Use of Pineapple Waste as Fuel in Microbial Fuel Cell for the Generation of Bioelectricity

Abstract

1. Introduction

2. Materials and Methods

2.1. Manufacture of Microbial Fuel Cells

2.2. Pineapple Waste Collection

2.3. Characterization of Microbial Fuel Cells

2.4. Isolation of Microorganisms from the Anode Chamber

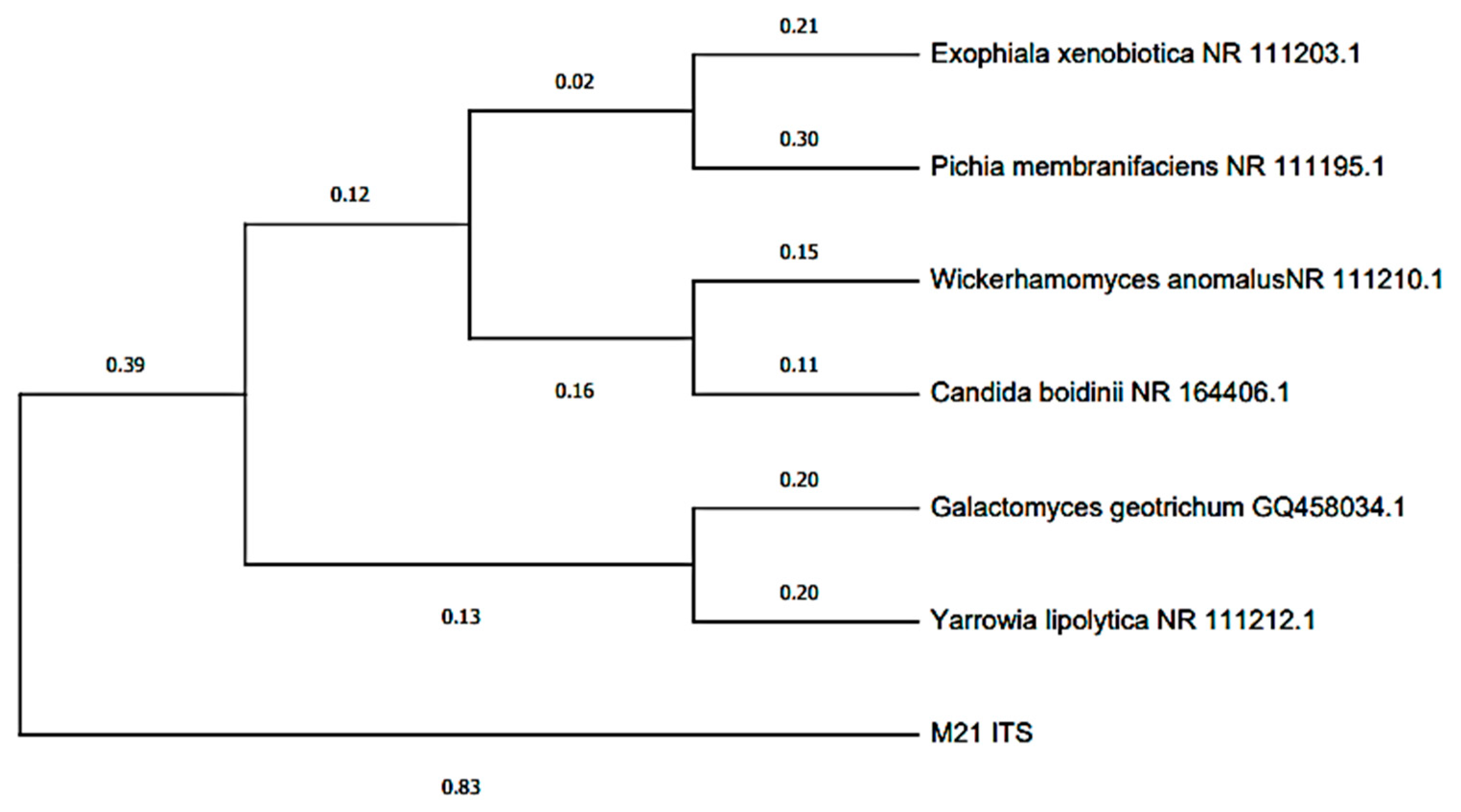

2.5. Molecular Identification of Fungi

2.6. Statistical Analysis

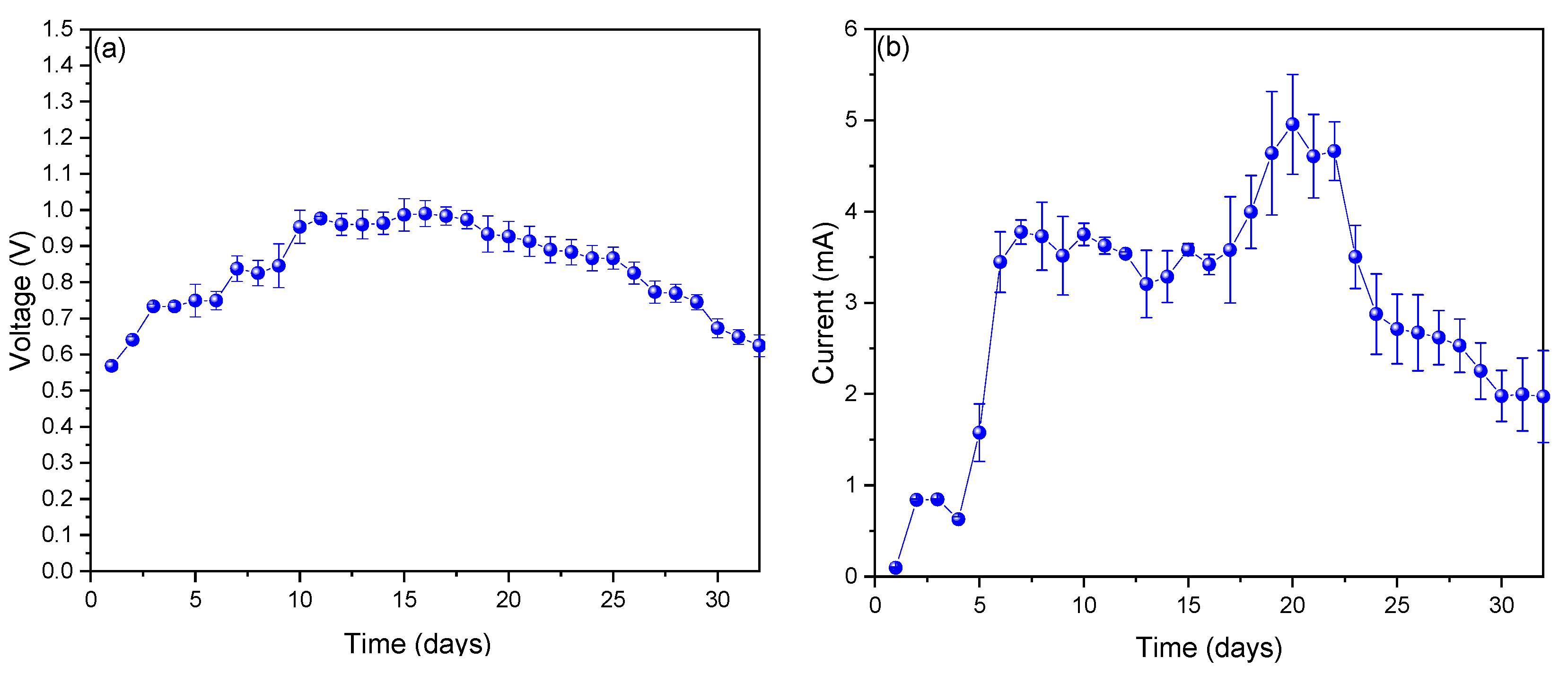

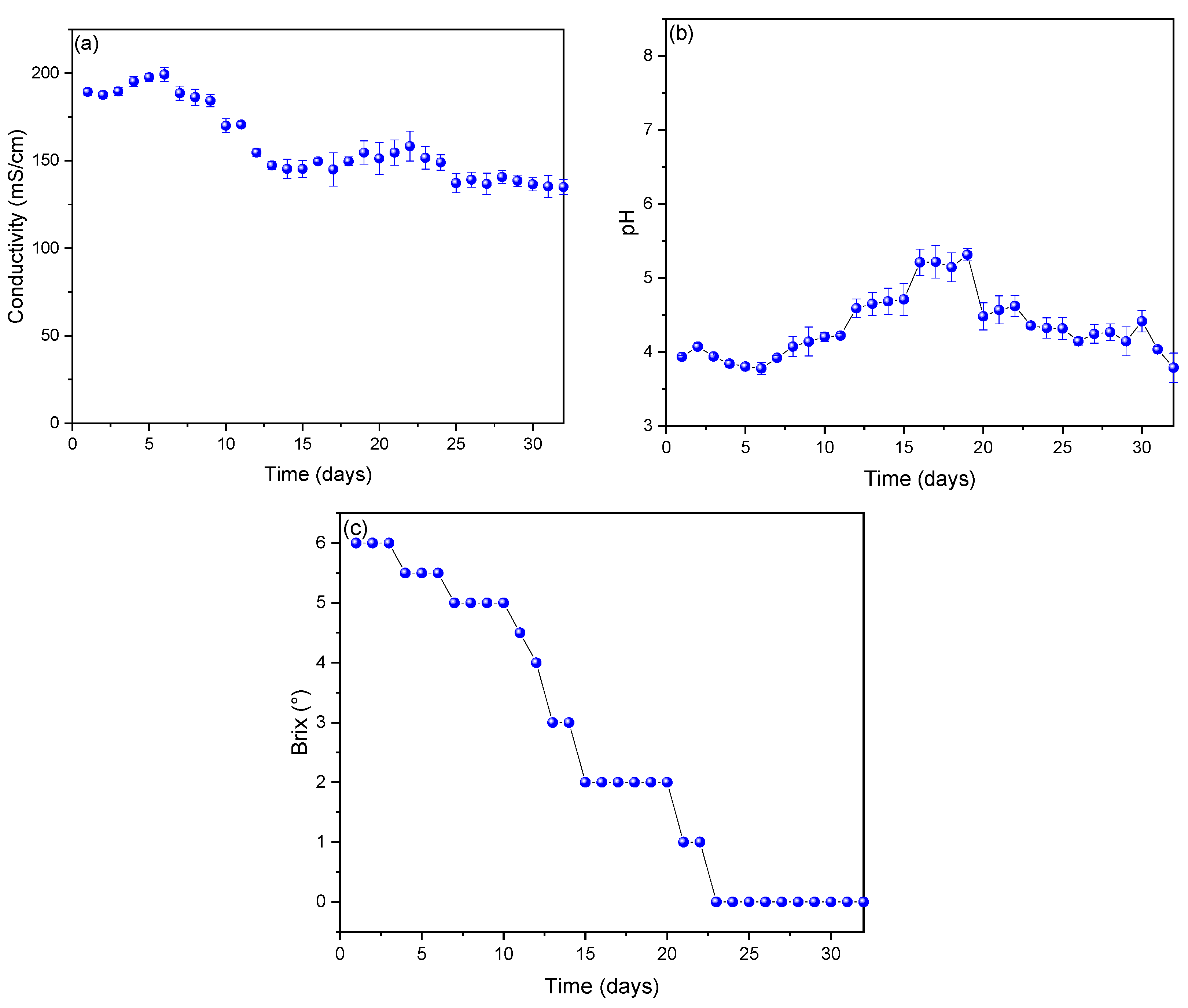

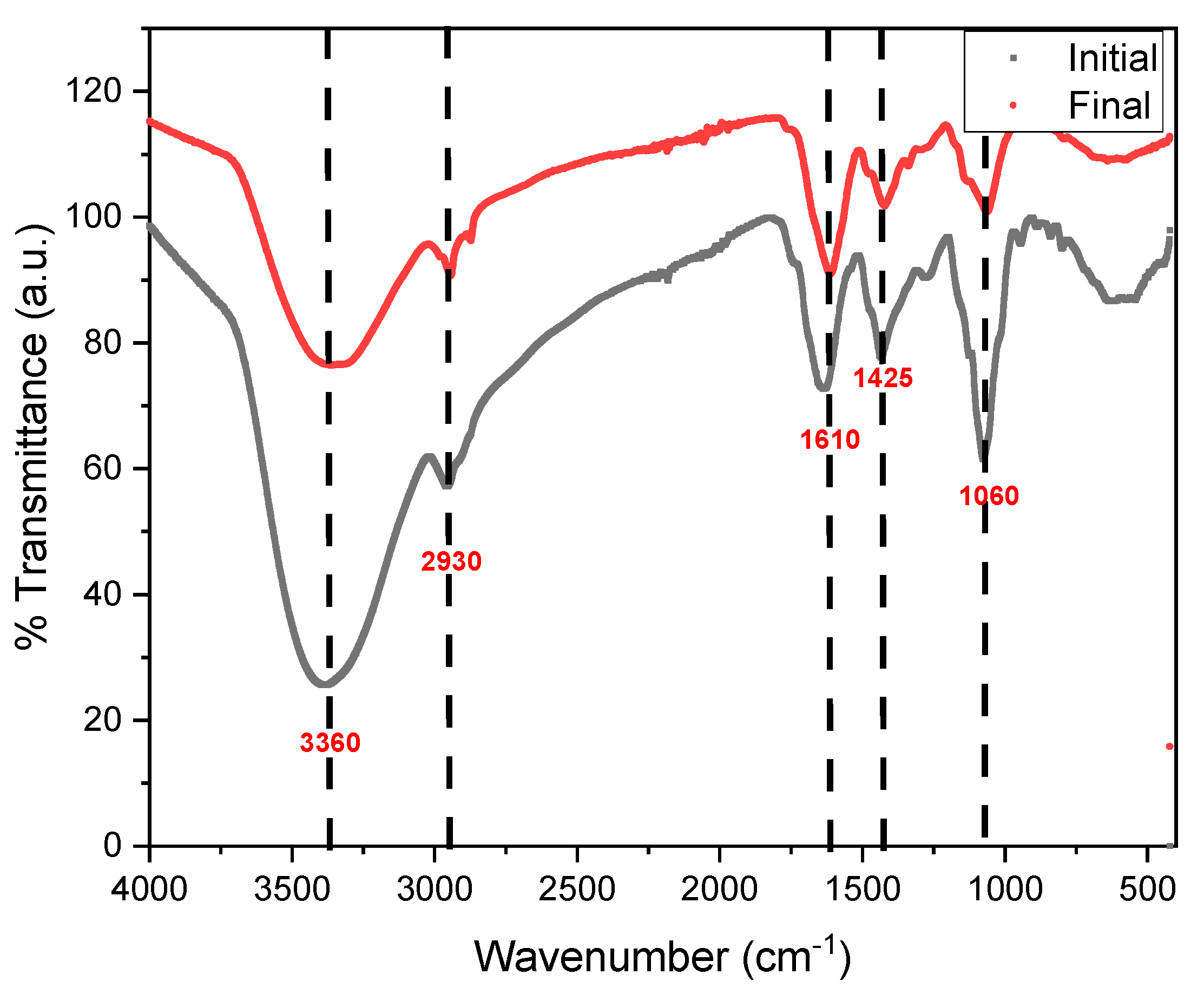

3. Results and Analysis

4. Conclusive Remarks and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bos, K.; Gupta, J. Climate change: The risks of stranded fossil fuel assets and resources to the developing world. Third World Q. 2018, 39, 436–453. [Google Scholar] [CrossRef]

- Pourghasemi, A.; Akhbari, M. The role of fossil fuel (oil and gas) in the world geopolitics of energy (case study of Iran 2000–2015). J. Ecophysiol. Occup. Health 2018, 18, 18–23. [Google Scholar] [CrossRef]

- Jackson, R.B.; Friedlingstein, P.; Andrew, R.M.; Canadell, J.G.; Le Quéré, C.; Peters, G.P. Persistent fossil fuel growth threatens the Paris Agreement and planetary health. Environ. Res. Lett. 2019, 14, 121001. [Google Scholar] [CrossRef]

- Martins, F.; Felgueiras, C.; Smitkova, M.; Caetano, N. Analysis of fossil fuel energy consumption and environmental impacts in European countries. Energies 2019, 12, 964. [Google Scholar] [CrossRef]

- Wan, D.; Xue, R.; Linnenluecke, M.; Tian, J.; Shan, Y. The impact of investor attention during COVID-19 on investment in clean energy versus fossil fuel firms. Financ. Res. Lett. 2021, 43, 101955. [Google Scholar] [CrossRef]

- Mulvaney, D.; Richards, R.M.; Bazilian, M.D.; Hensley, E.; Clough, G.; Sridhar, S. Progress towards a circular economy in materials to decarbonize electricity and mobility. Renew. Sustain. Energy Rev. 2021, 137, 110604. [Google Scholar] [CrossRef]

- Yaqoob, H.; Teoh, Y.H.; Din, Z.U.; Sabah, N.U.; Jamil, M.A.; Mujtaba, M.A.; Abid, A. The potential of sustainable biogas production from biomass waste for power generation in Pakistan. J. Clean. Prod. 2021, 307, 127250. [Google Scholar] [CrossRef]

- Naseer, M.N.; Zaidi, A.A.; Khan, H.; Kumar, S.; bin Owais, M.T.; Jaafar, J.; Suhaimin, N.S.; Wahab, Y.A.; Dutta, K.; Asif, M.; et al. Mapping the field of microbial fuel cell: A quantitative literature review (1970–2020). Energy Rep. 2021, 7, 4126–4138. [Google Scholar] [CrossRef]

- Gul, H.; Raza, W.; Lee, J.; Azam, M.; Ashraf, M.; Kim, K.H. Progress in microbial fuel cell technology for wastewater treatment and energy harvesting. Chemosphere 2021, 281, 130828. [Google Scholar] [CrossRef]

- Munoz-Cupa, C.; Hu, Y.; Xu, C.; Bassi, A. An overview of microbial fuel cell usage in wastewater treatment, resource recovery and energy production. Sci. Total Environ. 2021, 754, 142429. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, M.; Zhou, M.; Yang, H.; Liang, L.; Gu, T. Microbial fuel cell hybrid systems for wastewater treatment and bioenergy production: Synergistic effects, mechanisms and challenges. Renew. Sustain. Energy Rev. 2019, 103, 13–29. [Google Scholar] [CrossRef]

- Cui, Y.; Lai, B.; Tang, X. Microbial fuel cell-based biosensors. Biosensors 2019, 9, 92. [Google Scholar] [CrossRef] [PubMed]

- Al Lawati, M.J.; Jafary, T.; Baawain, M.S.; Al-Mamun, A. A mini review on biofouling on air cathode of single chamber microbial fuel cell; Prevention and mitigation strategies. Biocatal. Agric. Biotechnol. 2019, 22, 101370. [Google Scholar] [CrossRef]

- Greenman, J.; Gajda, I.; Ieropoulos, I. Microbial fuel cells (MFC) and microalgae; photo microbial fuel cell (PMFC) as complete recycling machines. Sustain. Energy Fuels 2019, 3, 2546–2560. [Google Scholar] [CrossRef]

- Anastopoulos, I.; Pashalidis, I.; Hosseini-Bandegharaei, A.; Giannakoudakis, D.A.; Robalds, A.; Usman, M.; Escudero, L.B.; Zhou, Y.; Colmenares, J.C.; Núñez-Delgado, A.; et al. Agricultural biomass/waste as adsorbents for toxic metal decontamination of aqueous solutions. J. Mol. Liq. 2019, 295, 111684. [Google Scholar] [CrossRef]

- Bilandzija, N.; Voca, N.; Jelcic, B.; Jurisic, V.; Matin, A.; Grubor, M.; Kricka, T. Evaluation of Croatian agricultural solid biomass energy potential. Renew. Sustain. Energy Rev. 2018, 93, 225–230. [Google Scholar] [CrossRef]

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J. Biomass waste utilisation in low-carbon products: Harnessing a major potential resource. Npj Clim. Atmos. Sci. 2019, 2, 35. [Google Scholar] [CrossRef]

- Hills, C.D.; Tripathi, N.; Singh, R.S.; Carey, P.J.; Lowry, F. Valorisation of agricultural biomass-ash with CO2. Sci. Rep. 2020, 10, 13801. [Google Scholar] [CrossRef]

- Siwal, S.S.; Zhang, Q.; Devi, N.; Saini, A.K.; Saini, V.; Pareek, B.; Gaidukovs, S.; Thakur, V.K. Recovery processes of sustainable energy using different biomass and wastes. Renew. Sustain. Energy Rev. 2021, 150, 111483. [Google Scholar] [CrossRef]

- Roda, A.; Lambri, M. Food uses of pineapple waste and by-products: A review. Int. J. Food Sci. Technol. 2019, 54, 1009–1017. [Google Scholar] [CrossRef]

- Vieira, I.M.M.; Santos, B.L.P.; Santos, C.V.M.; Ruzene, D.S.; Silva, D.P. Valorization of pineapple waste: A review on how the fruit’s potential can reduce residue generation. BioEnergy Res. 2022, 15, 924–934. [Google Scholar] [CrossRef]

- Aili Hamzah, A.F.; Hamzah, M.H.; Che Man, H.; Jamali, N.S.; Siajam, S.I.; Ismail, M.H. Recent updates on the conversion of pineapple waste (Ananas comosus) to value-added products, future perspectives and challenges. Agronomy 2021, 11, 2221. [Google Scholar] [CrossRef]

- Ali, M.M.; Hashim, N.; Abd Aziz, S.; Lasekan, O. Pineapple (Ananas comosus): A comprehensive review of nutritional values, volatile compounds, health benefits, and potential food products. Food Res. Int. 2020, 137, 109675. [Google Scholar]

- Banerjee, S.; Ranganathan, V.; Patti, A.; Arora, A. Valorisation of pineapple wastes for food and therapeutic applications. Trends Food Sci. Technol. 2018, 82, 60–70. [Google Scholar] [CrossRef]

- Hikal, W.M.; Mahmoud, A.A.; Said-Al Ahl, H.A.; Bratovcic, A.; Tkachenko, K.G.; Kačániová, M.; Rodriguez, R.M. Pineapple (Ananas comosus L. Merr.), waste streams, characterisation and valorisation: An Overview. Open J. Ecol. 2021, 11, 610–634. [Google Scholar] [CrossRef]

- Toding, O.S.L.; Virginia, C.; Suhartini, S. Conversion banana and orange peel waste into electricity using microbial fuel cell. IOP Conf. Ser. Earth Environ. Sci. 2018, 209, 012049. [Google Scholar]

- Manjrekar, Y.; Kakkar, S.; Durve-Gupta, A. Bio-electricity generation using kitchen waste and molasses powered MFC. IJSRSET 2018, 5, 181–187. [Google Scholar]

- Segundo, R.F.; Magaly, D.L.C.N.; Benites, S.M.; Daniel, D.N.; Angelats-Silva, L.; Díaz, F.; Luis, C.-C.; Fernanda, S.P. Increase in Electrical Parameters Using Sucrose in Tomato Waste. Fermentation 2022, 8, 335. [Google Scholar] [CrossRef]

- Rojas Flores, S.J.; Benites, S.M.; Agüero Quiñones, R.; Enríquez-León, R.; Angelats Silva, L. Bioelectricity through microbial fuel cells from decomposed fruits using lead and copper electrodes [Bioelectricidad mediante Celdas de Combustible Microbiana a partir de frutas descompuestas usando electrodos de plomo y cobre]. In Proceedings of the 18th LACCEI International Multi-Conference for Engineering, Education, and Technology: “Engineering, Integration, and Alliances for a Sustainable Development” “Hemispheric Cooperation for Competitiveness and Prosperity on a Knowledge-Based Economy”, Virtual Edition, Online, 27–31 July 2020. [Google Scholar]

- Flores, S.J.R.; Benites, S.M.; Rosa, A.L.R.; Zoilita, A.L.Z.; Luis, A.S. The Using Lime (Citrus × aurantiifolia), Orange (Citrus × sinensis), and Tangerine (Citrus reticulata) Waste as a Substrate for Generating Bioelectricity: Using lime (Citrus × aurantiifolia), orange (Citrus × sinensis), and tangerine (Citrus reticulata) waste as a substrate for generating bioelectricity. Environ. Res. Eng. Manag. 2020, 76, 24–34. [Google Scholar]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Milly Otiniano, N.; Benites, S.M.; Esparza, M.; Nazario-Naveda, R. Use of Onion Waste as Fuel for the Generation of Bioelectricity. Molecules 2022, 27, 625. [Google Scholar]

- Rojas-Flores, S.; Benites, S.M.; De La Cruz-Noriega, M.; Cabanillas-Chirinos, L.; Valdiviezo-Dominguez, F.; Quezada Álvarez, M.A.; Vega-Ybañez, V.; Angelats-Silva, L. Bioelectricity production from blueberry waste. Processes 2021, 9, 1301. [Google Scholar] [CrossRef]

- Raja, H.A.; Miller, A.N.; Pearce, C.J.; Oberlies, N.H. Fungal identification using molecular tools: A primer for the natural products research community. J. Nat. Prod. 2017, 80, 756–770. [Google Scholar] [CrossRef] [PubMed]

- Khan, A.M.; Hussain, M.S. Conversion of Wastes to Bioelectricity, Bioethanol, and Fertilizer: Khan and Hussain. Water Environ. Res. 2017, 89, 676–686. [Google Scholar] [CrossRef]

- Miran, W.; Nawaz, M.; Jang, J.; Lee, D.S. Conversion of orange peel waste biomass to bioelectricity using a mediator-less microbial fuel cell. Sci. Total Environ. 2016, 547, 197–205. [Google Scholar] [CrossRef] [PubMed]

- Kalagbor, I.A.; Azunda, B.I.; Igwe, B.C.; Akpan, B.J. Electricity generation from waste tomatoes, banana, pineapple fruits and peels using single chamber microbial fuel cells (SMFC). J. Waste Manag. Xenobiot. 2020, 3, 000142. [Google Scholar]

- Priya, A.D.; Setty, Y.P. Cashew apple juice as substrate for microbial fuel cell. Fuel 2019, 246, 75–78. [Google Scholar] [CrossRef]

- Takahashi, S.; Miyahara, M.; Kouzuma, A.; Watanabe, K. Electricity generation from rice bran in microbial fuel cells. Bioresour. Bioprocess. 2016, 3, 50. [Google Scholar] [CrossRef] [PubMed]

- Rojas-Flores, S.; De La Cruz-Noriega, M.; Nazario-Naveda, R.; Benites, S.M.; Delfín-Narciso, D.; Rojas-Villacorta, W.; Romero, C.V. Bioelectricity through microbial fuel cells using avocado waste. Energy Rep. 2022, 8, 376–382. [Google Scholar] [CrossRef]

- Flores, S.R.; Pérez-Delgado, O.; Naveda-Renny, N.; Benites, S.M.; De La Cruz–Noriega, M.; Narciso, D.A.D. Generation of Bioelectricity Using Molasses as Fuel in Microbial Fuel Cells. Environ. Res. Eng. Manag. 2022, 78, 19–27. [Google Scholar] [CrossRef]

- De La Cruz–Noriega, M.; Rojas-Flores, S.; Nazario-Naveda, R.; Benites, S.M.; Delfín-Narciso, D.; Rojas-Villacorta, W.; Diaz, F. Potential Use of Mango Waste and Microalgae Spirulina sp. for Bioelectricity Generation. Environ. Res. Eng. Manag. 2022, 78, 129–136. [Google Scholar] [CrossRef]

- Shao, Y.; Guizani, C.; Grosseau, P.; Chaussy, D.; Beneventi, D. Biocarbons from microfibrillated cellulose/lignosulfonate precursors: A study of electrical conductivity development during slow pyrolysis. Carbon 2018, 129, 357–366. [Google Scholar] [CrossRef]

- Zhang, S.; Tong, W.; Wang, M. Graphene-modified biochar anode on the electrical performance of MFC. Ferroelectrics 2021, 578, 1–14. [Google Scholar] [CrossRef]

- Bagchi, S.; Behera, M. Evaluation of the effect of anolyte recirculation and anolyte pH on the performance of a microbial fuel cell employing ceramic separator. Process Biochem. 2021, 102, 207–212. [Google Scholar] [CrossRef]

- Geng, Y.K.; Yuan, L.; Liu, T.; Li, Z.H.; Zheng, X.; Sheng, G.P. Thermal/alkaline pretreatment of waste activated sludge combined with a microbial fuel cell operated at alkaline pH for efficient energy recovery. Appl. Energy 2020, 275, 115291. [Google Scholar] [CrossRef]

- Li, L.; Dai, Q.; Zhang, S.; Liu, H. Degradation efficiency and mechanism of sulfur-containing azo dye wastewater by microbial fuel cell under different pH conditions. Chin. J. Environ. Eng. 2021, 15, 115–125. [Google Scholar]

- Zhang, Y.; Xu, Q.; Huang, G.; Zhang, L.; Liu, Y. Effect of dissolved oxygen concentration on nitrogen removal and electricity generation in self pH-buffer microbial fuel cell. Int. J. Hydrogen Energy 2020, 45, 34099–34109. [Google Scholar] [CrossRef]

- Dewanckele, L.; Jing, L.; Stefańska, B.; Vlaeminck, B.; Jeyanathan, J.; Van Straalen, W.M.; Koopmans, A.; Fievez, V. Distinct blood and milk 18-carbon fatty acid proportions and buccal bacterial populations in dairy cows differing in reticulorumen pH response to dietary supplementation of rapidly fermentable carbohydrates. J. Dairy Sci. 2019, 102, 4025–4040. [Google Scholar] [CrossRef]

- Yi, Y.; Xie, B.; Zhao, T.; Li, Z.; Stom, D.; Liu, H. Effect of external resistance on the sensitivity of microbial fuel cell biosensor for detection of different types of pollutants. Bioelectrochemistry 2019, 125, 71–78. [Google Scholar]

- Wang, H.; Peng, Z.; Sun, H. Antifungal activities and mechanisms of trans-cinnamaldehyde and thymol against food-spoilage yeast Zygosaccharomyces rouxii. J. Food Sci. 2022, 87, 1197–1210. [Google Scholar] [CrossRef]

- Rashid, T.; Sher, F.; Hazafa, A.; Hashmi, R.Q.; Zafar, A.; Rasheed, T.; Hussain, S. Design and feasibility study of novel paraboloid graphite based microbial fuel cell for bioelectrogenesis and pharmaceutical wastewater treatment. J. Environ. Chem. Eng. 2021, 9, 104502. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, X.; Yin, D.; Cai, L.; Zhang, L. Suspended anode-type microbial fuel cells for enhanced electricity generation. RSC Adv. 2020, 10, 9868–9877. [Google Scholar] [CrossRef]

- Abbas, S.Z.; Yong, Y.C.; Chang, F.X. Anode materials for soil microbial fuel cells: Recent advances and future perspectives. Int. J. Energy Res. 2022, 46, 712–725. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Ibrahim, M.N.M.; Yaakop, A.S.; Rafatullah, M. Utilization of biomass-derived electrodes: A journey toward the high performance of microbial fuel cells. Appl. Water Sci. 2022, 12, 99. [Google Scholar] [CrossRef]

- Xin, X.; Ma, Y.; Liu, Y. Electric energy production from food waste: Microbial fuel cells versus anaerobic digestion. Bioresour. Technol. 2018, 255, 281–287. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.; Duan, C.; Duan, W.; Sun, F.; Cui, H.; Zhang, S.; Chen, X. Role of electrode materials on performance and microbial characteristics in the constructed wetland coupled microbial fuel cell (CW-MFC): A review. J. Clean. Prod. 2021, 301, 126951. [Google Scholar] [CrossRef]

- Saragih, B.; Saragih, N.A.D. FTIR (Fourier Transform Infra Red) profile of banana corn flour, nutritional value and sensory properties of resulting brownies. J. Phys. Conf. Ser. 2021, 1882, 012112. [Google Scholar] [CrossRef]

- Suryanto, H.; Wijaya, H.W.; Yanuhar, U. FTIR analysis of alkali treatment on bacterial cellulose films obtained from pineapple peel juice. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1034, 012145. [Google Scholar] [CrossRef]

- Nora, A.; Wilapangga, A.; Kahfi, A.; Then, M.; Fairus, A. Antioxidant Activity, Total Phenolic Content, and FTIR Analysis of Fermented Baduy Honey with Pineapple. Bioedukasi 2022, 20, 21–25. [Google Scholar] [CrossRef]

- Satora, P.; Tarko, T.; Sroka, P.; Blaszczyk, U. The influence of Wickerhamomyces anomaluskiller yeast on the fermentation and chemical composition of apple wines. FEMS Yeast Res. 2014, 14, 729–740. [Google Scholar] [CrossRef] [PubMed]

- Kurtzman, C.P. Chapter 80—Wickerhamomyces Kurtzman, Robnett & Basehoar-Powers (2008). In The Yeasts, 5th ed.; Elsevier Science: Amsterdam, The Netherlands, 2011; pp. 899–917. [Google Scholar] [CrossRef]

- Roy, S.; Marzorati, S.; Schievano, A.; Pant, D. Microbial Fuel Cells. In Encyclopedia of Sustainable Technologies; Elsevier: Amsterdam, The Netherlands, 2017; pp. 245–259. [Google Scholar] [CrossRef]

- Li, M.; Zhou, M.; Tian, X.; Tan, C.; McDaniel, C.T.; Hassett, D.J.; Gu, T. Microbial fuel cell (MFC) power performance improvement through enhanced microbial electrogenicity. Biotechnol. Adv. 2018, 36, 1316–1327. [Google Scholar] [CrossRef]

- Hua, S.S.T.; Sarreal, S.B.L.; Chang, P.K.; Yu, J. Transcriptional regulation of aflatoxin biosynthesis and conidiation in Aspergillus flavus by Wickerhamomyces anomalus WRL-076 for reduction of aflatoxin contamination. Toxins 2019, 11, 81. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Guerrero-Barajas, C.; Ibrahim, M.N.M.; Umar, K.; Yaakop, A.S. Local fruit wastes driven benthic microbial fuel cell: A sustainable approach to toxic metal removal and bioelectricity generation. Environ. Sci. Pollut. Res. 2022, 29, 32913–32928. [Google Scholar] [CrossRef] [PubMed]

- Anjum, A.; Mazari, S.A.; Hashmi, Z.; Jatoi, A.S.; Abro, R. A review of role of cathodes in the performance of microbial fuel cells. J. Electroanal. Chem. 2021, 899, 115673. [Google Scholar] [CrossRef]

- Anappara, S.; Senthilkumar, K.; Krishnan, H. Chapter 11—Nanomaterial and nanocatalysts in microbial fuel cells. In Nanotechnology in Fuel Cells; Elsevier: Amsterdam, The Netherlands, 2022; pp. 261–284. [Google Scholar]

| Blast Characterization | Length of Consensus Sequence (nt) | % Maximum Identidad | Accession Number | Phylogeny |

|---|---|---|---|---|

| Wickerhamomyces anomalus | 545 | 99.82 | KJ527063.1 | Cellular organisms; Eukaryota; Opisthokonta; Fungi; Dikarya; Ascomycota; Saccharomyceta; Saccharomycetales; Phaffomycetaceae; Wickerhamomyces |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas-Flores, S.; Nazario-Naveda, R.; Benites, S.M.; Gallozzo-Cardenas, M.; Delfín-Narciso, D.; Díaz, F. Use of Pineapple Waste as Fuel in Microbial Fuel Cell for the Generation of Bioelectricity. Molecules 2022, 27, 7389. https://doi.org/10.3390/molecules27217389

Rojas-Flores S, Nazario-Naveda R, Benites SM, Gallozzo-Cardenas M, Delfín-Narciso D, Díaz F. Use of Pineapple Waste as Fuel in Microbial Fuel Cell for the Generation of Bioelectricity. Molecules. 2022; 27(21):7389. https://doi.org/10.3390/molecules27217389

Chicago/Turabian StyleRojas-Flores, Segundo, Renny Nazario-Naveda, Santiago M. Benites, Moisés Gallozzo-Cardenas, Daniel Delfín-Narciso, and Félix Díaz. 2022. "Use of Pineapple Waste as Fuel in Microbial Fuel Cell for the Generation of Bioelectricity" Molecules 27, no. 21: 7389. https://doi.org/10.3390/molecules27217389

APA StyleRojas-Flores, S., Nazario-Naveda, R., Benites, S. M., Gallozzo-Cardenas, M., Delfín-Narciso, D., & Díaz, F. (2022). Use of Pineapple Waste as Fuel in Microbial Fuel Cell for the Generation of Bioelectricity. Molecules, 27(21), 7389. https://doi.org/10.3390/molecules27217389