Pesticides Identification and Sustainable Viticulture Practices to Reduce Their Use: An Overview

Abstract

1. Introduction

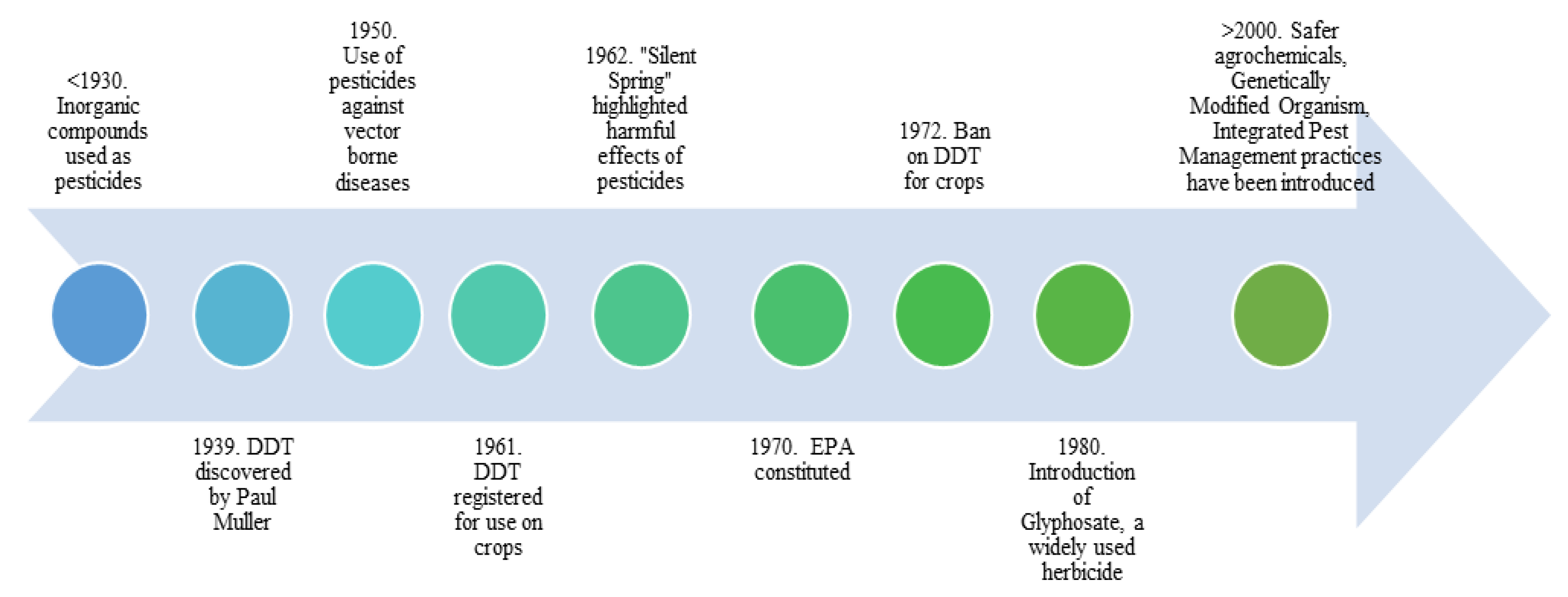

2. Pesticide Trends around the World

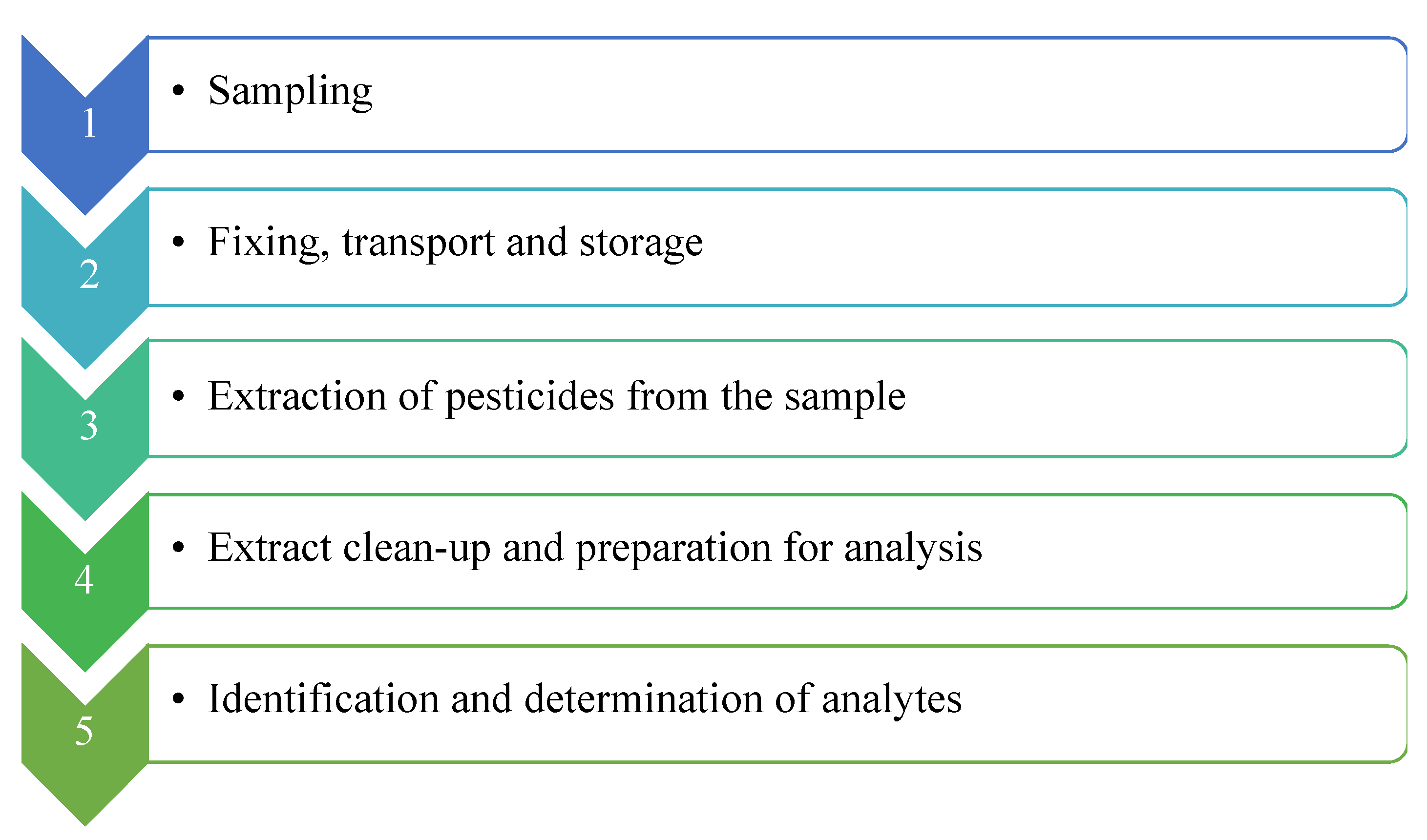

3. Pesticides Extraction and Detection

3.1. Pesticide Extraction

3.2. Pesticide Detection

4. Vineyard and Wine and Specific Research on Pesticides

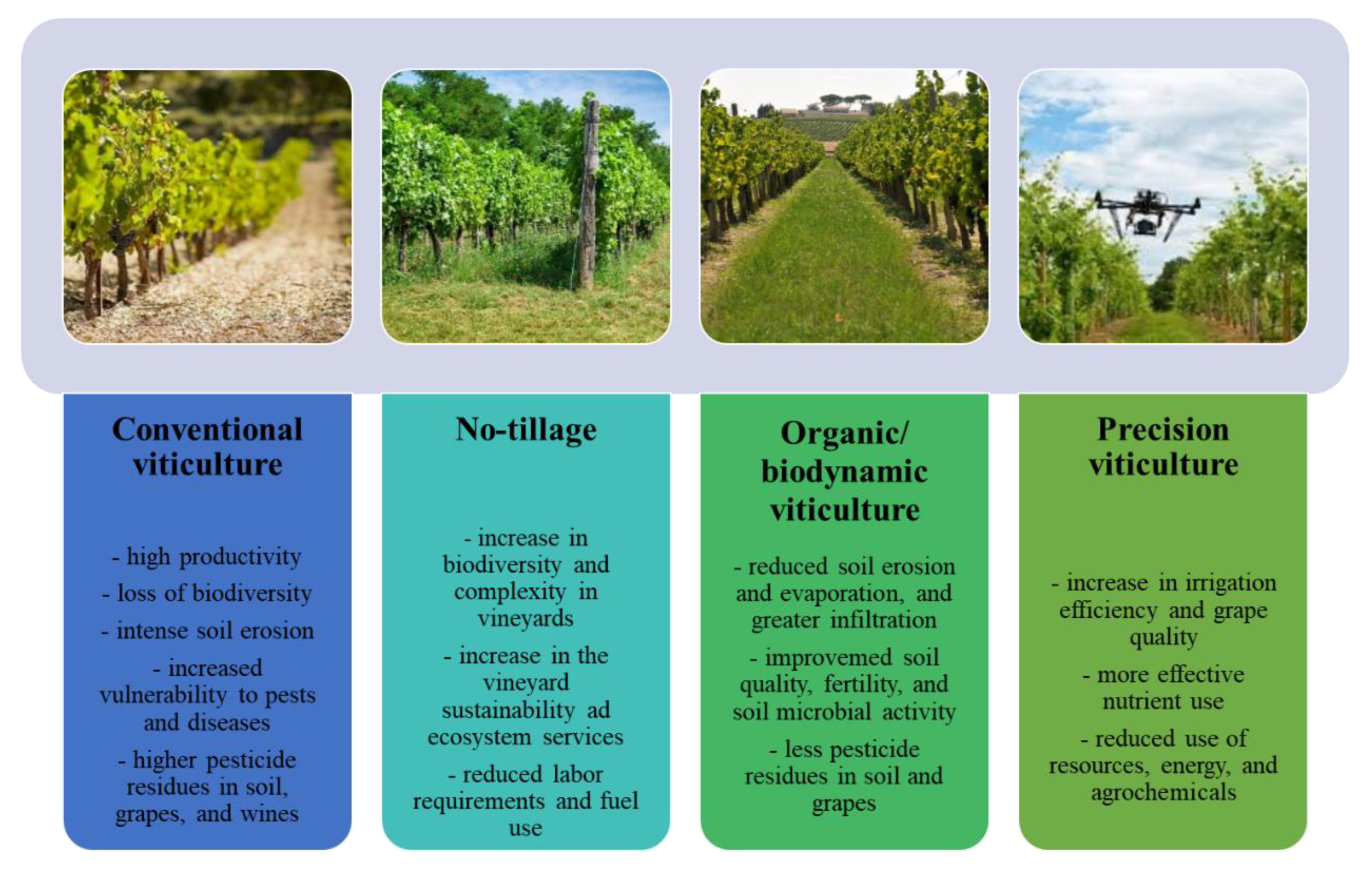

5. Sustainable Viticulture Practices to Reduce Pesticides Use

- No-tillage

- Organic vineyards

- Biodynamic vineyards

- Biopesticides and nanobiopesticide

- Precision Viticulture

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Commission. Pesticides. 2021. Available online: https://ec.europa.eu/food/plant/pesticides_en (accessed on 22 September 2022).

- International Union of Pure and Applied Chemistry. History of Pesticide Use. 2010. Available online: http://agrochemicals.iupac.org/index.php?option=com_sobi2&sobi2Task=sobi2Details&catid=3&sobi2Id=31 (accessed on 22 September 2022).

- Stockholm Convention. All POPs listed in the Stockholm Convention. 2019. Available online: http://www.pops.int/TheConvention/ThePOPs/AllPOPs/tabid/2509/Default.aspx (accessed on 22 September 2022).

- Environmental Protection Agency. DDT-A Brief History and Status. 2017. Available online: https://www.epa.gov/ingredients-used-pesticide-products/ddt-brief-history-and-status (accessed on 22 September 2022).

- Holt, J.S. Herbicides, Encyclopedia of Biodiversity, 2nd ed.; Academic Press: Waltham, MA, USA, 2013; pp. 87–95. [Google Scholar]

- National Pesticide Information Center. Insecticides. 2019. Available online: http://npic.orst.edu/ingred/ptype/insecticide.html (accessed on 3 October 2022).

- Canadian Centre for Occupational Health and Safety. Pesticides–General. 2019. Available online: https://www.ccohs.ca/oshanswers/chemicals/pesticides/general.html (accessed on 3 October 2022).

- United Nations. Department of Economic and Social Affairs. 2019. Available online: https://www.un.org/en/desa/world-population-projected-reach-98-billion-2050-and-112-billion-2100 (accessed on 3 October 2022).

- FAO. FAOSTAT Pesticides Trade Dataset. Annual. 2020. Available online: http://www.fao.org/faostat/en/#data/RT (accessed on 3 October 2022).

- FAO. FAOSTAT Agri-Environmental Indicators/Pesticides [www Document]. Annual. 2020. Available online: http://www.fao.org/faostat/en/#data/EP. (accessed on 3 October 2022).

- Fenik, J.; Tankiewicz, M.; Biziuk, M. Properties and determination of pesticides in fruits and vegetables. Trends Anal. Chem. 2011, 30, 814–826. [Google Scholar] [CrossRef]

- Thakur, M.; Deepak, P. Environmental fate of organic pollutants and effect on human health. Abat. Environ. Pollut.-Trends Strateg. 2020, 12, 245–262. [Google Scholar] [CrossRef]

- World Bank. Agriculture for Development-World Development Report; The World Bank: Whashington, DC, USA, 2008. [Google Scholar]

- Muhammad, G.; Rashid, I.; Firyal, S. Practical aspects of treatment of organophosphate and carbamate insecticide poisoning in animals. Matrix Sci. Pharma. 2017, 1, 10–11. [Google Scholar] [CrossRef]

- Sidhu, G.K.; Singh, S.; Kumar, V.; Dhanjal, D.S.; Datta, S.; Singh, J. Toxicity, monitoring and biodegradation of organophosphate pesticides: A review. Crit. Rev. Environ. Sci. Technol. 2019, 49, 1135–1187. [Google Scholar] [CrossRef]

- Urkude, R.; Dhurvey, V.; Kochhar, S. Pesticide Residues in Beverages. In Quality Control in the Beverage Industry: The Science of Beverages; Academic Press: Cambridge, MA, USA, 2019; Volume 17, pp. 529–560. [Google Scholar]

- FAO. Pesticide Database Codex., Codex Alimentarius. 2022. Available online: https://www.fao.org/fao-who-codexalimentarius/codex-texts/dbs/pestres/pesticides/en/ (accessed on 19 July 2022).

- Samsidar, A.; Siddiquee, S.; Shaarani, S.M. A review of extraction, analytical and advanced methods for determination of pesticides in environment and foodstuffs. Trends Food Sci. Technol. 2018, 71, 188–201. [Google Scholar] [CrossRef]

- Nasiri, M.; Ahmadzadeh, H.; Amiri, A. Sample preparation and extraction methods for pesticides in aquatic environments: A review. TrAC Trends Anal. Chem. 2020, 123, 115772. [Google Scholar] [CrossRef]

- Timofeeva, I.; Shishov, A.; Kanashina, D.; Dzema, D.; Bulatov, A. On-line insyringe sugaring-out liquid-liquid extraction coupled with HPLC-MS/MS for the determination of pesticides in fruit and berry juices. Talanta 2017, 167, 761–767. [Google Scholar] [CrossRef] [PubMed]

- Farajzadeh, M.A.; Khoshmaram, L.; Nabil, A.A.A. Determination of pyrethroid pesticides residues in vegetable oils using liquid-liquid extraction and dispersive liquid-liquid microextraction followed by gas chromatography-flame ionization detection. J. Food Compos. Anal. 2014, 34, 128–135. [Google Scholar] [CrossRef]

- Radišić, M.M.; Vasiljević, T.M.; Dujaković, N.N.; Laušević, M.D. Application of matrix solid-phase dispersion and liquid chromatography–ion trap mass spectrometry for the analysis of pesticide residues in fruits. Food Anal. Methods 2013, 6, 648–657. [Google Scholar] [CrossRef]

- Anastassiades, M.; Lehotay, S.J.; Stajnbaher, D.; Schenck, F.J. Fast and easy multiresidue method employing acetonitrile extraction/partitioning and “dispersive solid-phase extraction” for the determination of pesticide residues in produce. J. AOAC Int. 2003, 86, 412–431. [Google Scholar] [CrossRef]

- Lehotay, S.J.; de Kok, A.; Hiemstra, M.; Van Bodegraven, P. Validation of a fast and easy method for the determination of residues from 229 pesticides in fruits and vegetables using gas and liquid chromatography and mass spectrometric detection. J. AOAC Int. 2005, 88, 595–614. [Google Scholar] [CrossRef] [PubMed]

- Perestrelo, R.; Silva, P.; Porto-Figueira, P.; Pereira, J.A.M.; Silva, C.; Medina, S.; Câmara, J.S. QuEChERS-fundamentals, relevant improvements, applications and future trends. Anal. Chim. Acta 1070, 2019, 1–28. [Google Scholar] [CrossRef] [PubMed]

- Dumitriu Gabur, G.-D.; Gabur, I.; Cucolea, E.I.; Costache, T.; Rambu, D.; Cotea, V.V.; Teodosiu, C. Investigating Six Common Pesticides Residues and Dietary Risk Assessment of Romanian Wine Varieties. Foods 2022, 11, 2225. [Google Scholar] [CrossRef] [PubMed]

- Wilkowska, A.; Biziuk, M. Determination of pesticide residues in food matrices using the QuEChERS methodology. Food Chem. 2011, 125, 803–812. [Google Scholar] [CrossRef]

- D’Orazio, G.; Fanali, C.; Asensio-Ramos, M.; Fanali, S. Chiral separations in food analysis. TrAC Trends Anal. Chem. 2017, 96, 151–171. [Google Scholar] [CrossRef]

- Bletsou, A.A.; Jeon, J.; Hollender, J.; Archontaki, E.; Thomaidis, N. Targeted and non-targeted liquid chromatography-mass spectrometric workflows for identification of transformation products of emerging pollutants in the aquatic environment. Trends Anal. Chem. 2015, 66, 32–44. [Google Scholar] [CrossRef]

- Chen, L.X.; Dean, B.; Liang, X.R. Evaluation of polysaccharide-based chiral stationary phases in modern SFC-MS/MS for enantioselective bioanalysis. Bioanalysis 2019, 11, 251–266. [Google Scholar] [CrossRef]

- Koukouvinos, G.; Tsialla, Z.; Petrou, P.S.; Misiakos, K.; Goustouridis, D.; Moreno, A.U.; Fernandez-Alba, A.R.; Raptis, I.; Kakabakos, S.E. Fast simultaneous detection of three pesticides by a White Light Reflectance Spectroscopy sensing platform. Sens. Actuators B-Chem. 2017, 238, 1214–1223. [Google Scholar] [CrossRef]

- Weng, S.; Zhu, W.; Zhang, X.; Yuan, H.; Zheng, L.; Zhao, J.; Huang, L.; Han, P. Recent advances in Raman technology with applications in agriculture, food and biosystems: A review. Artif. Intell. Agric. 2019, 3, 1–10. [Google Scholar] [CrossRef]

- Kailani, M.H.; Al-Antary, T.M.; Alawi, M.A. Monitoring of pesticides residues in soil samples from the southern districts of Jordan in 2016/2017. Toxin Rev. 2019, 40, 198–214. [Google Scholar] [CrossRef]

- Nieto-Garcia, A.; Romero-Gonzalez, R.; Frenich, A.G. Multi-pesticide residue analysis in nutraceuticals from grape seed extracts by gas chromatography coupled to triple quadrupole mass spectrometry. Food Control 2014, 47, 369–380. [Google Scholar] [CrossRef]

- He, Z.; Xu, Y.; Wang, L.; Peng, Y.; Luo, M.; Cheng, H.; Liu, X. Wide-scope screening and quantification of 50 pesticides in wine by liquid chromatography/quadrupole time-of-flight mass spectrometry combined with liquid chromatography/quadrupole linear ion trap mass spectrometry. Food Chem. 2016, 196, 1248–1255. [Google Scholar] [CrossRef]

- Vaquero-Fernandez, L.; Sanz-Asensio, J.; Fernandez-Zurbano, P.; Lopez-Alonso, M.; Martinez-Soria, M. Determination of fungicide pyrimethanil in grapes, must, fermenting must and wine. J. Sci. Food Agric. 2012, 93, 1960–1966. [Google Scholar] [CrossRef] [PubMed]

- Perez-Ortega, P.; Gilbert-Lopez, B.; Garcia-Reyes, J.F.; Ramos-Martos, N.; Molina-Diaz, A. Generic sample treatment method for simultaneous determination of multiclass pesticides and mycotoxins in wines by liquid chromatography–mass spectrometry. J. Chromatogr. A 2012, 1249, 32–40. [Google Scholar] [CrossRef]

- Navarro, S.; Barba, A.; Navarro, G.; Vela, N.; Olivia, J. Multiresidue method for the rapid determination–in grape, must and wine–of fungicides frequently used on vineyards. J. Chromatogr. A 2000, 882, 221–229. [Google Scholar] [CrossRef] [PubMed]

- Pelajic, M.; Pecek, G.; Pavlovic, D.M.; Cepo, D.V. Novel multiresidue method for determination of pesticides in red wine using gas chromatography–mass spectrometry and solid phase extraction. Food Chem. 2016, 200, 98–106. [Google Scholar] [CrossRef]

- Gonzalez-Rodriguez, R.M.; Rial-Otero, R.; Cancho-Grande, B.; Gonzalez-Barreiro, C.; Simal-Gandara, J. A review on the fate of pesticides during the processes within the food-production Chain. Crit. Rev. Food Sci. Nutr. 2011, 51, 99–114. [Google Scholar] [CrossRef]

- Yang, M.; Luo, F.; Zhang, X.; Zhoa, X.; Lou, Z.; Zhao, M.; Chen, Z. Dissipation and Risk Assessment of Multiresidual Fungicides in Grapes under Field Conditions. J. Agric. Food Chem. 2020, 68, 1071–1078. [Google Scholar] [CrossRef]

- González-Rodríguez, R.M.; Cancho-Grande, B.; Torrado-Agrasar, A.; Simal-Gándara, J.; Mazaira-Pérez, J. Evolution of tebuconazole residues through the winemaking process of Mencía grapes. Food Chem. 2009, 117, 529–537. [Google Scholar] [CrossRef]

- Heshmati, A.; Nili-Ahmadabadi, A.; Rahimi, A.; Vahidinia, A.; Taheri, M. Dissipation behavior and risk assessment of fungicide and insecticide residues in grape under open-field, storage and washing conditions. J. Clean. Prod. 2020, 270, 122287. [Google Scholar] [CrossRef]

- Pan, X.; Dong, F.; Lie, N.; Cheng, Y.; Xu, J.; Liu, X.; Wu, X.; Chen, Z.; Zheng, Y. The fate and enantioselective behavior of zoxamide during wine-making process. Food Chem. 2018, 248, 14–20. [Google Scholar] [CrossRef]

- Paya, P.; Mulero, J.; Oliva, J.; Camara, M.A.; Barba, A. Influence of the matrix in bioavailability of flufenoxuron, lufenuron, pyriproxyfen and fenoxycarb residues in grapes and wine. Food Chem. Toxicol. 2013, 60, 419–423. [Google Scholar] [CrossRef] [PubMed]

- Cus, F.; Cesnik, H.B.; Bolta, S.V.; Gregoric, A. Pesticide residues in grapes and during vinification process. Food Control 2010, 21, 1512–1518. [Google Scholar] [CrossRef]

- Golge, O.; Kabak, B. Pesticide Residues in Table Grapes and Exposure Assessment. J. Agric. Food Chem. 2018, 66, 1701–1713. [Google Scholar] [CrossRef]

- Castro, G.; Perez-Mayan, L.; Carpinteiro, I.; Ramil, M.; Cela, R.; Rodriguez, I. Residues of anilinopyrimidine fungicides and suspected metabolites in wine samples. J. Chromatogr. A 2020, 1622, 461104. [Google Scholar] [CrossRef] [PubMed]

- Pose-Juan, E.; Cancho-Grande, B.; Rial-Otero, R.; Simal-Gándara, J. The dissipation rates of cyprodinil, fludioxonil, procymidone and vinclozoline during storage of grape juice. Food Control 2006, 17, 1012–1017. [Google Scholar] [CrossRef]

- Hall, R.M.; Penke, N.; Kriechbaum, M.; Kratschmer, S.; Jung, V.; Chollet, S.; Guernion, M.; Nicolai, A.; Burel, F.; Fertil, A.; et al. Vegetation man- agement intensity and landscape diversity alter plant species richness, functional traits and community composition across European vineyards. Agric. Syst. 2020, 177, 102706. [Google Scholar] [CrossRef]

- Kazakou, E.; Fried, G.; Richarte, J.; Gimenez, O.; Violle, C.; Metay, A. A plant trait-based response-and-effect framework to assess vineyard inter-row soil management. Bot. Lett. 2016, 163, 373–388. [Google Scholar] [CrossRef]

- Sánchez-Moreno, S.; Castro, J.; Alonso-Prados, E.; Alonso-Prados, J.L.; García-Baudín, J.M.; Talavera, M.; Durán-Zuazo, V.H. Tillage and herbicide decrease soil biodiversity in olive orchards. Agron. Sustain. Dev. 2015, 35, 691–700. [Google Scholar] [CrossRef]

- Capowiez, Y.; Cadoux, S.; Bouchant, P.; Ruy, S.; Roger-Estrade, J.; Richard, G.; Boizard, H. The effect of tillage type and cropping system on earthworm communities, macroporosity and water infiltration. Soil Till. Res. 2009, 105, 209–216. [Google Scholar] [CrossRef]

- Bruggisser, O.T.; Schmidt-Entling, M.H.; Bacher, S. Effects of vineyard management on biodiversity at three trophic levels. Biol. Conserv. 2010, 143, 1521–1528. [Google Scholar] [CrossRef]

- Mannini, F. Hot water treatment and field coverage of mother plant vineyards to prevent propagation material from phytoplasma infections. Bull. Insect. 2007, 60, 311–312. [Google Scholar]

- Valizadeh, H.; Abbasipour, H.; Farazmand, H.; Askarianzadeh, A. Evaluation of kaolin application on oviposition control of the Vine Cicada, Psalmocharias alhageos in Vineyards (Homoptera: Cicadidae). Entomol. Ger. 2013, 34, 279–286. [Google Scholar] [CrossRef]

- Dumitriu (Gabur), G.-D.; Teodosiu, C.; Cotea, V.V. Management of Pesticides from Vineyard to Wines: Focus on Wine Safety and Pesticides Removal by Emerging Technologies. In Grapes and Wine; Morata, A., Loira, I., González, C., Eds.; IntechOpen: London, UK, 2021. [Google Scholar]

- OIV. Focus OIV the World Organic Vineyard. 2021. Available online: https://www.oiv.int/public/medias/8514/en-focus-the-world-organic-vineyard.pdf (accessed on 3 October 2022).

- Steiner, R. Spiritual Foundations for the Renewal of Agriculture: A course of lectures held at Koberwitz, Silesia, June 7 to 16, 1924; Creeger, C.; Gardner, M., Translators; Bio-Dynamic Farming and Gardening Association Inc.: Kimberton, PA, USA, 1993. [Google Scholar]

- Lotter, D.W. Organic agriculture. J. Sustain. Agric. 2003, 21, 59–128. [Google Scholar] [CrossRef]

- Villanueva-Rey, P.; Vázquez-Rowe, I.; Moreira, M.T.; Feijoo, G. Comparative life cycle assessment in the wine sector: Biodynamic vs. conventional viticulture activities in NW Spain. J. Clean. Prod. 2014, 65, 330–341. [Google Scholar] [CrossRef]

- Chandler, D.; Bailey, A.S.; Tatchell, G.M.; Davidson, G.; Greaves, J.; Grant, W.P. The development, regulation and use of biopesticides for integrated pest management. Philos. Trans. R. Soc. B-Biol. Sci. 2012, 366, 1987–1998. [Google Scholar] [CrossRef]

- Chaudhary, S. Progress on Azadirachta indica Based Biopesticides in Replacing Synthetic Toxic Pesticides. Front. Plant Sci. 2017, 8, 610. [Google Scholar] [CrossRef]

- Tamhane, V.A.; Chougule, N.P.; Giri, A.P.; Dixit, A.R.; Sainani, M.N.; Gupta, V.S. In vivo and in vitro effects of Capsicum annum proteinase inhibitors on Helicoverpa armigera gut proteinases. Biochim. Biophys. Acta. 2005, 1722, 156–167. [Google Scholar] [CrossRef]

- Telang, M.A.; Giri, A.P.; Sainani, M.N.; Gupta, V.S. Characterization of two midgut proteinases of Helicoverpa armigera and their interaction with proteinase inhibitors. J. Insect Physiol. 2005, 51, 513–522. [Google Scholar] [CrossRef]

- Kanzok, S.M.; Jacobs-Lorena, M. Entomopathogenic fungi as biological insecticides to control malaria. Trends Parasitol. 2006, 22, 49–51. [Google Scholar] [CrossRef]

- Gayathri Devi, K.; Sowmiya, N.; Yasoda, K.; Muthulakshmi, K.; Kishore, B. Review on application of drones for crop health monitoring and spraying pesticides and fertilizer. J. Crit. Rev. 2020, 7, 667–672. [Google Scholar] [CrossRef]

- Geetharamani, G.; Arun, P.J. Identification of plant leaf diseases using a nine-layer deep convolutional neural network. Comput. Electr. Eng. 2019, 76, 323–338. [Google Scholar] [CrossRef]

- Koc, C. Design and Development of a Low-cost UAV for Pesticide Applications. J. Agric Fac. Gaziosmanpasa Univ. 2017, 34, 94–103. [Google Scholar] [CrossRef]

- Pallottino, F.; Biocca, M.; Nardi, P.; Figorilli, S.; Menesatti, P.; Costa, C. Science mapping approach to analyze the research evolution on precision agriculture: World, EU and Italian situation. Precis. Agric. 2018, 19, 1011–1026. [Google Scholar] [CrossRef]

| Pesticide | MRL mg/kg | Year of Adoption | EU Pesticides Data | Regulation European Union, European Food Safety Authority Joint Meeting on Pesticide Residues | ||

|---|---|---|---|---|---|---|

| ADI (mg/kg bw/day) | ARfT (mg/kg bw) | AOEL (mg/kg bw/day) | ||||

| Acetamiprid | 0.5 | 2012 | 0.025 | 0.025 | 0.025 | Reg. (EU) 2018/113 |

| Aldicarb | 0.2 | 1997 | Not approved Reg. (EC) No. 1107/2009 | |||

| Ametoctradin | 6 | 2013 | 10.0 | 2.0 | EFSA 2012 | |

| Amitrole | 0.05 | 2004 | 0.001 | 0.015 | 0.001 | EFSA 2015 |

| Azocyclotin | 0.3 | 2006 | 0.003 | 0.02 | JMPR 2005 | |

| Azoxystrobin | 2 | 2009 | 0.2 | 0.2 | EFSA 2010 | |

| Benalaxyl | 0.3 | 2010 | 0.04 | 0.5 | 0.05 | Reg. (EU) 2020/1280 |

| Benzovindiflupyr | 1 | 2017 | 0.05 | 0.1 | 0.04 | Reg. (EU) 2016/177 |

| Bifenazate | 0.7 | 2007 | 0.01 | 0.0028 | 05/58/EC | |

| Bifenthrin | 0.3 | 2016 | 0.015 | 0.03 | 0.0075 | Reg. (EU) 2018/291 |

| Boscalid | 5 | 2010 | 0.04 | 0.1 | 08/44/EC | |

| Bromopropylate | 2 | 1997 | Not approved Reg. (EC) No. 1107/2009 | |||

| Buprofezin | 1 | 2010 | 0.01 | 0.5 | 0.04 | Reg. (EU) 2017/360 |

| Captan | 25 | 2008 | 0.1 | 0.3 | 0.1 | Dir 07/5, SCoFCAH July 08 |

| Carbendazim | 3 | 2008 | 0.02 | 0.02 | 0.02 | Dir 06/135 |

| Chlormequat | 0.04 | 2018 | 0.04 | 0.09 | 0.04 | EFSA 08 |

| Chlorothalonil | 3 | 2011 | 0.015 | 0.05 | 0.003 | Reg. (EU) 2019/677 |

| Chlorpyrifos | 0.5 | 2003 | - | - | - | |

| Chlorpyrifos-Methyl | 1 | 2010 | - | - | - | |

| Clofentezine | 2 | 2008 | 0.02 | 0.01 | Dir 08/69 | |

| Clothianidin | 0.7 | 2012 | 0.097 | 0.1 | 0.1 | 06/41/EC |

| Cyazofamid | 1.5 | 2016 | 0.17 | 0.3 | 03/23/EC | |

| Cycloxydim | 0.3 | 2013 | 0.07 | 2.0 | 0.1 | EFSA 10 |

| Cyflumetofen | 0.6 | 2015 | 0.17 | 0.11 | Reg. (EU) No. 2019/716 | |

| Cyhexatin | 0.3 | 2006 | 0.003 | 0.02 | JMPR 2005 | |

| Cypermethrins (including alpha- and zeta-) | 0.2 | 2009 | 0.05 | 0.2 | 0.06 | Dir 05/53 |

| Cyprodinil | 3 | 2005 | 0.03 | 0.03 | Dir 06/64 | |

| Deltamethrin | 0.2 | 2004 | 0.01 | 0.01 | 0.0075 | Dir 03/5 |

| Dichlobenil | 0.05 | 2015 | Not approved Reg. (EC) No. 1107/2009 | |||

| Dichloran | 7 | 2004 | 0.005 | 0.025 | 0.005 | EFSA 10 |

| Difenoconazole | 3 | 2014 | 0.01 | 0.16 | 0.16 | Dir 08/69 |

| Dimethomorph | 3 | 2015 | 0.05 | 0.6 | 0.15 | Dir 07/25 |

| Dinotefuran | 0.9 | 2013 | - | - | - | |

| Dithiocarbamates | 5 | 2005 | - | - | - | |

| Emamectin benzoate | 0.03 | 2012 | 0.0005 | 0.01 | 0.0003 | EFSA 2012 |

| Ethephon | 0.8 | 2016 | 0.03 | 0.05 | 0.03 |

Dir 06/85, SCoFCAH December 08 |

| Etofenprox | 4 | 2013 | 0.03 | 1.0 | 0.06 | EFSA 08 |

| Etoxazole | 0.5 | 2011 | 0.04 | 0.03 | Reg. (EU) 2020/2105 | |

| Famoxadone | 2 | 2005 | 0.006 | 0.1 | 0.0024 | Reg. (EU) 2021/1379 |

| Fenamidone | 0.6 | 2015 | - | - | - | |

| Fenarimol | 0.3 | 1999 | 0.01 | 0.02 | Dir 06/134 | |

| Fenbuconazole | 1 | 1999 | 0.006 | 0.3 | 0.02 | EFSA 10 |

| Fenbutatin Oxide | 5 | 1995 | 0.05 | 0.1 | EFSA 10 | |

| Fenhexamid | 15 | 2006 | 0.2 | 0.2 | Reg. (EU) 2015/1201 | |

| Fenpyrazamine | 3 | 2018 | 0.13 | 0.3 | 0.2 | Reg. (EU) No. 595/2012 |

| Fenpyroximate | 0.1 | 2018 | 0.01 | 0.02 | 0.005 | EFSA 2013 |

| Fluazifop-p-butyl | 0.01 | 2017 | - | - | - | |

| Flubendiamide | 2 | 2011 | 0.017 | 0.1 | 0.006 | EFSA 2013 |

| Fludioxonil | 2 | 2006 | 0.37 | 0.59 | Dir 07/76 | |

| Flumioxazin | 0.02 | 2016 | 0.009 | 0.05 | 0.018 | 02/81/EC |

| Fluopicolide | 2 | 2010 | 0.08 | 0.18 | 0.05 | 2010/15/EU |

| Fluopyram | 2 | 2011 | 0.012 | 0.5 | 0.05 | Reg. (EU) No. 802/2013 |

| Flupyradifurone | 3 | 2017 | 0.064 | 0.15 | 0.064 | Reg. (EU) 2015/2084 |

| Flusilazole | 0.2 | 2008 | 0.002 | 0.005 | 0.005 | Dir 06/133 |

| Flutriafol | 0.8 | 2013 | 0.01 | 0.05 | 0.05 | 11/42/EU |

| Fluxapyroxad | 3 | 2016 | 0.02 | 0.25 | 0.04 | EFSA 12 |

| Folpet | 10 | 2006 | 0.1 | 0.2 | 0.1 | Dir 07/5, SCoFCAH July 08 |

| Fosetyl Al | 60 | 2018 | - | - | - | |

| Glufosinate-Ammonium | 0.15 | 2013 | 0.021 | 0.021 | 0.0021 | Dir 07/25 |

| Haloxyfop | 0.02 | 2011 | 0.00065 | 0.075 | EFSA 06 | |

| Hexythiazox | 1 | 2010 | 0.03 | 0.009 | 11/46/EU | |

| Imidacloprid | 1 | 2004 | 0.06 | 0.08 | 0.08 | Dir 08/116 |

| Indoxacarb | 2 | 2006 | 0.006 | 0.125 | 0.004 | 06/10/EC |

| Iprodione | 10 | - | 0.02 | 0.06 | 0.04 | Reg. (EU) 2017/2091 |

| Kresoxim-Methyl | 1.5 | 2019 | 0.4 | 0.9 | 99/1/EC | |

| Malathion | 5 | 2006 | 0.03 | 0.3 | 0.03 | Reg. (EU) 2018/1495 |

| Mandipropamid | 2 | 2009 | 0.15 | 0.17 | EFSA 2018 | |

| Meptyldinocap | 0.2 | 2011 | 0.016 | 0.12 | 0.008 | Reg. (EU) No. 1330/2014 |

| Metalaxyl | 1 | - | 0.08 | 0.5 | 0.08 | 2010/28/EU |

| Methidathion | 1 | 1999 | 0.001 | 0.01 | JMPR 1997 | |

| Methomyl | 0.3 | 2009 | 0.0025 | 0.0025 | 0.0025 | EFSA 06 |

| Methoxyfenozide | 1 | 2005 | 0.1 | 0.1 | 0.06 | Reg. (EU) 2019/158 |

| Metrafenone | 5 | 2015 | 0.25 | 0.43 | 07/6/EC | |

| Myclobutanil | 0.9 | 2015 | 0.025 | 0.31 | 0.03 | EFSA 10 |

| Oxathiapiprolin | 0.9 | 2017 | 0.14 | 0.04 | Reg. (EU) 2017/239 | |

| Parathion-Methyl | 0.5 | 2004 | Not approved Reg. (EC) No. 1107/2009 | |||

| Penconazole | 0.4 | 2017 | 0.03 | 0.5 | 0.03 | Dir 09/77 |

| Permethrin | 2 | - | Not approved Reg. (EC) No. 1107/2009 | |||

| Phosmet | 10 | 1999 | 0.01 | 0.045 | 0.02 | Dir 07/25 |

| Propargite | 7 | 2004 | 0.03 | 0.06 | EFSA 2018 | |

| Pyraclostrobin | 2 | 2006 | 0.03 | 0.03 | 0.015 | 04/30/EC |

| Pyrimethanil | 4 | 2008 | 0.17 | 0.12 | Dir 06/74 | |

| Quinoxyfen | 2 | 2007 | 0.2 | 0.14 | Directive 2004/60/EC | |

| Saflufenacil | 0.01 | 2012 | Not approved Reg. (EC) No. 1107/2009 | |||

| Spinetoram | 0.3 | 2013 | 0.025 | 0.1 | 0.0065 | EFSA 2013 |

| Spirodiclofen | 0.2 | 2010 | 0.015 | 0.009 | EFSA ’09 | |

| Spirotetramat | 2 | 2009 | 0.05 | 1.0 | 0.05 | EFSA 2013 |

| Sulfoxaflor | 2 | 2013 | 0.04 | 0.25 | 0.06 | Reg. (EU) 2015/1295 |

| Tebuconazole | 6 | 2012 | 0.03 | 0.03 | 0.03 | Dir 08/125, EFSA 08 |

| Tebufenozide | 2 | 2004 | 0.02 | 0.008 | ESFA 10 | |

| Teflubenzuron | 0.7 | 2017 | 0.01 | 0.016 | EFSA 08 | |

| Triadimefon | 0.3 | 2015 | 0.03 | 0.08 | JMPR 2004 | |

| Triadimenol | 0.3 | 2015 | 0.05 | 0.05 | 0.05 | EFSA 08, Dir 08/125 |

| Trifloxystrobin | 3 | 2006 | 0.1 | 0.5 | 0.06 | Reg. (EU) 2018/1060 |

| Triflumizole | 3 | 2014 | 0.05 | 0.1 | 0.05 | 2010/27/EU |

| Zoxamide | 5 | 2008 | 0.5 | 0.3 | Reg. (EU) 2018/692 | |

| Technique | Advantages | Drawbacks |

|---|---|---|

| Microwave-assisted extraction (MAE) |

|

|

| Accelerated solvent extraction (ASE) |

|

|

| Matrix solid-phase dispersion (MSPD) |

|

|

| Solid-phase microextraction (SPME) |

|

|

| Supercritical fluid extraction (SFE) |

|

|

| Membrane extraction techniques |

|

|

| Liquid liquid extraction (LLE) |

|

|

| Solid phase extraction (SPE) |

|

|

| Traditional column-based SPE |

|

|

| Dispersive SPE (d-SPE) |

|

|

| Quick, Easy, Cheap, Rugged, Effective and Safe (QuEChERS) |

|

|

| Dispersive liquid-liquid microextraction (DLLME) |

|

|

| Single Drop Microextraction (SDME) |

|

|

| Hollow fiber-liquid phase microextraction (HF-LPME) |

| |

| Continuous Flow Microextraction (CFME) |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tucker, S.; Dumitriu, G.-D.; Teodosiu, C. Pesticides Identification and Sustainable Viticulture Practices to Reduce Their Use: An Overview. Molecules 2022, 27, 8205. https://doi.org/10.3390/molecules27238205

Tucker S, Dumitriu G-D, Teodosiu C. Pesticides Identification and Sustainable Viticulture Practices to Reduce Their Use: An Overview. Molecules. 2022; 27(23):8205. https://doi.org/10.3390/molecules27238205

Chicago/Turabian StyleTucker, Samuel, Georgiana-Diana Dumitriu (Gabur), and Carmen Teodosiu. 2022. "Pesticides Identification and Sustainable Viticulture Practices to Reduce Their Use: An Overview" Molecules 27, no. 23: 8205. https://doi.org/10.3390/molecules27238205

APA StyleTucker, S., Dumitriu, G.-D., & Teodosiu, C. (2022). Pesticides Identification and Sustainable Viticulture Practices to Reduce Their Use: An Overview. Molecules, 27(23), 8205. https://doi.org/10.3390/molecules27238205