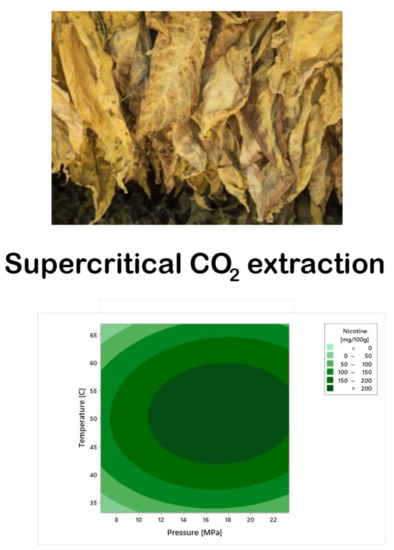

Supercritical Carbon Dioxide Extraction of Nicotiana tabacum Leaves: Optimization of Extraction Yield and Nicotine Content

Abstract

Highlights

- Nicotine was extracted from varieties Samsun and Virginia tobacco leaves using supercritical CO2 extraction.

- Response surface methodology was used to find factors that influence the supercritical CO2 extraction of tobacco leaves.

- The highest nicotine relative amount was at lower pressure (15 MPa), temperature of 50 °C and during 90 min extraction time.

- The quantity of nicotine and phytochemical composition in different tobacco varieties is specific.

Abstract

1. Introduction

2. Results

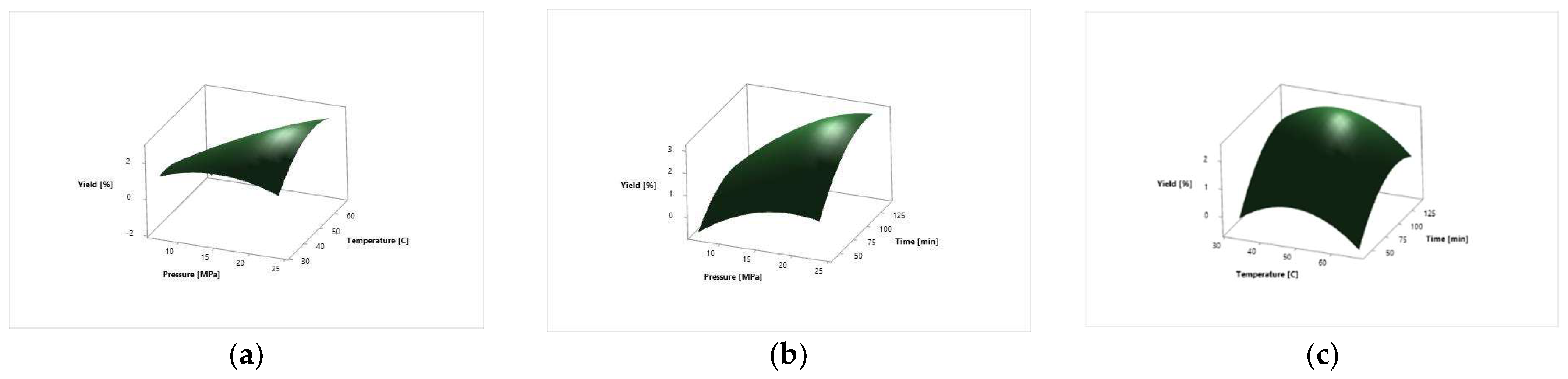

Optimization of SC CO2 Extraction of N. tabacum cv. Samsun and N. tabacum cv. Virginia Leaves

3. Discussion

4. Materials and Methods

4.1. Chemicals

4.2. Plant Material

4.3. Extraction Procedure

4.4. Experimental Design

4.5. GC–MS Analysis

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Coggins, C.R.E.; Richter, P. Tobacco. In Encyclopedia of Toxicology; Wexler, P., Ed.; Academic Press: Waltham, MA, USA, 2014; Volume 4, pp. 590–594. [Google Scholar] [CrossRef]

- Wolf, F.A. Turkish or Oriental tobacco. Econ. Bot. 1949, 3, 32–41. Available online: https://www.jstor.org/stable/4251921 (accessed on 7 August 2008). [CrossRef]

- Kinay, A.; Yilmaz, G.; Kandemir, N. Yield and quality of some oriental tobacco (Nicotiana tabacum L.) hybrids. Genetika 2020, 52, 735–750. [Google Scholar] [CrossRef]

- Leffingwell, J.C. Leaf Chemistry, Basic chemical constituents of tobacco leaf and differences among tobacco types. In Tobacco: Production, Chemistry, and Technology; Davis, D.L., Nielson, M.T., Eds.; Blackwell Science: Oxford, UK, 1999; pp. 265–284. [Google Scholar] [CrossRef]

- Dodd-Butera, T.; Broderick, M. Plants, Poisonous. In Encyclopedia of Toxicology, 2nd ed.; Wexler, P., Ed.; Elsevier Inc.: London, UK, 2005; pp. 443–448. [Google Scholar] [CrossRef]

- Kheawfu, K.; Kaewpinta, A.; Chanmahasathein, W.; Rachtanapun, P.; Jantrawut, P. Extraction of nicotine from tobacco leaves and development of fast dissolving nicotine extract film. Membranes 2021, 11, 403. [Google Scholar] [CrossRef]

- Hu, R.-S.; Wang, J.; Li, H.; Ni, H.; Chen, Y.-F.; Zhang, Y.-W.; Xiang, S.-P.; Li, H.-H. Simultaneous extraction of nicotine and solanesol from waste tobacco materials by the column chromatographic extraction method and their separation and purification. Sep. Purif. Technol. 2015, 146, 1–7. [Google Scholar] [CrossRef]

- Hubert, P.; Vitzthum, O.G. Fluid extraction of hops, spices, and tobacco with supercritical gases. Angew. Chem. Int. Ed. Engl. 1978, 17, 710–715. [Google Scholar] [CrossRef]

- Williams, D.F. Extraction with supercritical gases. Chem. Eng. Sci. 1981, 36, 1769–1788. [Google Scholar] [CrossRef]

- Coffa, B.G.; Coggins, C.R.E.; Werley, M.S.; Oldham, M.J.; Fariss, M.W. Chemical, physical, and in vitro characterization of research cigarettes containing denicotinized tobacco. RTP 2016, 79, 64–73. [Google Scholar] [CrossRef] [PubMed]

- Ruiz-Rodriguez, A.; Bronze, M.-R.; da Ponte, M.N. Supercritical fluid extraction of tobacco leaves: A preliminary study on the extraction of solanesol. J. Supercrit. Fluids 2008, 45, 171–176. [Google Scholar] [CrossRef]

- Ikhsanov, Y.S.; Nauryzbaev, M.; Musabekova, A.; Alimzhanova, M.; Burashaev, E. Study of Nicotiana tabacum L extraction, by methods of liquid and supercritical fluid extraction. JEAS 2019, 17, 338–353. [Google Scholar] [CrossRef]

- Fischer, M.; Jefferies, T.M. Optimization of nicotine extraction from tobacco using supercritical fluid technology with dynamic extraction modeling. J. Agric. Food Chem. 1996, 44, 1258–1264. [Google Scholar] [CrossRef]

- Rincón, J.; de Lucas, A.; Garcia, M.A.; Alvarez, A.; Carnicer, A. Preliminary study on the supercritical carbon dioxide extraction of nicotine from tobacco waste. Sep. Sci. Technol. 1998, 33, 411–423. [Google Scholar] [CrossRef]

- Sharif, K.M.; Rahman, M.M.; Azmir, J.; Mohamed, A.; Jahurul, M.H.A.; Sahena, F.; Zaidul, I.S.M. Experimental design of supercritical fluid extraction—A review. J. Food Eng. 2014, 124, 105–116. [Google Scholar] [CrossRef]

- Box, G.E.; Wilson, K. On the experimental attainment of optimum conditions. J. R. Stat. Society Ser. B Methodol. 1951, 13, 1–45. [Google Scholar] [CrossRef]

- Madamba, P.S. The response surface methodology: An application to optimize dehydration operations of selected agricultural crops. LWT 2002, 35, 584–592. [Google Scholar] [CrossRef]

- Fujimori, T.; Kasuga, R.; Matsushita, H.; Kaneko, H.; Noguchi, M. Neutral aroma constituents in Burley tobacco. Agric. Biol. Chem. 1976, 40, 303–315. [Google Scholar] [CrossRef]

- Alagic, S.; Stancic, I.; Palic, R.; Stojanovic, G.; Lepojevic, Z. Chemical composition of the supercritical CO2 extracts of the Yaka, Prilep and Otlja tobacco. J. Essent. Oil Res. 2006, 18, 185–188. [Google Scholar] [CrossRef]

- Roselius, W.; Vitzthum, O.; Hubert, P. Selective Extraction of Nicotine from Tobacco. Patent No. DE 2142205, 15 March 1973. [Google Scholar]

- Karbalaie, N.S.; Ghotbi, C.; Taghkhani, V.; Yamini, Y. Experimental study and modeling of supercritical extraction of nicotine from tobacco leaves. IJCCE 2009, 28, 51–59. [Google Scholar] [CrossRef]

- Djapic, N. Parrotia persica Yellow and Amber Leaves’ Lipophilic Phytochemicals Obtained by Supercritical Carbon Dioxide Extracton. Molecules 2022, 27, 5237. [Google Scholar] [CrossRef] [PubMed]

- Bas, D.; Boyaci, I.H. Modelling and optimization I: Usability of response surface methodology. J. Food Eng. 2007, 78, 836–845. [Google Scholar] [CrossRef]

| Levels | ||||||

|---|---|---|---|---|---|---|

| Independent Variables | Symbol | −1.414 | −1 | 0 | +1 | +1.414 |

| Pressure [MPa] | X1 | 8 | 10 | 15 | 20 | 22 |

| Temperature [°C] | X2 | 36 | 40 | 50 | 60 | 64 |

| Time [min] | X3 | 39.55 | 60 | 90 | 120 | 140.45 |

| No. | Pressure [MPa] | Temperature [°C] | Time [min] | Extraction Yield N. tabacum cv. Samsun [%] | Extraction Yield N. tabacum cv. Virginia [%] |

|---|---|---|---|---|---|

| 1. | 10 | 40 | 60 | 0.82 | 0.75 |

| 2. | 20 | 40 | 60 | 1.03 | 0.92 |

| 3. | 10 | 60 | 60 | 0.11 | 0.08 |

| 4. | 20 | 60 | 60 | 1.45 | 1.19 |

| 5. | 10 | 40 | 120 | 1.73 | 1.67 |

| 6. | 20 | 40 | 120 | 2.10 | 1.98 |

| 7. | 10 | 60 | 120 | 0.51 | 0.32 |

| 8. | 20 | 60 | 120 | 2.76 | 2.23 |

| 9. | 6.59 | 50 | 90 | 0.38 | 0.21 |

| 10. | 23.41 | 50 | 90 | 2.99 | 2.33 |

| 11. | 15 | 33.18 | 90 | 1.96 | 1.88 |

| 12. | 15 | 66.82 | 90 | 0.92 | 0.75 |

| 13. | 15 | 50 | 39.55 | 0.63 | 0.37 |

| 14. | 15 | 50 | 140.45 | 2.36 | 2.26 |

| 15. | 15 | 50 | 90 | 2.22 | 1.95 |

| 16. | 15 | 50 | 90 | 2.17 | 1.90 |

| 17. | 15 | 50 | 90 | 2.31 | 2.11 |

| 18. | 15 | 50 | 90 | 2.28 | 2.14 |

| 19. | 15 | 50 | 90 | 2.07 | 1.89 |

| 20. | 15 | 50 | 90 | 2.19 | 1.96 |

| Term | Coefficient | Standard Error Coefficient | T-Value | p-Value |

|---|---|---|---|---|

| Extraction yield N. tabacum cv. Samsun | ||||

| Constant | 2.2127 | 0.0980 | 22.57 | 0.000 |

| X1 | 0.6268 | 0.0651 | 9.63 | 0.000 |

| X2 | −0.1903 | 0.0651 | −2.93 | 0.015 |

| X3 | 0.4832 | 0.0651 | 7.43 | 0.000 |

| X1·X1 | −0.2236 | 0.0633 | −3.53 | 0.005 |

| X2·X2 | −0.3103 | 0.0633 | −4.90 | 0.001 |

| X3·X3 | −0.2908 | 0.0633 | −4.59 | 0.001 |

| X1·X2 | 0.3762 | 0.0850 | 4.43 | 0.001 |

| X1·X3 | 0.1338 | 0.0850 | 1.57 | 0.147 |

| X2·X3 | −0.0338 | 0.0850 | −0.40 | 0.700 |

| R2 = 0.9578 | ||||

| Extraction yield N. tabacum cv. Virginia | ||||

| Constant | 1.9954 | 0.0845 | 23.60 | 0.000 |

| X1 | 0.5174 | 0.0561 | 9.22 | 0.000 |

| X2 | −0.2490 | 0.0561 | −4.44 | 0.001 |

| X3 | 0.4715 | 0.0561 | 8.40 | 0.000 |

| X1·X1 | −0.2795 | 0.0546 | −5.12 | 0.000 |

| X2·X2 | −0.2636 | 0.0546 | −4.83 | 0.001 |

| X3·X3 | −0.2636 | 0.0546 | −4.83 | 0.001 |

| X1·X2 | 0.3175 | 0.0733 | 4.33 | 0.001 |

| X1·X3 | 0.1175 | 0.0733 | 1.60 | 0.140 |

| X2·X3 | −0.0875 | 0.0733 | −1.19 | 0.260 |

| R2 = 0.9628 |

| No. | Source | Adjusted Sum of Squares | Adjusted Mean Squares | F-Value | p-Value | Adjusted Sum of Squares | Adjusted Mean Squares | F-Value | p-Value |

|---|---|---|---|---|---|---|---|---|---|

| cv. Samsun | cv. Virginia | ||||||||

| Model | 9 | 13.1254 | 1.45838 | 25.24 | 0.000 | 11.1270 | 1.23633 | 28.77 | 0.000 |

| Linear | 3 | 9.0484 | 3.01615 | 52.19 | 0.000 | 7.5375 | 2.51249 | 58.46 | 0.000 |

| X1 | 1 | 5.3647 | 5.36468 | 92.83 | 0.000 | 3.6553 | 3.65530 | 85.06 | 0.000 |

| X2 | 1 | 0.4946 | 0.49463 | 8.56 | 0.015 | 0.8467 | 0.84667 | 19.70 | 0.001 |

| X3 | 1 | 3.1891 | 3.18913 | 55.18 | 0.000 | 3.0355 | 3.03550 | 70.63 | 0.000 |

| Square | 3 | 2.7922 | 0.93074 | 16.11 | 0.000 | 2.6113 | 0.87044 | 20.25 | 0.000 |

| X1·X1 | 1 | 0.7208 | 0.72083 | 12.47 | 0.005 | 1.1261 | 1.12606 | 26.20 | 0.000 |

| X2·X2 | 1 | 1.3873 | 1.38732 | 24.01 | 0.001 | 1.0015 | 1.00152 | 23.31 | 0.001 |

| X3·X3 | 1 | 1.2189 | 1.21887 | 21.09 | 0.001 | 1.0015 | 1.00152 | 23.31 | 0.001 |

| 2-Way Interaction | 3 | 1.2847 | 0.42825 | 7.41 | 0.007 | 0.9782 | 0.32605 | 7.59 | 0.006 |

| X1·X2 | 1 | 1.1325 | 1.13251 | 19.60 | 0.001 | 0.8065 | 0.80645 | 18.77 | 0.001 |

| X1·X3 | 1 | 0.1431 | 0.14311 | 2.48 | 0.147 | 0.1105 | 0.11045 | 2.57 | 0.140 |

| X2·X3 | 1 | 0.0091 | 0.00911 | 0.16 | 0.700 | 0.0612 | 0.06125 | 1.43 | 0.260 |

| Error | 10 | 0.5779 | 0.05779 | 0.4297 | 0.04297 | ||||

| Lack-of-Fit | 5 | 0.5414 | 0.10827 | 14.82 | 0.005 | 0.3723 | 0.07445 | 6.48 | 0.031 |

| Pure Error | 5 | 0.0365 | 0.00731 | 0.0575 | 0.01150 | ||||

| Total | 19 | 13.7033 | 11.5567 | ||||||

| No. | Compound | Run 1 | Run 2 | Run 3 | Run 4 | Run 5 | Run 6 | Run 7 | Run 8 | Run 9 | Run 10 | Run 11 | Run 12 | Run 13 | Run 14 | Run 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | trans-Anethole | 0.7 | 0.0 | 0.0 | 0.0 | 2.0 | 0.0 | 0.2 | 0.0 | 0.9 | 0.0 | 0.4 | 1.2 | 0.0 | 1.6 | 1.4 |

| 2 | Nicotine | 38.1 | 62.2 | 64.2 | 95.1 | 119.3 | 161.0 | 109.8 | 185.3 | 148.1 | 222.3 | 102.7 | 118.6 | 7.3 | 217.2 | 242.1 |

| 3 | β-Damascenone | 3.9 | 0.0 | 0.0 | 0.0 | 8.8 | 0.0 | 0.0 | 0.0 | 5.2 | 0.0 | 5.4 | 0.0 | 2.5 | 7.3 | 6.7 |

| 4 | Butylhydroxytoluene | 0.1 | 0.0 | 0.2 | 0.0 | 0.5 | 0.0 | 0.5 | 0.0 | 0.0 | 0.0 | 0.1 | 0.5 | 0.0 | 0.3 | 0.2 |

| 5 | 3-oxo-α-ionol | 3.5 | 0.0 | 0.0 | 0.0 | 7.5 | 0.0 | 0.0 | 0.0 | 1.7 | 0.0 | 9.2 | 0.0 | 0.0 | 0.0 | 0.0 |

| 6 | Neophytadiene | 10.4 | 14.7 | 7.7 | 14.3 | 22.3 | 30.9 | 17.7 | 31.7 | 28.0 | 36.8 | 21.8 | 24.1 | 17.8 | 36.5 | 32.0 |

| 7 | Hexahydrofarnesol | 0.2 | 0.0 | 0.0 | 0.0 | 0.6 | 0.0 | 0.1 | 0.0 | 0.3 | 0.0 | 0.1 | 1.5 | 0.2 | 1.2 | 0.9 |

| 8 | Thunbergol | 1.6 | 3.8 | 0.1 | 3.7 | 4.0 | 6.5 | 0.5 | 9.0 | 0.0 | 0.0 | 0.0 | 9.1 | 4.0 | 8.6 | 7.8 |

| 9 | Sclareolide | 0.0 | 0.9 | 0.0 | 0.9 | 0.0 | 2.1 | 0.0 | 2.1 | 0.0 | 1.5 | 1.3 | 1.8 | 0.2 | 1.7 | 1.5 |

| 10 | Phytol | 0.5 | 0.0 | 0.6 | 0.0 | 1.5 | 0.0 | 1.7 | 0.0 | 2.2 | 0.0 | 0.7 | 0.0 | 1.1 | 2.5 | 2.3 |

| 11 | Agatholic acid | 0.0 | 0.3 | 0.0 | 0.0 | 0.0 | 1.0 | 0.0 | 0.0 | 0.0 | 0.9 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 12 | (3β)-Stigmast-5-en-3-ol | 0.0 | 0.2 | 0.0 | 0.2 | 0.0 | 0.7 | 0.0 | 0.5 | 0.0 | 0.3 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| No. | Compound | Run 1 | Run 2 | Run 3 | Run 4 | Run 5 | Run 6 | Run 7 | Run 8 | Run 9 | Run 10 | Run 11 | Run 12 | Run 13 | Run 14 | Run 15 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Nicotine | 5.2 | 8.1 | 8.4 | 11.7 | 15.3 | 20.6 | 14.2 | 22.7 | 19.3 | 28.9 | 13.3 | 14.7 | 0.8 | 30.2 | 32.4 |

| 2 | Solanone | 1.2 | 1.7 | 0.2 | 0.5 | 1.6 | 2.1 | 0.5 | 0.7 | 1.4 | 2.6 | 1.9 | 3.3 | 0.0 | 2.1 | 2.0 |

| 3 | Norsolanadione | 0.5 | 0.7 | 0.3 | 0.3 | 0.8 | 1.2 | 0.6 | 0.5 | 0.7 | 1.4 | 1.7 | 1.5 | 0.0 | 1.3 | 0.9 |

| 4 | 3-oxo-α-ionol | 0.6 | 0.0 | 0.0 | 0.0 | 0.9 | 0.0 | 0.0 | 0.0 | 0.4 | 0.0 | 1.7 | 0.0 | 0.0 | 2.1 | 1.9 |

| 5 | Farnesol | 2.8 | 2.6 | 0.4 | 0.5 | 3.7 | 3.5 | 0.9 | 0.7 | 2.2 | 6.2 | 8.3 | 5.5 | 0.5 | 5.2 | 4.9 |

| 6 | Neophytadiene | 7.5 | 9.3 | 5.1 | 9.1 | 8.8 | 10.9 | 8.6 | 11.3 | 19.9 | 24.4 | 13.3 | 14.7 | 1.9 | 22.6 | 20.2 |

| 7 | 5-nonadecene | 0.0 | 0.1 | 0.0 | 0.2 | 0.0 | 0.3 | 0.0 | 0.3 | 0.0 | 1.2 | 1.3 | 0.9 | 0.0 | 1.8 | 0.8 |

| 8 | Thunbergol | 2.6 | 5.5 | 0.3 | 6.1 | 3.7 | 6.7 | 0.7 | 8.4 | 0.0 | 1.3 | 0.0 | 12.9 | 2.6 | 13.5 | 11.1 |

| 9 | Methyl linoleate | 0.0 | 0.8 | 0.0 | 0.8 | 0.0 | 1.3 | 0.0 | 1.2 | 0.0 | 3.8 | 4.3 | 3.1 | 0.0 | 4.2 | 3.4 |

| 10 | Sclareolide | 0.0 | 0.3 | 0.0 | 0.1 | 0.0 | 0.5 | 0.0 | 0.2 | 0.0 | 1.0 | 1.3 | 0.6 | 0.0 | 2.0 | 1.1 |

| 11 | 1-docosene | 0.0 | 2.2 | 0.0 | 4.4 | 0.0 | 2.8 | 0.0 | 7.5 | 0.0 | 5.4 | 5.0 | 5.6 | 0.9 | 5.1 | 4.3 |

| 12 | Geranyl geraniol | 0.1 | 0.2 | 0.0 | 0.0 | 0.3 | 0.5 | 0.0 | 0.0 | 0.0 | 0.6 | 0.1 | 0.5 | 0.0 | 0.7 | 0.4 |

| 13 | 4,8,13-duvatriene-1,3-diol | 0.0 | 0.0 | 1.1 | 2.4 | 0.0 | 0.0 | 2.3 | 3.7 | 3.9 | 3.9 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| 14 | 8,13-epoxy-14-labden-12-ol | 95.7 | 98.8 | 34.8 | 42.8 | 102.8 | 110.5 | 54.8 | 59.1 | 105.1 | 180.1 | 228.3 | 168.6 | 12.8 | 271.3 | 262.4 |

| 15 | (E)-stigmasta-5,22-dien-3β-ol | 0.0 | 0.2 | 0.0 | 0.3 | 0.0 | 0.4 | 0.0 | 0.5 | 0.0 | 1.6 | 0.0 | 0.3 | 0.0 | 0.0 | 0.0 |

| 16 | Triacontyl acetate | 0.5 | 0.1 | 2.0 | 1.1 | 1.1 | 0.2 | 3.1 | 1.8 | 0.0 | 2.2 | 0.0 | 2.0 | 0.0 | 2.2 | 1.8 |

| 17 | Solanesol | 6.1 | 8.3 | 0.5 | 9.2 | 7.3 | 9.7 | 8.2 | 11.3 | 18.2 | 24.4 | 5.1 | 15.0 | 1.6 | 16.2 | 6.3 |

| Term | Coefficient | Standard Error Coefficient | T-Value | p-Value |

|---|---|---|---|---|

| Nicotine relative amount N. tabacum cv. Samsun | ||||

| Constant | 234.41 | 7.83 | 29.94 | 0.000 |

| X1 | 21.26 | 5.19 | 4.09 | 0.002 |

| X2 | 6.71 | 5.19 | 1.29 | 0.225 |

| X3 | 47.05 | 5.19 | 9.06 | 0.000 |

| X1·X1 | −22.39 | 5.06 | −4.43 | 0.001 |

| X2·X2 | −48.75 | 5.06 | −9.64 | 0.000 |

| X3·X3 | −50.01 | 5.06 | −9.89 | 0.000 |

| X1·X2 | 4.24 | 6.79 | 0.62 | 0.546 |

| X1·X3 | 6.94 | 6.79 | 1.02 | 0.331 |

| X2·X3 | −6.64 | 6.79 | −0.98 | 0.351 |

| R2 = 0.9659 | ||||

| Nicotine relative amount N. tabacum cv. Virginia | ||||

| Constant | 31.46 | 1.28 | 24.58 | 0.000 |

| X1 | 2.647 | 0.849 | 3.12 | 0.011 |

| X2 | 0.744 | 0.849 | 0.88 | 0.402 |

| X3 | 6.506 | 0.849 | 7.66 | 0.000 |

| X1·X1 | −3.354 | 0.827 | −4.06 | 0.002 |

| X2·X2 | −6.925 | 0.827 | −8.38 | 0.000 |

| X3·X3 | −6.394 | 0.827 | −7.74 | 0.000 |

| X1·X2 | 0.45 | 1.11 | 0.41 | 0.694 |

| X1·X3 | 0.95 | 1.11 | 0.86 | 0.412 |

| X2·X3 | −0.73 | 1.11 | −0.65 | 0.528 |

| R2 = 0.9514 |

| No. | Source | Adjusted Sum of Squares | Adjusted Mean Squares | F-Value | p-Value | Adjusted Sum of Squares | Adjusted Mean Squares | F-Value | p-Value |

|---|---|---|---|---|---|---|---|---|---|

| cv. Samsun | cv. Virginia | ||||||||

| Model | 5 | 104,509 | 11,612.1 | 31.51 | 0.000 | 1927.23 | 214.136 | 21.75 | 0.000 |

| Linear | 3 | 37,020 | 12,340.1 | 33.49 | 0.000 | 681.19 | 227.065 | 23.06 | 0.000 |

| X1 | 1 | 6170 | 6170.4 | 16.75 | 0.002 | 95.66 | 95.665 | 9.72 | 0.011 |

| X2 | 1 | 615 | 614.9 | 1.67 | 0.225 | 7.55 | 7.550 | 0.77 | 0.402 |

| X3 | 1 | 30,235 | 30,235.1 | 82.06 | 0.000 | 577.98 | 577.980 | 58.70 | 0.000 |

| Square | 3 | 66,607 | 22,202.4 | 60.26 | 0.000 | 1232.99 | 410.995 | 41.74 | 0.000 |

| X1·X1 | 1 | 7227 | 7227.3 | 19.61 | 0.001 | 162.11 | 162.111 | 16.47 | 0.002 |

| X2·X2 | 1 | 34,252 | 34,251.7 | 92.96 | 0.000 | 691.07 | 691.068 | 70.19 | 0.000 |

| X3·X3 | 1 | 36,038 | 36,038.0 | 97.80 | 0.000 | 589.27 | 589.272 | 59.85 | 0.000 |

| 2-Way Interaction | 3 | 881 | 293.7 | 0.80 | 0.523 | 13.05 | 4.348 | 0.44 | 0.728 |

| X1·X2 | 1 | 144 | 143.7 | 0.39 | 0.546 | 1.62 | 1.620 | 0.16 | 0.694 |

| X1·X3 | 1 | 385 | 385.0 | 1.04 | 0.331 | 7.22 | 7.220 | 0.73 | 0.412 |

| X2·X3 | 1 | 352 | 352.5 | 0.96 | 0.351 | 4.21 | 4.205 | 0.43 | 0.528 |

| Error | 10 | 3685 | 368.5 | 98.46 | 9.846 | ||||

| Lack-of-Fit | 5 | 3555 | 711.1 | 27.47 | 0.001 | 96.18 | 19.237 | 42.31 | 0.000 |

| Pure Error | 5 | 129 | 25.9 | 2.27 | 0.455 | ||||

| Total | 19 | 108,193 | 2025.68 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Djapic, N. Supercritical Carbon Dioxide Extraction of Nicotiana tabacum Leaves: Optimization of Extraction Yield and Nicotine Content. Molecules 2022, 27, 8328. https://doi.org/10.3390/molecules27238328

Djapic N. Supercritical Carbon Dioxide Extraction of Nicotiana tabacum Leaves: Optimization of Extraction Yield and Nicotine Content. Molecules. 2022; 27(23):8328. https://doi.org/10.3390/molecules27238328

Chicago/Turabian StyleDjapic, Nina. 2022. "Supercritical Carbon Dioxide Extraction of Nicotiana tabacum Leaves: Optimization of Extraction Yield and Nicotine Content" Molecules 27, no. 23: 8328. https://doi.org/10.3390/molecules27238328

APA StyleDjapic, N. (2022). Supercritical Carbon Dioxide Extraction of Nicotiana tabacum Leaves: Optimization of Extraction Yield and Nicotine Content. Molecules, 27(23), 8328. https://doi.org/10.3390/molecules27238328