metall. Mater. Sci. Eng. 2007, 12, 13–19. [Google Scholar]

- Bajpai, S.; Bhadauria, A.; Venkateswaran, T.; Singh, S.S.; Balani, K. Spark plasma joining of HfB2-ZrB2 based Ultra High Temperature Ceramics using Ni interlayer. Mater. Sci. Eng. A 2022, 838, 142818. [Google Scholar] [CrossRef]

- Ren, J.; Duan, Y.; Lv, C.; Luo, J.; Zhang, Y.; Fu, Y. Effects of HfC/PyC core-shell structure nanowires on the microstructure and mechanical properties of Hf1-xZrxC coating. Ceram. Int. 2021, 47, 7853–7863. [Google Scholar] [CrossRef]

- Vinci, A.; Silvestroni, L.; Gilli, N.; Zoli, L.; Sciti, D. Advancements in carbon fibre reinforced ultra-refractory ceramic composites: Effect of rare earth oxides addition. Compos. Part A Appl. Sci. Manuf. 2022, 156, 106858. [Google Scholar] [CrossRef]

- Xu, B.; An, Y.; Wang, P.; Jin, X.; Zhao, G. Microstructure and ablation behavior of double anti-oxidation protection for carbon-bonded carbon fiber composites. Ceram. Int. 2017, 43, 783–790. [Google Scholar] [CrossRef]

- Du, B.; He, C.; Qian, J.; Wang, X.; Cai, M.; Shui, A. Ablation behaviors and mechanism of ultra-thick anti-oxidation layer coating on carbon-bonded carbon fiber composites. J. Am. Ceram. Soc. 2019, 102, 7543–7552. [Google Scholar] [CrossRef]

- Cheng, Y.; Lyu, Y.; Xie, Y.; Zhang, C.; Feng, J.; Xun, L.; Zhang, W.; Han, W.; Zhou, S.; Hu, P.; et al. Starting from essence to reveal the ablation behavior and mechanism of 3D PyC Cf/ZrC-SiC composite. Corros. Sci. 2022, 201, 110261. [Google Scholar] [CrossRef]

- Inoue, R.; Arai, Y.; Kubota, Y.; Goto, K.; Kogo, Y. Oxidation behavior of carbon fiber-dispersed ZrB2-SiC-ZrC triple phase matrix composites in an oxyhydrogen torch environment. Ceram. Int. 2018, 44, 8387–8396. [Google Scholar] [CrossRef]

- Kubota, Y.; Arai, Y.; Yano, M.; Inoue, R.; Goto, K.; Kogo, Y. Oxidation and recession of plain weave carbon fiber reinforced ZrB2-SiC-ZrC in oxygen–hydrogen torch environment. J. Eur. Ceram. Soc. 2019, 39, 2812–2823. [Google Scholar] [CrossRef]

- Vinci, A.; Reimer, T.; Zoli, L.; Sciti, D. Influence of pressure on the oxidation resistance of carbon fiber reinforced ZrB2/SiC composites at 2000 and 2200 °C. Corros. Sci. 2021, 184, 109377. [Google Scholar] [CrossRef]

- Ogasawara, T.; Aoki, T.; Hassan, M.S.A.; Mizokami, Y.; Watanabe, N. Ablation behavior of SiC fiber/carbon matrix composites under simulated atmospheric reentry conditions. Compos. Part A Appl. Sci. Manuf. 2011, 42, 221–228. [Google Scholar] [CrossRef]

- Fang, G.; Gao, X.; Song, Y. A Review on ceramic matrix composites and environmental barrier coatings for aero-engine: Material development and failure analysis. Coatings 2023, 13, 357. [Google Scholar] [CrossRef]

- Tejero-Martin, D.; Bennett, C.; Hussain, T. A review on environmental barrier coatings: History, current state of the art and future developments. J. Eur. Ceram. Soc. 2021, 41, 1747–1768. [Google Scholar] [CrossRef]

- Xiang, Y.; Li, W.; Wang, S.; Chen, Z.-H. Oxidation behavior of oxidation protective coatings for PIP–C/SiC composites at 1500 °C. Ceram. Int. 2012, 38, 9–13. [Google Scholar] [CrossRef]

- Yang, X.; Huang, Q.; Su, Z.; Chang, X.; Chai, L.; Liu, C.; Xue, L.; Huang, D. Resistance to oxidation and ablation of SiC coating on graphite prepared by chemical vapor reaction. Corros. Sci. 2013, 75, 16–27. [Google Scholar] [CrossRef]

- Fang, X.; Liu, F.; Lu, B.; Feng, X.; Kleebe, H.J. Bio-Inspired Microstructure Design to Improve Thermal Ablation and Oxidation Resistance: Experiment on SiC. J. Am. Ceram. Soc. 2015, 98, 4010–4015. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, Z.; Yu, S. Ablation behavior and mechanism analysis of C/SiC composites. J. Mater. Res. Technol. 2016, 5, 170–182. [Google Scholar] [CrossRef]

- Binner, J.; Porter, M.; Baker, B.; Zou, J.; Venkatachalam, V.; Diaz, V.R.; D’Angio, A.; Ramanujam, P.; Zhang, T.; Murthy, T.S.R.C. Selection, processing, properties and applications of ultra-high temperature ceramic matrix composites, UHTCMCs—A review. Int. Mater. Rev. 2019, 65, 389–444. [Google Scholar] [CrossRef]

- Liu, L.; Li, B.; Feng, W.; Tang, C.; Zhang, J.; Yao, X.; Yang, Z.; Guo, Y.; Wang, P.; Zhang, Y. Effect of loading spectrum with different single pulsing time on the cyclic ablation of C/C-SiC-ZrB2-ZrC composites in plasma. Corros. Sci. 2021, 192, 109817. [Google Scholar] [CrossRef]

- Ren, X.-R.; Wang, W.-G.; Sun, K.; Hu, Y.-W.; Xu, L.-H.; Feng, P.-Z. Preparation of MoSi2-modified HfB2-SiC ultra high temperature ceramic anti-oxidation coatings by liquid phase sintering. New Carbon Mater. 2022, 37, 603–614. [Google Scholar] [CrossRef]

- Lin, H.; Liu, Y.; Liang, W.; Miao, Q.; Zhou, S.; Sun, J.; Qi, Y.; Gao, X.; Song, Y.; Ogawa, K. Effect of the Y2O3 amount on the oxidation behavior of ZrB2-SiC-based coatings for carbon/carbon composites. J. Eur. Ceram. Soc. 2022, 42, 4770–4782. [Google Scholar] [CrossRef]

- Chen, B.-W.; Ni, D.-W.; Lu, J.; Cai, F.-Y.; Zou, X.-G.; Liao, C.-J.; Wang, H.-D.; Dong, S.-M. Long-term and cyclic ablation behavior of La2O3 modified Cf/ZrB2-SiC composites at 2500 °C. Corros. Sci. 2022, 206, 110538. [Google Scholar] [CrossRef]

- Zhang, P.; Cheng, C.; Xu, M.; Liu, B.; Zhu, X.; Fu, Q. High-entropy (Hf0.25Zr0.25Ti0.25Cr0.25)B2 ceramic incorporated SiC-Si composite coating to protect C/C composites against ablation above 2400 K. Ceram. Int. 2022, 48, 27106–27119. [Google Scholar] [CrossRef]

- Jin, X.; Fan, X.; Lu, C.; Wang, T. Advances in oxidation and ablation resistance of high and ultra-high temperature ceramics modified or coated carbon/carbon composites. J. Eur. Ceram. Soc. 2018, 38, 1–28. [Google Scholar] [CrossRef]

- Jiang, Y.; Ni, D.; Chen, B.; Lu, J.; Cai, F.; Zou, X.; Liao, C.; Wang, H.; Dong, S. Fabrication and optimization of 3D-Cf/HfC-SiC-based composites via sol-gel processing and reactive melt infiltration. J. Eur. Ceram. Soc. 2021, 41, 1788–1794. [Google Scholar] [CrossRef]

- Padture, N.P. Advanced structural ceramics in aerospace propulsion. Nat. Mater. 2016, 15, 804–809. [Google Scholar] [CrossRef]

- Lee, S.; Park, G.; Kim, J.G.; Paik, J.G. Evaluation System for Ablative Material in a High-Temperature Torch. Int. J. Aeronaut. Space Sci. 2019, 20, 620–635. [Google Scholar] [CrossRef]

- Fan, Y.; Yang, D.; Mei, H.; Xiao, S.; Yao, Y.; Cheng, L.; Zhang, L. Tuning SiC nanowires interphase to improve the mechanical and electromagnetic wave absorption properties of SiCf/SiCnw/Si3N4 composites. J. Alloys Compd. 2022, 896, 163017. [Google Scholar] [CrossRef]

- Mungiguerra, S.; Silvestroni, L.; Savino, R.; Zoli, L.; Esser, B.; Lagos, M.; Sciti, D. Qualification and reusability of long and short fibre-reinforced ultra-refractory composites for aerospace thermal protection systems. Corros. Sci. 2022, 195, 109955. [Google Scholar] [CrossRef]

- Jenkins, M.G.; Mello, M.D. Fabrication, Processing, and Characterization of Braided, Continuous SiC Fiber-Reinforced/CVI SiC Matrix Ceramic Composites. Mater. Manuf. Process. 1996, 11, 99–118. [Google Scholar] [CrossRef]

- Grantham, T.; Tanner, G.; Molina, R.; Duong, N.-M.; Koo, J.H. Ablation, thermal, and morphological properties of sic fibers reinforced ceramic matrix composites. In Proceedings of the 56th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Carney, C.M. 5.10 Ultra-High Temperature Ceramic-Based Composites. In Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 281–292. [Google Scholar]

- Lee, Y.-J.; Joo, H.J. Ablation characteristics of carbon fiber reinforced carbon (CFRC) composites in the presence of silicon carbide (SiC) coating. Surf. Coat. Technol. 2004, 180–181, 286–289. [Google Scholar] [CrossRef]

- Gao, P.; Xiao, H.; Wang, H.; Jin, Z. A study on the oxidation kinetics and mechanism of three-dimensional (3D) carbon fiber braid coated by gradient SiC. Mater. Chem. Phys. 2005, 93, 164–169. [Google Scholar] [CrossRef]

- Tang, S.; Deng, J.; Liu, W.; Yang, K. Mechanical and ablation properties of 2D-carbon/carbon composites pre-infiltrated with a SiC filler. Carbon 2006, 44, 2877–2882. [Google Scholar] [CrossRef]

- Chen, Z.; Fang, D.; Miao, Y.; Yan, B. Comparison of morphology and microstructure of ablation centre of C/SiC composites by oxy-acetylene torch at 2900 and 3550 °C. Corros. Sci. 2008, 50, 3378–3381. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, B. Morphology and Microstructure of Three-Dimensional Orthogonal C/SiC Composites Ablated by an Oxyacetylene Flame at 2900 °C. Int. J. Appl. Ceram. Technol. 2009, 6, 164–170. [Google Scholar] [CrossRef]

- Li, S.; Feng, Z.; Liu, Y.; Yang, W.; Zhang, W.; Cheng, L.; Zhang, L. Microstructural evolution of coating-modified 3D C/SiC composites after annealing in wet oxygen at different temperatures. Corros. Sci. 2010, 52, 2837–2845. [Google Scholar] [CrossRef]

- Nie, J.; Xu, Y.; Zhang, L.; Fan, S.; Xu, F.; Cheng, L.; Ma, J.; Yin, X. Microstructure, Thermophysical, and Ablative Performances of a 3D Needled C/C-SiC Composite. Int. J. Appl. Ceram. Technol. 2010, 7, 197–206. [Google Scholar] [CrossRef]

- Wei, L.; Yang, X.; Song, W.; Yan, M.; Zhao-hui, C. Ablation behavior of three-dimensional braided C/SiC composites by oxyacetylene torch under different environments. Ceram. Int. 2013, 39, 463–468. [Google Scholar] [CrossRef]

- Safi, S.; Kazemzadeh, A. MCMB–SiC composites; new class high-temperature structural materials for aerospace applications. Ceram. Int. 2013, 39, 81–86. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Feng, W.; Shi, X.; Wu, H.; Zhu, J. Effect of surface ablation products on the ablation resistance of C/C–SiC composites under oxyacetylene torch. Corros. Sci. 2013, 67, 60–66. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Shi, X.; Feng, W.; Wang, Y.; Yao, D. Effects of SiC addition on the ablation properties of C/C composites in different heat fluxes under oxyacetylene torch. Vacuum 2013, 90, 97–99. [Google Scholar] [CrossRef]

- Ni, C.; Li, K.; Liu, L.; Li, H.; Fu, Q.; Guo, L.; Liu, N. Ablation mechanism of SiC coated C/C composites at 0° angle in two flame conditions under an oxyacetylene flame. Corros. Sci. 2014, 84, 1–10. [Google Scholar] [CrossRef]

- Cui, Y.; Li, A.; Li, B.; Ma, X.; Bai, R.; Zhang, W.; Ren, M.; Sun, J. Microstructure and ablation mechanism of C/C–SiC composites. J. Eur. Ceram. Soc. 2014, 34, 171–177. [Google Scholar] [CrossRef]

- Luo, L.; Wang, Y.; Liu, L.; Duan, L.; Wang, G.; Lu, Y. Ablation behavior of C/SiC composites in plasma wind tunnel. Carbon 2016, 103, 73–83. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, A.; Mala, R.B.; Mokhasunavisu, R.R. Fabrication and Ablation Studies of 4D C/SiC Composite Nozzle Under Liquid Propulsion. Int. J. Appl. Ceram. Technol. 2015, 12, E176–E190. [Google Scholar] [CrossRef]

- Fang, X.; Liu, F.; Xia, B.; Ou, D.; Feng, X. Formation mechanisms of characteristic structures on the surface of C/SiC composites subjected to thermal ablation. J. Eur. Ceram. Soc. 2016, 36, 451–456. [Google Scholar] [CrossRef]

- Jiao, X.; Li, T.; Li, Y.; Zhang, Z.; Dai, F.; Feng, Z. Oxidation behavior of SiC/glaze-precursor coating on carbon/carbon composites. Ceram. Int. 2017, 43, 8208–8213. [Google Scholar] [CrossRef]

- Jin, X.; Fan, X.; Jiang, P.; Wang, Q. Microstructure Evolution and Ablation Mechanism of C/C and C/C-SiC Composites Under a Hypersonic Flowing Propane Torch. Adv. Eng. Mater. 2017, 19, 1700239. [Google Scholar] [CrossRef]

- Chen, L.; Yang, X.; Su, Z.A.; Fang, C.; Zeng, G.; Huang, Q. Fabrication and performance of micro-diamond modified C/SiC composites via precursor impregnation and pyrolysis process. Ceram. Int. 2018, 44, 9601–9608. [Google Scholar] [CrossRef]

- Frueh, S.J.; Coons, T.P.; Reutenauer, J.W.; Gottlieb, R.; Kmetz, M.A.; Suib, S.L. Carbon fiber reinforced ceramic matrix composites with an oxidation resistant boron nitride interface coating. Ceram. Int. 2018, 44, 15310–15316. [Google Scholar] [CrossRef]

- Jin, W.; Si, Z.; Lu, Y.; Bei-zhi, S.; Yi, W.; Guang-de, L.; Zhong-fang, X.; Jie, C.; Heng-ping, H.; Yang, X. Oxidation behavior and high-temperature flexural property of CVD-SiC-coated PIP-C/SiC composites. Ceram. Int. 2018, 44, 16583–16588. [Google Scholar] [CrossRef]

- da Silva, R.J.; Reis, R.I.; Pardini, L.C.; Sias, D.F.; Filho, G.P. Low-Energy Ablation and Low Thermal Diffusivity of a CFRC Composite Modified by SiC. Int. J. Thermophys. 2019, 40, 88. [Google Scholar] [CrossRef]

- Fan, X.; Dang, X.; Ma, Y.; Yin, X.; Zhang, L.; Cheng, L. Microstructure, mechanical and ablation behaviour of C/SiC–Si with different preforms. Ceram. Int. 2019, 45, 23104–23110. [Google Scholar] [CrossRef]

- Tang, Y.; Yue, M.; Fang, X.; Feng, X. Evolution of surface droplets and flow patterns on C/SiC during thermal ablation. J. Eur. Ceram. Soc. 2019, 39, 3566–3574. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.-J.; Liu, X.-S.; Li, N.; Song, Q. Effects of SiC nanowire decorated with carbon nanosheet on mechanical, heat-dissipation and anti-ablation properties of carbon/carbon composites. Ceram. Int. 2019, 45, 2521–2529. [Google Scholar] [CrossRef]

- Kim, J.; Kim, S.; Song, S.H.; Lee, D. Effects of residual Si on the ablation properties of biomorphic C/SiC composites for reusable thermal protection systems. Adv. Compos. Mater. 2020, 30, 91–102. [Google Scholar] [CrossRef]

- Huang, D.; Tan, R.; Liu, L.; Ye, C.; Zhu, S.; Fan, Z.; Zhang, P.; Wu, H.; Han, F.; Liu, H.; et al. Preparation and properties of the three-dimensional highly thermal conductive carbon/carbon-silicon carbide composite using the mesophase-pitch-based carbon fibers and pyrocarbon as thermal diffusion channels. J. Eur. Ceram. Soc. 2021, 41, 4438–4446. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, X.; Wang, G.; Wang, Z.; Gao, L. New ablation evolution behaviors in micro-hole drilling of 2.5D Cf/SiC composites with millisecond laser. Ceram. Int. 2021, 47, 29670–29680. [Google Scholar] [CrossRef]

- Shi, Y.-A.; Zha, B.-L.; Su, Q.-D.; Wang, J.-J.; Li, S.-Y. Thermal performance and ablation characteristics of C/C-SiC for thermal protection of hypersonic vehicle. J. Eur. Ceram. Soc. 2021, 41, 5427–5436. [Google Scholar] [CrossRef]

- Xu, M.; Guo, L.; Huang, J.; Zhang, P. Microstructure and resistance to thermal shock of SiC coatings that are prepared on C/C-composite pyrocarbon matrices of various textures. Ceram. Int. 2021, 47, 9818–9826. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, Y.; Cao, L.; Chen, J.; Qiu, G.; Wang, J. Preparation and analysis of micro-holes in C/SiC composites and ablation with a continuous wave laser. J. Eur. Ceram. Soc. 2021, 41, 176–184. [Google Scholar] [CrossRef]

- Zhang, Z.; Fang, C.; Chen, L.; Yang, X.; Shi, A.; Huang, Q.; Hu, H. Fabrication, microstructure and ablation resistance of C/C–SiC composites, by using a novel precursor of SiC. Ceram. Int. 2021, 47, 7224–7232. [Google Scholar] [CrossRef]

- Zhao, X.; Cao, Y.; Duan, L.; Li, Z.; Wang, Y. Low-surface-temperature jump behavior of C/SiC composites prepared via precursor impregnation and pyrolysis in high-enthalpy plasma flows. J. Eur. Ceram. Soc. 2021, 41, 7601–7609. [Google Scholar] [CrossRef]

- Zhu, Y.; Wei, H.; Yan, L.; Cui, H. Morphology and anti-ablation properties of PIP Cf/C–SiC composites with different CVI carbon content under 4.2 MW/m2 heat flux oxy-acetylene test. Ceram. Int. 2021, 47, 2194–2201. [Google Scholar] [CrossRef]

- Liu, N.; Guo, L.; Kou, G.; Li, Y.; Yin, X. Ablation behavior of thin-blade co-deposited C/Cx-SiCy composites under the influence of the complex fluid conditions of the oxyacetylene torch. Ceram. Int. 2022, 48, 16923–16932. [Google Scholar] [CrossRef]

- Liu, N.; Guo, L.; Kou, G.; Li, Y.; Yin, X. The influence of heat treatment on the ablation behavior of the C/Cx-SiCy composites tested by thin-blade under oxyacetylene torch. Ceram. Int. 2022, 48, 22564–22574. [Google Scholar] [CrossRef]

- Xu, M.; Guo, L.; Zhang, P.; Li, W. Effect of pyrolytic carbon texture on ablation behavior of carbon/carbon composites coated with SiC by pack cementation. Ceram. Int. 2022, 48, 10261–10270. [Google Scholar] [CrossRef]

- Guo, W.; Ye, Y.; Bai, S.; Zhu, L.A.; Li, S. Gel reactive melt infiltration: A new method for large-sized complex-shaped C/C components ceramic modification. Ceram. Int. 2019, 45, 14146–14152. [Google Scholar] [CrossRef]

- Chen, Z.F.; Wan, S.C.; Fang, D.; Zhu, J.X.; Zhang, J.Z. Morphology and ablation mechanism of Cf/Si3N4 composites ablated by oxyacetylene torch at 2200 °C. Corros. Eng. Sci. Technol. 2013, 46, 380–385. [Google Scholar] [CrossRef]

- Ding, Q.; Chen, B.; Ni, D.; Ni, N.; He, P.; Gao, L.; Wang, H.; Zhou, H.; Dong, S. Improved ablation resistance of 3D-Cf/SiBCN composites with (PyC/SiC)3 multi-layers as interphase. J. Eur. Ceram. Soc. 2021, 41, 1114–1120. [Google Scholar] [CrossRef]

- Yan, C.; Liu, R.; Cao, Y.; Zhang, C.; Zhang, D. Ablation behavior and mechanism of C/ZrC, C/ZrC–SiC and C/SiC composites fabricated by polymer infiltration and pyrolysis process. Corros. Sci. 2014, 86, 131–141. [Google Scholar] [CrossRef]

- Wang, J.; Duan, X.; Yang, Z.; Jia, D.; Zhou, Y. Ablation mechanism and properties of SiCf/SiBCN ceramic composites under an oxyacetylene torch environment. Corros. Sci. 2014, 82, 101–107. [Google Scholar] [CrossRef]

- Yang, X.; Su, Z.; Huang, Q.; Chang, X.; Fang, C.; Chen, L.; Zeng, G. Effects of oxidizing species on ablation behavior of C/C-ZrB2-ZrC-SiC composites prepared by precursor infiltration and pyrolysis. Ceram. Int. 2016, 42, 19195–19205. [Google Scholar] [CrossRef]

- Zhu, Q.; Wang, G.; Liao, X.; Liang, B.; Li, D.; Yang, Z.; Jia, D.; Zhou, Y.; Zhang, T.; Gao, C. Ablation properties and mechanisms of BN-coated Cf-reinforced SiBCNZr ceramic composites under an oxyacetylene combustion torch. Ceram. Int. 2021, 47, 15533–15541. [Google Scholar] [CrossRef]

- Tong, Y.; Zhang, H.; Hu, Y.; Zhang, P.; Hua, M.; Liang, X.; Chen, Y.; Zhang, Z. RMI-C/C-SiC-ZrSi2 composite serving in inert atmosphere up to 2100 °C: Thermal shock resistance, microstructure and damage mechanism. Ceram. Int. 2021, 47, 20371–20378. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, W.; Cheng, L.; Zhang, L. Preparation and properties of 2D C/ZrB2-SiC ultra high temperature ceramic composites. Mater. Sci. Eng. A 2009, 524, 129–133. [Google Scholar] [CrossRef]

- Tang, S.; Deng, J.; Wang, S.; Liu, W. Fabrication and Characterization of an Ultra-High-Temperature Carbon Fiber-Reinforced ZrB2-SiC Matrix Composite. J. Am. Ceram. Soc. 2007, 90, 3320–3322. [Google Scholar] [CrossRef]

- Tang, S.; Deng, J.; Wang, S.; Liu, W. Comparison of thermal and ablation behaviors of C/SiC composites and C/ZrB2–SiC composites. Corros. Sci. 2009, 51, 54–61. [Google Scholar] [CrossRef]

- Yao, X.; Li, H.; Zhang, Y.; Li, K.; Fu, Q.; Peng, H. Ablation Behavior of ZrB2-Based Coating Prepared by Supersonic Plasma Spraying for SiC-Coated C/C Composites Under Oxyacetylene Torch. J. Therm. Spray Technol. 2013, 22, 531–537. [Google Scholar] [CrossRef]

- Zou, X.; Fu, Q.; Liu, L.; Li, H.; Wang, Y.; Yao, X.; He, Z. ZrB2–SiC coating to protect carbon/carbon composites against ablation. Surf. Coat. Technol. 2013, 226, 17–21. [Google Scholar] [CrossRef]

- Li, H.-J.; Yao, X.-Y.; Zhang, Y.-L.; Li, K.-Z.; Guo, L.-J.; Liu, L. Effect of heat flux on ablation behaviour and mechanism of C/C–ZrB2–SiC composite under oxyacetylene torch flame. Corros. Sci. 2013, 74, 265–270. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Z.; Li, H.; Ren, J. Ablation resistance of ZrB2–SiC coating prepared by supersonic atmosphere plasma spraying for SiC-coated carbon/carbon composites. Ceram. Int. 2014, 40, 14749–14755. [Google Scholar] [CrossRef]

- Huang, D.; Zhang, M.-Y.; Huang, Q.-Z.; Wang, L.-P.; Tang, X.; Yang, X.; Tong, K. Fabrication and ablation property of carbon/carbon composites with novel SiC–ZrB2 coating. Trans. Nonferrous Met. Soc. China 2015, 25, 3708–3715. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Zhang, Y.; Shi, X.; Fu, Q.; Feng, W.; Feng, T. Effect of ZrB2 and SiC distributions on the ablation of modified carbon/carbon composites. Ceram. Int. 2015, 41, 1823–1829. [Google Scholar] [CrossRef]

- Wang, D.; Zeng, Y.; Xiong, X.; Li, G.; Chen, Z.; Sun, W.; Wang, Y. Preparation and ablation properties of ZrB2–SiC protective laminae for carbon/carbon composites. Ceram. Int. 2014, 40, 14215–14222. [Google Scholar] [CrossRef]

- Fang, X.; Liu, F.; Su, H.; Liu, B.; Feng, X. Ablation of C/SiC, C/SiC–ZrO2 and C/SiC–ZrB2 composites in dry air and air mixed with water vapor. Ceram. Int. 2014, 40, 2985–2991. [Google Scholar] [CrossRef]

- Yang, X.; Wei, L.; Song, W.; Bi-feng, Z.; Zhao-hui, C. ZrB2/SiC as a protective coating for C/SiC composites: Effect of high temperature oxidation on mechanical properties and anti-ablation property. Compos. Part B Eng. 2013, 45, 1391–1396. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Z.; Yang, B.; Ren, J.; Li, H. Effect of pre-oxidation on the ablation resistance of ZrB2–SiC coating for SiC-coated carbon/carbon composites. Ceram. Int. 2015, 41, 2582–2589. [Google Scholar] [CrossRef]

- Feng, T.; Li, H.-J.; Shi, X.-H.; Yang, X.; Wang, S.-L. Oxidation and ablation resistance of ZrB2–SiC–Si/B-modified SiC coating for carbon/carbon composites. Corros. Sci. 2013, 67, 292–297. [Google Scholar] [CrossRef]

- Liu, Y.; Fu, Q.; Wang, B.; Liu, T.; Sun, J. The ablation behavior and mechanical property of C/C-SiC-ZrB2 composites fabricated by reactive melt infiltration. Ceram. Int. 2017, 43, 6138–6147. [Google Scholar] [CrossRef]

- Ghelich, R.; Mehdinavaz Aghdam, R.; Jahannama, M.R. Elevated temperature resistance of SiC-carbon/phenolic nanocomposites reinforced with zirconium diboride nanofibers. J. Compos. Mater. 2017, 52, 1239–1251. [Google Scholar] [CrossRef]

- Liégaut, C.; Bertrand, P.; Maillé, L.; Rebillat, F. UHTC-based matrix as protection for Cf/C composites: Original manufacturing, microstructural characterisation and oxidation behaviour at temperature above 2000 °C. J. Eur. Ceram. Soc. 2022, 42, 3168–3182. [Google Scholar] [CrossRef]

- Bai, Y.; Wang, Q.; Ma, Z.; Liu, Y.; Chen, H.; Ma, K.; Sun, S. Characterization and ablation resistance of ZrB2-xSiC gradient coatings deposited with HPPS. Ceram. Int. 2020, 46, 14756–14766. [Google Scholar] [CrossRef]

- Zhu, Y.; Cheng, L.; Ma, B.; Liu, Y.; Zhang, L. Effect of CVD ZrB2 coating thickness on anti-ablation performance of C/SiC composites. Ceram. Int. 2018, 44, 8166–8175. [Google Scholar] [CrossRef]

- Sciti, D.; Zoli, L.; Vinci, A.; Silvestroni, L.; Mungiguerra, S.; Galizia, P. Effect of PAN-based and pitch-based carbon fibres on microstructure and properties of continuous Cf/ZrB2-SiC UHTCMCs. J. Eur. Ceram. Soc. 2021, 41, 3045–3050. [Google Scholar] [CrossRef]

- Kong, J.H.; Lee, S.Y.; Son, Y.I.; Kim, D.K. Synergistic reinforcement effects of ZrB2 on the ultra-high temperature stability of Cf/SiC composite fabricated by liquid silicon infiltration. J. Eur. Ceram. Soc. 2023, 43, 3062–3069. [Google Scholar] [CrossRef]

- Ma, Y.; Li, Q.; Dong, S.; Wang, Z.; Shi, G.; Zhou, H.; Wang, Z.; He, P. Microstructures and ablation properties of 3D 4-directional Cf/ZrC–SiC composite in a plasma wind tunnel environment. Ceram. Int. 2014, 40, 11387–11392. [Google Scholar] [CrossRef]

- Wang, D.; Dong, S.; Zhou, H.; Kan, Y.; Wang, Z.; Zhu, G.; Chen, X.; Cao, Y. Effect of pyrolytic carbon interface on the properties of 3D C/ZrC–SiC composites fabricated by reactive melt infiltration. Ceram. Int. 2016, 42, 10272–10278. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Zhang, S.; Wang, J.; Li, W.; Sun, F. Effect of reaction melt infiltration temperature on the ablation properties of 2D C/C–SiC–ZrC composites. Corros. Sci. 2012, 58, 12–19. [Google Scholar] [CrossRef]

- Li, Z.; Li, H.; Zhang, S.; Li, W.; Wang, J. Microstructures and ablation properties of C/C−SiC−ZrC composites prepared using C/C skeletons with various densities. Ceram. Int. 2013, 39, 8173–8181. [Google Scholar] [CrossRef]

- Li, K.-Z.; Jing, X.; Qian-gang, F.; He-jun, L.; Ling-jun, G. Effects of porous C/C density on the densification behavior and ablation property of C/C–ZrC–SiC composites. Carbon 2013, 57, 161–168. [Google Scholar] [CrossRef]

- Xie, J.; Li, K.; Li, H.; Fu, Q.; Liu, L. Cyclic ablation behavior of C/C–ZrC–SiC composites under oxyacetylene torch. Ceram. Int. 2014, 40, 5165–5171. [Google Scholar] [CrossRef]

- Feng, B.; Li, H.; Zhang, Y.; Liu, L.; Yan, M. Effect of SiC/ZrC ratio on the mechanical and ablation properties of C/C–SiC–ZrC composites. Corros. Sci. 2014, 82, 27–35. [Google Scholar] [CrossRef]

- Zhuang, L.; Fu, Q.-G.; Tan, B.-Y.; Guo, Y.-A.; Ren, Q.-W.; Li, H.-J.; Li, B.; Zhang, J.-P. Ablation behaviour of C/C and C/C–ZrC–SiC composites with cone-shaped holes under an oxyacetylene flame. Corros. Sci. 2016, 102, 84–92. [Google Scholar] [CrossRef]

- Chang, Y.; Sun, W.; Xiong, X.; Chen, Z.; Wang, Y.; Hao, Z.; Xu, Y. Microstructure and ablation behaviors of a novel gradient C/C-ZrC-SiC composite fabricated by an improved reactive melt infiltration. Ceram. Int. 2016, 42, 16906–16915. [Google Scholar] [CrossRef]

- Li, J.; Yang, X.; Su, Z.-A.; Xue, L.; Zhong, P.; Li, S.-P.; Huang, Q.-Z.; Liu, H.-W. Effect of ZrC–SiC content on microstructure and ablation properties of C/C composites. Trans. Nonferrous Met. Soc. China 2016, 26, 2653–2664. [Google Scholar] [CrossRef]

- Tong, Y.; Ye, Y.; Bai, S.; Zhang, H. Effects of zirconium addition on microstructure and ablation resistance of carbon fibre reinforced carbon and SiC ceramic matrix composite prepared by reactive melt infiltration. Adv. Appl. Ceram. 2014, 113, 307–310. [Google Scholar] [CrossRef]

- Liu, C.; Cao, L.; Chen, J.; Xue, L.; Tang, X.; Huang, Q. Microstructure and ablation behavior of SiC coated C/C–SiC–ZrC composites prepared by a hybrid infiltration process. Carbon 2013, 65, 196–205. [Google Scholar] [CrossRef]

- Liu, C.; Su, Z.; Huang, Q.; Chen, J.; Yang, X.; Cao, L.; Yin, T.; Zhong, P. Ablation behavior of ZrC–SiC coated C/C–ZrC–SiC composites prepared by precursor infiltration pyrolysis combined with reactive melt infiltration. J. Alloys Compd. 2014, 597, 236–242. [Google Scholar] [CrossRef]

- Yang, X.; Wei, L.; Song, W.; Chen, Z.-H.; Zhang, Y.-Z. Ablation behavior and mechanism of SiC/Zr–Si–C multilayer coating for PIP-C/SiC composites under oxyacetylene torch flame. Compos. Part B Eng. 2015, 69, 127–132. [Google Scholar] [CrossRef]

- Chen, S.A.; Zhang, C.; Zhang, Y.; Zhao, D.; Hu, H.; Zhang, Z. Mechanism of ablation of 3D C/ZrC–SiC composite under an oxyacetylene flame. Corros. Sci. 2013, 68, 168–175. [Google Scholar] [CrossRef]

- Xie, J.; Li, K.; Li, H.; Fu, Q.; Guo, L. Ablation behavior and mechanism of C/C–ZrC–SiC composites under an oxyacetylene torch at 3000 °C. Ceram. Int. 2013, 39, 4171–4178. [Google Scholar] [CrossRef]

- Zhu, Y.; Hu, Y.; Cui, H.; Yan, L.-S. Morphology and anti-ablation properties of composites nozzles under the Φ100 mm H2O2- polyethylene hybrid rocket motor test. Ceram. Int. 2021, 47, 6554–6561. [Google Scholar] [CrossRef]

- Wang, S.; Li, H.; Ren, M.; Zuo, Y.; Yang, M.; Zhang, J.; Sun, J. Microstructure and ablation mechanism of C/C-ZrC-SiC composites in a plasma flame. Ceram. Int. 2017, 43, 10661–10667. [Google Scholar] [CrossRef]

- Zhou, Z.; Sun, Z.; Ge, Y.; Peng, K.; Ran, L.; Yi, M. Microstructure and ablation performance of SiC–ZrC coated C/C composites prepared by reactive melt infiltration. Ceram. Int. 2018, 44, 8314–8321. [Google Scholar] [CrossRef]

- Zhou, H.; Ni, D.; He, P.; Yang, J.; Hu, J.; Dong, S. Ablation behavior of C/C-ZrC and C/SiC-ZrC composites fabricated by a joint process of slurry impregnation and chemical vapor infiltration. Ceram. Int. 2018, 44, 4777–4782. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, K.; Li, W.; Liu, Q.; Kou, G.; Zhang, Y. Preparation, ablation behavior and mechanism of C/C-ZrC-SiC and C/C-SiC composites. Ceram. Int. 2018, 44, 7481–7490. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, K.; Li, W.; Liu, Q.; Kou, G.; Zhang, Y. Ablation behavior of C/C-ZrC-SiC composites prepared by reactive melt infiltration under oxyacetylene torch at two heat fluxes. Ceram. Int. 2018, 44, 17345–17358. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, K.; Kou, G.; Liu, T.; Li, W. Mechanical properties and ablation behavior of C/C-ZrC and C/C-ZrC-SiC composites prepared by precursor infiltration and pyrolysis combined with chemical vapor infiltration. Ceram. Int. 2018, 44, 23191–23201. [Google Scholar] [CrossRef]

- Zhao, R.; Hu, C.; Wang, Y.; Pang, S.; Li, J.; Tang, S.; Cheng, H.-M. Construction of sandwich-structured C/C-SiC and C/C-SiC-ZrC composites with good mechanical and anti-ablation properties. J. Eur. Ceram. Soc. 2022, 42, 1219–1226. [Google Scholar] [CrossRef]

- Zeng, C.; Zhang, M.; He, H.; Wang, X.; Tong, K.; Wang, Y.; Xu, P.; Zheng, L.; Zeng, G.; Su, Z.; et al. The effect of carbon source addition order during sol-gel process on the properties of C/C–ZrC–SiC composites. Ceram. Int. 2021, 47, 35366–35377. [Google Scholar] [CrossRef]

- Xie, J.; Li, K.; Sun, G.; Li, H.; Su, X.; Han, Y.; Li, T. Effects of surface structure unit of 2D needled carbon fiber preform on the microstructure and ablation properties of C/C-ZrC-SiC composites. Ceram. Int. 2019, 45, 11912–11919. [Google Scholar] [CrossRef]

- Wu, X.; Su, Z.; Huang, Q.; Tong, K.; Xie, X.; Zeng, C. Effect of ZrC particle distribution on the ablation resistance of C/C-SiC-ZrC composites fabricated using precursor infiltration pyrolysis. Ceram. Int. 2020, 46, 16062–16067. [Google Scholar] [CrossRef]

- Tian, X.; Shi, X.; Yang, L.; Li, H.; Lin, H. Preparation and ablation properties of SiC nanowire-reinforced ZrC–SiC coating-matrix integrated C/C composites. Ceram. Int. 2021, 47, 31251–31258. [Google Scholar] [CrossRef]

- Guo, W.; Bai, S.; Ye, Y. Polymer-metal slurry reactive melt infiltration: A flexible and controllable ceramic modification strategy for irregular C/C components. Ceram. Int. 2021, 47, 32891–32899. [Google Scholar] [CrossRef]

- Tian, T.; Sun, W.; Qing, X.; Xiong, X.; Zhang, H.; Chu, Y.; Chen, Z.; Zeng, Y. Intelligent cooling structure design of "Z-pins like" silicon rods to enhance the ablation resistance of C/C-ZrC-SiC composites above 2500 °C. J. Eur. Ceram. Soc. 2020, 40, 3875–3886. [Google Scholar] [CrossRef]

- Qing, X.; Sun, W.; Tian, T.; Xiong, X.; Zhang, H.; Chen, Z.; Zeng, Y. Structural characteristics and ablative behavior of C/C–ZrC–SiC composites reinforced with “Z-pins like” Zr–Si–B–C multiphase ceramic rods. Ceram. Int. 2020, 46, 18895–18902. [Google Scholar] [CrossRef]

- Liu, R.; Liu, X.; Wang, Y.; Miao, H.; Song, C.; Qi, G.; Wan, F. Laser ablation behavior and mechanism of Cf/SiC–ZrC ultra-high temperature ceramic matrix composite prepared by PIP method. Ceram. Int. 2021, 47, 23610–23619. [Google Scholar] [CrossRef]

- Li, B.; Li, H.; Hu, X.; Feng, G.; Yao, X.; Wang, P. Effect of the curvature radius of sharp leading edge parts made of a SiC/ZrC-SiC coated C/C composite on their ablation resistance. J. Eur. Ceram. Soc. 2020, 40, 2768–2780. [Google Scholar] [CrossRef]

- He, Q.; Li, H.; Yin, X.; Wang, C.; Lu, J. Microstructure, mechanical and anti-ablation properties of SiCnw/PyC core-shell networks reinforced C/C–ZrC–SiC composites fabricated by a multistep method of chemical liquid-vapor deposition. Ceram. Int. 2019, 45, 20414–20426. [Google Scholar] [CrossRef]

- He, Q.; Li, H.; Wang, C.; Zhou, H.; Lu, J. Microstructure and ablation property of C/C-ZrC-SiC composites fabricated by chemical liquid-vapor deposition combined with precursor infiltration and pyrolysis. Ceram. Int. 2019, 45, 3767–3781. [Google Scholar] [CrossRef]

- He, Q.; Li, H.; Wang, C.; Li, T.; Lu, J. Microstructure and ablation property of gradient ZrC SiC modified C/C composites prepared by chemical liquid vapor deposition. Ceram. Int. 2019, 45, 13283–13296. [Google Scholar] [CrossRef]

- Feng, T.; Shi, X.; Hou, W.; Tong, M.; Li, H.; Lin, H.; Wen, S. The ablation and mechanical behaviors of C/(SiC-ZrC)n multi-layer structure matrix composites by chemical vapor infiltration. J. Eur. Ceram. Soc. 2022, 42, 4133–4143. [Google Scholar] [CrossRef]

- Feng, G.; Yu, Y.; Yao, X.; Jia, Y.; Sun, J.; Li, H. Ablation behavior of single and alternate multilayered ZrC-SiC coatings under oxyacetylene torch. J. Eur. Ceram. Soc. 2022, 42, 830–840. [Google Scholar] [CrossRef]

- Feng, G.; Li, H.; Yao, X.; Chen, L.; Yu, Y.; Wang, H.; Chen, M. Ablation behavior of ZrC and ZrO2 coatings on SiC coated C/C composites under oxyacetylene torch with different heat fluxes. Ceram. Int. 2021, 47, 21721–21729. [Google Scholar] [CrossRef]

- Chen, S.A.; Li, G.; Hu, H.; Li, Y.; Mei, M. Microstructure and properties of ablative C/ZrC–SiC composites prepared by reactive melt infiltration of zirconium and vapour silicon infiltration. Ceram. Int. 2017, 43, 3439–3442. [Google Scholar] [CrossRef]

- Chen, B.-W.; Ni, D.-W.; Wang, J.-X.; Jiang, Y.-L.; Ding, Q.; Gao, L.; Zhang, X.-Y.; Ding, Y.-S.; Dong, S.-M. Ablation behavior of Cf/ZrC-SiC-based composites fabricated by an improved reactive melt infiltration. J. Eur. Ceram. Soc. 2019, 39, 4617–4624. [Google Scholar] [CrossRef]

- Li, B.; Li, H.; Yao, X. Ablation behaviour of the CVD-(ZrC/SiC)3 alternate coating on C/C composites under oxyacetylene torch with different heat fluxes. Ceram. Int. 2022, 48, 11756–11763. [Google Scholar] [CrossRef]

- Feng, G.; Li, H.; Yao, X.; Sun, J.; Jia, Y. An optimized strategy toward multilayer ablation coating for SiC-coated carbon/carbon composites based on experiment and simulation. J. Eur. Ceram. Soc. 2022, 42, 3802–3811. [Google Scholar] [CrossRef]

- Huang, D.; Zhang, M.; Huang, Q.; Wang, L.; Xue, L.; Tang, X.; He, K. Ablation mechanism of C/C–ZrB2–ZrC–SiC composite fabricated by polymer infiltration and pyrolysis with preform of Cf/ZrB2. Corros. Sci. 2015, 98, 551–559. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, H.; Zhang, P.; Hu, Z.; Li, H.; Zhang, L. SiC/ZrB2–SiC–ZrC multilayer coating for carbon/carbon composites against ablation. Surf. Coat. Technol. 2016, 300, 1–9. [Google Scholar] [CrossRef]

- Li, H.; Liu, L.; Zhang, Y.; Li, K.; Shi, X.; Zhang, Y.; Feng, W. Effect of high temperature heat treatment on the ablation of SiC–ZrB2–ZrC particles modified C/C composites in two heat fluxes. J. Alloys Compd. 2015, 621, 18–25. [Google Scholar] [CrossRef]

- Liu, L.; Li, H.; Shi, X.; Fu, Q.; Feng, W.; Yao, X.; Ni, C. Influence of SiC additive on the ablation behavior of C/C composites modified by ZrB2–ZrC particles under oxyacetylene torch. Ceram. Int. 2014, 40, 541–549. [Google Scholar] [CrossRef]

- Hu, C.; Pang, S.; Tang, S.; Wang, S.; Huang, H.; Cheng, H.-M. Ablation and mechanical behavior of a sandwich-structured composite with an inner layer of Cf/SiC between two outer layers of Cf/SiC–ZrB2–ZrC. Corros. Sci. 2014, 80, 154–163. [Google Scholar] [CrossRef]

- Zhuang, L.; Fu, Q.-G.; Liu, T.-Y. Ablation resistance of wedge-shaped C/C-ZrB2-ZrC-SiC composites exposed to an oxyacetylene torch. Corros. Sci. 2016, 112, 462–470. [Google Scholar] [CrossRef]

- Kannan, R.; Rangaraj, L. Processing and characterization of Cf/ZrB2-SiC-ZrC composites produced at moderate pressure and temperature. Ceram. Int. 2017, 43, 2625–2631. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Li, T.; Fu, Y.; Ren, J. Ultra-high temperature ceramic coating for carbon/carbon composites against ablation above 2000 K. Ceram. Int. 2018, 44, 3056–3063. [Google Scholar] [CrossRef]

- Tong, Y.G.; Cai, Z.H.; Bai, S.X.; Hu, Y.L.; Hua, M.Y.; Xie, W.; Ye, Y.C.; Li, Y. Microstructures and properties of Si-Zr alloy based CMCs reinforced by various porous C/C performs. Ceram. Int. 2018, 44, 16577–16582. [Google Scholar] [CrossRef]

- Tong, Y.; Hu, Y.; Liang, X.; Zhang, Z.; Li, Y.; Chen, Z.; Xiong, X.; Hua, M. Carbon fiber reinforced ZrC based ultra-high temperature ceramic matrix composite subjected to laser ablation: Ablation resistance, microstructure and damage mechanism. Ceram. Int. 2020, 46, 14408–14415. [Google Scholar] [CrossRef]

- Tong, Y.; Bai, S.; Hu, Y.; Liang, X.; Ye, Y.; Qin, Q.H. Laser ablation resistance and mechanism of Si-Zr alloyed melt infiltrated C/C-SiC composite. Ceram. Int. 2018, 44, 3692–3698. [Google Scholar] [CrossRef]

- Subha, S.; Singh, D.; Venkatanarayanan, P.S.; Kavitha, N. Experimental investigation of mechanical, thermal, and ablation performance of ZrO2/SiC modified C-Ph composites. Int. J. Appl. Ceram. Technol. 2018, 16, 761–771. [Google Scholar] [CrossRef]

- Wang, P.; Li, D.; Meng, J.; Wei, C.; Li, S.; Geng, X.; Sun, H.; Li, X.; Wu, Y.; Wen, G. Effect of silicon/graphite ratio and temperature on oxidation protective properties of SiC/ZrB2–SiC coatings prepared by pack cementation. Ceram. Int. 2022, 48, 5187–5196. [Google Scholar] [CrossRef]

- Torabi, S.; Valefi, Z.; Ehsani, N. Evaluation of oxy-acetylene flame angle effect on the erosion resistance of SiC/ZrB2–SiC/ZrB2 multilayer coatings fabricated by the shielding shrouded plasma spray technique. Ceram. Int. 2022, 48, 8155–8168. [Google Scholar] [CrossRef]

- Hu, P.; Cheng, Y.; Xie, M.; Yang, Y.; Liu, C.; Qu, Q.; Zhang, X.; Du, S. Damage mechanism analysis to the carbon fiber and fiber-ceramic interface tailoring of Cf/ZrC-SiC using PyC coating. Ceram. Int. 2018, 44, 19038–19043. [Google Scholar] [CrossRef]

- Chen, X.; Feng, Q.; Kan, Y.; Ni, D.; Zhou, H.; Gao, L.; Zhang, X.; Ding, Y.; Dong, S. Effects of preform pore structure on infiltration kinetics and microstructure evolution of RMI-derived Cf/ZrC-ZrB2-SiC composite. J. Eur. Ceram. Soc. 2020, 40, 2683–2690. [Google Scholar] [CrossRef]

- Patra, N.; Al Nasiri, N.; Jayaseelan, D.D.; Lee, W.E. Thermal properties of Cf/HfC and Cf/HfC-SiC composites prepared by precursor infiltration and pyrolysis. J. Eur. Ceram. Soc. 2018, 38, 2297–2303. [Google Scholar] [CrossRef]

- Vinci, A.; Zoli, L.; Sciti, D.; Watts, J.; Hilmas, G.E.; Fahrenholtz, W.G. Influence of fibre content on the strength of carbon fibre reinforced HfC/SiC composites up to 2100 °C. J. Eur. Ceram. Soc. 2019, 39, 3594–3603. [Google Scholar] [CrossRef]

- Xu, J.; Sun, W.; Xiong, X.; Xu, Y.; Deng, N.; Li, W.; Chen, Z. Microstructure and ablation behaviour of a strong, dense, and thick interfacial ZrxHf1−xC/SiC multiphase bilayer coating prepared by a new simple one-step method. Ceram. Int. 2020, 46, 12031–12043. [Google Scholar] [CrossRef]

- Abdollahi, A.; Valefi, Z.; Ehsani, N. Erosion mechanism of ternary-phase SiC/ZrB2-MoSi2-SiC ultra-high temperature multilayer coating under supersonic flame at 90° angle with speed of 1400 m/s (Mach 4). J. Eur. Ceram. Soc. 2020, 40, 972–987. [Google Scholar] [CrossRef]

- Jia, J.; Li, C.; Chen, Q.; Bai, S.; Chang, J.; Xiong, D.; Gao, M.; Li, S.; Xiao, J. Effects of SiC content on the mechanical and thermophysical properties of 3D Cf/SiC–Al composites. Ceram. Int. 2022, 48, 20571–20578. [Google Scholar] [CrossRef]

- Tan, W.; Li, K.; Li, H.; Zhang, J.; Ni, C.; Cao, A.; Ma, C. Ablation behavior and mechanism of C/C-HfC-SiC composites. Vacuum 2015, 116, 124–129. [Google Scholar] [CrossRef]

- Luo, L.; Wang, Y.; Duan, L.; Liu, L.; Wang, G. Ablation behavior of C/SiC-HfC composites in the plasma wind tunnel. J. Eur. Ceram. Soc. 2016, 36, 3801–3807. [Google Scholar] [CrossRef]

- Wen, Q.; Luan, X.; Wang, L.; Xu, X.; Ionescu, E.; Riedel, R. Laser ablation behavior of SiHfC-based ceramics prepared from a single-source precursor: Effects of Hf-incorporation into SiC. J. Eur. Ceram. Soc. 2019, 39, 2018–2027. [Google Scholar] [CrossRef]

- Chinnaraj, R.K.; Hong, S.M.; Kim, H.S.; Oh, P.Y.; Choi, S.M. Ablation Experiments of Ultra-High-Temperature Ceramic Coating on Carbon–Carbon Composite Using ICP Plasma Wind Tunnel. Int. J. Aeronaut. Space Sci. 2020, 21, 889–905. [Google Scholar] [CrossRef]

- Wang, P.; Li, H.; Jia, Y.; Zhang, Y.; Yuan, R. Ablation resistance of HfB2-SiC coating prepared by in-situ reaction method for SiC coated C/C composites. Ceram. Int. 2017, 43, 12005–12012. [Google Scholar] [CrossRef]

- Tong, M.; Fu, Q.; Hu, D.; Zhou, L.; Feng, T. Improvement of ablation resistance of CVD-HfC/SiC coating on hemisphere shaped C/C composites by introducing diffusion interface. J. Eur. Ceram. Soc. 2021, 41, 4067–4075. [Google Scholar] [CrossRef]

- Duan, L.; Zhao, X.; Wang, Y. Comparative ablation behaviors of C/SiC-HfC composites prepared by reactive melt infiltration and precursor infiltration and pyrolysis routes. Ceram. Int. 2017, 43, 16114–16120. [Google Scholar] [CrossRef]

- Tang, Z.; Yi, M.; Xiang, Q.; Du, Y.; Peng, K. Mechanical and ablation properties of a C/C-HfB2-SiC composite prepared by high-solid-loading slurry impregnation combined with precursor infiltration and pyrolysis. J. Eur. Ceram. Soc. 2021, 41, 6160–6170. [Google Scholar] [CrossRef]

- Zhang, P.; Fu, Q.; Cheng, C.; Sun, J.; Zhang, J.; Xu, M.; Zhu, X. Microstructure evolution of in-situ SiC-HfB2-Si ternary coating and its corrosion behaviors at ultra-high temperatures. J. Eur. Ceram. Soc. 2021, 41, 6223–6237. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, Y.; Zhang, T.; Chen, R.; Zhu, X. Cyclic ablation behavior and microstructure evolution of multi-layer coating on C/C composites under oxyacetylene torch. Ceram. Int. 2022, 48, 21750–21757. [Google Scholar] [CrossRef]

- Luan, X.; Yuan, J.; Wang, J.; Tian, M.; Cheng, L.; Ionescu, E.; Riedel, R. Laser ablation behavior of Cf/SiHfBCN ceramic matrix composites. J. Eur. Ceram. Soc. 2016, 36, 3761–3768. [Google Scholar] [CrossRef]

- Feng, T.; Hou, W.; Tong, M.; Li, H.; Lin, H.; Wen, S. Effect of SiCnws on flexural strength of SiCf/HfC-SiC composites after impact and ablation. J. Eur. Ceram. Soc. 2021, 41, 6171–6180. [Google Scholar] [CrossRef]

- Qu, J.-L.; Fu, Q.-G.; Zhang, J.-P.; Zhang, P.-F. Ablation behavior of TaB2-SiC coating for carbon/carbon composites under oxyacetylene torch. Vacuum 2016, 131, 223–230. [Google Scholar] [CrossRef]

- Du, B.; Hong, C.; Zhang, X.; Wang, A.; Sun, Y. Ablation behavior of advanced TaSi2-based coating on carbon-bonded carbon fiber composite/ceramic insulation tile in plasma wind tunnel. Ceram. Int. 2018, 44, 3505–3510. [Google Scholar] [CrossRef]

- Liu, F.; Li, H.; Gu, S.; Yao, X.; Fu, Q. Ablation behavior and thermal protection performance of TaSi2 coating for SiC coated carbon/carbon composites. Ceram. Int. 2019, 45, 3256–3262. [Google Scholar] [CrossRef]

- Chen, Z.-K.; Xiong, X.; Li, G.-D.; Wang, Y.-L. Ablation behaviors of carbon/carbon composites with C-SiC-TaC multi-interlayers. Appl. Surf. Sci. 2009, 255, 9217–9223. [Google Scholar] [CrossRef]

- Jia, Y.; Li, H.; Li, L.; Fu, Q.; Li, K. Effect of Monolithic LaB6 on the Ablation Resistance of ZrC/SiC Coating Prepared by Supersonic Plasma Spraying for C/C Composites. J. Mater. Sci. Technol. 2016, 32, 996–1002. [Google Scholar] [CrossRef]

- Jia, Y.; Li, H.; Feng, L.; Sun, J.; Li, K.; Fu, Q. Ablation behavior of rare earth La-modified ZrC coating for SiC-coated carbon/carbon composites under an oxyacetylene torch. Corros. Sci. 2016, 104, 61–70. [Google Scholar] [CrossRef]

- Fang, C.; Huang, B.; Yang, X.; He, K.; Chen, L.; Shi, A.; Zhang, Z.; Huang, Q. Effects of LaB6 on the microstructures and ablation properties of 3D C/C-SiC-ZrB2-LaB6 composites. J. Eur. Ceram. Soc. 2020, 40, 2781–2790. [Google Scholar] [CrossRef]

- Chen, M.; Yao, X.; Feng, G.; Guo, Y. Anti-ablation performance of La2O3-modified ZrB2 coating on SiC-coated carbon/carbon composites. Ceram. Int. 2020, 46, 28758–28766. [Google Scholar] [CrossRef]

- Jia, Y.; Li, H.; Fu, Q.; Sun, J.; Li, L. Ablation behavior of ZrC-La2O3 coating for SiC-coated carbon/carbon composites under an oxyacetylene torch. Ceram. Int. 2016, 42, 14236–14245. [Google Scholar] [CrossRef]

- Lu, J.; Hao, K.; Liu, L.; Li, H.; Li, K.; Qu, J.; Yan, X. Ablation resistance of SiC–HfC–ZrC multiphase modified carbon/carbon composites. Corros. Sci. 2016, 103, 1–9. [Google Scholar] [CrossRef]

- Chen, Y.; Sun, W.; Xiong, X.; Chang, Y.; Xu, Y.; Peng, Z.; Tian, T.; Zeng, Y. Microstructure, thermophysical properties, and ablation resistance of C/HfC-ZrC-SiC composites. Ceram. Int. 2019, 45, 4685–4691. [Google Scholar] [CrossRef]

- Yang, Y.; Li, K.; Zhao, Z.; Liu, G. HfC-ZrC-SiC multiphase protective coating for SiC-coated C/C composites prepared by supersonic atmospheric plasma spraying. Ceram. Int. 2017, 43, 1495–1503. [Google Scholar] [CrossRef]

- Shojaie-Bahaabad, M.; Hasani-Arefi, A. Ablation properties of ZrC-SiC-HfB2 ceramic with different amount of carbon fiber under an oxyacetylene flame. Mater. Res. Express 2020, 7, 025604. [Google Scholar] [CrossRef]

- Liu, X.; Deng, C.; Deng, C.; Liu, M.; Zhou, K. Mullite-modified ZrB2-MoSi2 coating for carbon/carbon composites to withstand long term ablation. Ceram. Int. 2018, 44, 4330–4337. [Google Scholar] [CrossRef]

- Hu, D.; Fu, Q.; Liu, T.; Tong, M. Structural design and ablation performance of ZrB2/MoSi2 laminated coating for SiC coated carbon/carbon composites. J. Eur. Ceram. Soc. 2020, 40, 212–219. [Google Scholar] [CrossRef]

- Cheng, S.; Geng, L.; Liu, X.; Wang, Y. Laser ablation behavior and mechanism of C/SiC coated with ZrB2–MoSi2–SiC/Mo prepared by HVOF. Ceram. Int. 2020, 46, 17752–17762. [Google Scholar] [CrossRef]

- Sun, Y.; Dong, S.; Hong, C.; Zhang, X.; Han, J.; Qu, Q. A novel combination of precursor pyrolysis assisted sintering and rapid sintering for construction of multi-composition coatings to improve ablation resistance of SiOC ceramic modified carbon fiber needled felt preform composites. Ceram. Int. 2020, 46, 20163–20172. [Google Scholar] [CrossRef]

- Feng, G.; Li, H.; Yao, X.; Zhou, H.; Yu, Y.; Lu, J. Ablation resistance of HfC-TaC/HfC-SiC alternate coating for SiC-coated carbon/carbon composites under cyclic ablation. J. Eur. Ceram. Soc. 2021, 41, 3207–3218. [Google Scholar] [CrossRef]

- Tong, M.; Chen, C.; Fu, Q.; Feng, T.; Hou, W.; Zhang, J.; Sun, J.; Zhou, L. Exploring Hf-Ta-O precipitation upon ablation of Hf-Ta-Si-C coating on C/C composites. J. Eur. Ceram. Soc. 2022, 42, 2586–2596. [Google Scholar] [CrossRef]

- Feng, G.; Li, H.; Yao, X.; Chen, M.; Xue, Y. Ablation resistance of TaC-modified HfC coating prepared by supersonic plasma spraying for SiC-coated carbon/carbon composites. Ceram. Int. 2019, 45, 17936–17945. [Google Scholar] [CrossRef]

- Xu, Y.; Sun, W.; Miao, C.; Shen, Y.; Chen, H.; Liu, Y.; Zhang, H.; Xiong, X. Ablation properties of C/C-UHTCs and their preparation by reactive infiltration of K2MeF6 (Me = Zr, Ti) molten salt. J. Eur. Ceram. Soc. 2021, 41, 5405–5416. [Google Scholar] [CrossRef]

- Zeng, Y.; Wang, D.; Xiong, X.; Gao, S.; Chen, Z.; Sun, W.; Wang, Y. Ultra-high-temperature ablation behavior of SiC–ZrC–TiC modified carbon/carbon composites fabricated via reactive melt infiltration. J. Eur. Ceram. Soc. 2020, 40, 651–659. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, J.; Guo, L.; Fan, K.; Riedel, R.; Fu, Q. Ablation resistant ZrC coating modified by polymer-derived SiC/TiC nanocomposites for ultra-high temperature application. J. Eur. Ceram. Soc. 2022, 42, 18–29. [Google Scholar] [CrossRef]

- Fan, X.; Yin, X.; Wang, L.; Cheng, L.; Zhang, L. Processing, microstructure and ablation behavior of C/SiC–Ti3SiC2 composites fabricated by liquid silicon infiltration. Corros. Sci. 2013, 74, 98–105. [Google Scholar] [CrossRef]

- Yaghobizadeh, O.; Sedghi, A.; Baharvandi, H.R. Effect of Ti3SiC2 on the ablation behavior and mechanism of Cf-C-SiC-Ti3SiC2 composites under oxyacetylene torch at 3000 °C. Ceram. Int. 2019, 45, 777–785. [Google Scholar] [CrossRef]

- Zhang, J.-P.; Fu, Q.-G.; Zhuang, L.; Li, H.-J.; Sun, C. Preparation and Ablation Properties of Y2SiO5 Coating for SiC-Coated C/C Composites by Supersonic Plasma Spraying. J. Therm. Spray Technol. 2015, 24, 994–1001. [Google Scholar] [CrossRef]

- Zhang, J.-P.; Fu, Q.-G.; Li, H.-J.; Sun, G.-D.; Sun, C.; Nan, X.-Y.; Li, S.-F.; Liu, L. Ablation behavior of Y2SiO5/SiC coating for C/C composites under oxyacetylene torch. Corros. Sci. 2014, 87, 472–478. [Google Scholar] [CrossRef]

- Li, K.; Hu, M. Dynamic oxidation resistance and residual mechanical strength of ZrB2-CrSi2-SiC-Si/SiC coated C/C composites. Ceram. Int. 2017, 43, 4880–4887. [Google Scholar] [CrossRef]

- Huo, C.; Guo, L.; Wang, C.; Zhou, L.; Wang, J.; Li, K. Microstructure and high temperature anti-ablation behavior of Cr-modified ZrC coating for SiC-coated carbon/carbon composites. Ceram. Int. 2019, 45, 1777–1789. [Google Scholar] [CrossRef]

- Makurunje, P.; Monteverde, F.; Sigalas, I. Self-generating oxidation protective high-temperature glass-ceramic coatings for Cf/C-SiC-TiC-TaC UHTC matrix composites. J. Eur. Ceram. Soc. 2017, 37, 3227–3239. [Google Scholar] [CrossRef]

- Ren, J.; Feng, E.; Zhang, Y.; Zhang, J.; Ding, D.; Li, L. Influences of deposition temperature, gas flow rate and ZrC content on the microstructure and anti-ablation performance of CVD-HfC-ZrC coating. Ceram. Int. 2021, 47, 556–566. [Google Scholar] [CrossRef]

- Ren, J.; Feng, E.; Zhang, Y.; Zhang, J.; Li, L. Microstructure and anti-ablation performance of HfC-TaC and HfC-ZrC coatings synthesized by CVD on C/C composites. Ceram. Int. 2020, 46, 10147–10158. [Google Scholar] [CrossRef]

- Peng, Z.; Sun, W.; Xiong, X.; Xu, Y.; Chen, Y. A novel Cr-doped Al2O3-SiC-ZrC composite coating for ablative protection of C/C-ZrC-SiC composites. J. Eur. Ceram. Soc. 2018, 38, 2897–2902. [Google Scholar] [CrossRef]

- Tian, T.; Sun, W.; Qing, X.; Chu, Y.; Chen, H.; Liu, Y.; Xiong, X.; Zhang, H. Effect of surface structure unit of 3D needled carbon fiber preform on the ablation improvement of “Z-pins like” V0.9-Si0.1 rod for C/C–ZrC–SiC. Ceram. Int. 2021, 47, 33463–33475. [Google Scholar] [CrossRef]

- Hao, Z.; Sun, W.; Xiong, X.; Chen, Z.; Wang, Y.; Chang, Y.; Xu, Y. Microstructure and ablation properties of a gradient Cf/C-XSi2-SiC (X = Mo,Ti) composite fabricated by reactive melt infiltration. J. Eur. Ceram. Soc. 2016, 36, 3775–3782. [Google Scholar] [CrossRef]

- Bai, Z.; Cao, L.; Huang, J.; OuYang, H.; Li, C.; Zhao, X.; Wang, Y.; Yan, J. Microstructures and ablation properties of Cf/C-SiC-MoSi2 composites: Influence of the SiC:MoSi2 mass ratio. Ceram. Int. 2016, 42, 19296–19301. [Google Scholar] [CrossRef]

- Li, X.; Feng, J.; Jiang, Y.; Lin, H.; Feng, J. Preparation and properties of TaSi2-MoSi2-ZrO2-borosilicate glass coating on porous SiCO ceramic composites for thermal protection. Ceram. Int. 2018, 44, 19143–19150. [Google Scholar] [CrossRef]

- Liu, F.; Li, H.; Zhang, W.; Yao, X.; Fu, Q.; He, X. Effect of CrSi2 on the ablation resistance of a ZrSi2-Y2O3/SiC coating prepared by SAPS. Ceram. Int. 2021, 47, 15030–15038. [Google Scholar] [CrossRef]

- Chang, Y.; Sun, W.; Xiong, X.; Chen, Z.; Wang, Y.; Hao, Z.; Xu, Y. A novel design of Al-Cr alloy surface sealing for ablation resistant C/C-ZrC-SiC composite. J. Eur. Ceram. Soc. 2017, 37, 859–864. [Google Scholar] [CrossRef]

- Luo, L.; Liu, J.; Duan, L.; Wang, Y. Multiple ablation resistance of La2O3/Y2O3-doped C/SiC–ZrC composites. Ceram. Int. 2015, 41, 12878–12886. [Google Scholar] [CrossRef]

- Hao, Z.; Sun, W.; Xiong, X.; Chen, Z.; Wang, Y. Effects of Ti/Al addition on the microstructures and ablation properties of Cf/C–MoSi2–SiC composites. J. Eur. Ceram. Soc. 2016, 36, 457–464. [Google Scholar] [CrossRef]

- Silvestroni, L.; Vinci, A.; Failla, S.; Zoli, L.; Rubio, V.; Binner, J.; Sciti, D. Ablation behaviour of ultra-high temperature ceramic matrix composites: Role of MeSi2 addition. J. Eur. Ceram. Soc. 2019, 39, 2771–2781. [Google Scholar] [CrossRef]

- Xu, J.; Liu, Y.; Ma, Z.; Zhu, S.; Wang, Y.; Chen, H.; Ma, K. Infrared radiative performance and anti-ablation behaviour of Sm2O3 modified ZrB2/SiC coatings. Ceram. Int. 2021, 47, 400–408. [Google Scholar] [CrossRef]

- Wang, P.; Wei, F.; Zhang, H.; Yin, J.; Hao, Z.; Zhou, J. Effect of SiC whiskers on the mechanical and ablation performances of Cu modified C/C composite. Ceram. Int. 2022, 48, 5369–5376. [Google Scholar] [CrossRef]

- Wang, H.-H.; Kong, J.-A.; Ge, J.; Teng, L.; Shi, X.-H.; Li, H.-J. Effects of reflectivity on laser-ablation resistance of the laser-cladding repaired Nd2O3 modified SiO2 coatings on C/C composites. J. Eur. Ceram. Soc. 2021, 41, 6548–6558. [Google Scholar] [CrossRef]

- Liu, H.; Kang, P.; Yang, W.; Zhang, N.; Sun, Y.; Wu, G. Ablation behavior of Al20Si/graphite composite nozzle-throats in a solid rocket motor environment. Ceram. Int. 2020, 46, 13317–13323. [Google Scholar] [CrossRef]

- Kannan, R.; Rangaraj, L. Properties of Cf/SiC-ZrB2-TaxCy composite produced by reactive hot pressing and polymer impregnation pyrolysis (RHP/PIP). J. Eur. Ceram. Soc. 2019, 39, 2257–2265. [Google Scholar] [CrossRef]

- He, R.; Li, K.; Gu, S.; Liu, Q. Comparing ablation properties of NbC and NbC-25 mol.% ZrC coating on SiC-coated C/C composites. Ceram. Int. 2020, 46, 7055–7064. [Google Scholar] [CrossRef]

- Fang, C.; Yang, X.; He, K.; Chen, L.; Zeng, G.; Shi, A.; Huang, Q.; Huang, B. Microstructure and ablation properties of La2O3 modified C/C-SiC composites prepared via precursor infiltration pyrolysis. J. Eur. Ceram. Soc. 2019, 39, 762–772. [Google Scholar] [CrossRef]

- Cai, F.; Ni, D.; Chen, B.; Ye, L.; Sun, Y.; Lu, J.; Zou, X.; Zhou, H.; He, P.; Zhao, T. Fabrication and properties of Cf/(Ti0.2Zr0.2Hf0.2Nb0.2Ta0.2)C-SiC high-entropy ceramic matrix composites via precursor infiltration and pyrolysis. J. Eur. Ceram. Soc. 2021, 41, 5863–5871. [Google Scholar] [CrossRef]

- Tian, T.; Sun, W.; Xiong, X.; Xu, Y.; Chen, Y.; Zeng, Y.; Liu, F. Novel “Z-pins like” vanadium rods prepared by solid phase sintering to improve ablation resistance of the C/C-ZrC-SiC composites. J. Eur. Ceram. Soc. 2019, 39, 1696–1702. [Google Scholar] [CrossRef]

- Weng, Y.; Yang, X.; Chen, F.; Zhang, X.; Shi, A.; Yan, J.; Huang, Q. Effect of CVI SiC content on ablation and mechanism of C/C-SiC-ZrC-Cu composites. Ceram. Int. 2022, 48, 7937–7950. [Google Scholar] [CrossRef]

| Composites | Main Structure | Interphase | Matrix (Coating) | Preparing Method | Ablation Type | Mass Ablation Rate (mg∙s−1) | Liner Ablation Rate (mm∙s−1) | Ref. |

|---|---|---|---|---|---|---|---|---|

| C/SiC | 4D axes carbon fiber preform | SiC coating | arcplasma torch | 3 | 0.1311 | [39] | ||

| 3D braid carbon | SiC coating | isothermal oxidation | [40] | |||||

| 2D C/C needle | PyC | SiC | ICVI; PI; | engine torch | [41] | |||

| carbon fiber (M30) | PyC | SiC | CVI | oxyacetylene torch | [42] | |||

| 3D C orthogonal structure | SiC | PIP, HP | oxyacetylene torch | [43] | ||||

| 3D braid C/C | PyC | SiC | CVI, CVD | gas mixture (O2/H2O/Ar) | [44] | |||

| 3D needled (30 vol%) | PyC | SiC | CVI; LSI | oxyacetylene torch | 1.6 | 0.0039 | [45] | |

| 3D braided | PyC | SiC | PIP | oxyacetylene torch | [46] | |||

| 2D plain woven carbon- fabric | PyC | Ph/SiC | LSI | oxyacetylene torch | 1837 | [47] | ||

| needle punched disk felts | PyC | SiC | PIP; TCVI | oxyacetylene torch | 1.53 | [48] | ||

| 2.5D carbon fiber felts | PyC | SiC | PIP; TCVI | oxyacetylene torch | [49] | |||

| 2.5D needle puncher felts | PyC | SiC coating | TCVI; PC | oxyacetylene torch | [50] | |||

| needle-carbon fiber felts | PyC | SiC | CVI; molten infiltration | oxyacetylene torch | [51] | |||

| 3D needled felt (T300) | PyC | SiC coating | CVI | plasma wind tunnel | [52] | |||

| 4D woven carbon preforms | SiC | impregnation | UH25 was used as fuel; N2O4 as oxidizer | 0.005 | [53] | |||

| carbon fiber | PyC | SiC coating | CVD; ICVI | oxyacetylene torch | [54] | |||

| 2D C/C | PyC | SiC coating | slurry and sintering | isothermal | [55] | |||

| 2D C/C needle | PyC | SiC | CVI | hypersonic flowing propane flame | [56] | |||

| 2.5D needle punched carbon fiber felt | PyC | SiC | PI; PIP; CVI | plasma generator equipment | 0.017 | [57] | ||

| 2D carbon fiber | BN | SiC | CVD | temperature programmed oxidation | [58] | |||

| carbon fibers (T-300) | SiC/SiC coating | PIP; CVD | air | [59] | ||||

| carbon fiber plain fabrics | ph/silicon | LPI | thermal plasma torch | [60] | ||||

| 3D needle preform | PyC | SiC and Si | CVI; CVD | oxyacetylene torch | 6.2 | [61] | ||

| carbon fiber | PyC | SiC | CVD | wind-tunnel | [62] | |||

| carbon fiber cloth | PyC | SiC nanowires | CVD | oxyacetylene torch | 0.400 | [63] | ||

| carbon preform | graphitized | SiC | oxy-kerosene hypersonic torch | 0.09 | [64] | |||

| 3D preform | PyC | SiC | CVI; PIP | plasma arc ablation | 0.56 | 1.1 × 10−4 | [65] | |

| 2.5D preform | PyC | SiC | millisecond laser | [66] | ||||

| 2D carbon fiber felts | SiC | CVI; | plasma stream | [67] | ||||

| carbon fiber | PyC | SiC coating | PC | furnace | [68] | |||

| carbon fiber | SiC | CVI | continuous wave lasers | [69] | ||||

| 2.5D needle punched preform | PyC | SiC | CVI; PIP | plasma generator equipment | 0.133 | 0.0141 | [70] | |

| 3D needle-punched preform | PyC | SiC | CVI; PIP | plasma wind tunnel | [71] | |||

| needled preform of carbon felt | PyC | SiC | PIP | oxy-acetylene torch | [72] | |||

| 2.5D carbon fiber felt | PyCx-SiCy | CVI; | oxyacetylene torch | 0.0016 | [73] | |||

| carbon structure | PyCx-SiCy | CVI | oxyacetylene torch | 0.0013 | [74] | |||

| 2.5D needle punched preform | PyC | SiC coating | CVI; PC | oxyacetylene torch | 0.0001 | 0.0003 | [75] | |

| carbon fibre needled felts | PyC | SiC | RMI; CVI | oxyacetylene torch | 0.75 | [76] | ||

| Cf/Si3N4 | needle preform | Si3N4 | LPCVI; CVI | oxyacetylene torch | [77] | |||

| Cf/SiBCN | 3D needled carbon fiber preform | (PyC/SiC)3 | SiBCN | CVI; PIP | plasma ablation flame | 0.0427 | 0.0017 | [78] |

| Composites | Main Structure | Interphase | Matrix (Coating) | Preparing Method | Ablation Method | Mass Ablation Rate (mg∙s−1) | Liner Ablation Rate (mm∙s−1) | Ref. |

|---|---|---|---|---|---|---|---|---|

| C/ZrB2-SiC | 2D plain woven carbon cloth | PyC | ZrB2-SiC | CVI; SP | oxyacetylene torch | [84] | ||

| needle punched carbon fiber webs | PyC | ZrB2-SiC | CVI; HCVI | arc-heated wind tunnel | [85] | |||

| 2D needle punched carbon fiber preform | PyC | ZrB2-SiC | CVI | arc-heated wind tunnel | [86] | |||

| 2D C/C composites | ZrB2-SiC | SAPS | oxyacetylene torch | 1.7 × 10−4 | [87] | |||

| 2D C/C composites | ZrB2-SiC | pack-cementation | oxyacetylene torch | 0.062 | 0.0044 | [88] | ||

| needle punched integrated felt | PyC | ZrB2-SiC | TCVI; PIP | oxyacetylene torch | [89] | |||

| 2D C/C composites | ZrB2-SiC | SAPS; PC; SI | oxyacetylene torch | [90] | ||||

| 2D needled carbon fiber preform | ZrB2-SiC | slurry-sintering; CVR | plasma generator | [91] | ||||

| needle-punching carbon fiber preform | ZrB2-SiC | TCVI; PIP | oxyacetylene torch | [92] | ||||

| needled integrated preform | ZrB2-SiC | pressing, pyrolysis; RSI | oxyacetylene torch | 1.3 | [93] | |||

| C/C composites | PyC | SiC-ZrB2 | CVD; CVI | oxyacetylene torch | [94] | |||

| 3D braided C/SiC preform | ZrB2-SiC | painting slurry; CVD; PIP | oxyacetylene torch | 22.9 | 0.0236 | [95] | ||

| 2D SiC-coated C/C preform | ZrB2-SiC | TCVI; PC; SAPS | oxyacetylene torch | [96] | ||||

| 2D SiC-coated C/C preform | ZrB2-SiC-Si | PC | oxyacetylene torch | 1.5 | 0.00021 | [97] | ||

| 3D braided SiC-coated C/C preform | ZrB2-SiC | CVD; slurry painting; PIP | oxidation in air | [20] | ||||

| carbon fiber | ZrB2-SiC | slurry infiltration; HP | homemade testing chamber | [16] | ||||

| short random/aligned continuous carbon fiber | ZrB2-SiC | HP; SPS | arc-jet plasma | [35] | ||||

| porous C/C preform | SiC-ZrB2 | RMI; ICVI | oxyacetylene torch | 0.61 | 0.00672 | [98] | ||

| short carbon fiber | phenolic-ZrB2-SiC | oxyacetylene torch | 14 | 0.000168 | [99] | |||

| needle-punched carbon preform | PyC | ZrB2-SiC-Si | CVI | oxyacetylene torch | [100] | |||

| C/C preform | ZrB2-SiC | HPPS | oxyacetylene torch | 2.46 | [101] | |||

| 2D C/SiC preform | ZrB2-SiC | CVI; CVD | oxyhydrogen torch | [102] | ||||

| PAN-based carbon fiber | PyC | ZrB2-SiC | PIP | arc-jet wind tunnel | [103] | |||

| C/C carbon fabric | ZrB2-SiC | LSI; | oxyacetylene torch | 217 | [104] | |||

| C/ZrC-SiC | 3D 4-directional carbon fiber preform | ZrC-SiC | CVD; PIP | oxyacetylene torch | 0.69 | 0.026 | [79] | |

| 3D 4-directional carbon fiber preform | ZrC-SiC | PIP | plasma wind tunnel | 0.7 | 0.0009 | [105] | ||

| 3D needle-punched carbon fabrics | PyC | ZrC-SiC | CVI; SI; RMI; PIP | plasma wind tunnel | [106] | |||

| 2D C/C carbon felts | ZrC-SiC | ICVI; RMI | oxyacetylene torch | 0.24 | 0.00133 | [107] | ||

| 2D C/C carbon felts | ZrC-SiC | ICVI; RMI | oxyacetylene torch | 0.21 | 0.00144 | [108] | ||

| 2D needled C/C carbon fiber felts | ZrC-SiC | TCVI; PIP | oxyacetylene torch | 0.40 | 0.00102 | [109] | ||

| porous C/C preform | ZrC-SiC | PIP | oxyacetylene torch | 2.29 | 0.0003 | [110] | ||

| 2.5D carbon fiber felts | PyC | ZrC-SiC | TCVI; PIP | oxyacetylene torch | 1.9 | 0.012 | [111] | |

| 2.5D needled carbon felts | PyC | ZrC-SiC | TCVI; PIP | oxyacetylene torch | 0.585 | 0.00133 | [112] | |

| 2.5D needled integral C/C preform | ZrC-SiC | CVD; RMI | oxyacetylene torch | 0.02 | 3.3 × 10−4 | [113] | ||

| 2.5D needled C/C felts | ZrC-SiC | CVI; PIP | plasma generator | 1.57 | 3.7 × 10−4 | [114] | ||

| 3D orthogonal braided carbon fiber preform | PyC | ZrC-SiC | CVI; RMI | oxyacetylene torch | [115] | |||

| 2D needled C/C perform | ZrC-SiC | CVI; PIP; RMI | plasma generator | 2.6 | 3.7 × 10−3 | [116] | ||

| C/C preform | ZrC-SiC | RMI; PIP | plasma generator | 0.0045 | 4.8 × 10−3 | [117] | ||

| 3D braided carbon fibers | SiC/Zr-Si-C/SiC | PIP; CVD | oxyacetylene torch | 27.4 | 0.0255 | [118] | ||

| 3D carbon fiber preform | ZrC-SiC | CVD; PIP | oxyacetylene torch | [119] | ||||

| 2D needled C/C felts | ZrC-SiC | PIP | oxyacetylene torch | 37.5 | 2.48 × 10−3 | [120] | ||

| C/C felt preform | SiC-ZrC | CVI; PIP | Developed personally | 3 × 10−3 | [121] | |||

| needled carbon fiber integer preform | ZrC-SiC | CVI; PIP | plasma flame | 1.73 | 1.94 × 10−4 | [122] | ||

| porous needling C/C preform | SiC-ZrC | RMI; CVI | oxyacetylene flame | 1.18 | 2.47 × 10−3 | [123] | ||

| 3D needle-punched carbon fiber fabrics | SiC-ZrC | slurry impregnation; CVI | arc-heated air plasma | 0.039 | [124] | |||

| 2D needle-punched carbon felt | PyC | SiC-ZrC | CVI; PIP; ICVI; TCVI | oxyacetylene torch | 2.95 | 0.015 | [125] | |

| C/C preform | SiC-ZrC | RMI; ICVI | oxyacetylene torch | 1.21 | 5.9 × 10−3 | [126] | ||

| C/C preform | SiC-ZrC | CVI; PIP | oxyacetylene torch | [127] | ||||

| needle-punched carbon felt | PyC | SiC-ZrC | ICVI; PIP; ECVI | oxyacetylene flame | 0.04 | 3.7 × 10−4 | [128] | |

| 2.5D carbon fiber preforms | PyC | ZrC-SiC | CVI | oxyacetylene torch | 0.147 | 9.8 × 10−3 | [129] | |

| 2D needled carbon fiber preform | PyC | ZrC-SiC | TCVI | oxyacetylene flame | 0.298 | 8.2 × 10−4 | [130] | |

| needled carbon felt | ZrC-SiC | CVI; PIP | plasma generator | 0.558 | 0.01633 | [131] | ||

| 2D needled carbon felts | PyC | ZrC-SiC | CVI; PIP | oxyacetylene torch | 0.46 | 6.7 × 10−4 | [132] | |

| needled felt-structured C/C preform | SiC-ZrC | RMI | oxyacetylene torch | 0.29 | 2.48 × 10−3 | [133] | ||

| C/C preform | ZrC-SiC | liquid sintering; RIM | oxyacetylene torch | 0.87 | 2.8 × 10−4 | [134] | ||

| C/C preform | ZrC-SiC | RIM | oxyacetylene torch | 0.8 | 3.85 × 10−3 | [135] | ||

| T300 fiber cloth | ZrC-SiC | PIP | laser ablation | 0.0748 | [136] | |||

| 2D C/C preform | SiC/ZrC-SiC | oxyacetylene flame | 1.2 | [137] | ||||

| carbon felts | SiCnw/PyC/ZrC-SiC | CLVD | oxyacetylene torch | 0.47 | 7.3 × 10−4 | [138] | ||

| 2.5D needling carbon felt | ZrC-SiC | CLVD; PIP | oxyacetylene flame | 1.22 | 1.07 × 10−3 | [139] | ||

| 2.5D needled carbon fiber felts | ZrC-SiC | CLVD | oxyacetylene torch | 0.39 | 5.2 × 10−4 | [140] | ||

| 2D carbon fiber cloths | PyC | SiC-ZrC | CVI | oxyacetylene ablator | 1.17 | 7.5 × 10−3 | [141] | |

| 2D needled C/C preform | SiC-ZrC | CVI | oxyacetylene torch | 0.29 | 4.2 × 10−4 | [142] | ||

| 2D needle-punched C/C preform | SiC-ZrC | PC | oxyacetylene flame | 1.378 | 1.928 × 10−3 | [143] | ||

| 3D carbon fiber | PyC | SiC-ZrC | CVD | oxyacetylene flame | [13] | |||

| 3D needle-woven carbon fiber felt | SiC-ZrC | CVI | oxyacetylene torch | 7.1 | 4.7 × 10−3 | [144] | ||

| 3D needle- carbon fiber felt | PyC-SiC | SiC-ZrC | CVI; RMI | plasma torch | [145] | |||

| 2.5D needled C/C preform | ZrC/SiC | CVD | oxyacetylene torch | 0.84 | [146] | |||

| 2D needle-punched carbon felts | PyC | ZrC-SiC | CVI | oxyacetylene torch | 0.343 | 4.67 × 10−4 | [147] | |

| C/ZrB2-ZrC-SiC | 3D carbon fiber preform | PyC | ZrB2-ZrC-SiC | CVI; PIP | oxyacetylene; plasma torch | 0.5; 0.13 | 1 × 10−3; 4 × 10−5 | [81] |

| needled C/ZrB2 preform | ZrC-SiC | vacuum impregnation; PIP | plasma generator | 5.09 | 2.61 × 10−3 | [148] | ||

| 2D C/C preform | ZrB2-ZrC-SiC | CVD; PC; SAPS | oxyacetylene torch | 0.23 | 6.5 × 10−5 | [149] | ||

| 2D needle punched carbon fiber fabric | PyC | SiC-ZrB2-ZrC | TCVI; PIP | oxyacetylene torch | [150] | |||

| needle punched carbon fiber felts | PyC | SiC-ZrB2-ZrC | PIP; TCVI | oxyacetylene torch | [151] | |||

| 2D carbon fiber reinforcement felts | PyC | SiC-ZrB2-ZrC | CVI; PIP | oxyacetylene torch | 0.0252 | 4.15 × 10−4 | [152] | |

| carbon felts | PyC | ZrB2-ZrC-SiC | TCVI; PIP | oxyacetylene torch | [153] | |||

| pitch-based carbon fibers | ZrB2-ZrC-SiC | HP | oxyhydrogen torch | [14] | ||||

| plain weave carbon fiber | ZrB2-SiC-ZrC | Silicon melt-infiltration | oxyhydrogen torch | [15] | ||||

| 2.5D needle punched carbon fiber fabric | SiC-ZrB2-ZrC | TCVI; PIP | plasma and compressed air | [25] | ||||

| Carbon fiber cloth | ZrB2-SiC/ZrC | HP | oxyhydrogen torch | 2.8 | [154] | |||

| 2D C/C preform | ZrB2-SiC-ZrC | SAPS; RMI | oxyhydrogen torch | 0.016 | 1.3 × 10−3 | [155] | ||

| C/SiC-ZrSi2 | 3D needled carbon felts | PyC | SiC-ZrSi2 | CVI; RMI | oxyacetylene torch | [156] | ||

| C/Zr2Si | 3D needled carbon fiber felts | PyC | Zr2Si | RMI; CVI; arc melting | economical laser beam | [157] | ||

| C/SiC-Si-Zr | 3D needled carbon fiber felts | PyC | SiC-Si-Zr | RMI; CVI | economical laser beam | 0.0407 | [158] | |

| C/SiC/ZrO2 | carbon fabric | Ph/SiC/ZrO2 | ball milling | oxyacetylene flame | 70.848 | 0.031 | [159] |

| Added UHTC | Composites | Main Structure | Interphase | Matrix (Coating) | Preparing Method | Ablation Method | MR * (mg∙s−1) | LR * (mm∙s−1) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Si-Hf | C/SiC-HfC | 2D needled C/C felts | SiC-HfC | PIP; TCVI | oxyacetylene torch | 2.5 | 1.2 × 10−4 | [169] | |

| 3D needle-punched felt | PyC | SiC-HfC | CVI; RMI | plasma wind tunnel | [170] | ||||

| 2D carbon fabrics | SiC-HfC | SPS; PIP | CO2 laser | 12.6 | [171] | ||||

| C/C-HfC-SiC | SiC and HfC coating | CVR; VPS | ICP plasma wind tunnel | [172] | |||||

| C/C-HfB2-SiC | SiC-coated C/C preform | HfB2-SiC | PC; in situ reaction | oxyacetylene | 0.147 | 2.67 × 10−4 | [173] | ||

| C/C-SiC-HfC | 2.5D C/C preform | SiC-HfC | in situ reaction; CVD | oxyacetylene | 2.05 | 1.93 × 10−3 | [174] | ||

| C/SiC-HfC | 3D needle-punched preforms | PyC | SiC-HfC | CVI; RMI; PIP | oxyacetylene torch | 1.5 | 4 × 10−3 | [175] | |

| C/C-HfB2-SiC | 2.5D needled carbon fiber felts | PyC | HfB2-SiC | CVI; PIP; HSLSI | oxyacetylene flame | 0.5 | 4.15 × 10−4 | [176] | |

| C/C-SiC-HfB2-Si | 2.5D C/C preform | SiC-HfB2-Si | SP; GSI | oxyacetylene flame | 0.07 | 7.2 × 10−4 | [177] | ||

| C/C-SiC-HfC | C/C preform | (SiC-HfC)4/SiC | LPCVD; | oxyacetylene torch | 0.64 | 5.3 × 10−4 | [178] | ||

| C/SiHfBCN | 2D carbon fabric | SiHfBCN | PIP | CO2 laser beam | [179] | ||||

| SiCf/HfC-SiC | 2.5D SiC preform | PyC | HfC-SiC | CVI; PIP | oxyacetylene torch | 1.32 | 7.37 × 10−3 | [180] | |

| Si-Ta | C/TaB2-SiC | 2D-C/C preform | TaB2-SiC | PC; TCVI | oxyacetylene torch | 4.2 × 10−3 | [181] | ||

| C/TaSi2 | 3D carbon fiber preform | TaSi2 | pressure filtration | plasmatron | [182] | ||||

| C/SiCnw-TaSi2 | carbon fiber preform | SiCnw-TaSi2 | rapid sintering | oxyacetylene torch | [12] | ||||

| C/C-SiC-TaSi2 | 2D SiC-coated C/C preform | SiC-TaSi2 | SAPS; PC | oxyacetylene torch | 0.4 | 9 × 10−4 | [183] | ||

| C/C-SiC-TaC | needle-integrated C/C felts | PyC | C-SiC-TaC | CVI | oxyacetylene flame | [184] | |||

| Si-Zr-La | C/C/-ZrC-SiC-LaB6 | 2D C/C preform | ZrC-SiC-LaB6 | SPS; SAPS | oxyacetylene torch | [185] | |||

| C/C-SiC-ZrC-La | 2D C/C preform | SiC-ZrC-La | PC; SAPS | oxyacetylene torch | [186] | ||||

| C/C-SiC-ZrB2-LaB6 | 3D C/C preform | PyC | SiC-ZrB2-LaB6 | PIP; CVI; | plasma generator | 0.38 | 3.7 × 10−4 | [187] | |

| C/C-SiC-ZrB2-La2O3 | 2D C/C preform | SiC-ZrB2-La2O3 | PC; SAPS | oxyacetylene flame | 0.558 | 1.67 × 10−5 | [188] | ||

| C/C-ZrB2-SiC-La2O3 | 2D carbon fiber plain cloth | PyC | ZrB2-SiC-La2O3 | CVI; SI; PIP | air plasma flame | [28] | |||

| C/C-SiC-ZrC-La2O3 | 2D C/C preform | SiC-ZrC-La2O3 | SAPS | oxyacetylene torch | [189] | ||||

| Si-Zr-Hf | C/C-SiC-HfC-ZrC | 2D C/C preform | SiC-HfC-ZrC | TCVI; PIP | oxyacetylene torch | [190] | |||

| C/HfC-ZrC-SiC | 2.5D needled C/C preform | HfC-ZrC-SiC | RMI | oxyacetylene torch | 1.5 | 1.1 × 10−3 | [191] | ||

| C/C-HfC-ZrC-SiC | 3D C/C preform | HfC-ZrC-SiC | CVI; PC; SAPS | oxyacetylene torch | 0.017 | [192] | |||

| C/ZrC-SiC-HfB2 | short carbon fiber | ZrC-SiC-HfB2 | pressureless sintering | oxyacetylene flame | 2.46 | 3.51 × 10−3 | [193] | ||

| Si-Zr-Mo | C/C-ZrB2-MoSi2 | C/C preform | ZrB2-MoSi2 | plasma spraying | oxypropylene flame | 1.91 | 4.8 × 10−4 | [194] | |

| C/C-SiC-ZrB2/MoSi2 | 2.5D SiC-coated C/C preform | SiC-ZrB2/MoSi2 | SAPS; | oxyacetylene torch | 0.44 | 1.67 × 10−3 | [195] | ||

| C/C-Mo-ZrB2-MoSi2-SiC | 2D C/SiC preform | PyC | SiC-ZrB2-MoSi2-SiC/Mo | HVOF; CVI; SAPS | CO2 laser beam | [196] | |||

| C/SiOC-MoSi2-SiO2-SiC/ZrB2-MoSi2-SiC | carbon fiber needled felt | MoSi2-SiO2-SiC/ZrB2-MoSi2-SiC | PIP; slurry and precursor infiltration | oxyacetylene torch | [197] | ||||

| Si-Ta-Hf | C/HfC-TaC/HfC-SiC | 2D needled C/C preform | HfC-TaC/HfC-SiC | SAPS | oxyacetylene torch | [198] | |||

| C/C-Hf-Ta-Si | 2.5D C/C preform | Hf-Ta-Si-C | CVD; | oxyacetylene torch | 0.03 | 1.17 × 10−4 | [199] | ||

| C/C-SiC-HfC-TaC | 2D SiC-coated C/C preform | HfC-TaC | PC; SAPS | oxyacetylene torch | 0.35 | 1.05 × 10−3 | [200] | ||

| Si-Zr-Ti | C/C-ZrC-TiC-SiC | 2.5D needled C/C preform | PyC | ZrC-TiC-SiC | reactive infiltration | oxyacetylene torch | 2.6 | 8.2 × 10−4 | [201] |

| C/C-SiC-ZrC-TiC | needled C/C fabrics | PyC | SiC-ZrC-TiC | RMI; CVI | oxyacetylene torch | 0.008 | [202] | ||

| C/C-ZrC-SiC/TiC | 2.5D needled C/C preform | ZrC-SiC/TiC | SAPS; SSP; CVI; | oxyacetylene flames | 1 × 10−3 | [203] | |||

| Si-Ti | C/SiC-Ti3SiC2 | carbon cloths | PyC | SiC-Ti3SiC2 | LSI; CVI; SI | oxyacetylene torch | 6.3 | 0.024 | [204] |

| C/C-SiC-Ti3SiC2 | C/TiC preform | SiC-Ti3SiC2 | LSI | oxyacetylene flame | 11.8 | 0.06 | [205] | ||

| Si-Y | C/C-SiC-Y2SiO5 | 2D needle carbon fabric | SiC-Y2SiO5 | TCVI; PC; SPS | oxyacetylene torch | 0.031 | 2.6 × 10−3 | [206] | |

| C/C-Y2SiO5-SiC | 2D C/C preform | Y2SiO5-SiC | PC; SPS | oxyacetylene torch | 0.035 | 3.43 × 10−3 | [207] | ||

| Si-Zr-Cr | C/C-ZrB2-CrSi2-SiC-Si | 2D C/C preform | ZrB2-CrSi2-SiC-Si/SiC | PC | corundum tube furnace | [208] | |||

| C/C-SiC-Cr-ZrC | 2D C/C preform | SiC-Cr-ZrC | TCVI; SAPS | oxyacetylene flame | [209] | ||||

| Si-Hf-Ti | C/C-HfC-TiC-SiC | C/C | HfC, TiC and SiC coating | VPS; CVR | ICP plasma wind tunnel | [172] | |||

| Si-Ti-Ta | C/C-SiC-TiC-TaC | 2/2 C/C twill carbon cloth | SiC-TiC-TaC | MI; SPS; | oxyacetylene flame | 3.9 | 0.0022 | [210] | |

| Zr-Hf | C/C-HfC-ZrC | C/C preform | HfC-ZrC | CVD; | oxyacetylene torch | [211] | |||

| Hf-Ta-Zr | C/HfC-TaC(HfC-ZrC) | C/C preform | HfC-TaC/HfC-ZrC | CVD; | oxyacetylene torch | 0.63 | 2.1 × 10−4 | [212] | |

| SiZrHfTiCr | C/C-(HfZrTiCr)B2-SiC-Si | C/C preform | (Hf1/4Zr1/4Ti1/4Cr1/4)B2-SiC-Si | SP; GRSI | oxyacetylene ablator | 0.37 | 1.5 × 10−4 | [29] | |

| SiZrAlCr | C/C-ZrC-SiC-Al2O3-Cr | C/C-ZrC-SiC preform | Al2O3-SiC-ZrC-Cr | RMI; SI; plasma spray | oxyacetylene torch | 0.52 | 4.7 × 10−4 | [213] | |

| Si-Zr-V | C/C-ZrC-SiC-V0.9-Si0.1 | 3D needled carbon preform | ZrC-SiC-V0.9-Si0.1 | RMI; | oxyacetylene torch | 0.25 | 4.3 × 10−4 | [214] | |

| Si-Mo/Ti | C/C-(Mo,Ti)Si2-SiC | porous C/C preform | (Mo,Ti)Si2-SiC | RMI | oxyacetylene torch | 0.01 | 2 × 10−3 | [215] | |

| Si-Mo | C/C-SiC-MoSi2 | porous C/C preform | SiC-MoSi2 | VFI | oxyacetylene torch | 1.34 | 3.5 × 10−3 | [216] | |

| SiZrMoTa | C/SiCO-TaSi2-MoSi2-ZrO2 | carbon felts | TaSi2-MoSi2-ZrO2 | sol-gel; pyrolysis | oxyacetylene flame | 0.4 | 8.33 × 10−4 | [217] | |

| SiZrCrY | C/C-ZrSi2-CrSi2-Y2O3/SiC | 2D SiC-coated C/C preform | ZrSi2-CrSi2-Y2O3/SiC | SAPS; | oxyacetylene torch | 0.16 | 1 × 10−3 | [218] | |

| SiZrCrAl | C/C-ZrC-SiC-Al-Cr | 2.5D needled C/C preform | ZrC-SiC-Al-Cr | CVD; RMI | oxyacetylene torch | 0.02 | 2.5 × 10−4 | [219] | |

| Si-Zr-La/Y | C/SiC-ZrC-La2O3; C/SiC-ZrC-Y2O3 | 3D needled felt | SiC-ZrC-La2O3; SiC-ZrC-Y2O3 | CVI; RMI; PIP | oxyacetylene torch | 1.19; 4.52 | 9.93 × 10−3; 0.0178 | [220] | |

| Si-Mo-(Ti/Al) | C/C-MoSi2-SiC-(Ti/Al) | needle-punched C/C preform | PyC | MoSi2-SiC-(Ti/Al) | CVI | oxyacetylene torch | 0.01 | 2 × 10−3 | [221] |

| Si-Mo-Hf-W | C/ZrB2-SiC-MoSi2; C/ZrB2-SiC-HfSi2; C/ZrB2-SiC-WSi2; | short carbon fiber | ZrB2-SiC-MoSi2; ZrB2-SiC-HfSi2; ZrB2-SiC-WSi2; | ball-milling; hot-pressing | oxyacetylene torch | [222] | |||

| Si-Zr-Y | C/C-ZrB2-SiC-Y2O3/SiC | C/C preform | ZrB2-SiC-Y2O3/SiC | PC; APS | muffle furnace | [27] | |||

| Si-Zr-Sm | C/C-ZrB2/SiC-Sm2O3 | C/C preform | ZrB2/SiC-Sm2O3 | APS; IPS | plasma torch | 0.319 | [223] | ||

| Si-Cu | C/C-SiCW-Cu | carbon fiber bundle | SiCW-Cu | CVD; CVI; | oxyacetylene torch | 4.56 | 8 × 10−3 | [224] | |

| Si-Nd | C/C-Si-SiC-SiO2-Nd2O3 | SiC coated C/C preform | Si-SiC-SiO2-Nd2O3 | CVI; laser cladding | laser-ablation | [225] | |||

| Si-Al | C/C-Al20Si/graphite | 3D needled C/C preform | Al20Si/graphite | GCVI; | combustion chamber | [226] | |||

| Si-Zr-Ta | C/SiC-ZrB2-TaxCy | carbon fiber cloth mat | SiC-ZrB2-TaxCy | RHP; PIP | oxyacetylene torch | 1.33 | 1.9 × 10−4 | [227] | |

| Si-Zr-Nb | C/SiC-NbC-ZrC | 2D C/C preform | SiC-NbC-ZrC | SAPS | oxyacetylene torch | 0.48 | 1.3 × 10−4 | [228] | |

| Si-La | C/C-SiC-La2O3 | 2.5D carbon fiber felts | PyC | SiC-La2O3 | PIP; CVI; | plasma generator | 0.722 | 0.0333 | [229] |

| SiTiZrHfNbTa | C/(TiZrHfNbTa)C-SiC | 3D-needled carbon fiber | PyC/SiC | (TiZrHfNbTa)C-SiC | PIP; CVI; | air plasma torch | 2.60 | 2.89 × 10−3 | [230] |

| Si-Zr-V | C/C-ZrC-SiC-V | C/C preform | ZrC-SiC-V | RIM | oxyacetylene torch | 2 | 7 × 10−4 | [231] | |

| Si-Zr-Cu | C/C-SiC-ZrC-Cu | needled carbon fiber felts | PyC | SiC-ZrC-Cu | CVI; PIP; VPI | oxyacetylene flame | 3.4 | 3.5 × 10−3 | [232] |