Recent Progresses in Solution-Processed Tandem Organic and Quantum Dots Light-Emitting Diodes

Abstract

1. Introduction

2. ICLs for Tandem Devices

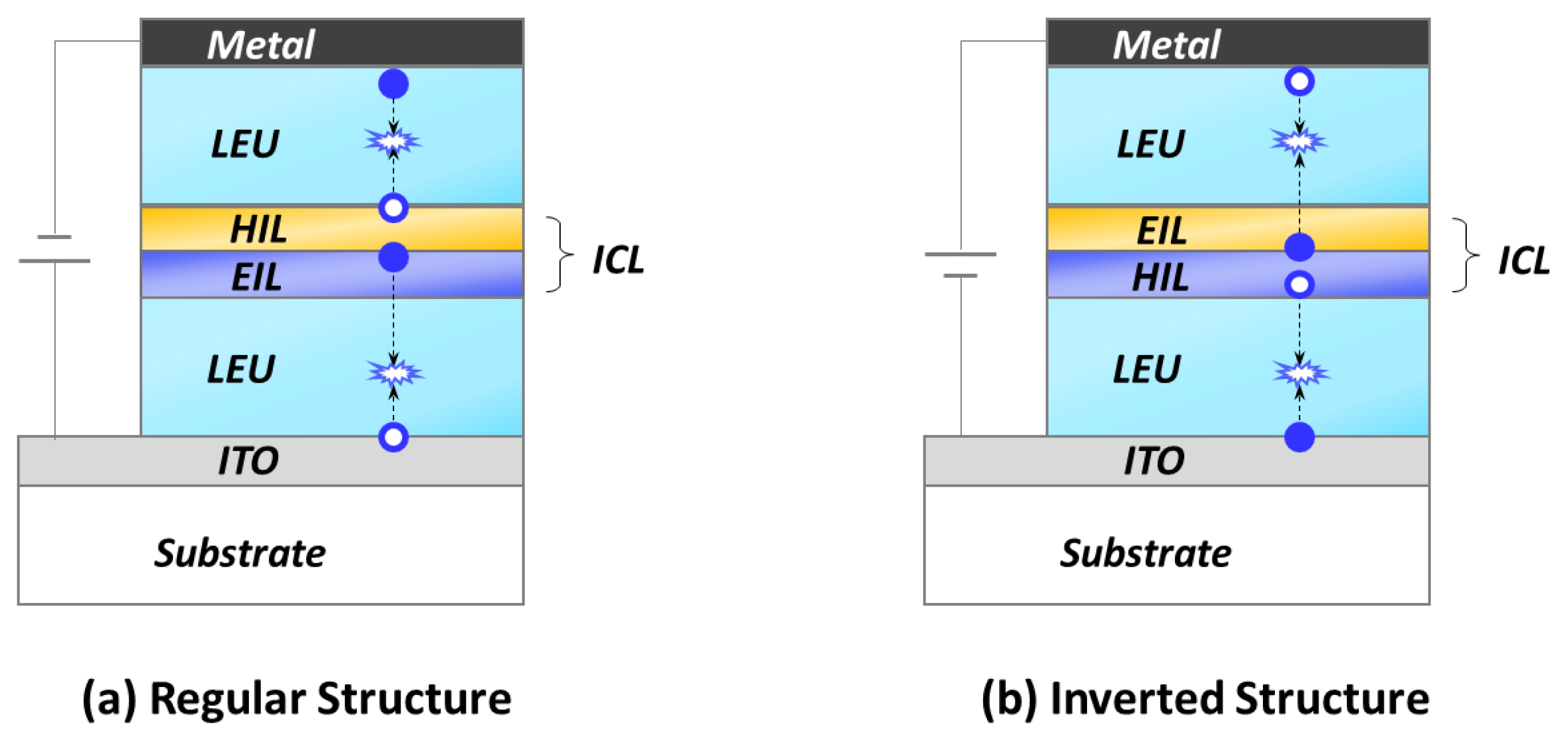

2.1. Type of ICLs

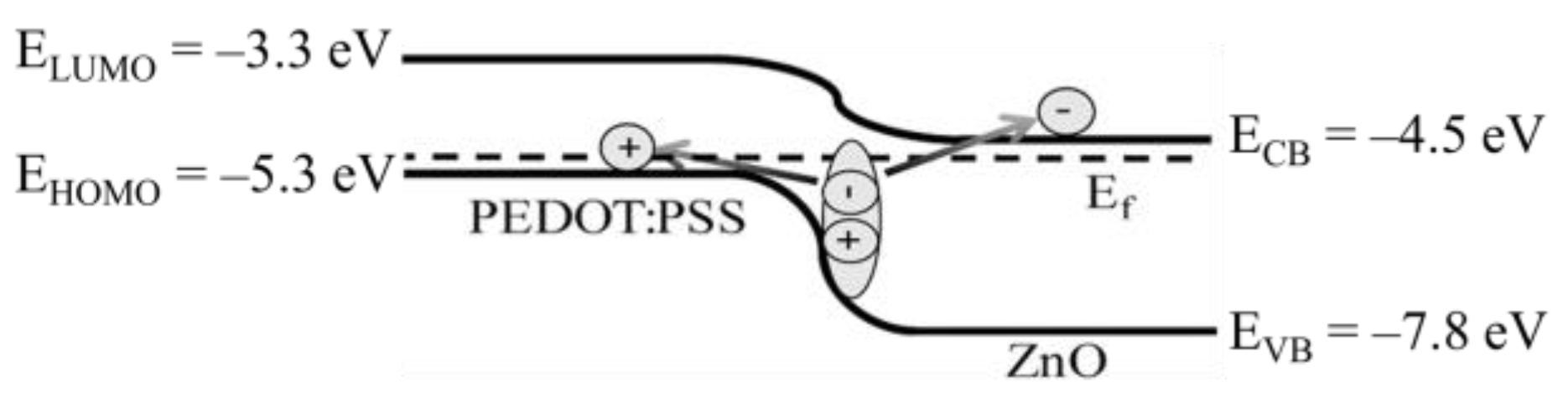

2.2. Charge Generation Mechanism

2.3. Remaining Issues

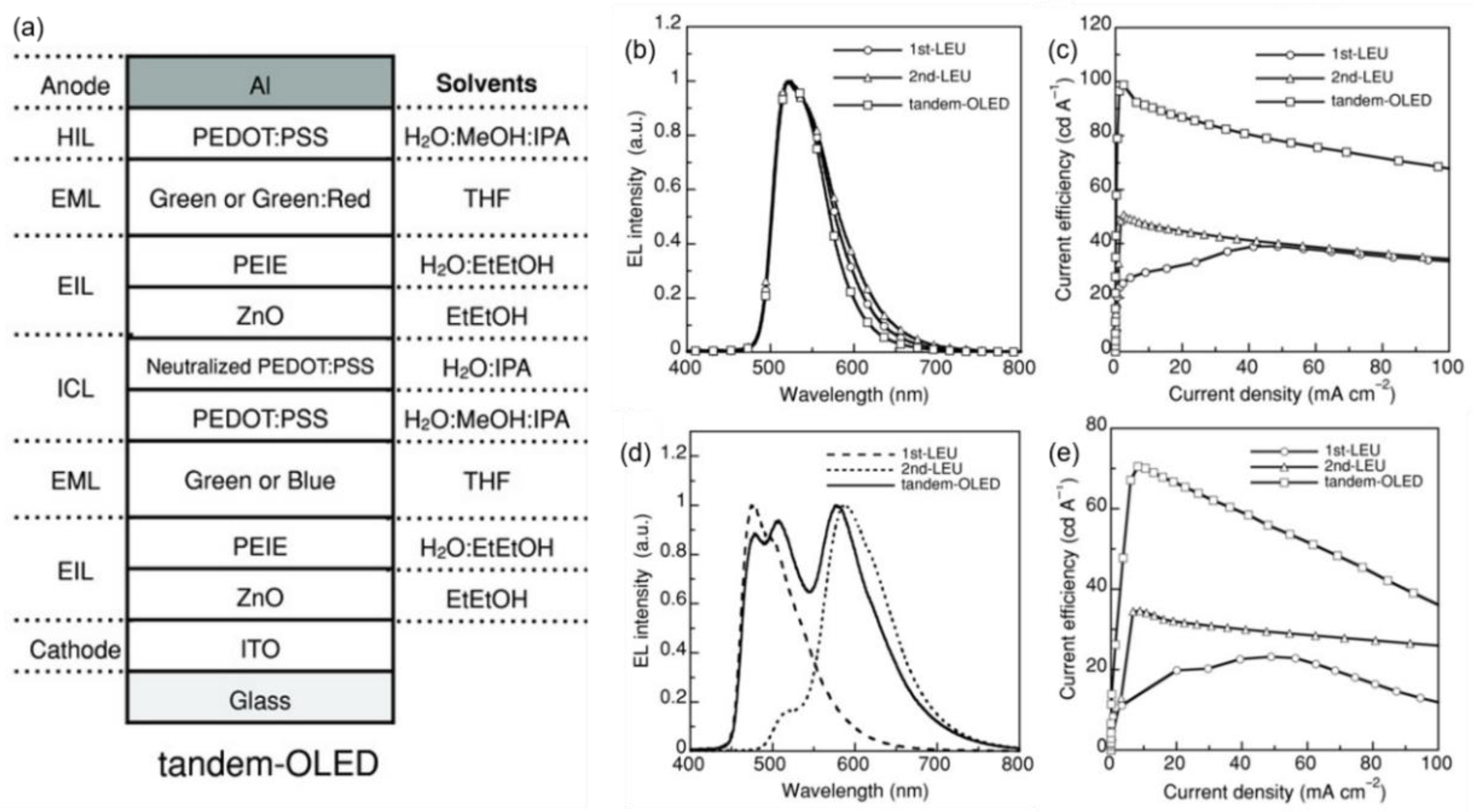

3. Solution-Processed Tandem OLEDs

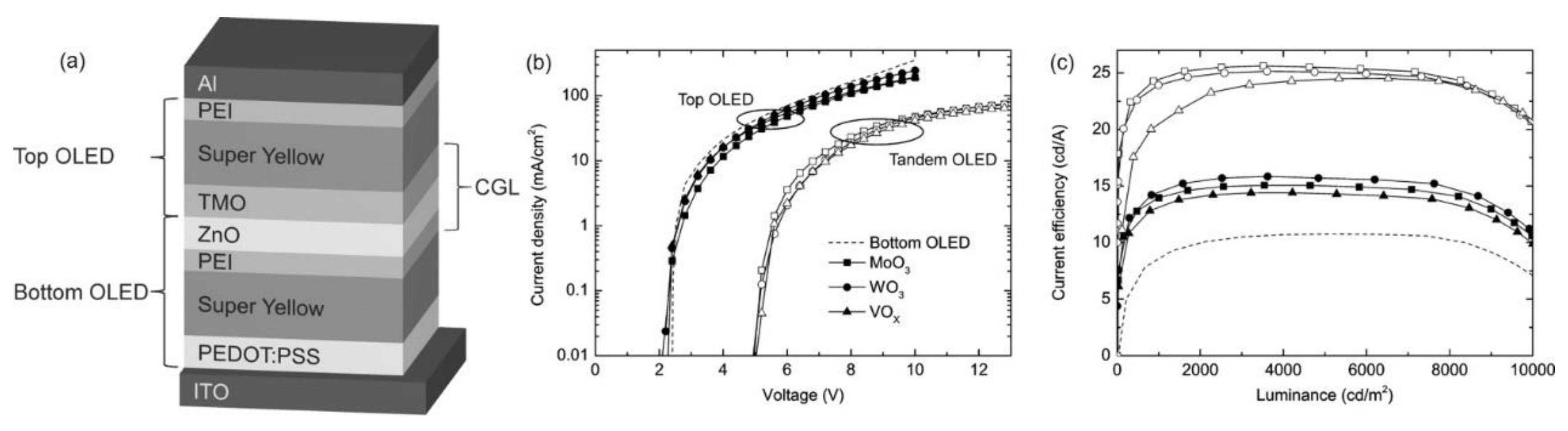

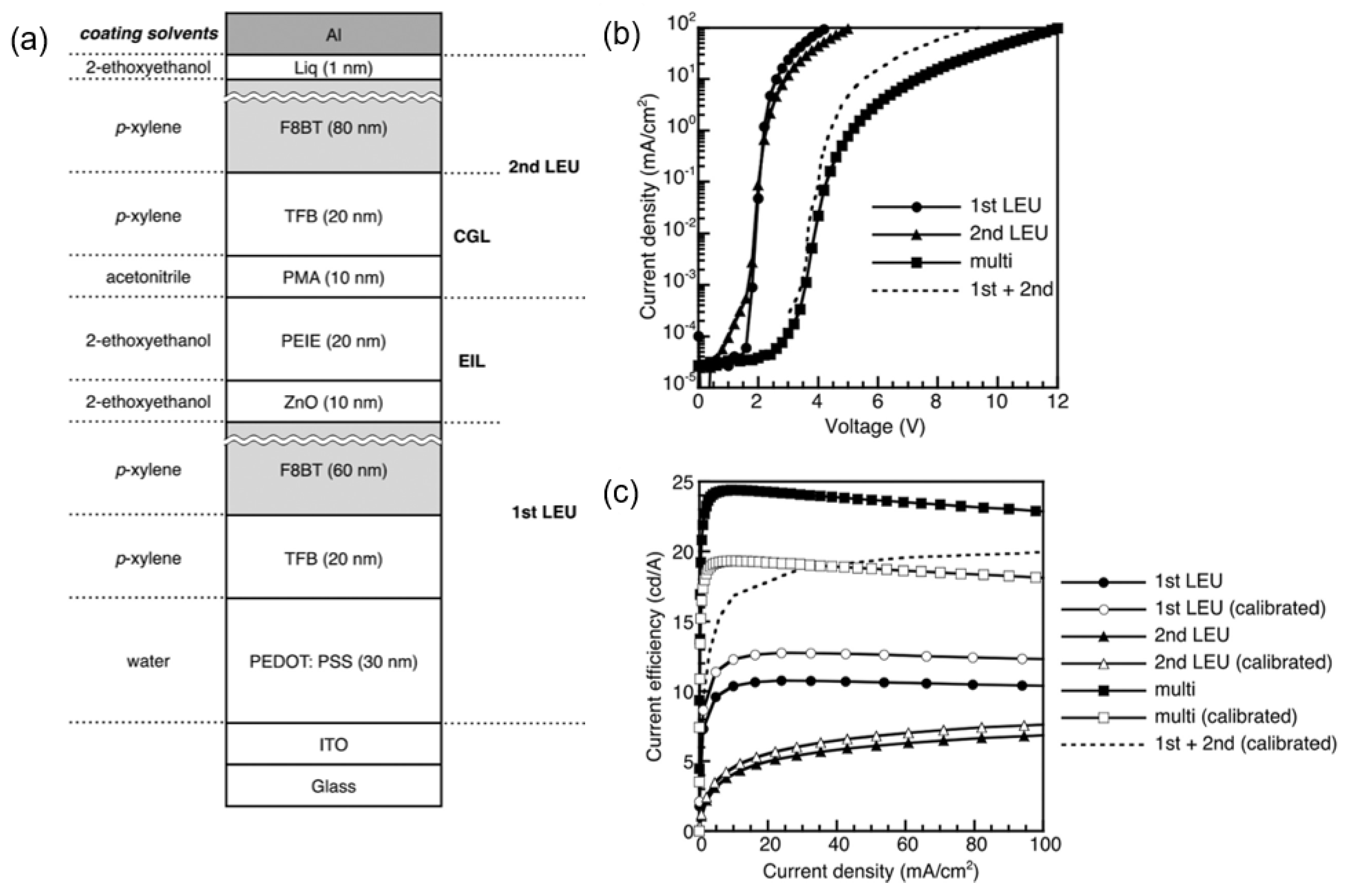

3.1. ICLs for Regular Structures

3.2. ICLs for Inverted Structures

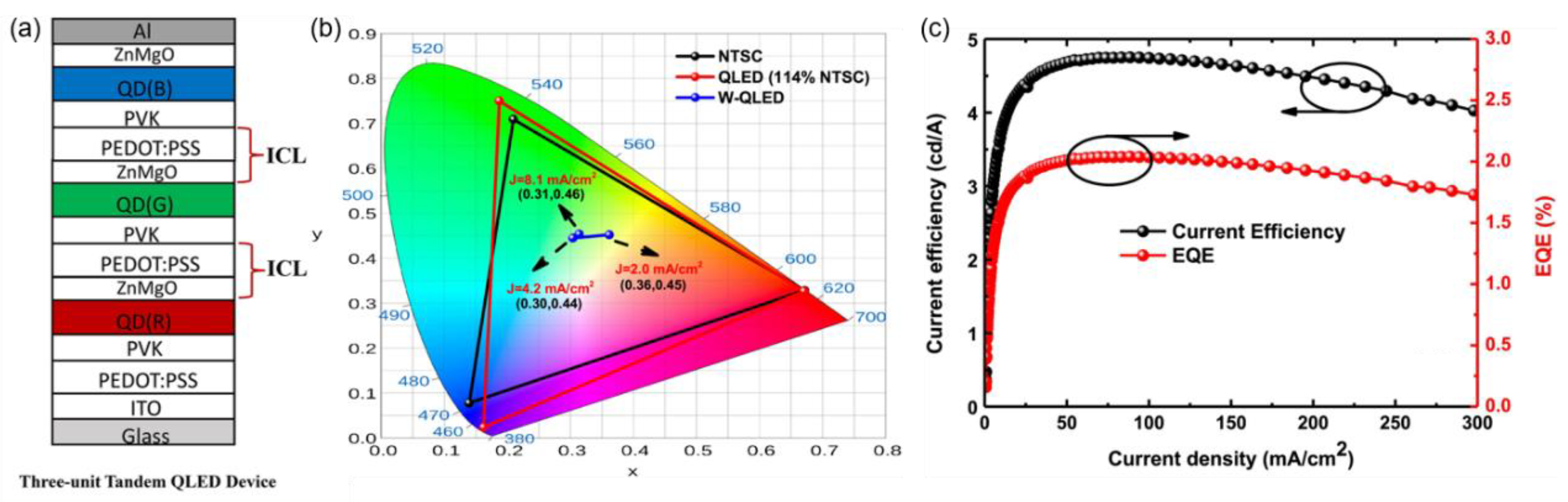

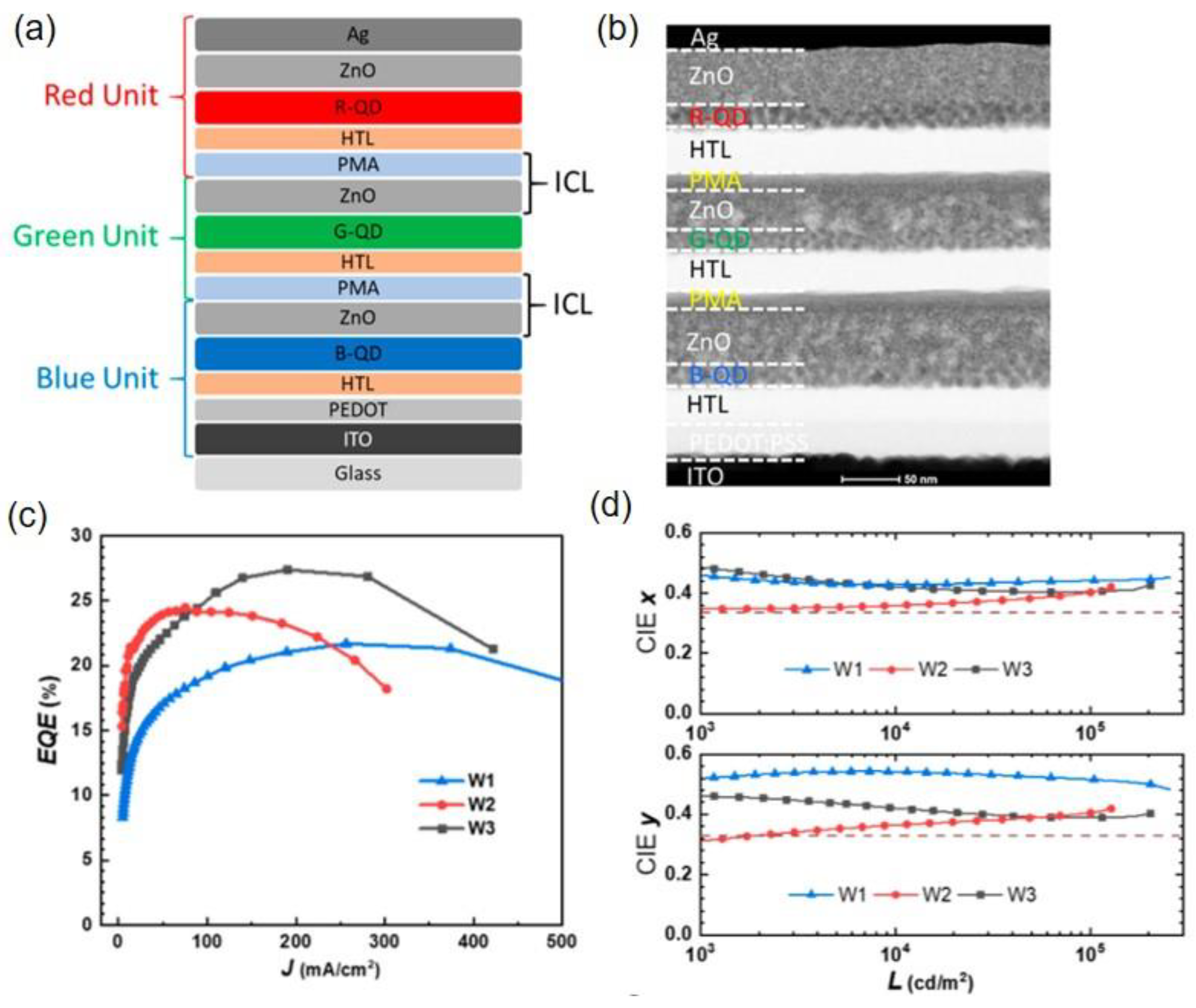

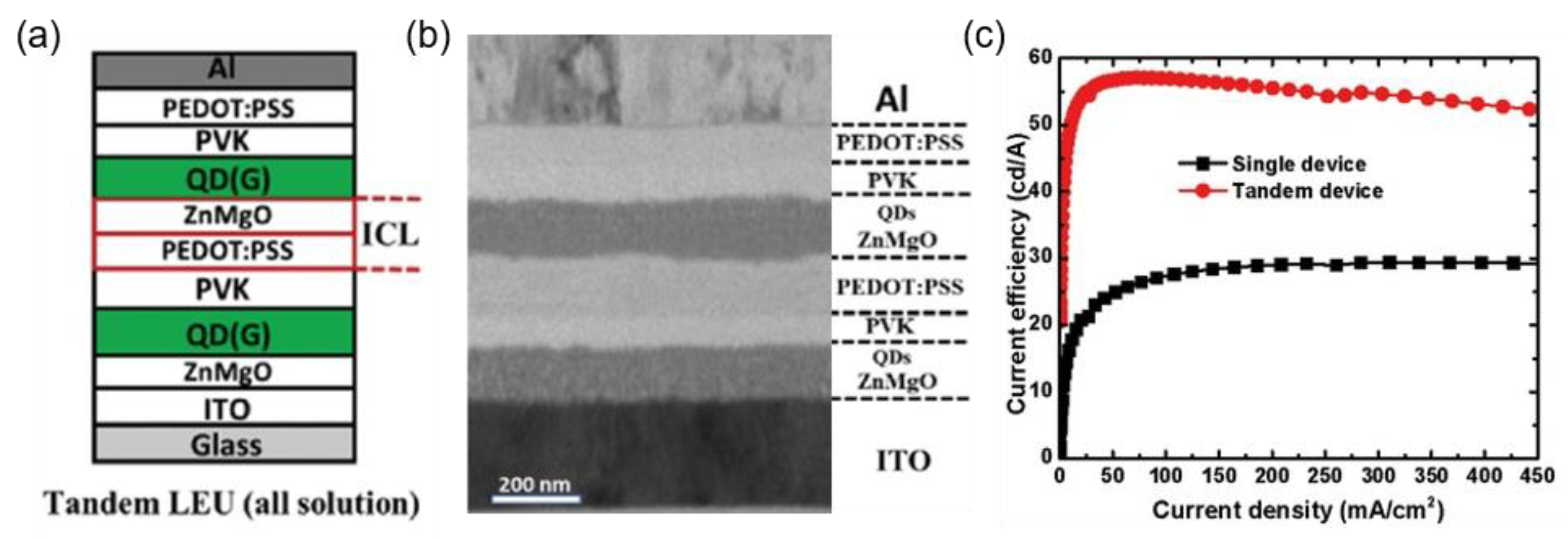

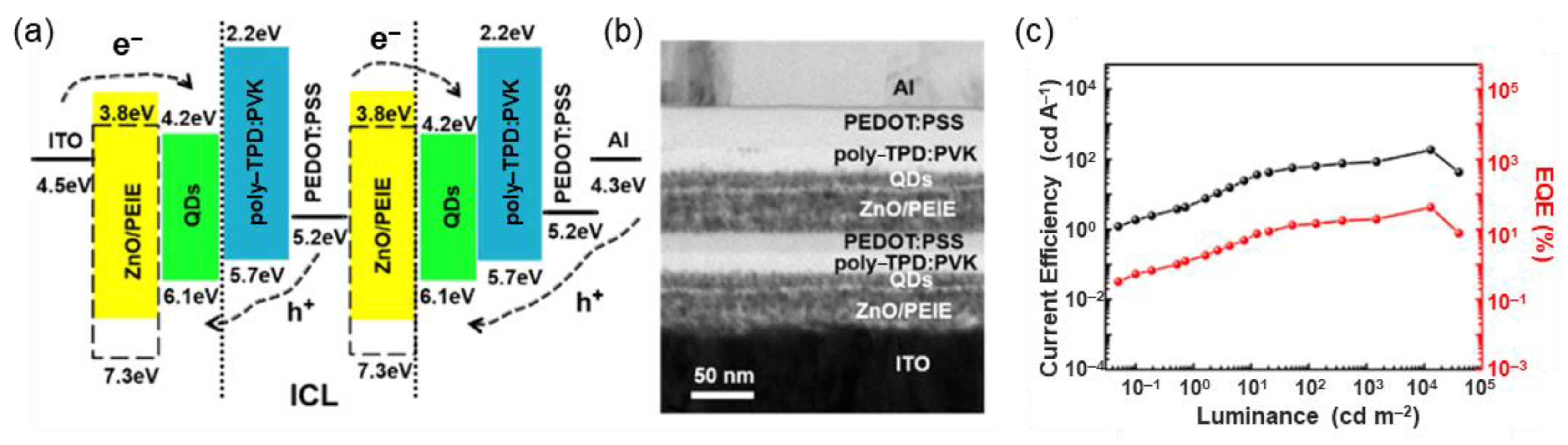

4. Solution-Processed Tandem QLEDs

4.1. ICLs for Regular Structure

4.2. ICLs for Inverted Structure

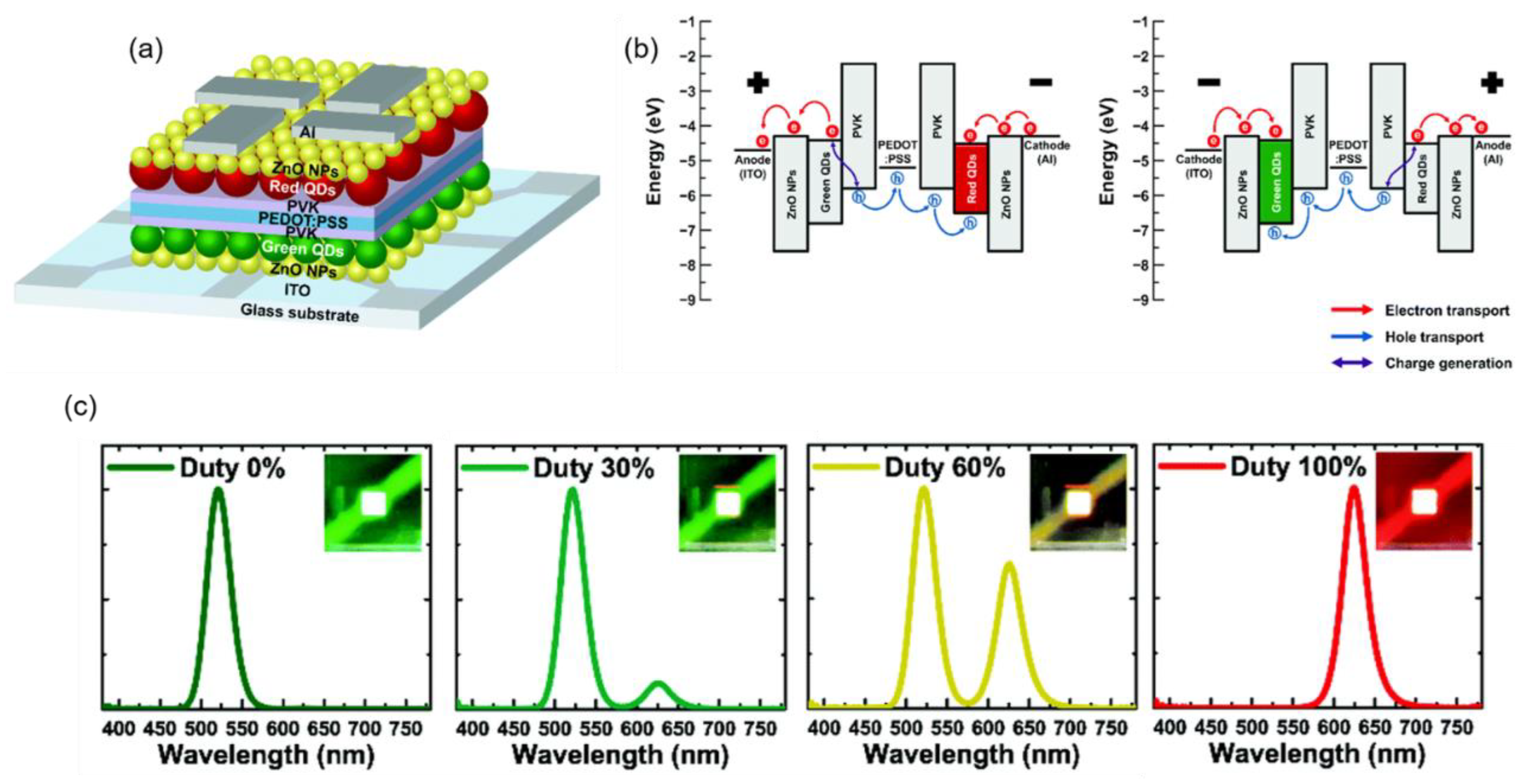

5. Color-Tunable Solution-Processed Tandem OLED/QLED

6. Outlooks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Tang, C.-W.; VanSlyke, S.-A. Organic electroluminescent diodes. Appl. Phys. Lett. 1987, 51, 913–915. [Google Scholar] [CrossRef]

- Reineke, S.; Lindner, F.; Schwartz, G.; Seidler, N.; Walzer, K.; Lussem, B.; Leo, K. White organic light-emitting diodes with fluorescent tube efficiency. Nature 2009, 459, 234–238. [Google Scholar] [CrossRef]

- Joo, W.-J.; Kyoung, J.; Esfandyarpour, M.; Lee, S.-H.; Koo, H.; Song, S.; Kwon, Y.-N.; Song, S.-H.; Bae, J.-C.; Jo, A.; et al. Metasurface-driven OLED displays beyond 10,000 pixels per inch. Science 2020, 370, 459–463. [Google Scholar] [CrossRef] [PubMed]

- Sasabe, H.; Kido, J. Development of high performance OLEDs for general lighting. J. Mater. Chem. C 2013, 1, 1699–1707. [Google Scholar] [CrossRef]

- Song, J.; Lee, H.; Jeong, E.-G.; Choi, K.-C.; Yoo, S. Organic light-emitting diodes: Pushing toward the limits and beyond. Adv. Mater. 2020, 32, 1907539. [Google Scholar] [CrossRef] [PubMed]

- Shibata, M.; Sakai, Y.; Yokoyama, D. Advantages and disadvantages of vacuum-deposited and spin-coated amorphous organic semiconductor films for organic light-emitting diodes. J. Mater. Chem. C 2015, 3, 11178–11191. [Google Scholar] [CrossRef]

- Markham, J.; Lo, S.-C.; Magennis, S.-W.; Burn, P.-L.; Samuel, I. High-efficiency green phosphorescence from spin-coated single-layer dendrimer light-emitting diodes. Appl. Phys. Lett. 2002, 80, 2645–2647. [Google Scholar] [CrossRef]

- Tian, Q.-S.; Shen, W.-S.; Yu, Y.-J.; Wang, X.-Q.; Cai, J.-H.; Hu, Y.; Jiang, Z.-Q.; Huang, J.-S.; Liao, L.-S. Systematic strategy for high-performance small molecular hybrid white OLED via blade coating at ambient condition. Org. Electron. 2022, 100, 106366. [Google Scholar] [CrossRef]

- Villani, F.; Vacca, P.; Nenna, G.; Valentino, O.; Burrasca, G.; Fasolino, T.; Minarini, C.; Della Sala, D. Inkjet printed polymer layer on flexible substrate for OLED applications. J. Phys. Chem. C 2009, 113, 13398–13402. [Google Scholar] [CrossRef]

- Choi, K.-J.; Lee, J.-Y.; Shin, D.-K.; Park, J. Investigation on slot-die coating of hybrid material structure for OLED lightings. J. Phys. Chem. Solids 2016, 95, 119–128. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, H.; Zhang, B.; Xie, Z.; Wong, W.-Y. Towards high-power-efficiency solution-processed OLEDs: Material and device perspectives. Mater. Sci. Eng. R. 2020, 140, 100547. [Google Scholar] [CrossRef]

- Friend, R.-H.; Gymer, R.-W.; Holmes, A.-B.; Burroughes, J.-H.; Marks, R.-N.; Taliani, C.; Bradley, D.; Santos, D.; Brédas, J.-L.; Lögdlund, M.; et al. Electroluminescence in conjugated polymers. Nature 1999, 397, 121–128. [Google Scholar] [CrossRef]

- Ho, S.; Liu, S.; Chen, Y.; So, F. Review of recent progress in multilayer solution-processed organic light-emitting diodes. J. Photonics Energy 2015, 5, 057611. [Google Scholar] [CrossRef]

- Huang, T.; Jiang, W.; Duan, L. Recent progress in solution processable TADF materials for organic light-emitting diodes. J. Mater. Chem. C 2018, 6, 5577–5596. [Google Scholar] [CrossRef]

- Yook, K.-S.; Lee, J.-Y. Small molecule host materials for solution processed phosphorescent organic light-emitting diodes. Adv. Mater. 2014, 26, 4218–4233. [Google Scholar] [CrossRef]

- Cui, L.-S.; Liu, Y.; Liu, X.-Y.; Jiang, Z.-Q.; Liao, L.-S. Design and synthesis of pyrimidine-based iridium(III) complexes with horizontal orientation for orange and white phosphorescent OLEDs. ACS. Appl. Mater. Interfaces 2015, 7, 11007–11014. [Google Scholar] [CrossRef]

- Peng, C.-C.; Yang, S.-Y.; Li, H.-C.; Xie, G.-H.; Cui, L.-S.; Zou, S.-N.; Poriel, C.; Jiang, Z.-Q.; Liao, L.-S. Highly efficient thermally activated delayed fluorescence via an unconjugated donor-acceptor system realizing EQE of over 30%. Adv. Mater. 2020, 32, 2003885. [Google Scholar] [CrossRef]

- Ikeda, N.; Oda, S.; Matsumoto, R.; Yoshioka, M.; Fukushima, D.; Yoshiura, K.; Yasuda, N.; Hatakeyama, T. Solution-processable pure green thermally activated delayed fluorescence emitter based on the multiple resonance effect. Adv. Mater. 2020, 32, 2004072. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, L.; Zhang, B.; Ding, J.; Xie, Z.; Wang, L.; Wong, W.-Y. High-energy-level blue phosphor for solution-processed white organic light-emitting diodes with efficiency comparable to fluorescent tubes. iScience 2018, 6, 128–137. [Google Scholar] [CrossRef]

- Zhang, Y.-X.; Wang, B.; Yuan, Y.; Hu, Y.; Jiang, Z.-Q.; Liao, L.-S. Solution-processed thermally activated delayed fluorescence exciplex hosts for highly efficient blue organic light-emitting diodes. Adv. Opt. Mater. 2017, 5, 1700012. [Google Scholar] [CrossRef]

- Sun, Y.; Jiang, Y.; Sun, X.-W.; Zhang, S.; Chen, S. Beyond OLED: Efficient quantum dot light-emitting diodes for display and lighting application. Chem. Rec. 2019, 19, 1729–1752. [Google Scholar] [CrossRef] [PubMed]

- Dai, X.; Deng, Y.; Peng, X.; Jin, Y. Quantum-dot light-emitting diodes for large-area displays: Towards the dawn of commercialization. Adv. Mater. 2017, 29, 201607022. [Google Scholar] [CrossRef] [PubMed]

- Shu, Y.; Lin, X.; Qin, H.; Hu, Z.; Jin, Y.; Peng, X. Quantum dots for display applications. Angew. Chem. Int. Ed. Engl. 2020, 59, 22312–22323. [Google Scholar] [CrossRef]

- Yang, J.; Choi, M.-K.; Yang, U.-J.; Kim, S.-Y.; Kim, Y.-S.; Kim, J.-H.; Kim, D.-H.; Hyeon, T. Toward full-color electroluminescent quantum dot displays. Nano Lett. 2021, 21, 26–33. [Google Scholar] [CrossRef]

- Tan, Y.; Jin, S.; Hamers, R.-J. Photostability of CdSe quantum dots functionalized with aromatic dithiocarbamate ligands. ACS. Appl. Mater. Interfaces. 2013, 5, 12975–12983. [Google Scholar] [CrossRef]

- Lee, J.-C.; Jang, E.-P.; Jang, D.-S.; Choi, Y.; Choi, M.; Yang, H. Solvothermal preparation and fluorescent properties of color-tunable InP/ZnS quantum dots. J. Lumin. 2013, 134, 798–805. [Google Scholar] [CrossRef]

- Zhang, F.; Wang, S.; Wang, L.; Lin, Q.; Shen, H.; Cao, W.; Yang, C.; Wang, H.; Yu, L.; Du, Z.; et al. Super color purity green quantum dot light-emitting diodes fabricated by using CdSe/CdS nanoplatelets. Nanoscale 2016, 8, 12182–12188. [Google Scholar] [CrossRef] [PubMed]

- Liao, L.-S.; Tang, C.-W. Providing an organic electroluminescent device having stacked electroluminescent units. US Patent Application 20030170491 A1. US Patent No. 6872472 B2, 29 March 2005. [Google Scholar]

- Kido, J.; Hayashi, T. Organic electroluminescent device. US Patent Application No. US20030189401 A1, 21 March 2003. [Google Scholar]

- Matsumoto, T.; Nakada, T.; Endo, J.; Mori, K.; Kawamura, N.; Yokoi, A.; Kido, J. Multiphoton organic EL device having charge generation layer. SID Symp. Dig. Tech. Pap. 2003, 34, 979. [Google Scholar] [CrossRef]

- Liao, L.-S.; Klubek, K.-P.; Tang, C.-W. High-efficiency tandem organic light-emitting diodes. Appl. Phys. Lett. 2004, 84, 167–169. [Google Scholar] [CrossRef]

- Lee, S.; Shin, H.; Kim, J.-J. High-efficiency orange and tandem white organic light-emitting diodes using phosphorescent dyes with horizontally oriented emitting dipoles. Adv. Mater. 2014, 26, 5864–5868. [Google Scholar] [CrossRef]

- Zhang, H.; Su, Q.; Sun, Y.; Chen, S. Efficient and color stable white quantum-dot light-emitting diodes with external quantum efficiency over 23%. Adv. Opt. Mater. 2018, 6, 1870062. [Google Scholar] [CrossRef]

- Kim, Y.-E.; Ko, A.; Jang, H.-J.; Yoon, S.-J.; Roh, S.-H.; Lee, J.-Y.; Lee, J.-Y.; Kim, D.; Kim, J.-K.; Yook, K.-S. Thermally cross-linkable spirobifluorene-core-based hole transport layer with high solvent-resistivity for solution processible OLEDs. Dyes Pigm. 2021, 187, 109122. [Google Scholar] [CrossRef]

- Zou, Y.; Ban, M.; Cui, W.; Huang, Q.; Wu, C.; Liu, J.; Wu, H.; Song, T.; Sun, B. A general solvent selection strategy for solution processed quantum dots targeting high performance light-emitting diode. Adv. Funct. Mater. 2017, 27, 201603325. [Google Scholar] [CrossRef]

- Fung, M.-K.; Li, Y.-Q.; Liao, L.-S. Tandem Organic Light-Emitting Diodes. Adv. Mater. 2016, 28, 10381–10408. [Google Scholar] [CrossRef] [PubMed]

- Law, C.-W.; Lau, K.-M.; Fung, M.-K.; Chan, M.-Y.; Wong, F.-L.; Lee, C.-S.; Lee, S.-T. Effective organic-based connection unit for stacked organic light-emitting devices. Appl. Phys. Lett. 2006, 89, 133511. [Google Scholar] [CrossRef]

- Zhou, D.-Y.; Zu, F.-S.; Zhang, Y.-J.; Shi, X.-B.; Aziz, H.; Liao, L.-S. Highly stable and efficient tandem organic light-emitting devices with intermediate connectors using lithium amide as n-type dopant. Appl. Phys. Lett. 2014, 105, 083301. [Google Scholar] [CrossRef]

- Zhou, D.-Y.; Cui, L.-S.; Zhang, Y.-J.; Liao, L.-S.; Aziz, H. Low driving voltage simplified tandem organic light-emitting devices by using exciplex-forming hosts. Appl. Phys. Lett. 2014, 105, 153302. [Google Scholar] [CrossRef]

- Liao, L.-S.; Klubek, K.-P. Power efficiency improvement in a tandem organic light-emitting diode. Appl. Phys. Lett. 2008, 92, 223311. [Google Scholar] [CrossRef]

- Zhou, D.-Y.; Siboni, H.Z.; Wang, Q.; Liao, L.-S.; Aziz, H. The influence of charge injection from intermediate connectors on the performance of tandem organic light-emitting devices. J. Appl. Phys. 2014, 116, 223708. [Google Scholar] [CrossRef]

- Bao, Q.-Y.; Yang, J.-P.; Li, Y.-Q.; Tang, J.-X. Electronic structures of MoO3-based charge generation layer for tandem organic light-emitting diodes. Appl. Phys. Lett. 2010, 97, 172. [Google Scholar] [CrossRef]

- Hamwi, S.; Meyer, J.; Kröger, M.; Winkler, T.; Witte, M.; Riedl, T.; Kahn, A.; Kowalsky, W. The role of transition metal oxides in charge-generation layers for stacked organic light-emitting diodes. Adv. Funct. Mater. 2010, 20, 1762–1766. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, J.; Ma, D.; Yan, D.; Wang, L.; Zhu, F. High power efficiency tandem organic light-emitting diodes based on bulk heterojunction organic bipolar charge generation layer. Appl. Phys. Lett. 2011, 98, 114. [Google Scholar] [CrossRef]

- Guo, Q.; Sun, H.; Wang, J.; Yang, D.; Chen, J.; Ma, D. Charge generation mechanism of tandem organic light emitting diodes with pentacene/C70 organic heterojunction as the connecting layer. J. Mater. Chem. C 2016, 4, 376–382. [Google Scholar] [CrossRef]

- Sun, J.-X.; Zhu, X.-L.; Peng, H.-J.; Wong, M.; Kwok, H.-S. Effective intermediate layers for highly efficient stacked organic light-emitting devices. Appl. Phys. Lett. 2005, 87, 093504. [Google Scholar] [CrossRef]

- Fan, X.; Nie, W.; Tsai, H.; Wang, N.; Huang, H.; Cheng, Y.; Wen, R.; Ma, L.; Yan, F.; Xia, Y. PEDOT:PSS for flexible and stretchable electronics: Modifications, strategies, and applications. Adv. Sci. 2019, 6, 1900813. [Google Scholar] [CrossRef] [PubMed]

- Sun, K.; Zhang, S.; Li, P.; Xia, Y.; Zhang, X.; Du, D.; Isikgor, F.H.; Ouyang, J. Review on application of PEDOTs and PEDOT:PSS in energy conversion and storage devices. J. Mater. Sci.-Mater. El. 2015, 26, 4438–4462. [Google Scholar] [CrossRef]

- Wang, Y.; Hu, Y.; Han, D.; Yuan, Q.; Cao, T.; Chen, N.; Zhou, D.; Cong, H.; Feng, L. Ammonia-treated graphene oxide and PEDOT:PSS as hole transport layer for high-performance perovskite solar cells with enhanced stability. Org. Electron. 2019, 70, 63–70. [Google Scholar] [CrossRef]

- Fu, Q.; Chen, J.; Shi, C.; Ma, D. Room-temperature sol-gel derived molybdenum oxide thin films for efficient and stable solution-processed organic light-emitting diodes. ACS. Appl. Mater. Interfaces 2013, 5, 6024–6029. [Google Scholar] [CrossRef]

- Hofle, S.; Bruns, M.; Strassle, S.; Feldmann, C.; Lemmer, U.; Colsmann, A. Tungsten oxide buffer layers fabricated in an inert sol-gel process at room-temperature for blue organic light-emitting diodes. Adv. Mater. 2013, 25, 4113–4116. [Google Scholar] [CrossRef]

- Mashford, B.-S.; Stevenson, M.; Popovic, Z.; Hamilton, C.; Zhou, Z.; Breen, C.; Steckel, J.; Bulovic, V.; Bawendi, M.; Coe-Sullivan, S.; et al. High-efficiency quantum-dot light-emitting devices with enhanced charge injection. Nat. Photon. 2013, 7, 407–412. [Google Scholar] [CrossRef]

- Kim, H.-H.; Park, S.; Yi, Y.; Son, D.-I.; Park, C.; Hwang, D.-K.; Choi, W.-K. Inverted quantum dot light emitting diodes using polyethylenimine ethoxylated modified ZnO. Sci. Rep. 2015, 5, 8968. [Google Scholar] [CrossRef] [PubMed]

- Zhou, D.-Y.; Shi, X.-B.; Liu, Y.; Gao, C.-H.; Wang, K.; Liao, L.-S. Role of hole injection layer in intermediate connector of tandem organic light-emitting devices. Org. Electron. 2014, 15, 3694–3701. [Google Scholar] [CrossRef]

- Kröger, M.; Hamwi, S.; Meyer, J.; Dobbertin, T.; Riedl, T.; Kowalsky, W.; Johannes, H.-H. Temperature-independent field-induced charge separation at doped organic/organic interfaces: Experimental modeling of electrical properties. Phys. Rev. B 2007, 75, 235321. [Google Scholar] [CrossRef]

- Matsushima, T.; Jin, G.-H.; Kanai, Y.; Yokota, T.; Kitada, S.; Kishi, T.; Murata, H. Interfacial charge transfer and charge generation in organic electronic devices. Org. Electron. 2011, 12, 520–528. [Google Scholar] [CrossRef]

- Hong, K.; Lee, J.-L. Charge generation mechanism of metal oxide interconnection in tandem organic light emitting diodes. J. Phys. Chem. C 2012, 116, 6427–6433. [Google Scholar] [CrossRef]

- Cai, Y.; Wei, H.-X.; Li, J.; Bao, Q.-Y.; Zhao, X.; Lee, S.-T.; Li, Y.-Q.; Tang, J.-X. Mechanism of Cs2CO3 as an n-type dopant in organic electron-transport film. Appl. Phys. Lett. 2011, 98, 60. [Google Scholar] [CrossRef]

- Lee, S.; Lee, J.-H.; Lee, J.-H.; Kim, J.-J. The mechanism of charge generation in charge-generation units composed of p-doped hole-transporting layer/HATCN/n-doped electron-transporting layers. Adv. Funct. Mater. 2012, 22, 855–860. [Google Scholar] [CrossRef]

- Yook, K.-S.; Jeon, S.-O.; Min, S.-Y.; Lee, J.-Y.; Yang, H.-J.; Noh, T.; Kang, S.-K.; Lee, T.-W. Highly efficient p-i-n and tandem organic light-emitting devices using an air-stable and low-temperature-evaporable metal azide as an n-dopant. Adv. Funct. Mater. 2010, 20, 1797–1802. [Google Scholar] [CrossRef]

- Lei, Y.; Liu, Z.; Fan, C.-J.; Peng, X.-F.; Ji, X.-X.; Li, G.-Q.; Xiong, Z.-H.; Yang, X.-H. Solution-processed conducting polymer/metal oxide charge generation layer: Preparation, electrical properties, and charge generation mechanism. J. Phys. Chem. C. 2017, 121, 793–800. [Google Scholar] [CrossRef]

- Lin, P.; Yan, X.; Zhang, Z.; Shen, Y.; Zhao, Y.; Bai, Z.; Zhang, Y. Self-powered UV photosensor based on PEDOT:PSS/ZnO micro/nanowire with strain-modulated photoresponse. ACS. Appl. Mater. Interfaces 2013, 5, 3671–3676. [Google Scholar] [CrossRef]

- Dong, J.-Y.; Ji, W.-Y.; Wang, S.-P.; Yuan, Q.-L.; Kong, Y.-C.; Su, S.-C.; Ng, K.-W.; Tang, Z.-K. Solvent effects on the interface and film integrity of solution-processed ZnO electron transfer layers for quantum dot light-emitting diodes. ACS. Appl. Electron. Mater. 2020, 2, 1074–1080. [Google Scholar] [CrossRef]

- Chiba, T.; Pu, Y.-J.; Sasabe, H.; Kido, J.; Yang, Y. Solution-processed organic light-emitting devices with two polymer light-emitting units connected in series by a charge-generation layer. J. Mater. Chem. 2012, 22, 22769–22773. [Google Scholar] [CrossRef]

- Hofle, S.; Bernhard, C.; Bruns, M.; Kubel, C.; Scherer, T.; Lemmer, U.; Colsmann, A. Charge generation layers for solution processed tandem organic light emitting diodes with regular device architecture. ACS. Appl. Mater. Interfaces. 2015, 7, 8132–8137. [Google Scholar] [CrossRef] [PubMed]

- Pu, Y.-J.; Chiba, T.; Ideta, K.; Takahashi, S.; Aizawa, N.; Hikichi, T.; Kido, J. Fabrication of organic light-emitting devices comprising stacked light-emitting units by solution-based processes. Adv. Mater. 2015, 27, 1327–1332. [Google Scholar] [CrossRef]

- Ohisa, S.; Takahashi, T.; Igarashi, M.; Fukuda, H.; Hikichi, T.; Komatsu, R.; Ueki, E.; Pu, Y.-J.; Chiba, T.; Kido, J. An indolocarbazole-based thermally activated delayed fluorescence host for solution-processed phosphorescent tandem organic light-emitting devices exhibiting extremely small efficiency roll-off. Adv. Funct. Mater. 2019, 29, 1808022. [Google Scholar] [CrossRef]

- Hofle, S.; Schienle, A.; Bernhard, C.; Bruns, M.; Lemmer, U.; Colsmann, A. Solution processed, white emitting tandem organic light-emitting diodes with inverted device architecture. Adv. Mater. 2014, 26, 5155–5159. [Google Scholar] [CrossRef]

- Chiba, T.; Pu, Y.-J.; Kido, J. Solution-processed white phosphorescent tandem organic light-emitting devices. Adv. Mater. 2015, 27, 4681–4687. [Google Scholar] [CrossRef]

- Krucaite, G.; Blazevicius, D.; Tavgeniene, D.; Grigalevicius, S.; Lin, C.-H.; Shao, C.-M.; Chang, C.-H. Tetramer of triphenylamine and similar derivatives with bromine atoms as hole injecting/transporting materials for efficient red phosphorescent OLEDs. Opt. Mater. 2020, 108, 110225. [Google Scholar] [CrossRef]

- Xue, R.; Zhang, M.; Xu, G.; Zhang, J.; Chen, W.; Chen, H.; Yang, M.; Cui, C.; Li, Y.; Li, Y. Molecular design with silicon core: Toward commercially available hole transport materials for high-performance planar p–i–n perovskite solar cells. J. Mater. Chem. A 2018, 6, 404–413. [Google Scholar] [CrossRef]

- Du, X.; Zhao, J.; Liu, W.; Wang, K.; Yuan, S.; Zheng, C.; Lin, H.; Tao, S.; Zhang, X.-H. Bromine-substituted triphenylamine derivatives with improved hole-mobility for highly efficient green phosphorescent OLEDs with a low operating voltage. J. Mater. Chem. C 2016, 4, 10301–10308. [Google Scholar] [CrossRef]

- Xu, J.; Peng, F.; Hu, Z.; Yu, L.; Huang, F.; Yang, W.; Cao, Y. Efficient tandem polymer light-emitting diodes with PTPA-P/ZnO as the charge generation layer. J. Mater. Chem. C 2019, 7, 8003–8010. [Google Scholar] [CrossRef]

- Kim, J.-H.; Lee, K.-H.; Kang, H.-D.; Park, B.; Hwang, J.-Y.; Jang, H.-S.; Do, Y.-R.; Yang, H. Fabrication of a white electroluminescent device based on bilayered yellow and blue quantum dots. Nanoscale 2015, 7, 5363–5370. [Google Scholar] [CrossRef] [PubMed]

- Shen, P.; Li, X.; Cao, F.; Ding, X.; Yang, X. Highly efficient, all-solution-processed, flexible white quantum dot light-emitting diodes. J. Mater. Chem. C 2018, 6, 9642–9648. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, S.; Sun, X.; Chen, S. All solution-processed white quantum-dot light-emitting diodes with three-unit tandem structure. J. Soc. Inf. Disp. 2017, 25, 143–150. [Google Scholar] [CrossRef]

- Jiang, C.; Zou, J.; Liu, Y.; Song, C.; He, Z.; Zhong, Z.; Wang, J.; Yip, H.-L.; Peng, J.; Cao, Y. Fully solution-processed tandem white quantum-dot light-emitting diode with an external quantum efficiency exceeding 25%. ACS Nano 2018, 12, 6040–6049. [Google Scholar] [CrossRef]

- Hack, M.; Kwong, R.; Weaver, M.-S.; Lu, M.; Brown, J.-J. Active-matrix technology for high-efficiency OLED displays. J. Soc. Inf. Disp. 2002, 10, 323–327. [Google Scholar] [CrossRef]

- Huang, Y.; Hsiang, E.-L.; Deng, M.-Y.; Wu, S.-T. Mini-LED, Micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, X.; Chen, S. Over 100 cd A−1 efficient quantum dot light-emitting diodes with inverted tandem structure. Adv. Funct. Mater. 2017, 27, 1700610. [Google Scholar] [CrossRef]

- Shen, P.; Cao, F.; Wang, H.; Wei, B.; Wang, F.; Sun, X.-W.; Yang, X. Solution-processed double-junction quantum-dot light-emitting diodes with an EQE of over 40%. ACS. Appl. Mater. Interfaces. 2019, 11, 1065–1070. [Google Scholar] [CrossRef]

- Cao, F.; Zhao, D.; Shen, P.; Wu, J.; Wang, H.; Wu, Q.; Wang, F.; Yang, X. High-efficiency, solution-processed white quantum dot light-emitting diodes with serially stacked red/green/blue units. Adv. Opt. Mater. 2018, 6, 1800652. [Google Scholar] [CrossRef]

- Fröbel, M.; Schwab, T.; Kliem, M.; Hofmann, S.; Leo, K.; Gather, M.-C. Get it white: Color-tunable AC/DC OLEDs. Light Sci. Appl. 2015, 4, e247. [Google Scholar] [CrossRef]

- Sun, J.; Wang, H.; Shi, H.; Wang, S.; Xu, J.; Ma, J.; Ma, B.; Wen, M.; Li, J.; Zhao, J.; et al. Large-area tunable red/green/blue tri-stacked quantum dot light-emitting diode using sandwich-structured transparent silver nanowires electrodes. ACS. Appl. Mater. Interfaces 2020, 12, 48820–48827. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Su, Q.; Chen, S. Quantum-dot and organic hybrid tandem light-emitting diodes with multi-functionality of full-color-tunability and white-light-emission. Nat. Commun. 2020, 11, 2826. [Google Scholar] [CrossRef] [PubMed]

- Song, S.-H.; Park, S.-J.; Bae, T.-J.; Jung, K.-M.; Park, W.-H.; Kim, Y.-S.; Yan, Q.-F.; Kim, S.-S.; Song, J.-K. All-solution-processed colour-tuneable tandem quantum-dot light-emitting diode driven by AC signal. Nanoscale 2020, 12, 17020–17028. [Google Scholar] [CrossRef]

- Xie, B.; Hu, R.; Luo, X. Quantum dots-converted light-emitting diodes packaging for lighting and display: Status and perspectives. J. Electron. Packag. 2016, 138, 020803. [Google Scholar] [CrossRef]

- Xie, B.; Wang, Y.; Liu, H.; Ma, J.; Zhou, S.; Yu, X.; Lan, W.; Wang, K.; Hu, R.; Luo, X. Targeting cooling for quantum dots by 57.3°C with air-bubbles-assembled three-dimensional hexagonal boron nitride heat dissipation networks. Chem. Eng. J. 2022, 427, 130958. [Google Scholar] [CrossRef]

| Scheme | ICL | Color | CE | Ref. |

|---|---|---|---|---|

| Regular | PVPy:ZnO:Cs2CO3/MoO3 | Green | 10 cd/A | [64] |

| TMO(WO3)/PEI/ZnO | Yellow | 25 cd/A | [65] | |

| PMA/PEIE/ZnO | Red | 50 cd/A | [67] | |

| PMA/PEIE/ZnO | Green | 19 cd/A | [66] | |

| Inverted | WO3/PEDOT:PSS/ZnO/PEI | Yellow | 18 cd/A | [68] |

| PEDOT:PSS/n-PEODT:PSS/ZnO/PEIE | Green | 94 cd/A | [69] | |

| PEDOT:PSS/PTPA-P/ZnO/PFN-OX | Green | 27 cd/A | [73] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, S.-G.; Zhu, X.-Z.; Zhou, D.-Y.; Liao, L.-S. Recent Progresses in Solution-Processed Tandem Organic and Quantum Dots Light-Emitting Diodes. Molecules 2023, 28, 134. https://doi.org/10.3390/molecules28010134

Meng S-G, Zhu X-Z, Zhou D-Y, Liao L-S. Recent Progresses in Solution-Processed Tandem Organic and Quantum Dots Light-Emitting Diodes. Molecules. 2023; 28(1):134. https://doi.org/10.3390/molecules28010134

Chicago/Turabian StyleMeng, Shu-Guang, Xiao-Zhao Zhu, Dong-Ying Zhou, and Liang-Sheng Liao. 2023. "Recent Progresses in Solution-Processed Tandem Organic and Quantum Dots Light-Emitting Diodes" Molecules 28, no. 1: 134. https://doi.org/10.3390/molecules28010134

APA StyleMeng, S.-G., Zhu, X.-Z., Zhou, D.-Y., & Liao, L.-S. (2023). Recent Progresses in Solution-Processed Tandem Organic and Quantum Dots Light-Emitting Diodes. Molecules, 28(1), 134. https://doi.org/10.3390/molecules28010134