Experimental Design Optimization of Acrylate—Tannin Photocurable Resins for 3D Printing of Bio-Based Porous Carbon Architectures

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

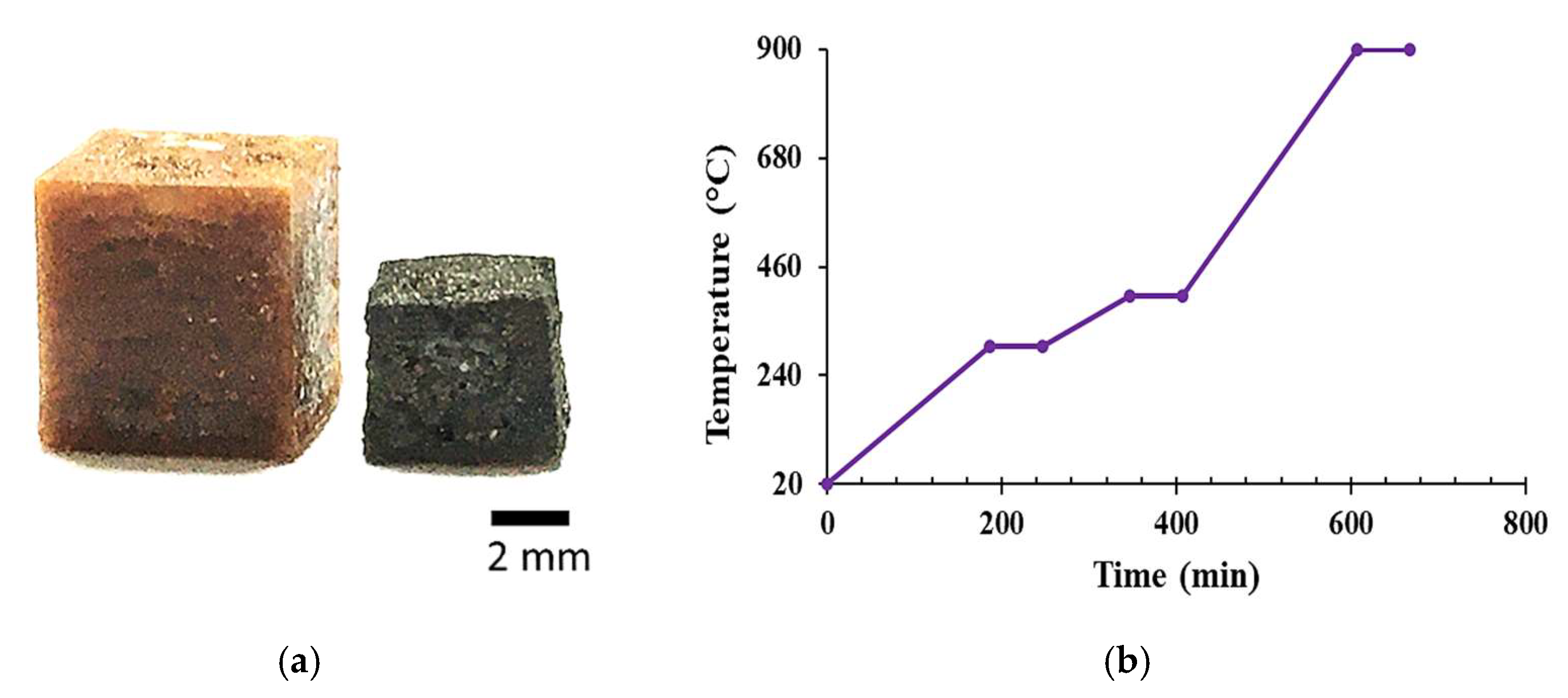

2.2. Preparation of 3D-Printed Carbon Architectures Based on Acrylate–Tannin Resins

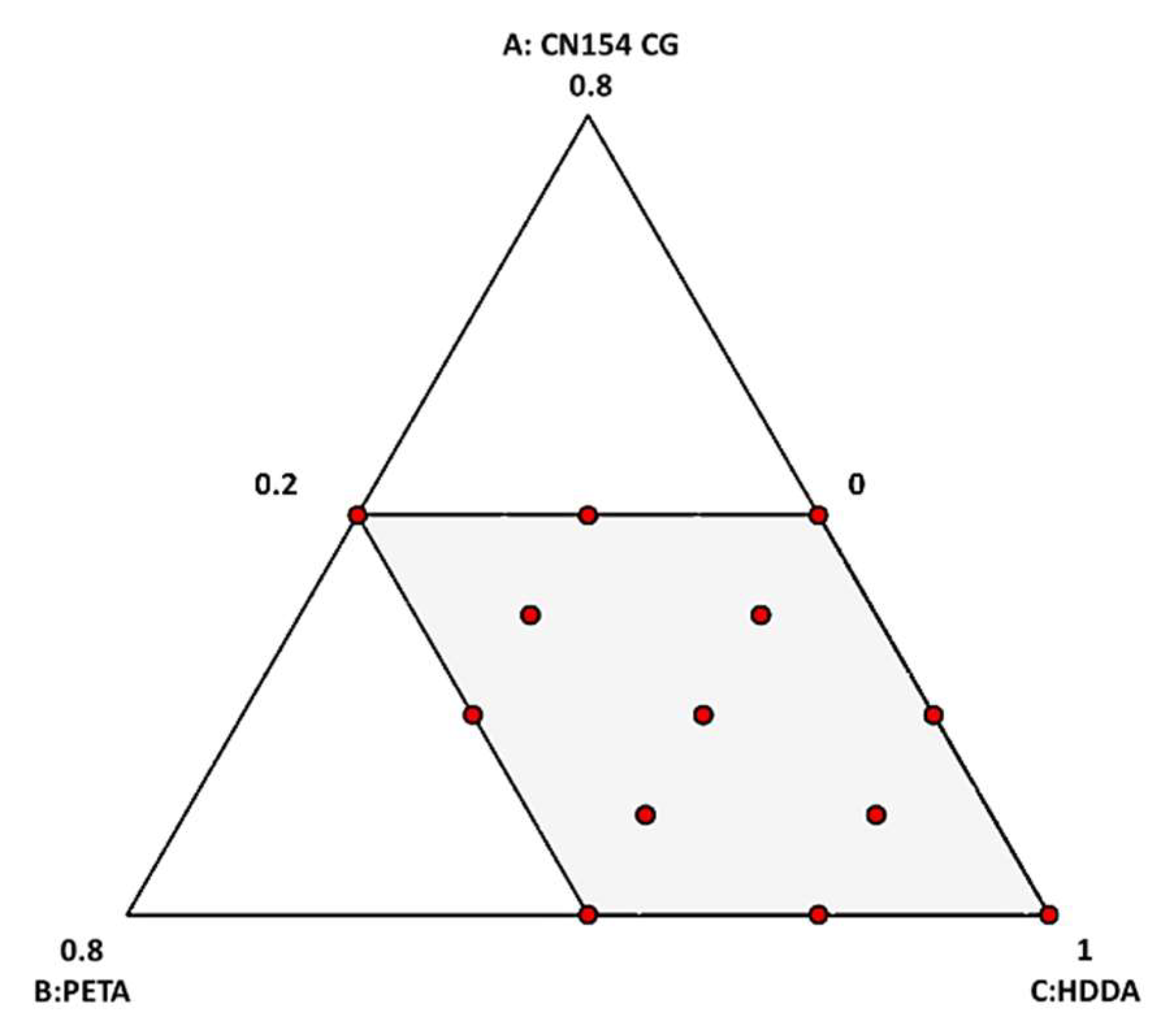

2.3. Experimental Design

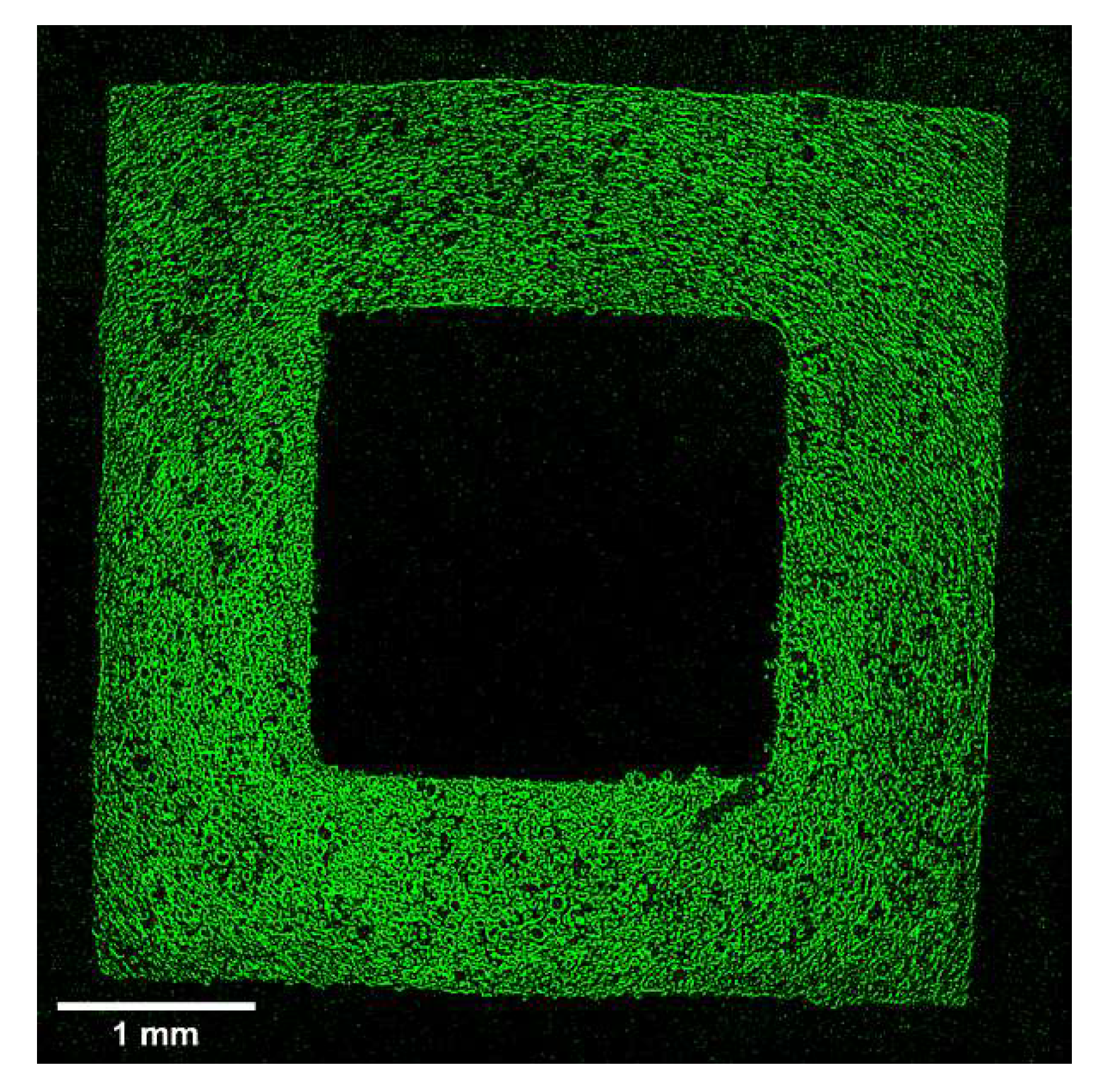

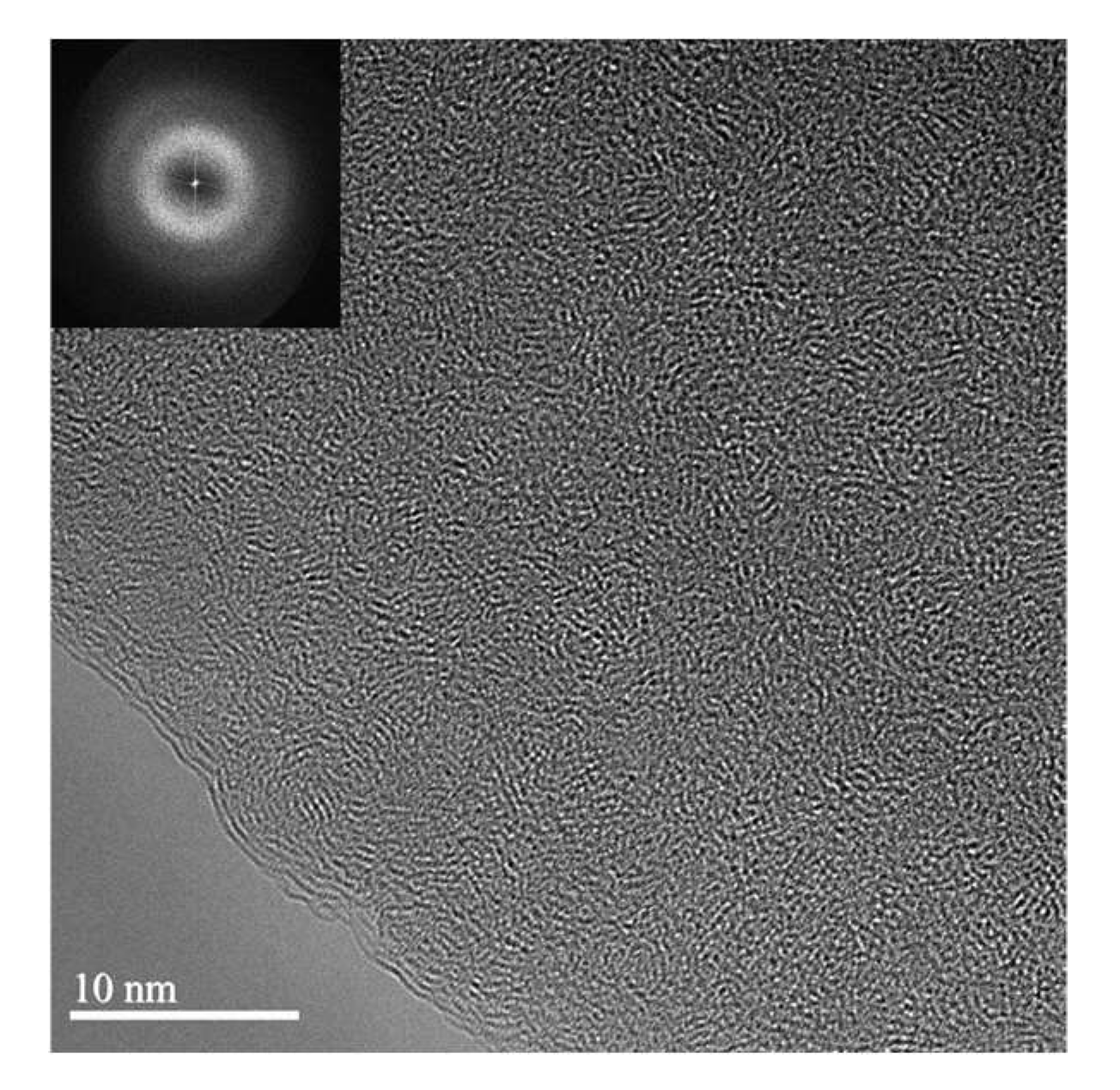

2.4. Characterisation of 3D-Printed Carbon Architectures

3. Results and Discussion

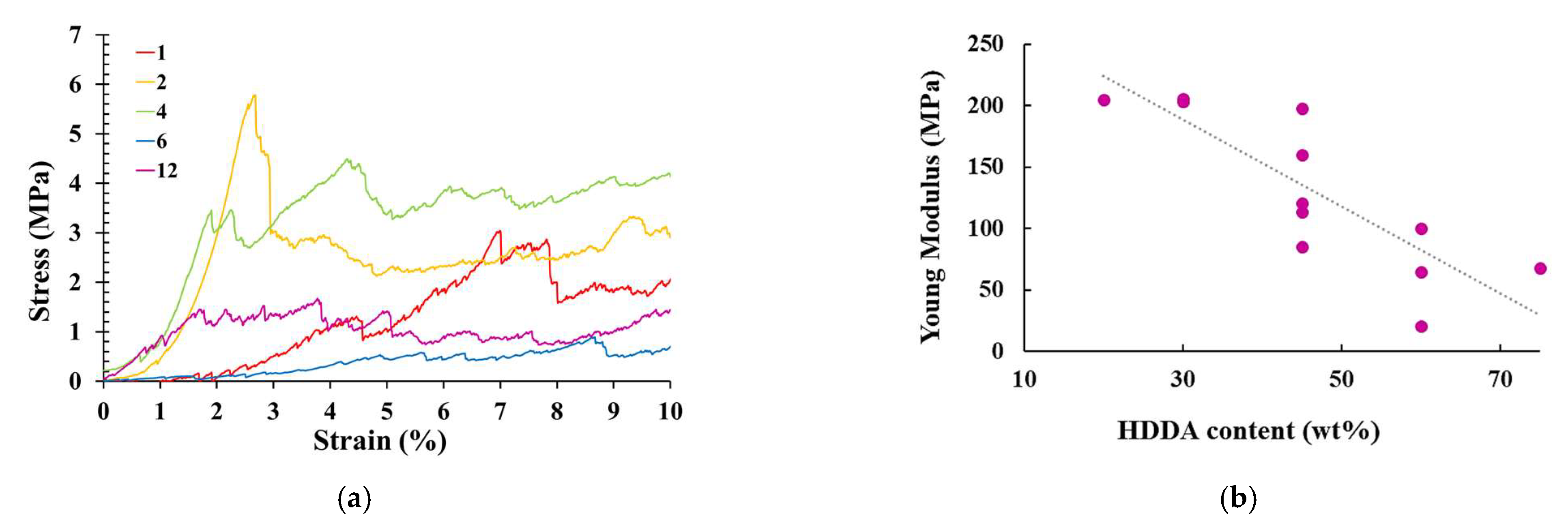

3.1. Properties of 3D-Printed Carbons

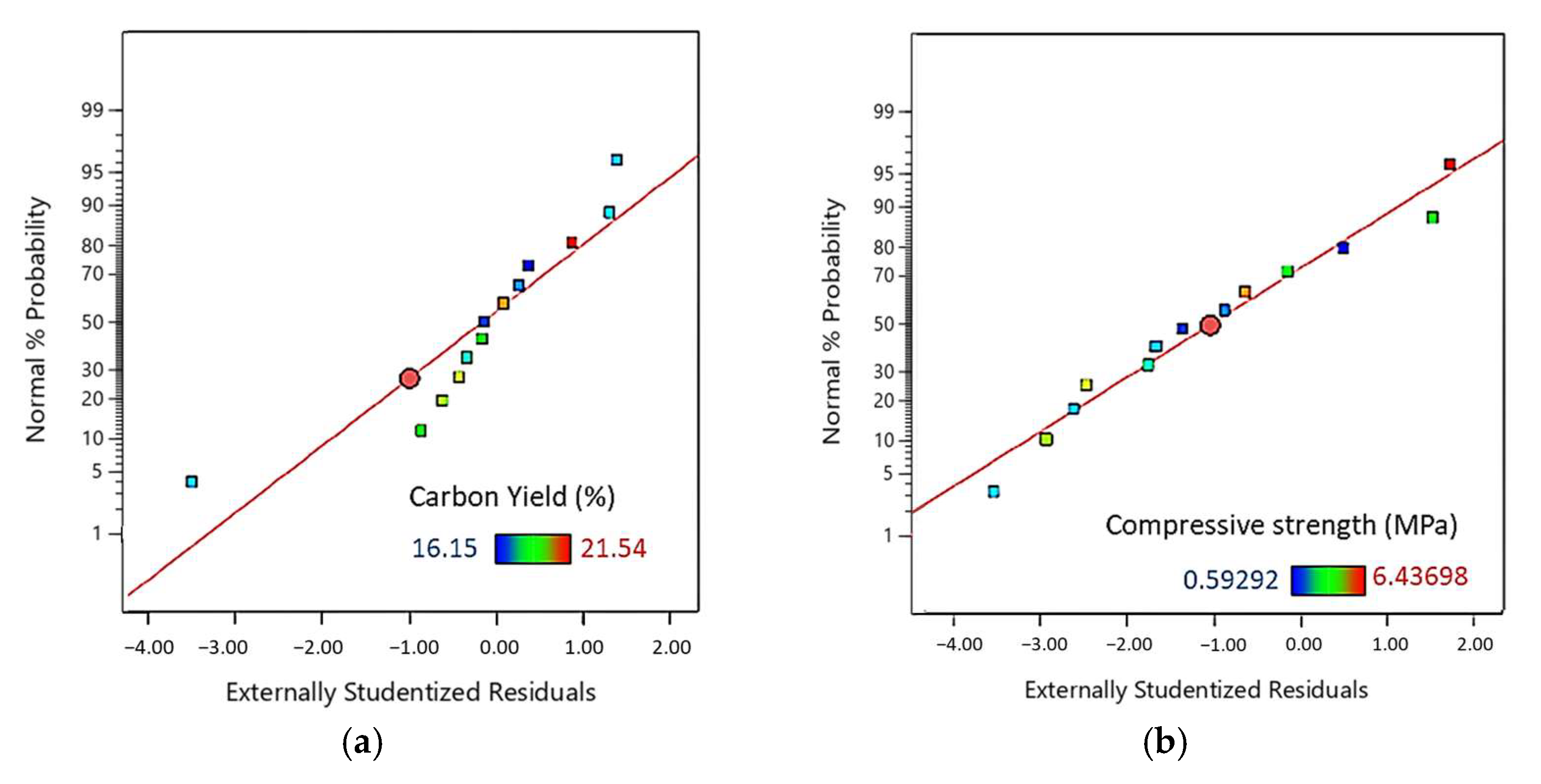

3.2. Results of the Experimental Design and Related Statistical Analysis

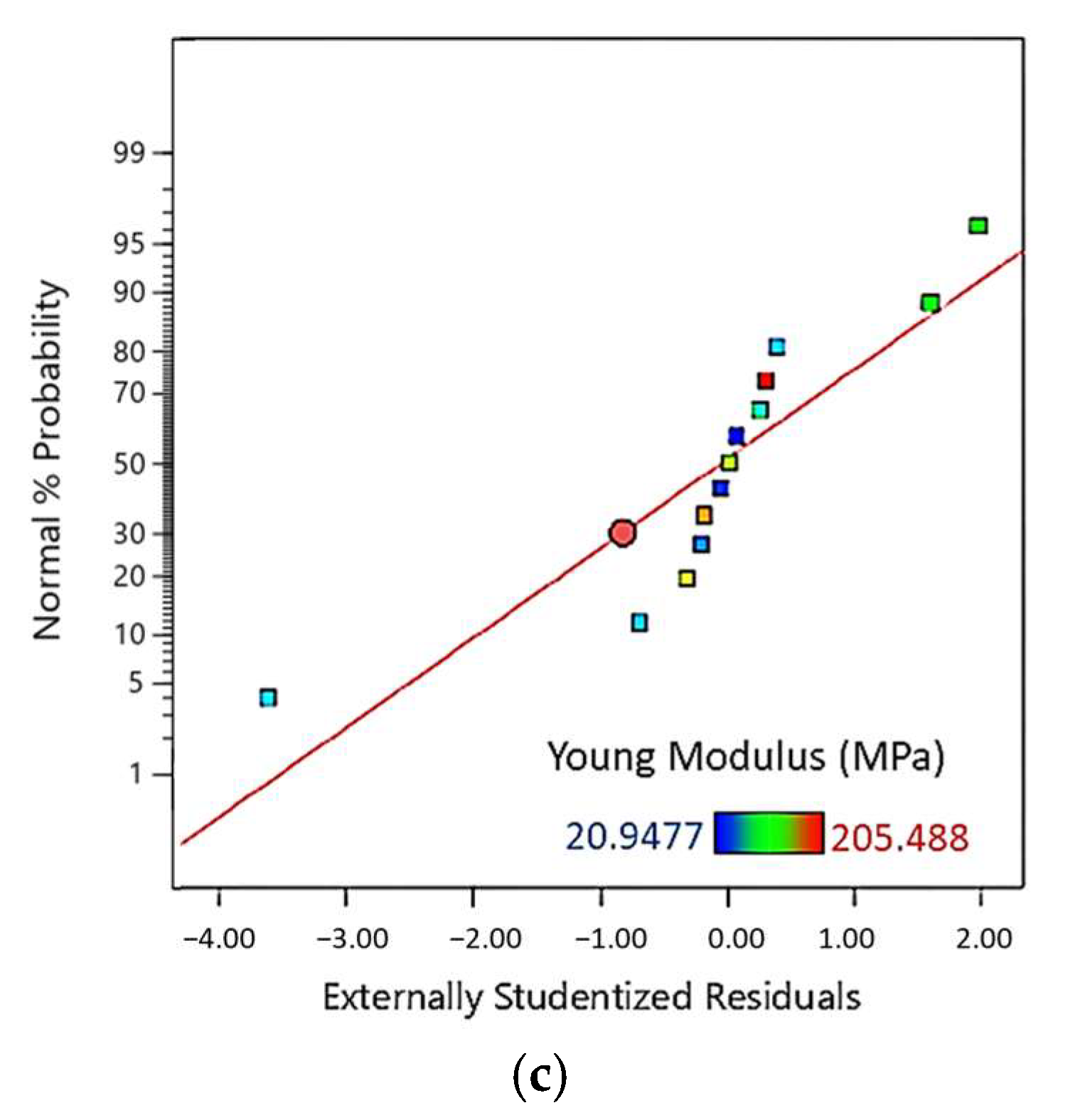

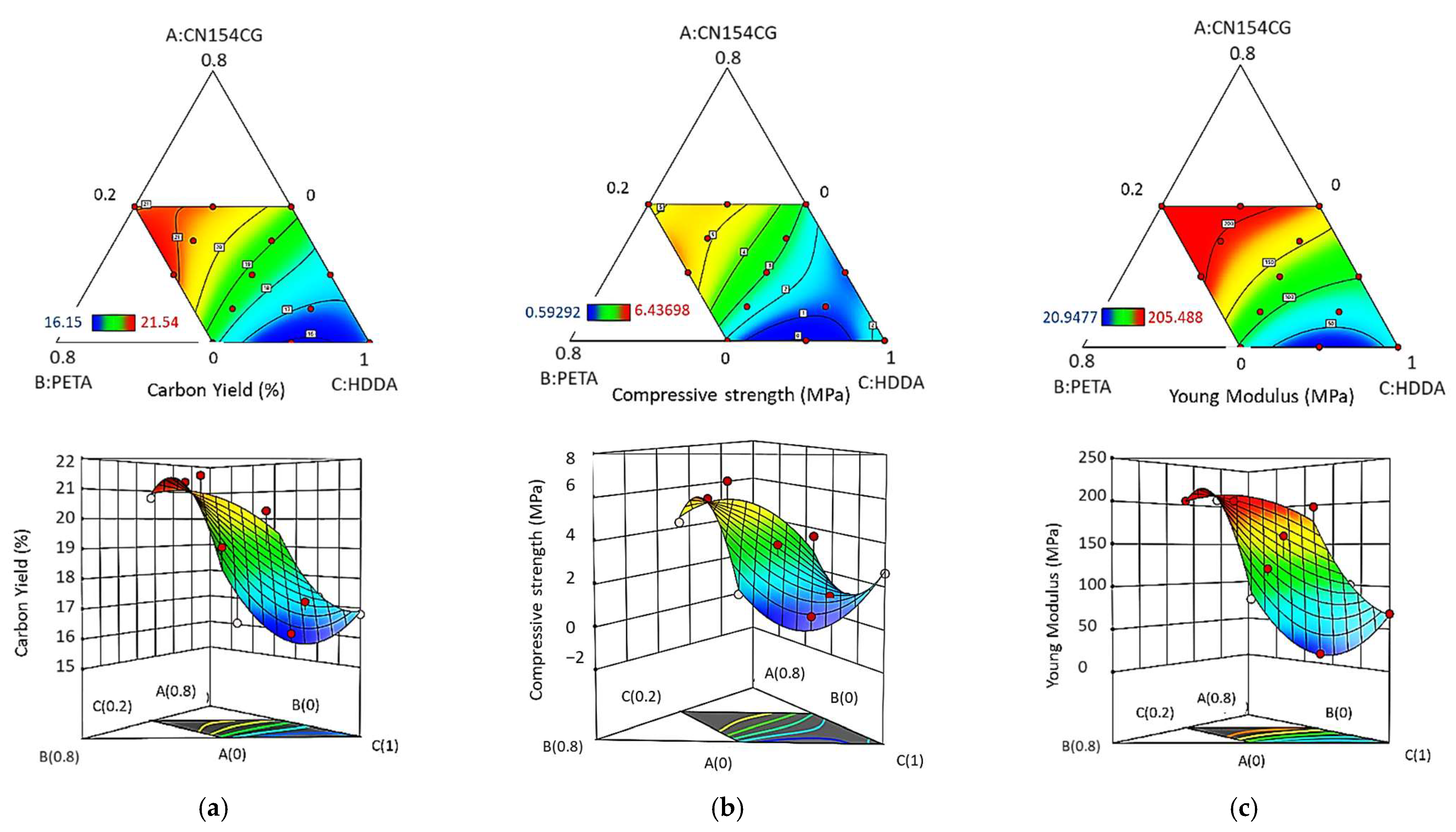

3.3. Response Surface Methodology

3.4. Optimisation of the Formulation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

Appendix A

Appendix A.1. Mercury Intrusion

Appendix A.2. X-ray Tomography

Appendix B

Appendix B.1. Scheffé Mixture Models

Appendix B.2. Analysis of Variance (ANOVA)

References

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Blyweert, P.; Nicolas, V.; Fierro, V.; Celzard, A. 3D Printing of Carbon-Based Materials: A Review. Carbon 2021, 183, 449–485. [Google Scholar] [CrossRef]

- Quan, H.; Zhang, T.; Xu, H.; Luo, S.; Nie, J.; Zhu, X. Photo-Curing 3D Printing Technique and Its Challenges. Bioact. Mater. 2020, 5, 110–115. [Google Scholar] [CrossRef] [PubMed]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive Manufacturing: Technology, Applications, Markets, and Opportunities for the Built Environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Rezaei, B.; Pan, J.Y.; Gundlach, C.; Keller, S.S. Highly Structured 3D Pyrolytic Carbon Electrodes Derived from Additive Manufacturing Technology. Mater. Des. 2020, 193, 108834. [Google Scholar] [CrossRef]

- Bian, B.; Shi, D.; Cai, X.; Hu, M.; Guo, Q.; Zhang, C.; Wang, Q.; Sun, A.X.; Yang, J. 3D Printed Porous Carbon Anode for Enhanced Power Generation in Microbial Fuel Cell. Nano Energy 2018, 44, 174–180. [Google Scholar] [CrossRef]

- Wang, P.; Zhang, H.; Wang, H.; Li, D.; Xuan, J.; Zhang, L. Hybrid Manufacturing of 3D Hierarchical Porous Carbons for Electrochemical Storage. Adv. Mater. Technol. 2020, 5, 1901030. [Google Scholar] [CrossRef]

- Kleger, N.; Minas, C.; Bosshard, P.; Mattich, I.; Masania, K.; Studart, A.R. Hierarchical Porous Materials Made by Stereolithographic Printing of Photo-Curable Emulsions. Sci. Rep. 2021, 11, 22316. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, R.; Chen, X.; Hu, H.; Li, T.; Liu, Y.; Duan, Y. Carbon Scaffold with Controllable Small Pore Structure Based on Mask Projection Stereolithography. Mater. Today Commun. 2021, 28, 102694. [Google Scholar] [CrossRef]

- Szczurek, A.; Ortona, A.; Ferrari, L.; Rezaei, E.; Medjahdi, G.; Fierro, V.; Bychanok, D.; Kuzhir, P.; Celzard, A. Carbon Periodic Cellular Architectures. Carbon 2015, 88, 70–85. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, G.; Wu, Y.; Huang, Y.; Liu, Y.; He, J.; Wang, L.; Lian, Q.; Li, D. Cellular Carbon Microstructures Developed by Using Stereolithography. Carbon 2017, 123, 34–44. [Google Scholar] [CrossRef]

- Steldinger, H.; Esposito, A.; Brunnengräber, K.; Gläsel, J.; Etzold, B.J.M. Activated Carbon in the Third Dimension—3D Printing of a Tuned Porous Carbon. Adv. Sci. 2019, 6, 1901340. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Celzard, A.; Fierro, V. “Green”, Innovative, Versatile and Efficient Carbon Materials from Polyphenolic Plant Extracts. Carbon 2020, 167, 792–815. [Google Scholar] [CrossRef]

- Celzard, A.; Fierro, V.; Pizzi, A.; Zhao, W. Multifunctional Porous Solids Derived from Tannins. J. Phys. Conf. Ser. 2013, 416, 012023. [Google Scholar] [CrossRef] [Green Version]

- Koopmann, A.-K.; Torres-Rodríguez, J.; Salihovic, M.; Schoiber, J.; Musso, M.; Fritz-Popovski, G.; Huesing, N.; Elsaesser, M.S. Tannin-Based Nanoscale Carbon Spherogels as Electrodes for Electrochemical Applications. ACS Appl. Nano Mater. 2021, 4, 14115–14125. [Google Scholar] [CrossRef]

- Roux, D.G.; Ferreira, D.; Hundt, H.K.; Malan, E. Structure, Stereochemistry, and Reactivity of Natural Condensed Tannins as Basis for Their Extended Industrial Application. Appl. Polym. Symp. 1975, 28, 335–353. [Google Scholar]

- Blyweert, P.; Nicolas, V.; Macutkevic, J.; Fierro, V.; Celzard, A. Tannin-Based Resins for 3D Printing of Porous Carbon Architectures. ACS Sustain. Chem. Eng. 2022. Submitted. [Google Scholar]

- Cornell, J.A. Experiments with Mixtures: Designs, Models, and the Analysis of Mixture Data, 1st ed.; Wiley Series in Probability and Statistics; Wiley: Hoboken, NJ, USA, 2002; ISBN 978-0-471-39367-2. [Google Scholar]

- Liang, Y.; Fang, K.; Xu, Q. Uniform Design and Its Applications in Chemistry and Chemical Engineering. Chemom. Intell. Lab. Syst. 2001, 58, 43–57. [Google Scholar] [CrossRef]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef] [Green Version]

- Lundstedt, T.; Seifert, E.; Abramo, L.; Thelin, B.; Nyström, A.; Pettersen, J.; Bergman, R. Experimental Design and Optimization. Chemom. Intell. Lab. Syst. 1998, 42, 3–40. [Google Scholar] [CrossRef]

- Griffith, M.L.; Halloran, J.W. Freeform Fabrication of Ceramics via Stereolithography. J. Am. Ceram. Soc. 1996, 79, 2601–2608. [Google Scholar] [CrossRef] [Green Version]

- Zakeri, S.; Vippola, M.; Levänen, E. A Comprehensive Review of the Photopolymerization of Ceramic Resins Used in Stereolithography. Addit. Manuf. 2020, 35, 101177. [Google Scholar] [CrossRef]

- Montgomery, D.C.; Loredo, E.N.; Jearkpaporn, D.; Testik, M.C. Experimental Designs for Constrained Regions. Qual. Eng. 2002, 14, 587–601. [Google Scholar] [CrossRef]

- Autodesk Standard Clear Prototyping Resin (PR48) 2015. Available online: https://cdn2.hubspot.net/hubfs/1545937/Autodesk_Standard_Clear_PR48_Formulation.pdf?__hss (accessed on 15 February 2022).

- Schaub, D.A.; Montgomery, D.C. Using Experimental Design to Optimize the Stereolithography Process. Qual. Eng. 1997, 9, 575–585. [Google Scholar] [CrossRef]

- Chockalingam, K.; Jawahar, N.; Ramanathan, K.N.; Banerjee, P.S. Optimization of Stereolithography Process Parameters for Part Strength Using Design of Experiments. Int. J. Adv. Manuf. Technol. 2006, 29, 79–88. [Google Scholar] [CrossRef]

- Quintana, R. Design of Experiments Approach for Statistical Classification of Stereolithography Manufacturing Build Parameters: Effects of Build Orientation on Mechanical Properties for ASTM D-638 Type I Tensile Test Specimens of DSM Somos 11120 Resin; The University of Texas: Austin, TX, USA, 2007. [Google Scholar] [CrossRef]

- Gibson, L.J. Cellular Solids. MRS Bull. 2003, 28, 270–274. [Google Scholar] [CrossRef] [Green Version]

- Tondi, G.; Petutschnigg, A. Middle Infrared (ATR FT-MIR) Characterization of Industrial Tannin Extracts. Ind. Crops Prod. 2015, 65, 422–428. [Google Scholar] [CrossRef]

- Szczurek, A.; Martinez de Yuso, A.; Fierro, V.; Pizzi, A.; Celzard, A. Tannin-Based Monoliths from Emulsion-Templating. Mater. Des. 2015, 79, 115–126. [Google Scholar] [CrossRef]

- Szczurek, A.; Fierro, V.; Pizzi, A.; Celzard, A. Mayonnaise, Whipped Cream and Meringue, a New Carbon Cuisine. Carbon 2013, 58, 245–248. [Google Scholar] [CrossRef]

- Vivo-Vilches, J.F.; Karakashov, B.; Celzard, A.; Fierro, V.; El Hage, R.; Brosse, N.; Dufour, A.; Etienne, M. Carbon Monoliths with Hierarchical Porous Structure for All-Vanadium Redox Flow Batteries. Batteries 2021, 7, 55. [Google Scholar] [CrossRef]

- Wilson, P.; Vijayan, S.; Prabhakaran, K. Carbon Foams with a Triplex Pore Structure by Compression Molding of Molten Sucrose–NaCl Powder Pastes. Carbon 2017, 118, 545–555. [Google Scholar] [CrossRef]

- Gupta, S.; Dey, M.; Javaid, S.; Ji, Y.; Payne, S. On the Design of Novel Biofoams Using Lignin, Wheat Straw, and Sugar Beet Pulp as Precursor Material. ACS Omega 2020, 5, 17078–17089. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Gui, Y.; Zuo, S.; Li, J.; Wang, S. Preparation of Lignin-Based Carbon Foam Monoliths with High Strength and Developed Micrometer-Sized Cell/Nano-Sized Porous Structures Using a Self-Bubbling Method; Social Science Research Network: Rochester, NY, USA, 2021. [Google Scholar]

- Bao, L.; Xie, C.; Shi, J.; Teramoto, Y. Development of Lignin-Based Carbon Foam for Use as an FRP Sandwich Core Material. Polym. Compos. 2021, 42, 634–641. [Google Scholar] [CrossRef]

- Sartomer EMEA (France), Technical Data Sheet—SR238—1.6-Hexanediol Diacrylate Monomer. Available online: https://emea.sartomer.com/en/product-finders/product/f/sartomer_MonomerAcrylates_EMEA/p/sr238/ (accessed on 15 February 2022).

- Kumar, V.; Bhardwaj, Y.K.; Sabharwal, S. Coating Characteristics of Electron Beam Cured Bisphenol a Diglycidyl Ether Diacrylate Resin Containing 1,6-Hexanediol Diacrylate on Wood Surface. Prog. Org. Coat. 2006, 55, 316–323. [Google Scholar] [CrossRef]

- Davies, I.J.; Rawlings, R.D. Mechanical Properties in Compression of Low Density Carbon/Carbon Composites. Composites 1994, 25, 229–236. [Google Scholar] [CrossRef]

- Maiti, S.K.; Ashby, M.F.; Gibson, L.J. Fracture Toughness of Brittle Cellular Solids. Scr. Metall. 1984, 18, 213–217. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 978-1-119-11347-8. [Google Scholar]

| Component | Function | Content (wt.%) |

|---|---|---|

| Tannin | Bio-based carbon precursor | 25 |

| BAPO | Photoinitiator | 0.3 |

| CN154CG | Acrylated aromatic oligomer | 29.9 |

| PETA | Acrylated monomer | 29.9 |

| HDDA | Reactive diluent | 14.9 |

| Formulation Number | Acrylate Component and Its Weight Fraction | ||

|---|---|---|---|

| CN154CG | PETA | HDDA | |

| 1 | 0 | 0 | 1 |

| 2 | 0.4 | 0 | 0.6 |

| 3 | 0 | 0.4 | 0.6 |

| 4 | 0.4 | 0.4 | 0.2 |

| 5 | 0.2 | 0 | 0.8 |

| 6 | 0 | 0.2 | 0.8 |

| 7 | 0.4 | 0.2 | 0.4 |

| 8 | 0.2 | 0.4 | 0.4 |

| 9 | 0.2 | 0.2 | 0.6 |

| 10 | 0.1 | 0.1 | 0.8 |

| 11 | 0.3 | 0.1 | 0.6 |

| 12 | 0.1 | 0.3 | 0.6 |

| 13 | 0.3 | 0.3 | 0.4 |

| No. | Carbon Yield (%) | ρb (g·cm−3) | ρs (g·cm−3) | Φ (-) | Compressive Strength (MPa) | Strain at Break (%) | Young’s Modulus (MPa) |

|---|---|---|---|---|---|---|---|

| 1 | 16.8 | 0.411 | 1.620 | 0.746 | 2.6 | 3.72 | 67.9 |

| 2 | 18.9 | 0.467 | 1.624 | 0.732 | 3.6 | 3.92 | 197.7 |

| 3 | 19.1 | 0.399 | 1.694 | 0.764 | 1.6 | 2.55 | 85.3 |

| 4 | 20.8 | 0.404 | 1.847 | 0.781 | 4.3 | 1.67 | 205.0 |

| 5 | 17.3 | 0.447 | 1.656 | 0.730 | 1.1 | 2.24 | 100.2 |

| 6 | 16.2 | 0.385 | 1.779 | 0.784 | 0.6 | 5.90 | 20.9 |

| 7 | 20.5 | 0.422 | 1.755 | 0.759 | 4.7 | 3.88 | 205.5 |

| 8 | 21.3 | 0.432 | 1.756 | 0.757 | 5.7 | 4.62 | 203.3 |

| 9 | 18.6 | 0.433 | 1.720 | 0.748 | 3.5 | 1.66 | 160.0 |

| 10 | 17.2 | 0.427 | 1.793 | 0.767 | 1.3 | 6.01 | 65.0 |

| 11 | 20.3 | 0.457 | 1.716 | 0.734 | 1.8 | 3.58 | 113.6 |

| 12 | 16.4 | 0.463 | 1.666 | 0.722 | 1.7 | 1.96 | 120.5 |

| 13 | 21.5 | 0.419 | 1.689 | 0.752 | 6.4 | 4.94 | 203.9 |

| Source | Sum of Squares | Degree of Freedom | Mean Square | F-Value | Prob > F |

|---|---|---|---|---|---|

| ANOVA Carbon Yield | |||||

| Model | 36.61 | 6 | 6.10 | 4.79 | 0.0390 * |

| (1) Linear Mixture | 31.51 | 2 | 15.75 | 12.38 | 0.0074 * |

| AB | 2.76 | 1 | 2.76 | 2.17 | 0.1916 |

| AC | 0.7971 | 1 | 0.7971 | 0.6264 | 0.4588 |

| BC | 3.96 | 1 | 3.96 | 3.12 | 0.1280 x |

| ABC | 4.16 | 1 | 4.16 | 3.27 | 0.1207 x |

| Residual | 7.63 | 6 | 1.27 | ||

| Corrected Total Sum of Squares | 44.24 | 12 | |||

| R-squared | 0.8274 | ||||

| ANOVA Compressive Strength | |||||

| Model | 35.90 | 6 | 5.98 | 5.76 | 0.0256 * |

| (1) Linear Mixture | 22.04 | 2 | 11.02 | 10.61 | 0.0107 * |

| AB | 4.78 | 1 | 4.78 | 4.60 | 0.0755 |

| AC | 3.40 | 1 | 3.40 | 3.27 | 0.1204 |

| BC | 7.18 | 1 | 7.18 | 6.91 | 0.0391 * |

| ABC | 11.57 | 1 | 11.57 | 11.14 | 0.0157 * |

| Residual | 6.23 | 6 | 1.04 | ||

| Corrected Total Sum of Squares | 42.13 | 12 | |||

| R-Squared | 0.8521 | ||||

| ANOVA Young Modulus | |||||

| Model | 47,545.51 | 6 | 7924.25 | 15.64 | 0.0020 * |

| (1) Linear Mixture | 41,471.29 | 2 | 20,735.65 | 40.93 | 0.0003 * |

| AB | 2994.04 | 1 | 2994.04 | 5.91 | 0.0511 |

| AC | 622.50 | 1 | 622.50 | 1.23 | 0.3101 |

| BC | 4793.88 | 1 | 4793.88 | 9.46 | 0.0218 * |

| ABC | 4573.96 | 1 | 4573.96 | 9.03 | 0.0239 * |

| Residual | 3039.61 | 6 | 506.60 | ||

| Corrected Total Sum of Squares | 50,585.12 | 12 | |||

| R-Squared | 0.9399 | ||||

| Experimental | Predicted by the Model | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Sample | Desirability | ρb (g·cm−3) | Carbon Yield (%) | Compressive Strength (MPa) | Young’s Modulus (MPa) | Carbon Yield (%) | Compressive Strength (MPa) | Young’s Modulus (MPa) | |

| OF-1 | 0.952 | 0.465 | 23.09 ± 1.0 | 5.2 ± 0.3 | 216.7 ± 2.2 | 21.46 | 5.7 | 218.4 | |

| OF-2 | 0.905 | 0.450 | 22.68 ± 1.2 | 5.4 ± 0.1 | 211.4 ± 2.3 | 20 | 20.99 | 5.4 | 212.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blyweert, P.; Nicolas, V.; Fierro, V.; Celzard, A. Experimental Design Optimization of Acrylate—Tannin Photocurable Resins for 3D Printing of Bio-Based Porous Carbon Architectures. Molecules 2022, 27, 2091. https://doi.org/10.3390/molecules27072091

Blyweert P, Nicolas V, Fierro V, Celzard A. Experimental Design Optimization of Acrylate—Tannin Photocurable Resins for 3D Printing of Bio-Based Porous Carbon Architectures. Molecules. 2022; 27(7):2091. https://doi.org/10.3390/molecules27072091

Chicago/Turabian StyleBlyweert, Pauline, Vincent Nicolas, Vanessa Fierro, and Alain Celzard. 2022. "Experimental Design Optimization of Acrylate—Tannin Photocurable Resins for 3D Printing of Bio-Based Porous Carbon Architectures" Molecules 27, no. 7: 2091. https://doi.org/10.3390/molecules27072091

APA StyleBlyweert, P., Nicolas, V., Fierro, V., & Celzard, A. (2022). Experimental Design Optimization of Acrylate—Tannin Photocurable Resins for 3D Printing of Bio-Based Porous Carbon Architectures. Molecules, 27(7), 2091. https://doi.org/10.3390/molecules27072091