Comparative Study of Chemically Treated Sugarcane and Kevlar Fiber to Develop Brake Resistance Composites

Abstract

1. Introduction

2. Results and Discussion

2.1. Physical, Chemical, Mechanical and Tri-Biological Characterization of SCF/KF Compounds

| Properties | Standard Applied [40,41,42,43,44] | KV-1 | FS-1 | KV-2 | FS-2 | FS-3 | FS-4 |

|---|---|---|---|---|---|---|---|

| % Porosity | JISD 4418 standard | 3.8 | 3.85 | 3.9 | 3.95 | 3.43 | 4.4 |

| % Ash content | ASTM D570-98 | 85.8 | 83.87 | 84.85 | 82.6 | 79.63 | 78.74 |

| % Water absorption | ISO 6310 standard | 2.45 | 2.7 | 2.6 | 2.75 | 3.2 | 3.27 |

| % Acetone extraction | ASTM D494 standard | 0.6 | 0.62 | 0.65 | 0.67 | 0.7 | 0.75 |

| Density (g/cm3) | ASTM C271/C271 M-16 | 2.8 | 2.75 | 2.7 | 2.7 | 2.65 | 2.62 |

| % Compressibility | ISO 6310 | 1.45 | 1.48 | 1.53 | 1.55 | 1.6 | 1.65 |

| Hardness (HRR) | Rockwell-R scale | 115.9 | 113.6 | 113.7 | 111.4 | 110.8 | 109.3 |

| % Heat swelling | SAE J 160 JNU80 | 1.5 | 1.65 | 1.75 | 1.95 | 2.05 | 2.1 |

| Impact energy (J) | ASTM D256 | 0.47 | 0.465 | 0.464 | 0.45 | 0.39 | 0.385 |

| Shear strength (kgf) | ASTM D732 | 1560 | 1423 | 1510 | 1490 | 1367 | 1320 |

| Tensile strength (MPa) | ASTM E8 | 17.98 | 17.5 | 16.7 | 16.2 | 13.39 | 12.98 |

| Flexural strength (MPa) | ASTM D790 | 68.29 | 64.37 | 66.76 | 61.65 | 58.34 | 57.28 |

| Tensile modulus (MPa) | ASTM E8 | 4832 | 4675 | 4640 | 4543 | 4376 | 4174 |

| Flexural modulus (GPa) | ASTM D790 | 2.59 | 2.4 | 2.45 | 2.65 | 2.7 | 2.8 |

| Failure strain (%) | ASTM E8 | 1.65 | 1.7 | 1.6 | 1.85 | 2.05 | 2.1 |

| Proof stress (MPa) | ASTM E8 | 4.5 | 4.75 | 4.7 | 4.8 | 4.98 | 5 |

| Ultimate compressive strength (MPa) | ASTM E8 | 178.7 | 172.5 | 180.6 | 164.3 | 160.7 | 158.3 |

2.2. Tri-Biological Properties of Samples

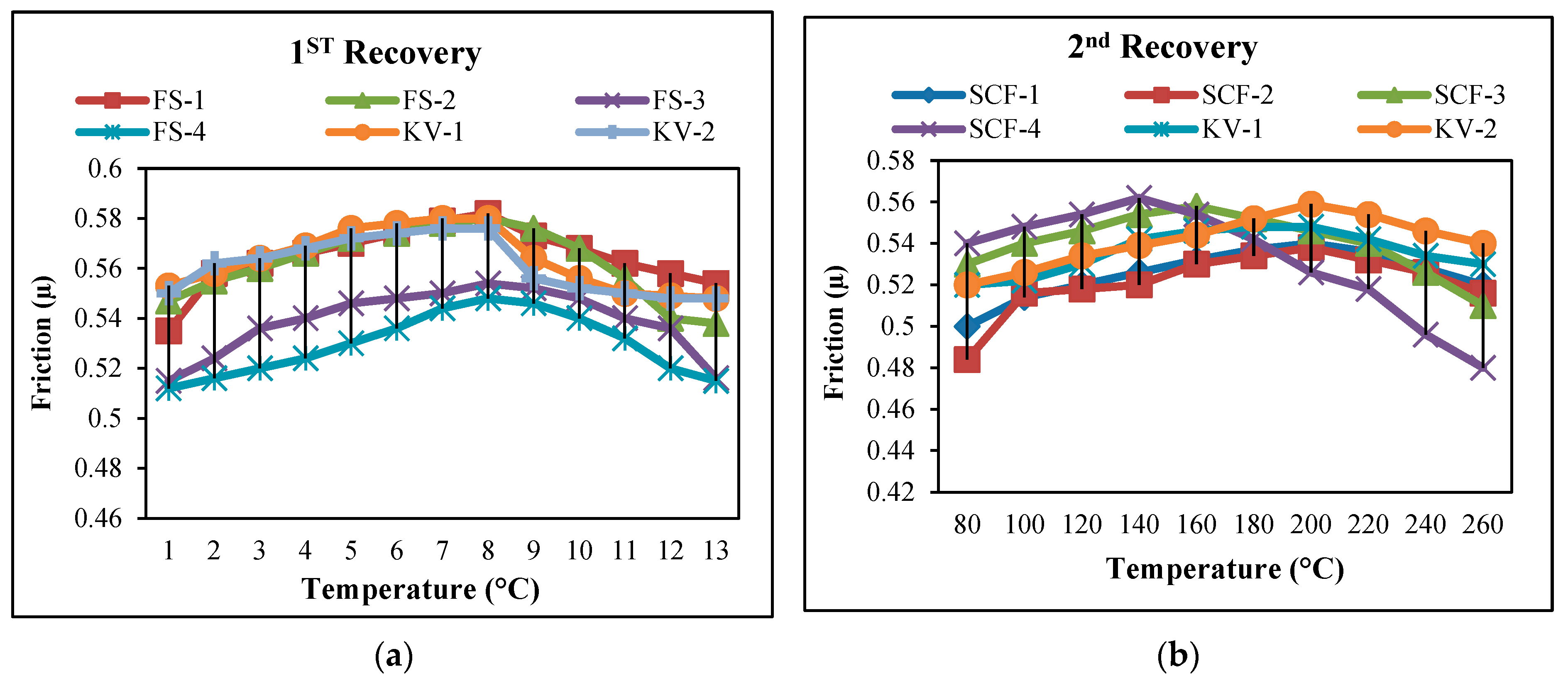

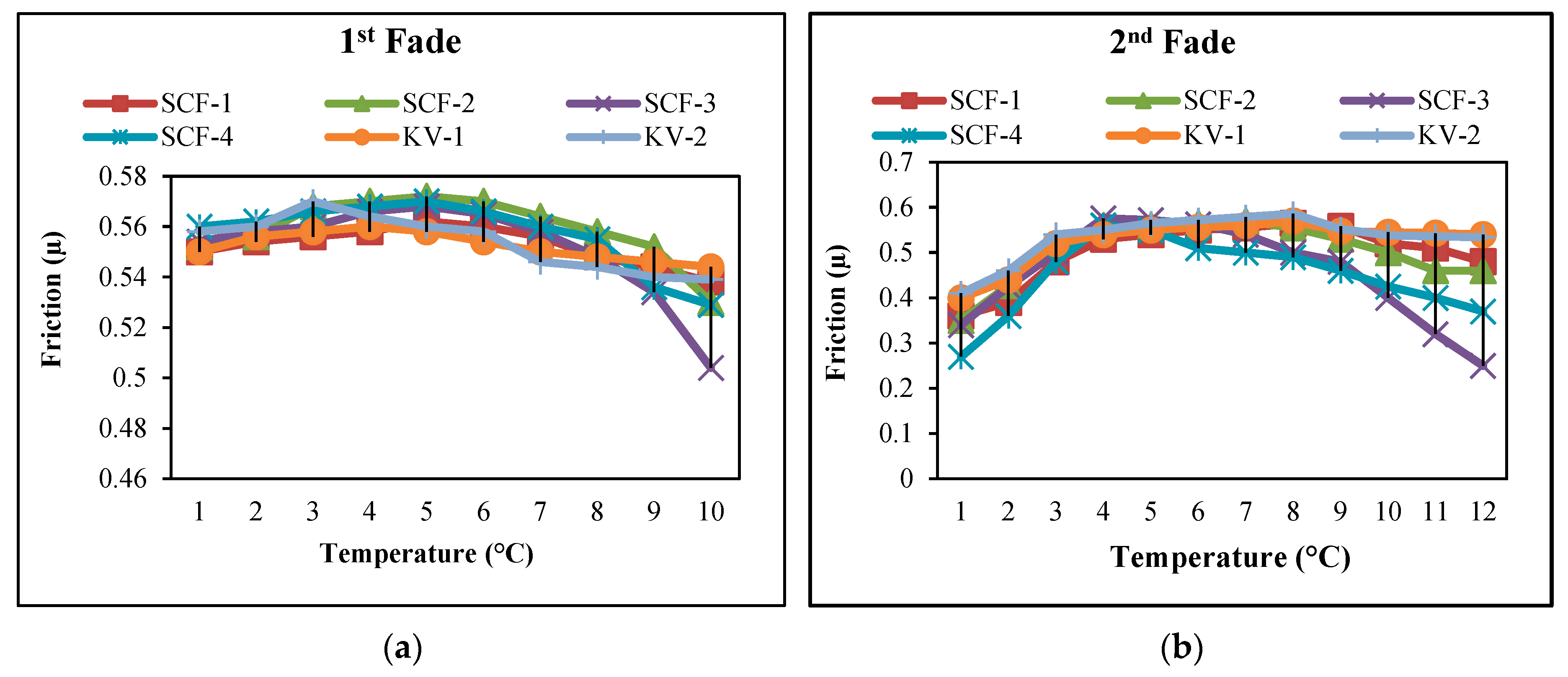

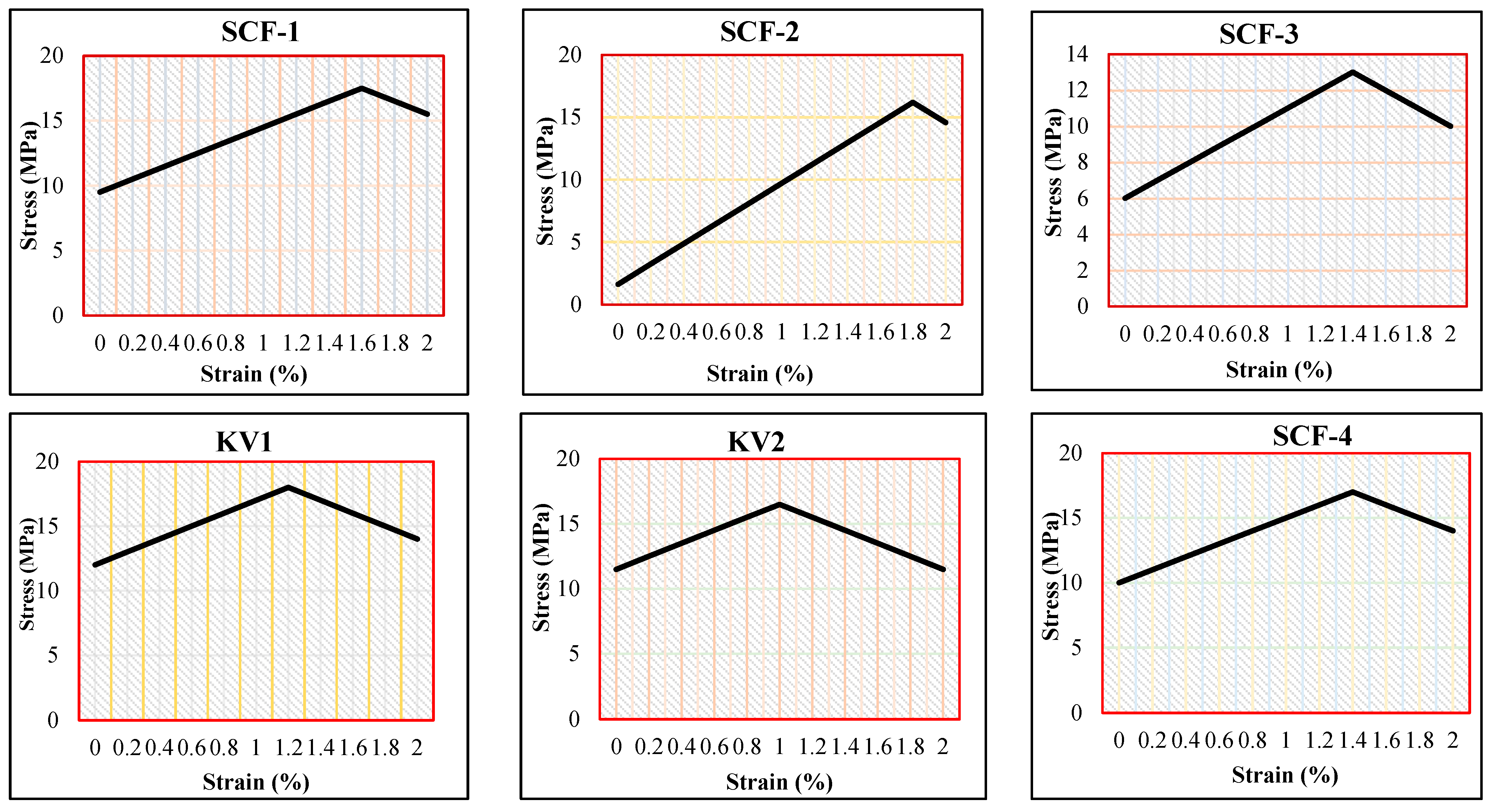

2.3. Effect of Friction (µ) in Fade and Recovery Phases

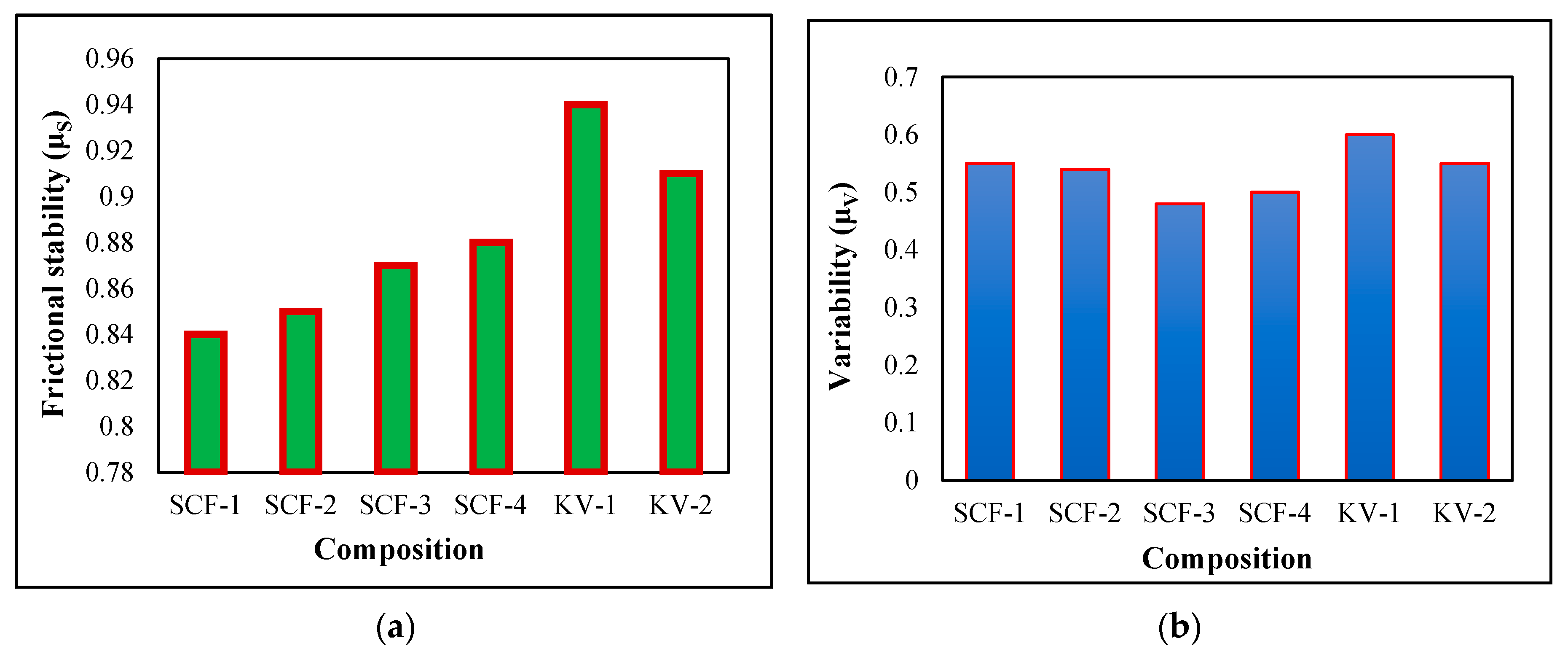

2.4. Frictional Stability (μS) and Variability (μV) Coefficient Performance

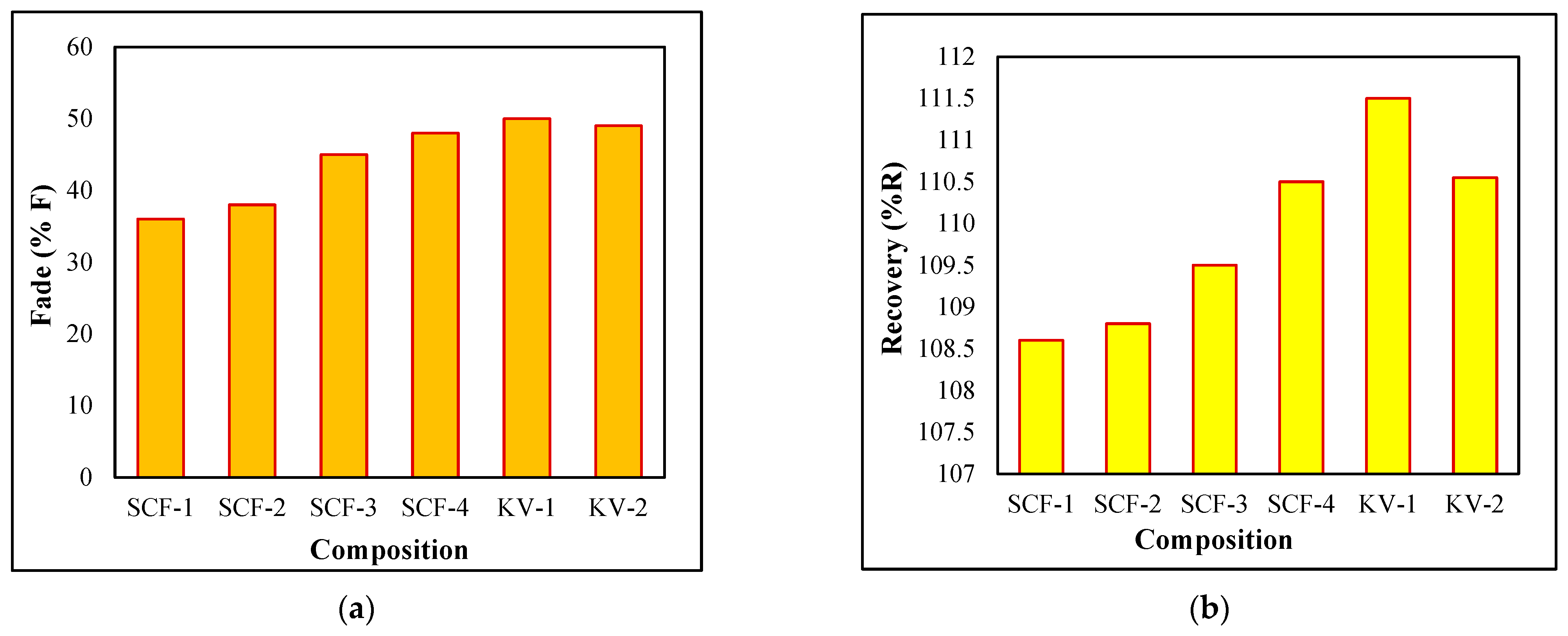

2.5. Fade (F) (%) and Recovery (R) Performance Analysis

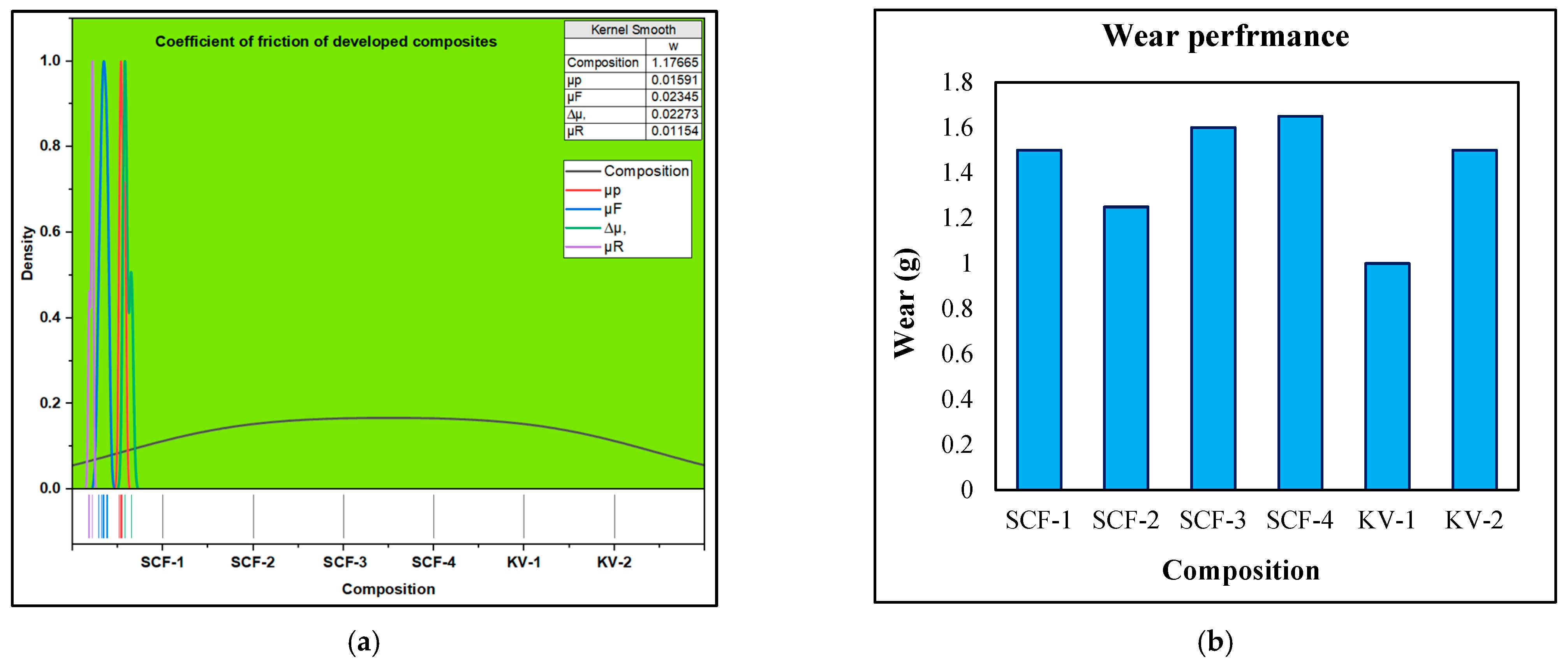

2.6. μP, μR, μF and Δμ Performance of SCF Compounds

2.7. Wear Performance

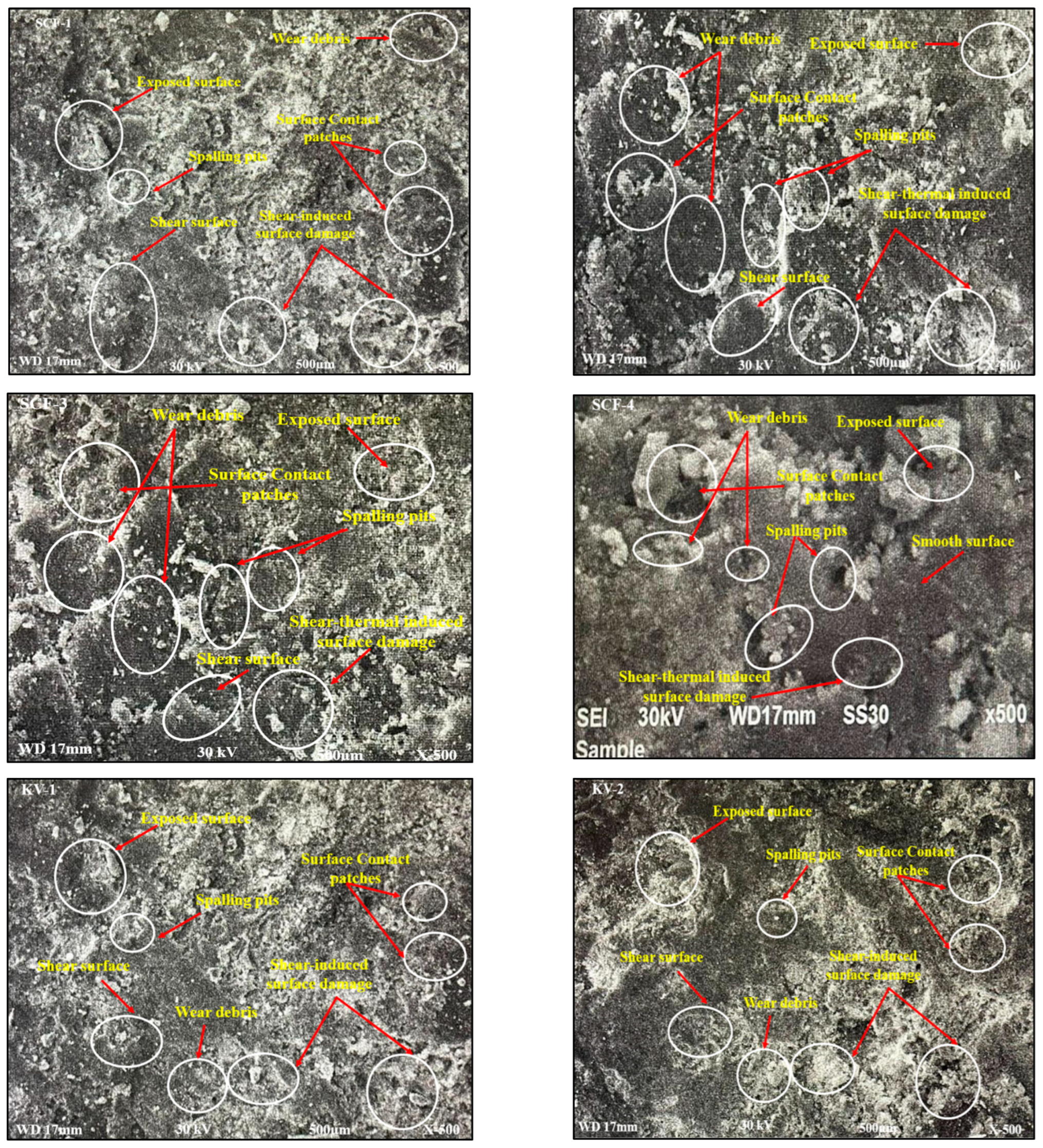

2.8. Worn Surface Assessment

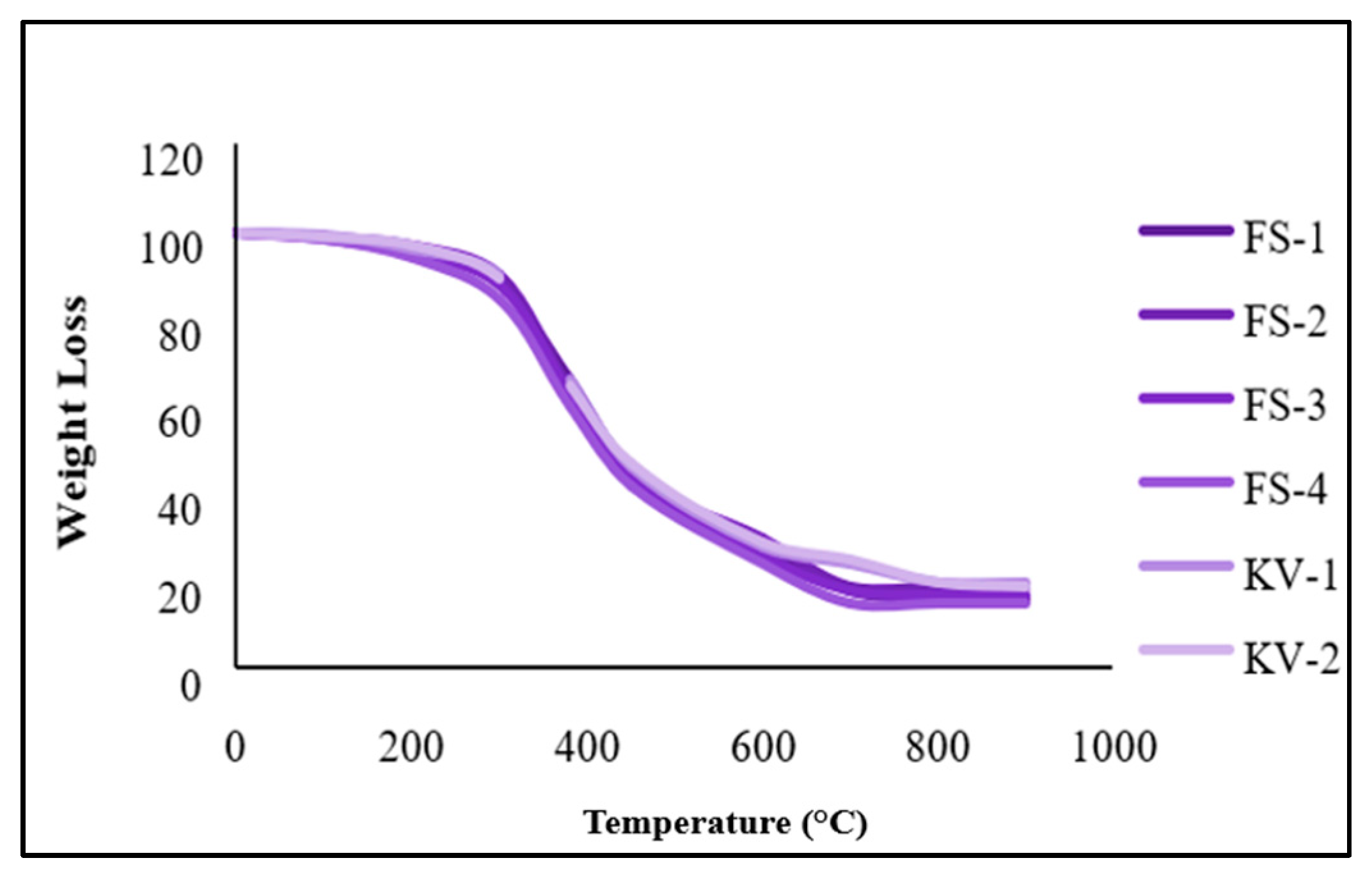

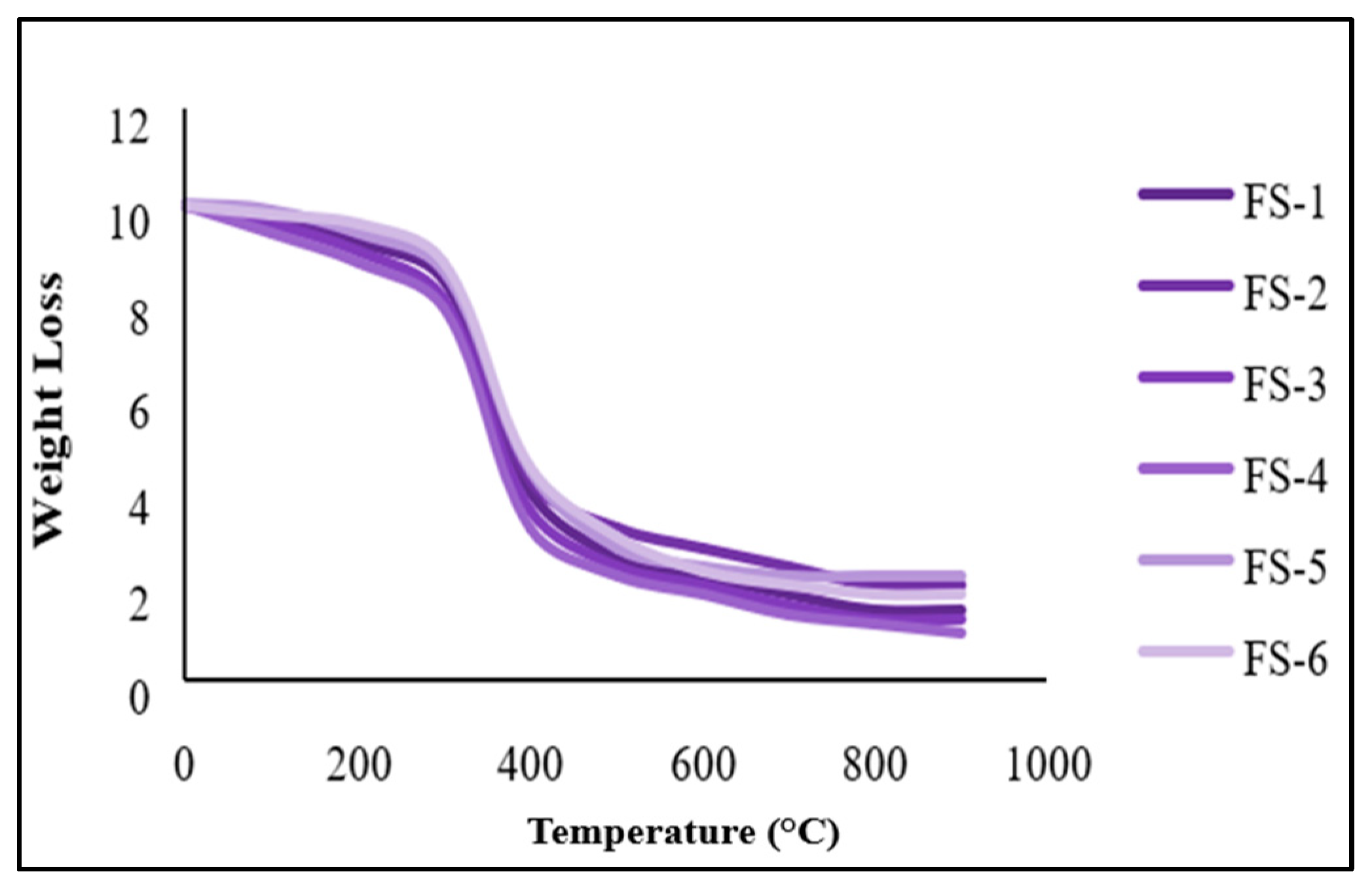

2.9. TGA of SCF-Based Experiments

3. Materials and Methods

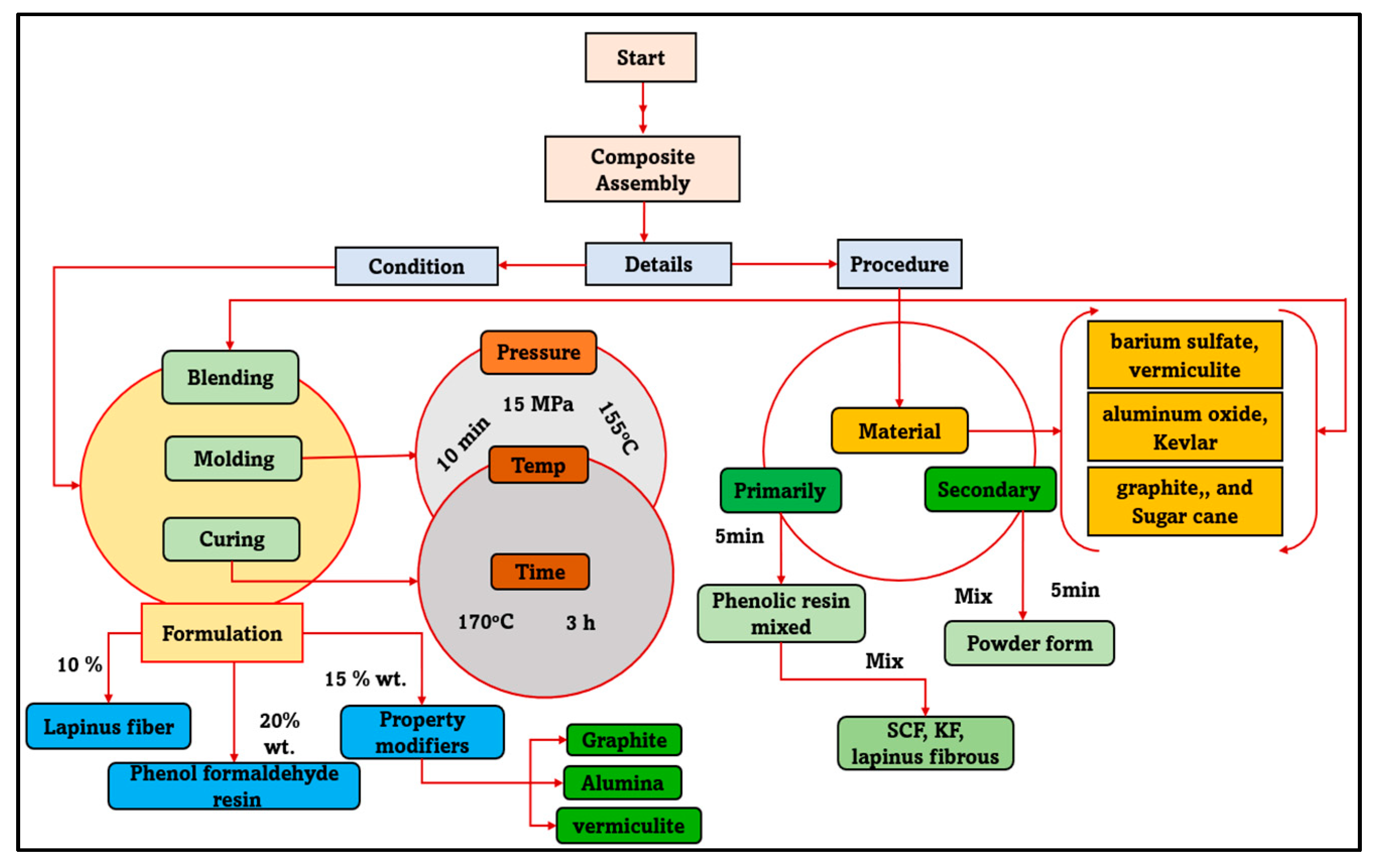

3.1. Compound or Composite Assembly

3.2. Physico-Mechanical and Thermal Attributes

3.3. Assessment of Tri-Biological Attributes of Established Compounds

4. Conclusions

- (1)

- The tensile strength, ultimate compressive strength, flexural strength, tensile modulus, flexural modulus and impact energy revealed the most excellent performance for SCF-1 (5 wt.%) brake pad composite, including all SCF composites. The SCF brake pads have shown the most mechanical results near Kevlar-based compounds. It has also been observed that the percentage of wear and friction level increases with the addition of SCF in the mix.

- (2)

- The ultimate shear strength and proof stress revealed the best performance for SCF-2 brake pad compounds, including the entire SCF composites. In contrast, Kevlar composites have shown their maximum value of 5 wt—% (KV-1) compounds. SCF-1 sample showed the highest and lowest values of µs and µ, respectively.

- (3)

- The value of µs enhances with SCF proportion, while µv decreases with an increasing proportion of SCF. The SCF compounds (SCF-4) showed the ultimate value of recovery percentage. Although, the (%) recovery has been discovered to be over the hundred percent for all the desirable compounds. SCF-1 showed the utmost value of the performance of COF, with minor wear.

- (4)

- The comparative study determined that the Kevlar-based brake pad samples revealed slightly improved %-fade, µ, wear and thermal stability results than SCF and KV-2 compounds. Thermal stability for SCF compounds exhibited the maximum value of OI (5.84) at 20 wt—% SCF composites. From the analysis, it has been concluded that SCF-based brake pad samples indicated excellent performance in physical and chemical mechanical properties and noticed values very near Kevlar composites. Moreover, SCF-1 compounds exhibit improved thermal, tri-biological and mechanical outcomes among all SCF compounds.

- (5)

- The worn surface study reveals that, in addition to abrasive and adhesive wear processes, the development of primary and secondary contact patches/plateaus is one of the most critical elements in determining the tribological performance of the composite.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Mohanty, S.; Chugh, Y.P. Development of fly ash-based automotive brake lining. Tribol. Int. 2007, 40, 1217–1224. [Google Scholar] [CrossRef]

- Ramazzini, C. Call for an international ban on asbestos. J. Occup. Environ. Med. 1999, 41, 830–832. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Asbestos: Elimination of Asbestos-Related Diseases; World Health Organization: Geneva, Switzerland, 2010; Fact sheet No. 343.

- Ahmadiokani, F.; Shojaei, A.; Arjmand, M.; Alaei, Y.; Yan, N. Effect of short carbon fiber on thermal, mechanical, and tribological behavior of phenolic-based brake friction materials. Compos. Part B Eng. 2019, 168, 98–105. [Google Scholar] [CrossRef]

- Singh, T.; Patnaik, A.; Chauhan, R.; Rishiraj, A. Assessment of braking performance of Lupinus wollastonite fiber reinforced friction composite materials. J. King Saud Univ. 2017, 29, 183–190. [Google Scholar] [CrossRef]

- Kumar, M.; Bijwe, J. Optimized selection of metallic fillers for best combination of performance properties of friction materials: A comprehensive study. Wear 2013, 303, 569–583. [Google Scholar] [CrossRef]

- Aranganathan, N.; Mahale, V.; Bijwe, J. Effects of aramid fiber concentration on the friction and wear characteristics of non-asbestos organic friction composites using standardized braking test. Wear 2016, 354–355, 69–77. [Google Scholar] [CrossRef]

- Kim, S.J.; Cho, M.H.; Lim, D.S.; Jang, H. Synergistic effects of aramid pulp and potassium titanate whiskers in the automotive friction material. Wear 2001, 251, 1484–1491. [Google Scholar] [CrossRef]

- Park, S.H. Types, and health hazards of fibrous materials used as asbestos substitutes. Saf. Health Work 2018, 9, 360–364. [Google Scholar] [CrossRef]

- Dunnigan, J.; Nadeau, D.; Paradis, D. Cytotoxic effects of aramid fibers on rat pulmonary macrophages: Comparison with chrysotile asbestos. Toxicol. Lett. 1984, 20, 277–282. [Google Scholar] [CrossRef]

- Drummond, G.; Bevan, R.; Harrison, P. A comparison of the results from intra-pleural and intra-peritoneal studies with those from inhalation and intratracheal tests for the assessment of pulmonary responses to inhalable dust and fibers. Regul. Toxicol. Pharmacol. 2016, 81, 89–105. [Google Scholar] [CrossRef]

- Harrison, P.T.; Levy, L.S.; Patrick, G.; Pigott, G.H.; Smith, L.L. Comparative hazards of chrysotile asbestos and its substitutes: A European perspective. Environ. Health Perspect. 1999, 107, 607–611. [Google Scholar] [CrossRef]

- Cruz, J.; Fangueiro, R. Surface modification of natural fibers: A review. Proceeding Eng. 2016, 155, 285–288. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Thermal degradation of flax: The determination of kinetic parameters with thermogravimetric analysis. J. Appl. Polym. 2002, 83, 2634–2643. [Google Scholar] [CrossRef]

- Wallenberger, F.T.; Weston, N. Natural Fibers Plastics and Composites; Springer: New York, NY, USA, 2004. [Google Scholar] [CrossRef]

- Maleque, M.A.; Atiqah, A. Development and Characterization of Coir Fibre Reinforced Composite Brake Friction Materials. Arab. J. Sci. Eng. 2013, 38, 3191–3199. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in bio composites based on natural fibers and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Yun, R.; Filip, P.; Lu, Y. Performance and evaluation of eco-friendly brake friction materials. Tribol. Int. 2010, 43, 2010–2019. [Google Scholar] [CrossRef]

- Faga, M.G.; Casamassa, E.; Iodice, V.; Sin, A.; Gautier, G. Morphological and structural features affecting the friction properties of carbon materials for brake pads. Tribol. Int. 2019, 140, 105889. [Google Scholar] [CrossRef]

- Puglia, D.; Biagiotti, J.; Kenny, J.M. A Review on Natural Fiber-Based Composites-Part II: Application of Natural Reinforcements in Composite Materials for Automotive Industry. J. Nat. Fibers 2004, 2, 23–65. [Google Scholar] [CrossRef]

- Koronis, G.; Silva, A.; Fontul, M. Green Composites: A Review of Adequate Materials for Automotive Applications. Compos. Part B 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Ticoalu, A.; Aravinthan, T.; Cardona, F. A review of current development in natural fiber composites for structural and infrastructure applications. In Proceedings of the SREC2010-F1-5, 2010 Conference on Call for an International Ban on Asbestos, Toowoomba, Australia, 11–12 November 2010. [Google Scholar]

- Savage, L. Eco-Friendly Brake Pads Promise Greener Transport. 2007, pp. 1–2. Available online: http://www.ohlsti.co.uk/ohl/stipdfs/ohl_sti74.pdf (accessed on 26 April 2023).

- Glória, G.O.; Teles, M.C.A.; Neves, A.C.C.; Vieira, C.M.F.; Lopes, F.P.D.; Gomes, M.A.; Margem, F.M.; Monteiro, S.N. Bending test in epoxy composites reinforced with continuous and aligned PALF fibers. J. Mater. Res. Technol. 2017, 6, 411–416. [Google Scholar] [CrossRef]

- Todkar, S.S.; Patil, S.A. Review on mechanical properties evaluation of pineapple leaf fiber (PALF) reinforced polymer composites. Compos. Part B Eng. 2019, 174, 106927. [Google Scholar] [CrossRef]

- Ridzuan, M.J.M.; Abdul Majid, M.S.; Khasri, A.; Gan, E.H.D.; Razlan, Z.M.; Syahrullail, S. Effect of pineapple leaf (PALF), Napier, and hemp fibers as filler on the scratch resistance of epoxy composites. J. Mater. Res. Technol. 2019, 8, 5384–5395. [Google Scholar] [CrossRef]

- Fu, Z.; Suo, B.; Yun, R.; Lu, Y.; Wang, H.; Qi, S.; Jiang, S.; Lu, Y.; Matejka, V. Development of eco-friendly brake friction composites containing flax fibers. J. Reinf. Plast. Compos. 2012, 31, 681–689. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Che, J.; Duanmu, L.; Zhuang, J.; Tong, J. Natural fibre reinforced non-asbestos organic non-metallic friction composites: Effect of abaca fibre on mechanical and tribological behaviour. Mater. Res. Express 2018, 5, 055101. [Google Scholar] [CrossRef]

- Xin, X.; Xu, C.G.; Qing, L.F. Friction properties of sisal fibre reinforced resin brake composites. Wear 2007, 262, 736–741. [Google Scholar] [CrossRef]

- Candido, R.G.; Godoy, G.G.; Gonsalves, A.R. Study of sugarcane bagasse pretreatment with sulfuric acid as a step of cellulose obtaining. Int. J. Nutr. Food Eng. 2012, 6, 6–10. [Google Scholar] [CrossRef]

- Candido, V.S.; Da Silva, A.C.R.; Simonassib, N.T.; Luz, F.S.; Monteiro, S.N. Toughness of polyester matrix composites reinforced with sugarcane bagasse fibers evaluated by Charpy impact tests. J. Mater. Res. Technol. 2017, 64, 334–338. [Google Scholar] [CrossRef]

- Cao, Y.; Shibata, S.; Fukumoto, I. Mechanical properties of biodegradable composites reinforced with bagasse fiber before and after alkali treatments. Compos. Part A Appl. Sci. Manuf. 2006, 37, 423–429. [Google Scholar] [CrossRef]

- Cerqueira, E.F.; Baptista, C.A.R.P.; Mulinari, D.R. Mechanical behaviour of polypropylene reinforced sugarcane bagasse fibers composites. Procedia Eng. 2011, 10, 2046–2051. [Google Scholar] [CrossRef]

- Kumar, N.; Singh, T.; Grewal, J.S.; Patnaik, A.; Fekete, G. Experimental investigation on the physical, mechanical and tribological properties of hemp fiber-based non-asbestos organic brake friction composites. Mater. Res. Express 2019, 6, 085710. [Google Scholar] [CrossRef]

- Ma, Y.; Shen, S.; Tong, J.; Ye, W.; Yang, Y.; Zhou, J. Effects of bamboo fibers on friction performance of friction materials. J. Plast. Compos. Mater. 2012, 26, 845–859. [Google Scholar] [CrossRef]

- Mustafa, A.; Abdollah, M.F.B.; Shuhimi, F.F.; Ismail, N.; Amiruddin, H.; Umehara, N. Selection and verification of kenaf fibres as an alternative friction material using Weighted Decision Matrix method. Mater. Des. 2015, 67, 577–582. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, S.; Zhuang, J.; Tong, J.; Qi, H. Tribological and physio-mechanical characterization of cow dung fibers reinforced friction composites: An effective utilization of cow dung waste. Tribol. Int. 2019, 131, 200–211. [Google Scholar] [CrossRef]

- Kumar, N.; Singh, T.; Grewal, J.S.; Patnaik, A.; Fekete, G. A novel hybrid AHP-SAW approach for optimal selection of natural fiber reinforced non-asbestos organic brake friction composites. Mater. Res. Express 2019, 6, 065701. [Google Scholar] [CrossRef]

- Singh, T.; Kumar, N.; Grewal, J.S.; Ashok Raj, J.; Fekete, G. Natural fiber reinforced non-asbestos brake friction composites: Influence of ramie fiber on physic mechanical and tribological properties. Mater. Res. Express 2019, 6, 115701. [Google Scholar] [CrossRef]

- Kumar, N.; Grewal, J.S.; Kumar, S. Mechanical and Thermal Properties of NaOH treated Sisal natural fiber reinforced polymer composites: Barium uses as filler. Mater. Today Proc. 2021, 45, 5575–5578. [Google Scholar] [CrossRef]

- Kumar, N.; Mehta, V.; Kumar, S.; Grewal, J.S.; Ali, S.; Kashyap, K.; Kumar, N.; Devi, S. Physical mechanical, tribological, and thermal properties of new developed composites with Grewia optiva fiber and pan material. Polym. Compos. 2022, 1–7. [Google Scholar] [CrossRef]

- Grewal, J.S.; Kumar, N.; Singh, T. Experimental investigation on the physical, mechanical, and thermal properties of chemical treated ramie fiber-based non-asbestos organic brake friction composites. Trans. Stellar 2021, 10, 2249–6890. [Google Scholar]

- Grewal, J.S.; Kumar, N.; Singh, T. Mechanical and thermal properties of chemical treated hemp natural fiber reinforced polymer composites. Int. J. Mech. Prod. Eng. Res. Dev. 2020, 10, 879–888. [Google Scholar]

- Singh, T.; Rathi, M.K.; Patnaik, A.; Chauhan, R.; Ali, S.; Fekete, G. Application of waste tire rubber particles in non-asbestos organic brake friction composite materials. Mater. Res. Express 2019, 6, 035703. [Google Scholar] [CrossRef]

- Singh, T.; Patnaik, A.; Fekete, G.; Chauhan, R.; Gangil, B. Application of hybrid analytical hierarchy process and complex proportional assessment approach for optimal design of brake friction materials. Polym. Compos. 2019, 40, 1602–1608. [Google Scholar] [CrossRef]

- Singh, T.; Chauhan, R.; Patnaik, A.; Gangil, B.; Nain, R.; Kumar, A. Parametric study and optimization of multi-walled carbon nanotube fulfilled friction composite materials using taguchi method. Polym. Compos. 2018, 39, 9–17. [Google Scholar] [CrossRef]

- Singh, T.; Tiwari, A.; Patnaik, A.; Chauhan, R.; Ali, S. Influence of wollastonite shape and amount on tribo-performance of no asbestos organic brake friction composites. Wear 2017, 386–387, 157–164. [Google Scholar] [CrossRef]

- Matějka, V.; Fu, Z.; Kukutschová, J.; Qi, S.; Jiang, S.; Zhang, X.; Yun, R.; Vaculik, M.; Heliova, M.; Lu, Y. Jute fibers and powderized hazelnut shells as natural fillers in non-asbestos organic non-metallic friction composites. Mater. Des. 2013, 51, 847–853. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Wang, J.; Ma, Y.H. The evaluation of physic mechanical and tribological properties of corn straw fiber-reinforced environment-friendly friction composites. Adv. Mater. Sci. Eng. 2018, 2018, 1562363. [Google Scholar]

- Singh, T.; Patnaik, A. Performance assessment of lapinus-aramid based brake pad hybrid phenolic composites in friction braking. Arch. Mech. Eng. 2015, 15, 151–161. [Google Scholar] [CrossRef]

- Lertwassana, W.; Parnklang, T.; Mora, P.; Jubsilp, C.; Rimdusit, S. High-performance aramid pulp/carbon fiber-reinforced poly benzoxazine composites as friction materials. Compos. Part B Eng. 2019, 177, 107280. [Google Scholar] [CrossRef]

- Singaravelu, D.L.; Vijay, R.; Filip, P. Influence of various cashew friction dusts on the fade and recovery characteristics of non-asbestos copper-free brake friction composites. Wear 2019, 426–427, 1129–1141. [Google Scholar] [CrossRef]

- Mosquera, M.E.G.; Jamond, M.; Martinez, A.; Tascon, J.M.D. Thermal transformations of Kevlar aramid fibers during pyrolysis: Infrared and thermal analysis studies. Chem. Mater. 1994, 6, 1918–1924. [Google Scholar] [CrossRef]

- Amit, C. Thermal degradation analysis of thermoset resins. J. Appl. Polym. Sci. 2009, 114, 1417–1425. [Google Scholar]

- Kumar, N.; Kumar, S.; Grewal, J.S.; Mehta, V.; Ali, S. Comparative study of Abaca fiber and Kevlar fibers-based brake friction composites. Compos. Polym. 2021, 43, 730–740. [Google Scholar] [CrossRef]

- Kumar, N.; Grewal, J.S.; Singh, A.; Mehta, V. A Comparative study of alkali-treated date palm fiber-based brake friction composites and standard Kevlar-based brake friction composites. Compos. Polym. 2021, 43, 239–249. [Google Scholar] [CrossRef]

- Kumar, N.; Grewal, J.S. Tribo-performance evaluation of eco-friendly brake friction composite materials. AIP Conf. Proc. 2018, 1953, 090083. [Google Scholar] [CrossRef]

- Kumar, N.; Fekete, G.; Singh, T.; Grewal, J.S. Natural Fiber Reinforced brake friction composites: Optimization using hybrid AHP- Moora Approach. AIP Conf. Proc. 2019, 2142, 150015. [Google Scholar] [CrossRef]

| Favorable Value of Elements | |||||||

|---|---|---|---|---|---|---|---|

| µP | µv | %Fade | µs | % R | µR | µF | Wear rate |

| µ-standard | Least | Small | Larger | Larger | Larger | Small | Least |

| Samples | SCF-4 | SCF-3 | SCF-2 | SCF-1 | KV-1 | KV-2 |

|---|---|---|---|---|---|---|

| % residue (O2) of SCF compounds | 80.5 | 79.8 | 78.9 | 77.4 | 80.7 | 79.7 |

| Oxidation index of SCF composites | 5.63 | 5.58 | 5.55 | 5.40 | 5.65 | 5.60 |

| % residue (N2) of SCF composites | 83.70 | 83.45 | 82.69 | 82.58 | 83.72 | 82.9 |

| Oxidation index (OI) N2 | 5.84 | 5.76 | 5.72 | 5.70 | 5.85 | 5.80 |

| Sample | SCF-1 | KV-1 | SCF-2 | KV-2 | SCF-3 | SCF-4 |

|---|---|---|---|---|---|---|

| KF (wt.%) | - | 05 | - | 10 | - | - |

| BaSO4 (wt.%) | 50 | 50 | 45 | 45 | 40 | 35 |

| SCF (wt.%) | 05 | - | 10 | - | 15 | 20 |

| Composition | 45 | 45 | 45 | 45 | 45 | 45 |

| Instrument | Shimadzu Scientific Instruments |

|---|---|

| Fabricated friction compound on TA-60WS model | 10 ± 0.1 mg (around) |

| Heating ratio | 50 °C to 800 °C and 10 °C/min |

| Flow value | 40 mL/min (air and nitrogen) |

| Calculation of oxidation index (OI) | Vary with a weight of carbonaceous char (CR) |

| Test Parameters | Application Applied | Heating (Status) | Applied Load (N) | Speed (rpm) | Max. Temp. (°C) | Time (min.) | Min. Temp. (°C) |

|---|---|---|---|---|---|---|---|

| Primary fade | 1 | off | 440 | 308 | 93 | 20 | - |

| Primary recovery | 1 | on | 660 | 411 | 289 | 10 | 82 |

| Secondary fade | 1 | off | 660 | 411 | 261 | 10 | 93 |

| Secondary recovery | 1 | off | 660 | 411 | 317 | 10 | 82 |

| Burnish | 1 | off | 660 | 411 | 345 | 10 | 93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mehta, V.; Kumar, N.; Algahtani, A.; Tirth, V.; Al-Mughanam, T.; Chau, K.-W. Comparative Study of Chemically Treated Sugarcane and Kevlar Fiber to Develop Brake Resistance Composites. Molecules 2023, 28, 4861. https://doi.org/10.3390/molecules28124861

Mehta V, Kumar N, Algahtani A, Tirth V, Al-Mughanam T, Chau K-W. Comparative Study of Chemically Treated Sugarcane and Kevlar Fiber to Develop Brake Resistance Composites. Molecules. 2023; 28(12):4861. https://doi.org/10.3390/molecules28124861

Chicago/Turabian StyleMehta, Vikas, Naresh Kumar, Ali Algahtani, Vineet Tirth, Tawfiq Al-Mughanam, and Kwok-Wing Chau. 2023. "Comparative Study of Chemically Treated Sugarcane and Kevlar Fiber to Develop Brake Resistance Composites" Molecules 28, no. 12: 4861. https://doi.org/10.3390/molecules28124861

APA StyleMehta, V., Kumar, N., Algahtani, A., Tirth, V., Al-Mughanam, T., & Chau, K.-W. (2023). Comparative Study of Chemically Treated Sugarcane and Kevlar Fiber to Develop Brake Resistance Composites. Molecules, 28(12), 4861. https://doi.org/10.3390/molecules28124861