Waste Cooking Oil-Modified Epoxy Asphalt Rubber Binders with Improved Compatibility and Extended Allowable Construction Time

Abstract

1. Introduction

2. Results and Discussion

2.1. Viscosity vs. Time Curves

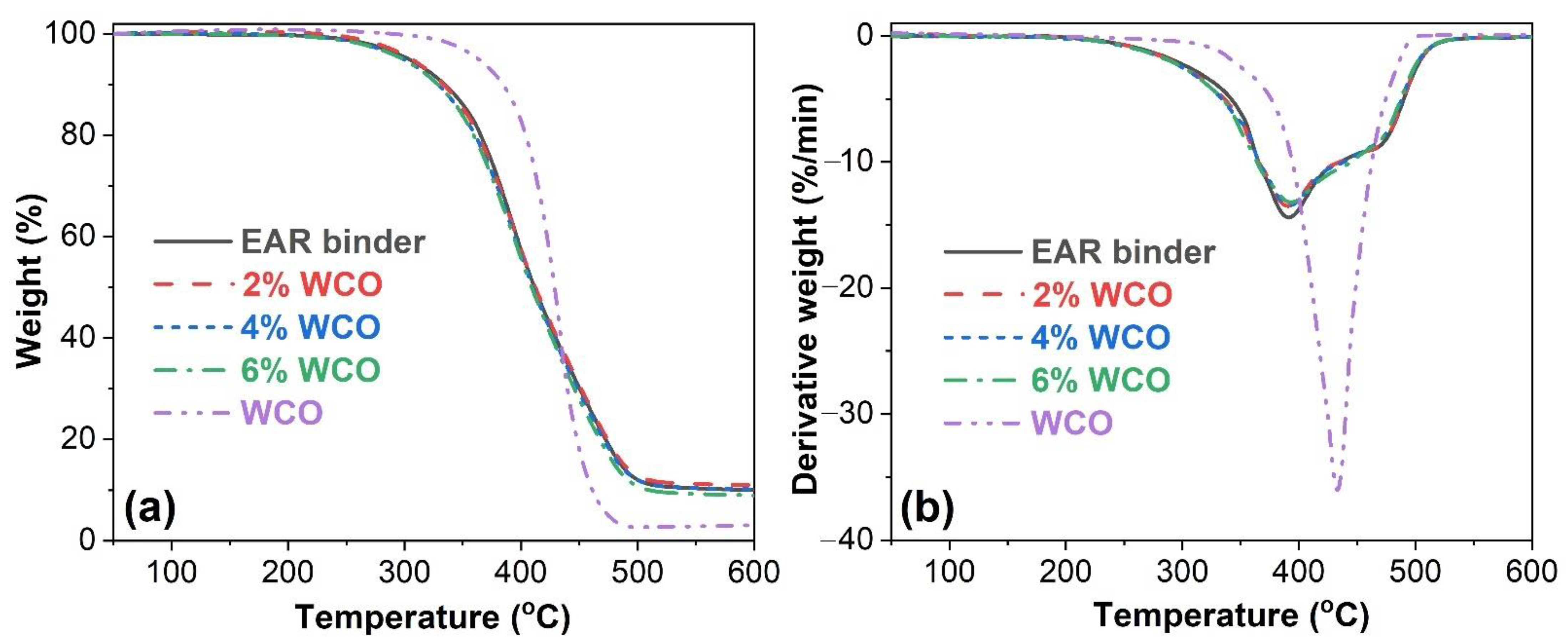

2.2. Thermal Stability

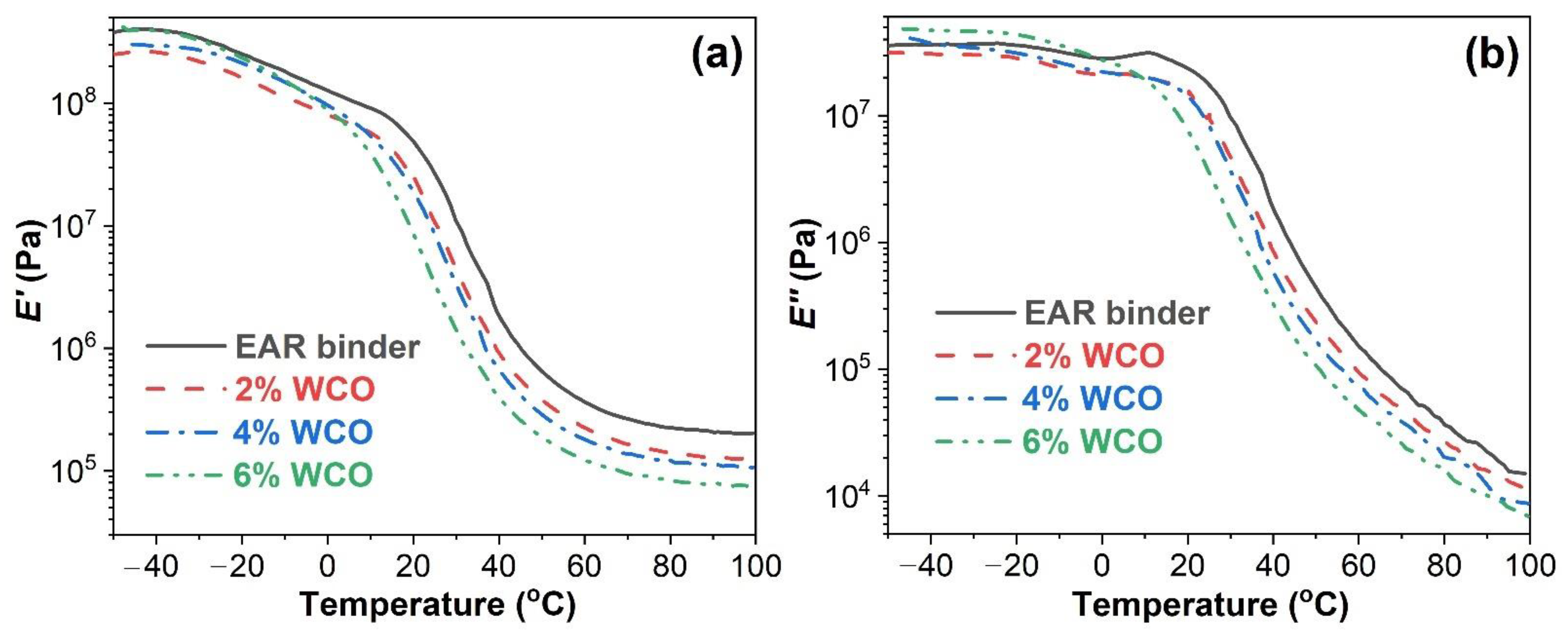

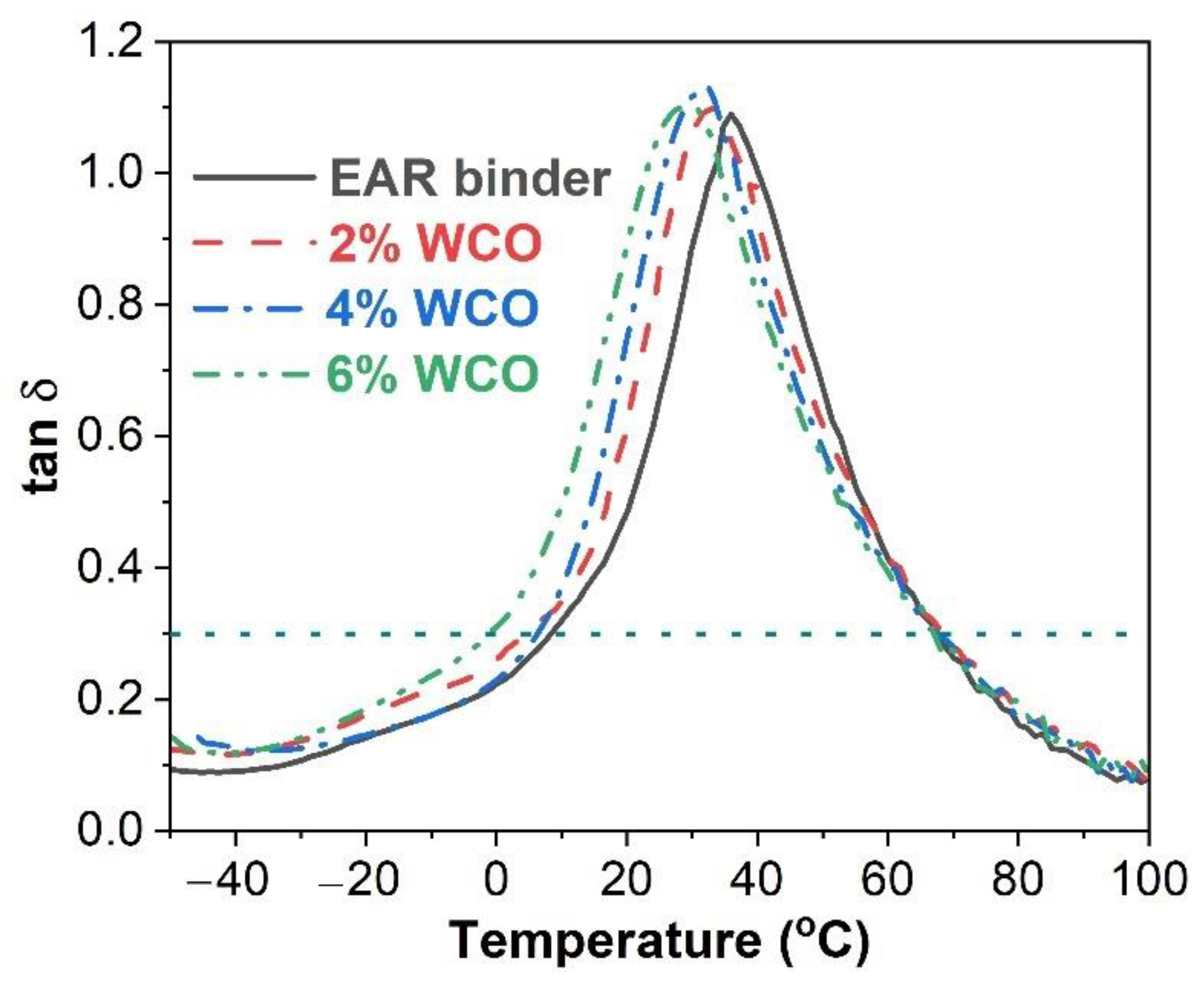

2.3. Dynamic Mechanical Properties

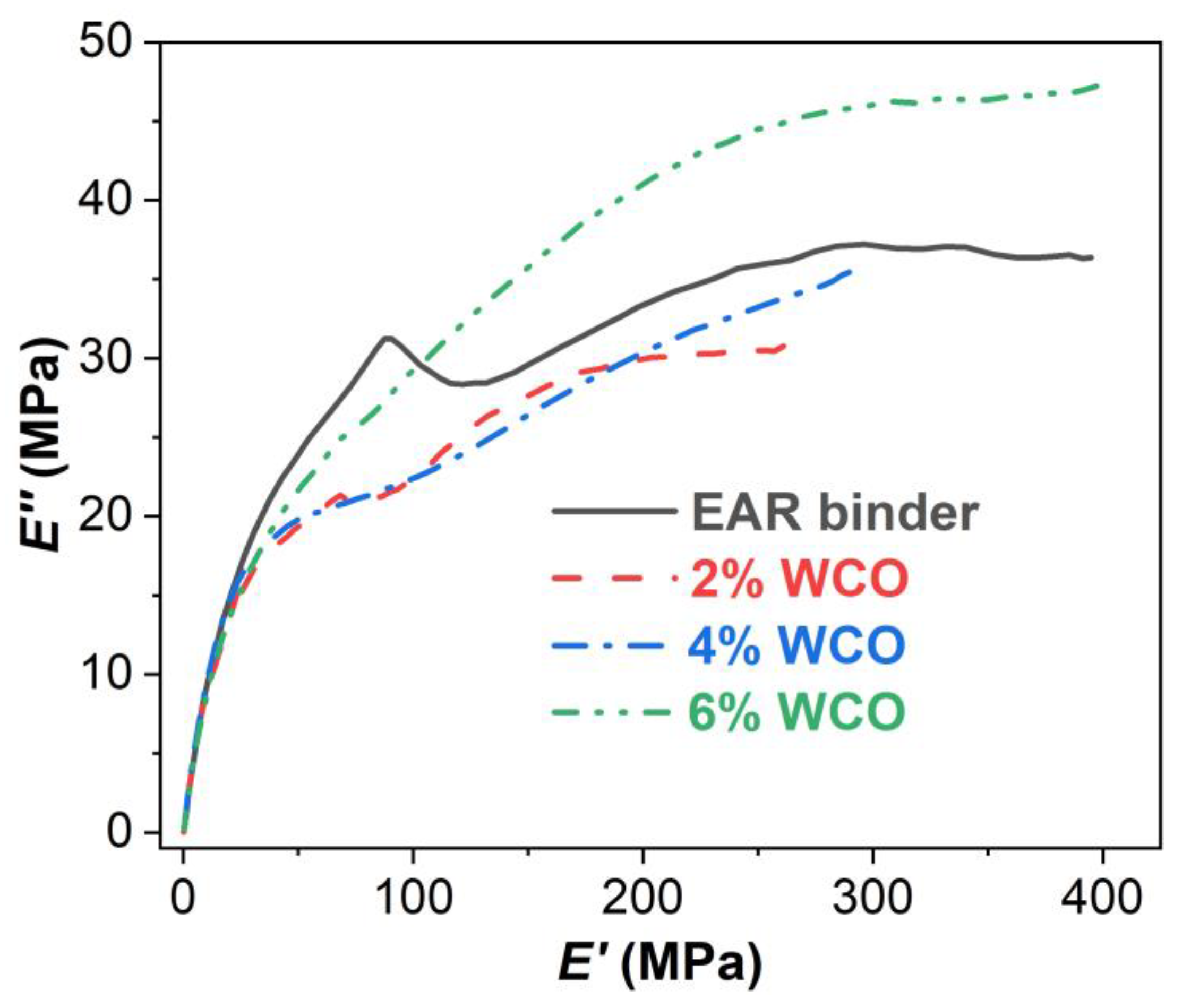

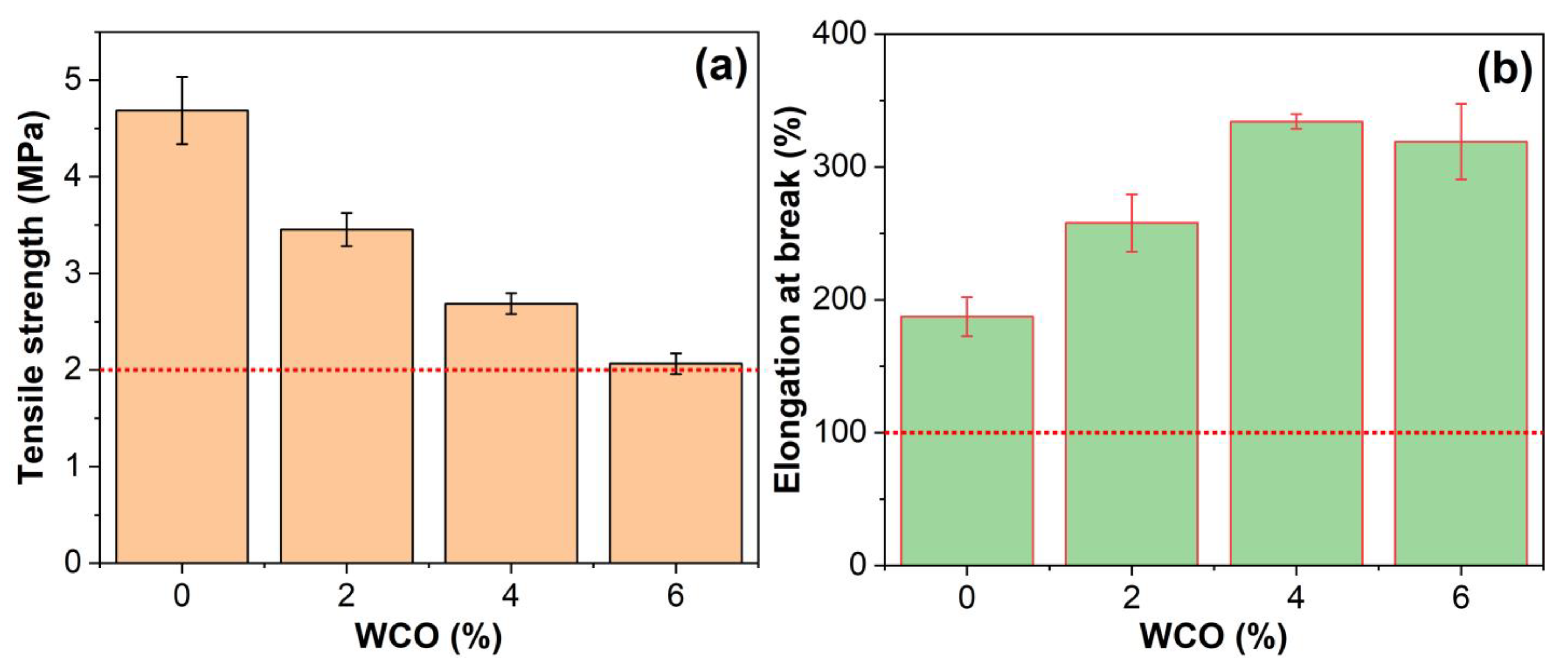

2.4. Mechanical Performance

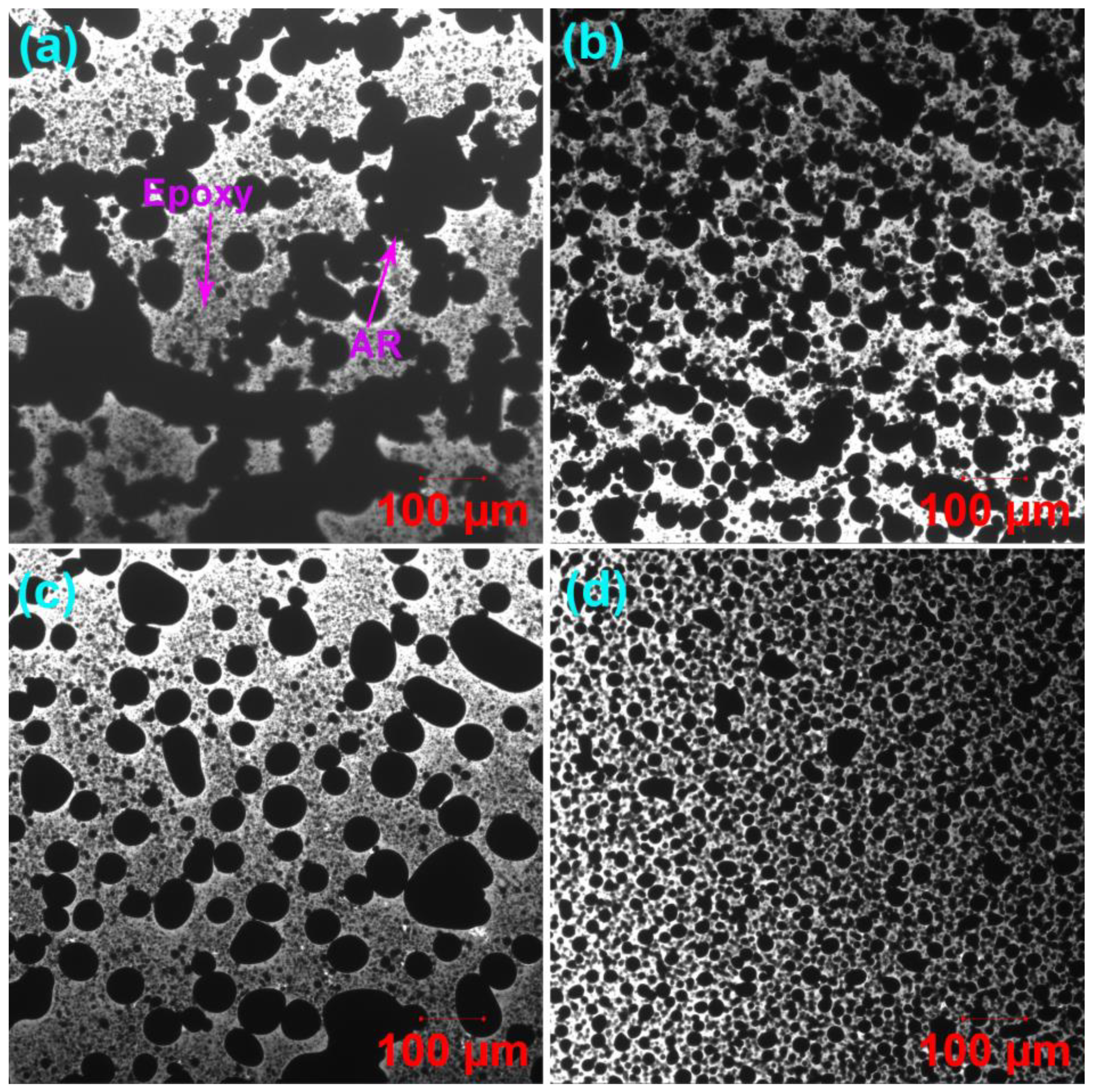

2.5. Phase-Separated Morphology

3. Materials and Methods

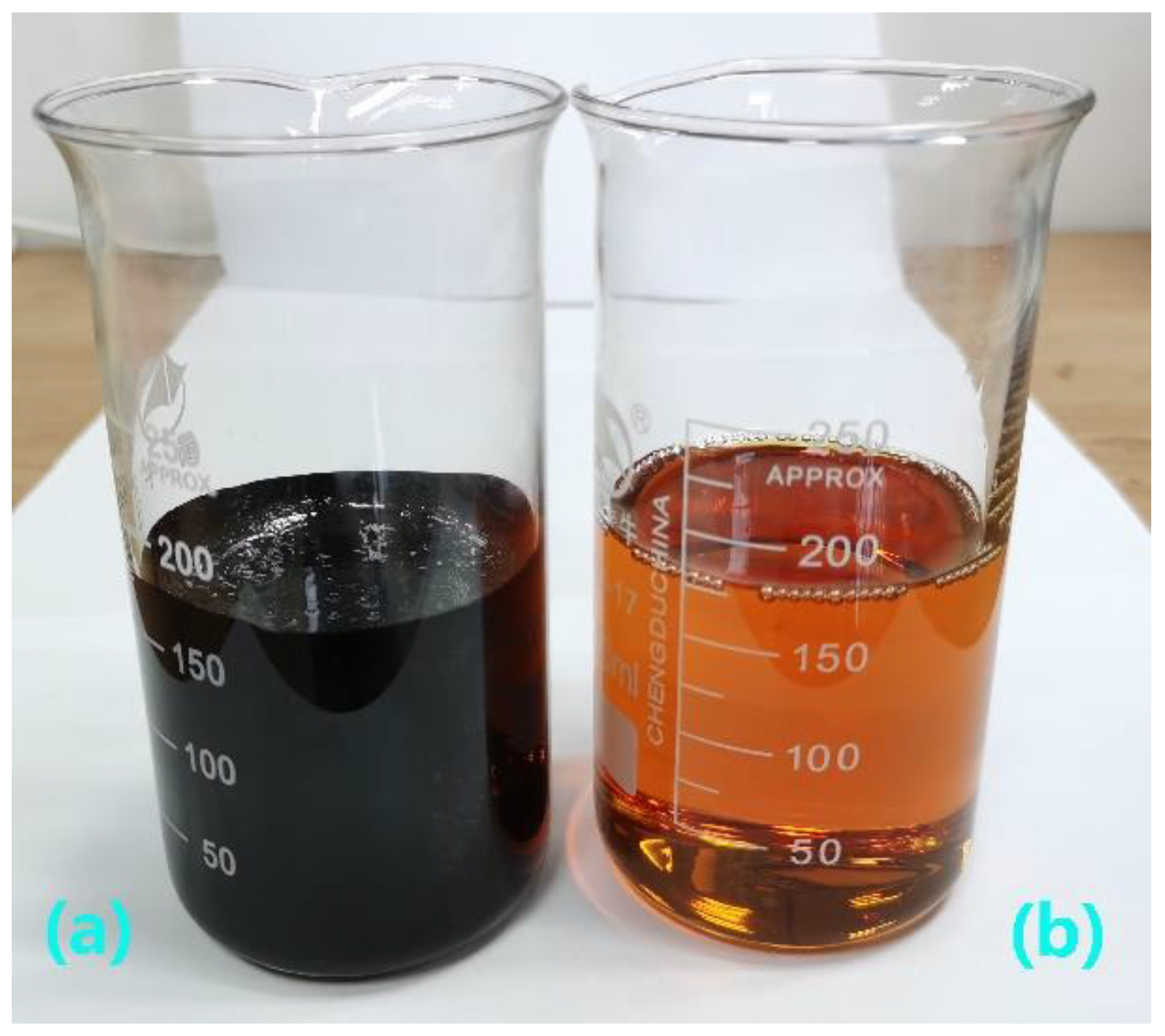

3.1. Materials

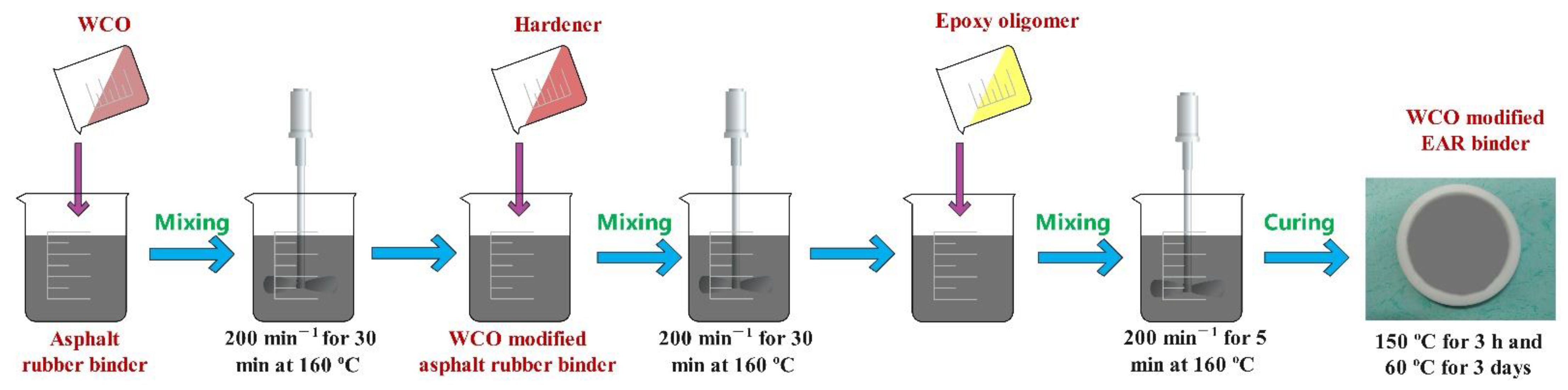

3.2. Preparation of Asphalt Rubber Binder

3.3. Preparation of WCO-Modified Asphalt Rubber Binders

3.4. Preparation of WCO-Modified EAR Binders

3.5. Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, R.; Jing, F.; Wang, R.; Cai, J.; Zhang, J.; Wang, Q.; Xie, H. Influence of oligomer content on viscosity and dynamic mechanical properties of epoxy asphalt binders. Constr. Build. Mater. 2022, 338, 127524. [Google Scholar] [CrossRef]

- Chen, R.; Gong, J.; Jiang, Y.; Wang, Q.; Xi, Z.; Xie, H. Halogen-free flame retarded cold-mix epoxy asphalt binders: Rheological, thermal and mechanical characterization. Constr. Build. Mater. 2018, 186, 863–870. [Google Scholar] [CrossRef]

- Zhang, Y.; Pan, X.; Sun, Y.; Xu, W.; Pan, Y.; Xie, H.; Cheng, R. Flame retardancy, thermal, and mechanical properties of mixed flame retardant modified epoxy asphalt binders. Constr. Build. Mater. 2014, 68, 62–67. [Google Scholar] [CrossRef]

- Chen, R.; Zhao, R.; Liu, Y.; Cai, J.; Xi, Z.; Zhang, J.; Wang, Q.; Xie, H. Development of eco-friendly fire-retarded warm-mix epoxy asphalt binders using reactive polymeric flame retardants for road tunnel pavements. Constr. Build. Mater. 2021, 284, 122752. [Google Scholar] [CrossRef]

- Yin, H.; Jin, H.; Wang, C.; Sun, Y.; Yuan, Z.; Xie, H.; Wang, Z.; Cheng, R. Thermal, damping, and mechanical properties of thermosetting epoxy-modified asphalts. J. Therm. Anal. Calorim. 2014, 115, 1073–1080. [Google Scholar] [CrossRef]

- Kang, Y.; Jin, R.; Wu, Q.; Pu, L.; Song, M.; Cheng, J.; Yu, P. Anhydrides-cured bimodal rubber-like epoxy asphalt composites: From thermosetting to quasi-thermosetting. Polymers 2016, 8, 104. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Liu, Y.; Gong, J.; Han, X.; Xi, Z.; Zhang, J.; Wang, Q.; Xie, H. Thermal and bonding properties of epoxy asphalt bond coats. J. Therm. Anal. Calorim. 2022, 147, 2013–2025. [Google Scholar] [CrossRef]

- Yin, H.; Zhang, Y.; Sun, Y.; Xu, W.; Yu, D.; Xie, H.; Cheng, R. Performance of hot mix epoxy asphalt binder and its concrete. Mater. Struct. 2015, 48, 3825–3835. [Google Scholar] [CrossRef]

- Li, M.; Min, Z.; Wang, Q.; Huang, W.; Shi, Z. Effect of epoxy resin content and conversion rate on the compatibility and component distribution of epoxy asphalt: A MD simulation study. Constr. Build. Mater. 2022, 319, 126050. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Jiang, Y.; Xu, K.; Xi, Z.; Xie, H. Thermal and mechanical properties of natural fibrous nanoclay reinforced epoxy asphalt adhesives. Int. J. Adhes. Adhes. 2018, 85, 308–314. [Google Scholar] [CrossRef]

- Luo, S.; Liu, Z.; Yang, X.; Lu, Q.; Yin, J. Construction technology of warm and hot mix epoxy asphalt paving for long-span steel bridge. J. Constr. Eng. Manag. 2019, 145, 04019074. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, Y.; Xu, K.; Xu, W.; Yu, D.; Zhu, L.; Xie, H.; Cheng, R. Thermal, mechanical properties, and low-temperature performance of fibrous nanoclay-reinforced epoxy asphalt composites and their concretes. J. Appl. Polym. Sci. 2015, 132, 41694. [Google Scholar] [CrossRef]

- Gong, J.; Han, X.; Su, W.; Xi, Z.; Cai, J.; Wang, Q.; Li, J.; Xie, H. Laboratory evaluation of warm-mix epoxy SBS modified asphalt binders containing Sasobit. J. Build. Eng. 2020, 32, 101550. [Google Scholar] [CrossRef]

- Gong, J.; Liu, Y.; Jiang, Y.; Wang, Q.; Xi, Z.; Cai, J.; Xie, H. Performance of epoxy asphalt binder containing warm-mix asphalt additive. Int. J. Pavement Eng. 2021, 22, 223–232. [Google Scholar] [CrossRef]

- Li, C.; Han, X.; Gong, J.; Su, W.; Xi, Z.; Zhang, J.; Wang, Q.; Xie, H. Impact of waste cooking oil on the viscosity, microstructure and mechanical performance of warm-mix epoxy asphalt binder. Constr. Build. Mater. 2020, 251, 118994. [Google Scholar] [CrossRef]

- Loizides, M.I.; Loizidou, X.I.; Orthodoxou, D.L.; Petsa, D. Circular bioeconomy in action: Collection and recycling of domestic used cooking oil through a social, reverse logistics system. Recycling 2019, 4, 16. [Google Scholar] [CrossRef]

- Teixeira, M.R.; Nogueira, R.; Nunes, L.M. Quantitative assessment of the valorisation of used cooking oils in 23 countries. Waste Manag. 2018, 78, 611–620. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Li, C.; Chen, X.; Peng, W.; Aghbashlo, M.; Lam, S.S.; Tabatabaei, M. Managing the hazardous waste cooking oil by conversion into bioenergy through the application of waste-derived green catalysts: A review. J. Hazard. Mater. 2022, 424, 127636. [Google Scholar] [CrossRef] [PubMed]

- Foo, W.H.; Chia, W.Y.; Tang, D.Y.Y.; Koay, S.S.N.; Lim, S.S.; Chew, K.W. The conundrum of waste cooking oil: Transforming hazard into energy. J. Hazard. Mater. 2021, 417, 126129. [Google Scholar] [CrossRef]

- Foo, W.H.; Koay, S.S.N.; Chia, S.R.; Chia, W.Y.; Tang, D.Y.Y.; Nomanbhay, S.; Chew, K.W. Recent advances in the conversion of waste cooking oil into value-added products: A review. Fuel 2022, 324, 124539. [Google Scholar] [CrossRef]

- Mannu, A.; Garroni, S.; Ibanez Porras, J.; Mele, A. Available technologies and materials for waste cooking oil recycling. Processes 2020, 8, 366. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar] [CrossRef]

- Su, N.; Xiao, F.; Wang, J.; Cong, L.; Amirkhanian, S. Productions and applications of bio-asphalts—A review. Constr. Build. Mater. 2018, 183, 578–591. [Google Scholar] [CrossRef]

- Sun, Z.; Yi, J.; Huang, Y.; Feng, D.; Guo, C. Properties of asphalt binder modified by bio-oil derived from waste cooking oil. Constr. Build. Mater. 2016, 102, 496–504. [Google Scholar] [CrossRef]

- Xie, H.; Li, C.; Wang, Q. A critical review on performance and phase separation of thermosetting epoxy asphalt binders and bond coats. Constr. Build. Mater. 2022, 326, 126792. [Google Scholar] [CrossRef]

- Xiao, M.; Luo, R.; Yu, X.; Chen, Y. Comprehensive ranking of road safety condition by using the functional and material performance index. Constr. Build. Mater. 2022, 324, 126644. [Google Scholar] [CrossRef]

- Wang, X.; Wu, R.; Zhang, L. Development and performance evaluation of epoxy asphalt concrete modified with glass fibre. Road Mater. Pavement Des. 2019, 20, 715–726. [Google Scholar] [CrossRef]

- Xue, Y.; Qian, Z. Development and performance evaluation of epoxy asphalt concrete modified with mineral fiber. Constr. Build. Mater. 2016, 102, 378–383. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, Y.; Gong, J.; Li, C.; Xi, Z.; Cai, J.; Xie, H. Microstructures, thermal and mechanical properties of epoxy asphalt binder modified by SBS containing various styrene-butadiene structures. Mater. Struct. 2018, 51, 86. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhao, R.; Xi, Z.; Cai, J.; Yuan, Z.; Zhang, J.; Wang, Q.; Xie, H. Improving toughness of epoxy asphalt binder with reactive epoxidized SBS. Mater. Struct. 2021, 54, 145. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, J.; Chen, R.; Cai, J.; Xi, Z.; Xie, H. Ethylene vinyl acetate copolymer modified epoxy asphalt binders: Phase separation evolution and mechanical properties. Constr. Build. Mater. 2017, 137, 55–65. [Google Scholar] [CrossRef]

- Li, C.; Gong, J.; Zhao, R.; Xi, Z.; Wang, Q.; Xie, H. Laboratory performance of recycled polyethylene modified epoxy asphalt binders. Int. J. Pavement Eng. 2022. [Google Scholar] [CrossRef]

- Su, W.; Zhao, R.; Wang, R.; Xi, Z.; Cai, J.; Zhang, J.; Wang, Q.; Xie, H. Microstructure and performance of epoxy asphalt binders modified by core-shell rubbers containing different core polymers. Constr. Build. Mater. 2021, 304, 124689. [Google Scholar] [CrossRef]

- Xu, P.; Zhu, X.; Cong, P.; Du, X.; Zhang, R. Modification of alkyl group terminated hyperbranched polyester on paving epoxy asphalt. Constr. Build. Mater. 2018, 165, 295–302. [Google Scholar] [CrossRef]

- Min, Z.; Wang, Q.; Xie, Y.; Xie, J.; Zhang, B. Influence of polyethylene glycol (PEG) chain on the performance of epoxy asphalt binder and mixture. Constr. Build. Mater. 2021, 272, 121614. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Z.; Wang, L.; Liu, H.; Ban, X.; Ye, J. Investigation on the epoxy/polyurethane modified asphalt binder cured with bio-based curing agent: Properties and optimization. Constr. Build. Mater. 2022, 320, 126221. [Google Scholar] [CrossRef]

- Liu, Y.; Xi, Z.; Cai, J.; Xie, H. Laboratory investigation of the properties of epoxy asphalt rubber (EAR). Mater. Struct. 2017, 50, 219. [Google Scholar] [CrossRef]

- Min, Z.; Wang, Q.; Zhang, K.; Shen, L.; Lin, G.; Huang, W. Investigation on the properties of epoxy asphalt mixture containing crumb rubber for bridge expansion joint. Constr. Build. Mater. 2022, 331, 127344. [Google Scholar] [CrossRef]

- Yao, Z.; Zhang, J.; Gao, F.; Liu, S.; Yu, T. Integrated utilization of recycled crumb rubber and polyethylene for enhancing the performance of modified bitumen. Constr. Build. Mater. 2018, 170, 217–224. [Google Scholar] [CrossRef]

- Lo Presti, D. Recycled tyre rubber modified bitumens for road asphalt mixtures: A literature review. Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Ding, X.; Chen, L.; Ma, T.; Ma, H.; Gu, L.; Chen, T.; Ma, Y. Laboratory investigation of the recycled asphalt concrete with stable crumb rubber asphalt binder. Constr. Build. Mater. 2019, 203, 552–557. [Google Scholar] [CrossRef]

- Ma, T.; Wang, H.; He, L.; Zhao, Y.; Huang, X.; Chen, J. Property characterization of asphalt binders and mixtures modified by different crumb rubbers. J. Mater. Civ. Eng. 2017, 29, 04017036. [Google Scholar] [CrossRef]

- Zheng, W.; Wang, H.; Chen, Y.; Ji, J.; You, Z.; Zhang, Y. A review on compatibility between crumb rubber and asphalt binder. Constr. Build. Mater. 2021, 297, 123820. [Google Scholar] [CrossRef]

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Bressi, S.; Fiorentini, N.; Huang, J.; Losa, M. Crumb rubber modifier in road asphalt pavements: State of the art and statistics. Coatings 2019, 9, 384. [Google Scholar] [CrossRef]

- Gong, J.; Liu, Y.; Wang, Q.; Xi, Z.; Cai, J.; Ding, G.; Xie, H. Performance evaluation of warm mix asphalt additive modified epoxy asphalt rubbers. Constr. Build. Mater. 2019, 204, 288–295. [Google Scholar] [CrossRef]

- Ma, J.; Hu, M.; Sun, D.; Lu, T.; Sun, G.; Ling, S.; Xu, L. Understanding the role of waste cooking oil residue during the preparation of rubber asphalt. Resour. Conserv. Recycl. 2021, 167, 105235. [Google Scholar] [CrossRef]

- Lyu, L.; Pei, J.; Hu, D.; Fini, E.H. Durability of rubberized asphalt binders containing waste cooking oil under thermal and ultraviolet aging. Constr. Build. Mater. 2021, 299, 124282. [Google Scholar] [CrossRef]

- Ruikun, D.; Huifang, Y.; Mengzhen, Z.; Wang, H. Preparation of asphalt modifier made of waste tire crumb rubber and waste cooking oil. J. Mater. Civ. Eng. 2022, 34, 04022175. [Google Scholar] [CrossRef]

- Sun, Y.; Han, X.; Su, W.; Gong, J.; Xi, Z.; Zhang, J.; Wang, Q.; Xie, H. Mechanical and bonding properties of pristine montmorillonite reinforced epoxy asphalt bond coats. Polym. Compos. 2020, 41, 3034–3042. [Google Scholar] [CrossRef]

- Huang, W.; Guo, W.; Wei, Y. Prediction of paving performance for epoxy asphalt mixture by its time- and temperature-dependent properties. J. Mater. Civ. Eng. 2020, 32, 04020017. [Google Scholar] [CrossRef]

- Farooq, M.; Ramli, A.; Subbarao, D. Biodiesel production from waste cooking oil using bifunctional heterogeneous solid catalysts. J. Clean. Prod. 2013, 59, 131–140. [Google Scholar] [CrossRef]

- Seidelt, S.; Müller-Hagedorn, M.; Bockhorn, H. Description of tire pyrolysis by thermal degradation behaviour of main components. J. Anal. Appl. Pyrolysis 2006, 75, 11–18. [Google Scholar] [CrossRef]

- Xie, H.; Zhao, R.; Wang, R.; Xi, Z.; Yuan, Z.; Zhang, J.; Wang, Q. Influence of thermal shock on the performance of B-staged epoxy bond coat for orthotropic steel bridge pavements. Constr. Build. Mater. 2021, 294, 123598. [Google Scholar] [CrossRef]

- Jing, F.; Zhao, R.; Li, C.; Xi, Z.; Wang, Q.; Xie, H. Influence of the epoxy/acid stoichiometry on the cure behavior and mechanical properties of epoxy vitrimers. Molecules 2022, 27, 6335. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Gong, J.; Liu, Y.; Jiang, Y.; Xi, Z.; Cai, J.; Xie, H. Viscous, damping, and mechanical properties of epoxy asphalt adhesives containing different penetration-grade asphalts. J. Appl. Polym. Sci. 2019, 136, 47027. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U.; Ekblad, J. Low-temperature properties of styrene–butadiene–styrene polymer modified bitumens. Constr. Build. Mater. 1998, 12, 405–414. [Google Scholar] [CrossRef]

- Wang, C.; Dai, L.; Yang, Z.; Ge, C.; Li, S.; He, M.; Ding, L.; Xie, H. Reinforcement of castor oil-based polyurethane with surface modification of attapulgite. Polymers 2018, 10, 1236. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Xu, K.; Zhang, Y.; Zhang, J.; Chen, R.; Yuan, Z.; Xie, H.; Cheng, R. Organic montmorillonite reinforced epoxy mortar binders. Constr. Build. Mater. 2016, 107, 378–384. [Google Scholar] [CrossRef]

- Zhao, R.; Jing, F.; Li, C.; Wang, R.; Xi, Z.; Cai, J.; Wang, Q.; Xie, H. Viscosity-curing time behavior, viscoelastic properties, and phase separation of graphene oxide/epoxy asphalt composites. Polym. Compos. 2022, 43, 5454–5464. [Google Scholar] [CrossRef]

- Han, X.; Su, W.; Gong, J.; Xi, Z.; Zhang, J.; Cai, J.; Wang, Q.; Xie, H. Microstructure and dynamic mechanical properties epoxy/asphaltene composites. J. Therm. Anal. Calorim. 2022, 147, 2209–2219. [Google Scholar] [CrossRef]

- JTG/T3364-02-2019; Specifications for Design and Construction of Pavement on Highway Steel Bridge. People’s Communication Press: Beijing, China, 2019.

- Liu, Y.; Zhang, J.; Jiang, Y.; Li, C.; Xi, Z.; Cai, J.; Xie, H. Investigation of secondary phase separation and mechanical properties of epoxy SBS-modified asphalts. Constr. Build. Mater. 2018, 165, 163–172. [Google Scholar] [CrossRef]

- Zhang, J.; Su, W.; Liu, Y.; Gong, J.; Xi, Z.; Zhang, J.; Wang, Q.; Xie, H. Laboratory investigation on the microstructure and performance of SBS modified epoxy asphalt binder. Constr. Build. Mater. 2021, 270, 121378. [Google Scholar] [CrossRef]

- Lapkovskis, V.; Mironovs, V.; Kasperovich, A.; Myadelets, V.; Goljandin, D. Crumb rubber as a secondary raw material from waste rubber: A short review of end-of-life mechanical processing methods. Recycling 2020, 5, 32. [Google Scholar] [CrossRef]

- Paddock, S.W. Confocal laser scanning microscopy. BioTechniques 1999, 27, 992–1004. [Google Scholar] [CrossRef]

- Su, W.; Han, X.; Gong, J.; Xi, Z.; Zhang, J.; Wang, Q.; Xie, H. Toughening epoxy asphalt binder using core-shell rubber nanoparticles. Constr. Build. Mater. 2020, 258, 119716. [Google Scholar] [CrossRef]

- Pipintakos, G.; Hasheminejad, N.; Lommaert, C.; Bocharova, A.; Blom, J. Application of atomic force (AFM), environmental scanning electron (ESEM) and confocal laser scanning microscopy (CLSM) in bitumen: A review of the ageing effect. Micron 2021, 147, 103083. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, R.; Zhao, R.; Jing, F.; Li, C.; Wang, Q.; Xie, H. Graphene oxide-modified epoxy asphalt bond coats with enhanced bonding properties. Materials 2022, 15, 6846. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, M.; Wu, S.; Liu, J.; Amirkhanian, S. Analysis of the relationships between waste cooking oil qualities and rejuvenated asphalt properties. Materials 2017, 10, 508. [Google Scholar] [CrossRef]

| WCO (%) | Tonset (°C) | Tmax1 (°C) | Tmax2 (°C) |

|---|---|---|---|

| 0 | 304 | 391 | 435 |

| 2 | 308 | 391 | 436 |

| 4 | 300 | 392 | 433 |

| 6 | 300 | 393 | 435 |

| 100 | 364 | 433 | - |

| WCO (%) | Tg of Epoxy (°C) | Tg of Asphalt Rubber (°C) | CD (mol m−3) |

|---|---|---|---|

| 0 | 35.9 | −14.8 | 27.2 |

| 2 | 33.0 | −16.7 | 18.1 |

| 4 | 31.2 | −18.9 | 15.9 |

| 6 | 28.7 | −22.7 | 15.7 |

| WCO (%) | (tan δ)max | ΔT (K) | TA (K) |

|---|---|---|---|

| 0 | 1.09 | 59.4 (8.3–67.7) | 51.5 |

| 2 | 1.10 | 65.4 (4.1–69.5) | 56.0 |

| 4 | 1.13 | 61.5 (6.2–67.7) | 55.5 |

| 6 | 1.10 | 68.4 (−1.3–67.1) | 59.4 |

| WCO (%) | Dn (μm) | Dw (μm) | PDI | Area Fraction of Dispersed Phase (%) |

|---|---|---|---|---|

| 0 | 32.8 | 210.4 | 6.41 | 58.4 |

| 2 | 37.8 | 128.2 | 3.40 | 59.3 |

| 4 | 32.9 | 62.7 | 1.91 | 42.5 |

| 6 | 24.5 | 38.1 | 1.56 | 47.9 |

| Property | Asphalt Rubber Binder |

|---|---|

| Penetration (25 °C, 0.1 mm) | 50 |

| Softening point (°C) | 68.0 |

| Viscosity (170 °C, Pa·s) | 4.0 |

| Property | Asphalt Rubber Binder |

|---|---|

| Color | Light brown |

| Density (25 °C, g cm−3) | 0.925 |

| Viscosity (25 °C, mPa·s) | 135 |

| Acid value (mg KOH/g) | 2.36 |

| Iodine value (g I/g) | 99 |

| Saponification value (mg KOH/g) | 190 |

| Moisture content (%) | 0.12 |

| Palmitic acid (%) | 3.6 |

| Stearic acid (%) | 20.2 |

| Linoleic acid (%) | 61.8 |

| Oleic acid (%) | 2.7 |

| Property | Epoxy Oligomer | Hardener |

|---|---|---|

| Viscosity (25 °C, mPa·s) | 5800 | 65 |

| Density (25 °C, g cm−3) | 1.16 | 0.95 |

| Color | Yellow liquid | Brown liquid |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, J.; Jing, F.; Zhao, R.; Li, C.; Cai, J.; Wang, Q.; Xie, H. Waste Cooking Oil-Modified Epoxy Asphalt Rubber Binders with Improved Compatibility and Extended Allowable Construction Time. Molecules 2022, 27, 7061. https://doi.org/10.3390/molecules27207061

Gong J, Jing F, Zhao R, Li C, Cai J, Wang Q, Xie H. Waste Cooking Oil-Modified Epoxy Asphalt Rubber Binders with Improved Compatibility and Extended Allowable Construction Time. Molecules. 2022; 27(20):7061. https://doi.org/10.3390/molecules27207061

Chicago/Turabian StyleGong, Jie, Fan Jing, Ruikang Zhao, Chenxuan Li, Jun Cai, Qingjun Wang, and Hongfeng Xie. 2022. "Waste Cooking Oil-Modified Epoxy Asphalt Rubber Binders with Improved Compatibility and Extended Allowable Construction Time" Molecules 27, no. 20: 7061. https://doi.org/10.3390/molecules27207061

APA StyleGong, J., Jing, F., Zhao, R., Li, C., Cai, J., Wang, Q., & Xie, H. (2022). Waste Cooking Oil-Modified Epoxy Asphalt Rubber Binders with Improved Compatibility and Extended Allowable Construction Time. Molecules, 27(20), 7061. https://doi.org/10.3390/molecules27207061