Optimisation of Additives to Maximise Performance of Expandable Graphite-Based Intumescent-Flame-Retardant Polyurethane Composites

Abstract

1. Introduction

2. Results and Discussion

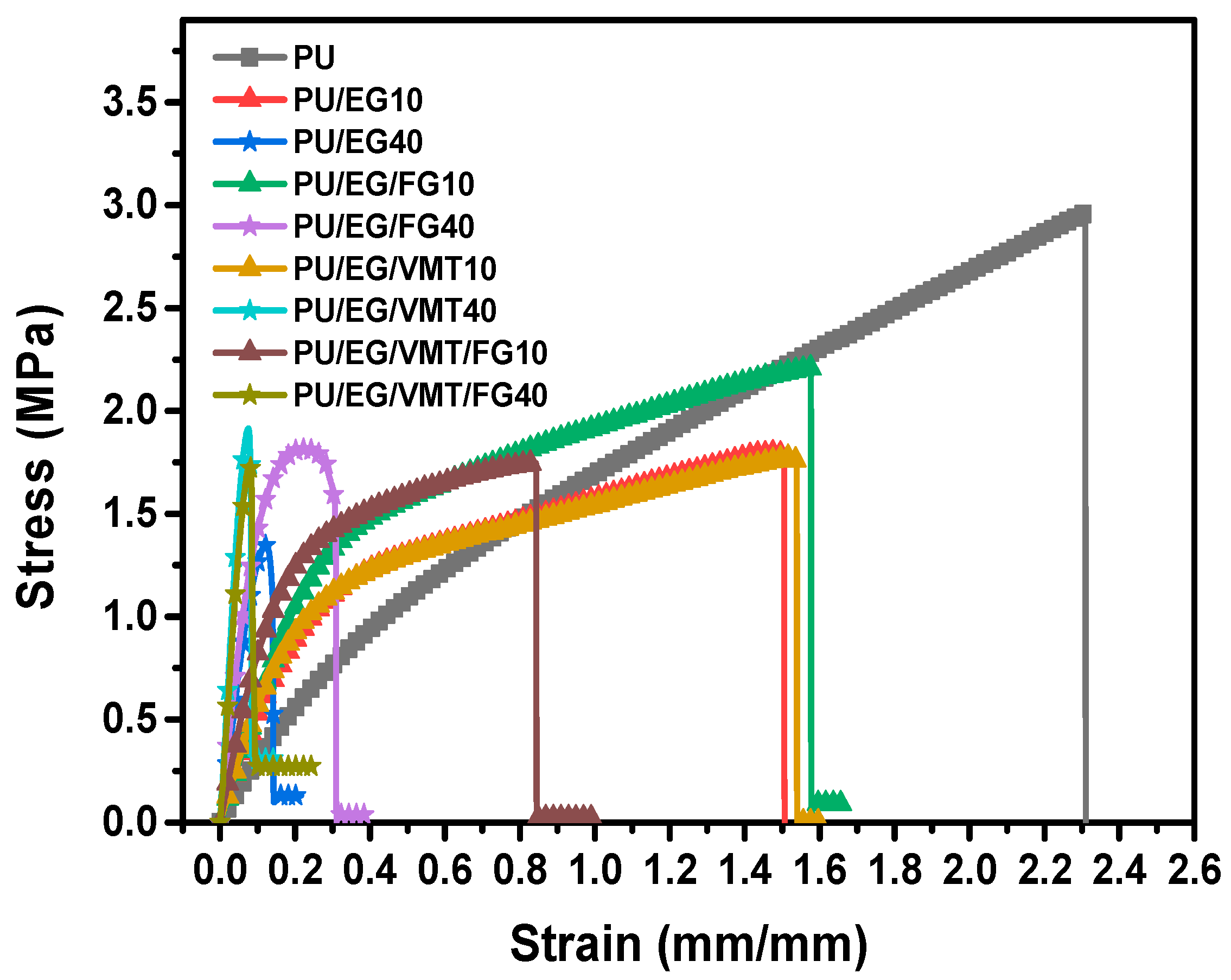

2.1. Mechanical Properties: Tensile

2.2. SEM

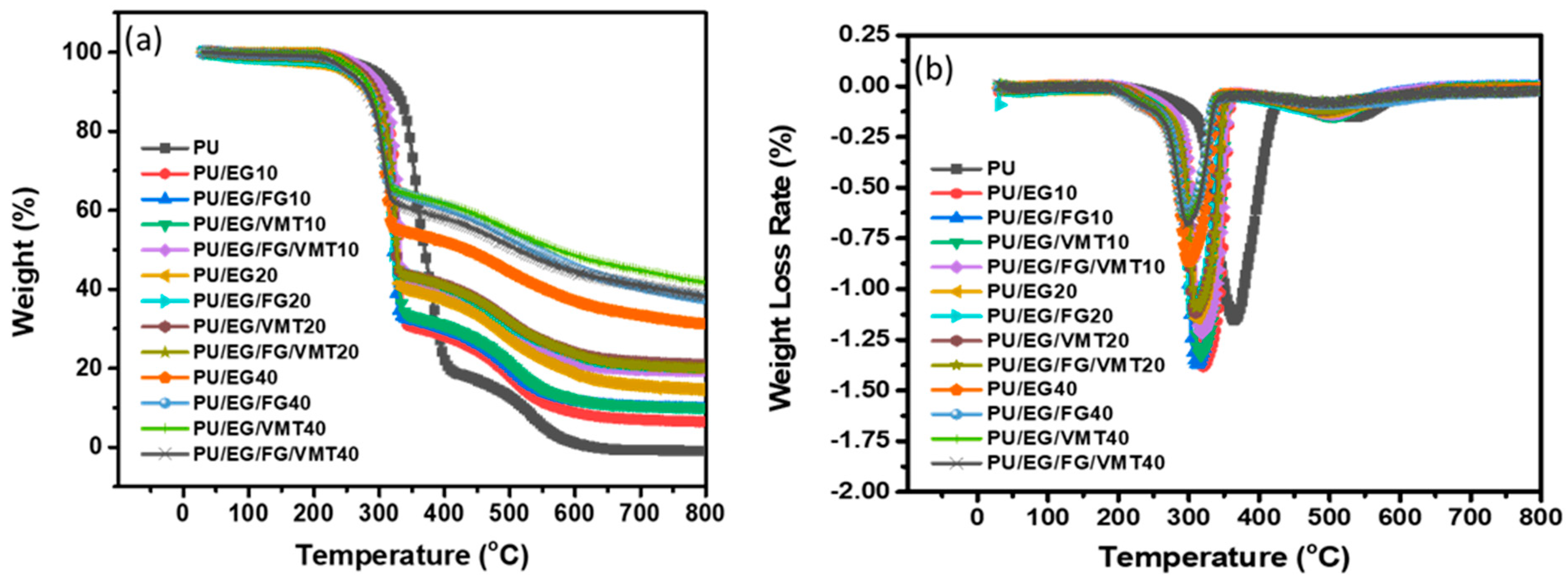

2.3. Thermal Properties: TGA/DTG

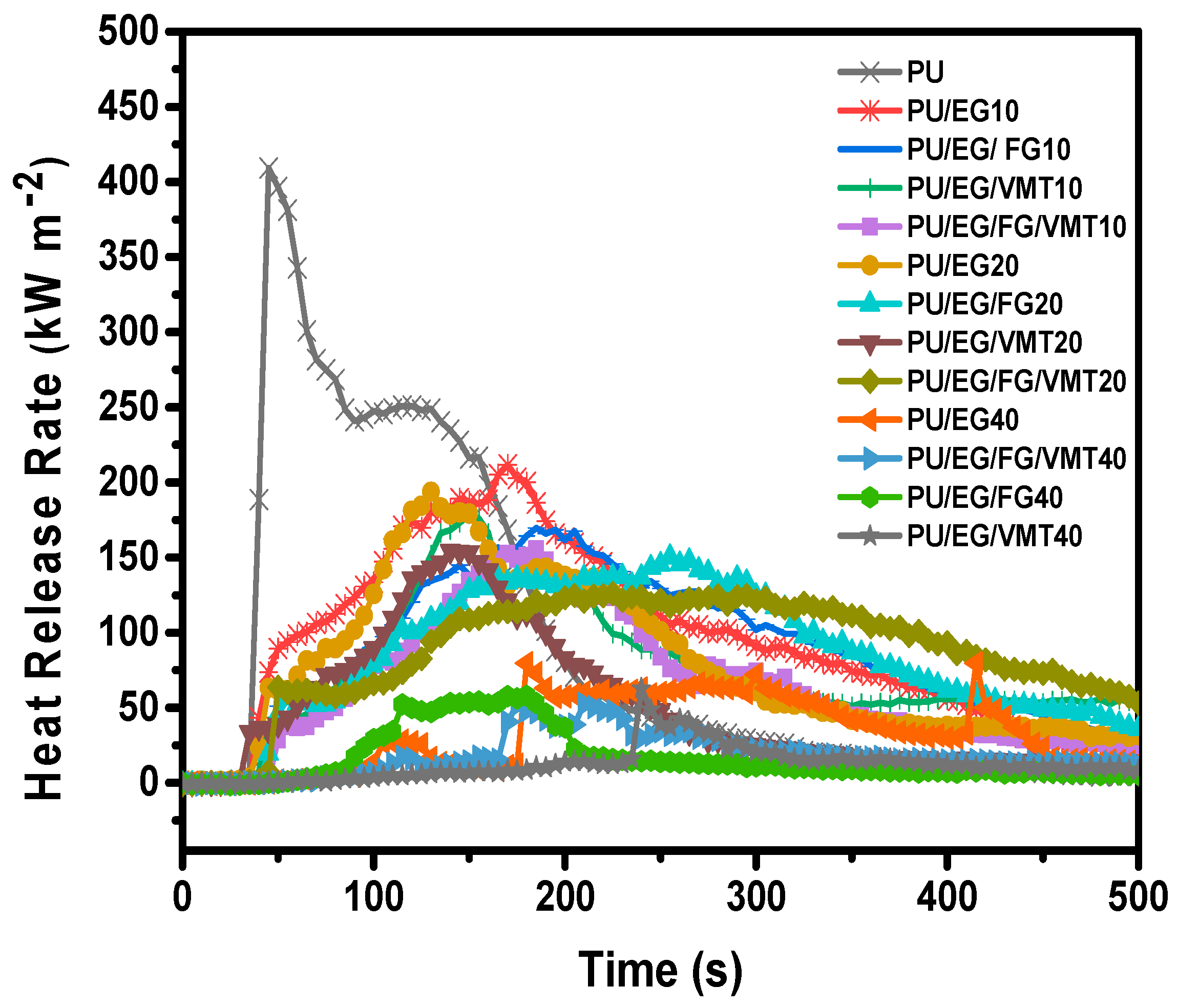

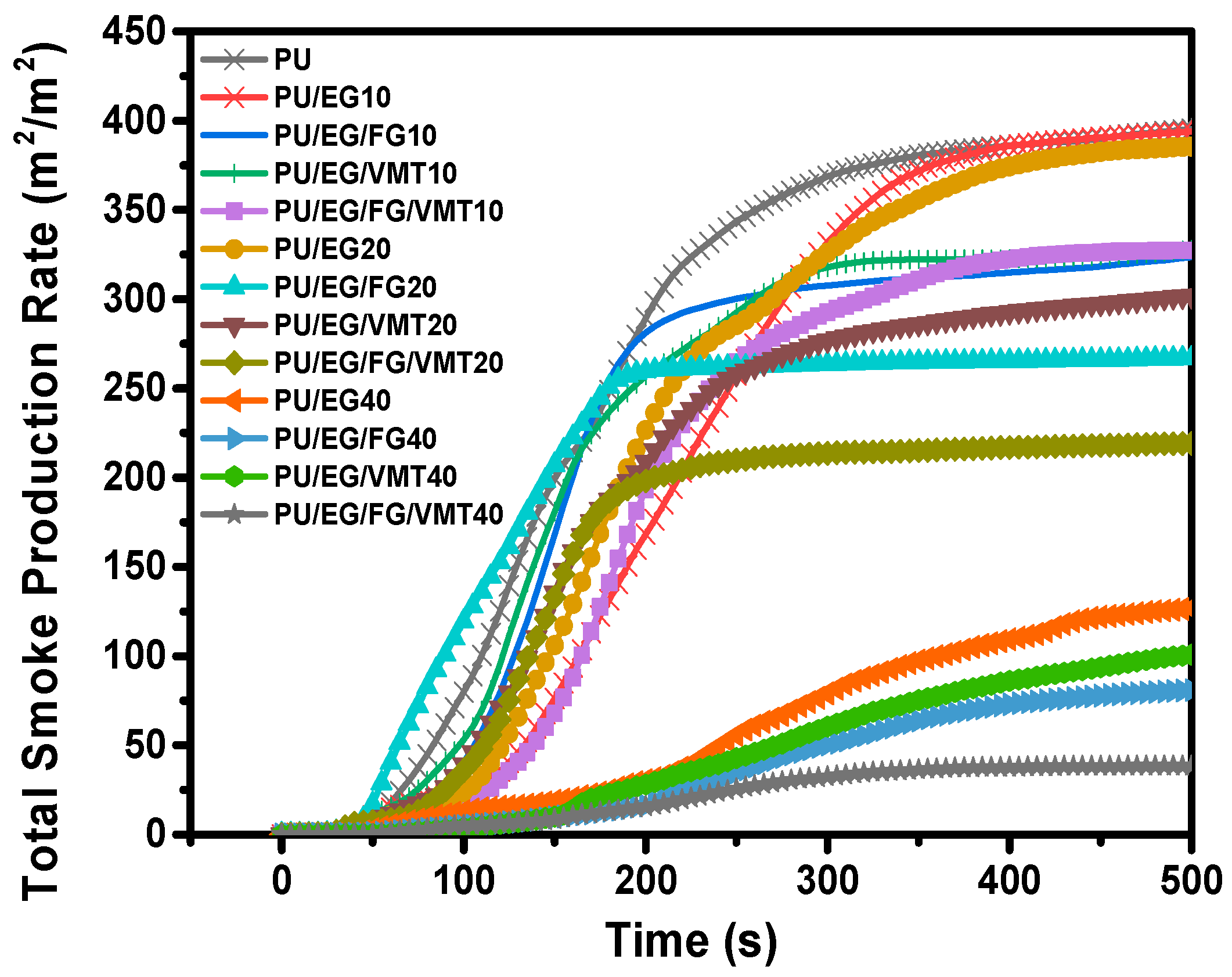

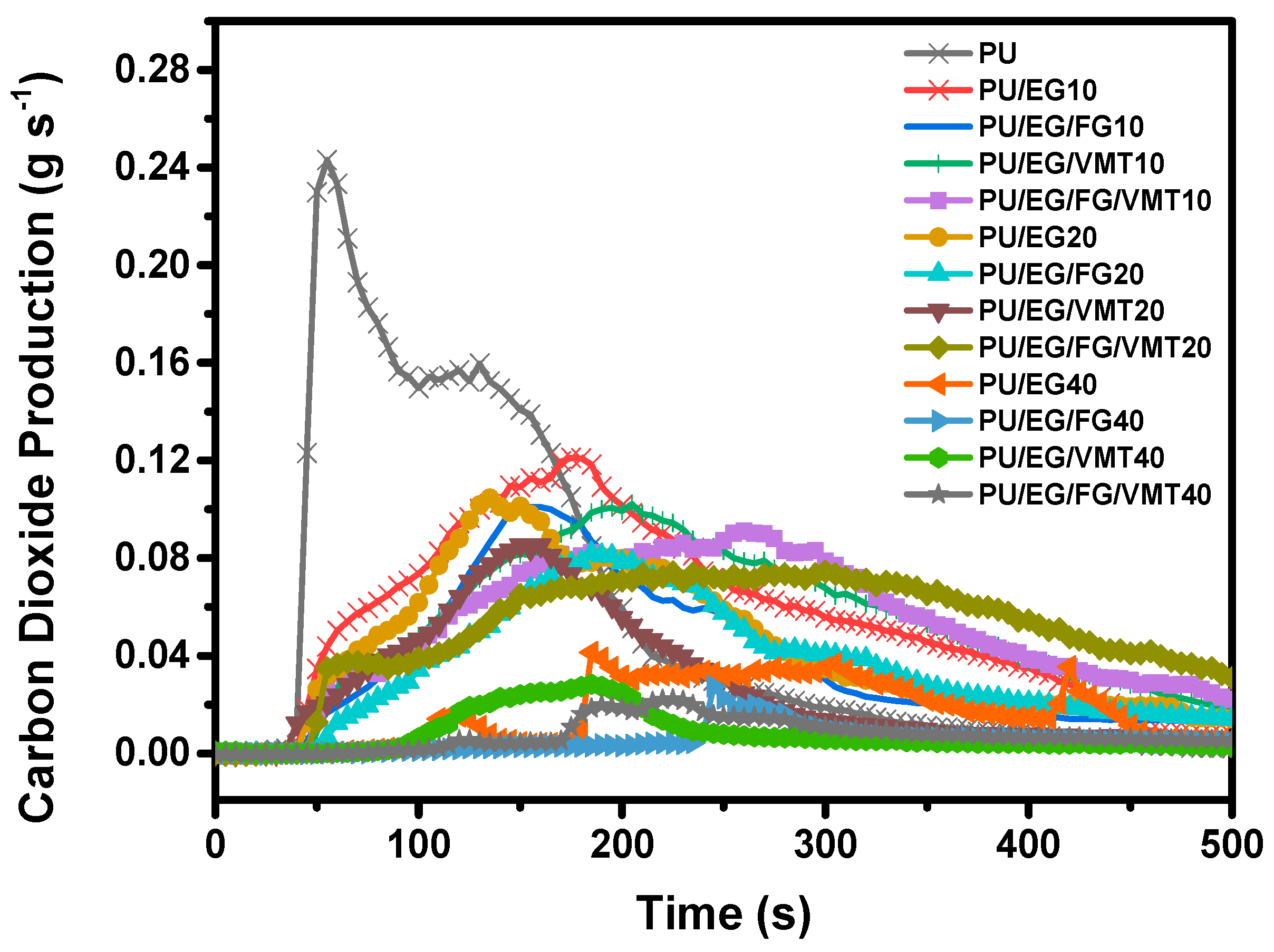

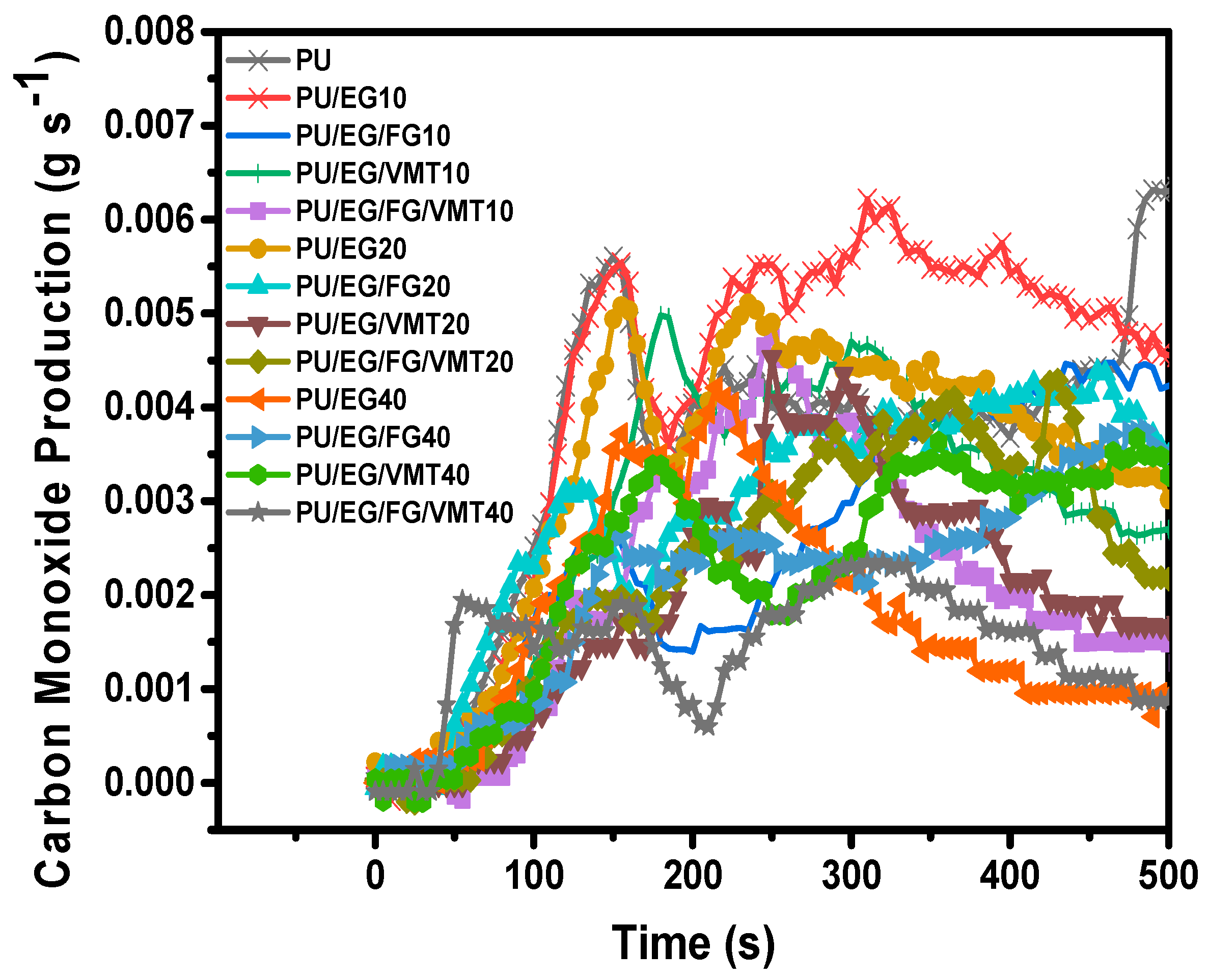

2.4. Flammability Properties: Cone Calorimeter

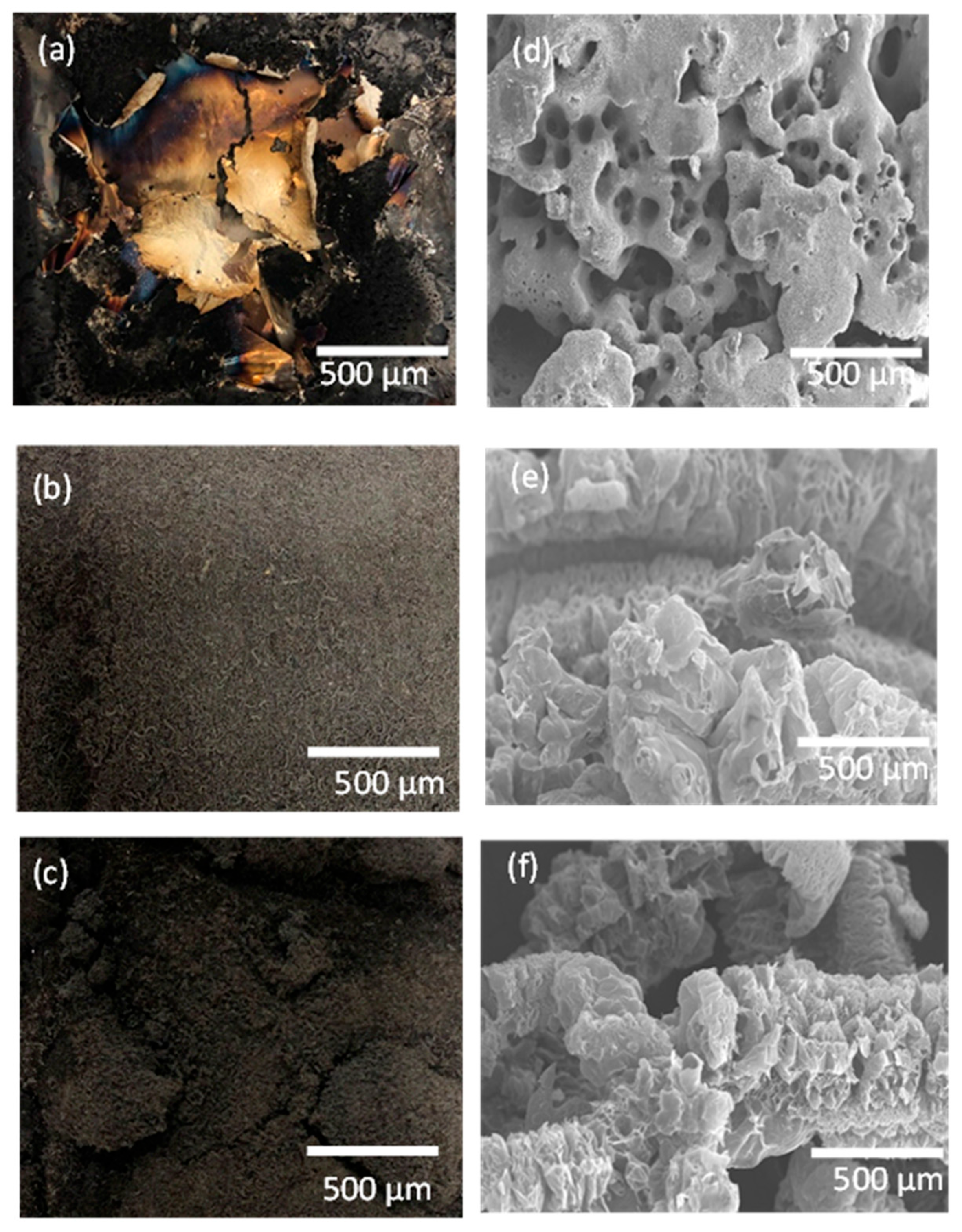

2.5. Char Residue

3. Experimental Section

3.1. Materials

3.2. Sample Characterisation

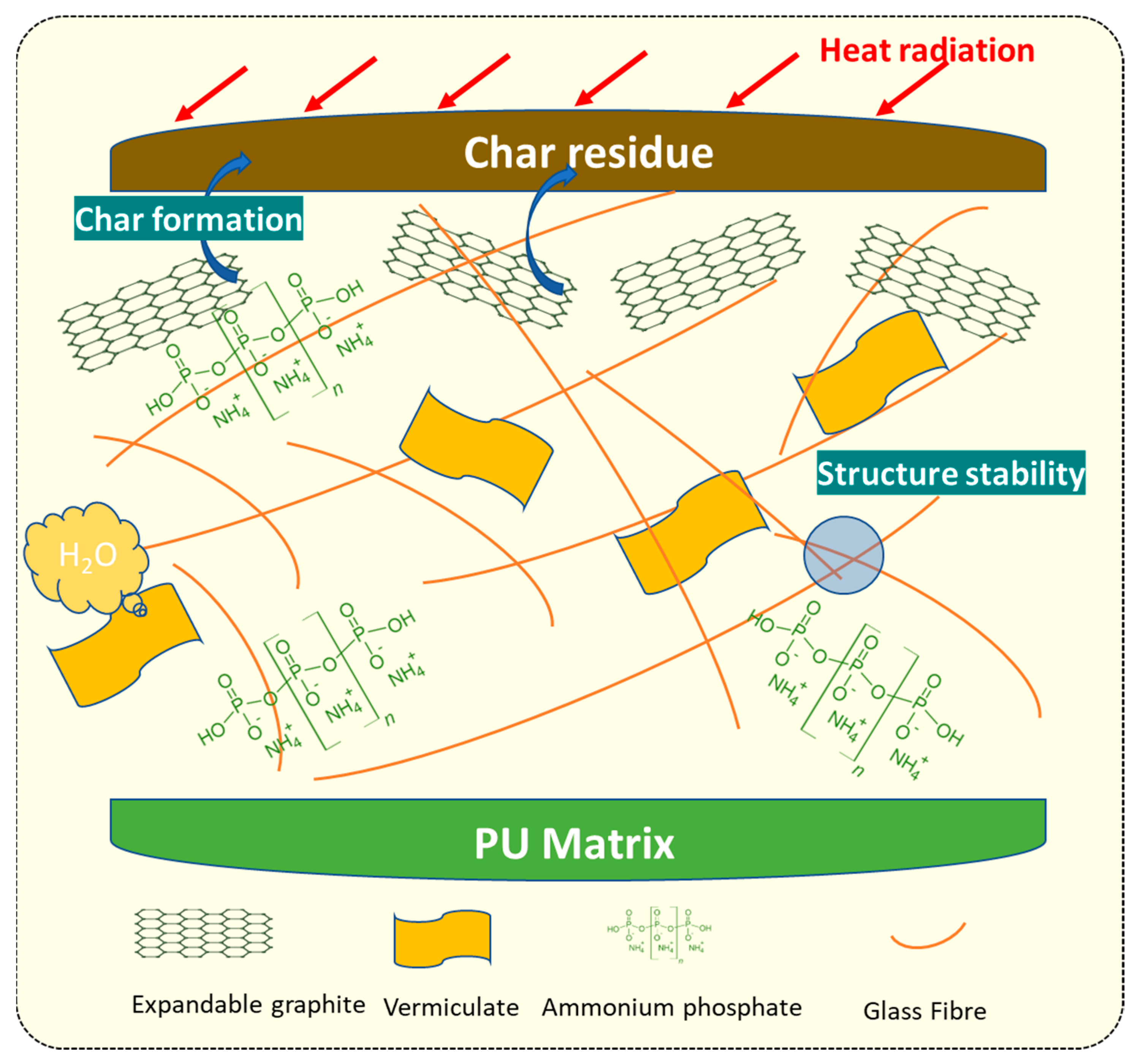

3.3. Combustion Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Visakh, M.; Semkin, A.O.; Rezaev, I.A.; Fateev, A.V. Review on soft polyurethane flame retardant. Constr. Build. Mater. 2019, 227, 116673. [Google Scholar] [CrossRef]

- Song, L.; Hu, Y.; Tang, Y.; Zhang, R.; Chen, Z.; Fan, W. Study on the properties of flame retardant polyurethane/organoclay nanocomposite. Polym. Degrad. Stab. 2005, 87, 111–116. [Google Scholar] [CrossRef]

- Xu, W.; Li, A.; Liu, Y.; Chen, R.; Li, W. CuMoO4@hexagonal boron nitride hybrid: An ecofriendly flame retardant for polyurethane elastomer. J. Mater. Sci. 2018, 53, 11265–11279. [Google Scholar] [CrossRef]

- Thirumal, M.; Khastgir, D.; Singha, N.K.; Manjunath, B.S.; Naik, Y.P. Effect of expandable graphite on the properties of intumescent flame-retardant polyurethane foam. J. Appl. Polym. Sci. 2008, 110, 2586–2594. [Google Scholar] [CrossRef]

- Wang, Z.; Han, E.; Ke, W. Influence of expandable graphite on fire resistance and water resistance of flame-retardant coatings. Corros. Sci. 2007, 49, 2237–2253. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Beg, M.; Ghazali, S.; Islam, M.R.; Jeyaratnam, N.; Yuvaraj, A.R. Polyurethane types, synthesis and applications—A review. RSC Adv. 2016, 6, 114453–114482. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Yakovlev, A.V.; Lopukhova, M.I. Directional control of physico-chemical and mechanical properties of epoxide composites by the addition of graphite-graphene structures. Polym.-Plast. Technol. Mater. 2020, 59, 874–883. [Google Scholar] [CrossRef]

- Bao, X.; Wu, F.; Wang, J. Thermal degradation behavior of epoxy resin containing modified carbon nanotubes. Polymers 2021, 13, 3332. [Google Scholar] [CrossRef]

- Bekeshev, A.; Mostovoy, A.; Shcherbakov, A.; Zhumabekova, A.; Serikbayeva, G.; Vikulova, M.; Svitkina, V. Effect of phosphorus and chlorine containing plasticizers on the physicochemical and mechanical properties of epoxy composites. J. Compos. Sci. 2023, 7, 178. [Google Scholar] [CrossRef]

- Zhou, S.; Tao, R.; Dai, P.; Luo, Z.; He, M. Two-step fabrication of lignin-based flame retardant for enhancing the thermal and fire retardancy properties of epoxy resin composites. Polymer Compos. 2020, 41, 2025–2035. [Google Scholar] [CrossRef]

- Guo, C.; Zhou, L.; Lv, J. Effects of expandable graphite and modified ammonium polyphosphate on the flame-retardant and mechanical properties of wood flour-polypropylene composites. Polym. Polym. Compos. 2013, 21, 449–456. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, J.; Xiaojing, M. Effect of expandable graphite on polyester resin-based intumescent flame retardant coating. Prog. Org. Coat. 2019, 132, 178–183. [Google Scholar] [CrossRef]

- Meng, X.Y.; Ye, L.; Zhang, X.G.; Tang, M.; Tang, J.H.; Ji, X.; Li, Z.M. Effects of expandable graphite and ammonium polyphosphate on the flame-retardant and mechanical properties of rigid polyurethane foams. J. Appl. Polym. Sci. 2009, 114, 853–863. [Google Scholar] [CrossRef]

- Muhammed Raji, A.; Hambali, H.U.; Khan, Z.I.; Binti Mohamad, Z.; Azman, H.; Ogabi, R. Emerging trends in flame retardancy of rigid polyurethane foam and its composites: A review. J. Cell. Plast. 2022, 59, 0021955X221144564. [Google Scholar] [CrossRef]

- Liu, L.; Wang, Z.; Zhu, M. Flame retardant, mechanical and thermal insulating properties of rigid polyurethane foam modified by nano zirconium amino-tris-(methylenephosphonate) and expandable graphite. Polym. Degrad. Stab. 2019, 170, 108997. [Google Scholar] [CrossRef]

- Liu, Y.; He, J.; Yang, R. Effects of dimethyl methylphosphonate, aluminum hydroxide, ammonium polyphosphate, and expandable graphite on the flame retardancy and thermal properties of polyisocyanurate–polyurethane foams. Ind. Eng. Chem. Res. 2015, 54, 5876–5884. [Google Scholar] [CrossRef]

- Xu, B.; Shao, L.; Wang, J.; Liu, Y.; Qian, L. Enhancement of the intumescent flame retardant efficiency in polypropylene by synergistic charring effect of a hypophosphite/cyclotetrasiloxane bi-group compound. Polym. Degrad. Stab. 2020, 181, 109281. [Google Scholar] [CrossRef]

- Mariappan, T. Recent developments of intumescent fire protection coatings for structural steel: A review. J. Fire Sci. 2016, 34, 120–163. [Google Scholar] [CrossRef]

- Liu, Y.; Deng, C.L.; Zhao, J.; Wang, J.S.; Chen, L.; Wang, Y.Z. An efficiently halogen-free flame-retardant long-glass-fiber-reinforced polypropylene system. Polym. Degrad. Stab. 2011, 96, 363–370. [Google Scholar] [CrossRef]

- Zhao, C.S.; Huang, F.L.; Xiong, W.C.; Wang, Y.Z. A novel halogen-free flame retardant for glass-fiber-reinforced poly (ethylene terephthalate). Polym. Degrad. Stab. 2008, 93, 1188–1193. [Google Scholar] [CrossRef]

- Gunes, O.C.; Gomek, R.; Tamar, A.; Kandemir, O.K.; Karaorman, A.; Albayrak, A.Z. Comparative study on flame retardancy, thermal, and mechanical properties of glass fiber reinforced polyester composites with ammonium polyphosphate, expandable graphite, and aluminum tri-hydroxide. Arab. J. Sci. Eng. 2018, 43, 6211–6218. [Google Scholar] [CrossRef]

- Cheong, J.Y.; Ahn, J.; Seo, M.; Nam, Y.S. Flame-retardant, flexible vermiculite–polymer hybrid film. RSC Adv. 2015, 5, 61768–61774. [Google Scholar] [CrossRef]

- Wang, J.; Wang, F.; Gao, Z.; Zheng, M.; Sun, J. Flame retardant medium-density fiberboard with expanded vermiculite. BioResources 2016, 11, 6940–6947. [Google Scholar] [CrossRef]

- Ning, H.; Ma, Z.; Zhang, Z.; Zhang, D.; Wang, Y. Core–shell expandable graphite@ layered double hydroxide as a flame retardant for polyvinyl alcohol. J. Therm. Anal. Calorim. 2012, 147, 6249–6258. [Google Scholar] [CrossRef]

- Zhao, H.; Lin, R. Preparation of boric acid modified expandable graphite and its influence on polyethylene combustion characteristics. J. Chil. Chem. Soc. 2016, 61, 2767–2771. [Google Scholar] [CrossRef]

- Yun, G.W.; Lee, J.H.; Kim, S.H. Flame retardant and mechanical properties of expandable graphite/polyurethane foam composites containing iron phosphonate dopamine-coated cellulose. Polym. Compos. 2020, 41, 2816–2828. [Google Scholar] [CrossRef]

- Pang, X.Y.; Xin, Y.; Shi, X.Z.; Xu, J.Z. Effect of different size-modified expandable graphite and ammonium polyphosphate on the flame retardancy, thermal stability, physical, and mechanical properties of rigid polyurethane foam. Polym. Eng. Sci. 2019, 59, 1381–1394. [Google Scholar] [CrossRef]

- Kabir, I.I.; Fu, Y.; de Souza, N.; Nazir, M.T.; Baena, J.C.; Yuen, A.C.Y.; Yeoh, G.H. Improved flame-retardant properties of polydimethylsiloxane/multi-walled carbon nanotube nanocomposites. J. Mater. Sci. 2021, 56, 2192–2211. [Google Scholar] [CrossRef]

- Feng, C.; Liang, M.; Chen, W.; Huang, J.; Liu, H. Flame retardancy and thermal degradation of intumescent flame retardant EVA composite with efficient charring agent. J. Anal. Appl. Pyrolysis 2015, 113, 266–273. [Google Scholar] [CrossRef]

- Shi, X.; Jiang, S.; Zhu, J.; Li, G.; Peng, X. Establishment of a highly efficient flame-retardant system for rigid polyurethane foams based on bi-phase flame-retardant actions. RSC Adv. 2018, 8, 9985–9995. [Google Scholar] [CrossRef]

- Chan, Y.Y.; Ma, C.; Zhou, F.; Hu, Y.; Schartel, B. A liquid phosphorous flame retardant combined with expandable graphite or melamine in flexible polyurethane foam. Polym. Adv. Technol. 2022, 33, 326–339. [Google Scholar] [CrossRef]

| Sample | Average Elongation (mm) | Young’s Modulus (MPa) | Ultimate Tensile Strength (MPa) |

|---|---|---|---|

| Pure PU | 78.96 ± 0.35 | 2.86 ± 0.25 | 2.96 ± 0.27 |

| PU/EG10 | 52.14 ± 0.27 | 5.33 ± 0.02 | 1.80 ± 0.17 |

| PU/EG40 | 7.14 ± 0.15 | 15.05 ± 0.03 | 1.35 ± 0.18 |

| PU/EG/FG10 | 54.65 ± 0.22 | 5.69 ± 0.02 | 2.21 ± 0.15 |

| PU/EG/FG40 | 12.79 ± 0.12 | 17.57 ± 0.06 | 1.81 ± 0.12 |

| PU/EG/VMT10 | 53.04 ± 0.15 | 5.63 ± 0.05 | 1.77 ± 0.09 |

| PU/EG/VMT40 | 5.11 ± 0.06 | 34.78 ± 0.12 | 1.91 ± 0.04 |

| PU/VMT/FG/EG10 | 32.73 ± 0.21 | 9.25 ± 0.03 | 1.75 ± 0.07 |

| PU/VMT/FG/EG40 | 8.23 ± 0.02 | 29.17 ± 0.04 | 1.73 ± 0.02 |

| Polyurethane Elastomer (PU-WC565) | Part (A/B), Shore-A Hardness: 65 A | Barnes Pty. AU |

|---|---|---|

| Ammonium polyphosphate (APP) | AP 422 (phase II)- Powder (≤100 µm) | Clariant |

| Expandable Graphite (EG) | Carbonfoil-FF 80-Flakes (≤250 µm) | Metachem Manuf Co. |

| VMT | Powder (≤100 µm) | Allnex Compos (AU) |

| FG | Flakes (≤450 µm) | Allnex Compos (AU) |

| Sample Code | PU (Mass%) | EG (Mass%) | FG (Mass%) | VMT (Mass%) |

|---|---|---|---|---|

| Pure PU | 100 | -- | -- | -- |

| PU/EG10 * | 70 | 10 | -- | -- |

| PU/EG/FG10 * | 65 | 10 | 5 | -- |

| PU/EG/VMT10 * | 65 | 10 | -- | 5 |

| PU/EG/FG/VMT10 * | 60 | 10 | 5 | 5 |

| PU/EG20 * | 60 | 20 | -- | -- |

| PU/EG/FG20 * | 55 | 20 | 5 | -- |

| PU/EG/VMT20 * | 55 | 20 | -- | 5 |

| PU/EG/FG/VMT20 * | 50 | 20 | 5 | 5 |

| PU/EG40 * | 40 | 40 | -- | -- |

| PU/EG/FG40 * | 35 | 40 | 5 | |

| PU/EG/VMT40 * | 35 | 40 | -- | 5 |

| PU/EG/FG/VMT40 * | 30 | 40 | 5 | 5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kabir, I.I.; Carlos Baena, J.; Wang, W.; Wang, C.; Oliver, S.; Nazir, M.T.; Khalid, A.; Fu, Y.; Yuen, A.C.Y.; Yeoh, G.H. Optimisation of Additives to Maximise Performance of Expandable Graphite-Based Intumescent-Flame-Retardant Polyurethane Composites. Molecules 2023, 28, 5100. https://doi.org/10.3390/molecules28135100

Kabir II, Carlos Baena J, Wang W, Wang C, Oliver S, Nazir MT, Khalid A, Fu Y, Yuen ACY, Yeoh GH. Optimisation of Additives to Maximise Performance of Expandable Graphite-Based Intumescent-Flame-Retardant Polyurethane Composites. Molecules. 2023; 28(13):5100. https://doi.org/10.3390/molecules28135100

Chicago/Turabian StyleKabir, Imrana I., Juan Carlos Baena, Wei Wang, Cheng Wang, Susan Oliver, Muhammad Tariq Nazir, Arslan Khalid, Yifeng Fu, Anthony Chun Yin Yuen, and Guan Heng Yeoh. 2023. "Optimisation of Additives to Maximise Performance of Expandable Graphite-Based Intumescent-Flame-Retardant Polyurethane Composites" Molecules 28, no. 13: 5100. https://doi.org/10.3390/molecules28135100

APA StyleKabir, I. I., Carlos Baena, J., Wang, W., Wang, C., Oliver, S., Nazir, M. T., Khalid, A., Fu, Y., Yuen, A. C. Y., & Yeoh, G. H. (2023). Optimisation of Additives to Maximise Performance of Expandable Graphite-Based Intumescent-Flame-Retardant Polyurethane Composites. Molecules, 28(13), 5100. https://doi.org/10.3390/molecules28135100