An Accessible Method to Improve the Stability and Reusability of Porcine Pancreatic α-Amylase via Immobilization in Gellan-Based Hydrogel Particles Obtained by Ionic Cross-Linking with Mg2+ Ions

Abstract

1. Introduction

2. Results and Discussions

2.1. Characterization of the Free Enzyme

- Determination of the time required for a hydrolysis reaction

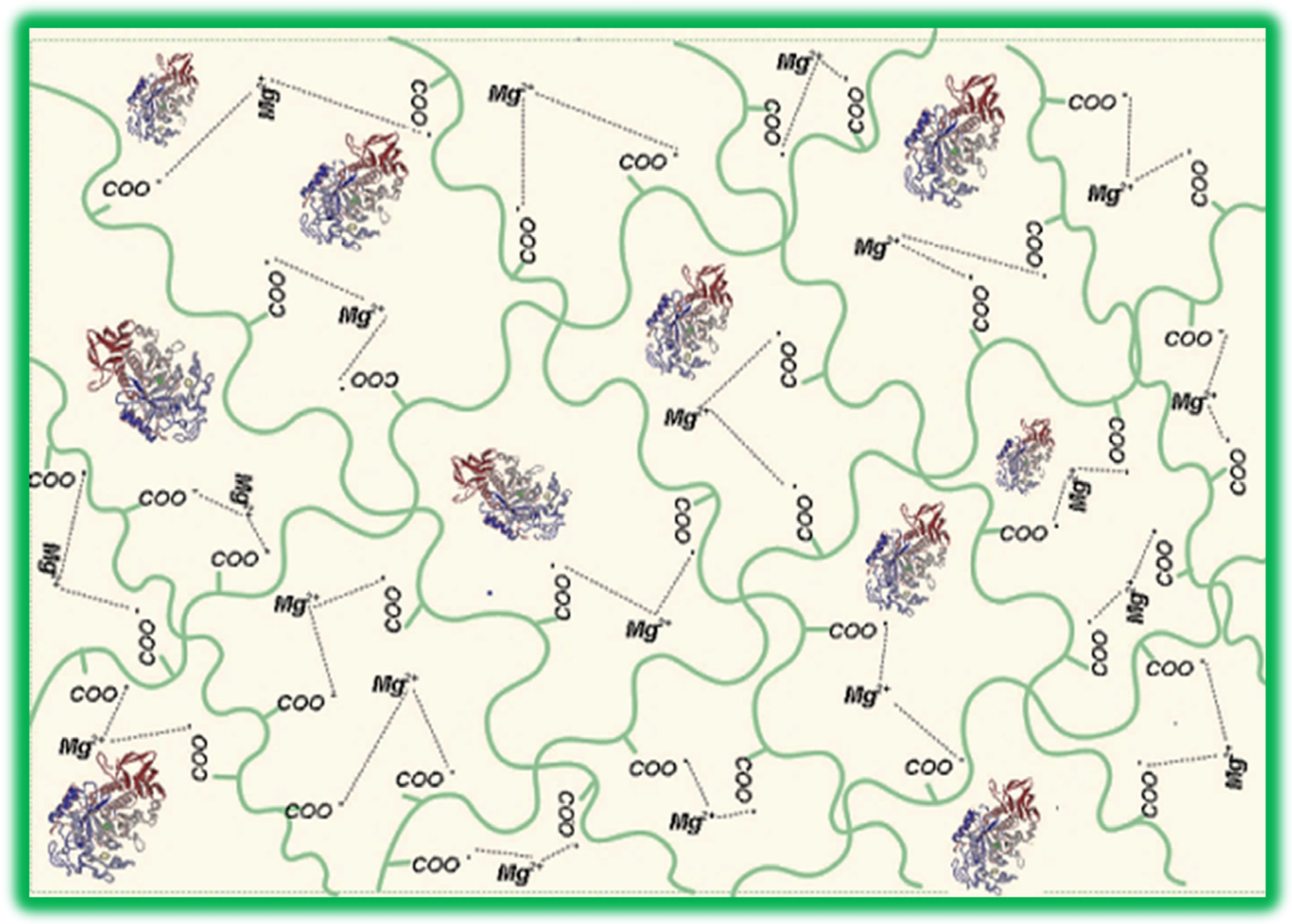

2.2. Obtaining Gellan Particles with Immobilized α-Amylase

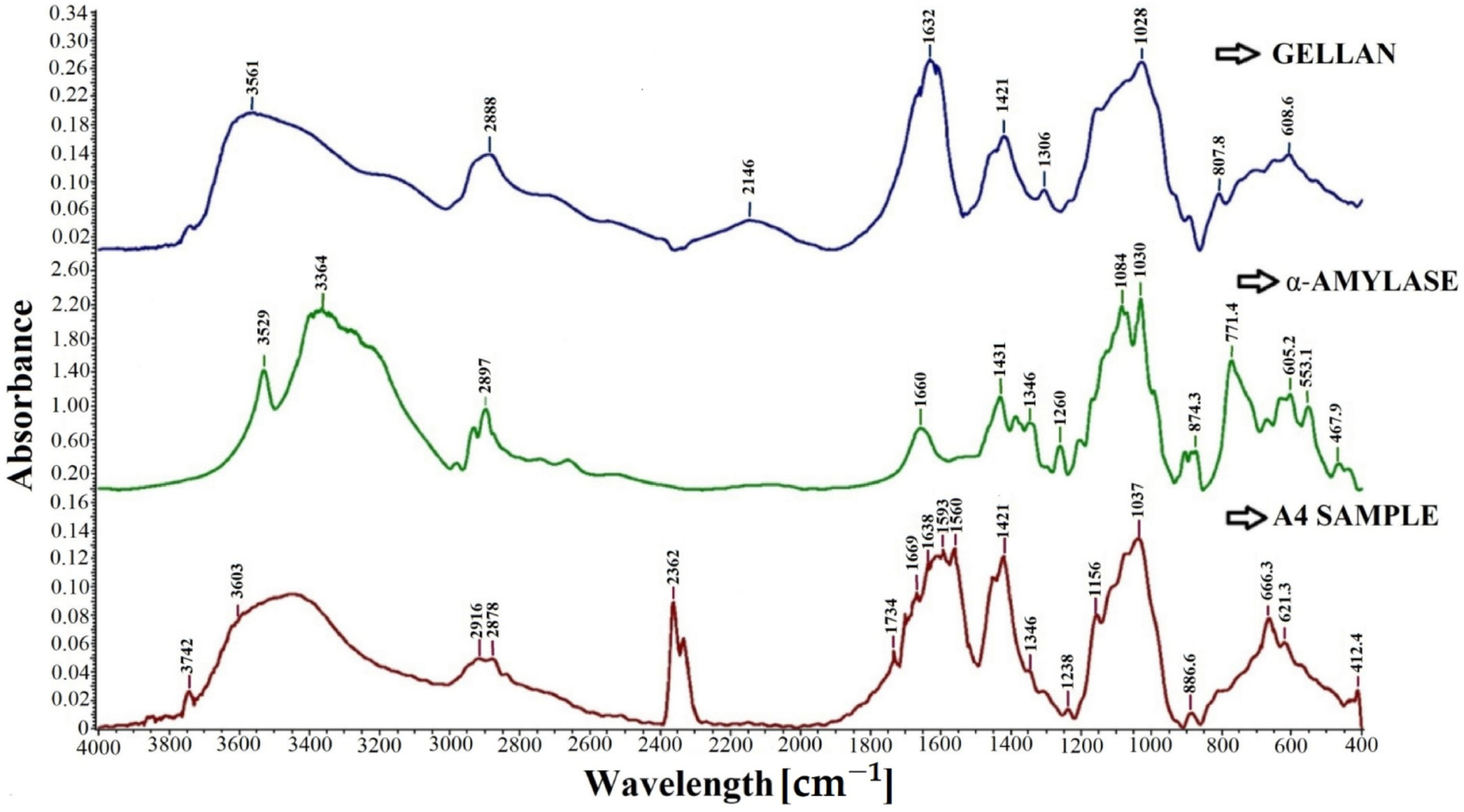

2.3. FT-IR Spectroscopy

2.4. Morphology of the Particles with Immobilized α-Amylase

2.5. Swelling Behavior

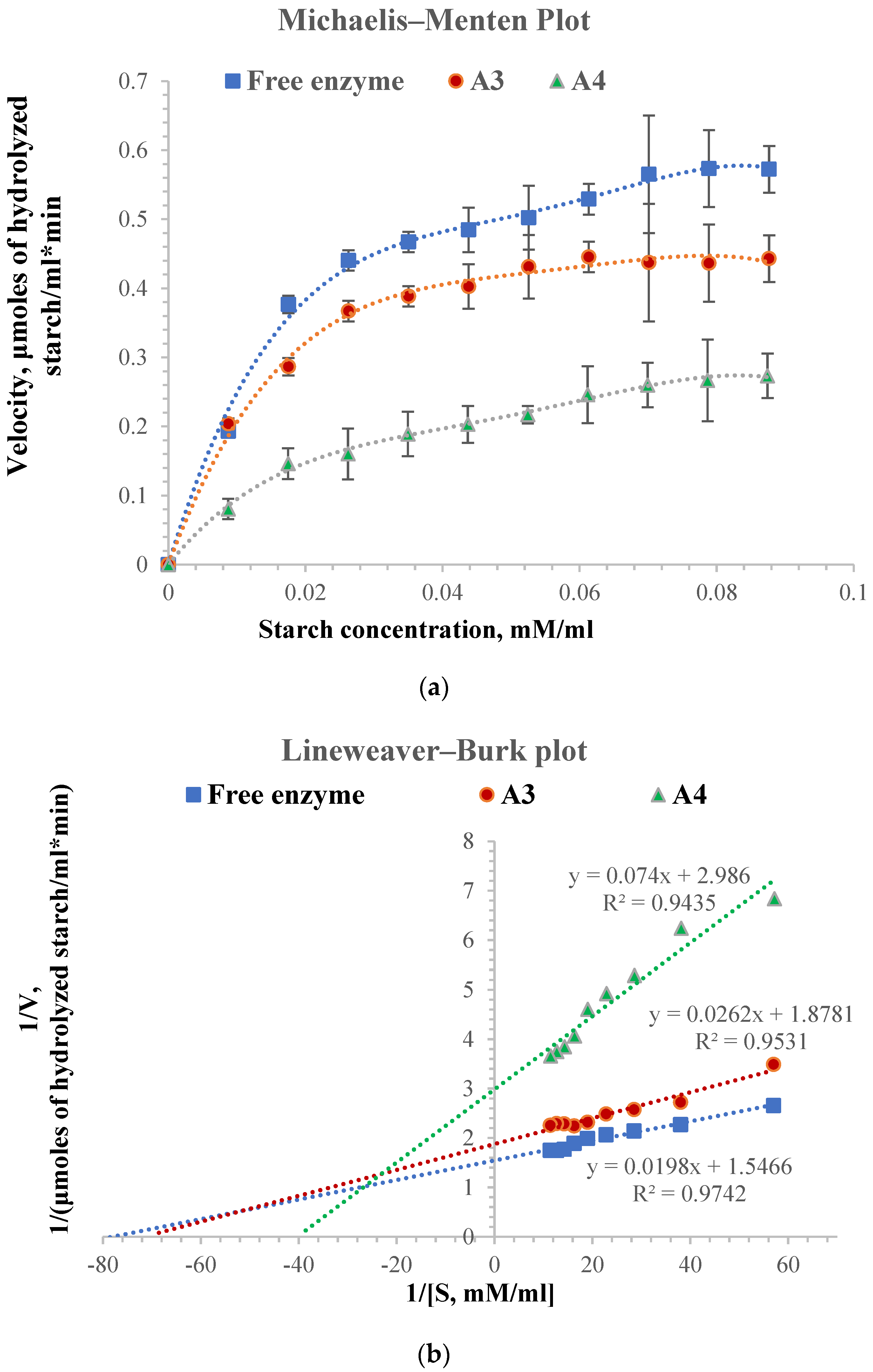

2.6. Determination of the Michaelis–Menten Constant, the Maximum Rate of Hydrolysis Vmax, and the Constant Km

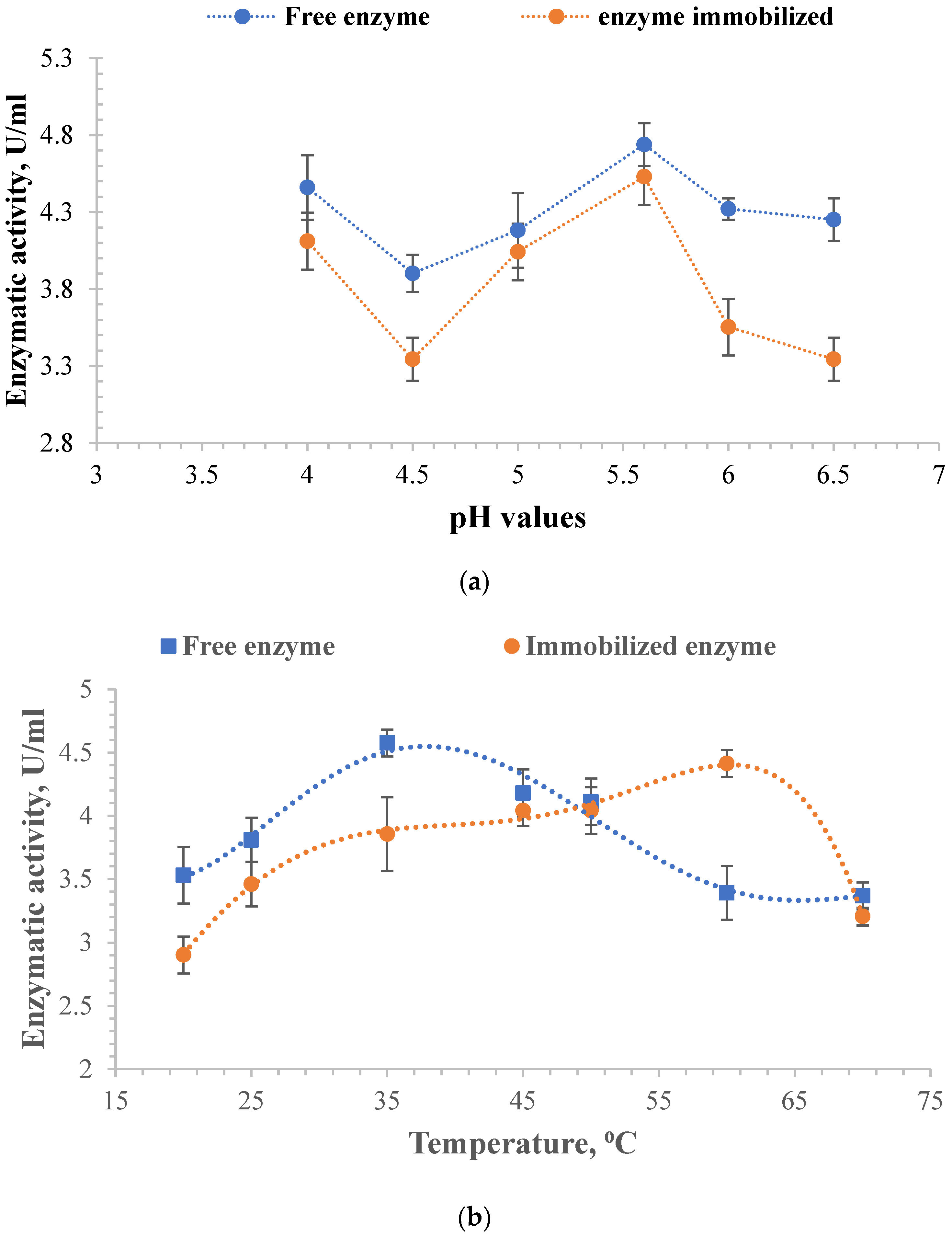

2.7. Influence of pH and Temperature on Free and Immobilized Enzyme Activity

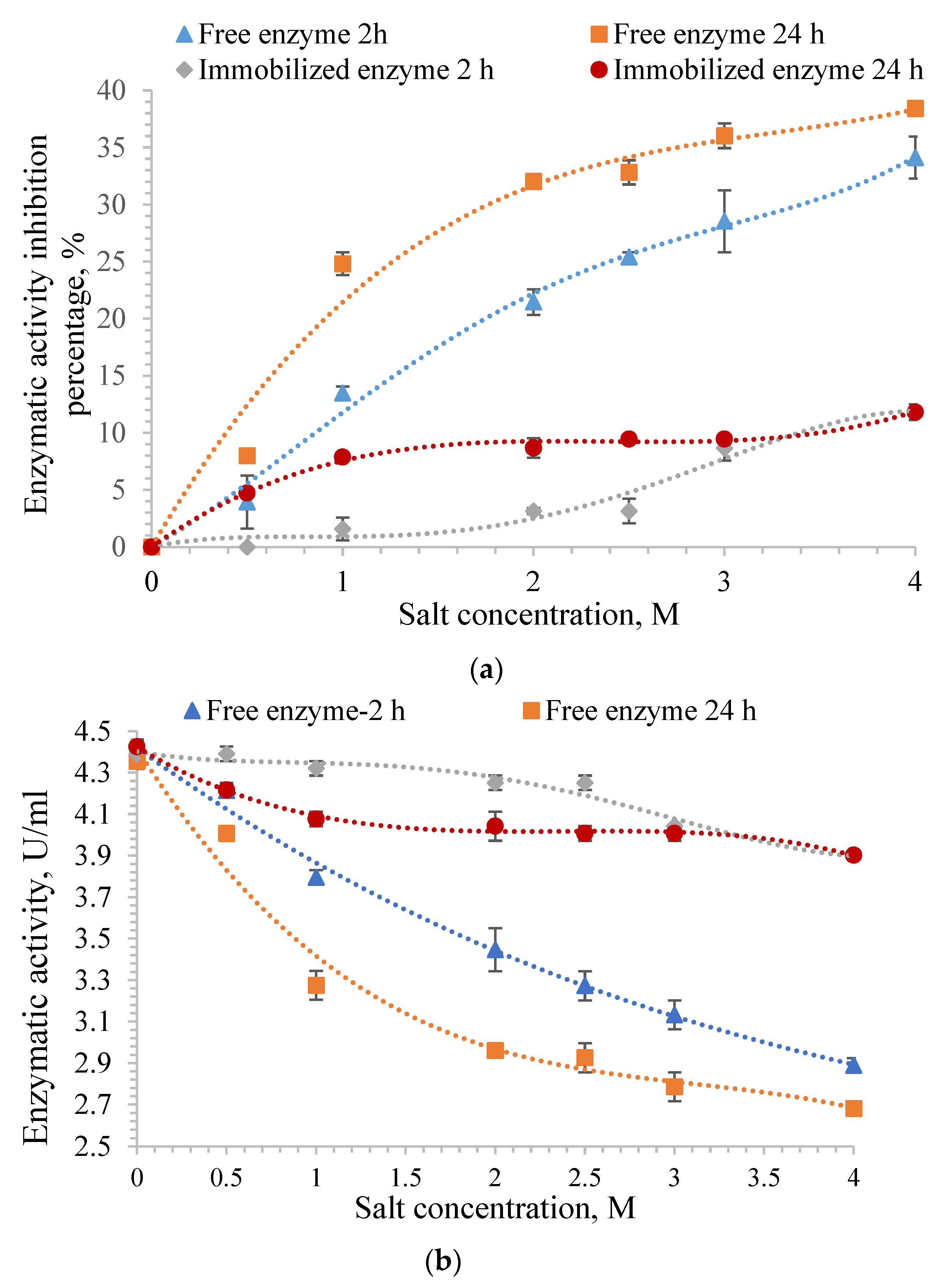

2.8. The Influence of NaCl Concentration on the Degree of Inhibition of Enzyme Activity for Free and Immobilized α-Amylase

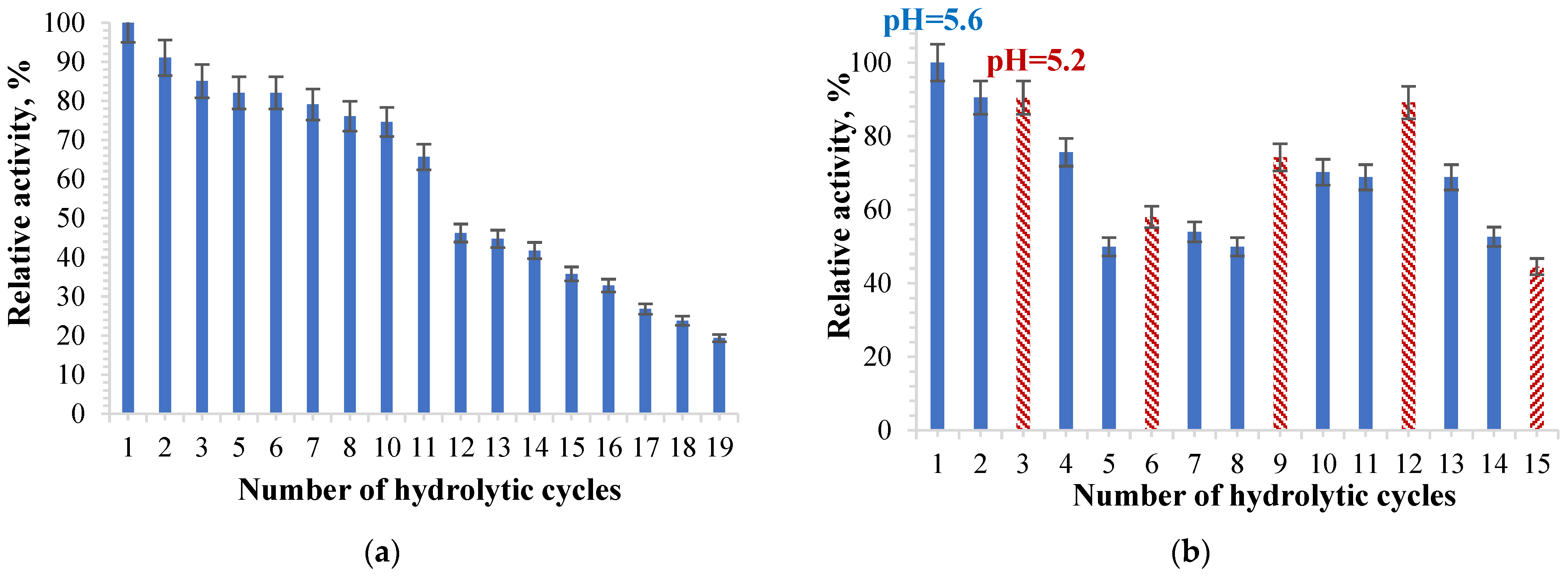

2.9. Enzymatic Activity Assay of the Immobilized Enzyme in Several Hydrolytic Cycles

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Free Enzyme Tests

- Preparation of Free Enzyme Solution

- Determination of the Enzymatic Activity of Free α-Amylase

- Establishing the Time Required for an Enzymatic Reaction

- Enzyme Activity Calibration Curve

3.2.2. Preparation of Particles Containing α-Amylase Immobilized in Gellan Matrix

3.2.3. Determination of the Optimal Temperature and Amount of α-Amylase That Can Be Encapsulated in Gellan Particles by Determining the Immobilization Efficiency and by Testing the Enzyme Activity

- Determination of Immobilization Efficiency, Ef%

- Determination of the Optimal Amount of Enzymes that Can Be Immobilized

- Determination of the Optimal Temperature for the Immobilization of α-Amylase

3.2.4. FT-IR Spectroscopy

3.2.5. Particle Morphology (Scanning Electron Microscopy)

3.2.6. Swelling Degree

3.2.7. Determination of the Michaelis–Menten Constant and the Maximum Hydrolysis Rate of Free and Immobilized α-Amylase

3.2.8. Influence of pH and Temperature on Enzymatic Activity

3.2.9. The Influence of NaCl Concentration on the Degree of Inhibition of Enzyme Activity for Free and Immobilized α-Amylase

- AC: enzymatic activity assay of NaCl-free α-amylase solution/particles used as a control solution;

- AP: enzymatic activity for the samples used in which the free or immobilized enzyme was immersed in different concentrations of NaCl.

3.2.10. Enzymatic Activity Testing of Particles Containing Immobilized Enzyme in Several Hydrolytic Cycles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Zhang, H.; Wang, L.; Shen, Q.; Wu, B.; Gao, P. A novel approach for estimating the relationship between the kinetics and thermodynamics of glycoside hydrolases. Acta Biochim. Biophys. Sin. 2011, 43, 409–417. [Google Scholar] [CrossRef] [PubMed]

- Chapman, J.; Ismail, A.E.; Dinu, C.Z. Industrial Applications of Enzymes: Recent Advances, Techniques, and Outlooks. Catalysts 2018, 8, 238. [Google Scholar] [CrossRef]

- Karmee, S.K. Moving towards the Application of Biocatalysis in Food Waste Biorefinery. Fermentation 2023, 9, 73. [Google Scholar] [CrossRef]

- Mohamad, N.R.; Marzuki, N.H.C.; Buang, N.A.; Huyop, F.; Wahab, R.A. An overview of technologies for immobilization of enzymes and surface analysis techniques for immobilized enzymes. Biotechnol. Biotechnol. Equip. 2015, 29, 205–220. [Google Scholar] [CrossRef] [PubMed]

- Reetz, M.T. What are the Limitations of Enzymes in Synthetic Organic Chemistry? Chem. Rec. 2016, 16, 2449–2459. [Google Scholar] [CrossRef]

- Miłek, J. Determination of Activation Energies and the Optimum Temperatures of Hydrolysis of Starch by α-Amylase from Porcine Pancreas. Molecules 2021, 26, 4117. [Google Scholar] [CrossRef]

- Sky-Peck, H.H.; Thuvasethakul, P. Human Pancreatic a-Amylase II. Effects of pH, Substrate and Ions on the Activity of the Enzyme. Ann. Clin. Lab. Sci. 1977, 7, 310–317. Available online: http://www.annclinlabsci.org/content/7/4/310.full.pdf+html (accessed on 1 June 2023).

- Bai, Y.; Atluri, S.; Zhang, Z.; Gidley, M.J.; Li, E.; Gilbert, R.G. Structural reasons for inhibitory effects of pectin on α-amylase enzyme activity and in-vitro digestibility of starch. Food Hydrocoll. 2021, 114, 106581. [Google Scholar] [CrossRef]

- Tallapragada, P.; Dikshit, R.; Jadhav, A.; Sarah, U. Partial purification and characterization of amylase enzyme under solid state fermentation from Monascus sanguineus. J. Genet. Eng. Biotechnol. 2017, 15, 95–101. [Google Scholar] [CrossRef]

- Nijabat, A.; Manzoor, S.; Faiz, S.; Naveed, N.H.; Bolton, A.; Khan, B.A.; Ali, A.; Simon, P. Variation in Seed Germination and Amylase Activity of Diverse Carrot (Daucus carota (L.)) Germplasm under Simulated Drought Stress. HortScience 2023, 58, 205–214. [Google Scholar] [CrossRef]

- Shohreh, A.; Behrouz, Z.; Seyedeh Fatemeh, S.M.; Kaveh, K.; Morteza, M.; Swapnoneel, R.; Ghasem, H.S. Highly Efficient Computationally Derived Novel Metagenome α-Amylase With Robust Stability Under Extreme Denaturing Conditions. Front. Microbiol. 2021, 12, 713125. Available online: https://www.frontiersin.org/articles/10.3389/fmicb.2021.713125 (accessed on 5 June 2023).

- Pan, S.; Yao, T.; Du, L.; Wei, Y. Site-saturation mutagenesis at amino acid 329 of Klebsiella pneumoniae halophilic α-amylase affects enzymatic properties. J. Biosci. Bioeng. 2020, 129, 155–159. [Google Scholar] [CrossRef] [PubMed]

- Che Hussian, C.H.A.; Leong, W.Y. Thermostable enzyme research advances: A bibliometric analysis. J. Genet. Eng. Biotechnol. 2023, 21, 37. [Google Scholar] [CrossRef] [PubMed]

- Mesbah Noha, M. Industrial Biotechnology Based on Enzymes From Extreme Environments. Front. Bioeng. Biotechnol. 2022, 10, 870083. Available online: https://www.frontiersin.org/articles/10.3389/fbioe.2022.870083 (accessed on 3 June 2023). [CrossRef] [PubMed]

- Guzik, U.; Hupert-Kocurek, K.; Wojcieszyńska, D. Immobilization as a Strategy for Improving Enzyme Properties-Application to Oxidoreductases. Molecules 2014, 19, 8995–9018. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.; Shen, J.; Salmon, S. Developing Enzyme Immobilization with Fibrous Membranes: Longevity and Characterization Considerations. Membranes 2023, 13, 532. [Google Scholar] [CrossRef]

- Xu, K.; Chen, X.; Zheng, R.; Zheng, Y. Immobilization of Multi-Enzymes on Support Materials for Efficient Biocatalysis. Front. Bioeng. Biotechnol. 2020, 8, 660. [Google Scholar] [CrossRef]

- Gupta, K.; Jana, A.K.; Kumar, S.; Maiti, M. Immobilization of amyloglucosidase from SSF of Aspergillus niger by crosslinked enzyme aggregate onto magnetic nanoparticles using minimum amount of carrier and characterizations. J. Mol. Catal. B Enzym. 2013, 98, 30–36. [Google Scholar] [CrossRef]

- Shan, Z.; Qianchun, D.; Ya, L.; Mingming, Z.; Chuyun, W.; Chang, Z.; Hu, T.; Fenghong, H.; Jie, S. Novel amphiphilic polyvinylpyrrolidone functionalized silicone particles as carrier for low-cost lipase immobilization. R. Soc. Open Sci. 2018, 5, 172368. [Google Scholar] [CrossRef]

- Kahar, U.M.; Sani, M.H.; Chan, K.-G.; Goh, K.M. Immobilization of α-Amylase from Anoxybacillus sp. SK3-4 on ReliZyme and Immobead Supports. Molecules 2016, 21, 1196. [Google Scholar] [CrossRef]

- Singh, R.K.; Tiwari, M.K.; Singh, R.; Lee, J.-K. From Protein Engineering to Immobilization: Promising Strategies for the Upgrade of Industrial Enzymes. Int. J. Mol. Sci. 2013, 14, 1232–1277. [Google Scholar] [CrossRef]

- Wu, H.; Mu, W. Application prospects and opportunities of inorganic nanomaterials for enzyme immobilization in the food-processing industry. Curr. Opin. Food Sci. 2022, 47, 100909. [Google Scholar] [CrossRef]

- Maghraby, Y.R.; El-Shabasy, R.M.; Ibrahim, A.H.; El-Said Azzazy, H.M. Enzyme Immobilization Technologies and Industrial Applications. ACS Omega 2023, 8, 5184–5196. [Google Scholar] [CrossRef]

- Rodrigues, R.C.; Berenguer-Murcia, Á.; Carballares, D.; Morellon-Sterling, R.; Fernandez-Lafuente, R. Stabilization of enzymes via immobilization: Multipoint covalent attachment and other stabilization strategies. Biotechnol. Adv. 2021, 52, 107821. [Google Scholar] [CrossRef]

- Almulaiky, Y.Q.; Aqlan, F.M.; Aldhahri, M.; Baeshen, M.; Khan, T.J.; Khan, K.A.; Afifi, M.; AL-Farga, A.; Warsi, M.K.; Alkhaled, M.; et al. α-Amylase Immobilization on Amidoximated Acrylic Microfibres Activated by Cyanuric Chloride. R. Soc. Open Sci. 2018, 5, 172164. Available online: https://royalsocietypublishing.org/doi/abs/10.1098/rsos.172164 (accessed on 3 June 2023). [CrossRef]

- Temoçin, Z. Immobilization of α-amylase on reactive modified fiber and its application for continuous starch hydrolysis in a packed bed bioreactor. Starch–Stärke 2014, 66, 376–384. [Google Scholar] [CrossRef]

- Talebi, M.; Vaezifar, S.; Jafary, F.; Fazilati, M.; Motamedi, S. Stability Improvement of Immobilized α-amylase using Nano Pore Zeolite. Iran. J. Biotechnol. 2016, 14, 33–38. Available online: https://www.ijbiotech.com/article_13562.html (accessed on 27 May 2023). [CrossRef] [PubMed]

- Pereira, S.E.; Fernandes, K.F.; Ulhoa, C.J. Immobilization of Cryptococcus flavus α-amylase on glass tubes and its application in starch hydrolysis. Starch–Stärke 2017, 69, 1600189. [Google Scholar] [CrossRef]

- Guzik, U.; Matos, M.J.; Pina, A.S.; Roque, A. Rational design of affinity ligands for bioseparation. J. Chromatogr. A 2020, 1619, 460871. [Google Scholar] [CrossRef]

- Boudrant, J.; Woodley, J.M.; Fernandez-Lafuente, R. Parameters necessary to define an immobilized enzyme preparation. Process. Biochem. 2020, 90, 66–80. [Google Scholar] [CrossRef]

- Datta, S.; Christena, L.R.; Rajaram, Y.R. Enzyme immobilization: An overview on techniques and support materials. 3 Biotech 2013, 3, 1–9. [Google Scholar] [CrossRef]

- Zucca, P.; Fernandez-Lafuente, R.; Sanjust, E. Agarose and Its Derivatives as Supports for Enzyme Immobilization. Molecules 2016, 21, 1577. [Google Scholar] [CrossRef] [PubMed]

- Azizi, V.; Mohammadi, M.; Rezaei Mokarram, R.; Sowti Khiabani, M.; Hamishehkar, H. Immobilization of α-amylase on modified magnetic zeolite (MAZE) coated with carboxymethyl cellulose (CMC) composite and its properties. LWT 2021, 144, 111214. [Google Scholar] [CrossRef]

- Kahraman, M.V.; Bayramoğlu, G.; Kayaman-Apohan, N.; Güngör, A. α-Amylase immobilization on functionalized glass beads by covalent attachment. Food Chem. 2007, 104, 1385–1392. [Google Scholar] [CrossRef]

- Silva, F.S.; Pio, F.S.; Ribeiro, E.J.; de Resende, M.M. Immobilization of alpha-amylase (Termamyl® 2X) in Duolite® A-568 resin. Biocatal. Agric. Biotechnol. 2023, 49, 102661. [Google Scholar] [CrossRef]

- Migneault, I.; Dartiguenave, C.; Bertrand, M.J.; Waldron, K.C. Glutaraldehyde: Behavior in aqueous solution, reaction with proteins, and application to enzyme crosslinking. BioTechniques 2004, 37, 790–802. [Google Scholar] [CrossRef] [PubMed]

- Serra, I.; Benucci, I.; Robescu, M.S.; Lombardelli, C.; Esti, M.; Calvio, C.; Pregnolato, M.; Terreni, M.; Bavaro, T. Developing a Novel Enzyme Immobilization Process by Activation of Epoxy Carriers with Glucosamine for Pharmaceutical and Food Applications. Catalysts 2019, 9, 843. [Google Scholar] [CrossRef]

- Basso, A.; Serban, S. Industrial applications of immobilized enzymes—A review. Mol. Catal. 2019, 479, 110607. [Google Scholar] [CrossRef]

- Takeuchi, T.; Kozu, T.; Watanabe, S.; Morita, M.; Shiratori, K.; Shibata, I. Substrate specificity for pancreatic amylase. Gastroenterol. Jpn. 1978, 13, 395–400. [Google Scholar] [CrossRef]

- Beyler-Çiğil, A.; Çakmakçı, E.; Danış, Ö.; Demir, S.; Kahraman, M.V. Alpha-amylase Immobilization on Modified Polyimide Material. Chem. Eng. Trans. 2013, 32, 1687–1692. Available online: https://www.aidic.it/cet/13/32/282.pdf (accessed on 2 June 2023).

- Mateo, C.; Palomo, J.M.; Fernandez-Lorente, G.; Guisan, J.M.; Fernandez-Lafuente, R. Improvement of enzyme activity, stability and selectivity via immobilization techniques. Enzyme Microb. Technol. 2007, 40, 1451–1463. [Google Scholar] [CrossRef]

- Zdarta, J.; Meyer, A.S.; Jesionowski, T.; Pinelo, M.A. General Overview of Support Materials for Enzyme Immobilization: Characteristics, Properties, Practical Utility. Catalysts 2018, 8, 92. [Google Scholar] [CrossRef]

- Al-Najada, A.R.; Almulaiky, Y.Q.; Aldhahri, M.; El-Shishtawy, R.M.; Mohamed, S.A.; Baeshen, M.; Al-Farga, A.; Abdulaal, W.H.; Al-Harbi, S.A. Immobilisation of α-amylase on activated amidrazone acrylic fabric: A new approach for the enhancement of enzyme stability and reusability. Sci. Rep. 2019, 9, 12672. [Google Scholar] [CrossRef]

- Jin, W.; Wang, Z.; Peng, D.; Shen, W.; Zhu, Z.; Cheng, S.; Li, B.; Huang, Q. Effect of linear charge density of polysaccharides on interactions with α-amylase: Self-Assembling behavior and application in enzyme immobilization. Food Chem. 2020, 331, 127320. [Google Scholar] [CrossRef] [PubMed]

- Cipolatti, E.P.; Silva, M.J.A.; Klein, M.; Feddern, V.; Feltes, M.M.C.; Oliveira, J.V.; Ninow, J.L.; de Oliveira, D. Current status and trends in enzymatic nano immobilization. J. Mol. Catal. B Enzym. 2014, 99, 56–67. [Google Scholar] [CrossRef]

- Singh, V.; Rakshit, K.; Rathee, S.; Angmo, S.; Kaushal, S.; Garg, P.; Chung, J.H.; Sandhir, R.; Sangwan, R.S.; Singhal, N. Metallic/bimetallic magnetic nanoparticle functionalization for immobilization of α-amylase for enhanced reusability in bio-catalytic processes. Bioresour. Technol. 2016, 214, 528–533. [Google Scholar] [CrossRef]

- Mafakher, L.; Ahmadi, Y.; Khalili Fard, J.; Yazdansetad, S.; Rezaei Gomari, S.; Elyasi Far, B. Alpha-Amylase Immobilization; Methods and Challenges. Pharm. Sci. 2022, 29, 144–155. Available online: https://ps.tbzmed.ac.ir/Article/ps-38190 (accessed on 27 March 2023). [CrossRef]

- Bié, J.; Sepodes, B.; Fernandes, P.C.B.; Ribeiro, M.H.L. Enzyme Immobilization and Co-Immobilization: Main Framework, Advances and Some Applications. Processes 2022, 10, 494. [Google Scholar] [CrossRef]

- Gonçalves, M.; Amaral, J.C.; Lopes, L.A.; Fernandez-Lafuente, R.; Tardioli, P.W. Stabilization and operational selectivity alteration of Lipozyme 435 by its coating with polyethyleneimine: Comparison of the biocatalyst performance in the synthesis of xylose fatty esters. Int. J. Biol. Macromol. 2021, 192, 665–674. [Google Scholar] [CrossRef]

- Imam, T.I.; Marr, P.C.; Marr, A.C. Enzyme entrapment, biocatalyst immobilization without covalent attachment. Green. Chem. 2021, 23, 4980–5005. [Google Scholar] [CrossRef]

- Nisha, S.; Karthick, S.A.; Gobi, N. A Review on Methods, Application and Properties of Immobilized Enzyme. Chem. Sci. Rev. Lett. 2012, 1, 148–155. Available online: https://chesci.com/wp-content/uploads/2016/12/V1i3_4_CS17204211.pdf (accessed on 27 March 2023).

- Thangaraj, B.; Solomon, P.R. Immobilization of lipases—A review. Part I: Enzyme immobilization. ChemBioEng. Rev. 2019, 6, 157–166. [Google Scholar] [CrossRef]

- Bilal, M.; Iqbal, H.M. Naturally-derived biopolymers: Potential platforms for enzyme immobilization. Int. J. Biol. Macromol. 2019, 130, 462–482. [Google Scholar] [CrossRef]

- Arruda, L.M.O.; Vitolo, M. Characterization of invertase entrapped into calcium alginate beads. Appl. Biochem. Biotechnol. 1999, 81, 23–33. [Google Scholar] [CrossRef]

- Quiroga, E.; Illanes, C.O.; Ochoa, N.A.; Barberis, S. Performance improvement of araujiain, a cystein phytoprotease, by immobilization within calcium alginate beads. Process. Biochem. 2011, 46, 1029–1034. [Google Scholar] [CrossRef]

- Sundarram, A.; Murthy, T.P.K. α-Amylase Production and Applications: A Review. Appl. Environ. Microbiol. 2014, 2, 166–175. Available online: https://pubs.sciepub.com/jaem/2/4/10 (accessed on 11 October 2022).

- Rodríguez, V.B.; Alameda, E.J.; Gallegos, J.F.M.; Requena, A.R.; López, A.I.G. Enzymatic Hydrolysis of Soluble Starch with an α-Amylase from Bacillus licheniformis. Biotechnol. Progress 2006, 22, 718–722. [Google Scholar] [CrossRef]

- Ishikawa, K.; Matsui, I.; Honda, K.; Kobayashi, S.; Nakatani, H. The pH dependence of the action pattern in porcine pancreatic alpha-amylase-catalyzed reaction for maltooligosaccharide substrates. Arch. Biochem. Biophys. 1991, 289, 124–129. [Google Scholar] [CrossRef] [PubMed]

- Warren, F.J.; Zhang, B.; Waltzer, G.; Gidley, M.J.; Dhital, S. The interplay of rmalpha-amylase and amyloglucosidase activities on the digestion of starch in in vitro enzymic systems. Carbohydr. Polym. 2015, 117, 192–200. [Google Scholar] [CrossRef]

- Far, B.E.; Ahmadi, Y.; Khosroshahi, A.Y.; Dilmaghani, A. Microbial Alpha-Amylase Production: Progress, Challenges and Perspectives. Adv. Pharm. Bull. 2020, 10, 350–358. [Google Scholar] [CrossRef]

- Tiarsa, E.R.; Yandri, Y.; Suhartati, T.; Satria, H.; Irawan, B.; Hadi, S. The Stability Improvement of Aspergillus fumigatus α-Amylase by Immobilization onto Chitin-Bentonite Hybrid. Biochem. Res. Int. 2022, 2022, 5692438. [Google Scholar] [CrossRef]

- Umit, U.; Melike, Y.A. Immobilization and some application of α-amylase purified from Rhizoctonia solani AG-4 strain ZB-34. Turkish J. Biochem. 2019, 44, 397–407. [Google Scholar] [CrossRef]

- Qin, T.; Liu, Y.; Zhao, H.; Xia, X.; Lei, X. Cloning, expression, and characterization of a porcine pancreatic α-amylase in Pichia pastoris. Anim. Nutr. 2018, 4, 234–240. [Google Scholar] [CrossRef]

- Robyt, J.F.; French, D. Multiple attack hypothesis of α-amylase action: Action of porcine pancreatic, human salivary, and aspergillus oryzae α-amylases. Arch. Biochem. Biophys. 1967, 122, 8–16. [Google Scholar] [CrossRef] [PubMed]

- Robyt, J.F.; French, D. The action pattern of porcine pancreatic α-amylase in relationship to the substrate binding site of the enzyme. J. Biol. Chem. 1970, 245, 3917–3927. [Google Scholar] [CrossRef]

- Breyer, W.A.; Matthews, B.W. A structural basis for processivity. Protein Sci. 2001, 10, 1699–1711. [Google Scholar] [CrossRef]

- Larson, S.B.; Day, J.S.; McPherson, A. X-ray Crystallographic Analyses of Pig Pancreatic α-Amylase with Limit Dextrin, Oligosaccharide and α-Cyclodextrin. Biochemistry 2010, 49, 3101. [Google Scholar] [CrossRef]

- Kyukiumar, S.; Chakravarty, S. Amylases. In Enzymes in Human and Animal Nutrition; Nunes, C.S., Kumar, V., Eds.; Academic Press: New York, NY, USA; Elsevier Inc.: Amsterdam, The Netherlands, 2018; pp. 163–180. [Google Scholar] [CrossRef]

- Anitha Gopal, B.; Muralikrishna, G. Porcine Pancreatic α-Amylase and its Isoforms: Purification and Kinetic Studies. Int. J. Food Prop. 2009, 12, 571–586. [Google Scholar] [CrossRef]

- Fatoki, O.A.; Onilude, A.A. Characterisation of alpha-amylase inhibitor from Streptomyces xinghaiensis AAI2 in solid substrate. Sci. Afr. 2022, 15, e01086. [Google Scholar] [CrossRef]

- Liao, M.; Liang, G.; Zhu, J.; Lu, B.; Peng, X.; Wang, Y.; Wei, T.; Zhou, P.; Huang, B. Influence of Calcium Ions on the Thermal Characteristics of α-amylase from Thermophilic Anoxybacillus sp. GXS-BL. Protein Pept. Lett. 2019, 26, 148–157. [Google Scholar] [CrossRef]

- Prejanò, M.; Alberto, M.E.; Russo, N.; Toscano, M.; Marino, T. The Effects of the Metal Ion Substitution into the Active Site of Metalloenzymes: A Theoretical Insight on Some Selected Cases. Catalysts 2020, 10, 1038. [Google Scholar] [CrossRef]

- Saha, K.; Maity, S.; Roy, S.; Pahan, K.; Pathak, R.; Majumdar, S.; Gupta, S. Optimization of Amylase Production from B. amyloliquefaciens (MTCC 1270) Using Solid State Fermentation. Int. J. Microbiol. 2014, 2014, 764046. [Google Scholar] [CrossRef]

- Hardwicke, J.T.; Hart, J.; Bell, A.; Duncan, R.; Thomas, D.W.; Moseley, R. The effect of dextrin–rhEGF on the healing of full-thickness, excisional wounds in the (db/db) diabetic mouse. J. Control. Release 2011, 152, 411–417. [Google Scholar] [CrossRef] [PubMed]

- Hardwicke, J.; Ferguson, E.L.; Moseley, R.; Stephens, P.; Thomas, D.W.; Duncan, R. Dextrin–rhEGF conjugates as bioresponsive nanomedicines for wound repair. J. Control. Release 2008, 130, 275–283. [Google Scholar] [CrossRef]

- Azzopardi, E.A.; Conlan, R.S.; Whitaker, I.S. Polymer therapeutics in surgery: The next frontier. J. Interdiscip. Nanomed. 2016, 1, 19–29. [Google Scholar] [CrossRef]

- Ritivoiu, M.-E.; Drăgoi, C.M.; Matei, D.; Stan, I.V.; Nicolae, A.C.; Craiu, M.; Dumitrescu, I.-B.; Ciolpan, A.A. Current and Future Therapeutic Approaches of Exocrine Pancreatic Insufficiency in Children with Cystic Fibrosis in the Era of Personalized Medicine. Pharmaceutics 2023, 15, 162. [Google Scholar] [CrossRef]

- Iurciuc, C.E.; Savin, A.; Lungu, C.; Martin, P.; Popa, M. Gellan. Food Applications. Cell. Chem. Technol. 2016, 50, 1–13. Available online: https://cellulosechemtechnol.ro/pdf/CCT1(2016)/p.1-13.pdf (accessed on 10 September 2022).

- Iurciuc, C.E.; Lungu, C.; Martin, P.; Popa, M. Gellan. Pharmaceutical, Medical and Cosmetic Applications. Cell. Chem. Technol. 2017, 51, 187–202. Available online: https://www.cellulosechemtechnol.ro/pdf/CCT3-4(2017)/p.187-202.pdf (accessed on 10 September 2022).

- Chakraborty, S.; Jana, S.; Gandhi, A.; Sen, K.K.; Zhiang, W.; Kokare, C. Gellan gum microspheres containing a novel α-amylase from marine Nocardiopsis sp. strain B2 for immobilization. Int. J. Biol. Macromol. 2014, 70, 292–299. [Google Scholar] [CrossRef] [PubMed]

- Jadhav, S.B.; Singhal, R.S. Screening of polysaccharides for preparation of α-amylase conjugate to enhance stability and storage life. Carbohydr. Polym. 2013, 92, 1724–1729. [Google Scholar] [CrossRef]

- Iurciuc, C.E.; Alupei, L.; Savin, A.; Ibănescu, C.; Martin, P.; Popa, M. Yeast cells immobilized in spherical gellan particles cross-linked with magnesium acetate. J. Biotechnol. 2016, 236, 45–56. [Google Scholar] [CrossRef] [PubMed]

- Iurciuc, C.E.; Peptu, C.; Savin, A.; Atanase, L.I.; Souidi, K.; Mackenzie, G.; Martin, P.; Riess, G.; Popa, M. Microencapsulation of Baker’s Yeast in Gellan Gum Beads Used in Repeated Cycles of Glucose Fermentation. Int. J. Polym. Sci. 2017, 2017, 7610420. [Google Scholar]

- Iurciuc, C.E.; Savin, A.; Atanase, L.I.; Danu, M.; Martin, P.; Popa, M. Encapsulation of Saccharomyces cerevisiae in hydrogel particles based gellan ionically cross-linked with zinc acetate. Powder Technol. 2018, 325, 476–489. [Google Scholar] [CrossRef]

- Swami, O.C.; Shah, N.J. Functional dyspepsia and the role of digestive enzymes supplement in its therapy. Int. J. Basic Clin. Pharmacol. 2017, 6, 1035–1041. [Google Scholar] [CrossRef]

- Iurciuc-Tincu, C.E.; Atanase, L.I.; Ochiuz, L.; Jérôme, C.; Sol, V.; Martin, P.; Popa, M. Curcumin-loaded polysaccharides-based complex particles obtained by polyelectrolyte complexation and ionic gelation. I-Particles obtaining and characterization. Int. J. Biol. Macromol. 2020, 147, 629–642. [Google Scholar] [CrossRef]

- Oliveira, H.M.; Pinheiro, A.Q.; Fonseca, A.J.; Cabrita, A.R.; Maia, M.R. Flexible and expeditious assay for quantitative monitoring of alpha-amylase and amyloglucosidase activities. MethodsX 2019, 6, 246–258. [Google Scholar] [CrossRef]

- Xiao, Z.; Storms, R.; Tsang, A. A quantitative starch–iodine method for measuring alpha-amylase and glucoamylase activities. Anal. Biochem. 2006, 351, 146–148. [Google Scholar] [CrossRef]

- Aksoy, S.; Tumturk, H.; Hasirci, N. Stability of α-amylase immobilized on poly(methylmethacrylate-acrylic acid) microspheres. J. Biotechnol. 1998, 60, 37–46. [Google Scholar] [CrossRef]

- Guo, H.; Tang, Y.; Yu, Y.; Xue, L.; Qian, J.-Q. Covalent immobilization of α-amylase on magnetic particles as catalyst for hydrolysis of high-amylose starch. Int. J. Biol. Macromol. 2016, 87, 537–544. [Google Scholar] [CrossRef]

- Sohrabi, N.; Rasouli, N.; Torkzadeh, M. Enhanced stability and catalytic activity of immobilized α-amylase on modified Fe3O4 nanoparticles. Chem. Eng. J. 2014, 240, 426–433. [Google Scholar] [CrossRef]

- Akhond, M.; Pashangeh, K.; Karbalaei-Heidari, H.R.; Absalan, G. Efficient Immobilization of Porcine Pancreatic α-Amylase on Amino-Functionalized Magnetite Nanoparticles: Characterization and Stability Evaluation of the Immobilized Enzyme. Appl. Biochem. Biotechnol. 2016, 180, 954–968. [Google Scholar] [CrossRef]

- Derkach, S.R.; Voron’ko, N.G.; Sokolan, N.I.; Kolotova, D.S.; Kuchina, Y.A. Interactions between gelatin and sodium alginate: UV and FTIR studies. J. Dispers. Sci. Technol. 2020, 41, 690–698. [Google Scholar] [CrossRef]

- Ernest, V.; Nirmala, M.J.; Gajalakshmi, S.; Mukherjee, A.; Chandrasekaran, N. Biophysical Investigation of α-Amylase Conjugated Silver Nanoparticles Proves Structural Changes Besides Increasing Its Enzyme Activity. J. Bionanosci. 2013, 7, 271–275. [Google Scholar] [CrossRef]

- Mikula, K.; Skrzypczak, D.; Ligas, B.; Witek-Krowiak, A. Preparation of hydrogel composites using Ca2+ and Cu2+ ions as cross-linking agents. SN Appl. Sci. 2019, 1, 643. [Google Scholar] [CrossRef]

- Charlet, A.; Lutz-Bueno, V.; Mezzenga, R.; Amstad, E. Shape retaining self-healing metal-coordinated hydrogels. Nanoscale 2021, 13, 4073–4084. [Google Scholar] [CrossRef]

- Fukuda, H. Polyelectrolyte Complexes of Chitosan with Sodium Carboxymethylcellulose. Bull. Chem. Soc. Jpn. 1980, 53, 837–840. [Google Scholar] [CrossRef]

- Dellali, M.; Iurciuc, C.E.; Savin, C.L.; Spahis, N.; Djennad, M.; Popa, M. Hydrogel Films Based on Chitosan and Oxidized Carboxymethylcellulose Optimized for the Controlled Release of Curcumin with Applications in Treating Dermatological Conditions. Molecules 2021, 26, 2185. [Google Scholar] [CrossRef]

- Derkach, S.R.; Kuchina, Y.A. Intermolecular Interactions in the Formation of Polysaccharide-Gelatin Complexes: A Spectroscopic Study. Polymers 2022, 14, 2777. [Google Scholar] [CrossRef] [PubMed]

- Kanyuck, K.M.; Mills, T.B.; Norton, I.T.; Norton-Welch, A.B. Swelling of high acyl gellan gum hydrogel: Characterization of network strengthening and slower release. Carbohydr. Polym. 2021, 259, 117758. [Google Scholar] [CrossRef]

- Picone, C.S.F.; Cunha, R.L. Influence of pH on formation and properties of gellan gels. Carbohydr. Polym. 2011, 84, 662–668. [Google Scholar] [CrossRef]

- Santos, T.P.; Cunha, R.L. Role of process variables on the formation and in vitro digestion of gellan gels. Carbohydr. Polym. 2018, 192, 111–117. [Google Scholar] [CrossRef]

- Talekar, S.; Chavare, S. Optimization of Immobilization of α-Amylase in Alginate Gel and Its Comparative Biochemical Studies with Free α-Amylase. Recent. Res. Sci. Technol. 2012, 4, 1–5. Available online: https://updatepublishing.com/journal/index.php/rrst/article/view/861/845 (accessed on 10 May 2023).

- Zhang, C.; Grossier, R.; Candoni, N.; Veesler, S. Preparation of alginate hydrogel microparticles by gelation introducing cross-linkers using droplet-based microfluidics: A review of methods. Biomater. Res. 2021, 25, 41. [Google Scholar] [CrossRef] [PubMed]

- Lyu, X.; Gonzalez, R.; Horton, A.; Li, T. Immobilization of Enzymes by Polymeric Materials. Catalysts 2021, 11, 1211. [Google Scholar] [CrossRef]

- Yadav, J.K.; Prakash, V. Stabilization of α-Amylase, the Key Enzyme in Carbohydrates Properties Alterations, at Low pH. Int. J. Food Prop. 2011, 14, 1182–1196. [Google Scholar] [CrossRef]

- Ahmed, N.E.; El Shamy, A.R.; Awad, H.M. Optimization and immobilization of amylase produced by Aspergillus terreus using pomegranate peel waste. Bull. Natl. Res. Cent. 2020, 44, 109. [Google Scholar] [CrossRef]

- El-Banna, T.E.; Abd-Aziz, A.A.; Abou-Dobara, M.I.; Reham, I.I. Production and Immobilization of α-Amylase from Bacillus subtilis. Pak. J. Biol. Sci. 2007, 10, 2039–2047. Available online: https://scialert.net/abstract/?doi=pjbs.2007.2039.2047 (accessed on 10 March 2023).

- Hemanchi, H.K.; Sanjay, N.P. Immobilization of α-Amylase by Entrapment Method and Its Comparative Study with Free α-Amylase. Int. J. Res. Appl. Sci. Eng. Technol. 2019, 7, 293. Available online: https://www.ijraset.com/fileserve.php?FID=22019 (accessed on 1 June 2022).

- Udema, I.I. Calcium Ion Binding Characteristics of Porcine Pancreatic AlphaAmylase outside Active Site Domain and Implications: Theory and Experimentation. Adv. Res. 2016, 7, 1–17. [Google Scholar] [CrossRef]

- Castañeda Ruiz, A.J.; Shetab Boushehri, M.A.; Phan, T.; Carle, S.; Garidel, P.; Buske, J.; Lamprecht, A. Alternative Excipients for Protein Stabilization in Protein Therapeutics: Overcoming the Limitations of Polysorbates. Pharmaceutics 2022, 14, 2575. [Google Scholar] [CrossRef]

- Singh, V.; Kumar, P. Carboxymethyl tamarind gum–silica nanohybrids for effective immobilization of amylase. J. Mol. Catal. B Enzym. 2011, 70, 67–73. [Google Scholar] [CrossRef]

- Sinha, R.; Khare, S.K. Protective role of salt in catalysis and maintaining structure of halophilic proteins against denaturation. Front. Microbiol. 2014, 5, 165. [Google Scholar] [CrossRef]

- Dutta, T.K.; Jana, M.; Pahari, P.R.; Bhattacharya, T. The Effect of Temperature, pH, and Salt on Amylase in Heliodiaptomus viduus (Gurney) (Crustacea: Copepoda: Calanoida). Turk. Zool. Derg. 2006, 30, 187–195. Available online: http://journals.tubitak.gov.tr/zoology/issues/zoo-06-30-2/zoo-30-2-11-0507-14.pdf (accessed on 4 March 2023).

- Dey, G.; Singh, B.; Banerjee, R. Immobilization of α-Amylase Produced by Bacillus circulans GRS 313. Braz. Arch. Biol. Technol. 2003, 46, 167–176. Available online: https://www.scielo.br/j/babt/a/gSsLsWyR3nXHGtFPdyQXTVF/?format=pdf&lang=en (accessed on 4 March 2023). [CrossRef]

- Qiu, H.; Xu, C.; Huang, X.; Ding, Y.; Qu, Y.; Gao, P. Immobilization of Laccase on Nanoporous Gold: Comparative Studies on the Immobilization Strategies and the Particle Size Effects. J. Phys. Chem. C 2009, 113, 2521–2525. [Google Scholar] [CrossRef]

- Defaei, M.; Taheri-Kafrani, A.; Miroliaei, M.; Yaghmaei, P. Improvement of stability and reusability of α-amylase immobilized on naringin functionalized magnetic nanoparticles: A robust nanobiocatalyst. Int. J. Biol. Macromol. 2018, 113, 354–360. [Google Scholar] [CrossRef]

- Yoo, Y.J.; Hong, J.; Hatch, R.T. Comparison of alpha-amylase activities from different assay methods. Biotechnol. Bioeng. 1987, 30, 147–151. [Google Scholar] [CrossRef] [PubMed]

- Lowry, O.H.; Rosebrough, N.J.; Farr, A.L.; Randall, R.J. Protein Measurement with the Folin Phenol Reagent. J. Biol. Chem. 1951, 193, 265–275. Available online: https://www.jbc.org/article/S0021-9258(19)52451-6/pdf (accessed on 3 March 2019). [CrossRef] [PubMed]

- Al-Mayah, A.M.R. Simulation of Enzyme Catalysis in Calcium Alginate Beads. Enzyme Res. 2012, 2012, 459190. [Google Scholar] [CrossRef]

| Sample Code * | α-Amylase Concentration, mg/mL | Magnesium Acetate Concentration, % | Immobilization Efficiency, Ef% | Enzymatic Activity/g of Particles·mL |

|---|---|---|---|---|

| A1 | 1 | 2 | 66.7 ± 4.8 | 3.97 ± 0.3 |

| A2 | 2 | 2 | 68.45 ± 6.6 | 4.36 ± 0.05 |

| A3 | 3 | 1 | 63.49 ± 1.6 | 4.71 ± 0.05 |

| A4 | 3 | 2 | 75.56 ± 5.1 | 4.28 ± 0.15 |

| A5 | 3 | 3 | 89.68 ± 3.1 | 4.15 ± 0.05 |

| A6 | 3.5 | 2 | 66.89 ± 0.6 | 3.83 ± 0.1 |

| A7 | 4 | 2 | 66.07 ± 0.6 | 4.63 ± 0.05 |

| A8 | 5 | 2 | 56.9 ± 1.7 | 3.66 ± 0.05 |

| Sample | Km (mmoles) | Vmax (µmoles Hydrolyzed Starch/mL·min) |

|---|---|---|

| Free enzyme | 0.0128 ± 0.0028 | 0.65 ± 0.043 |

| A3 | 0.014 ± 0.001 | 0.53 ± 0.011 |

| A4 | 0.0248 ± 0.008 | 0.33 ± 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tincu, C.E.; Bouhadiba, B.; Atanase, L.I.; Stan, C.S.; Popa, M.; Ochiuz, L. An Accessible Method to Improve the Stability and Reusability of Porcine Pancreatic α-Amylase via Immobilization in Gellan-Based Hydrogel Particles Obtained by Ionic Cross-Linking with Mg2+ Ions. Molecules 2023, 28, 4695. https://doi.org/10.3390/molecules28124695

Tincu CE, Bouhadiba B, Atanase LI, Stan CS, Popa M, Ochiuz L. An Accessible Method to Improve the Stability and Reusability of Porcine Pancreatic α-Amylase via Immobilization in Gellan-Based Hydrogel Particles Obtained by Ionic Cross-Linking with Mg2+ Ions. Molecules. 2023; 28(12):4695. https://doi.org/10.3390/molecules28124695

Chicago/Turabian StyleTincu (Iurciuc), Camelia Elena, Brahim Bouhadiba, Leonard Ionut Atanase, Corneliu Sergiu Stan, Marcel Popa, and Lăcrămioara Ochiuz. 2023. "An Accessible Method to Improve the Stability and Reusability of Porcine Pancreatic α-Amylase via Immobilization in Gellan-Based Hydrogel Particles Obtained by Ionic Cross-Linking with Mg2+ Ions" Molecules 28, no. 12: 4695. https://doi.org/10.3390/molecules28124695

APA StyleTincu, C. E., Bouhadiba, B., Atanase, L. I., Stan, C. S., Popa, M., & Ochiuz, L. (2023). An Accessible Method to Improve the Stability and Reusability of Porcine Pancreatic α-Amylase via Immobilization in Gellan-Based Hydrogel Particles Obtained by Ionic Cross-Linking with Mg2+ Ions. Molecules, 28(12), 4695. https://doi.org/10.3390/molecules28124695

.png)