Characterisation of Flavour Attributes in Egg White Protein Using HS-GC-IMS Combined with E-Nose and E-Tongue: Effect of High-Voltage Cold Plasma Treatment Time

Abstract

1. Introduction

2. Results and Discussions

2.1. Chemical Components Composition of High-Voltage Cold Plasma Treated Egg White Protein

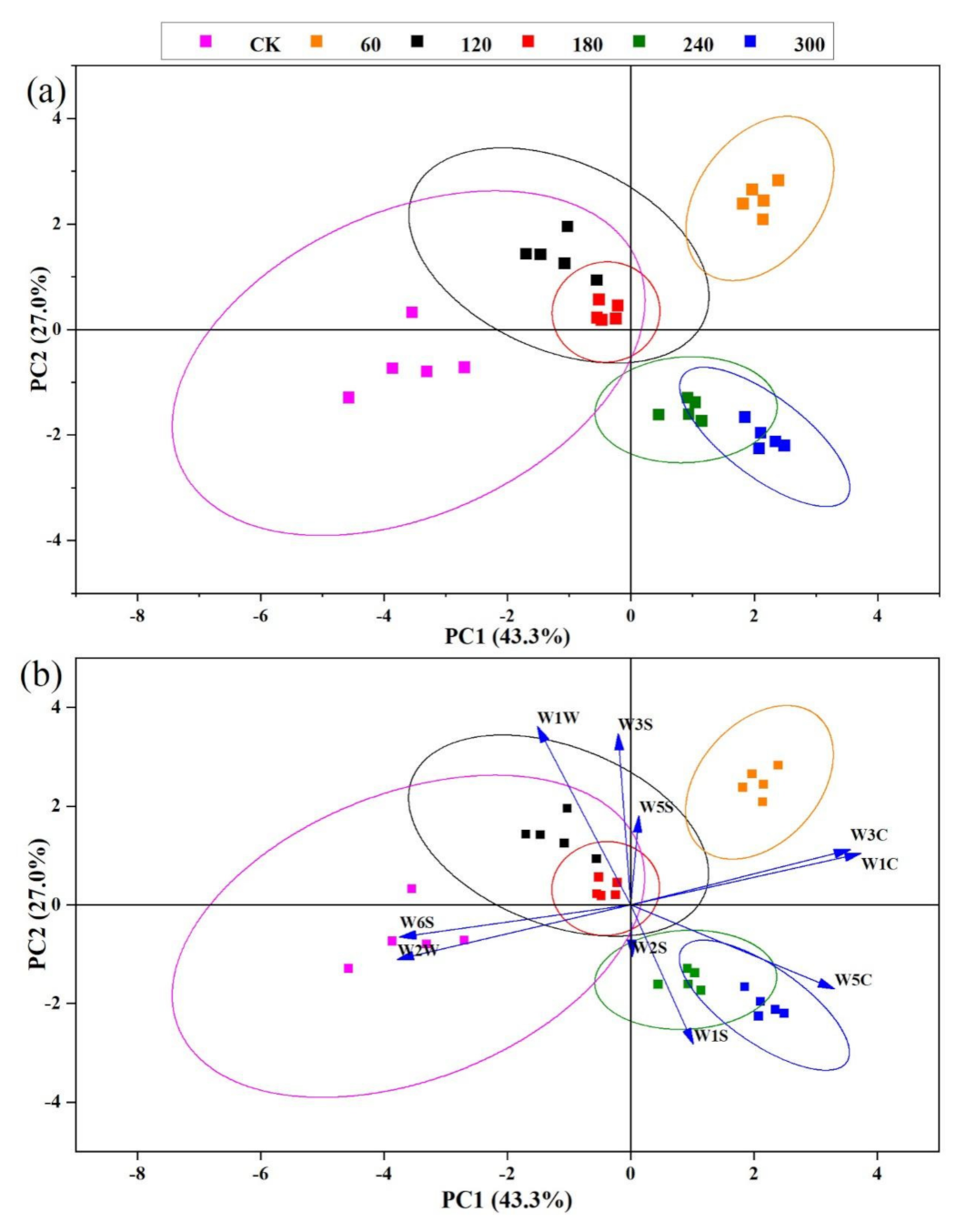

2.2. Analysis of Odour Attributes Using Electronic Nose

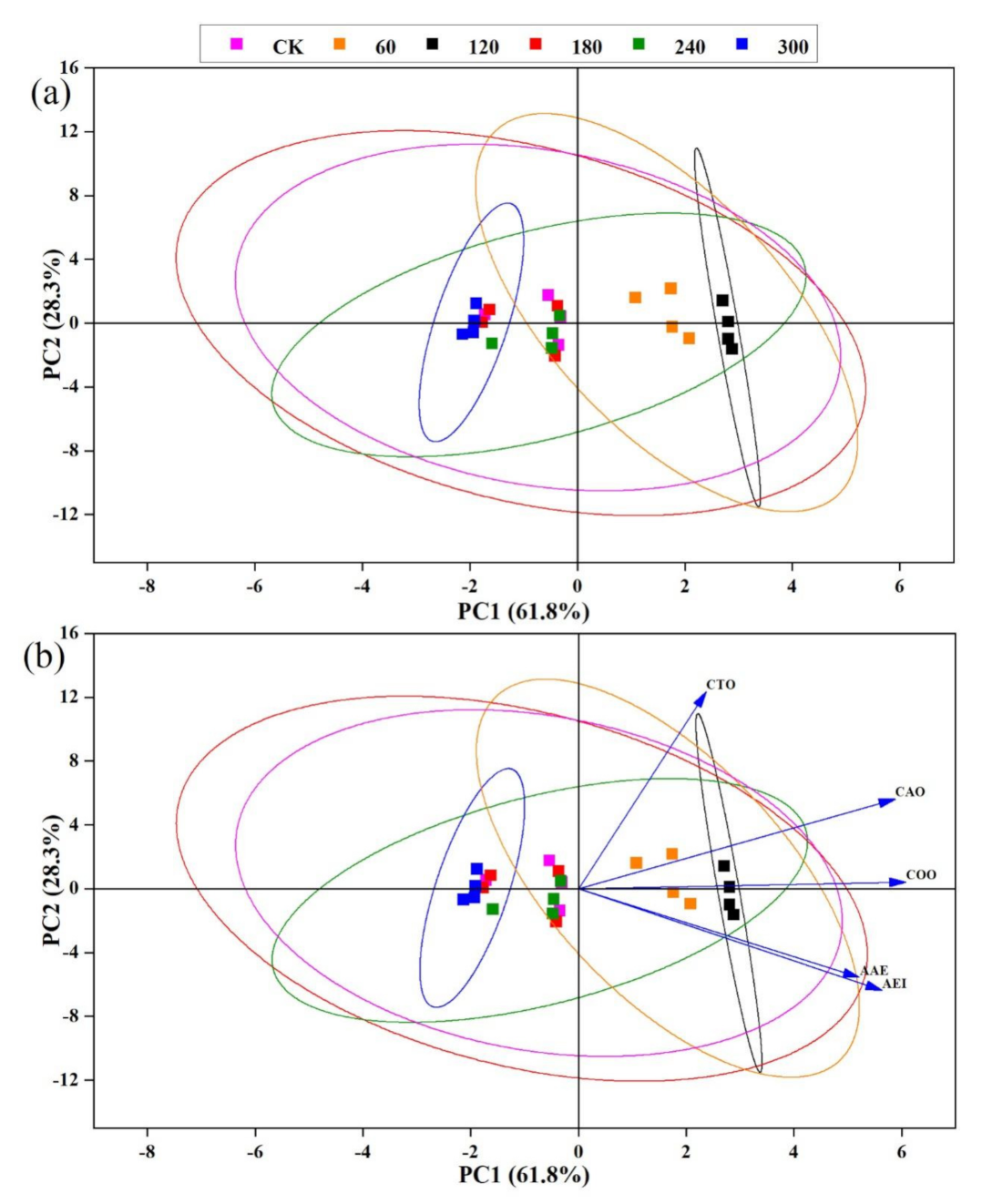

2.3. Analysis of Taste Attributes Using E-Tongue

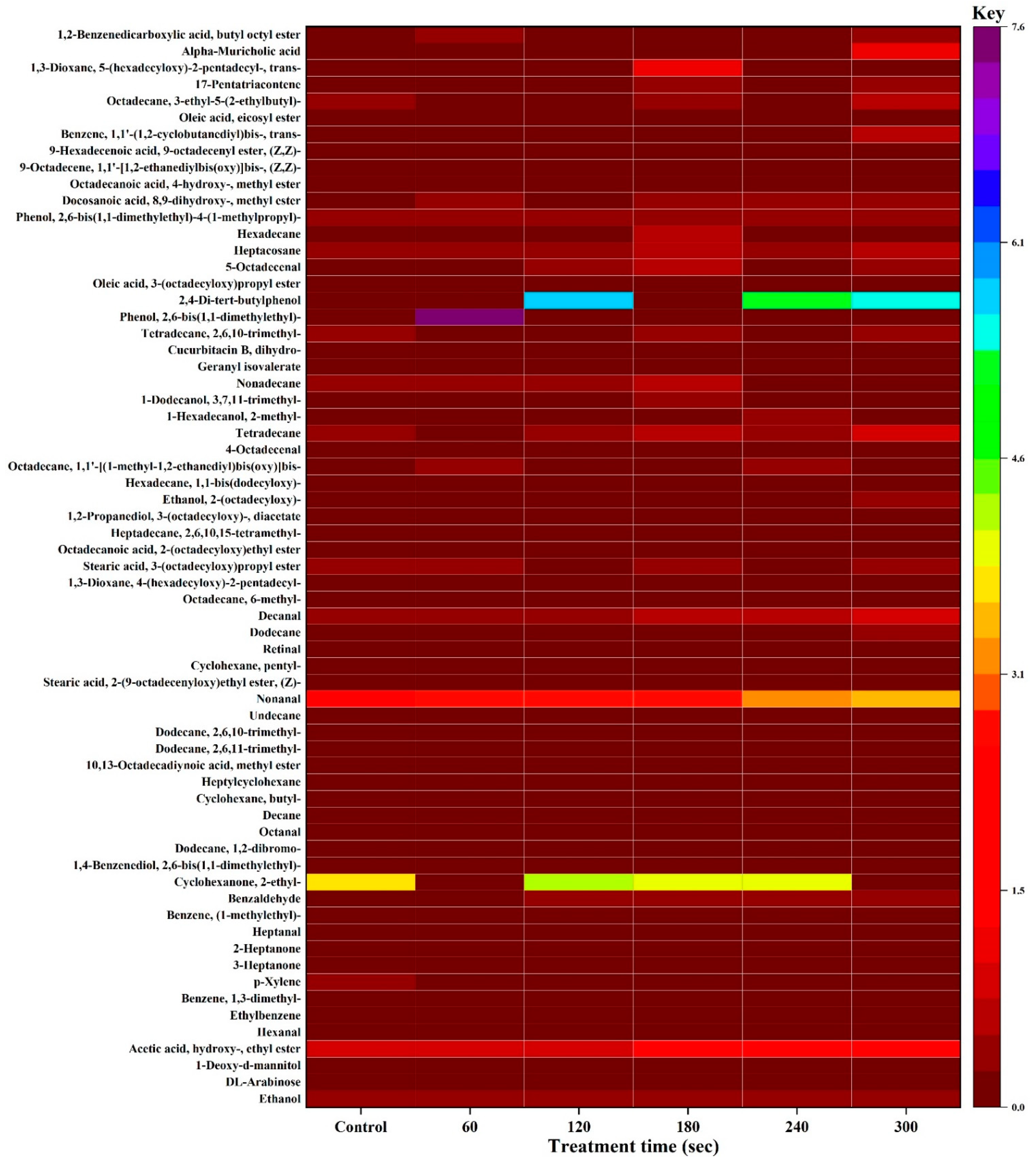

2.4. Volatile Organic Compounds Analysis

2.4.1. Identification of Volatile Compounds from Plasma-Treated Egg White Protein

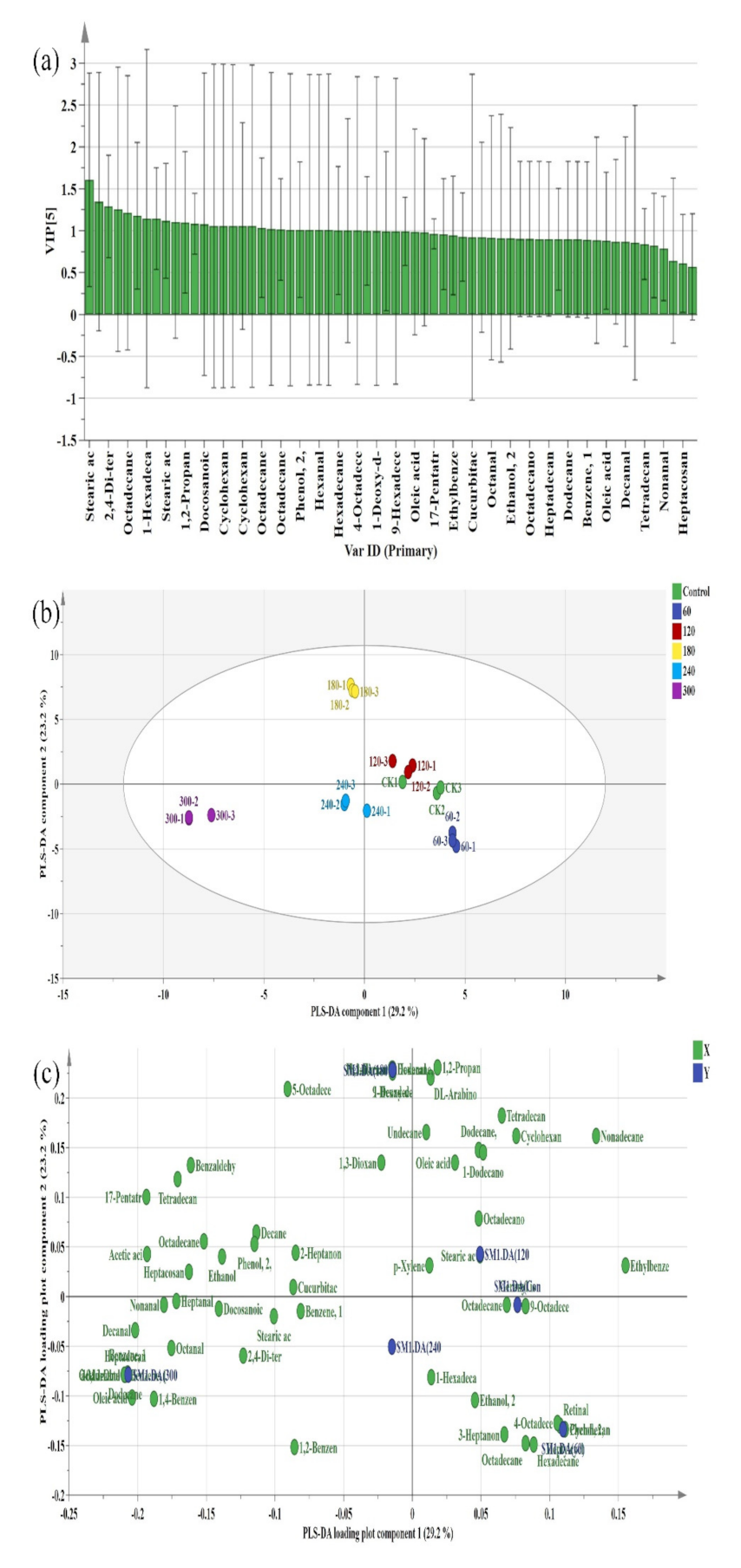

2.4.2. Discrimination of Volatile Compounds from Plasma-Treated Egg White Protein

2.4.3. Classification of Volatile Compounds from Plasma-Treated Egg White Protein

Acids

Alcohols

Aldehydes

Alkanes

Cucurbitacins

Esters

Hydrocarbons

Ketones

3. Materials and Methods

3.1. Reagents and Solutions

3.2. Egg White Protein Preparation

3.3. High-Voltage Cold Plasma Device and Treatment

3.4. Chemical Components Analysis of Egg White Protein

3.5. Electronic Nose Analysis of Egg White Protein

3.6. Electronic Tongue Analysis of Egg White Protein

3.7. Headspace-Gas Chromatography-Ion Mobility Spectrometry

3.8. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cheng, Y.; Chi, Y.; Geng, X.; Chi, Y. Effect of 2,2′-azobis(2-amidinopropane) dihydrochloride (AAPH) induced oxidation on the physicochemical properties, in vitro digestibility, and nutritional value of egg white protein. LWT 2021, 143, 111103. [Google Scholar] [CrossRef]

- Belchior, D.C.V.; Freire, M.G. Simultaneous separation of egg white proteins using aqueous three-phase partitioning systems. J. Mol. Liq. 2021, 336, 116245. [Google Scholar] [CrossRef]

- Jiang, Z.; Kimura, Y.; Shirouchi, B.; Tanaka, Y.; Tsai, W.-T.; Yuan, X.; Sato, M. Dietary Egg White Protein Hydrolysate Improves Orotic Acid-Induced Fatty Liver in Rats by Promoting Hepatic Phospholipid Synthesis and Microsomal Triglyceride Transfer Protein Expression. J. Nutr. Biochem. 2021, 98, 108820. [Google Scholar] [CrossRef]

- Guha, S.; Majumder, K.; Mine, Y. Egg Proteins. In Encyclopedia of Food Chemistry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 74–84. [Google Scholar]

- Mine, Y. Recent advances in the understanding of egg white protein functionality. Trends Food Sci. Technol. 1995, 6, 225–232. [Google Scholar] [CrossRef]

- Wang, C.; Li, J.; Li, X.; Chang, C.; Zhang, M.; Gu, L.; Su, Y.; Yang, Y. Emulsifying properties of glycation or glycation-heat modified egg white protein. Food Res. Int. 2019, 119, 227–235. [Google Scholar] [CrossRef] [PubMed]

- Yüceer, M.; Caner, C. Effects of protease-hydrolyzed egg white on the meringue batter properties and meringue textural and sensory properties during storage. Int. J. Gastron. Food Sci. 2021, 25, 100409. [Google Scholar] [CrossRef]

- Akkouche, Z.; Aissat, L.; Madani, K. Effect of Heat on Egg White Proteins. In Proceedings of the International Conference on Applied Life Sciences (ICALS2012), Konya, Turkey, 10–12 September 2012; p. 6. [Google Scholar]

- Wu, L.; Zhao, W.; Yang, R.; Chen, X. Effects of pulsed electric fields processing on stability of egg white proteins. J. Food Eng. 2014, 139, 13–18. [Google Scholar] [CrossRef]

- He, W.; Ren, F.; Wang, Y.; Gao, X.; Wang, X.; Dai, X.; Song, J. Application of GC-IMS in Detection of Food Flavor Substances. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Qingdao, China, 12–14 June 2020; Volume 545. [Google Scholar] [CrossRef]

- Tan, F.; Wang, P.; Zhan, P.; Tian, H. Characterization of key aroma compounds in flat peach juice based on gas chromatography-mass spectrometry-olfactometry (GC-MS-O), odor activity value (OAV), aroma recombination, and omission experiments. Food Chem. 2021, 366, 130604. [Google Scholar] [CrossRef]

- Cavanna, D.; Zanardi, S.; Dall’Asta, C.; Suman, M. Ion mobility spectrometry coupled to gas chromatography: A rapid tool to assess eggs freshness. Food Chem. 2019, 271, 691–696. [Google Scholar] [CrossRef]

- Jin, Y.; Liang, R.; Liu, J.; Lin, S.; Yu, Y.; Cheng, S. Effect of structure changes on hydrolysis degree, moisture state, and thermal denaturation of egg white protein treated by electron beam irradiation. LWT 2017, 77, 134–141. [Google Scholar] [CrossRef]

- Ren, L.; Ma, J.; Lv, Y.; Tong, Q.; Guo, H. Characterization of key off-odor compounds in thermal duck egg gels by GC-olfactometry-MS, odor activity values, and aroma recombination. LWT 2021, 143, 111182. [Google Scholar] [CrossRef]

- Nasiru, M.M.; Frimpong, E.B.; Muhammad, U.; Qian, J.; Mustapha, A.T.; Yan, W.; Zhuang, H.; Zhang, J. Dielectric barrier discharge cold atmospheric plasma: Influence of processing parameters on microbial inactivation in meat and meat products. Compr. Rev. Food Sci. Food Saf. 2021, 20, 2626–2659. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Q.; Cheng, Z.; Zhang, J.; Nasiru, M.M.; Wang, Y.; Fu, L. Atmospheric cold plasma treatment of soybean protein isolate: Insights into the structural, physicochemical, and allergenic characteristics. J. Food Sci. 2020, 86, 68–77. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Zhuang, H.; Nasiru, M.M.; Yuan, Y.; Zhang, J.; Yan, W. Changes in color, myoglobin, and lipid oxidation in beef patties treated by dielectric barrier discharge cold plasma during storage. Meat Sci. 2021, 176, 108456. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Nasiru, M.M.; Yan, W.; Zhuang, H.; Zhou, G.; Zhang, J. Effects of dielectric barrier discharge cold plasma treatment on the structure and binding capacity of aroma compounds of myofibrillar proteins from dry-cured bacon. LWT 2020, 117, 108606. [Google Scholar] [CrossRef]

- Thirumdas, R.; Kadam, D.; Annapure, U.S. Cold Plasma: An Alternative Technology for the Starch Modification. Food Biophys. 2017, 12, 129–139. [Google Scholar] [CrossRef]

- Luo, J.; Yan, W.; Nasiru, M.M.; Zhuang, H.; Zhou, G.; Zhang, J. Evaluation of physicochemical properties and volatile compounds of Chinese dried pork loin curing with plasma-treated water brine. Sci. Rep. 2019, 9, 13793. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.; Ramaswamy, H. Effect of high pressure processing on color and textural properties of eggs. J. Food Res. 2013, 2, 11. [Google Scholar] [CrossRef][Green Version]

- Van der Plancken, I.; Van Loey, A.; Hendrickx, M.E. Foaming properties of egg white proteins affected by heat or high pressure treatment. J. Food Eng. 2007, 78, 1410–1426. [Google Scholar] [CrossRef]

- Liu, X.D.; Han, R.X.; Yun, H.; Jung, K.C.; Jin, D.I.; Lee, B.D.; Min, T.S.; Jo, C. Effect of irradiation on foaming properties of egg white proteins. Poult. Sci. 2009, 88, 2435–2441. [Google Scholar] [CrossRef]

- Song, H.-P.; Kim, B.; Choe, J.-H.; Jung, S.; Kim, K.-S.; Kim, D.-H.; Jo, C. Improvement of foaming ability of egg white product by irradiation and its application. Radiat. Phys. Chem. 2009, 78, 217–221. [Google Scholar] [CrossRef]

- Jun, S.; Yaoyao, M.; Hui, J.; Obadi, M.; Zhongwei, C.; Bin, X. Effects of single- and dual-frequency ultrasound on the functionality of egg white protein. J. Food Eng. 2020, 277, 109902. [Google Scholar] [CrossRef]

- Xiong, W.; Wang, Y.; Zhang, C.; Wan, J.; Shah, B.R.; Pei, Y.; Zhou, B.; Li, J.; Li, B. High intensity ultrasound modified ovalbumin: Structure, interface and gelation properties. Ultrason. Sonochem. 2016, 31, 302–309. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, R.; Tang, Y.; Lu, R. Combined effects of heat and PEF on microbial inactivation and quality of liquid egg whites. Int. J. Food Eng. 2007, 3. [Google Scholar] [CrossRef]

- Zhao, W.; Yang, R.; Tang, Y.; Zhang, W.; Hua, X. Investigation of the Protein−Protein Aggregation of Egg White Proteins under Pulsed Electric Fields. J. Agric. Food Chem. 2009, 57, 3571–3577. [Google Scholar] [CrossRef]

- Chen, T.; Qi, X.; Chen, M.; Chen, B. Gas Chromatography-Ion Mobility Spectrometry Detection of Odor Fingerprint as Markers of Rapeseed Oil Refined Grade. J. Anal. Methods Chem. 2019, 2019, 3163204. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Yang, R.; Lin, S.; Ye, H.; Chen, F. Identification of key volatiles responsible for aroma changes of egg white antioxidant peptides during storage by HS-SPME-GC-MS and sensory evaluation. J. Food Meas. Charact. 2017, 11, 1118–1127. [Google Scholar] [CrossRef]

- Chen, X.; Chen, H.; Xiao, J.; Liu, J.; Tang, N.; Zhou, A. Variations of volatile flavour compounds in finger citron (Citrus medica L. var. sarcodactylis) pickling process revealed by E-nose, HS-SPME-GC-MS and HS-GC-IMS. Food Res. Int. 2020, 138, 109717. [Google Scholar] [CrossRef] [PubMed]

- Alty, L.T. Analysis of Fatty Acid Methyl Esters in Egg Yolk Using GC–MS. J. Chem. Educ. 2009, 86, 962. [Google Scholar] [CrossRef]

- Gouda, M.; Ma, M.; Sheng, L.; Xiang, X. SPME-GC-MS & metal oxide E-Nose 18 sensors to validate the possible interactions between bio-active terpenes and egg yolk volatiles. Food Res. Int. 2019, 125, 108611. [Google Scholar] [CrossRef] [PubMed]

- Plagemann, I.; Zelena, K.; Krings, U.; Berger, R.G. Volatile flavours in raw egg yolk of hens fed on different diets. J. Sci. Food Agric. 2011, 91, 2061–2065. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Wu, M.; Lin, R.; Li, X.; Ding, H.; Han, L.; Yang, W.; Song, X.; Li, W.; Qu, H.; et al. Application and development trends of gas chromatography–ion mobility spectrometry for traditional Chinese medicine, clinical, food and environmental analysis. Microchem. J. 2021, 168, 106527. [Google Scholar] [CrossRef]

- Wang, S.; Chen, H.; Sun, B. Recent progress in food flavor analysis using gas chromatography-ion mobility spectrometry (GC-IMS). Food Chem. 2020, 315, 126158. [Google Scholar] [CrossRef]

- Chen, J.; Tao, L.; Zhang, T.; Zhang, J.; Wu, T.; Luan, D.; Ni, L.; Wang, X.; Zhong, J. Effect of four types of thermal processing methods on the aroma profiles of acidity regulator-treated tilapia muscles using E-nose, HS-SPME-GC-MS, and HS-GC-IMS. LWT 2021, 147, 111585. [Google Scholar] [CrossRef]

- Yongwei, W.; Wang, J.; Zhou, B.; Lu, Q. Monitoring storage time and quality attribute of egg based on electronic nose. Anal. Chim. Acta 2009, 650, 183–188. [Google Scholar] [CrossRef] [PubMed]

- Dutta, R.; Hines, E.L.; Gardner, J.W.; Udrea, D.D.; Boilot, P. Non-destructive egg freshness determination: An electronic nose based approach. Meas. Sci. Technol. 2003, 14, 190–198. [Google Scholar] [CrossRef]

- Yimenu, S.M.; Kim, J.Y.; Kim, B.S. Prediction of egg freshness during storage using electronic nose. Poult. Sci. 2017, 96, 3733–3746. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Jin, G.; Jin, Y.; Ma, M.; Wang, N.; Liu, C.; He, L. Discriminating eggs from different poultry species by fatty acids and volatiles profiling: Comparison of SPME-GC/MS, electronic nose, and principal component analysis method. Eur. J. Lipid Sci. Technol. 2014, 116, 1044–1053. [Google Scholar] [CrossRef]

- Blanco, C.A.; de la Fuente, R.; Caballero, I.; Rodríguez-Méndez, M.L. Beer discrimination using a portable electronic tongue based on screen-printed electrodes. J. Food Eng. 2015, 157, 57–62. [Google Scholar] [CrossRef]

- Gutiérrez-Capitán, M.; Santiago, J.-L.; Vila-Planas, J.; Llobera, A.; Boso, S.; Gago, P.; Martínez, M.-C.; Jiménez-Jorquera, C. Classification and Characterization of Different White Grape Juices by Using a Hybrid Electronic Tongue. J. Agric. Food Chem. 2013, 61, 9325–9332. [Google Scholar] [CrossRef] [PubMed]

- Persaud, K. Electronic Noses and Tongues in the Food Industry. In Electronic Noses and Tongues in Food Science; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–12. [Google Scholar]

- Rodríguez-Méndez, M.L.; Apetrei, C.; De Saja, J.A. Electronic Tongues Purposely Designed for the Organoleptic Characterization of Olive Oils. In Olives and Olive Oil in Health and Disease Prevention; Preedy, V.R., Watson, R.R., Eds.; Academic Press: San Diego, CA, USA, 2010; pp. 525–532. [Google Scholar]

- Chen, C.; Chi, Y.-J.; Xu, W. Comparisons on the Functional Properties and Antioxidant Activity of Spray-Dried and Freeze-Dried Egg White Protein Hydrolysate. Food Bioprocess Technol. 2011, 5, 2342–2352. [Google Scholar] [CrossRef]

- Song, J.; Shao, Y.; Yan, Y.; Li, X.; Peng, J.; Guo, L. Characterization of volatile profiles of three colored quinoas based on GC-IMS and PCA. LWT 2021, 146, 111292. [Google Scholar] [CrossRef]

- Scott, S.M.; James, D.; Ali, Z. Data analysis for electronic nose systems. Microchim. Acta 2006, 156, 183–207. [Google Scholar] [CrossRef]

- Harlina, P.W.; Ma, M.; Shahzad, R.; Gouda, M.M.; Qiu, N. Effect of clove extract on lipid oxidation, antioxidant activity, volatile compounds and fatty acid composition of salted duck eggs. J. Food Sci. Technol. 2018, 55, 4719–4734. [Google Scholar] [CrossRef] [PubMed]

- Sun, J.; Chang, C.; Su, Y.; Gu, L.; Yang, Y.; Li, J. Impact of saccharides on the foam properties of egg white: Correlation between rheological, interfacial properties and foam properties. Food Hydrocolloids 2022, 122, 107088. [Google Scholar] [CrossRef]

- Hou, H.; Liu, C.; Lu, X.; Fang, D.; Hu, Q.; Zhang, Y.; Zhao, L. Characterization of flavor frame in shiitake mushrooms (Lentinula edodes) detected by HS-GC-IMS coupled with electronic tongue and sensory analysis: Influence of drying techniques. LWT 2021, 146, 111402. [Google Scholar] [CrossRef]

- AguinagaBósquez, J.P.; Kovacs, Z.; Gillay, Z.; Bázár, G.; Palkó, C.; Hingyi, H.; Csavajda, É.; Üveges, M.; JókainéSzatura, Z.; Barbulescu, I.D.; et al. Evaluating the Effect of a Brewery By-Product as Feed Supplementation on the Quality of Eggs by Means of a Human Panel and E-Tongue and E-Nose Analysis. Chemosensors 2021, 9, 213. [Google Scholar] [CrossRef]

- Feng, X.; Wang, H.; Wang, Z.; Huang, P.; Kan, J. Discrimination and characterization of the volatile organic compounds in eight kinds of huajiao with geographical indication of China using electronic nose, HS-GC-IMS and HS-SPME-GC–MS. Food Chem. 2021, 375, 131671. [Google Scholar] [CrossRef]

- Schwolow, S.; Gerhardt, N.; Rohn, S.; Weller, P. Data fusion of GC-IMS data and FT-MIR spectra for the authentication of olive oils and honeys—is it worth to go the extra mile? Anal. Bioanal. Chem. 2019, 411, 6005–6019. [Google Scholar] [CrossRef] [PubMed]

- Umair, M.; Jabbar, S.; Nasiru, M.; Sultana, T.; Senan, A.; Awad, F.; Hong, Z.; Zhang, J. Exploring the Potential of High-Voltage Electric Field Cold Plasma (HVCP) Using a Dielectric Barrier Discharge (DBD) as a Plasma Source on the Quality Parameters of Carrot Juice. Antibiotics 2019, 8, 235. [Google Scholar] [CrossRef] [PubMed]

- Kern, F., Jr. Normal plasma cholesterol in an 88-year-old man who eats 25 eggs a day. Mechanisms of adaptation. N. Engl. J. Med. 1991, 324, 896–899. [Google Scholar] [CrossRef]

- Xiang, X.L.; Jin, G.F.; Gouda, M.; Jin, Y.G.; Ma, M.H. Characterization and classification of volatiles from different breeds of eggs by SPME-GC-MS and chemometrics. Food Res. Int. 2019, 116, 767–777. [Google Scholar] [CrossRef] [PubMed]

- Garg, S.; Kaul, S.; Wadhwa, R. Cucurbitacin B and cancer intervention: Chemistry, biology and mechanisms (Review). Int. J. Oncol. 2017, 52, 19–37. [Google Scholar] [CrossRef] [PubMed]

- Luo, J.; Nasiru, M.M.; Zhuang, H.; Zhou, G.; Zhang, J. Effects of partial NaCl substitution with high-temperature ripening on proteolysis and volatile compounds during process of Chinese dry-cured lamb ham. Food Res. Int. 2021, 140, 110001. [Google Scholar] [CrossRef]

- Maga, J.A. Egg and egg product flavor. J. Agric. Food Chem. 1982, 30, 9–14. [Google Scholar] [CrossRef]

- Yang, P.; Zheng, Y.; You, M.; Song, H.; Zou, T. Characterization of key aroma-active compounds in four commercial egg flavorSachimas with differing egg content. J. Food Biochem. 2019, 43, e13040. [Google Scholar] [CrossRef] [PubMed]

- Umair, M.; Jabbar, S.; Ayub, Z.; Aadil, R.M.; Abid, M.; Zhang, J.; Liqing, Z. Recent Advances in Plasma Technology: Influence of Atmospheric Cold Plasma on Spore Inactivation. Food Rev. Int. 2021, 1–23. [Google Scholar] [CrossRef]

- Umair, M.; Jabbar, S.; Nasiru, M.M.; Senan, A.M.; Zhuang, H.; Zhang, J. Sequential Application of High-Voltage Electric Field Cold Plasma Treatment and Acid Blanching Improves the Quality of Fresh Carrot Juice (Daucus carota L.). J. Agric. Food Chem. 2020, 68, 15311–15318. [Google Scholar] [CrossRef] [PubMed]

- Umair, M.; Jabbar, S.; Yue, L.; Nasiru, M.M.; Jianhao, Z.; Abid, M.; Murtaza, M.A.; Zhao, L. Comparative study: Thermal and non thermal treatment on enzyme deactivation and selected quality attributes of fresh carrot juice. Int. J. Food Sci. Technol. 2021, 57, 827–841. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC International. In Association of Official Analysis Chemistry, 18th ed.; AOAC: Washington, DC, USA, 2005. [Google Scholar]

- Qian, J.; Zhuang, H.; Nasiru, M.M.; Muhammad, U.; Zhang, J.; Yan, W. Action of plasma-activated lactic acid on the inactivation of inoculated Salmonella Enteritidis and quality of beef. Innov. Food Sci. Emerg. 2019, 57, 102196. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, Y.; Meng, Q.; Li, N.; Ren, L. Evaluation of Beef by Electronic Tongue System TS-5000Z: Flavor Assessment, Recognition and Chemical Compositions According to Its Correlation with Flavor. PLoS ONE 2015, 10, e0137807. [Google Scholar] [CrossRef] [PubMed]

| Chemical Component Composition (%w/w) | Treatment Time (s) | |||||

|---|---|---|---|---|---|---|

| 0 | 60 | 120 | 180 | 240 | 300 | |

| Moisture content | 88.33 ± 0.58 a | 88.33 ± 0.58 a | 88.37 ± 1.00 a | 87.77 ± 0.55 a | 87.43 ± 0.78 a | 88.33 ± 0.79 a |

| Protein | 11.00 ± 0.00 a | 10.83 ± 0.21 a | 10.83 ± 0.21 a | 10.79 ± 0.17 a | 10.92 ± 0.07 a | 11.00 ± 0.07 a |

| Minerals | 0.79 ± 0.01 a | 0.79 ± 0.01 a | 0.75 ± 0.06 a | 0.80 ± 0.13 a | 0.95 ± 0.03 b | 0.95 ± 0.03 b |

| Reducing sugars | 0.19 ± 0.01 a | 0.18 ± 0.02 a | 0.18 ± 0.02 a | 0.18 ± 0.02 a | 0.19 ± 0.01 a | 0.19 ± 0.01 a |

| Classification | RT | Volatile Compounds Attributes | Area (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compound Name | SI | RSI | CAS No. | Formula | Control | 60 s | 120 s | 180 s | 240 s | 300 s | ||

| Acids | 43.03 | Alpha-Muricholic acid | 607 | 629 | 2393-58-0 | C24H40O5 | - | - | - | - | - | 1.48 ± 0.11 vA |

| Total | 1.48 ± 0.11 | |||||||||||

| Alcohols | 3.08 | Ethanol | 860 | 867 | 64-17-5 | C2H6O | 0.39 ± 0.04 aA | 0.41 ± 0.06 aA | 0.50 ± 0.09 aB | 0.58 ± 0.12 aB | 0.45 ± 0.36 aB | 0.65 ± 0.15 aC |

| 4.82 | 1-Deoxy-d-mannitol | 639 | 676 | 60965-81-3 | C14H14O5 | - | - | - | 0.02 ± 0.01 bA | - | - | |

| 21.42 | 1,4-Benzenediol, 2,6-bis(1,1-dimethylethyl)- | 608 | 629 | 2444-28-2 | C14H22O2 | - | - | - | - | 0.19 ± 0.03 cA | 0.19 ± 0.02 iB | |

| 33.31 | Ethanol, 2-(octadecyloxy)- | 727 | 755 | 2136-72-3 | C20H42O2 | - | 0.22 ± 0.03 mA | 0.23 ± 0.08 iA | 0.26 ± 0.08 oB | 0.30 ± 0.27 aB | 0.37 ± 0.02 oB | |

| 34.46 | 1-Hexadecanol, 2-methyl- | 694 | 720 | 2490-48-4 | C17H36O | - | 0.18 ± 0.03 hA | - | - | 0.66 ± 0.31 wB | - | |

| 34.64 | 1-Dodecanol, 3,7,11-trimethyl- | 725 | 755 | 6750-34-1 | C15H32O | - | 0.18 ± 0.10 hA | 0.25 ± 0.11 dA | 0.66 ± 0.31 pB | - | - | |

| 36.94 | Phenol, 2,6-bis(1,1-dimethylethyl)- | 875 | 927 | 128-39-2 | C14H22O | - | 11.01 ± 1.11 oA | - | - | - | - | |

| 36.94 | 2,4-Di-tert-butylphenol | 889 | 889 | 96-76-4 | C14H22O | - | - | 8.98 ± 0.64 oA | - | 7.82 ± 0.58 lA | 6.86 ± 0.82 qA | |

| 39.15 | Phenol, 2,6-bis(1,1-dimethylethyl)-4-(1-methylpropyl)- | 815 | 857 | 17540-75-9 | C18H30O | 0.59 ± 0.10 hA | 0.52 ± 0.02 pB | 0.53 ± 0.06 pC | 0.63 ± 0.03 yD | 0.54 ± 0.06 mE | 0.61 ± 0.02 tF | |

| Total | 0.98 ± 0.14 A | 12.52 ± 1.33 B | 10.49 ± 0.98 C | 2.15 ± 0.55 D | 9.96 ± 1.61 E | 10.29 ± 1.03 F | ||||||

| Aldehydes | 4.81 | DL-Arabinose | 628 | 662 | 20235-19-2 | C5H10O5 | - | - | 0.01 ± 0.01 bA | 0.02 ± 0.01 bA | - | 0.01 ± 0.01 bA |

| 12.63 | Hexanal | 709 | 893 | 66-25-1 | C6H12O | - | - | - | 0.19 ± 0.02 dA | - | - | |

| 17.59 | Heptanal | 717 | 810 | 111-71-7 | C7H14O | 0.09 ± 0.01 aA | 0.14 ± 0.03 dB | 0.16 ± 0.02 iC | 0.18 ± 0.02 dB | 0.23 ± 0.03 cE | 0.20 ± 0.02 fE | |

| 21.12 | Cyclohexanone, 2-ethyl- | 756 | 779 | 4423-94-3 | C8H14O | 5.07 ± 1.31 eA | - | 6.6 ± 0.30 kA | 5.39 ± 0.65 jA | 5.84 ± 0.21 gA | - | |

| 21.77 | Octanal | 748 | 889 | 124-13-0 | C8H16O | 0.10 ± 0.1 aA | 0.14 ± 0.02 dB | 0.14 ± 0.03 iC | 0.15 ± 0.02 eB | 0.21 ± 0.02 cD | 0.19 ± 0.01 iD | |

| 25.43 | Nonanal | 818 | 876 | 124-19-6 | C9H18O | 2.90 ± 0.38 fA | 3.68 ± 0.34 ìA | 4.03 ± 0.36 mA | 3.83 ± 0.30 kB | 4.77 ± 0.11 hC | 4.52 ± 0.35 lD | |

| 20.28 | Benzaldehyde | 636 | 873 | 100-52-7 | C7H6O | - | - | 0.59 ± 0.03 jA | 0.61 ± 0.03 iB | 0.44 ± 0.12 aB | 0.55 ± 0.05 hB | |

| 27.26 | Retinal | 603 | 704 | 116-31-4 | C20H28O | - | 0.13 ± 0.03 dA | - | - | - | - | |

| 28.74 | Decanal | 838 | 873 | 112-31-4 | C20H28O | 0.54 ± 0.05 aA | 0.72 ± 0.05 jA | 0.7 ± 0.17 nA | 0.87 ± 0.05 mB | 1.09 ± 0.05 iC | 1.15 ± 0.15 nD | |

| 34.09 | 4-Octadecenal | 716 | 747 | 56554-98-4 | C18H34O | - | 0.11 ± 0.04 gA | - | - | - | - | |

| 38.32 | 5-Octadecenal | 724 | 757 | 56554-88-2 | C18H34O | 0.30 ± 0.10 aA | 0.20 ± 0.13 hB | 0.49 ± 0.13 aC | 0.82 ± 0.08 vD | 0.33 ± 0.06 aA | 0.46 ± 0.03 rC | |

| Total | 9.00 ± 1.95 A | 5.12 ± 0.64 B | 12.72 ± 1.18 C | 12.06 ± 1.15 D | 12.92 ± 0.60 E | 7.08 ± 0.62 F | ||||||

| Alkanes | 28.82 | Octadecane, 6-methyl- | 705 | 785 | 10544-96-4 | C19H40 | 0.23 ± 0.14 aA | - | - | - | - | - |

| 33.45 | Hexadecane, 1,1-bis(dodecyloxy)- | 727 | 733 | 56554-64-4 | C40H82O2 | - | 0.20 ± 0.04 hA | - | - | 0.14 ± 0.05 cB | - | |

| 36.75 | Tetradecane, 2,6,10-trimethyl- | 739 | 815 | 14905-56-7 | C17H36 | 0.42 ± 0.15 aA | - | 0.36 ± 0.24 eB | 0.46 ± 0.27 sA | - | 0.55 ± 0.27 hA | |

| 41.04 | (Z,Z)-9-Octadecene, 1,1’-[1,2-ethanediylbis(oxy)]bis- | 678 | 695 | 17367-13-4 | C38H74O2 | 0.22 ± 0.12 aA | - | 0.18 ± 0.02 iA | - | 0.16 ± 0.02 cA | - | |

| 41.59 | Octadecane, 3-ethyl-5-(2-ethylbutyl)- | 715 | 721 | 55282-12-7 | C26H54 | 0.41 ± 0.23 aA | - | - | 0.51 ± 0.02 aB | - | 0.72 ± 0.21 uC | |

| Total | 1.28 ± 0.64 A | 0.20 ± 0.04 B | 0.54 ± 0.26 C | 0.97 ± 0.29 D | 0.30 ± 0.07 E | 1.27 ± 0.48 F | ||||||

| Cucurbitacins | 36.28 | Cucurbitacin B, dihydro- | 600 | 661 | 13201-14-4 | C32H48O8 | - | 0.18 ± 0.03 hA | 0.13 ± 0.07 iA | 0.20 ± 0.04 dA | 0.22 ± 0.03 cA | 0.18 ± 0.10 jA |

| Total | 0.18 ± 0.03 A | 0.13 ± 0.07 A | 0.20 ± 0.04 A | 0.22 ± 0.03 A | 0.18 ± 0.10 A | |||||||

| Esters | 9.05 | Acetic acid, hydroxy-, ethyl ester | 867 | 970 | 623-50-7 | C4H8O3 | 1.18 ± 0.14 bA | 1.25 ± 0.09 bA | 1.47 ± 0.16 cA | 1.79 ± 0.14 cB | 1.89 ± 0.25 bB | 1.91 ± 0.34 cB |

| 24.60 | 10,13-Octadecadiynoic acid, methyl ester | 615 | 621 | 18202-24-9 | C19H30O2 | - | - | - | - | - | 0.01 ± 0.00 bA | |

| 25.80 | (Z)-Stearic acid, 2-(9-octadecenyloxy)ethyl ester | 627 | 648 | 29027-97-2 | C38H74O3 | - | - | 0.04 ± 0.01 fA | - | - | - | |

| 29.09 | 1,3-Dioxane, 4-(hexadecyloxy)-2-pentadecyl- | 603 | 725 | 34315-34-9 | C35H70O3 | - | - | - | 0.22 ± 0.06 dA | 0.23 ± 0.06 cA | - | |

| 31.03 | Stearic acid, 3-(octadecyloxy)propyl ester | 553 | 642 | 17367-40-7 | C39H78O3 | 0.33 ± 0.22 aA | 0.39 ± 0.20 lA | - | 0.42 ± 0.08 nA | 0.27 ± 0.11 dB | 0.5 ± 0.03 mC | |

| 31.15 | Octadecanoic acid, 2-(octadecyloxy)ethyl ester | 644 | 658 | 28843-25-6 | C38H76O3 | - | - | - | - | - | 0.26 ± 0.02 eA | |

| 33.19 | 1,2-Propanediol, 3-(octadecyloxy)-, diacetate | 631 | 679 | 21994-81-0 | C25H48O5 | - | - | 0.16 ± 0.06 iA | 0.20 ± 0.03 dB | - | - | |

| 33.57 | Octadecane, 1,1’-[(1-methyl-1,2-ethanediyl)bis(oxy)]bis- | 562 | 673 | 35545-51-8 | C39H80O2 | - | 0.56 ± 0.04 kA | - | - | 0.47 ± 0.12 aA | - | |

| 36.09 | Geranyl isovalerate | 625 | 660 | 109-20-6 | C15H26O2 | 0.09 ± 0.03 aA | - | - | - | - | - | |

| 37.31 | Oleic acid, 3-(octadecyloxy)propyl ester | 678 | 709 | 17367-41-8 | C39H76O3 | - | 0.13 ± 0.13 dA | 0.13 ± 0.09 iB | 0.33 ± 0.04 uC | 0.29 ± 0.04 aC | - | |

| 39.55 | Docosanoic acid, 8,9-dihydroxy-, methyl ester | 616 | 635 | 56555-06-7 | C23H46O4 | - | 0.43 ± 0.04 qA | - | 0.52 ± 0.03 zB | 0.53 ± 0.03 mB | 0.55 ± 0.03 hC | |

| 39.99 | Octadecanoic acid, 4-hydroxy-, methyl ester | 627 | 681 | 2420-38-4 | C19H76O4 | - | 0.22 ± 0.15 hA | - | 0.27 ± 0.13 tB | - | - | |

| 41.05 | (Z,Z)-9-Hexadecenoic acid, 9-octadecenyl ester | 672 | 691 | 22393-98-2 | C34H64O2 | - | - | - | 0.22 ± 0.04 cA | - | - | |

| 41.50 | Oleic acid, eicosyl ester | 655 | 670 | 22393-88-0 | C38H74O2 | - | - | - | - | 0.14 ± 0.02 cA | 0.20 ± 0.04 fB | |

| 43.02 | 1,3-Dioxane, 5-(hexadecyloxy)-2-pentadecyl-, trans- | 603 | 725 | 56599-40-7 | C35H70O3 | - | - | - | 1.5 ± 0.04 cA | - | - | |

| 43.22 | 1,2-Benzenedicarboxylic acid, butyl octyl ester | 741 | 803 | 84-78-6 | C20H30O4 | - | 0.49 ± 0.21 rA | - | - | - | 0.5 ± 0.16 mB | |

| Total | 1.60 ± 0.39 A | 3.47 ± 0.86 B | 1.80 ± 0.32 C | 5.47 ± 0.55 D | 3.82 ± 0.63 E | 3.43 ± 0.58 F | ||||||

| Hydrocarbons | 16.05 | Ethylbenzene | 737 | 887 | 100-41-4 | C8H10 | 0.16 ± 0.12 aA | 0.24 ± 0.01 cA | 0.24 ± 0.13 dA | 0.14 ± 0.09 eA | 0.17 ± 0.11 cA | 0.09 ± 0.00 dA |

| 16.08 | Benzene, 1,3-dimethyl- | 843 | 873 | 108-38-3 | C8H10 | - | 0.14 ± 0.10 dA | 0.25 ± 0.16 dB | 0.15 ± 0.11 eA | 0.28 ± 0.17 dB | 0.21 ± 0.10 fB | |

| 16.29 | p-Xylene | 831 | 888 | 106-42-3 | C8H10 | 0.37 ± 0.21 aA | 0.24 ± 0.01 cA | 0.34 ± 0.07 eA | 0.29 ± 0.05 fA | 0.34 ± 0.08 aA | 0.26 ± 0.02 eA | |

| 18.69 | Benzene, (1-methylethyl)- | 661 | 772 | 98-82-8 | C9H12 | - | - | - | - | - | 0.04 ± 0.01 aD | |

| 21.68 | Dodecane, 1,2-dibromo- | 606 | 675 | 55334-42-4 | C12H24Br2 | - | - | - | 0.14 ± 0.01 eA | - | - | |

| 21.96 | Decane | 622 | 871 | 124-18-5 | C10H22 | 0.1 ± 0.04 aA | - | - | - | - | - | |

| 23.12 | Cyclohexane, butyl- | 740 | 812 | 4292-92-6 | C11H22 | - | 0.10 ± 0.01 gA | - | - | - | - | |

| 23.93 | Heptylcyclohexane | 694 | 781 | 5617-41-4 | C13H26 | - | 0.12 ± 0.02 dA | - | - | 0.12 ± 0.03 cA | 0.16 ± 0.02 jB | |

| 24.77 | Dodecane, 2,6,11-trimethyl- | 717 | 864 | 31295-56-4 | C15H32 | - | - | - | - | - | 0.31 ± 0.09 bA | |

| 24.95 | Dodecane, 2,6,10-trimethyl- | 773 | 859 | 3891-98-3 | C15H32 | - | 0.18 ± 0.07 hA | - | 0.34 ± 0.19 lB | - | - | |

| 25.29 | Undecane | 713 | 869 | 1120-21-4 | C11H24 | - | - | 0.29 ± 0.01 lA | 0.30 ± 0.02 fB | 0.32 ± 0.02 aB | - | |

| 26.73 | Cyclohexane, pentyl- | 680 | 821 | 4292-92-6 | C11H22 | - | 0.12 ± 0.02 dA | - | - | - | - | |

| 28.55 | Dodecane | 725 | 799 | 112-40-3 | C12H44 | - | - | - | - | - | 0.50 ± 0.03 mA | |

| 31.60 | Heptadecane, 2,6,10,15-tetramethyl- | 717 | 815 | 54833-48-6 | C21H44 | - | - | - | - | - | 0.28 ± 0.03 eA | |

| 34.36 | Tetradecane | 802 | 904 | 629-59-4 | C10H30 | 0.66 ± 0.26 gA | - | 0.64 ± 0.22 nB | 1.00 ± 0.12 rC | 0.71 ± 0.19 jB | 1.04 ± 0.01 pD | |

| 35.79 | Nonadecane | 804 | 904 | 629-92-5 | C19H40 | 0.66 ± 0.25 gA | 0.59 ± 0.02 kA | 0.71 ± 0.16 nA | 0.96 ± 0.08 xB | - | - | |

| 38.36 | Heptacosane | 783 | 823 | 593-49-7 | C27H56 | 0.54 ± 0.15 aA | 0.55 ± 0.03 kA | 0.67 ± 0.09 nA | 0.73 ± 0.22 qB | 0.66 ± 0.05 kA | 0.84 ± 0.15 sC | |

| 38.64 | Hexadecane | 799 | 874 | 544-76-3 | C16H34 | - | - | - | 0.95 ± 0.07 xA | - | - | |

| 41.49 | Benzene, 1,1’-(1,2-cyclobutanediyl)bis-, trans- | 678 | 868 | 20071-09-4 | C16H16 | - | - | - | - | - | 0.71 ± 0.09 aA | |

| 41.72 | 17-Pentatriacontene | 658 | 672 | 6971-40-0 | C35H70 | - | - | 0.32 ± 0.04 qA | 0.41 ± 0.01 nB | 0.33 ± 0.03 aA | 0.45 ± 0.01 wC | |

| Total | 2.49 ± 1.03 A | 2.28 ± 0.29 B | 3.46 ± 0.89 C | 5.41 ± 0.97 D | 2.93 ± 0.68 E | 4.89 ± 0.55 F | ||||||

| Ketones | 17.01 | 2-Heptanone | 660 | 744 | 110-43-0 | C7H14O | 0.05 ± 0.01 cA | 0.06 ± 0.01 eB | 0.07 ± 0.00 gC | 0.07 ± 0.01 gD | - | 0.09 ± 0.01 dE |

| 16.88 | 3-Heptanone | 652 | 730 | 106-35-4 | C7H14O | - | 0.06 ± 0.01 eA | - | - | 0.08 ± 0.02 | - | |

| Total | 0.05± 0.01 A | 0.12 ± 0.02 B | 0.07 ± 0.00 C | 0.07 ± 0.01 C | 0.08 ± 0.02 D | 0.09 ± 0.01 E | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nasiru, M.M.; Umair, M.; Boateng, E.F.; Alnadari, F.; Khan, K.-u.R.; Wang, Z.; Luo, J.; Yan, W.; Zhuang, H.; Majrashi, A.; et al. Characterisation of Flavour Attributes in Egg White Protein Using HS-GC-IMS Combined with E-Nose and E-Tongue: Effect of High-Voltage Cold Plasma Treatment Time. Molecules 2022, 27, 601. https://doi.org/10.3390/molecules27030601

Nasiru MM, Umair M, Boateng EF, Alnadari F, Khan K-uR, Wang Z, Luo J, Yan W, Zhuang H, Majrashi A, et al. Characterisation of Flavour Attributes in Egg White Protein Using HS-GC-IMS Combined with E-Nose and E-Tongue: Effect of High-Voltage Cold Plasma Treatment Time. Molecules. 2022; 27(3):601. https://doi.org/10.3390/molecules27030601

Chicago/Turabian StyleNasiru, Mustapha Muhammad, Muhammad Umair, Evans Frimpong Boateng, Fawze Alnadari, Kashif-ur Rehman Khan, Zhaobin Wang, Ji Luo, Wenjing Yan, Hong Zhuang, Ali Majrashi, and et al. 2022. "Characterisation of Flavour Attributes in Egg White Protein Using HS-GC-IMS Combined with E-Nose and E-Tongue: Effect of High-Voltage Cold Plasma Treatment Time" Molecules 27, no. 3: 601. https://doi.org/10.3390/molecules27030601

APA StyleNasiru, M. M., Umair, M., Boateng, E. F., Alnadari, F., Khan, K.-u. R., Wang, Z., Luo, J., Yan, W., Zhuang, H., Majrashi, A., Zhang, J., & Korma, S. A. (2022). Characterisation of Flavour Attributes in Egg White Protein Using HS-GC-IMS Combined with E-Nose and E-Tongue: Effect of High-Voltage Cold Plasma Treatment Time. Molecules, 27(3), 601. https://doi.org/10.3390/molecules27030601