Investigation on the Potential Application of Na-Attapulgite as an Excipient in Domperidone Sustained-Release Tablets

Abstract

1. Introduction

2. Results and Discussion

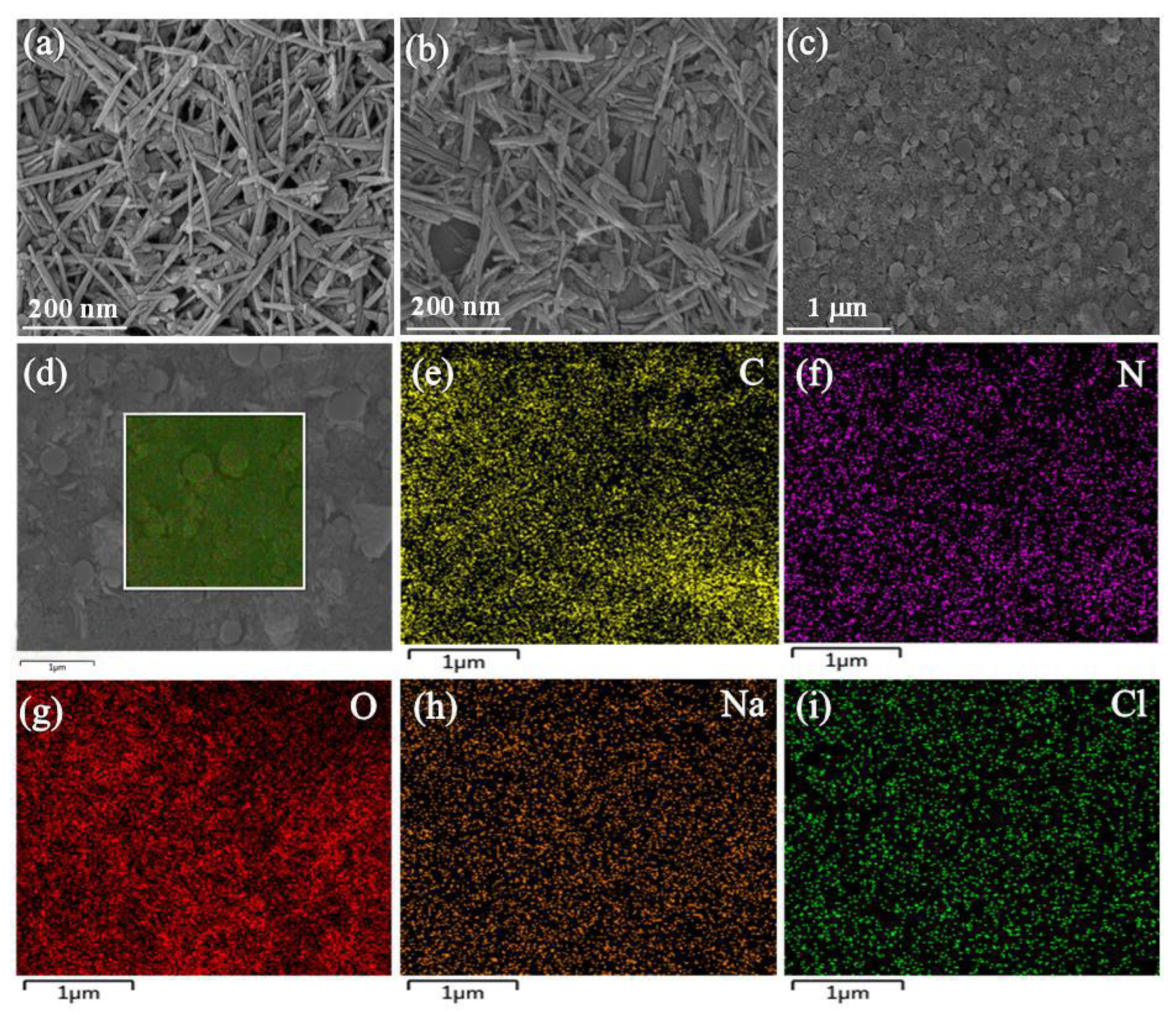

2.1. SEM and EDS Analysis

2.2. Tablets Properties

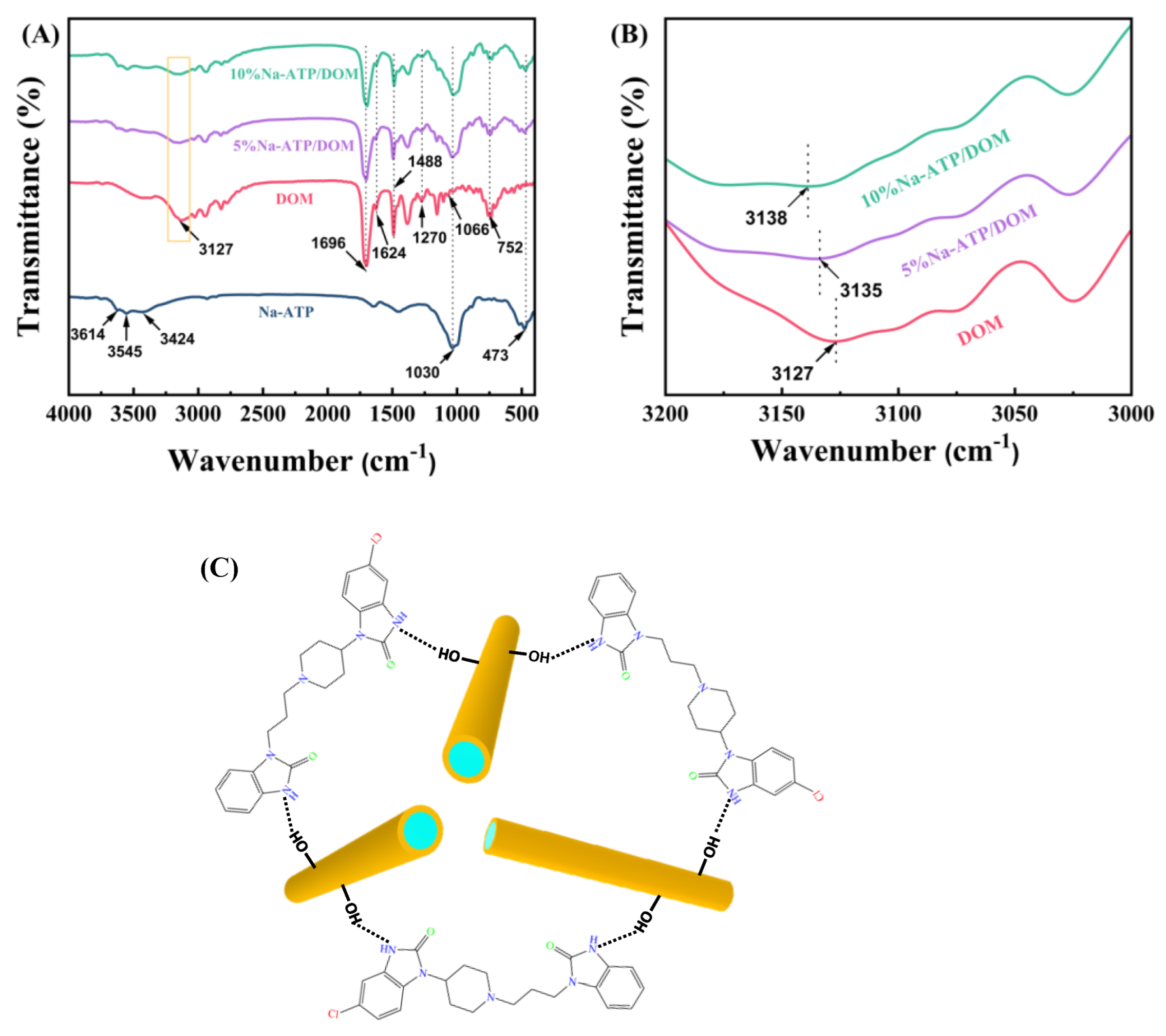

2.3. FT-IR Analysis

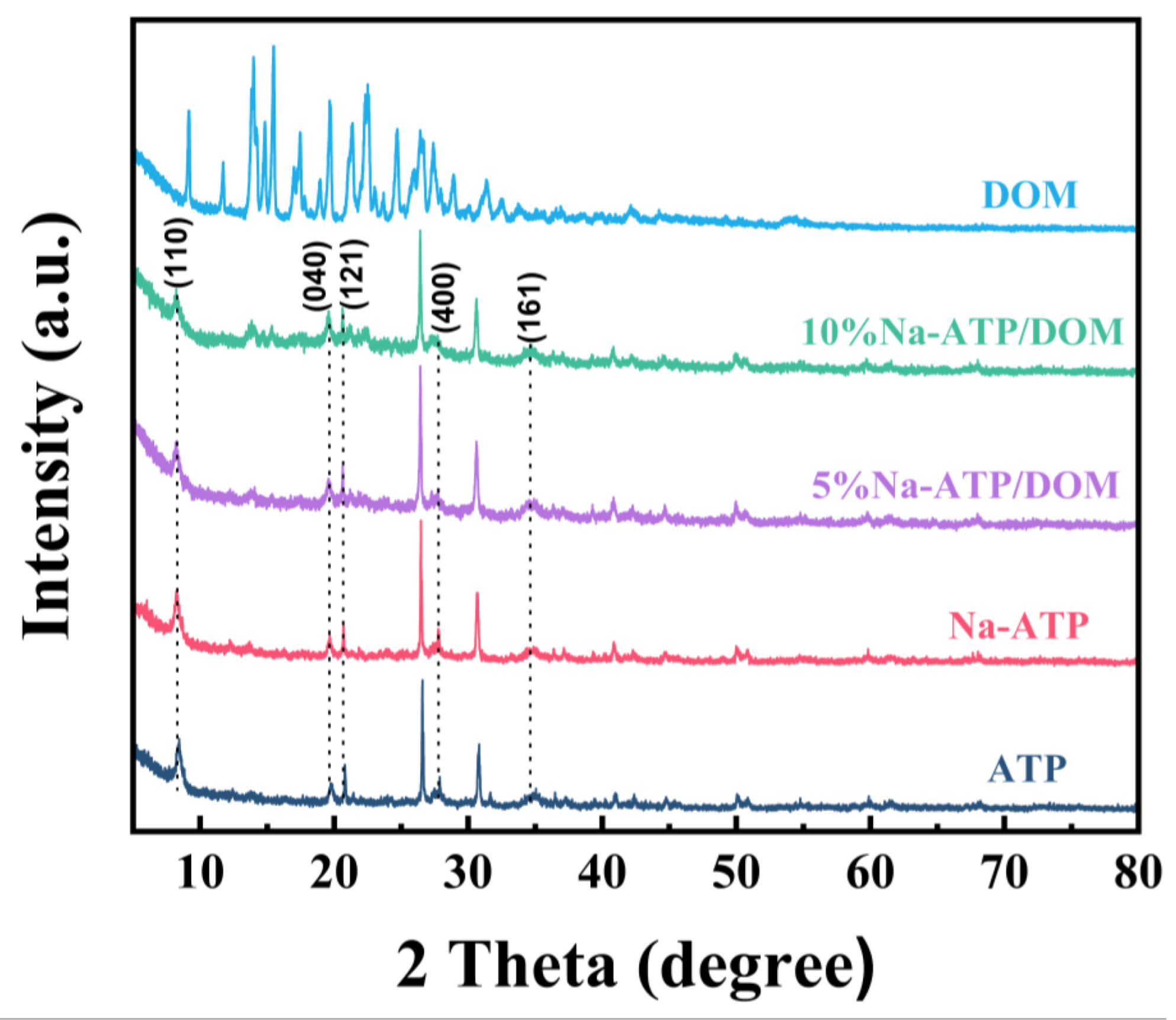

2.4. XRD Analysis

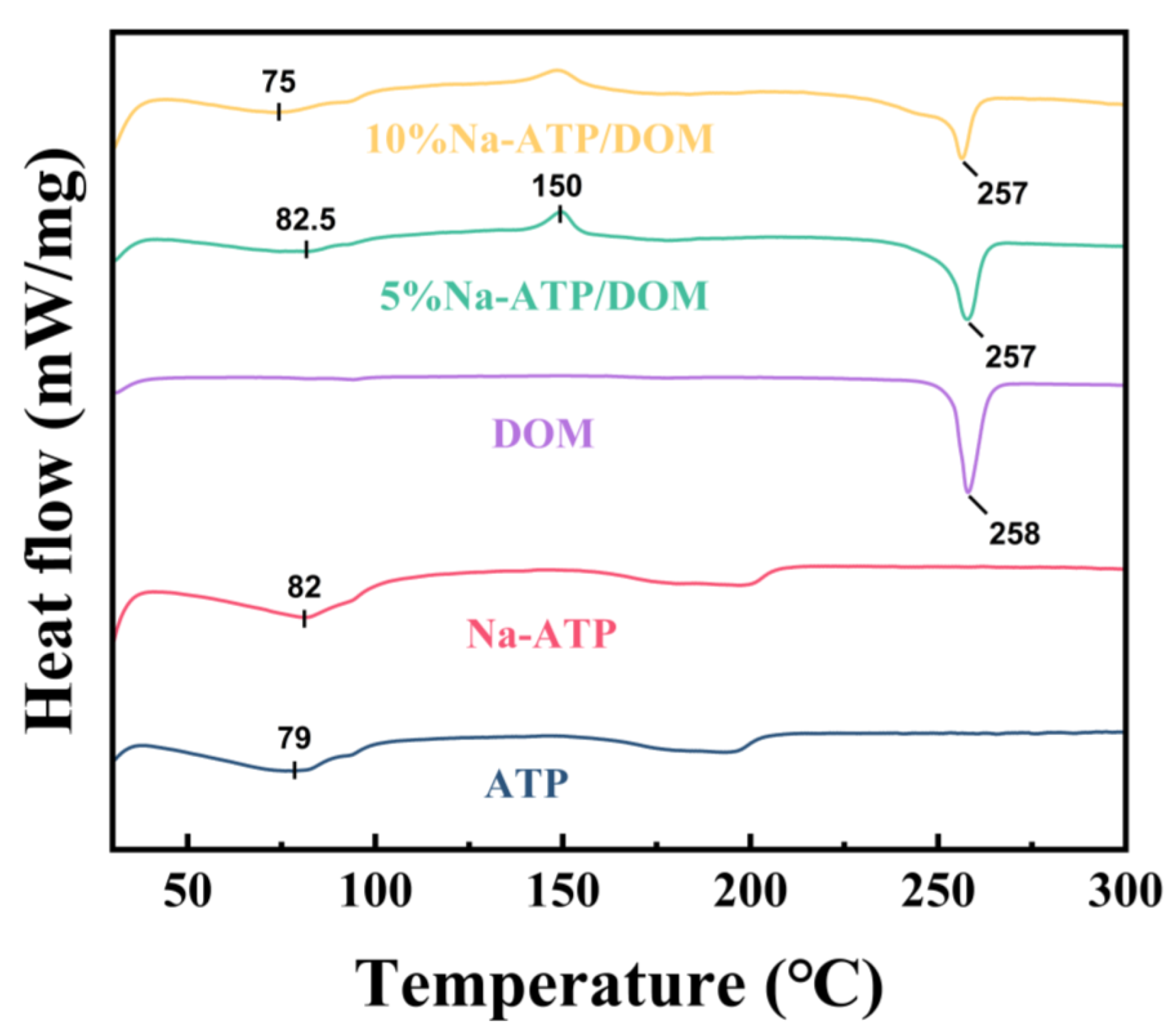

2.5. Thermal Analysis

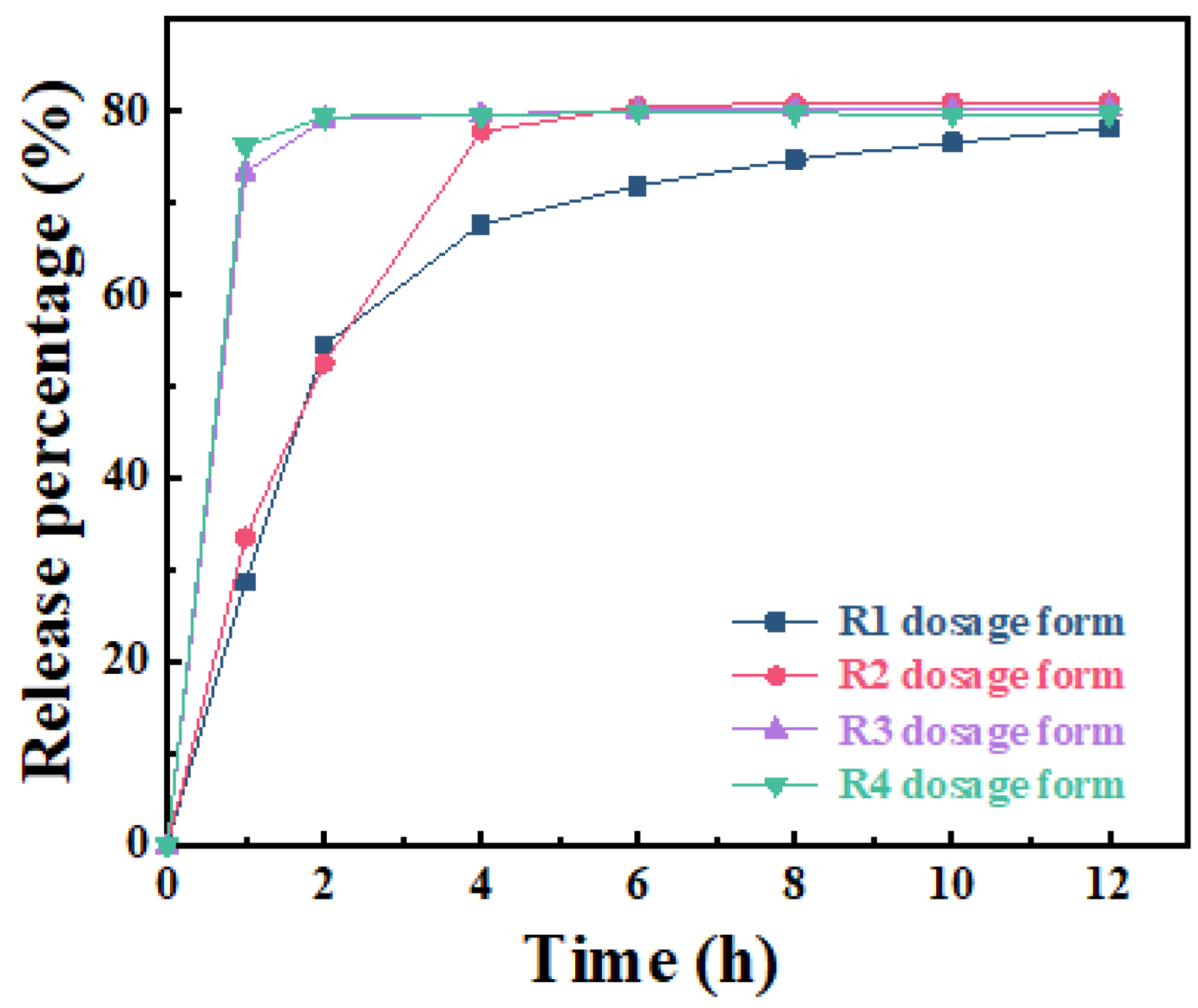

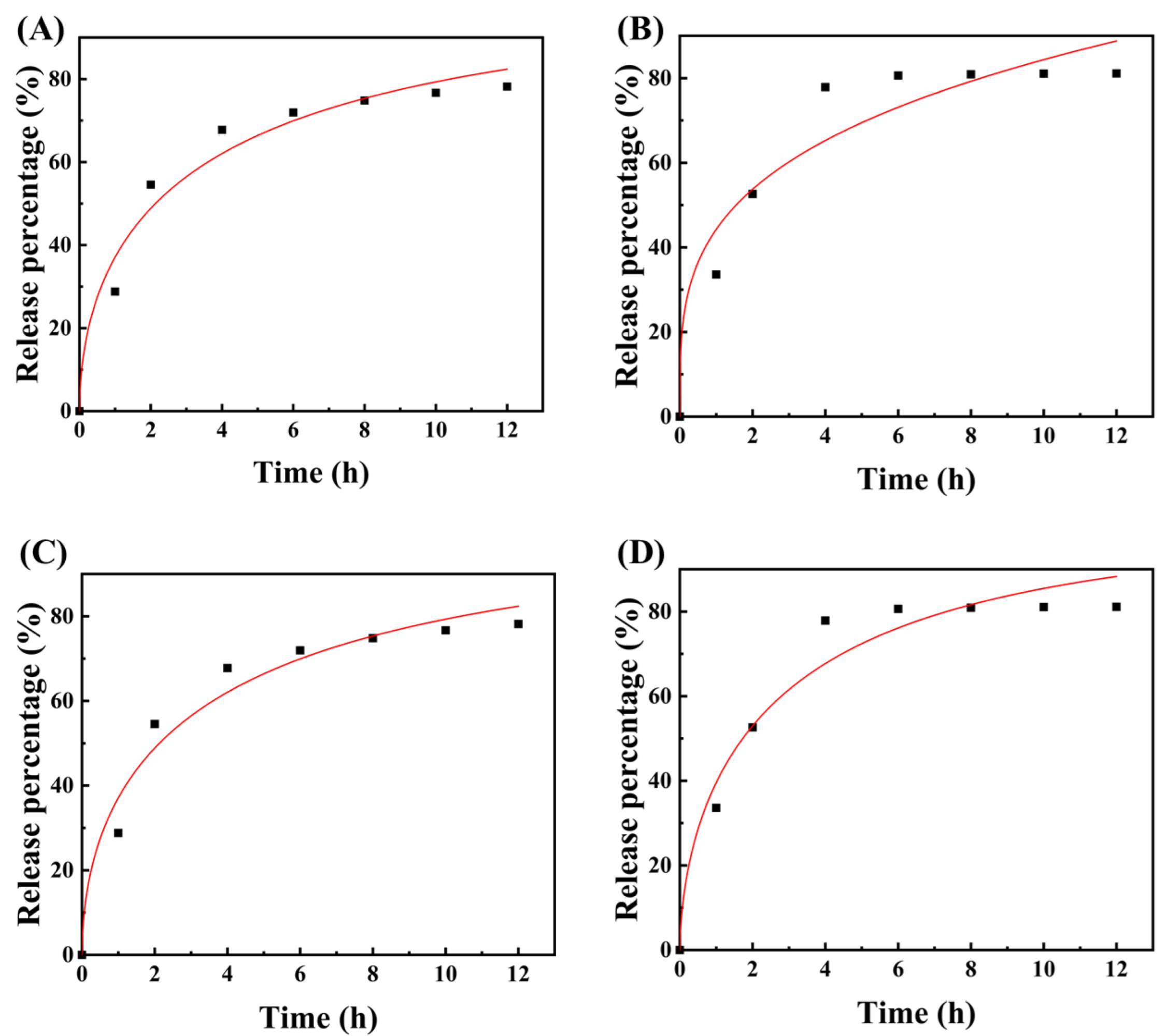

2.6. Drug Release Kinetics Study

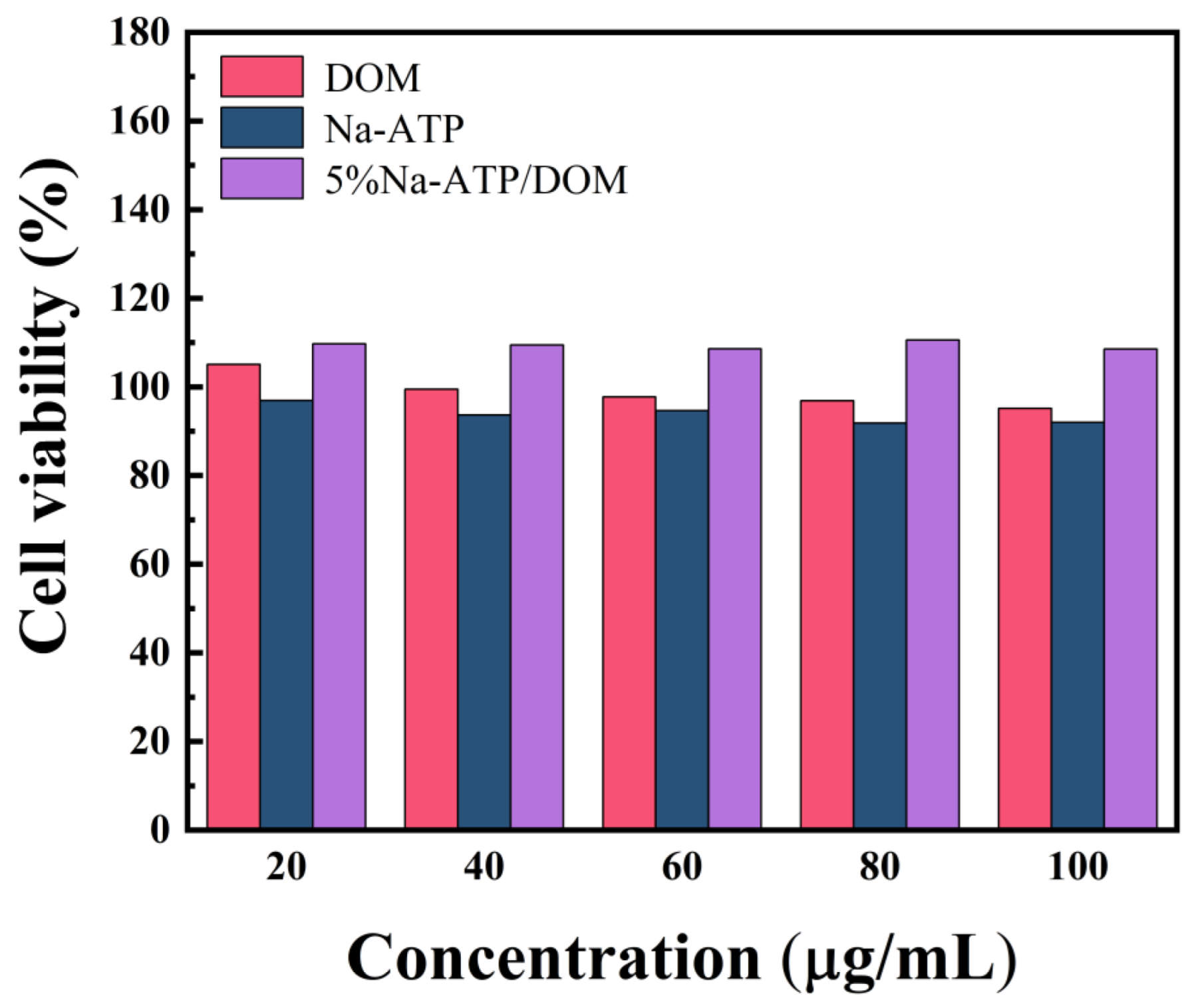

2.7. Cell Viability Analysis

2.8. Analysis of Drug Sustained-Release Principle

- The modification of Na2CO3 makes ion exchange occur on the surface of ATP, which is negatively charged as a whole, and the rod crystals repel each other, making them dissociated to a certain extent, which increases the contact probability between the rod crystals and drug molecules.

- Through ball milling, there is hydrogen bond interaction between the DOM molecule and -OH on the Na-ATP surface. This hydrogen bonding interaction will become stronger with the increase of Na ATP content, which is more conducive to the slow release of drugs.

3. Materials and Methods

3.1. Materials

3.2. Methods

3.2.1. Modification of ATP

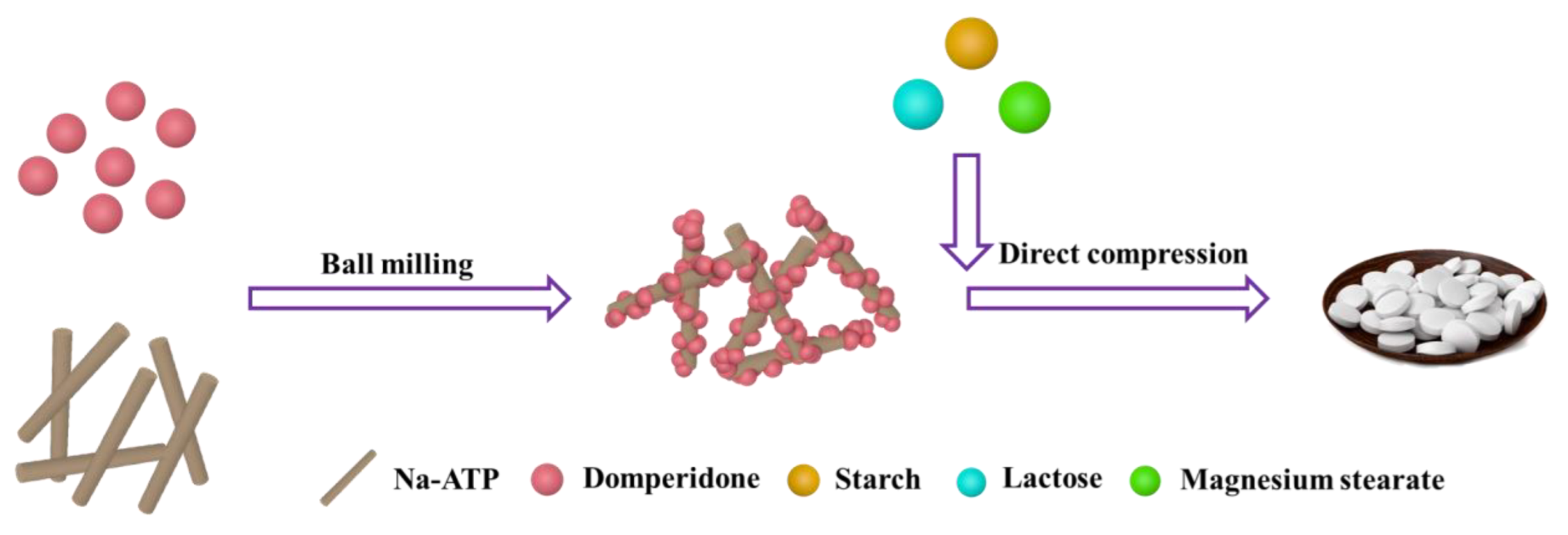

3.2.2. Preparation of Powder and Direct Compression

3.2.3. SEM and EDS Measurements

3.2.4. Friability Measurement

3.2.5. Hardness and Diameter Measurement

3.2.6. Drug Content

3.2.7. Fourier Transform Infrared (FT-IR) Spectroscopy

3.2.8. X-ray Powder Diffraction Method

3.2.9. Differential Scanning Calorimeter (DSC) Measurements

3.2.10. Drug Release Experiments

3.2.11. Mathematical Modelling of Release Profiles

3.2.12. Cell Viability Assay

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Aguzzi, C.; Cerezo, P.; Viseras, C.; Caramella, C. Use of clays as drug delivery systems: Possibilities and limitations. Appl. Clay Sci. 2007, 36, 22–36. [Google Scholar] [CrossRef]

- Moraes, J.D.D.; Bertolino, S.R.A.; Cuffini, S.L.; Ducart, D.F.; Bretzke, P.E.; Leonardi, G.R. Clay minerals: Properties and applications to dermocosmetic products and perspectives of natural raw materials for therapeutic purposes—A review. Int. J. Pharm. 2017, 534, 213–219. [Google Scholar] [CrossRef] [PubMed]

- Viseras, C.; Aguzzi, C.; Cerezo, P.; Galindo, A.L. Uses of clay minerals in semisolid health care and therapeutic products. Appl. Clay Sci. 2007, 36, 37–50. [Google Scholar] [CrossRef]

- Murugesan, S.; Scheibel, T. Copolymer/Clay Nanocomposites for Biomedical Applications. Adv. Funct. Mater. 2020, 30, 1908101. [Google Scholar] [CrossRef]

- Martín, S.; Pérez, I.; Rivera, A. Hosting of the antibiotic Vancomycin by bentonite: Characterization and slow release study. Appl. Clay Sci. 2021, 202, 105965. [Google Scholar] [CrossRef]

- Jauković, V.; Krajišnik, D.; Daković, A.; Damjanović, A.; Krstić, J.; Stojanović, J.; Čalija, B. Influence of selective acid-etching on functionality of halloysite-chitosan nanocontainers for sustained drug release. Mater. Sci. Eng. C 2021, 123, 112029. [Google Scholar] [CrossRef]

- Palem, R.R.; Rao, K.M.; Shimoga, G.; Saratale, R.G.; Shinde, S.K.; Ghodake, G.S.; Lee, S.-H. Physicochemical characterization, drug release, and biocompatibility evaluation of carboxymethyl cellulose-based hydrogels reinforced with sepiolite nanoclay. Int. J. Biol. Macromol. 2021, 178, 464–476. [Google Scholar] [CrossRef]

- Wang, W.; Wang, A. Palygorskite Nanomaterials: Structure, Properties, and Functional Applications. Nanomater. Clay Miner. 2019, 2019, 21–133. [Google Scholar] [CrossRef]

- Huang, J.; Liu, Y.; Jin, Q.; Wang, X.; Yang, J. Adsorption Studies of a Water Soluble Dye, Reactive Red MF-3B, Using Sonication-Surfactant-Modified Attapulgite Clay. J. Hazard. Mater. 2007, 143, 541–548. [Google Scholar] [CrossRef] [PubMed]

- Kawashima, S.; Chaouche, M.; Corr, D.; Shah, S.P. Rate of thixotropic rebuilding of cement pastes modified with highly purified attapulgite clays. Cem. Concr. Res. 2013, 53, 112–118. [Google Scholar] [CrossRef]

- Choi, H.Y.; Lee, Y.S. Characteristics of moisture-absorbing film impregnated with synthesized attapulgite with acrylamide and its effect on the quality of seasoned laver during storage. J. Food Eng. 2013, 116, 829–839. [Google Scholar] [CrossRef]

- Wang, Q.; Zhang, J.; Wang, A. Preparation and characterization of a novel pH-sensitive chitosan-g-poly (acrylic acid)/attapulgite/sodium alginate composite hydrogel bead for controlled release of diclofenac sodium. Carbohydr. Polym. 2009, 78, 731–737. [Google Scholar] [CrossRef]

- Qingli, X.; Zhengdong, Z.; Kai, H.; Shanzhi, X.; Chuang, M.; Chenge, C.; Huan, Y.; Yang, Y.; Yongjie, Y. Ni supported on MgO modified attapulgite as catalysts for hydrogen production from glycerol steam reforming. Int. J. Hydrogen Energy 2021, 46, 27380–27393. [Google Scholar] [CrossRef]

- Xu, L.; Liu, Y.; Wang, J.; Tang, Y.; Zhang, Z. Selective adsorption of Pb2+ and Cu2+ on amino-modified attapulgite: Kinetic, thermal dynamic and DFT studies. J. Hazard. Mater. 2020, 404, 124140. [Google Scholar] [CrossRef] [PubMed]

- Neter, E.; Gorzynski, E.A. The Adsorption of Enterobacterial Endotoxins by Activated Attapulgite. J. Am. Pharm. Assoc. (Sci. Ed.) 1958, 47, 651–653. [Google Scholar] [CrossRef]

- Li, X.; Zhong, H.; Li, X.; Jia, F.; Cheng, Z.; Zhang, L.; Yin, J.; An, L.; Guo, L. Synthesis of attapulgite/N-isopropylacrylamide and its use in drug release. Mater. Sci. Eng. C 2014, 45, 170–175. [Google Scholar] [CrossRef]

- Dos Santos Soares, D.; Fernandes, C.S.; Da Costa, A.C.S.; Raffin, F.N.; Acchar, W.; de Lima e Moura, T.F.A. Characterization of palygorskite clay from Piauí, Brazil and its potential use as excipient for solid dosage forms containing anti-tuberculosis drugs. J. Therm. Anal. Calorim. 2013, 113, 551–558. [Google Scholar] [CrossRef]

- Jin, X.; Hu, X.; Wang, Q.; Wang, K.; Yao, Q.; Tang, G.; Chu, P.K. Multifunctional cationic polymer decorated and drug intercalated layered silicate (NLS) for early gastric cancer prevention. Biomaterials 2014, 35, 3298–3308. [Google Scholar] [CrossRef] [PubMed]

- Yamamoto, K.; Hagino, M.; Kotaki, H.; Iga, T. Quantitative determination of domperidone in rat plasma by high-performance liquid chromatography with fluorescence detection. J. Chromatogr. B Biomed. Sci. Appl. 1998, 720, 251–255. [Google Scholar] [CrossRef] [PubMed]

- Papich, M.G. Domperidone. In Papich Handbook of Veterinary Drugs, 5th ed.; Saunders: Philadelphia, PA, USA, 2021; pp. 299–301. [Google Scholar] [CrossRef]

- Daihom, B.A.; Bendas, E.R.; Mohamed, M.I.; Badawi, A.A. Development and in vitro evaluation of domperidone/Dowex resinate embedded gastro-floatable emulgel and effervescent alginate beads. J. Drug Deliv. Sci. Technol. 2020, 59, 101941. [Google Scholar] [CrossRef]

- Zafar, A.; Afzal, M.; Quazi, A.M.; Yasir, M.; Kazmi, I.; Al-Abaasi, F.A.; Alruwaili, N.K.; Alharbi, K.S.; Alzarea, S.I.; Sharma, S.; et al. Chitosan-ethyl cellulose microspheres of domperidone for nasal delivery: Preparation, in-vitro characterization, in-vivo study for pharmacokinetic evaluation and bioavailability enhancement. J. Drug Deliv. Sci. Technol. 2021, 63, 102471. [Google Scholar] [CrossRef]

- Zayed, G.M.; Rasoul, S.A.-E.; Ibrahim, M.A.; Saddik, M.S.; Alshora, D.H. In vitro and in vivo characterization of domperidone-loaded fast dissolving buccal films. Saudi Pharm. J. 2020, 28, 266–273. [Google Scholar] [CrossRef]

- Daihom, B.A.; Bendas, E.R.; Mohamed, M.I.; Badawi, A.A. Domperidone resinate complex as new formulation for gastroretentive drug delivery. J. Drug Deliv. Sci. Technol. 2020, 58, 101868. [Google Scholar] [CrossRef]

- Varshosaz, J.; Enteshari, S. Solubility Enhancement of Domperidone by Solvent Change In Situ Micronization Technique. Adv. Biomed. Res. 2018, 7, 109. [Google Scholar] [CrossRef]

- Kulinowski, P.; Woyna-Orlewicz, K.; Obrał, J.; Rappen, G.-M.; Haznar-Garbacz, D.; Węglarz, W.P.; Jachowicz, R.; Wyszogrodzka, G.; Klaja, J.; Dorożyński, P.P. Multimodal approach to characterization of hydrophilic matrices manufactured by wet and dry granulation or direct compression methods. Int. J. Pharm. 2016, 499, 263–270. [Google Scholar] [CrossRef] [PubMed]

- Jivraj, M.; Martini, L.G.; Thomson, C.M. An overview of the different excipients useful for the direct compression of tablets. Pharm. Sci. Technol. Today 2000, 3, 58–63. [Google Scholar] [CrossRef] [PubMed]

- Tang, J.; Mu, B.; Zong, L.; Zheng, M.; Wang, A. Facile and green fabrication of magnetically recyclable carboxyl-functionalized attapulgite/carbon nanocomposites derived from spent bleaching earth for wastewater treatment. Chem. Eng. J. 2017, 322, 102–114. [Google Scholar] [CrossRef]

- Xu, J.; Wang, W.; Mu, B.; Wang, A. Effects of inorganic sulfates on the microstructure and properties of ion-exchange treated palygorskite clay. Colloids Surf. A Physicochem. Eng. Asp. 2012, 405, 59–64. [Google Scholar] [CrossRef]

- Frost, R.L.; Locos, O.B.; Ruan, H.; Kloprogge, J. Near-infrared and mid-infrared spectroscopic study of sepiolites and palygorskites. Vib. Spectrosc. 2001, 27, 1–13. [Google Scholar] [CrossRef]

- Yan, W.; Liu, D.; Tan, D.; Yuan, P.; Chen, M. FTIR spectroscopy study of the structure changes of palygorskite under heating. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2012, 97, 1052–1057. [Google Scholar] [CrossRef] [PubMed]

- Al-Saif, F.A.; El-Habeeb, A.A.; Refat, M.S.; Eldaroti, H.H.; Adam, A.M.A.; Fetooh, H.; Saad, H.A. Chemical and physical properties of the charge transfer complexes of domperidone antiemetic agent with π-acceptors. J. Mol. Liq. 2019, 293, 111517. [Google Scholar] [CrossRef]

- Sun, S.; Zeng, X.; Gao, Y.; Zhang, W.; Zhou, L.; Zeng, X.; Liu, W.; Jiang, Q.; Jiang, C.; Wang, S. Iron oxide loaded biochar/attapulgite composites derived camellia oleifera shells as a novel bio-adsorbent for highly efficient removal of Cr(VI). J. Clean. Prod. 2021, 317, 128412. [Google Scholar] [CrossRef]

- Kenawy, E.-R.; Seggiani, M.; Cinelli, P.; Elnaby, H.M.H.; Azaam, M.M. Swelling capacity of sugarcane bagasse-g-poly(acrylamide)/attapulgite superabsorbent composites and their application as slow release fertilizer. Eur. Polym. J. 2020, 133, 109769. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, W.; Zhang, J.; Liu, P.; Wang, A. A comparative study about adsorption of natural palygorskite for methylene blue. Chem. Eng. J. 2014, 262, 390–398. [Google Scholar] [CrossRef]

- Fan, Q.; Shao, D.; Lu, Y.; Wu, W.; Wang, X. Effect of pH, ionic strength, temperature and humic substances on the sorption of Ni(II) to Na–attapulgite. Chem. Eng. J. 2009, 150, 188–195. [Google Scholar] [CrossRef]

- Zhang, N.; Guo, H.; Xiong, L.; Zhang, H.; Chen, X. Preparation and characterization of paraffin/palygorskite shape-stable composite phase change materials for thermal energy storage. J. Energy Storage 2020, 34, 102189. [Google Scholar] [CrossRef]

- Meneguin, A.; Pacheco, G.; Silva, J.M.; de Araujo, F.P.; Silva-Filho, E.C.; Bertolino, L.C.; Barud, H.D.S. Nanocellulose/palygorskite biocomposite membranes for controlled release of metronidazole. Int. J. Biol. Macromol. 2021, 188, 689–695. [Google Scholar] [CrossRef] [PubMed]

- Luo, Z.; Liu, C.; Quan, P.; Yang, D.; Zhao, H.; Wan, X.; Fang, L. Mechanistic insights of the controlled release capacity of polar functional group in transdermal drug delivery system: The relationship of hydrogen bonding strength and controlled release capacity. Acta Pharm. Sin. B 2019, 10, 928–945. [Google Scholar] [CrossRef] [PubMed]

- Alkrad, J.A.; Abu Shmeis, R.; Alshwabkeh, I.; Abazid, H.; Mohammad, M.A. Investigation of the potential application of sodium bentonite as an excipient in formulation of sustained release tablets. Asian J. Pharm. Sci. 2017, 12, 259–265. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.; Qian, L.; Chen, Y.; Ouyang, D.; Han, L.; Shang, X.; Li, J.; Gu, M.; Chen, M. Nanoscale zero-valent iron supported by attapulgite produced at different acid modification: Synthesis mechanism and the role of silicon on Cr(VI) removal. Chemosphere 2021, 267, 129183. [Google Scholar] [CrossRef]

- Kiortsis, S.; Kachrimanis, K.; Broussali, T.; Malamataris, S. Drug release from tableted wet granulations comprising cellulosic (HPMC or HPC) and hydrophobic component. Eur. J. Pharm. Biopharm. 2005, 59, 73–83. [Google Scholar] [CrossRef] [PubMed]

- Goldsmith, J.A.; Randall, N.; Ross, S.D. On methods of expressing dissolution rate data. J. Pharm. Pharmacol. 1978, 30, 347–349. [Google Scholar] [CrossRef] [PubMed]

- Papadopoulou, V.; Kosmidis, K.; Vlachou, M.; Macheras, P. On the use of the Weibull function for the discernment of drug release mechanisms. Int. J. Pharm. 2006, 309, 44–50. [Google Scholar] [CrossRef] [PubMed]

- Shi, N.; Sun, K.; Zhang, Z.; Zhao, J.; Geng, L.; Lei, Y. Amino-modified carbon dots as a functional platform for drug delivery: Load-release mechanism and cytotoxicity. J. Ind. Eng. Chem. 2021, 101, 372–378. [Google Scholar] [CrossRef]

- Mdlovu, N.V.; Lin, K.-S.; Weng, M.-T.; Lin, Y.-S. Design of doxorubicin encapsulated pH-/thermo-responsive and cationic shell-crosslinked magnetic drug delivery system. Colloids Surf. B Biointerfaces 2021, 209, 112168. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Hui, A.; Zhao, H.; Ye, X.; Zhang, C.; Wang, A.; Zhang, C. A Novel 3D-bioprinted Porous Nano Attapulgite Scaffolds with Good Performance for Bone Regeneration. Int. J. Nanomed. 2020, 15, 6945–6960. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Qin, W.; Wang, Y.; Ma, J.; Liu, J.; Wu, S.; Zhao, H. 3D Printed Gelatin/Sodium Alginate Hydrogel Scaffolds Doped with Nano-Attapulgite for Bone Tissue Repair. Int. J. Nanomed. 2021, 16, 8417–8432. [Google Scholar] [CrossRef] [PubMed]

- Zhu, T.; Yu, K.; Bhutto, M.A.; Wang, J.; Shen, W.; Song, W.; Zhou, X.; Ei-Hamshary, H.; Al-Deyab, S.S.; Mo, X. A facile approach for the fabrication of nano-attapulgite/poly(vinyl pyrrolidone)/biopolymers core–sheath ultrafine fibrous mats for drug controlled release. RSC Adv. 2016, 6, 49817–49823. [Google Scholar] [CrossRef]

- Ha, W.; Wang, Z.; Zhao, X.; Shi, Y. Reinforced Supramolecular Hydrogels from Attapulgite and Cyclodextrin Pseudopolyrotaxane for Sustained Intra-Articular Drug Delivery. Macromol. Biosci. 2020, 21, e2000299. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Zhao, Y.; Luo, Y.; Wang, S.; Shen, M.; Tomás, H.; Zhu, M.; Shi, X. Attapulgite-doped electrospun poly(lactic-co-glycolic acid) nanofibers enable enhanced osteogenic differentiation of human mesenchymal stem cells. RSC Adv. 2014, 5, 2383–2391. [Google Scholar] [CrossRef]

- United States Pharmacopeia Convention. United States Pharmacopeia and National Formulary (USP 34-NF29); United States Pharmacopeia Convention: Rockville, MD, USA, 2010. [Google Scholar]

- Siepmann, J.; Peppas, N.A. Modeling of drug release from delivery systems based on hydroxypropyl methylcellulose (HPMC). Adv. Drug Deliv. Rev. 2012, 64, 163–174. [Google Scholar] [CrossRef]

- Costa, P.; Lobo, J.M.S. Modeling and comparison of dissolution profiles. Eur. J. Pharm. Sci. 2001, 13, 123–133. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, Y.; Zheng, H.; Du, M.; Zhang, Z. Investigation on the Potential Application of Na-Attapulgite as an Excipient in Domperidone Sustained-Release Tablets. Molecules 2022, 27, 8266. https://doi.org/10.3390/molecules27238266

Xiao Y, Zheng H, Du M, Zhang Z. Investigation on the Potential Application of Na-Attapulgite as an Excipient in Domperidone Sustained-Release Tablets. Molecules. 2022; 27(23):8266. https://doi.org/10.3390/molecules27238266

Chicago/Turabian StyleXiao, Yuxuan, Haiyu Zheng, Meng Du, and Zhe Zhang. 2022. "Investigation on the Potential Application of Na-Attapulgite as an Excipient in Domperidone Sustained-Release Tablets" Molecules 27, no. 23: 8266. https://doi.org/10.3390/molecules27238266

APA StyleXiao, Y., Zheng, H., Du, M., & Zhang, Z. (2022). Investigation on the Potential Application of Na-Attapulgite as an Excipient in Domperidone Sustained-Release Tablets. Molecules, 27(23), 8266. https://doi.org/10.3390/molecules27238266