Effect of Microwave Plasma Pre-Treatment on Cotton Cellulose Dissolution

Abstract

1. Introduction

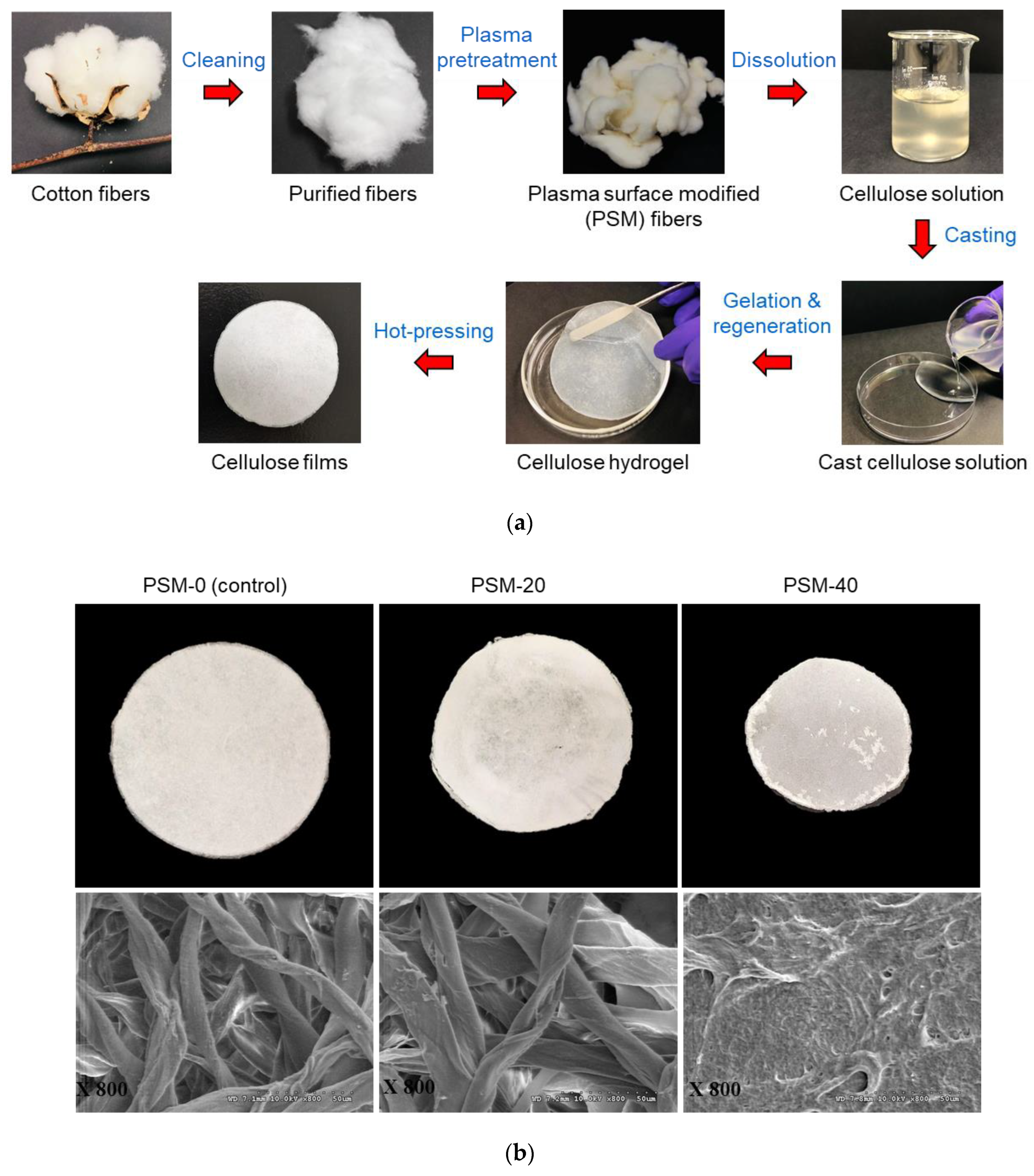

2. Results and Discussion

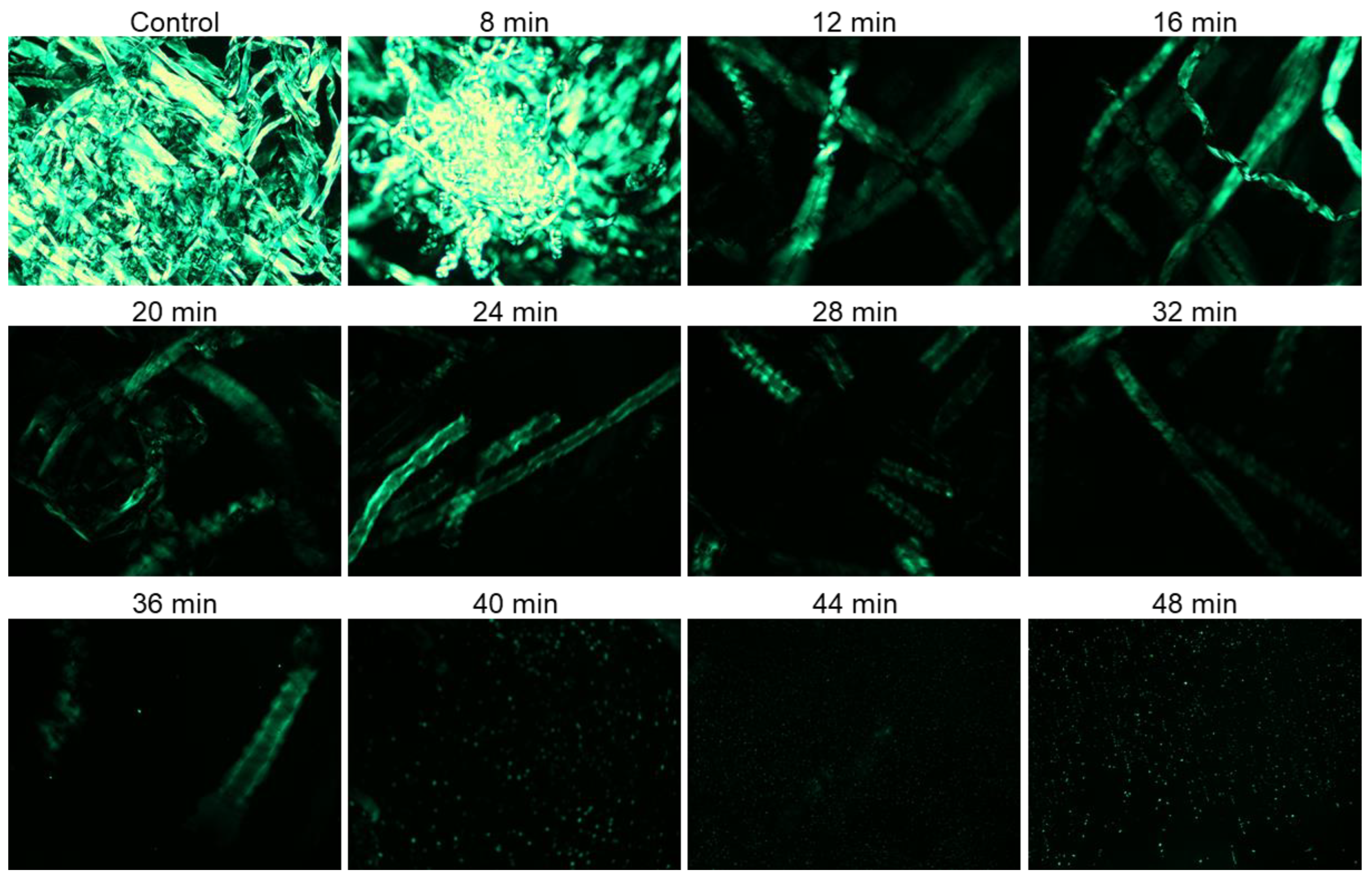

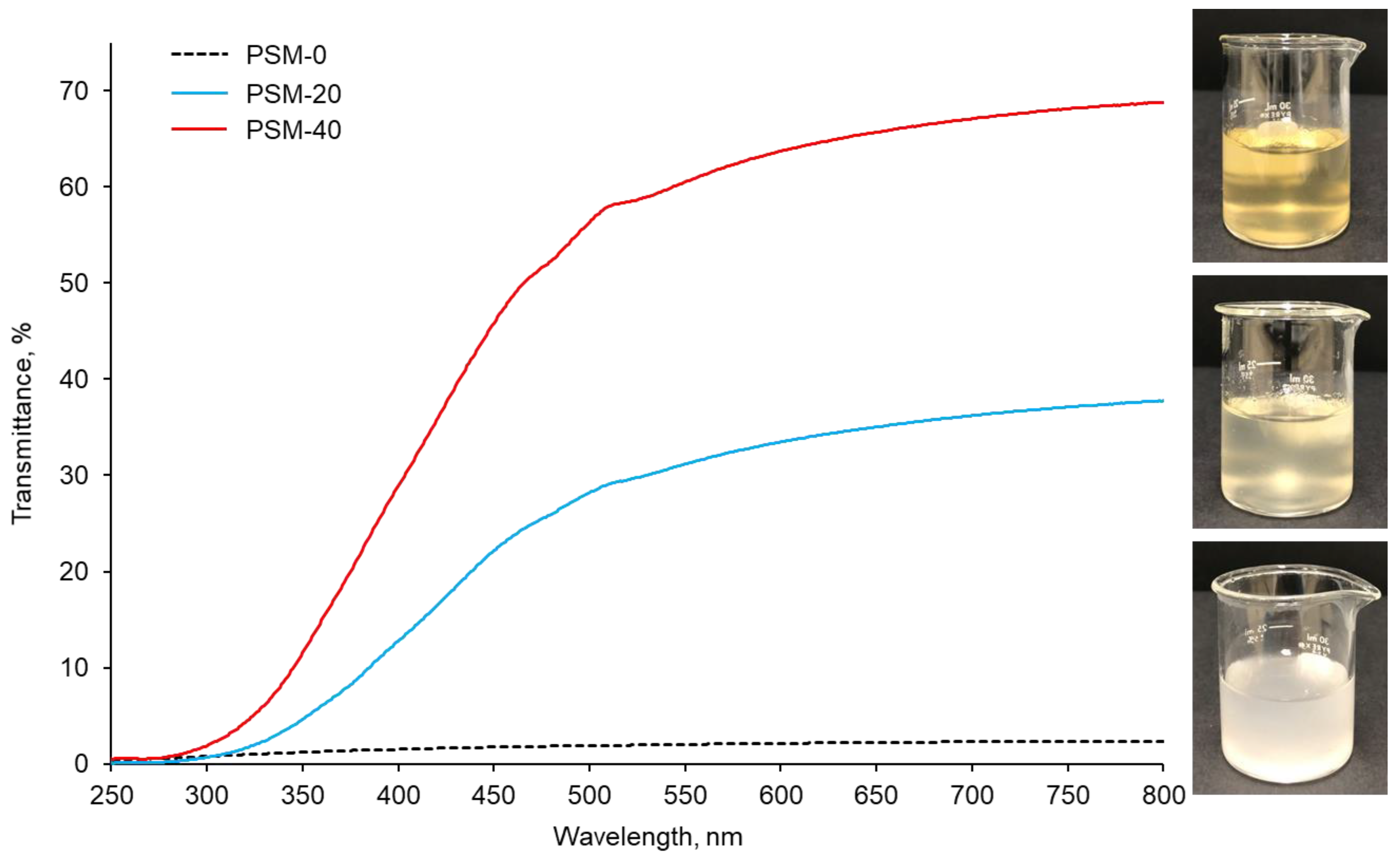

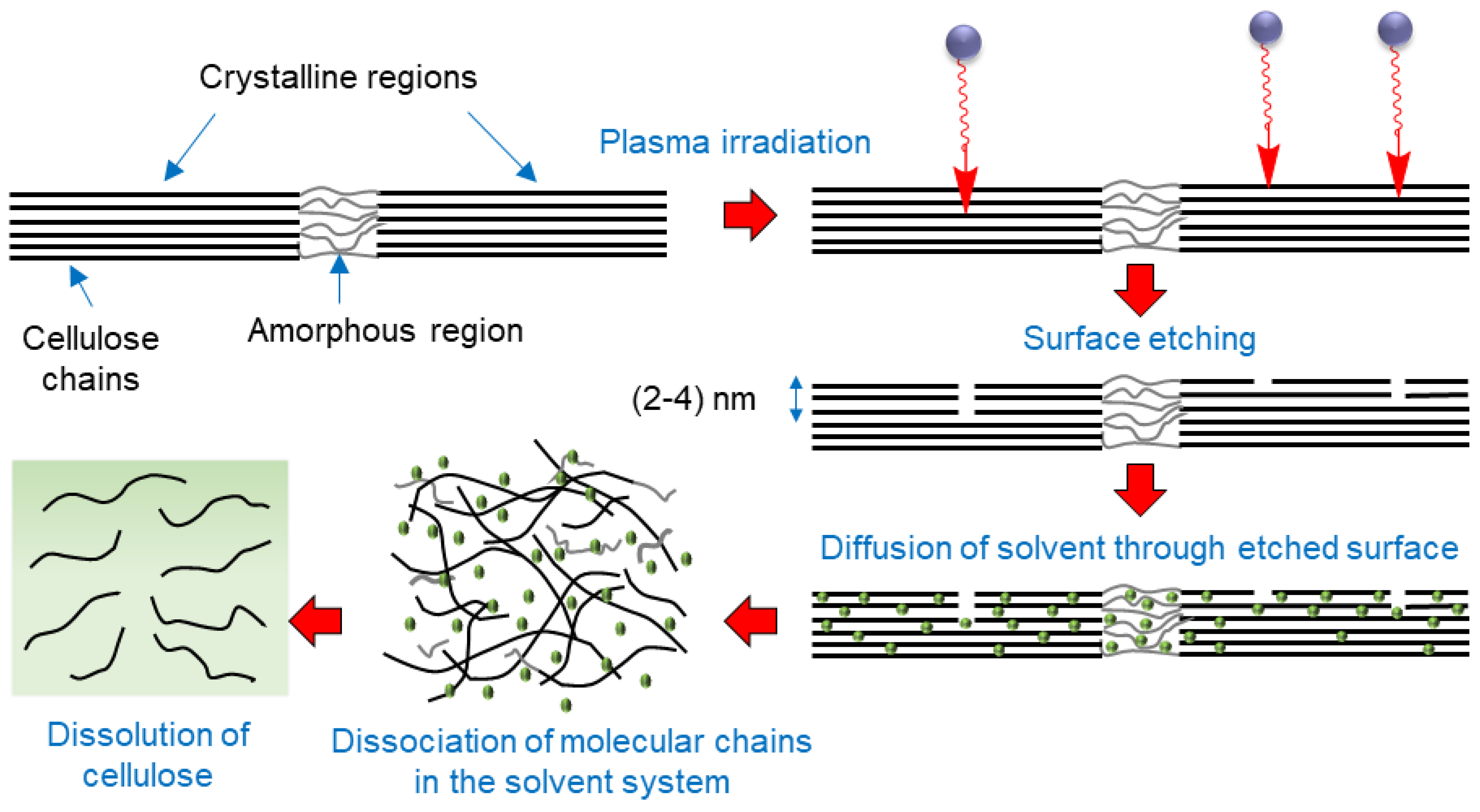

2.1. Dissolution of Cotton Fiber in Aqueous NaOH/Urea Solvent System

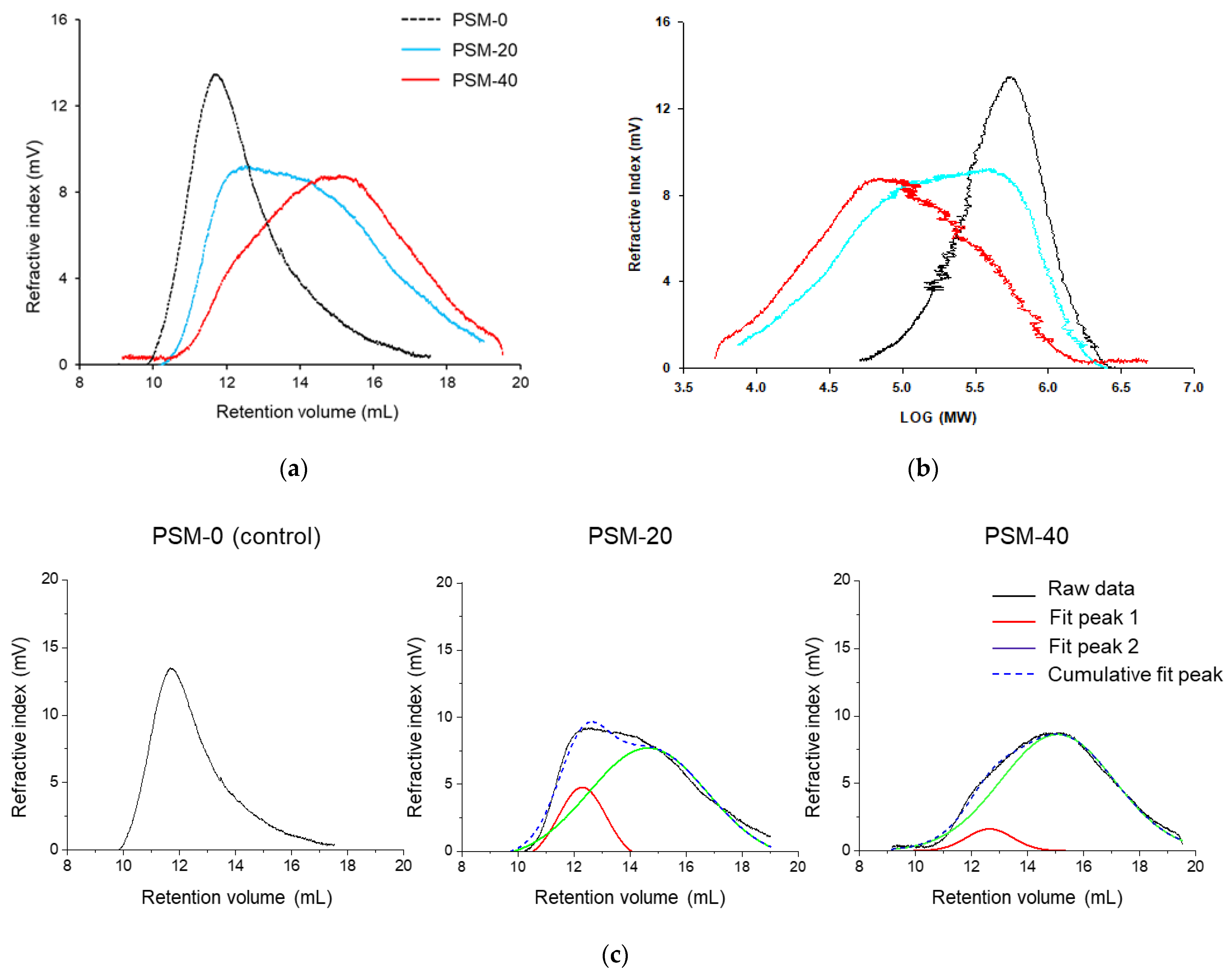

2.2. Effect of Plasma Treatment on Molecular Weight (MW) and Molecular Weight Distribution (MWD) of Cotton Fiber Cellulose

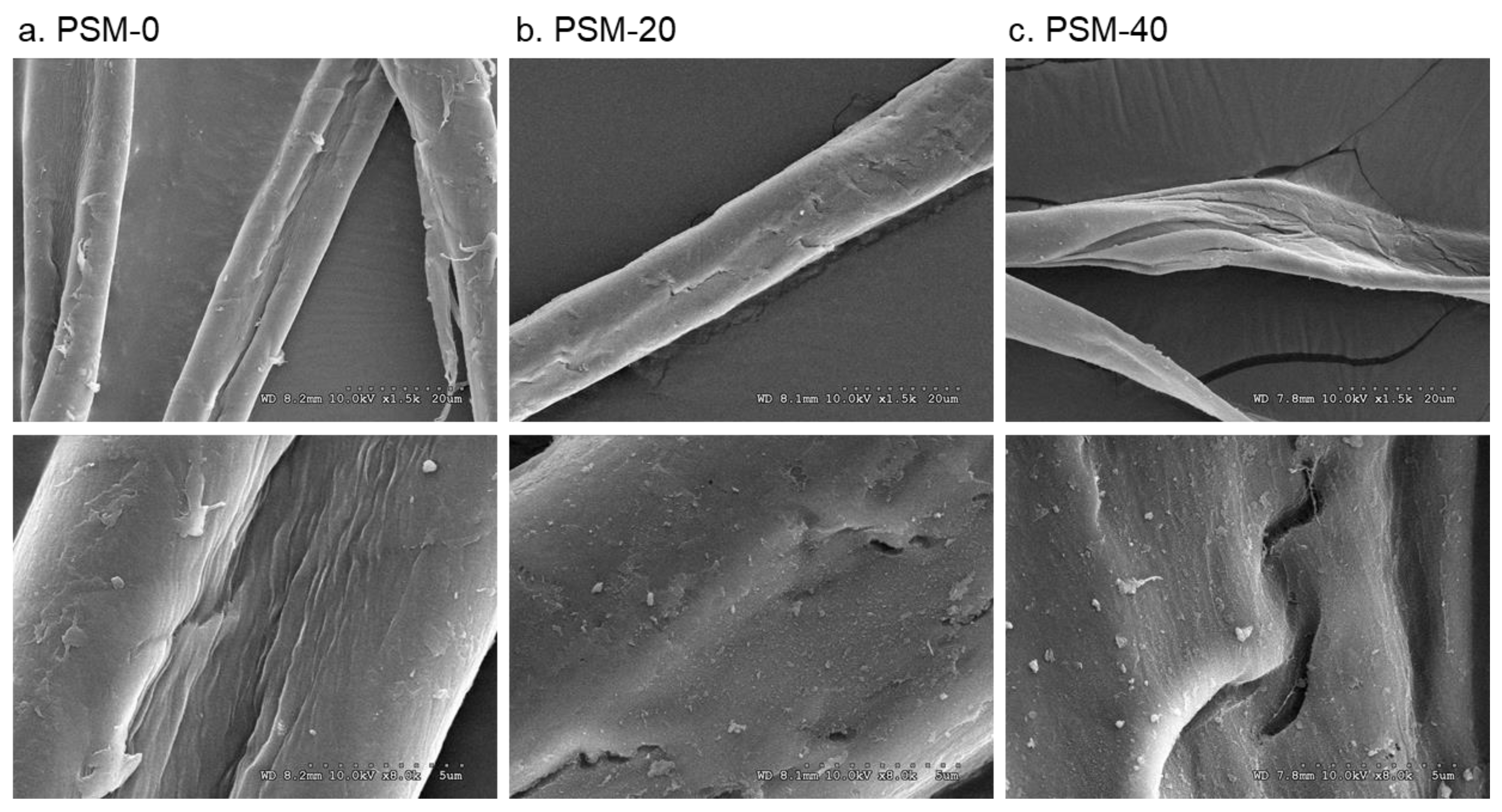

2.3. Effect of Plasma Pretreatment on Surface Morphology of Cotton Fibers

2.4. Effect of Plasma Pretreatment on Surface Morphology of Cellulose Films

2.5. Attenuated Total Reflectance (ATR) Fourier Transform Infrared (FTIR) Spectroscopy Analysis of Control and PSM Cotton Fibers

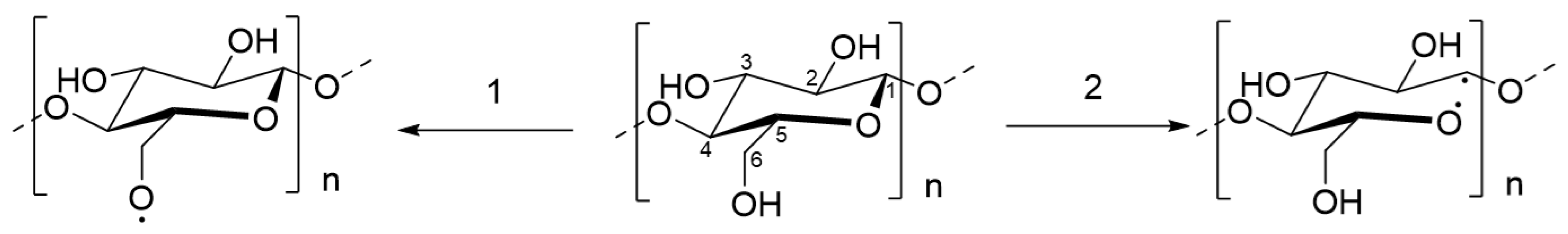

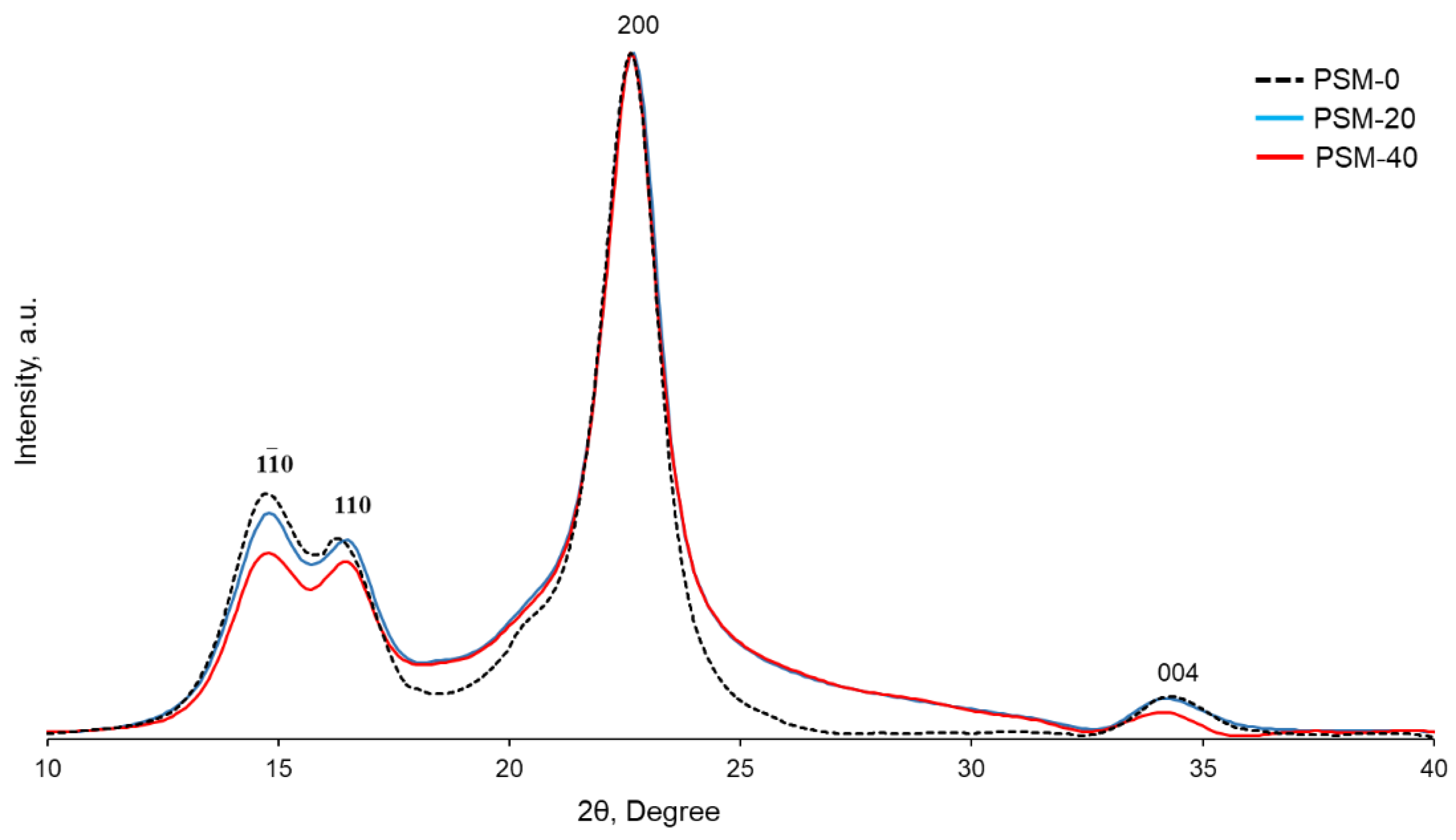

2.6. Effect of Plasma Pretreatment on Crystalline Structures of Cotton Cellulose

3. Methods

3.1. Materials

3.2. Methods

3.2.1. Microwave Pretreatment of Cotton Fibers

3.2.2. Fiber Dissolution

3.2.3. Solubility of the Plasma-Treated Cotton Fibers

3.2.4. Film Preparation

3.3. Characterization

3.3.1. Gel Permeation Chromatography (GPC)

3.3.2. Scanning Electron Microscopy (SEM)

3.3.3. Attenuated Total Reflectance (ATR) Fourier Transform Infrared Spectroscopy (FTIR)

3.3.4. Powder X-ray Diffraction (pXRD)

3.3.5. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Acharya, S.; Liyanage, S.; Abidi, N.; Parajuli, P.; Rumi, S.S.; Shamshina, J.L. Utilization of Cellulose to Its Full Potential: A Review on Cellulose Dissolution, Regeneration, and Applications. Polymers 2021, 13, 4344. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Wu, J.; Shi, H.; Xia, Z.; Sahoo, J.K.; Yeo, J.; Kaplan, D.L. Fiber-Based Biopolymer Processing as a Route toward Sustainability. Adv. Mater. 2022, 34, 2105196. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ahmed, S.; Sameen, D.E.; Wang, Y.; Lu, R.; Dai, J.; Li, S.; Qin, W. A Review of Cellulose and Its Derivatives in Biopolymer-Based for Food Packaging Application. Trends Food Sci. Technol. 2021, 112, 532–546. [Google Scholar] [CrossRef]

- Shahzadi, K.; Ge, X.; Sun, Y.; Chen, S.; Jiang, Y. Fire Retardant Cellulose Aerogel with Improved Strength and Hydrophobic Surface by One-Pot Method. J. Appl. Polym. Sci. 2021, 138, 50224. [Google Scholar] [CrossRef]

- Wang, J.; Wang, L.; Gardner, D.J.; Shaler, S.M.; Cai, Z. Towards a Cellulose-Based Society: Opportunities and Challenges. Cellulose 2021, 28, 4511–4543. [Google Scholar] [CrossRef]

- Acharya, S.; Parajuli, P.; Rumi, S.S.; Abidi, N. Cellulose Nanocrystals-Sources, Preparation, and Applications-Research Advances. In Cellulose Nanocrystals: Advances in Research and Applications; Nova Science Publishers: Hauppauge, NY, USA, 2019; pp. 1–55. ISBN 9781536167481. [Google Scholar]

- Klemm, D.; Heublein, B.; Fink, H.P.; Bohn, A. Cellulose: Fascinating Biopolymer and Sustainable Raw Material. Angew. Chem.-Int. Ed. 2005, 44, 3358–3393. [Google Scholar] [CrossRef]

- Liyanage, S.; Abidi, N. Molecular Weight and Organization of Cellulose at Different Stages of Cotton Fiber Development. Text. Res. J. 2019, 89, 726–738. [Google Scholar] [CrossRef]

- Holt, C. The Degree of Polymerisation and the Polydispersity of Cotton Cellulose; University of Leeds (Astbury Department of Biophysics): Leeds, UK, 1974. [Google Scholar]

- Michud, A.; Hummel, M.; Sixta, H. Influence of Molar Mass Distribution on the Final Properties of Fibers Regenerated from Cellulose Dissolved in Ionic Liquid by Dry-Jet Wet Spinning. Polymer 2015, 75, 1–9. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, X.; Zhang, J.; Cheng, Y.; Wu, J.; Yu, J.; Zhang, J. Molecular Weight Characterization of Cellulose Using Ionic Liquids. Polym. Test. 2021, 93, 106985. [Google Scholar] [CrossRef]

- Uusi-Tarkka, E.K.; Skrifvars, M.; Haapala, A. Fabricating Sustainable All-Cellulose Composites. Appl. Sci. 2021, 11, 10069. [Google Scholar] [CrossRef]

- Chang, X.X.; Mubarak, N.M.; Mazari, S.A.; Abdul, S.J.; Ahmad, A.; Khalid, M.; Walvekar, R.; Abdullah, E.C.; Karri, R.R.; Siddiqui, M.T.H.; et al. A Review on the Properties and Applications of Chitosan, Cellulose and Deep Eutectic Solvent in Green Chemistry. J. Ind. Eng. Chem. 2021, 104, 362–380. [Google Scholar] [CrossRef]

- Haward, S.J.; Sharma, V.; Butts, C.P.; McKinley, G.H.; Rahatekar, S.S. Shear and Extensional Rheology of Cellulose/Ionic Liquid Solutions. Biomacromolecules 2012, 13, 1688–1699. [Google Scholar] [CrossRef] [PubMed]

- Utomo, N.W.; Nazari, B.; Parisi, D.; Colby, R.H. Determination of Intrinsic Viscosity of Native Cellulose Solutions in Ionic Liquids. J. Rheol. 2020, 64, 1063–1073. [Google Scholar] [CrossRef]

- Mccormick, C.L.; Callais, P.A.; Hutchinson, B.H. Solution Studies of Cellulose in Lithium Chloride and N,N-Dimethylacetamide. Macromolecules 1985, 18, 2394–2401. [Google Scholar] [CrossRef]

- Fink, H.P.; Weigel, P.; Purz, H.J.; Ganster, J. Structure Formation of Regenerated Cellulose Materials from NMMO-Solutions. Prog. Polym. Sci. 2001, 26, 1473–1524. [Google Scholar] [CrossRef]

- Swatloski, R.P.; Spear, S.K.; Holbrey, J.D.; Rogers, R.D. Dissolution of Cellose with Ionic Liquids. J. Am. Chem. Soc. 2002, 124, 4974–4975. [Google Scholar] [CrossRef] [PubMed]

- Luo, X.; Zhang, L. New Solvents and Functional Materials Prepared from Cellulose Solutions in Alkali/Urea Aqueous System. Food Res. Int. 2013, 52, 387–400. [Google Scholar] [CrossRef]

- Zhou, J.; Lina, Z. Solubility of Cellulose in NaOH/Urea Aqueous Solution. Polym. Sci. 2000, 32, 866–870. [Google Scholar] [CrossRef]

- Zhang, L.; Ruan, D.; Zhou, J. Structure and Properties of Regenerated Cellulose Films Prepared from Cotton Linters in NaOH/Urea Aqueous Solution. Ind. Eng. Chem. Res. 2001, 40, 5923–5928. [Google Scholar] [CrossRef]

- Hu, Y.; Acharya, S.; Abidi, N. Cellulose Porosity Improves Its Dissolution by Facilitating Solvent Diffusion. Int. J. Biol. Macromol. 2019, 123, 1289–1296. [Google Scholar] [CrossRef]

- Ghasemi, M.; Tsianou, M.; Alexandridis, P. Fundamental Understanding of Cellulose Dissolution Can Improve the Efficiency of Biomass Processing. Agric. Res. Technol. Open Access J. 2018, 16, 555985. [Google Scholar] [CrossRef]

- Lindman, B.; Karlström, G.; Stigsson, L. On the Mechanism of Dissolution of Cellulose. J. Mol. Liq. 2010, 156, 76–81. [Google Scholar] [CrossRef]

- Shamshina, J.L.; Acharya, S.; Rumi, S.S.; Liyanage, S.; Parajuli, P.; Abidi, N. Cryogenic Grinding of Cotton Fiber Cellulose: The Effect on Physicochemical Properties. Carbohydr. Polym. 2022, 289, 119408. [Google Scholar] [CrossRef] [PubMed]

- Acharya, S.; Hu, Y.; Moussa, H.; Abidi, N. Preparation and Characterization of Transparent Cellulose Films Using an Improved Cellulose Dissolution Process. J. Appl. Polym. Sci. 2017, 134, 1–12. [Google Scholar] [CrossRef]

- Hu, Y.; Thalangamaarachchige, V.D.; Acharya, S.; Abidi, N. Role of Low-Concentration Acetic Acid in Promoting Cellulose Dissolution. Cellulose 2018, 25, 4389–4405. [Google Scholar] [CrossRef]

- Lao, T.L.B.; Cordura, S.L.A.; Diaz, L.J.L.; Vasquez, M.R. Influence of Plasma Treatment on the Dissolution of Cellulose in Lithium Chloride–Dimethylacetamide. Cellulose 2020, 27, 9801–9811. [Google Scholar] [CrossRef]

- Shi, Z.; Liu, Y.; Xu, H.; Yang, Q.; Xiong, C.; Kuga, S.; Matsumoto, Y. Facile Dissolution of Wood Pulp in Aqueous NaOH/Urea Solution by Ball Milling Pretreatment. Ind. Crops Prod. 2018, 118, 48–52. [Google Scholar] [CrossRef]

- Parajuli, P.; Acharya, S.; Hu, Y.; Abidi, N. Cellulose-based Monoliths with Enhanced Surface Area and Porosity. J. Appl. Polym. Sci. 2020, 137, 48975. [Google Scholar] [CrossRef]

- Kihlman, M.; Wallberg, O.; Stigsson, L.; Germgård, U. Dissolution of Dissolving Pulp in Alkaline Solvents after Steam Explosion Pretreatments. Holzforschung 2011, 65, 613–617. [Google Scholar] [CrossRef]

- Wawro, D.; Steplewski, W.; Bodek, A. Manufacture of Cellulose Fibres from Alkaline Solutions of Hydrothermally—Treated Cellulose Pulp. Fibres Text. East. Eur. 2009, 17, 18–22. [Google Scholar]

- Ishii, D.; Tatsumi, D.; Matsumoto, T. Effect of Solvent Exchange on the Supramolecular Structure, the Molecular Mobility and the Dissolution Behavior of Cellulose in LiCl/DMAc. Carbohydr. Res. 2003, 343, 919–928. [Google Scholar] [CrossRef] [PubMed]

- Ochiai, B.; Watanabe, T.; Hanzawa, C.; Akiyama, K.; Matsumura, Y.; Shimura, R.; Koda, T.; Nishioka, A. Milling in Seconds Accelerates Acetylation of Cellulose in Hours. ACS Omega 2019, 4, 17542–17546. [Google Scholar] [CrossRef] [PubMed]

- Shrotri, A.; Lambert, L.K.; Tanksale, A.; Beltramini, J. Mechanical Depolymerisation of Acidulated Cellulose: Understanding the Solubility of High Molecular Weight Oligomers. Green Chem. 2013, 15, 2761–2768. [Google Scholar] [CrossRef]

- Ling, Z.; Wang, T.; Makarem, M.; Santiago Cintrón, M.; Cheng, H.N.; Kang, X.; Bacher, M.; Potthast, A.; Rosenau, T.; King, H.; et al. Effects of Ball Milling on the Structure of Cotton Cellulose. Cellulose 2019, 26, 305–328. [Google Scholar] [CrossRef]

- Vanhatalo, K.M.; Dahl, O.P. Effect of Mild Acid Hydrolysis Parameters on Properties of Microcrystalline Cellulose. BioResources 2014, 9, 4729–4740. [Google Scholar] [CrossRef]

- Battista, O.A. Hydrolysis and Crystallization of Cellulose. Ind. Eng. Chem. 1950, 42, 502–507. [Google Scholar] [CrossRef]

- Trygg, J.; Fardim, P. Enhancement of Cellulose Dissolution in Water-Based Solvent via Ethanol-Hydrochloric Acid Pretreatment. Cellulose 2011, 18, 987–994. [Google Scholar] [CrossRef]

- Alonso-Montemayor, F.J.; Navarro-Rodríguez, D.; Delgado-Aguilar, M.; Neira-Velázquez, M.G.; Aguilar, C.N.; Castañeda-Facio, A.O.; Reyes-Acosta, Y.K.; Narro-Céspedes, R.I. Plasma-Treated Lignocellulosic Fibers for Polymer Reinforcement. A Review. Cellulose 2022, 29, 659–683. [Google Scholar] [CrossRef]

- Cabrales, L.; Abidi, N. Microwave Plasma Induced Grafting of Oleic Acid on Cotton Fabric Surfaces. Appl. Surf. Sci. 2012, 258, 4636–4641. [Google Scholar] [CrossRef]

- Calvimontes, A.; Mauersberger, P.; Nitschke, M.; Dutschk, V.; Simon, F. Effects of Oxygen Plasma on Cellulose Surface. Cellulose 2011, 18, 803–809. [Google Scholar] [CrossRef]

- Song, Z.; Tang, J.; Li, J.; Xiao, H. Plasma-Induced Polymerization for Enhancing Paper Hydrophobicity. Carbohydr. Polym. 2013, 92, 928–933. [Google Scholar] [CrossRef] [PubMed]

- Rumi, S.S.; Liyanage, S.; Abidi, N. Conversion of Low-Quality Cotton to Bioplastics. Cellulose 2021, 28, 2021–2038. [Google Scholar] [CrossRef]

- Prabhu, S.; Vaideki, K.; Anitha, S. Effect of Microwave Argon Plasma on the Glycosidic and Hydrogen Bonding System of Cotton Cellulose. Carbohydr. Polym. 2017, 156, 34–44. [Google Scholar] [CrossRef] [PubMed]

- Cao, Y.; Hua, H.; Yang, P.; Chen, M.; Chen, W.; Wang, S.; Zhou, X. Investigation into the Reaction Mechanism Underlying the Atmospheric Low-Temperature Plasma-Induced Oxidation of Cellulose. Carbohydr. Polym. 2020, 233, 115632. [Google Scholar] [CrossRef]

- Abidi, N.; Hequet, E. Cotton Fabric Graft Copolymerization Using Microwave Plasma. I. Universal Attenuated Total Reflectance-FTIR Study. J. Appl. Polym. Sci. 2004, 93, 145–154. [Google Scholar] [CrossRef]

- Wright, A.; Marsh, A.; Ricciotti, F.; Shaw, A.; Iza, F.; Holdich, R.; Bandulasena, H. Microbubble-Enhanced Dielectric Barrier Discharge Pretreatment of Microcrystalline Cellulose. Biomass Bioenergy 2018, 118, 46–54. [Google Scholar] [CrossRef]

- Zhu, H.; Han, Z.; Cheng, J.H.; Sun, D.W. Modification of Cellulose from Sugarcane (Saccharum Officinarum) Bagasse Pulp by Cold Plasma: Dissolution, Structure and Surface Chemistry Analysis. Food Chem. 2022, 374, 131675. [Google Scholar] [CrossRef]

- Wang, Y.; Ding, Z.; Zhang, Y.; Wei, C.; Xie, Z. Luffa Pretreated by Plasma Oxidation and Acidity to Be Used as Cellulose Films. Polymers 2018, 11, 37. [Google Scholar] [CrossRef]

- Cai, J.; Zhang, L. Rapid Dissolution of Cellulose in LiOH/Urea and NaOH/Urea Aqueous Solutions. Macromol. Biosci. 2005, 5, 539–548. [Google Scholar] [CrossRef]

- Shepherd, L.M.; Frey, M.W. The Degradation of Cellulose by Radio Frequency Plasma. Fibers 2018, 6, 61. [Google Scholar] [CrossRef]

- Jun, W.; Fengcai, Z.; Bingqiang, C. The Solubility of Natural Cellulose after DBD Plasma Treatment. Plasma Sci. Technol. 2008, 10, 743–747. [Google Scholar] [CrossRef]

- Nithya, E.; Radhai, R.; Rajendran, R.; Shalini, S.; Rajendran, V.; Jayakumar, S. Synergetic Effect of DC Air Plasma and Cellulase Enzyme Treatment on the Hydrophilicity of Cotton Fabric. Carbohydr. Polym. 2011, 83, 1652–1658. [Google Scholar] [CrossRef]

- Vaideki, K.; Jayakumar, S.; Thilagavathi, G.; Rajendran, R. A Study on the Antimicrobial Efficacy of RF Oxygen Plasma and Neem Extract Treated Cotton Fabrics. Appl. Surf. Sci. 2007, 253, 7323–7329. [Google Scholar] [CrossRef]

- Kolářová, K.; Vosmanská, V.; Rimpelová, S.; Švorčík, V. Effect of Plasma Treatment on Cellulose Fiber. Cellulose 2013, 20, 953–961. [Google Scholar] [CrossRef]

- Abidi, N.; Cabrales, L.; Haigler, C.H. Changes in the Cell Wall and Cellulose Content of Developing Cotton Fibers Investigated by FTIR Spectroscopy. Carbohydr. Polym. 2014, 100, 9–16. [Google Scholar] [CrossRef]

- Yang, Y.P.; Zhang, Y.; Lang, Y.X.; Yu, M.H. Structural ATR-IR Analysis of Cellulose Fibers Prepared from a NaOH Complex Aqueous Solution. IOP Conf. Ser. Mater. Sci. Eng. 2017, 213, 012039. [Google Scholar] [CrossRef]

- Marchessault, R.H.; Liang, C.Y. Infrared Spectra of Crystalline Polysaccharides. III. Mercerized Cellulose. J. Polym. Sci. 1960, 43, 71–84. [Google Scholar] [CrossRef]

- Vizireanu, S.; Panaitescu, D.M.; Nicolae, C.A.; Frone, A.N.; Chiulan, I.; Ionita, M.D.; Satulu, V.; Carpen, L.G.; Petrescu, S.; Birjega, R.; et al. Cellulose Defibrillation and Functionalization by Plasma in Liquid Treatment. Sci. Rep. 2018, 8, 15473. [Google Scholar] [CrossRef]

- Wang, C.X.; Liu, Y.; Xu, H.L.; Ren, Y.; Qiu, Y.P. Influence of Atmospheric Pressure Plasma Treatment Time on Penetration Depth of Surface Modification into Fabric. Appl. Surf. Sci. 2008, 254, 2499–2505. [Google Scholar] [CrossRef]

- Qi, H.; Chang, C.; Zhang, L. Effects of Temperature and Molecular Weight on Dissolution of Cellulose in NaOH/Urea Aqueous Solution. Cellulose 2008, 15, 779–787. [Google Scholar] [CrossRef]

- Liu, G.; Li, W.; Chen, L.; Zhang, X.; Niu, D.; Chen, Y.; Yuan, S.; Bei, Y.; Zhu, Q. Molecular Dynamics Studies on the Aggregating Behaviors of Cellulose Molecules in NaOH/Urea Aqueous Solution. Colloids Surf. A Physicochem. Eng. Asp. 2020, 594, 124663. [Google Scholar] [CrossRef]

- Cai, J.; Zhang, L.; Zhou, J.; Qi, H.; Chen, H.; Kondo, T.; Chen, X.; Chu, B. Multifilament Fibers Based on Dissolution of Cellulose in NaOH/Urea Aqueous Solution: Structure and Properties. Adv. Mater. 2007, 19, 821–825. [Google Scholar] [CrossRef]

- Park, S.; Baker, J.O.; Himmel, M.E.; Parilla, P.A.; Johnson, D.K. Cellulose Crystallinity Index: Measurement Techniques and Their Impact on Interpreting Cellulase Performance. Biotechnol. Biofuels 2010, 3, 10. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Yamagishi, N.; Gotoh, Y.; Potthast, A.; Rosenau, T. High performance cellulose fibers regenerated from 1-butyl-3-methylimidazolium chloride solution: Effects of viscosity and molecular weight. J. Appl. Polym. 2020, 137, 48681. [Google Scholar] [CrossRef]

- Xie, K.; Tu, H.; Dou, Z.; Liu, D.; Wu, K.; Liu, Y.; Chen, F.; Zhang, L.; Fu, Q. The effect of Cellulose Molecular Weight on Internal Structure and Properties of Regenerated Cellulose Fibers as Spun from the Alkali/U Aqueous System. Polymer 2021, 215, 123379. [Google Scholar] [CrossRef]

- Zhu, C.; Richardson, R.M.; Potter, K.D.; Koutsomitopoulou, A.F.; van Duijneveldt, J.S.; Vincent, S.R.; Wanasekara, N.D.; Eichhorn, S.J.; Rahatekar, S.S. High Modulus Regenerated Cellulose Fibers Spun from a Low Molecular Weight Microcrystalline Cellulose Solution. ACS Sustain. Chem. Eng. 2016, 4, 4545–4553. [Google Scholar] [CrossRef]

- Tanpichai, S.; Quero, F.; Nogi, M.; Yano, H.; Young, R.J.; Lindström, T.; Sampson, W.W.; Eichhorn, S.J. Effective Young’s Modulus of Bacterial and Microfibrillated Cellulose Fibrils in Fibrous Networks. Biomacromolecules 2012, 13, 1340–1349. [Google Scholar] [CrossRef]

- Chartrand, A.; Lavoie, J.M.; Huneault, M.A. Surface Modification of Microcrystalline Cellulose (MCC) and Its Application in LDPE-Based Composites. J. Appl. Polym. Sci. 2017, 134, 1–9. [Google Scholar] [CrossRef]

- Iyer, K.A.; Flores, A.M.; Torkelson, J.M. Comparison of Polyolefin Biocomposites Prepared with Waste Cardboard, Microcrystalline Cellulose, and Cellulose Nanocrystals via Solid-State Shear Pulverization. Polymer 2015, 75, 78–87. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Performance Properties of Microcrystalline Cellulose as a Reinforcing Agent in Wood Plastic Composites. Compos. Part B Eng. 2010, 41, 578–581. [Google Scholar] [CrossRef]

- Thoorens, G.; Krier, F.; Leclercq, B.; Carlin, B.; Evrard, B. Microcrystalline Cellulose, a Direct Compression Binder in a Quality by Design Environment—A Review. Int. J. Pharm. 2014, 473, 64–72. [Google Scholar] [CrossRef] [PubMed]

- Egal, M.; Budtova, T.; Navard, P. The Dissolution of Microcrystalline Cellulose in Sodium Hydroxide-Urea Aqueous Solutions. Cellulose 2008, 15, 361–370. [Google Scholar] [CrossRef]

| Plasma Treatment Time (min) | Average MW, Da | Average Mn, Da | DP | PDI (MW/Mn) |

|---|---|---|---|---|

| 0 min (PSM-0) | 394,889 ± 80,480 | 211,902 ± 81,973 | 2438 ± 497 | 2.09 ± 0.83 |

| 20 min (PSM-20) | 253,592 ± 4198 | 122,151 ± 26,173 | 1566 ± 26 | 7.10 ± 5.44 |

| 40 min (PSM-40) | 159,192 ± 24,634 | 285,844 ± 39,225 | 983 ± 152 | 3.82 ± 2.00 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rumi, S.S.; Liyanage, S.; Shamshina, J.L.; Abidi, N. Effect of Microwave Plasma Pre-Treatment on Cotton Cellulose Dissolution. Molecules 2022, 27, 7007. https://doi.org/10.3390/molecules27207007

Rumi SS, Liyanage S, Shamshina JL, Abidi N. Effect of Microwave Plasma Pre-Treatment on Cotton Cellulose Dissolution. Molecules. 2022; 27(20):7007. https://doi.org/10.3390/molecules27207007

Chicago/Turabian StyleRumi, Shaida S., Sumedha Liyanage, Julia L. Shamshina, and Noureddine Abidi. 2022. "Effect of Microwave Plasma Pre-Treatment on Cotton Cellulose Dissolution" Molecules 27, no. 20: 7007. https://doi.org/10.3390/molecules27207007

APA StyleRumi, S. S., Liyanage, S., Shamshina, J. L., & Abidi, N. (2022). Effect of Microwave Plasma Pre-Treatment on Cotton Cellulose Dissolution. Molecules, 27(20), 7007. https://doi.org/10.3390/molecules27207007