RE(III) 3-Furoate Complexes: Synthesis, Structure, and Corrosion Inhibiting Properties

Abstract

1. Introduction

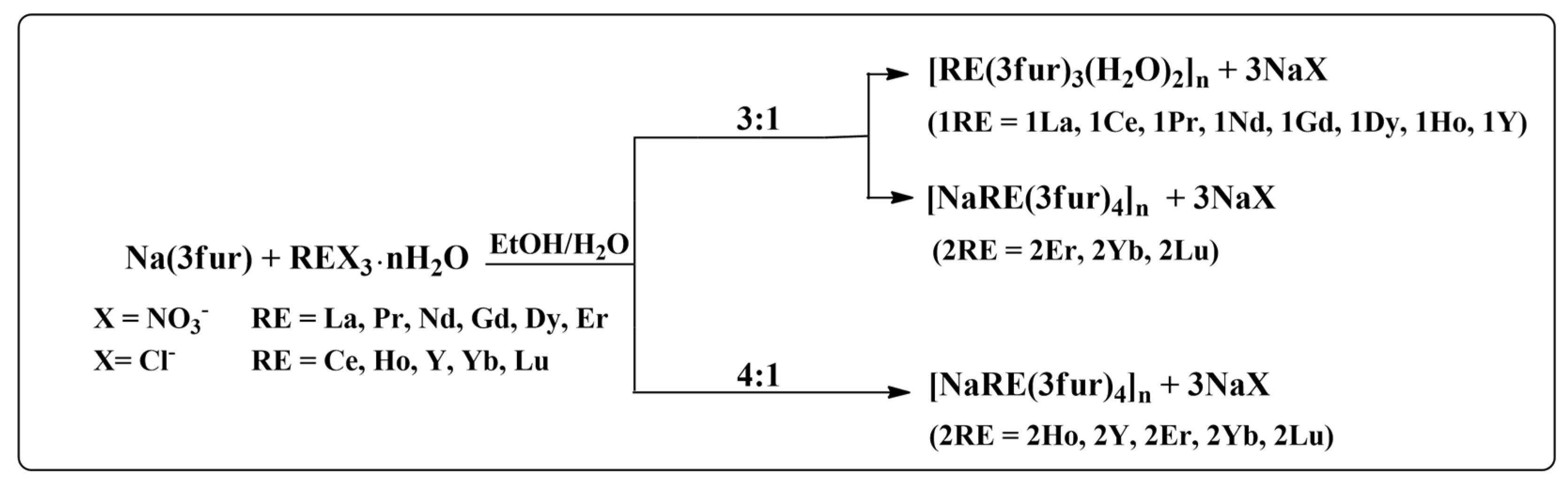

2. Results

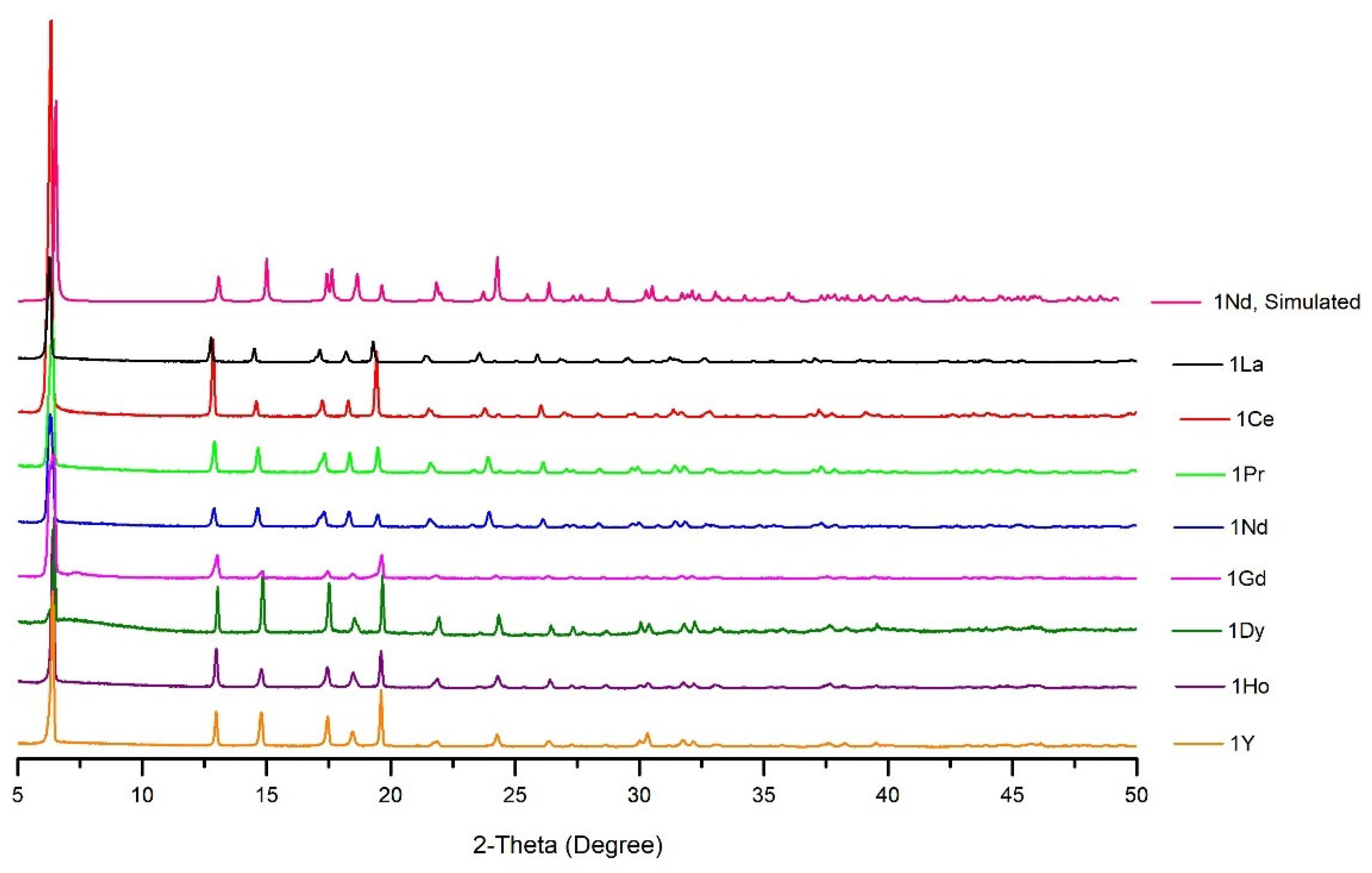

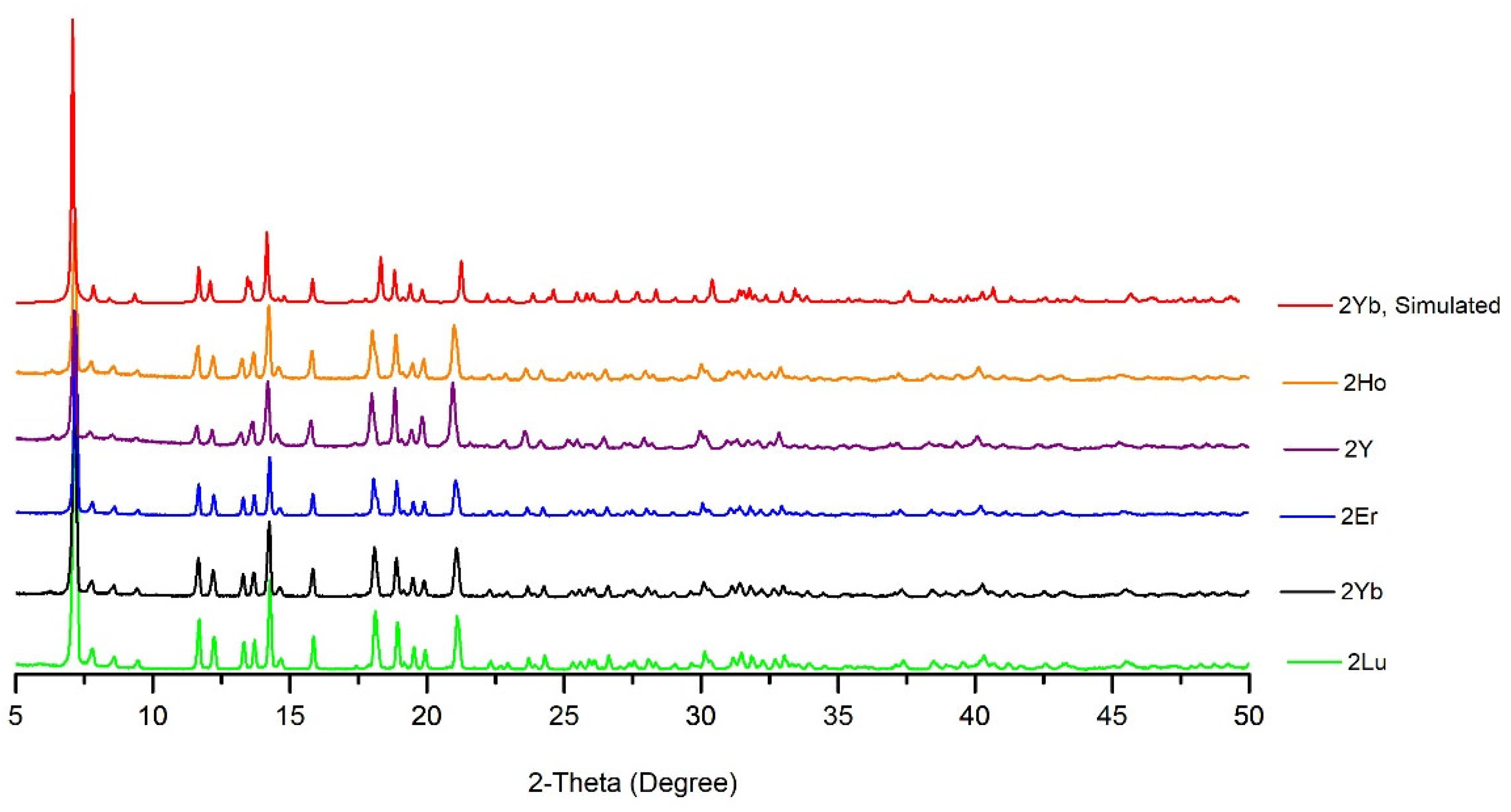

2.1. Synthesis and Characterization

2.2. X-ray Crystallography

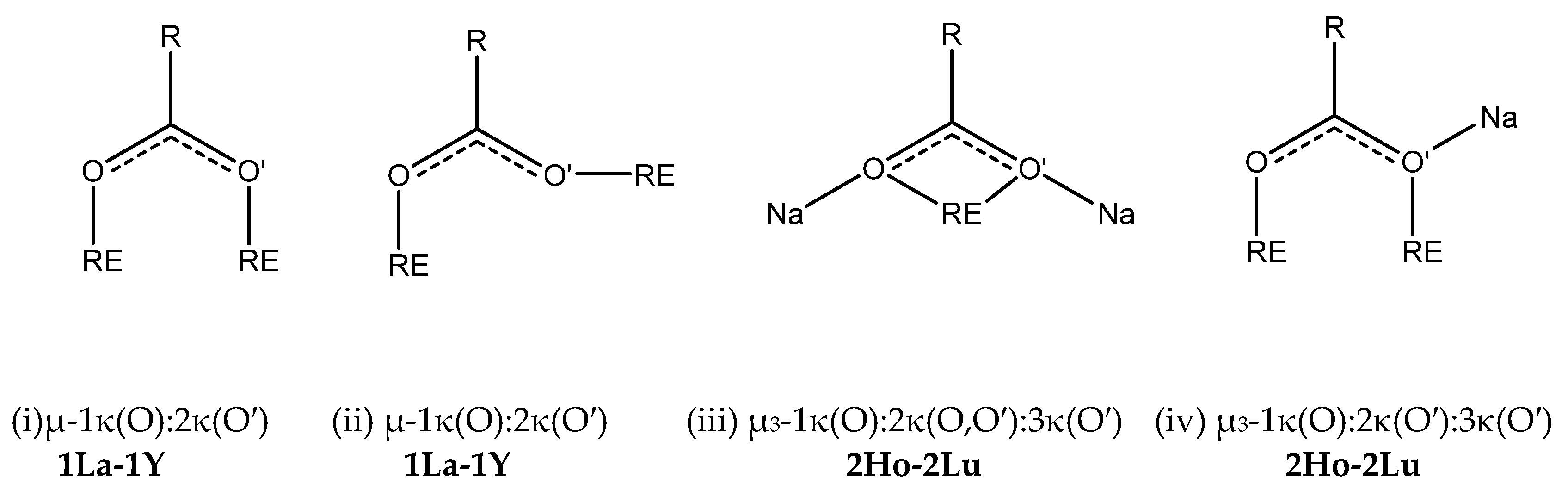

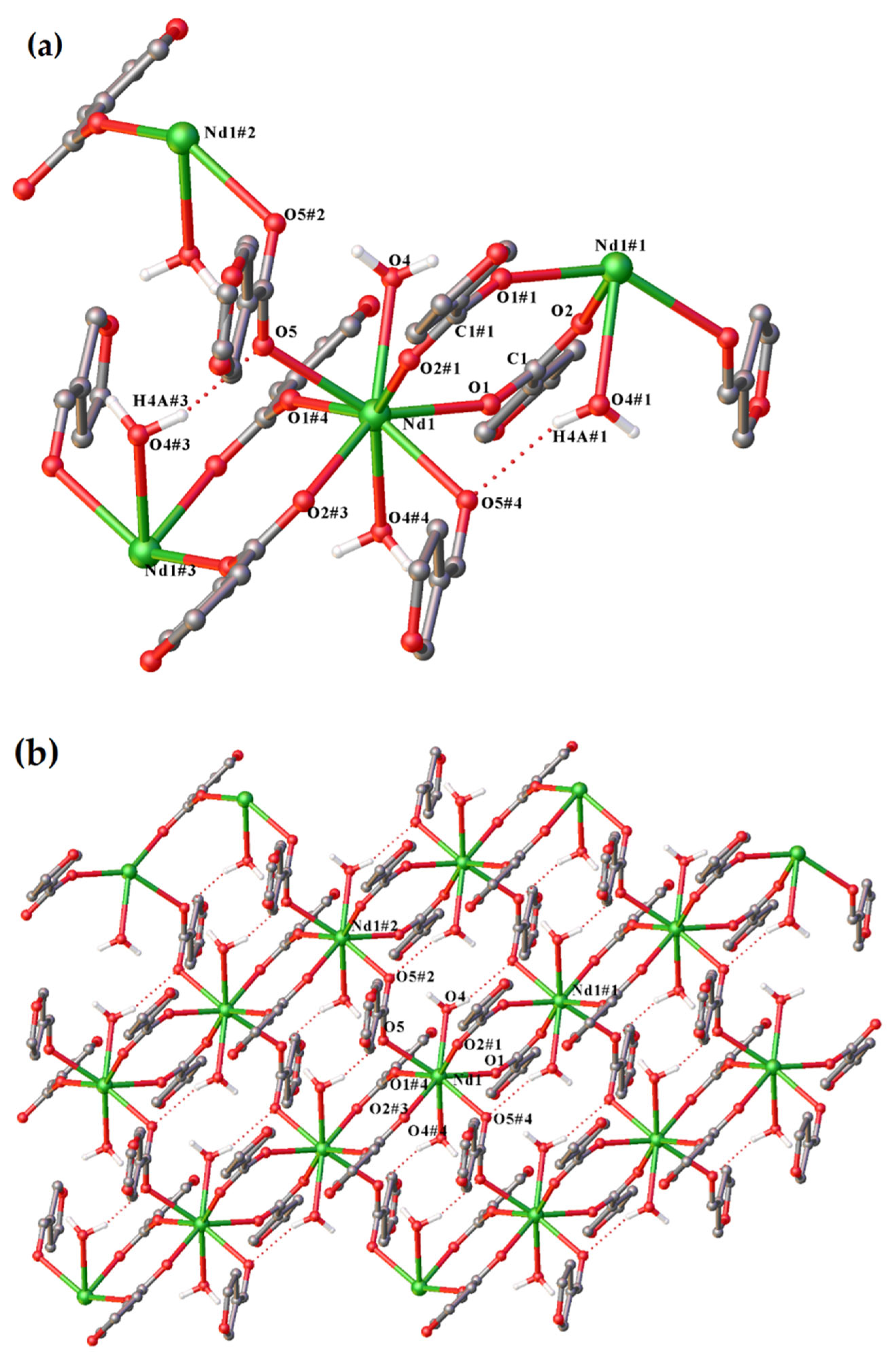

2.2.1. Monometallic 2D Polymeric Chains of [RE(3fur)3(H2O)2]n Complexes (1RE = 1La, 1Ce, 1Pr, 1Nd, 1Gd, 1Dy, 1Ho, 1Y)

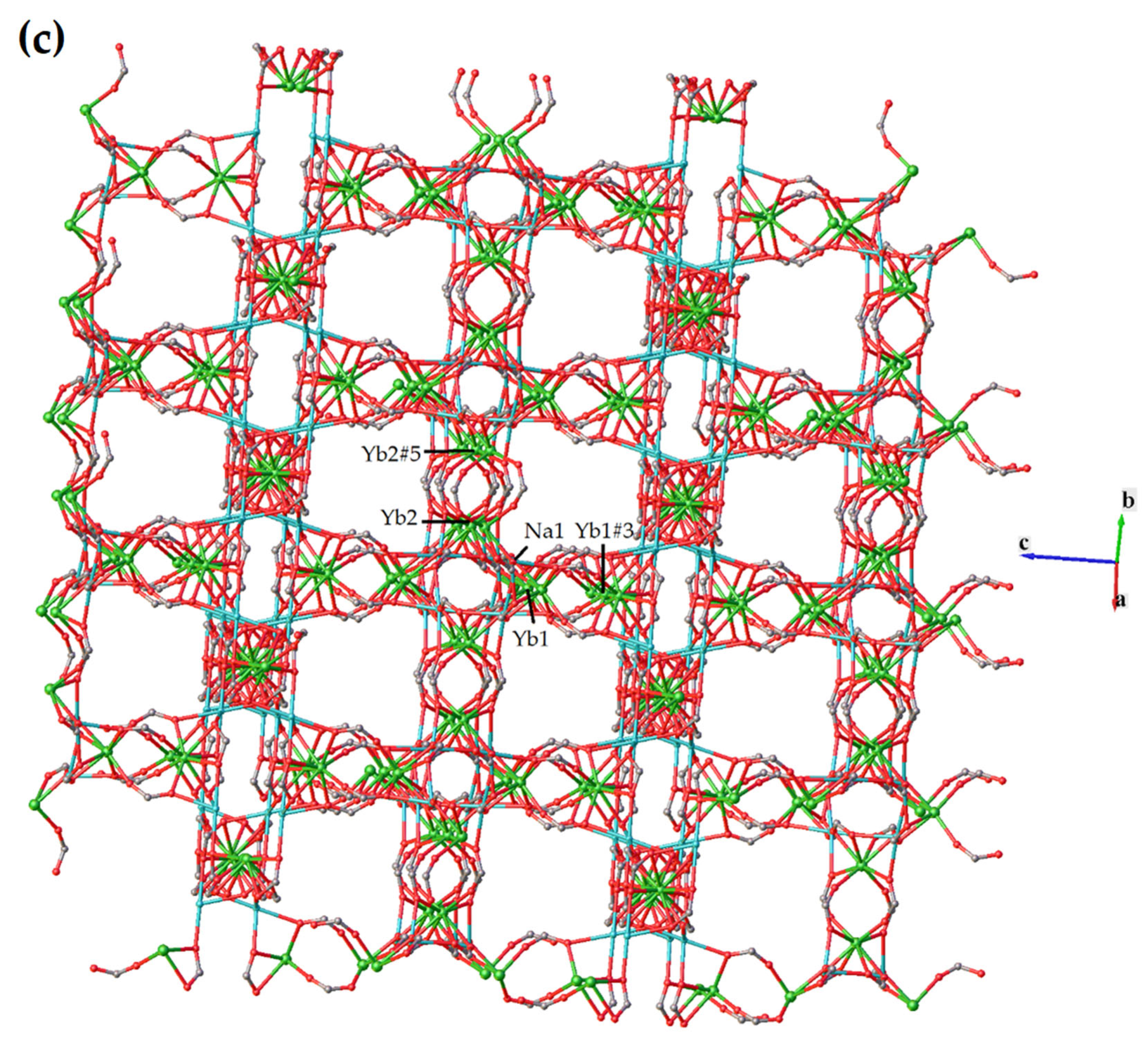

2.2.2. Bimetallic 3D Polymeric Chains of [NaRE(3fur)4]n Complexes (2RE = 2Ho, 2Y, 2Er, 2Yb, 2Lu)

2.3. Corrosion Inhibition

2.3.1. Immersion Tests

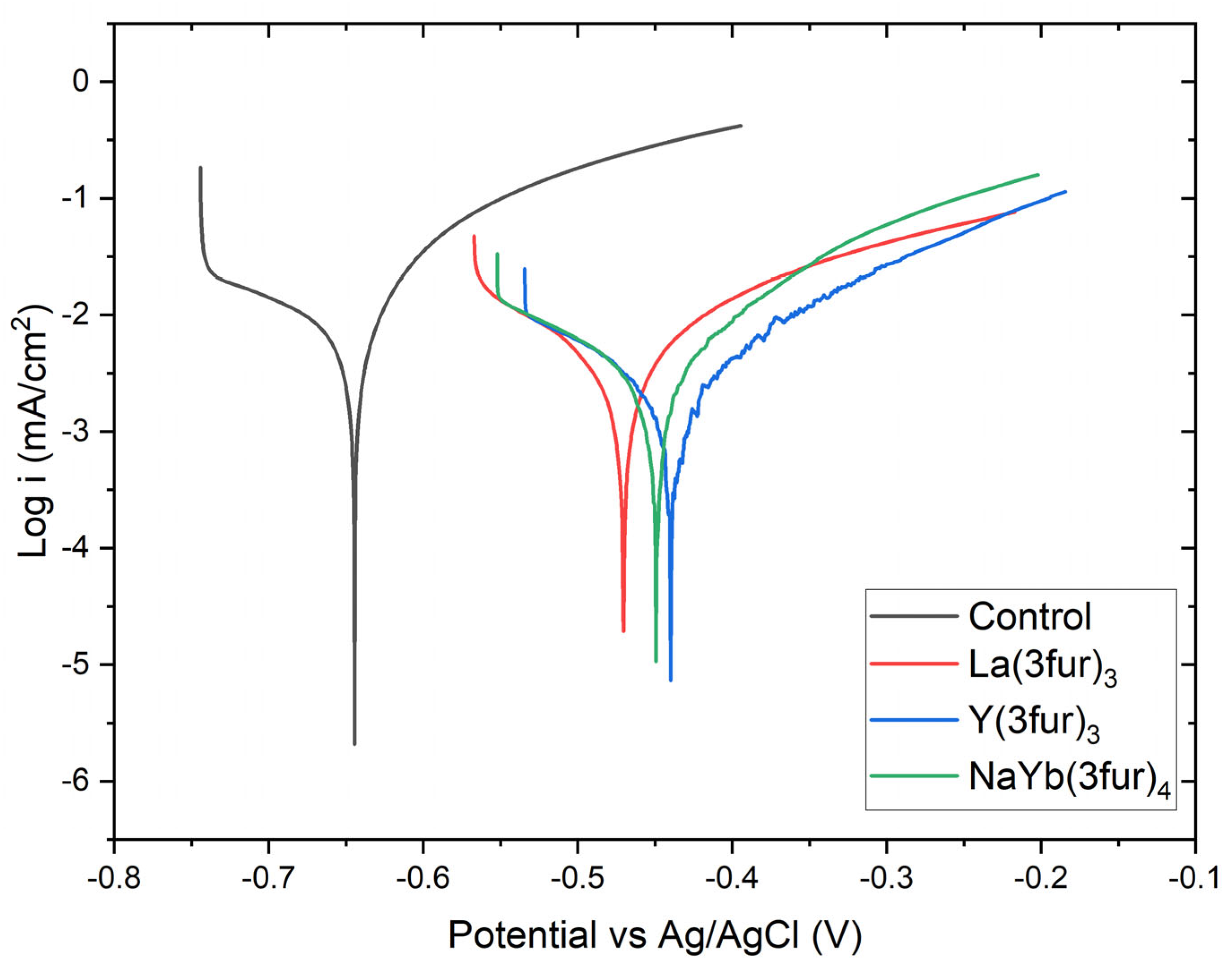

2.3.2. Potentiodynamic Polarisation

3. Materials and Methods

3.1. General Consideration

3.2. X-ray Crystallography

3.3. Synthesis of [RE(3fur)3(H2O)2]n and [NaRE(3fur)4]n Complexes

3.4. Corrosion Testing

4. Conclusions

- Type 1-Monometallic 2D polymeric network of [RE(3fur)3(H2O)2]n(1RE = 1La, 1Ce, 1Pr, 1Nd, 1Gd, 1Dy, 1Ho, 1Y)

- Type 2-Bimetallic 3D polymeric network of [NaRE(3fur)4]n(2RE = 2Ho, 2Y, 2Er, 2Yb, 2Lu)

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Odio, O.B.; Chinwuko, C.E.; Chukwuneke, L.J.; Sinebe, E.J. Investigation of The Effect of Corrosion on Mild Steel in Five Different Environments. Int. J. Sci. Technol. Res. 2014, 3, 306–310. [Google Scholar]

- Garcia, S.J.; Mol, J.M.C.; de Wit, J.H.W.; Muster, T.H.; Hughes, A.E.; Miller, T.; Markley, T.; Mardel, J.; Terryn, H. Advances in the Selection and Use of Rare-Earth-Based Inhibitors for Self-Healing Organic Coatings. In Self-Healing Properties of New Surface Treatments; Fedrizzi, L., Fürbeth, W., Montemor, F., Eds.; Maney Publishing: Leeds, UK, 2011; Volume 58, pp. 148–183. [Google Scholar]

- Hossain, N.; Chowdhury, M.A.; Kchaou, M. An overview of green corrosion inhibitors for sustainable and environment friendly industrial development. J. Adhes. Sci. Technol. 2020, 35, 673–690. [Google Scholar] [CrossRef]

- Mottram, E.; Hamilton, S.; Moon, J.S.; Wang, J.; Bousrez, G.; Somers, A.E.; Deacon, G.B.; Junk, P.C. Synthesis, structure, and corrosion inhibiting properties of phenylacetato-rare earth (III) complexes. J. Coord. Chem. 2020, 73, 2677–2697. [Google Scholar] [CrossRef]

- Bowman, E.; Thompson, N.; Gl, D.; Moghissi, O.; Gould, M.; Payer, J. International Measures of Prevention, Application, and Economics of Corrosion Technologies Study; NACE International: Houston, TX, USA, 2016. [Google Scholar]

- Somers, A.E.; Hinton, B.R.; de Bruin-Dickason, C.; Deacon, G.B.; Junk, P.C.; Forsyth, M. New, environmentally friendly, rare earth carboxylate corrosion inhibitors for mild steel. Corros. Sci. 2018, 139, 430–437. [Google Scholar] [CrossRef]

- Forsyth, M.; Wilson, K.; Behrsing, T.; Forsyth, C.; Deacon, G.B.; Phanasgoankar, A. Effectiveness of Rare-Earth Metal Compounds as Corrosion Inhibitors for Steel. Corrosion 2002, 58, 953–960. [Google Scholar] [CrossRef]

- Chong, A.L.; Mardel, J.I.; MacFarlane, D.R.; Forsyth, M.; Somers, A.E. Synergistic Corrosion Inhibition of Mild Steel in Aqueous Chloride Solutions by an Imidazolinium Carboxylate Salt. ACS Sustain. Chem. Eng. 2015, 4, 1746–1755. [Google Scholar] [CrossRef]

- Ghorbani, M.; Soto Puelles, J.; Forsyth, M.; Catubig, R.A.; Ackland, L.; Machuca, L.; Terryn, H.; Somers, A.E. Corrosion Inhibition of Mild Steel by Cetrimonium Trans-4-Hydroxy Cinnamate: Entrapment and Delivery of the Anion Inhibitor through Speciation and Micellar Formation. J. Phys. Chem. Lett. 2020, 11, 9886–9892. [Google Scholar] [CrossRef]

- Forsyth, M.; Seter, M.; Hinton, B.; Deacon, G.; Junk, P. New “Green” Corrosion Inhibitors Based on Rare Earth Compounds. Aust. J. Chem. 2011, 64, 812–819. [Google Scholar] [CrossRef]

- Peng, Y.; Hughes, A.E.; Deacon, G.B.; Junk, P.C.; Hinton, B.R.; Forsyth, M.; Mardel, J.I.; Somers, A.E. A study of rare-earth 3-(4-methylbenzoyl)-propanoate compounds as corrosion inhibitors for AS1020 mild steel in NaCl solutions. Corros. Sci. 2018, 145, 199–211. [Google Scholar] [CrossRef]

- Hinton, B. Corrosion Prevention and Control. In Handbook on the Physics and Chemistry of Rare Earths; Gschneidner, K.A., Eyring, L., Eds.; Elsevier: Amsterdam, The Netherlands, 1995; Volume 21, pp. 29–92. [Google Scholar]

- Hinton, B.R.W. Corrosion Inhibition with Rare Earth Metal Salts. J. Alloys Compd. 1992, 180, 15–25. [Google Scholar] [CrossRef]

- Mendez, J.A.C.; Vong, Y.M.; Bueno, J.D.J.P. Cerium and Other Rare Earth Salts as Corrosion Inhibitors—A Review. Prot. Met. Phys. Chem. Surf. 2022, 58, 801–810. [Google Scholar] [CrossRef]

- Somers, A.E.; Deacon, G.B.; Hinton, B.R.W.; Macfarlane, D.R.; Junk, P.C.; Tan, M.Y.J.; Forsyth, M. Recent Developments in Environment-Friendly Corrosion Inhibitors for Mild Steel. J. Indian Inst. Sci. 2016, 96, 285–292. [Google Scholar]

- Somers, A.E.; Peng, Y.; Chong, A.L.; Forsyth, M.; MacFarlane, D.R.; Deacon, G.B.; Hughes, A.E.; Hinton, B.R.W.; Mardel, J.I.; Junk, P.C. Advances in the Development of Rare Earth Metal and Carboxylate Compounds as Corrosion Inhibitors for Steel. Corros. Eng. Sci. Technol. 2020, 55, 311–321. [Google Scholar] [CrossRef]

- Forsyth, M.; Hinton, B. Rare Earth-Based Corrosion Inhibitors, 1st ed.; Woodhead Publishing: Cambridge, UK, 2014. [Google Scholar]

- Sinko, J. Challenges of chromate inhibitor pigments replacement in organic coatings. Prog. Org. Coat. 2001, 42, 267–282. [Google Scholar] [CrossRef]

- Winkler, D.A.; Breedon, M.; Hughes, A.E.; Burden, F.R.; Barnard, A.S.; Harvey, T.G.; Cole, I. Towards Chromate-Free Corrosion Inhibitors: Structure-Property Models for Organic Alternatives. Green Chem. 2014, 16, 3349–3357. [Google Scholar] [CrossRef]

- Daoud, D.; Douadi, T.; Hamani, H.; Chafaa, S.; Al-Noaimi, M. Corrosion Inhibition of Mild Steel by Two New S-Heterocyclic Compounds in 1 M HCl: Experimental and Computational Study. Corros. Sci. 2015, 94, 21–37. [Google Scholar] [CrossRef]

- Verma, C.; Ebenso, E.E.; Quraishi, M.A. Ionic Liquids as Green Corrosion Inhibitors for Industrial Metals and Alloys. In Green Chemistry; Saleh, H.E.-D.M., Koller, M., Eds.; IntechOpen: London, UK, 2018. [Google Scholar]

- Pham, T.H.; Lee, W.-H.; Son, G.-H.; Tran, T.T.; Kim, J.-G. Synthesis and Corrosion Inhibition Potential of Cerium/Tetraethylenepentamine Dithiocarbamate Complex on AA2024-T3 in 3.5% NaCl. Materials 2022, 15, 6631. [Google Scholar] [CrossRef]

- Vaidyanathan, H.; Hackerman, N. Effect of furan derivatives on the anodic dissolution of Fe. Corros. Sci. 1971, 11, 737–750. [Google Scholar] [CrossRef]

- Khaled, K.F. Understanding Corrosion Inhibition of Mild Steel in Acid Medium by Some Furan Derivatives: A Comprehensive Overview. J. Electrochem. Soc. 2010, 157, C116–C124. [Google Scholar] [CrossRef]

- Ouchi, A.; Suzuki, Y.; Ohki, Y.; Koizumi, Y. Structure of Rare Earth Carboxylates in Dimeric and Polymeric Forms. Coord. Chem. Rev. 1988, 92, 29–43. [Google Scholar] [CrossRef]

- Mehrotra, R.C.; Bohra, R. Metal Carboxylates; Academic Press: London, UK, 1983. [Google Scholar]

- Janicki, R.; Mondry, A.; Starynowicz, P. Carboxylates of Rare Earth Elements. Coord. Chem. Rev. 2017, 340, 98–133. [Google Scholar] [CrossRef]

- Behrsing, T.; Deacon, G.B.; Junk, P.C. The Chemistry of Rare Earth Metals, Compounds, and Corrosion Inhibitors. In Rare Earth-Based Corrosion Inhibitors; Forsyth, M., Hinton, B., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 1–37. [Google Scholar]

- Markley, T.; Blin, F.; Forsyth, M.; Hinton, B. Multifunctional Rare Earth Organic Corrosion Inhibitors. In Rare Earth-Based Corrosion Inhibitors; Forsyth, M., Hinton, B., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 117–142. [Google Scholar]

- Blin, F.; Leary, S.G.; Deacon, G.B.; Junk, P.C.; Forsyth, M. The Nature of the Surface Film on Steel Treated with Cerium and Lanthanum Cinnamate Based Corrosion Inhibitors. Corros. Sci. 2006, 48, 404–419. [Google Scholar] [CrossRef]

- Vithana, V.P.; Guo, Z.; Deacon, G.B.; Somers, A.E.; Junk, P.C. Synthesis, Structure, and Corrosion Inhibiting Properties of REIII 3-Thiophenecarboxylate Complexes. N. J. Chem. 2022, 46, 19104–19111. [Google Scholar] [CrossRef]

- Lajunen, L.H.; Choppin, G.R. Analytical Chemistry of the Lanthanides Part 1. Atomic Absorption and Plasma Atomic Emission Spectroscopic Methods. Rev. Anal. Chem. 1989, 9, 91–130. [Google Scholar] [CrossRef]

- Sitzmann, H.; Dezember, T.; Schmitt, O.; Weber, F.; Wolmershäuser, G.; Ruck, M. Metallocenes of Samarium, Europium, and Ytterbium with the Especially Bulky Cyclopentadienyl Ligands C5H(CHMe2)4, C5H2(CMe3)3, and C5(CHMe2)5. Z. Anorg. Allg. Chem. 2000, 626, 2241–2244. [Google Scholar] [CrossRef]

- Daniels, D.P.; Deacon, G.B.; Harakat, D.; Jaroschik, F.; Junk, P.C. Synthesis and Characterisation of Alkaline Earth (Diphenylphosphano)Metallocene Complexes and Heterobimetallic Alkaline Metal/Platinum (II) Complexes [Ae(Thf)x(η5-C5H4PPh2)2Pt(Me)2] (Ae = Ca, Sr, Ba). Dalton Trans. 2012, 41, 267–277. [Google Scholar] [CrossRef] [PubMed]

- Moxey, G.J.; Blake, A.J.; Lewis, W.; Kays, D.L. Alkaline Earth Complexes of a Sterically Demanding Guanidinate Ligand. Eur. J. Inorg. Chem. 2015, 2015, 5892–5902. [Google Scholar] [CrossRef]

- Kelly, R.P.; Bell, T.D.M.; Cox, R.P.; Daniels, D.P.; Deacon, G.B.; Jaroschik, F.; Junk, P.C.; le Goff, X.F.; Lemercier, G.; Martinez, A.; et al. Divalent Tetra- and Penta-Phenylcyclopentadienyl Europium and Samarium Sandwich and Half-Sandwich Complexes: Synthesis, Characterization, and Remarkable Luminescence Properties. Organometallics 2015, 34, 5624–5636. [Google Scholar] [CrossRef]

- Hirneise, L.; Maichle-Mössmer, C.; Anwander, R. Pentamethylcyclopentadienyl Complexes of Cerium (IV): Synthesis, Reactivity, and Electrochemistry. Inorg. Chem. 2021, 60, 18211–18224. [Google Scholar] [CrossRef]

- Salehisaki, M.; Rad, N.E.; Deacon, G.B.; Wang, J.; Guo, Z.; Junk, P.C. Synthesis and Reactivity of Rare-Earth-N,N’-(Diphenyl) Formamidinate and Rare-Earth-N,N’-Bis(2,4-Dimethylphenyl) Formamidinate Complexes. Inorg. Chim. Acta. 2022, 539, 120997. [Google Scholar] [CrossRef]

- Deacon, G.B.; Phillips, R.J. Relationships between the Carbon-Oxygen Stretching Frequencies of Carboxylato Complexes and the Type of Carboxylate Coordination. Coord. Chem. Rev. 1980, 33, 227–250. [Google Scholar] [CrossRef]

- Chesman, A.S.R.; Turner, D.R.; Moubaraki, B.; Murray, K.S.; Deacon, G.B.; Batten, S.R. Lanthaballs: Chiral, Structurally Layered Polycarbonate Tridecanuclear Lanthanoid Clusters. Chem. A Eur. J. 2009, 15, 5203–5207. [Google Scholar] [CrossRef]

- Chesman, A.S.R.; Turner, D.R.; Moubaraki, B.; Murray, K.S.; Deacon, G.B.; Batten, S.R. Tetradecanuclear Polycarbonatolanthanoid Clusters: Diverse Coordination Modes of Carbonate Providing Access to Novel Core Geometries. Dalton Trans. 2012, 41, 10903–10909. [Google Scholar] [CrossRef] [PubMed]

- Vallina, B.; Rodriguez-Blanco, J.D.; Brown, A.P.; Blanco, J.A.; Benning, L.G. Amorphous Dysprosium Carbonate: Characterization, Stability, and Crystallization Pathways. J. Nanopart. Res. 2013, 15, 1438. [Google Scholar] [CrossRef]

- Deacon, G.B. Syntheses of Organometallic Compounds by Thermal Decarboxylation. Organomet. Chem. Rev. Sect. A 1970, 5, 355. [Google Scholar]

- Deacon, G.B.; Faulks, S.J.; Pain, G.N. The Synthesis of Organometallics by Decarboxylation Reactions. Adv. Organomet. Chem. 1986, 25, 237–276. [Google Scholar]

- Shannon, R.D. Revised effective ionic radii and systematic studies of interatomic distances in halides and chalcogenides. Acta Cryst. 1976, A32, 751–766. [Google Scholar] [CrossRef]

- Blin, F.; Leary, S.G.; Wilson, K.; Deacon, G.; Junk, P.; Forsyth, M. Corrosion Mitigation of Mild Steel by New Rare Earth Cinnamate Compounds. J. Appl. Electrochem. 2004, 34, 591–599. [Google Scholar] [CrossRef]

- MacRae, C.F.; Sovago, I.; Cottrell, S.J.; Galek, P.T.A.; McCabe, P.; Pidcock, E.; Platings, M.; Shields, G.P.; Stevens, J.S.; Towler, M.; et al. Mercury 4.0: From Visualization to Analysis, Design and Prediction. J. Appl. Crystallogr. 2020, 53, 226–235. [Google Scholar] [CrossRef]

- McPhillips, T.M.; McPhillips, S.E.; Chiu, H.J.; Cohen, A.E.; Deacon, A.M.; Ellis, P.J.; Garman, E.; Gonzalez, A.; Sauter, N.K.; Phizackerley, R.P.; et al. Blu-Ice and the Distributed Control System: Software for Data Acquisition and Instrument Control at Macromolecular Crystallography Beamlines. J. Synchrotron Radiat. 2002, 9, 401–406. [Google Scholar] [CrossRef] [PubMed]

- Kabsch, W. Automatic Processing of Rotation Diffraction Data from Crystals of Initially Unknown Symmetry and Cell Constants. J. Appl. Crystallogr. 1993, 26, 795–800. [Google Scholar] [CrossRef]

- Sheldrick, G.M. Crystal structure refinement with SHELXL. Acta Crystallogr. Sect. C Struct. Chem. 2015, C71, 3–8. [Google Scholar] [CrossRef] [PubMed]

- Dolomanov, O.V.; Bourhis, L.J.; Gildea, R.J.; Howard, J.A.K.; Puschmann, H. OLEX2: A Complete Structure Solution, Refinement and Analysis Program. J. Appl. Crystallogr. 2009, 42, 339–341. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. American-Standard-Test-Methods in ASTM G31-72; American Society for Testing and Materials: Philadelphia, PA, USA, 2004. [Google Scholar]

- Cowieson, N.P.; Aragao, D.; Clift, M.; Ericsson, D.; Gee, C.; Harrop, S.J.; Mudie, N.; Panjikar, S.; Price, J.; Riboldi-Tunnicliffe, A.; et al. MX1: A bending-magnet crystallography beamline serving both chemical and macromolecular crystallography communities at the Australian Synchrotron. J. Synchrotron Radiat. 2015, 22, 187–190. [Google Scholar] [CrossRef] [PubMed]

| Compound | ν(OH)water | νas(CO2−) | νs(CO2−) | Δν = (νas−νs)avg | δ(CO2) |

|---|---|---|---|---|---|

| [Nd(3fur)3(H2O)2]n (1Nd) | 3431 | 1505 | 1365 | 140 | 598 |

| [NaYb(3fur)4]n (2Yb) | - | 1502 | 1366 | 136 | 598 |

| Solution | Concentration | Solubility in 0.01 M NaCl (ppm) | Avg Weight Loss (mg) | Corrosion Rate (g/m2h) | Inhibition, η (%) | |

|---|---|---|---|---|---|---|

| ppm | mM | |||||

| Control-NaCl | 580 | 10 | - | 19.6 | 1406.1 | - |

| [La(3fur)3(H2O)2]n 1La | 800 | 1.57 | 2000 | 2.6 | 185.2 | 87 |

| [Ce(3fur)3(H2O)2]n 1Ce | 800 | 1.57 | 3000 | 3.7 | 298.6 | 79 |

| [Pr(3fur)3(H2O)2]n 1Pr | 800 | 1.57 | 3000 | 6.1 | 380.7 | 73 |

| [Nd(3fur)3(H2O)2]n 1Nd | 800 | 1.56 | 2500 | 5.1 | 365.9 | 74 |

| [Gd(3fur)3(H2O)2]n 1Gd | 800 | 1.57 | 1000 | 6.2 | 403.9 | 71 |

| [Dy(3fur)3(H2O)2]n 1Dy | 800 | 1.52 | 830 | 3.0 | 229.6 | 84 |

| [Ho(3fur)3(H2O)2]n 1Ho | 800 | 1.50 | 920 | 2.9 | 210.9 | 85 |

| [Y(3fur)3(H2O)2]n 1Y | 800 | 1.75 | 800 | 1.9 | 140.6 | 90 |

| [NaHo(3fur)4]n 2Ho | 800 | 1.27 | 1800 | 6.0 | 431.7 | 70 |

| [NaY(3fur)4]n 2Y | 800 | 1.44 | 1900 | 4.9 | 355.1 | 75 |

| [NaEr(3fur)4]n 2Er | 800 | 1.26 | 1800 | 5.1 | 365.9 | 74 |

| [NaYb(3fur)4]n 2Yb | 800 | 1.25 | 1700 | 2.4 | 168.7 | 88 |

| [NaLu(3fur)4]n 2Lu | 800 | 1.25 | 1500 | 7.7 | 480.6 | 66 |

| [Na(3fur)] | 800 | 5.97 | >7000 | 16.51 | 993.6 | 29 |

| Solution | icorr (µA/cm2) | Std. Dev. | Ecorr (mV) | Std. Dev. | Percentage Inhibition |

|---|---|---|---|---|---|

| Control-NaCl | 2.88 | 0.11 | −638 | 4 | |

| [La(3fur)3(H2O)2]n 1La | 1.09 | 0.09 | −473 | 5 | 62 |

| [Y(3fur)3(H2O)2]n 1Y | 0.56 | 0.08 | −445 | 4 | 80 |

| [NaYb(3fur)4]n 2Yb | 0.89 | 0.07 | −468 | 29 | 69 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vithana, V.P.; Guo, Z.; Deacon, G.B.; Somers, A.E.; Junk, P.C. RE(III) 3-Furoate Complexes: Synthesis, Structure, and Corrosion Inhibiting Properties. Molecules 2022, 27, 8836. https://doi.org/10.3390/molecules27248836

Vithana VP, Guo Z, Deacon GB, Somers AE, Junk PC. RE(III) 3-Furoate Complexes: Synthesis, Structure, and Corrosion Inhibiting Properties. Molecules. 2022; 27(24):8836. https://doi.org/10.3390/molecules27248836

Chicago/Turabian StyleVithana, Vidushi P., Zhifang Guo, Glen B. Deacon, Anthony E. Somers, and Peter C. Junk. 2022. "RE(III) 3-Furoate Complexes: Synthesis, Structure, and Corrosion Inhibiting Properties" Molecules 27, no. 24: 8836. https://doi.org/10.3390/molecules27248836

APA StyleVithana, V. P., Guo, Z., Deacon, G. B., Somers, A. E., & Junk, P. C. (2022). RE(III) 3-Furoate Complexes: Synthesis, Structure, and Corrosion Inhibiting Properties. Molecules, 27(24), 8836. https://doi.org/10.3390/molecules27248836