MoS2 and MoS2 Nanocomposites for Adsorption and Photodegradation of Water Pollutants: A Review

Abstract

1. Introduction

2. MoS2 Structure and Properties

3. Common Synthesis Methods and Modifications of MoS2

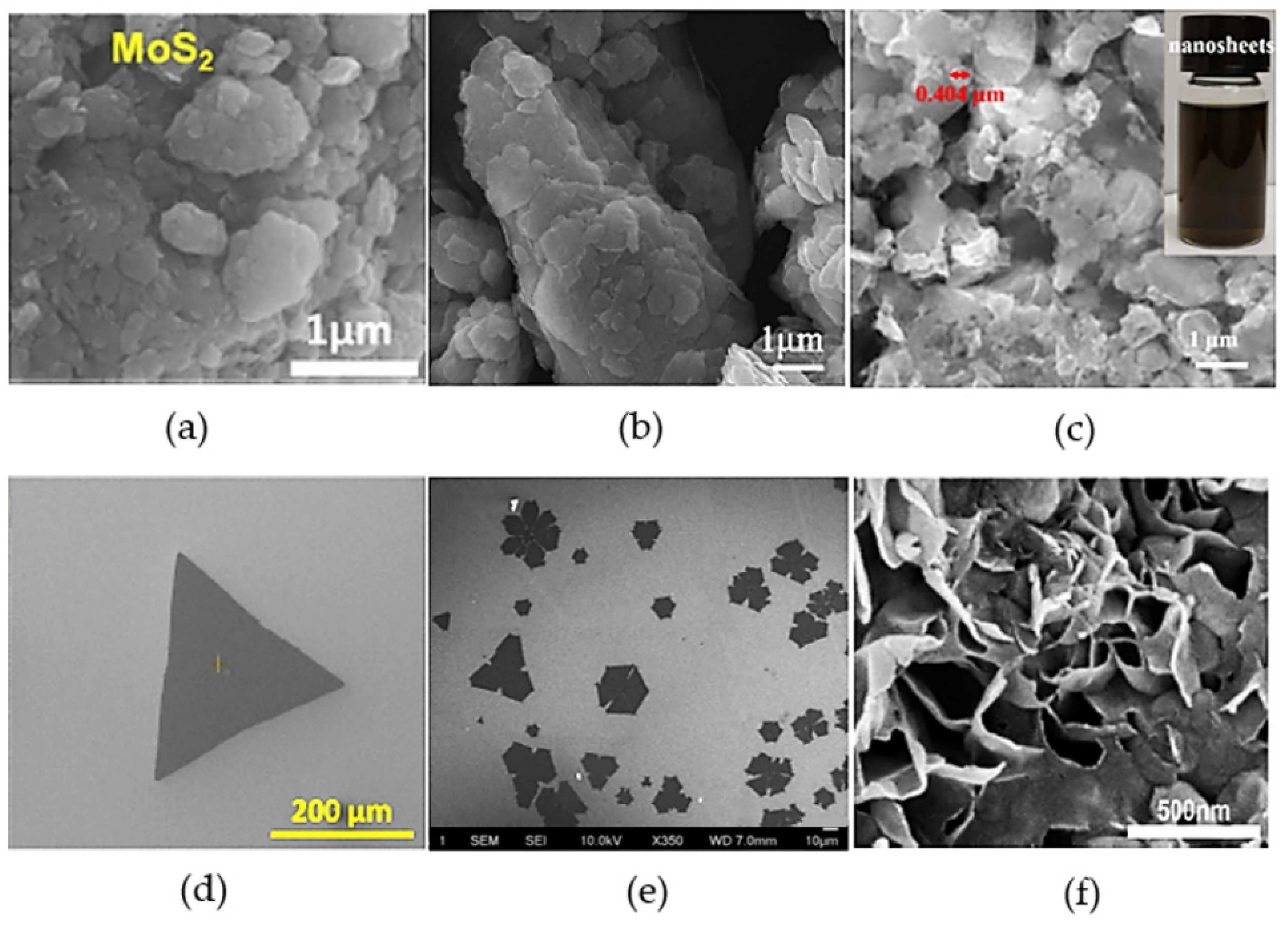

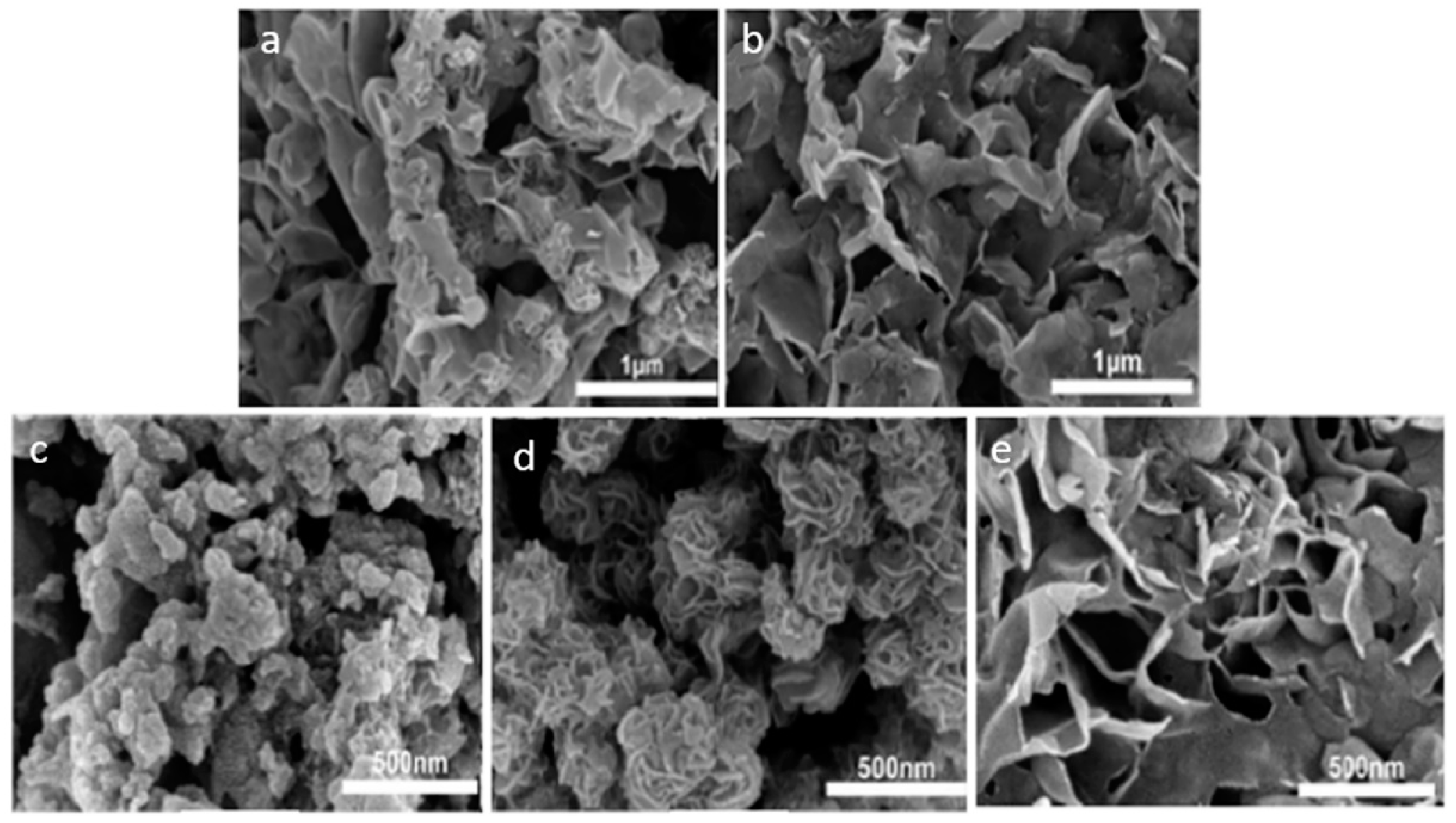

3.1. Top-Down Methods

3.2. Bottom-Up Methods

3.3. MoS2 Modification Methods

4. Adsorption Applications

4.1. Heavy Metal Species

4.2. Organic Contaminants

4.3. Kinetic and Isotherm Studies

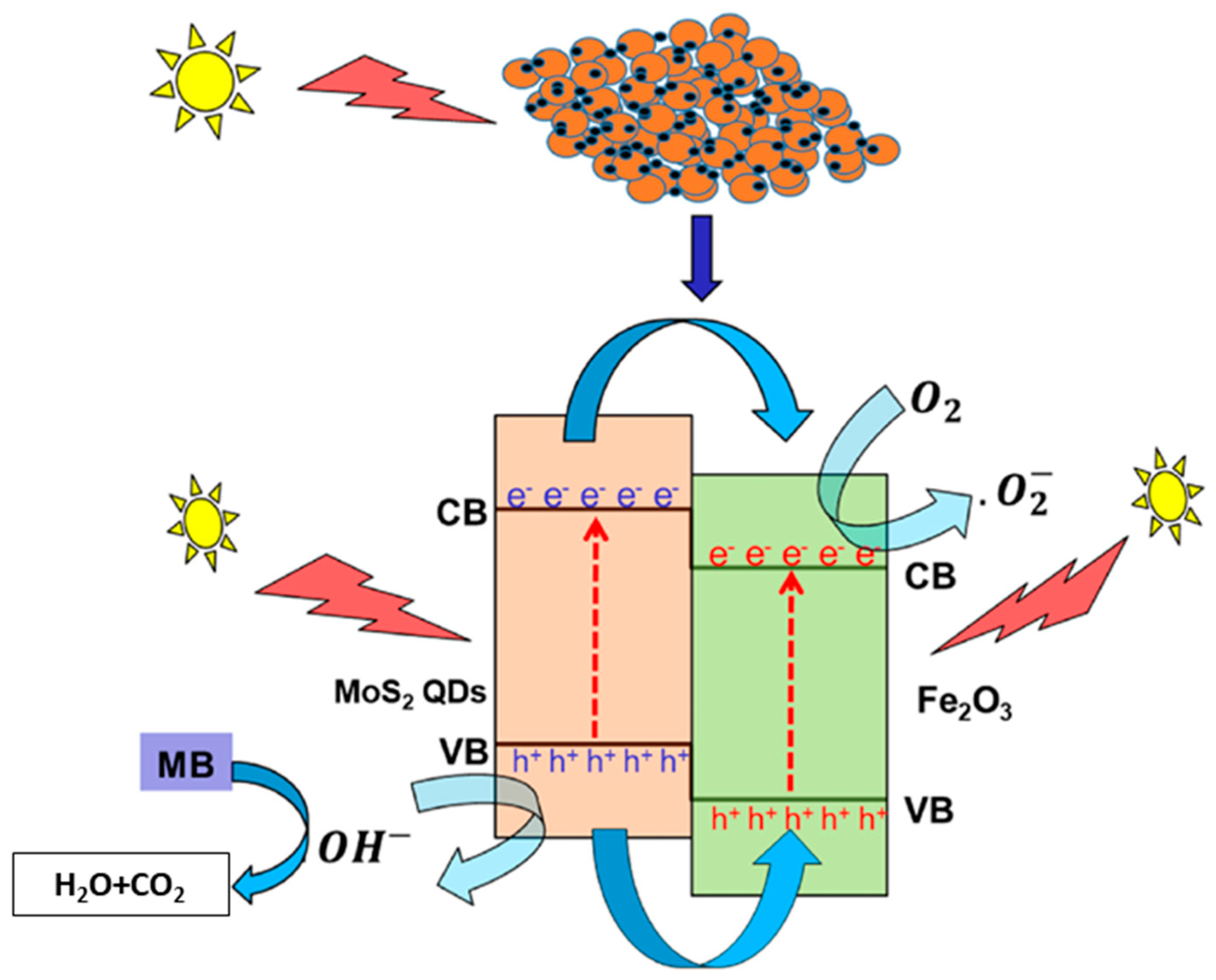

5. Photocatalytic Applications

6. MoS2-Based Nanocomposites

7. Reuse of MoS2-Based Composites for Adsorption and Photocatalysis

8. Application of MoS2-Based Composites in Real Environmental Samples

9. Environmental Impact of MoS2-Based Composites

10. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, D.; Yang, Y.; Xia, J. Hydrological cycle and water resources in a changing world: A review. Geogr. Sustain. 2021, 2, 115–122. [Google Scholar] [CrossRef]

- Chen, X.; Shuai, C.; Wu, Y.; Zhang, Y. Understanding the sustainable consumption of energy resources in global industrial sector: Evidences from 114 countries. Environ. Impact Assess. Rev. 2021, 90, 106609. [Google Scholar] [CrossRef]

- Hao, L.; Ju, P.; Zhang, Y.; Zhai, X.; Sun, C.; Duan, J.; Su, Y.; Lu, Z.; Liao, D. Fabrication of hierarchical flower-like BiOI/MoS2 heterostructures with highly enhanced visible-light photocatalytic activities. Colloids Surf. A Physicochem. Eng. Asp. 2021, 610, 125714. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, C.; Zhang, X.; Ngo, H.N.; Guo, W.; Zhang, M.; Zhang, D. Role of structural characteristics of MoS2 nanosheets on Pb2+ removal in aqueous solution. Environ. Technol. Innov. 2021, 22, 101385. [Google Scholar] [CrossRef]

- Shahid, M.K.; Kashif, A.; Fuwad, A.; Choi, Y. Current advances in treatment technologies for removal of emerging contaminants from water—A critical review. Coord. Chem. Rev. 2021, 442, 101385. [Google Scholar] [CrossRef]

- Soares, S.F.; Fernandes, T.; Trindade, T.; Daniel-da-Silva, A.L. Recent advances on magnetic biosorbents and their applications for water treatment. Environ. Chem. Lett. 2020, 18, 151–164. [Google Scholar] [CrossRef]

- Jaswal, A.; Kaur, M.; Singh, S.; Kansal, S.K.; Umar, A.; Garoufalis, C.S.; Baskoutas, S. Adsorptive removal of antibiotic ofloxacin in aqueous phase using rGO-MoS2 heterostructure. J. Hazard. Mater. 2021, 417, 125982. [Google Scholar] [CrossRef] [PubMed]

- Pandey, S.; Fosso-Kankeu, E.; Spiro, M.J.; Waanders, F.; Kumar, N.; Ray, S.S.; Kim, J.; Kang, M. Equilibrium, kinetic, and thermodynamic studies of lead ion adsorption from mine wastewater onto MoS2- clinoptilolite composite. Mater. Today Chem. 2020, 18, 100376. [Google Scholar] [CrossRef]

- Estrada, A.C.; Daniel-da-Silva, A.L.; Leal, C.; Monteiro, C.; Lopes, C.B.; Nogueira, H.I.S.; Lopes, I.; Martins, M.J.; Martins, N.C.T.; Gonçalves, N.P.F.; et al. Colloidal nanomaterials for water quality improvement and monitoring. Front. Chem. 2022, 10, 1011186. [Google Scholar] [CrossRef]

- Tan, C.; Cao, X.; Wu, X.J.; He, Q.; Yiang, J.; Zhang, X.; Chen, J.; Zhao, W.; Han, S.; Nam, G.H.; et al. Recent advances in ultrathin two-dimensional nanomaterials. Chem. Rev. 2017, 117, 6225–6331. [Google Scholar] [CrossRef]

- Darvishi, M.; Foroutan, M. Molecular investigation of water adsorption on MoS2 and graphene surfaces. J. Mol. Liq. 2017, 225, 1–10. [Google Scholar] [CrossRef]

- Singh, A.; Shirodkar, S.N.; Waghmare, U.V. 1H and 1T polymorphs, structural transitions and anomalous properties of (Mo,W) (S,Se)2 monolayers: First-principles analysis. 2D Mater. 2015, 2, 035013. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, Y.; Zhang, X.; Huang, X.; Liao, W.; Zhao, Y. MoS2-based membranes in water treatment and purification. Chem. Eng. J. 2021, 422, 130082. [Google Scholar] [CrossRef]

- Zhang, W.; Huang, J.K.; Chen, C.H.; Chang, Y.H.; Cheng, Y.J.; Li, L.J. High-gain phototransistors based on a CVD MoS2 monolayer. Adv. Mater. 2013, 25, 3456–3461. [Google Scholar] [CrossRef] [PubMed]

- Shan, J.; Li, J.; Chu, X.; Xu, M.; Jin, F.; Fang, X.; Wei, Z.; Wang, X. Enhanced photoresponse characteristics of transistors using CVD-grown MoS2/WS2 heterostructures. Appl. Surf. Sci. 2018, 443, 31–38. [Google Scholar] [CrossRef]

- Christinelli, W.A.; Shimizu, F.M.; Facure, M.H.M.; Cerri, R.; Oliveira Jr, O.N.; Correa, D.S.; Mattoso, L.H.C. Two-dimensional MoS2-based impedimetric electronic tongue for the discrimination of endocrine disrupting chemicals using machine learning. Sens. Actuators B Chem. 2021, 336, 129696. [Google Scholar] [CrossRef]

- Raadnui, S.; Mahathanabodee, S.; Tongsri, R.; Morakotjinda, M.; Wila, P. Comparison of dry sliding tribological behavior of SS 316L impregnated with MoS2 vs. h-BN solid lubricants: A statistical point of view. Wear 2021, 476, 203676. [Google Scholar] [CrossRef]

- Dawari, C.K.; Haq, I.; Mönkkönen, K.; Suvanto, M.; Saarinen, J.J. Reduced sliding friction on flat and microstructured metal injection molded (MIM) WC-Co hard metals with MoS2 composite lubricants. Tribol. Int. 2021, 160, 107020. [Google Scholar] [CrossRef]

- Kasinathan, K.; Marimuthu, K.; Murigesan, B.; Pandiyan, N.; Pandi, B.; Mahalingam, S.; Selvaraj, B. Cyclodextrin functionalized multi-layered MoS2 nanosheets and its biocidal activity against pathogenic bacteria and MCF-7 breast cancer cells: Synthesis, characterization and in-vitro biomedical evaluation. J. Mol. Liq. 2021, 323, 114631. [Google Scholar] [CrossRef]

- Sha, R.; Bhattacharyya, T.K. MoS2-based nanosensors in biomedical and environmental monitoring applications. Electrochim. Acta. 2020, 349, 136370. [Google Scholar] [CrossRef]

- Kumar, R.R.; Murugesan, T.; Dash, A.; Hsu, C.; Gupta, S.; Manikandan, A.; Anbalagan, A.k.; Lee, C.; Tai, N.; Chueh, Y.; et al. Ultrasensitive and light-activated NO2 gas sensor based on networked MoS2/ZnO nanohybrid with adsorption/desorption kinetics study. Appl. Surf. Sci. 2021, 536, 147933. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, W.; Wang, R.; Li, H.; Yan, J.; Jin, Q.; Feng, P.; Wang, K.; Jiang, K. Crystal water assisting MoS2 nanoflowers for reversible zinc storage. J. Alloys. Compd. 2021, 872, 159599. [Google Scholar] [CrossRef]

- Zhang, L.; Mu, L.; Zhou, Q.; Hu, X. Solar-assisted fabrication of dimpled 2H-MoS2 membrane for highly efficient water desalination. Water Res. 2020, 170, 115367. [Google Scholar] [CrossRef]

- Peng, W.; Wang, W.; Qi, M.; Miao, Y.; Huang, Y.; Yu, F. Enhanced capacitive deionization of defect-containing MoS2/graphene composites through introducing appropriate MoS2 defect. Electrochim. Acta. 2021, 383, 138363. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, S.; Zhang, D.; Yu, C.; Lu, J.; Wang, D.; Sun, J. Magnetically recyclable visible-light responsive MoS2@Fe3O4 photocatalysts targeting efficient wastewater treatment. J. Mater. Sci. 2018, 53, 1135–1147. [Google Scholar] [CrossRef]

- Zhu, Q.; Xu, Q.; Du, M.; Zeng, X.; Zhong, G.; Qiu, B.; Zhang, J. Recent progress of metal sulfide photocatalysts for solar energy conversion. Adv. Mater. 2022, 2202929. [Google Scholar] [CrossRef]

- Hasija, V.; Raizada, P.; Thakur, V.K.; Parwaz Khan, A.A.; Asiri, A.M.; Singh, P. An overview of strategies for enhancement in photocatalytic oxidative ability of MoS2 for water purification. J. Environ. Chem. Eng. 2020, 8, 104307. [Google Scholar] [CrossRef]

- Zhao, M.; Huang, Z.; Wang, S.; Zhang, L. Ultrahigh efficient and selective adsorption of Au(III) from water by novel Chitosan-coated MoS2 biosorbents: Performance and mechanisms. Chem. Eng. J. 2020, 401, 126006. [Google Scholar] [CrossRef]

- Yang, X.; Li, J.; Liang, T.; Ma, C.; Zhang, Y.; Chen, H.; Hanagata, N.; Su, H.; Xu, M. Antibacterial activity of two-dimensional MoS2 sheets. Nanoscale 2014, 6, 10126–10133. [Google Scholar] [CrossRef]

- Fan, J.; Li, Y.; Nguyen, H.N.; Yao, Y.; Rodrigues, D.F. Toxicity of exfoliated-MoS2 and annealed exfoliated-MoS2 towards planktonic cells, biofilms, and mammalian cells in the presence of electron donor. Environ. Sci. Nano. 2015, 2, 370–379. [Google Scholar] [CrossRef]

- Cheng, A.; Zhang, H.; Zhong, W.; Li, Z.; Tang, Y.; Li, Z. Enhanced electrochemical properties of single-layer MoS2 embedded in carbon nanofibers by electrospinning as anode materials for sodium-ion batteries. J. Electroanal. Chem. 2019, 843, 31–36. [Google Scholar] [CrossRef]

- Zhao, P.; Zheng, J.; Guo, P.; Jiang, Z.; Cao, L.; Wan, Y. Electronic and magnetic properties of Re-doped single-layer MoS2: A DFT study. Comput. Mater. Sci. 2017, 128, 287–293. [Google Scholar] [CrossRef]

- Gangwar, R.; Pandey, D.; Kancharlapalli, S.; Raychaudhuri, D.; Chakrabarti, A.; Banerjee, A.; Ghanti, T.K. Ab Initio Study of Adsorption of Fission Gas Atoms Xe and Kr on MoS2 Monolayer Functionalized with 3d Transition Metals. J. Phys. Chem. C. 2021, 125, 1493–1508. [Google Scholar] [CrossRef]

- Arefi-Oskoui, S.; Khataee, A.; Ucun, O.K.; Kobya, M.; Hanci, T.Ö.; Arslan-Alaton, I. Toxicity evaluation of bulk and nanosheet MoS2 catalysts using battery bioassays. Chemosphere 2021, 268, 128822. [Google Scholar] [CrossRef]

- Rani, A.; Singh, K.; Patel, A.S.; Chakraborti, A.; Kumar, S.; Ghosh, K.; Sharma, P. Visible light driven photocatalysis of organic dyes using SnO2 decorated MoS2 nanocomposites. Chem. Phys. Lett. 2020, 738, 136874. [Google Scholar] [CrossRef]

- Chang, M.J.; Cui, W.N.; Liu, J.; Wang, K.; Du, H.L.; Qiu, L.; Fan, S.M.; Luo, Z.M. Construction of novel TiO2/Bi4Ti3O12/MoS2 core/shell nanofibers for enhanced visible light photocatalysis. J. Mater. Sci. Technol. 2020, 36, 97–105. [Google Scholar] [CrossRef]

- Eda, G.; Yamaguchi, H.; Voiry, D.; Fujita, T.; Chen, M.; Chhowalla, M. Photoluminescence from chemically exfoliated MoS2. Nano Lett. 2011, 11, 5111–5116. [Google Scholar] [CrossRef]

- Radisavljevic, B.; Radenovic, A.; Brivio, J.; Giacometti, V.; Kis, A. Single-layer MoS2 transistors. Nat. Nanotechnol. 2011, 6, 147–150. [Google Scholar] [CrossRef]

- Han, Y.; Chen, P.; Zhang, C.; Dong, J.; Liu, H. The buckling behavior of single-layer MoS2 sheets with kirigami-inspired structures under compression. Comput. Mater. Sci. 2021, 188, 110188. [Google Scholar] [CrossRef]

- Splendiani, A.; Sun, L.; Zhang, Y.; Li, T.; Kim, J.; Chim, C.Y.; Galli, G.; Wang, F. Emerging photoluminescence in monolayer MoS2. Nano Lett. 2010, 10, 1271–1275. [Google Scholar] [CrossRef]

- Han, B.; Hu, Y.H. MoS2 as a co-catalyst for photocatalytic hydrogen production from water. Energy Sci. Eng. 2016, 4, 285–304. [Google Scholar] [CrossRef]

- Szary, M.J.; Michalewicz, M.T.; Radny, M.W. Giant spin splitting induced by a symmetry-braking van der Waals interaction. Appl. Surf. Sci. 2019, 494, 619–626. [Google Scholar] [CrossRef]

- Kumar, S.; Mishra, T. Shock wave induced exfoliation of molybdenum disulfide (MoS2) in various solvents: All-atom molecular dynamics simulation. J. Mol. Liq. 2020, 314, 113671. [Google Scholar] [CrossRef]

- Zhao, X.; Ning, S.; Fu, W.; Pennycook, S.J.; Loh, K.P. Differentiating polymorphs in molybdenum disulfide via electron microscopy. Adv. Mater. 2018, 30, 1802397. [Google Scholar] [CrossRef]

- Szary, M.J. Al doped MoS2 for adsorption-based water collection. Appl. Surf. Sci. 2020, 529, 147083. [Google Scholar] [CrossRef]

- Ramsdell, L.S. Studies on silicon carbide. Am. Mineral. 1947, 32, 64–82. [Google Scholar]

- Krishnan, U.; Kaur, M.; Singh, K.; Kumar, M.; Kumar, A. A synoptic review of MoS2: Synthesis to applications. Superlattices Microstruct. 2019, 128, 274–297. [Google Scholar] [CrossRef]

- Wang, Z.; Mi, B. Environmental Applications of 2D Molybdenum Disulfide (MoS2) Nanosheets. Environ. Sci. Technol. 2017, 51, 8229–8244. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, P.; Late, D.J.; Kumar, A.; Patel, S.; Singh, J. 2D layered transition metal dichalcogenides (MoS2): Synthesis, applications and theoretical aspects. Appl. Mater. Today 2018, 13, 242–270. [Google Scholar] [CrossRef]

- Evans, P.E.; Komesu, T.; Schwier, E.F.; Kumar, S.; Shimada, K.; Dowben, P.A. The band shifts in MoS2(0001) and WSe2(0001) induced by palladium adsorption. J. Phys. Condens. Matter. 2020, 32, 465001. [Google Scholar] [CrossRef]

- Yun, W.S.; Han, S.W.; Hong, S.C.; Kim, I.G.; Lee, J.D. Thickness and strain effects on electronic structures of transition metal dichalcogenides: 2H-MX2 semiconductors (M = Mo, W, X = S, Se, Te). Phys. Rev. B Condens. Matter. Mater. Phys. 2012, 85, 033305. [Google Scholar] [CrossRef]

- Tang, Q.; Jiang, D.E. Mechanism of hydrogen evolution reaction on 1T-MoS2 from first principles. ACS Catal. 2016, 6, 4953–4961. [Google Scholar] [CrossRef]

- Liu, Q.; Fang, Q.; Chu, W.; Wan, Y.; Li, X.; Xu, W.; Habib, M.; Tao, S.; Zhou, Y.; Liu, D.; et al. Electron-doped 1T-MoS2 via interface engineering for enhanced electrocatalytic hydrogen evolution. Chem. Mater. 2017, 29, 4738–4744. [Google Scholar] [CrossRef]

- Hu, T.; Li, R.; Dong, J. A new (2 × 1) dimerized structure of monolayer 1T-molybdenum disulfide, studied from first principles calculations. J. Chem. Phys. 2013, 139, 174702. [Google Scholar] [CrossRef]

- Wu, M.H.; Li, L.; Liu, N.; Wang, D.J.; Xue, Y.C.; Tang, L. Molybdenum disulfide (MoS2) as a co-catalyst for photocatalytic degradation of organic contaminants: A review. Process Saf. Environ. Prot. 2018, 118, 40–58. [Google Scholar]

- Kour, P.; Deeksha; Yadav, K. Electrochemical performance of mixed-phase 1T/2H MoS2 synthesized by conventional hydrothermal v/s microwave-assisted hydrothermal method for supercapacitor applications. J. Alloys. Compd. 2022, 922, 166194. [Google Scholar] [CrossRef]

- Mishra, S.; Maurya, P.K.; Mishra, A.K. 2H–MoS2 nanoflowers based high energy density solid state supercapacitor. Mater Chem Phys. 2020, 255, 123551. [Google Scholar] [CrossRef]

- Nie, C.; Yin, M.; Zhao, Y.; Zhao, C.; Zhang, B.; Song, X.; Yi, X.; Zhang, Y.; Luo, L.; Wang, S. Tailoring the fluorescent and electronic properties of 2H-MoS2 by step-by-step functionalization. J. Phys. Chem. C 2021, 125, 25739–25748. [Google Scholar] [CrossRef]

- Li, F.; Shen, T.; Xu, L.; Hu, C.; Qi, J. Strain improving the performance of a flexible monolayer MoS2 photodetector. Adv Electron Mater. 2019, 5, 1900803. [Google Scholar] [CrossRef]

- Bai, H.; Wu, Q.; Ai, H.; Liu, D.; Feng, J.; Ang, L.K.; Lu, Y.; Yang, M.; Pan, H. Interlayer-incorporation of MoS2 (TM-MoS2) to achieve unique magnetic and electronic properties for spintronics. Adv. Electron. Mater. 2022, 2200209. [Google Scholar] [CrossRef]

- Panasci, S.E.; Koos, A.; Schilirò, E.; Di Franco, S.; Greco, G.; Fiorenza, P.; Roccaforte, F.; Agnello, S.; Cannas, M.; Gelardi, F.M.; et al. Multiscale investigation of the structural, electrical and photoluminescence properties of MoS2 obtained by MoO3 sulfurization. Nanomaterials 2022, 12, 182. [Google Scholar] [CrossRef] [PubMed]

- Pradhan, G.; Sharma, A.K. Temperature controlled 1T/2H phase ratio modulation in mono- and a few layered MoS2 films. Appl. Surf. Sci. 2019, 479, 1236–1245. [Google Scholar] [CrossRef]

- Silambarasan, K.; Archana, J.; Harish, S.; Navaneethan, M.; Ganesh, R.S.; Ponnusamy, S.; Muthamizhchelvan, C.; Hara, K. One-step fabrication of ultrathin layered 1T@2H phase MoS2 with high catalytic activity based counter electrode for photovoltaic devices. J. Mater. Sci. Technol. 2020, 51, 94–101. [Google Scholar]

- Tan, D.; Willatzen, M.; Wang, Z.L. Prediction of strong piezoelectricity in 3R-MoS2 multilayer structures. Nano Energy 2018, 56, 512–515. [Google Scholar] [CrossRef]

- Strachan, J.; Masters, A.F.; Maschmeyer, T. 3R-MoS2 in review: History, status, and outlook. ACS Appl. Energy Mater. 2021, 4, 7405–7418. [Google Scholar] [CrossRef]

- Shi, J.; Yu, P.; Liu, F.; He, P.; Wang, R.; Qin, L.; Zhou, J.; Li, X.; Zhou, J.; Sui, X.; et al. 3R MoS2 with broken inversion symmetry: A promising ultrathin nonlinear optical device. Adv. Mater. 2017, 29, 1701486. [Google Scholar] [CrossRef] [PubMed]

- Anghel, S.; Chumakov, Y.; Kravtsov, V.; Volodina, G.; Mitioglu, A.; Plochocka, P.; Sushkevich, K.; Mishina, E.; Kulyuk, L. Site-selective luminescence spectroscopy of bound excitons and local band structure of chlorine intercalated 2H- and 3R-MoS2 polytypes. J. Lumin. 2016, 177, 331–336. [Google Scholar] [CrossRef]

- Chen, J.; Zhao, X.; Grinblat, G.; Chen, Z.; Tan, S.J.R.; Fu, W.; Ding, Z.; Abdelwahab, I.; Li, Y.; Geng, D.; et al. Homoepitaxial growth of large-scale highly organized transition metal dichalcogenide patterns. Adv. Mater. 2018, 30, 1704674. [Google Scholar] [CrossRef]

- Saber, M.R.; Khabiri, G.; Maarouf, A.A.; Ulbricht, M.; Khalil, A.S.G. A comparative study on the photocatalytic degradation of organic dyes using hybridized 1T/2H, 1T/3R and 2H MoS2 nano-sheets. RSC Adv. 2018, 8, 26364–26370. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Cao, J.; Zhou, J.; Wang, W.; Zhang, Y.; Liu, X. Computational screening for enhanced hydrogen sensing by doped-2H and pristine-1T MoS2. Chem. Phys. Lett. 2020, 749, 137450. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, Q.; Yang, J.; Feng, S.; Lei, M.; Quhe, R. Computational study of phase engineered transition metal dichalcogenides heterostructures. Comput. Mater. Sci. 2018, 142, 129–134. [Google Scholar] [CrossRef]

- Xiao, Y.; Tan, M.; Li, Z.; He, L.; Gao, B.; Chen, Y.; Zheng, Y.; Lin, B. Ethylenediamine-assisted phase engineering of 1T/2H–MoS2/graphene for efficient and stable electrocatalytic hydrogen evolution. Int. J. Hydrog. Energy 2021, 46, 11688–11700. [Google Scholar] [CrossRef]

- Pirarath, R.; Shivashanmugam, P.; Syed, A.; Elgorban, A.M.; Anandan, S.; Ashokkumar, M. Mercury removal from aqueous solution using petal-like MoS2 nanosheets. Front. Environ. Sci. Eng. 2021, 15, 1–10. [Google Scholar] [CrossRef]

- Zeng, M.; Yang, B.; Yan, H.; Qu, H.; Hu, Y. Efficient recovery of Ag(I) from aqueous solution using MoS2 nanosheets: Adsorption study and DFT calculation. Chem. Phys. Lett. 2020, 757, 137865. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, W.; Qiu, Y.; Yi, X.; Bussche, A.; Kane, A.; Gao, H.; Koski, K.; Hurt, R. Biological and environmental interactions of emerging two-dimensional nanomaterials. Chem. Soc. Rev. 2016, 45, 1750–1780. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.R.; Liu, Z.; Cheng, Z.L. A top-down exfoliation for MoS2 nanosheets based on Li+/Na+ -intercalated and shearing synergistic process. Mater. Lett. 2019, 248, 236–240. [Google Scholar] [CrossRef]

- Deepak, D.R.; Nair, M.G.; Halder, S.; Sharma, A.L.; Mohapatra, S.R. Liquid phase exfoliation of MoS2 nano-sheets and observation of resistive switching memory in MoS2 Nano-sheets-PVDF-HFP composite films. Mater. Today Proc. 2019, 18, 5447–5453. [Google Scholar] [CrossRef]

- Hai, N.Q.; Kwon, S.H.; Kim, H.; Kim, I.T.; Lee, S.G.; Hur, J. High-performance MoS2-based nanocomposite anode prepared by high-energy mechanical milling: The effect of carbonaceous matrix on MoS2. Electrochim. Acta. 2018, 260, 129–138. [Google Scholar] [CrossRef]

- Li, Y.; Yin, X.; Huang, X.; Liu, X.; Wu, W. Efficient and scalable preparation of MoS2 nanosheet/carbon nanotube composites for hydrogen evolution reaction. Int. J. Hydrog. Energy 2020, 45, 16489–16499. [Google Scholar] [CrossRef]

- Yang, X.; Chen, Z.; Fang, J.; Yang, Q.; Zhao, W.; Qian, X.; Liu, C.; Zhou, D.; Tao, S.; Liu, X. Efficient exfoliation to MoS2 nanosheets by salt-assisted refluxing and ultrasonication with photocatalytic application. Mater. Lett. 2019, 255, 126596. [Google Scholar] [CrossRef]

- Tsigkourakos, M.; Kainourgiaki, M.; Skotadis, E.; Giannakopoulos, K.P.; Tsoukalas, D.; Raptis, Y.S. Capping technique for chemical vapor deposition of large and uniform MoS2 flakes. Thin Solid Film 2021, 733, 138808. [Google Scholar] [CrossRef]

- Luo, S.; Cullen, C.P.; Guo, G.; Zhong, J.; Duesberg, G.S. Investigation of growth-induced strain in monolayer MoS2 grown by chemical vapor deposition. Appl. Surf. Sci. 2020, 508, 145126. [Google Scholar] [CrossRef]

- Luo, L.; Shi, M.; Zhao, S.; Tan, W.; Lin, X.; Wang, H.; Jiang, F. Hydrothermal synthesis of MoS2 with controllable morphologies and its adsorption properties for bisphenol A. J. Saudi Chem. Soc. 2019, 23, 762–773. [Google Scholar] [CrossRef]

- Shan, J.; Li, J.; Chu, X.; Xu, M.; Jin, F.; Wang, X.; Ma, L.; Fang, X.; Wei, Z.; Wang, X. High sensitivity glucose detection at extremely low concentrations using a MoS2-based field-effect transistor. RSC Adv. 2018, 8, 7942–7948. [Google Scholar] [CrossRef] [PubMed]

- Ambrosi, A.; Chia, X.; Sofer, Z.; Pumera, M. Enhancement of electrochemical and catalytic properties of MoS2 through ball-milling. Electrochem. Commun. 2015, 54, 36–40. [Google Scholar] [CrossRef]

- Tayyebi, A.; Ogino, N.; Hayashi, T.; Komatsu, N. Size-controlled MoS2 nanosheet through ball milling exfoliation: Parameter optimization, structural characterization and electrocatalytic application. Nanotechnology 2020, 31, 75704. [Google Scholar] [CrossRef]

- Ma, H.; Ben, S.; Shen, Z.; Zhang, X.; Wu, C.; Liao, S.; An, F. Investigating the exfoliation behavior of MoS2 and graphite in water: A comparative study. Appl. Surf. Sci. 2020, 512, 145588. [Google Scholar] [CrossRef]

- Manamel, L.T.; Mukherjee, A.; Das, B.C. Two-dimensional nanohybrid of MoS2 and Rose Bengal: Facile solution growth and band structure probing. Appl. Surf. Sci. 2020, 530, 147063. [Google Scholar] [CrossRef]

- Singla, R.; Kumar, S.; Hackett, T.A.; Reshak, A.H.; Kashyap, M.K. Genesis of magnetism in graphene/MoS2 van der Waals heterostructures via interface engineering using Cr-adsorption. J. Alloys Compd. 2021, 859, 157776. [Google Scholar] [CrossRef]

- Li, H.; Zhu, X.; Tang, Z.K.; Zhang, X.H. Low-temperature photoluminescence emission of monolayer MoS2 on diverse substrates grown by CVD. J. Lumin. 2018, 199, 210–215. [Google Scholar] [CrossRef]

- Park, H.J.; Kim, M.S.; Kim, J.; Joo, J. Photo-responsive transistors of CVD grown single-layer MoS2 and its nanoscale optical characteristics. Curr. Appl. Physics 2016, 16, 1320–1325. [Google Scholar] [CrossRef]

- Khabiri, G.; Aboraia, A.M.; Soliman, M.; Guda, A.A.; Butova, V.V.; Yahia, I.S.; Soldatov, A.V. A novel α-Fe2O3@MoS2QDs heterostructure for enhanced visible-light photocatalytic performance using ultrasonication approach. Ceram. Int. 2020, 46, 19600–19608. [Google Scholar] [CrossRef]

- Gang, R.; Xu, L.; Xia, Y.; Cai, J.; Zhan, L.; Wang, S.; Li, R. Fabrication of MoS2 QDs/ZnO nanosheet 0D/2D heterojunction photocatalysts for organic dyes and gaseous heavy metal removal. J. Colloid. Interface Sci. 2020, 579, 853–861. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, Y.; Xing, H.; Yang, X.; Zong, Y.; Feng, J.; Zhu, X.; Shi, Z.; Li, X.; Zheng, X. Construction of flower-like core-shell Fe3O4@2H-MoS2 heterostructures: Boosting the interfacial polarization for high-performance microwave absorption. Ceram Int. 2022, 48, 9918–9926. [Google Scholar] [CrossRef]

- Wu, Y.; Su, M.; Chen, J.; Xu, Z.; Tang, J.; Chang, X.; Chen, D. Superior adsorption of methyl orange by h-MoS2 microspheres: Isotherm, kinetics, and thermodynamic studies. Dye. Pigment. 2019, 170, 1–8. [Google Scholar] [CrossRef]

- Liu, P.; Cai, S.; Zuo, Y.; Tian, M.; Wang, Z.; Ling, L.; Sun, X. Synthesis of interlayer expanded MoS2 by sulfurization of MoO3 with enhanced sodium-ion storage. J Alloys Compd. 2022, 895, 162691. [Google Scholar] [CrossRef]

- Ai, K.; Ruan, C.; Shen, M.; Lu, L. MoS2 nanosheets with widened interlayer spacing for high-efficiency removal of mercury in aquatic systems. Adv. Funct. Mater. 2016, 26, 5542–5549. [Google Scholar] [CrossRef]

- Yuan, W.; Kuang, J.; Yu, M.; Huang, Z.; Zou, Z.; Zhu, L. Facile preparation of MoS2@Kaolin composite by one-step hydrothermal method for efficient removal of Pb(II). J. Hazard. Mater. 2021, 405, 124261. [Google Scholar] [CrossRef]

- Mário, E.D.A.; Liu, C.; Ezugwu, C.I.; Mao, S.; Jia, F.; Song, S. Molybdenum disulfide/montmorillonite composite as a highly efficient adsorbent for mercury removal from wastewater. Appl. Clay. Sci. 2020, 184, 105370. [Google Scholar] [CrossRef]

- Song, H.J.; You, S.; Jia, X.H.; Yang, J. MoS2 nanosheets decorated with magnetic Fe3O4 nanoparticles and their ultrafast adsorption for wastewater treatment. Ceram. Int. 2015, 41, 13896–13902. [Google Scholar] [CrossRef]

- Chen, Y.; Song, B.; Tang, X.; Lu, L.; Xue, J. Ultrasmall Fe3O4 nanoparticle/MoS2 nanosheet composites with superior performances for lithium ion batteries. Small 2014, 10, 1536–1543. [Google Scholar] [CrossRef] [PubMed]

- Xin, X.; Song, Y.; Guo, S.; Zhang, Y.; Wang, B.; Wang, Y.; Li, X. One-step synthesis of P-doped MoS2 for efficient photocatalytic hydrogen production. J. Alloys. Compd. 2020, 829, 154635. [Google Scholar] [CrossRef]

- Liu, F.; Wang, N.; Shi, C.; Sha, J.; Ma, L.; Liu, E.; Zhao, N. Phosphorus doping of 3D structural MoS2 to promote catalytic activity for lithium-sulfur batteries. Chem. Eng. J. 2022, 431, 133923. [Google Scholar] [CrossRef]

- Li, J.; He, T.; Zhao, Y.; Zhang, X.; Zhong, W.; Zhang, X.; Ren, J.; Chen, Y. In-situ N-doped ultrathin MoS2 anchored on N-doped carbon nanotubes skeleton by Mo-N bonds for fast pseudocapacitive sodium storage. J Alloys Compd. 2022, 897, 163170. [Google Scholar] [CrossRef]

- Zhang, Z.; Dong, Y.; Liu, G.; Li, J.; Sun, H.; Luo, H.; Liu, S. The ultrafine monolayer 1 T/2H-MoS2: Preparation, characterization and amazing photocatalytic characteristics. Colloids Surf. A Phys. Eng. Asp. 2020, 589, 124431. [Google Scholar] [CrossRef]

- Luo, N.; Chen, C.; Yang, D.; Hu, W.; Dong, F. S defect-rich ultrathin 2D MoS2: The role of S point-defects and S stripping-defects in the removal of Cr(VI) via synergistic adsorption and photocatalysis. Appl. Catal. B. 2021, 299, 120664. [Google Scholar] [CrossRef]

- Liu, S.; Nie, C.; Zhou, D.; Shen, J.; Feng, S. Direct growth of vertical structure MoS2 nanosheets array film via CVD method for photodetection. Physica E Low Dimens. Syst. Nanostruct. 2020, 117, 113592. [Google Scholar] [CrossRef]

- Cui, B.; Cai, X.; Wang, W.; Saha, P.; Wang, G. Nano storage-boxes constructed by the vertical growth of MoS2 on graphene for high-performance Li-S batteries. J. Energy Chem. 2022, 66, 91–99. [Google Scholar] [CrossRef]

- Zhi, L.; Zuo, W.; Chen, F.; Wang, B. 3D MoS2 composition aerogels as chemosensors and adsorbents for colorimetric detection and high-capacity adsorption of Hg2+. ACS Sustain. Chem. Eng. 2016, 4, 3398–3408. [Google Scholar] [CrossRef]

- Zhuang, Y.T.; Zhang, X.; Wang, D.H.; Yu, Y.L.; Wang, J.H. Three-dimensional molybdenum disulfide/graphene hydrogel with tunable heterointerfaces for high selective Hg(II) scavenging. J. Colloid. Interface Sci. 2018, 514, 715–722. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; Wen, T.; Liu, X.; Wang, Y.; Yang, H.; Sun, J.; Feng, J.; Dong, S.; Sun, J. Highly effective remediation of Pb(II) and Hg(II) contaminated wastewater and soil by flower-like magnetic MoS2 nanohybrid. Sci. Total Environ. 2020, 699, 134341. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Zhang, Z.; Zhong, X.; Zhuo, Z.; Tian, S.; Fu, S.; Chen, Y.; Liu, Y. Constructing MoS2/Lignin derived carbon nanocomposites for highly efficient removal of Cr(VI) from aqueous environment. J. Hazard. Mater. 2021, 408, 124847. [Google Scholar] [CrossRef] [PubMed]

- Gao, D.; Zhang, Y.; Yan, H.; Li, B.; He, Y.; Song, P.; Wang, R. Construction of UiO-66@MoS2 flowerlike hybrids through electrostatically induced self-assembly with enhanced photodegradation activity towards lomefloxacin. Sep. Purif. Technol. 2021, 265, 118486. [Google Scholar] [CrossRef]

- Shi, W.; Chu, Y.; Xia, M.; Wang, F.; Fu, C. The adsorption performance and micro-mechanism of MoS2/montmorillonite composite to atenolol and acebutolol: Adsorption experiments and a novel visual study of interaction. Ecotoxicol. Environ. Saf. 2021, 213, 111993. [Google Scholar] [CrossRef] [PubMed]

- Jayadharan Salini, A.N.; Ramachandran, A.; Sadasivakurup, S.; Yesodha, S.K. Versatile MoS2 hollow nanoroses for a quick-witted removal of Hg (II), Pb (II) and Ag (I) from water and the mechanism: Affinity or Electrochemistry? Appl. Mater. Today 2020, 20, 100642. [Google Scholar] [CrossRef]

- Prieto-Rodriguez, L.; Miralles-Cuevas, S.; Oller, I.; Agüera, A.; Puma, G.L.; Malato, S. Treatment of emerging contaminants in wastewater treatment plants (WWTP) effluents by solar photocatalysis using low TiO2 concentrations. J. Hazard. Mater. 2012, 211–212, 131–137. [Google Scholar] [CrossRef] [PubMed]

- Yuan, Y.J.; Lu, H.W.; Yu, Z.T.; Zou, Z.G. Noble-metal-free molybdenum disulfide cocatalyst for photocatalytic hydrogen production. Chem. Sus. Chem. 2015, 8, 4113–4127. [Google Scholar] [CrossRef]

- Chen, L.; Chuang, Y.; Nguyen, T.B.; Chang, J.H.; Lam, S.S.; Chen, C.W.; Dong, C.D. Novel molybdenum disulfide heterostructure nanohybrids with enhanced visible-light-induced photocatalytic activity towards organic dyes. J. Alloys. Compd. 2020, 848, 156448. [Google Scholar] [CrossRef]

- Abraham, T.; Priyanka, R.N.; Joseph, S.; Plathanam, N.J.; Gigimol, M.G.; Mathew, B. Flower-like MoS2/BiFeO3 doped silver orthophosphate catalyst for visible-light assisted treatment of refractory organic pollutants. Appl. Mater. Today 2020, 21, 100845. [Google Scholar] [CrossRef]

- Fu, Y.; Ren, Z.; Wu, J.; Li, Y.; Liu, W.; Li, P.; Xing, L.; Ma, J.; Wang, H.; Xue, X. Direct Z-scheme heterojunction of ZnO/MoS2 nanoarrays realized by flowing-induced piezoelectric field for enhanced sunlight photocatalytic performances. Appl. Catal. B Environ. 2021, 285, 119785. [Google Scholar] [CrossRef]

- Quan, Y.; Su, R.; Hu, M.; Lang, J.; Fan, H.; Shen, H.; Gao, M.; Li, B.; Liu, Y.; Yang, J. Construction of an MZO heterojunction system with improved photocatalytic activity for degradation of organic dyes. Cryst. Eng. Comm. 2020, 22, 7059–7065. [Google Scholar] [CrossRef]

- Guo, P.; Zhao, F.; Hu, X. Fabrication of a direct Z-scheme heterojunction between MoS2 and B/Eu-g- C3N4 for an enhanced photocatalytic performance toward tetracycline degradation. J. Alloys. Compd. 2021, 867, 159044. [Google Scholar] [CrossRef]

- Ahamad, T.; Naushad, M.; Alzaharani, Y.; Alshehri, S.M. Photocatalytic degradation of bisphenol-A with g-C3N4/MoS2-PANI nanocomposite: Kinetics, main active species, intermediates and pathways. J. Mol. Liq. 2020, 311, 113339. [Google Scholar] [CrossRef]

- Putritama, V.; Fauzia, V.; Supangat, A. The effect of the layer number of MoS2 nanosheets on the photocatalytic efficiency of ZnO/MoS2. Surf. Interfaces 2020, 21, 100745. [Google Scholar] [CrossRef]

- Liang, H.; Bai, J.; Xu, T.; Li, C. Enhancing photocatalytic performance of heterostructure MoS2/g-C3N4 embeded in PAN frameworks by electrospining process. Mater. Sci. Semicond. Process 2021, 121, 105414. [Google Scholar] [CrossRef]

- Zhang, X.; Xia, M.; Wang, F.; Lei, W. Cu2O/MoS2 composites: A novel photocatalyst for photocatalytic degradation of organic dyes under visible light. Ionics 2020, 26, 6359–6369. [Google Scholar] [CrossRef]

- Mahalakshmi, G.; Rajeswari, M.; Ponnarasi, P. Fabrication of dandelion clock-inspired preparation of core-shell TiO2@MoS2 composites for unprecedented high visible light-driven photocatalytic performance. J. Mater. Sci. Mater. Electron. 2020, 31, 22252–22264. [Google Scholar] [CrossRef]

- Mahalakshmi, G.; Rajeswari, M.; Ponnarasi, P. Synthesis of few-layer g-C3N4 nanosheets-coated MoS2/TiO2 heterojunction photocatalysts for photo-degradation of methyl orange (MO) and 4-nitrophenol (4-NP) pollutants. Inorg. Chem. Commun. 2020, 120, 108146. [Google Scholar] [CrossRef]

- Adhikari, S.; Mandai, S.; Kim, D.H. Free-standing Ag nanoparticle-decorated MoS2 microflowers grown on carbon cloth for photocatalytic oxidation of Rhodamine, B. Korean J. Chem. Eng. 2020, 37, 2359–2367. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, S.; Liu, Y.; Zhang, Y.; Xia, J.; Yang, Q. TiO2 coupled to predominantly metallic MoS2 for photocatalytic degradation of rhodamine B. J. Mater. Sci. 2020, 55, 12274–12286. [Google Scholar] [CrossRef]

- Kumaresan, N.; Karuppasamy, P.; Pandian, M.S.; Ramasamy, P. Formation of face-contact interaction in 2D/2D/2D heterostructure ternary nanocomposites of g-C3N4/MoS2/GO for effective photocatalytic activity against the organic pollutants under the visible light irradiation. J. Mater. Sci. Mater. Electron. 2022, 33, 11970–11988. [Google Scholar] [CrossRef]

- Rao Akshatha, S.; Sreenivasa, S.; Parashuram, L.; Raghu, M.S.; Yogesh Kumar, K.; Madhu Chakrapani Rao, T. Visible-light-induced photochemical hydrogen evolution and degradation of crystal violet dye by interwoven layered MoS2/Wurtzite ZnS Heterostructure Photocatalyst. Chem. Select. 2020, 5, 6918–6926. [Google Scholar]

- Jaleel, U.C.J.R.; Devi, K.R.S.; Madhushree, R.; Pinheiro, D. Statistical and experimental studies of MoS2/g-C3N4/TiO2: A ternary Z-scheme hybrid composite. J. Mater. Sci. 2021, 56, 6922–6944. [Google Scholar] [CrossRef]

- Shi, Z.; Zhang, Y.; Duoerkun, G.; Cao, W.; Liu, T.; Zhang, L.; Liu, J.; Li, M.; Chen, Z. Fabrication of MoS2/BiOBr heterojunctions on carbon fibers as a weaveable photocatalyst for tetracycline hydrochloride 65 degradation and Cr (VI) reduction under visible light. Environ. Sci. Nano. 2020, 7, 2708–2722. [Google Scholar] [CrossRef]

- Guo, J.; Yang, C.; Sun, Z.; Yang, Z.; Wang, L.; Lu, C.; Ma, Z.; Guo, F. Ternary Fe3O4/MoS2/BiVO4 nanocomposites: Novel magnetically separable visible light-driven photocatalyst for efficiently degradation of antibiotic wastewater through p–n heterojunction. J. Mater. Sci. Mater. Electron. 2020, 31, 16746–16758. [Google Scholar] [CrossRef]

- Liu, J.; Lin, H.; He, Y.; Dong, Y.; Rose, E.; Menzembere, G.Y. Novel CoS2/MoS2@Zeolite with excellent adsorption and photocatalytic performance for tetracycline removal in simulated wastewater. J. Clean. Prod. 2020, 260, 121047. [Google Scholar] [CrossRef]

- Chen, L.; Huang, C.P.; Chuang, Y.; Nguyen, T.B.; Chen, C.W.; Dong, C.D. Z-Scheme MoS2/TiO2/graphene nanohybrid photocatalysts for visible light-induced degradation for highly efficient water disinfection and antibacterial activity. New J. Chem. 2022, 46, 14159–14169. [Google Scholar] [CrossRef]

- Chen, L.; Chuang, Y.; Chen, C.W.; Dong, C.D. Facile synthesis of MoS2/ZnO quantum dots for enhanced visible-light photocatalytic performance and antibacterial applications. Nano Struct. Nano Objects 2022, 30, 100873. [Google Scholar] [CrossRef]

- Vaizoğullar, A.İ. Ternary CdS/MoS2/ZnO photocatalyst: Synthesis, characterization and degradation of ofloxacin under visible light irradiation. J. Inorg. Organomet. Polym. Mater. 2020, 30, 4129–4141. [Google Scholar] [CrossRef]

- Zou, X.; Zhao, X.; Zhang, J.; Lv, W.; Qiu, L.; Zhang, Z. Photocatalytic degradation of ranitidine and reduction of nitrosamine dimethylamine formation potential over MXene–Ti3C2/MoS2 under visible light irradiation. J. Hazard. Mater. 2021, 413, 125424. [Google Scholar] [CrossRef]

- Ghasemipour, P.; Fattahi, M.; Rasekh, B.; Yazdian, F. Developing the ternary ZnO doped MoS2 nanostructures grafted on CNT and reduced graphene oxide (RGO) for photocatalytic degradation of aniline. Sci. Rep. 2020, 10, 4414. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, X.; Liu, Z.; Yan, Y.; Yang, B.; Zhu, Z. Fabrication of a Z-scheme MoS2/CuO heterojunction for enhanced 2-mercaptobenzothiazole degradation activity and mechanism insight. New J. Chem. 2020, 44, 18264–18273. [Google Scholar] [CrossRef]

- Sajjad, M.; Tahir, M.B.; Mubeen, I.; Kabli, M.R. Tailorable and rationally designed MoS2 based heterostructure photocatalyst for efficient photocatalytic degradation of phenol under the visible light. J. Inorg. Organomet. Polym. Mater. 2020, 30, 3965–3972. [Google Scholar] [CrossRef]

- Bhati, A.; Anand, S.R.; Saini, D.; Gunture, S.; Sonkar, K. Sunlight-induced photoreduction of Cr(VI) to Cr(III) in wastewater by nitrogen-phosphorus-doped carbon dots. NPJ Clean Water 2019, 2, 12. [Google Scholar] [CrossRef]

- Kumari, A.; Chaudhary, D.R. Engineered microbes and evolving plastic bioremediation technology. INC. 2020, 417–443. [Google Scholar]

- Somasundar, Y.; Burton, A.E.; Mills, M.R.; Zhang, D.Z.; Ryabov, A.D.; Collins, T.J. Quantifying evolving toxicity in the TAML/peroxide mineralization of propranolol. iScience 2021, 24, 101897. [Google Scholar] [CrossRef]

- Zeng, Z.; Ye, S.; Wu, H.; Xiao, R.; Zeng, G.; Liang, J.; Zhang, C.; Yu, J.; Fang, Y.; Song, B. Research on the sustainable efficacy of g-MoS2 decorated biochar nanocomposites for removing tetracycline hydrochloride from antibiotic-polluted aqueous solution. Sci. Total Environ. 2019, 648, 206–217. [Google Scholar] [CrossRef]

- Huang, S.; Chen, C.; Tsai, H.; Shaya, J.; Lu, C. Photocatalytic degradation of thiobencarb by a visible light-driven MoS2 photocatalyst. Sep. Purif. Technol. 2018, 197, 147–155. [Google Scholar] [CrossRef]

- Chandrabose, G.; Dey, A.; Gaur, S.S.; Pitchaimuthu, S.; Jagadeesan, H.; Braithwaite, N.J.; Selvaraj, V.; Kumar, V.; Krishnamurthy, S. Removal and degradation of mixed dye pollutants by integrated adsorption photocatalysis technique using 2-D MoS2/TiO2 nanocomposite. Chemosphere 2021, 279, 130467. [Google Scholar] [CrossRef]

- Saleh, T.A. Trends in the sample preparation and analysis of nanomaterials as environmental contaminants. Trends Environ. Anal. Chem. 2020, 28, e00101. [Google Scholar] [CrossRef]

- Louie, S.M.; Ma, R.; Lowry, G.V. Transformations of nanomaterials in the environment. Front. Nanosci. 2014, 7, 55–87. [Google Scholar]

- Cicuéndez, M.; Silva, V.S.; Santos, J.; Coimbra, A.; Oliveira, H.; Ayán-Varela, M.; Paredes, J.I.; VillarRodil, S.; Vila, M. MoS2 flakes stabilized with DNA/RNA nucleotides: In vitro cell response. Mater. Sci. Eng. C 2019, 100, 11–22. [Google Scholar] [CrossRef]

| Composite | MoS2 Preparation Method | Adsorption Compound | Temperature (°C) | Adsorption Kinetics | Adsorption Isotherms | Ref. | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| PFO | PSO | Langmuir | Freundlich | ||||||||

| Metal species | |||||||||||

| MoS2 | HT | Hg(II) | 27 | qe (mg/g) | 208.5 | 303 | [73] | ||||

| k1 (min−1) | 0.032 | - | |||||||||

| k2 (g/(mg min)) | - | 2.710 | |||||||||

| R2 | 0.941 | 0.998 | |||||||||

| Au/Fe3O4/MoS2CAs | Commercial | Hg(II) | qe (mg/g) | 0.479 | 20.408 | qm (mg/g) | 1527 | n | 3.040 | [109] | |

| k1 (min−1) | 0.089 | - | KL (L/mg) | 0.083 | KF (mg/g) | 200.85 | |||||

| k2 (g/(mg min)) | - | 1.2 | R2 | 0.999 | R2 | 0.774 | |||||

| R2 | 0.779 | 0.999 | |||||||||

| 3D MoS2-rGO | HT | Hg(II) | 25 | qe (mg/g) | 30.55 | qm (mg/g) | 400 | n | 1.046 | [110] | |

| k1 (min−1) | 0.117 | - | KL (L/mg) | 65.68 | KF (mg/g) | 5.936 | |||||

| k2 (g/(mg min)) | - | 3.75 × 10−3 | R2 | 0.9998 | R2 | 0.999 | |||||

| R2 | 0.785 | 0.999 | |||||||||

| W-DR-N-MoS2 | HT | Hg(II) | qe (mg/g) | - | - | qm (mg/g) | 2562.8 | n | [97] | ||

| k1 (min−1) | - | - | KL (L/mg) | 3.029 | KF (mg/g) | ||||||

| k2 (g/(mg min)) | - | 1.42 | R2 | 0.999 | R2 | ||||||

| R2 | - | 0.9999 | |||||||||

| MoS2/Fe3O4 | HT | Hg(II) | 25 | qe (mg/g) | 84.46 | 254.3 | qm (mg/g) | 428.9 | N | 198.8 | [111] |

| k1 (min−1) | 0.142 | - | KL (L/mg) | 1.586 | KF (mg/g) | 5.085 | |||||

| k2 (g/(mg min)) | - | 3.9 × 10−3 | R2 | 1.000 | R2 | 0.723 | |||||

| R2 | 0.922 | 1.000 | |||||||||

| MoS2/MMT | HT | Hg(II) | 35 | qe (mg/g) | 1119.9 | 1390.81 | qm (mg/g) | 2055.9 | n | 0.759 | [99] |

| k1 (min−1) | 5.426 × 10−3 | - | KL (L/mg) | 0.030 | KF (mg/g) | 3.204 | |||||

| k2 (g/(mg min)) | - | 3.840 × 10−6 | R2 | 0.944 | R2 | 0.838 | |||||

| R2 | 0.982 | 0.96089 | |||||||||

| MoS2-clinoptilolite | Commercial | Pb(II) | 25 | qe (mg/g) | 1.317 | 50 | qm (mg/g) | 3.45 | n | 2.048 | [8] |

| k1 (min−1) | 6.17 × 10−2 | - | KL (L/mg) | 0.38 | KF (mg/g) | 1.527 | |||||

| k2 (g/(mg min)) | - | 2.0 × 10−2 | R2 | 0.964 | R2 | 0.837 | |||||

| R2 | 0.723 | 1.000 | |||||||||

| MoS2/Fe3O4 | HT | Pb(II) | 25 | qe (mg/g) | 119.1 | 199.3 | qm (mg/g) | 263.6 | n | 61.62 | [111] |

| k1 (min−1) | 0.011 | - | KL (L/mg) | 0.1468 | KF (mg/g) | 3.354 | |||||

| k2 (g/(mg min)) | - | 1.7 × 10−4 | R2 | 1.000 | R2 | 0.841 | |||||

| R2 | 0.919 | 0.922 | |||||||||

| MoS2-kaolin | HT | Pb(II) | 25 | qe (mg/g) | 12.23 | 65.94 | qm (mg/g) | 280.39 | n | 5.71 | [98] |

| k1 (min−1) | −0.086 | KL (L/mg) | 2.93 | KF (mg/g) | 105.43 | ||||||

| k2 (g/(mg min)) | 0.015 | R2 | 0.863 | R2 | 0.790 | ||||||

| R2 | 0.0484 | 0.9922 | |||||||||

| MoS2/LDC | HT | Cr(IV) | 25 | qe (mg/g) | 7.65 | 204.08 | qm (mg/g) | 306.85 | n | 8.333 | [112] |

| k1 (min−1) | 1.4 × 10−2 | - | KL (L/mg) | 0.97 | KF (mg1-n Ln/g) | 20.73 | |||||

| k2 (g/(mg min)) | - | 4 × 10−4 | R2 | 0.86 | R2 | 0.76 | |||||

| R2 | 0.68 | 0.999 | |||||||||

| 2D MoS2 | HT | Ag(I) | 25 | qe (mg/g) | 392.73 | 410.24 | qm (mg/g) | 813.01 | n | 3.62 | [74] |

| k1 (min−1) | 0.921 | - | KL (L/mg) | 0.12 | KF (mg/g) | 206.51 | |||||

| k2 (g/(mg min)) | - | 3.0 × 10−3 | R2 | 0.999 | R2 | 0.911 | |||||

| R2 | 0.988 | 0.997 | |||||||||

| chitosan-coated MoS2 1:2 | Precipitation method | Au(III) | 30 | qe (mg/g) | 1230.84 | 1338.55 | qm (mg/g) | 3434.96 | n | 807.74 | [28] |

| k1 (min−1) | 0.074 | - | KL (L/mg) | 0.043 | KF (mg/g) | 3.857 | |||||

| k2 (g/(mg min)) | - | 6.45 × 10−5 | R2 | 0.991 | R2 | 0.938 | |||||

| R2 | 0.724 | 0.901 | |||||||||

| Organic Contaminants | |||||||||||

| MoS2 | HT | Bisphenol A | 25 | qe (mg/g) | 28.57 | 30.25 | qm (mg/g) | n | [83] | ||

| k1 (min−1) | - | - | KL (L/mg) | KF (mg/g) | |||||||

| k2 (g/(mg min)) | - | - | R2 | R2 | |||||||

| R2 | 0.901 | 0.998 | |||||||||

| rGO/MoS2 | HT | Ofloxacin | qe (mg/g) | - | 43.104 | qm (mg/g) | 37.31 | n | 3.84 | [7] | |

| k1 (min−1) | - | - | KL (L/mg) | 0.46 | KF (mg/g) | 15.07 | |||||

| k2 (g/(mg min)) | - | 2.69 × 10−4 | R2 | 0.989 | R2 | 0.845 | |||||

| R2 | - | 0.918 | |||||||||

| UiO−66/MoS2 | HT | Lomefloxanin | qe (mg/g) | 45.6 | 80.67 | qm (mg/g) | 32.36 | n | 5.152 | [113] | |

| k1 (min−1) | 0.2434 | - | KL (L/mg) | 0.28606 | KF (mg/(g(L/mg)1/n)) | 14.957 | |||||

| k2 (g/(mg min)) | - | 1.7 × 10−4 | R2 | 0.786 | R2 | 0.940 | |||||

| R2 | 0.974 | 0.973 | |||||||||

| MoS2/MTT | HT | Atenolol | 25 | qe (mg/g) | 88.85 | 96.62 | qm (mg/g) | 145.6 | n | 3.363 | [114] |

| k1 (min−1) | 0.151 | - | KL (L/mg) | 0.197 | KF (L/g) | 41.38 | |||||

| k2 (g/(mg min)) | - | 2.364 × 10−3 | R2 | 0.974 | R2 | 0.859 | |||||

| R2 | 0.957 | 0.991 | |||||||||

| MoS2/MTT | HT | Acebutolol | 25 | qe (mg/g) | 63.85 | 69.25 | qm (mg/g) | 130.8 | n | 2.772 | [114] |

| k1 (min−1) | 0.287 | - | KL (L/mg) | 0.107 | KF (L/g) | 25.42 | |||||

| k2 (g/(mg min)) | - | 5.617 × 10−3 | R2 | 0.945 | R2 | 0.831 | |||||

| R2 | 0.829 | 0.982 | |||||||||

| h-MoS2 | HT | MO | 25 | qe (mg/g) | 12.86 | 42.44 | qm (mg/g) | 38.11 | n | 1.897 | [91] |

| k1 (min−1) | 0.518 | - | KL (L/mg) | 0.285 | KF (mg/(g(L/mg)1/n)) | 5.342 | |||||

| k2 (g/(mg min)) | - | 9.35 × 10−3 | R2 | 0.952 | R2 | 0.992 | |||||

| R2 | 0.848 | 0.999 | |||||||||

| MoS2-Based Catalyst | Contaminant | MoS2 Production Method | Band Gap (eV) | CSA (m2/g) | Irradiation | Irradiation Time (min) | Removal Rate | PFO Kinetics k (min−1) | Ref. |

|---|---|---|---|---|---|---|---|---|---|

| Dyes | |||||||||

| α-Fe2O3/MoS2QDs | MB | HT | 2.22 | 5.852 | Vis (400–700 nm) | 1 120 | 83% 91% | 1st min 0.892 > 28 min 0.0049 | [92] |

| MoS2/ZnO | MB | HT | - | 14.785 | Vis | 40 | 97% | 0.0701 | [121] |

| 5 wt% MoS2/BiFeO3/Ag3PO4 | MB | C | 2.07 | 7.705 | UV-Vis | 5 | 97% | 0.625 | [119] |

| ZnO/MoS2 8 h | MB | LPE | 1.77 | - | UV-Vis | 37.5 | Vis-85% UV-78% | - | [124] |

| Ni foam with ZnO/MoS2 | MB | HT | - | 4.85 | UV-Vis | 50 | 72% | - | [120] |

| 1.9% MoS2/g-C3N4/PAN | MB | HT | 2.76 | 15.6 | Vis (>420 nm) | 120 | 85% | - | [125] |

| MoS2/Fe3O4 (MF-17) | MB | HT | - | 4,5 | Vis | 120 | 98% | - | [25] |

| CM12 (Cu2O/MoS2) | MB | HT | Cu2O—2.15 MoS2—1.76 | - | Vis (>420 nm) | 30 | 90% | 0.084 | [126] |

| MoS2-TiO2 | MO | HT | 2.76 | 103.5 | - | 60 | 86% | 0.016 | [127] |

| CoO/meso-CN/MoS2 (1%) (S6) | MO | HT | 2.82–2.86 | 37.64 | VIS | 60 | 84% | - | [118] |

| 5 wt% MoS2/BiFeO3/Ag3PO4 | MO | C | 2.07 | 7.704 | UV-Vis | 5 | 98% | 0.376 | [119] |

| g-C3N4/MoS2/TiO2 (CMT5) | MO | HT | 2.64 | 97.5 | Vis (400–700 nm) | 60 | 98% | 0.061 | [128] |

| Ni foam with ZnO/MoS2 | MO | HT | - | 4.85 | UV-vis | 10 | 93% | 0.059 | [122] |

| 5% MoS2/ZnO | RhB | HT | 3.18 | - | UV | 50 | 95% | 0.057 | [119] |

| 5 wt% MoS2/BiFeO3/Ag3PO4 | RhB | C | 2.07 | 7.704 | UV-Vis | 5 | 97% | 0.676 | [119] |

| Ag/MoS2/CC | RhB | HT | - | 27 | Vis | 20 40 | 90% 99% | 72.1 × 10−3 | [129] |

| CTAB-MoS2-P25 | RhB | HT | 2.06 | - | - | 120 | 91% | - | [130] |

| Ni foam with ZnO/MoS2 | RhB | HT | - | 4.85 | UV-vis | 80 | 8% | - | [120] |

| 1.9% MoS2/g-C3N4/PAN | RhB | HT | 2.76 | 15.6 | Vis (>420 nm) | 120 | 48% | 0.006 | [125] |

| BiOI/MoS2 (BMS-8) | RhB | HT | BiOI—1.42 MoS2—1.73 | 30.76 | Vis (>420 nm) | 90 | 100% | 0.023 | [3] |

| MoS2/Fe3O4 (MF-17) | RhB | HT | - | 4,5 | Vis | 120 | 96% | - | [25] |

| g-C3N4/MoS2/GO (AT3G15) | RhB | HT | 2.05 | - | Vis | 60 | 99% | - | [131] |

| 5wt% MoS2/BiFeO3/Ag3PO4 | Acrid red 18 | C | 2.07 | 7.7045 | UV-Vis | 7 | 98% | 0.484 | [119] |

| CoO/meso-CN/MoS2(1%) (S6) | Methyl red | HT | 2.82–2.86 | 37.64 | Vis | 60 | 96% | 0.072 | [118] |

| CoO/meso-CN/MoS2(1%) (S6) | Congo red | HT | 2.82–2.86 | 37.64 | Vis | 60 | 95% | - | [118] |

| g-C3N4/MoS2/TiO2 (CMT5) | 4-Nitrophenol | HT | 2.64 | 97.5 | Vis (400–700 nm)) | 60 | 87% | - | [128] |

| MoS2-ZnS | Crystal violet | HT | - | - | Vis | 40 | 99% | 41.26 × 10−3 | [132] |

| Ni foam with ZnO/MoS2 | Congo red | HT | - | 4.85 | UV-Vis | 80 | 77% | [120] | |

| MoS2/g-C3N4/TiO2 | Malachite green | HT | 2.42 | - | Vis | 60 | 86% | 0.045 | [133] |

| Antibiotics | |||||||||

| MoS2/BiOBr/CF | TC | HT | MoS2—1.81 BiOBr—2.88 | - | Vis | 120 | 89% | - | [134] |

| Fe3O4/MoS2/BiVO4 (FMB3) | TC | HT | MoS2—1.56 BiVO4—2.44 | - | Vis (>420 nm) | 120 | 86% | 0.01576 | [135] |

| 5 wt% MoS2/BiFeO3/Ag3PO4 | TC | C | 2.07 | 7.704 | UV-Vis | 120 | 90% | - | [119] |

| MoS2/Z-50 | TC | HT | - | 17.32 | Vis (>420 nm) | 120 | 97% | - | [136] |

| 20 wt% MoS2/BEuCN | TC | HT | 2.85 | 44.12 | Vis | 50 | 99% | 0.087 | [122] |

| MoS2/TiO2/graphene (MTG-48) | TC | HT | 3.17 | 58.6 | UV-Vis (300–750 nm) | 60 | 92% | 0.05 | [137] |

| MoS2/ZnO QDs | TC | HT | - | - | Vis | 80 | 96% | 0.01 | [138] |

| CdS/MoS2/ZnO(CMZ) | Ofloxacin | chemical co-precipitation method | CdS—2.145 MoS2—2.015 ZnO—2.981 | - | Vis (>420 nm) | 90 | 89% | 0.024 | [139] |

| UiO-66/MoS2 (UMS-0.15) | Lomefloxacin | HT | - | 37.176 | Vis | 90 | 87% | - | [113] |

| Other organic compounds | |||||||||

| MXene-Ti3C2/MoS2 (MT-4) | Ranitidine | HT | 1.59 | 11.93 | Vis | 60 | 88% | - | [140] |

| rGO10%/ZnO20%/MoS2 | Aniline | HT | 2.24 | - | Vis | 120 | 100% | - | [141] |

| MoS2-TiO2 | 4-Nitrophenol | HT | 2.76 | 103.5 | Vis | 60 | 97% | 0.024 | [127] |

| MoS2/CuO-25% | 2-MBT | HT | MoS2—1.52 CuO—2.16 | 47 | Vis | 120 | 96% | - | [142] |

| Cu2S-1.0%MoS2 | Phenol | C | 1.42 | - | Vis | 90 | 90% | - | [143] |

| g-C3N4/MoS2/GO (AT3G15) | 4-CP | HT | 2.05 | - | Vis | 60 | 89% | - | [131] |

| 5 wt% MoS2/BiFeO3/Ag3PO4 | 2,4-D | C | 2.07 | 7.704 | UV-Vis | 180 | 90% | - | [119] |

| 5 wt% MoS2/BiFeO3/Ag3PO4 | Acephate | C | 2.07 | 7.704 | UV-Vis | 60 | 85% | - | [119] |

| g-C3N4/MoS2−PANI | Bisphenol-A | HT | 2.67 | 184.21 | Vis | 60 | 93% | 0.040 | [123] |

| Metal ion species | |||||||||

| MoS2/BiOBr/CF | Cr(VI) | HT | MoS2—1.81 BiOBr—2.88 | - | Vis | 120 | 85% | - | [134] |

| Ni foam with ZnO/MoS2 | Cr(VI) | HT | - | 4.85 | UV-Vis | 25 | 75% | - | [120] |

| MoS2/TiO2/graphene (MTG-48) | Pb(II) | HT | 3.17 | 58.6 | UV-Vis (300–750 nm) | 60 | 88% | - | [137] |

| MoS2-Based Catalyst | Contaminant | Irradiation Time (min) | Photodegradation/Removal Rate | Mineralization Evaluation | Ref. |

|---|---|---|---|---|---|

| 5 wt % MoS2/BiFeO3/Ag3PO4 | MB | 5 | 97% | >85% | [119] |

| CoO/meso-CN/MoS2(1%) (S6) | MO | 60 | 84% | 54% | [118] |

| 5 wt % MoS2/BiFeO3/Ag3PO4 | MO | 5 | 98% | > 85% | [119] |

| g-C3N4/MoS2/TiO2 (CMT5) | MO | 60 | 98% | 91% | [128] |

| 5 wt % MoS2/BiFeO3/Ag3PO4 | RhB | 5 | 97% | >85% | [119] |

| BiOI/MoS2 (BMS-8) | RhB | 90 | 100% | 78% * | [3] |

| g-C3N4/MoS2/GO (AT3G15) | RhB | 60 | 99% | 85% | [131] |

| 5 wt % MoS2/BiFeO3/Ag3PO4 | Acrid red 18 | 7 | 98% | >85% | [119] |

| CoO/meso-CN/MoS2(1%) (S6) | Methyl red | 60 | 96% | 80% | [118] |

| CoO/meso-CN/MoS2(1%) (S6) | Congo red | 60 | 95% | 71% | [118] |

| MoS2/BiOBr/CF | TC | 120 | 92% | 55% ** | [134] |

| 5 wt % MoS2/BiFeO3/Ag3PO4 | TC | 120 | 90% | 91% | [119] |

| MoS2/TiO2/graphene (MTG-48) | TC | 60 | 92% | 33.8% | [137] |

| MXene-Ti3C2/MoS2 (MT-4) | Ranitidine | 60 | 88% | 74% | [140] |

| 5 wt % MoS2/BiFeO3/Ag3PO4 | 2,4-D | 180 | 90% | 87% | [119] |

| 5 wt % MoS2/BiFeO3/Ag3PO4 | Acephate | 60 | 85% | 93% | [119] |

| Adsorption | |||||||||

| Composite | Contaminant | Specific Area (m2/g) | Contact Time (min) | Comparative Adsorption Parameters | Ref. | ||||

| W-DR-N-MoS2 | Hg(II) | - | - | Interlaying spacing | 9.42 Å | Maximum adsorption capacity (qmax) (mg g−1) | 2562.8 | [97] | |

| MoS2 | Hg(II) | - | - | 6.15 Å | 35.5 | ||||

| MoS2/MTT | Hg(II) | - | - | Adsorption capacity in equilibrium, according to the pseudo-first-order kinetic model (mg g−1) | 1119.94 | [99] | |||

| MoS2 | Hg(II) | - | - | 936.62 | |||||

| MoS2-kaolin | Pb(II) | 14.56 | 10 | Adsorption capacity (mg g−1) | 55.10 | Removal rate | 89% | [98] | |

| MoS2 | Pb(II) | 13.08 | 10 | 35.68 | 54% | ||||

| MoS2/MTT | Atenolol | - | 150 | Adsorption capacity (mg g−1) | 132.08 | [114] | |||

| MoS2 | Atenolol | - | 150 | 74.23 | |||||

| MoS2/MTT | Acebutolol | - | 150 | Adsorption capacity (mg g−1) | 113.82 | [114] | |||

| MoS2 | Acebutolol | - | 150 | 36.05 | |||||

| Photocatalysis | |||||||||

| Catalyst | Contaminant | Band Gap (eV) | Specific Area (m2/g) | Irradiation Time (min) | Removal Rate (%) | PFO Kinetics k (min−1) | Ref. | ||

| MZO (MoS2/ZnO) | MB | - | 14.785 | 40 | 97 | 0.070 | [121] | ||

| MoS2 | MB | - | 3.795 | 40 | 44 | 0.010 | |||

| MoS2/Fe3O4 (MF-17) | MB | - | 4.5 | 120 | 98 | - | [25] | ||

| MoS2 | MB | - | 9.0 | 120 | 92 | - | |||

| MoS2-TiO2 | MO | 2.76 | 103.5 | 60 | 86 | 0.016 | [127] | ||

| MoS2 | MO | 3.26 | 88.5 | 60 | 53 | 0.008 | |||

| BiOI/MoS2 (BMS-8) | RhB | BiOI 1.42 MoS2 1.73 | 30.76 | 90 | 100 | 0.023 | [3] | ||

| MoS2 | RhB | MoS2 1.73 | 49.59 | 90 | 60 | 0.009 | |||

| MoS2/Fe3O4 (MF-17) | RhB | - | 4.5 | 120 | 96 | - | [25] | ||

| MoS2 | RhB | - | 9.0 | 120 | 82 | - | |||

| MoS2/TiO2/graphene (MTG-48) | TC | 3.17 | 58.6 | 60 | 92 | 0.05 | [137] | ||

| MoS2 | TC | 2.66 | 29.3 | 60 | 54 | 0.018 | |||

| MoS2-ZnS | Crystal violet | - | - | 40 | 98.5 | 41.26 × 10−3 | [132] | ||

| MoS2 | Crystal violet | - | - | 40 | 60 | 24.23 × 10−3 | |||

| MoS2-TiO2 | 4-Nitrophenol | 2.76 | 103.5 | 60 | 97 | 0.024 | [127] | ||

| MoS2 | 4-Nitrophenol | 3.26 | 88.5 | 60 | 59 | 0.009 | |||

| UiO-66/MoS2 (UMS-0.15) | Lomefloxacin | - | 37.176 | 90 | 87 | 37.176 | [113] | ||

| MoS2 | Lomefloxacin | - | 7.775 | 90 | 38.2 | 7.775 | |||

| MoS2/CuO-25% | 2-MBT | MoS2 1.52 CuO 2.16 | 47 | 120 | 96 | - | [142] | ||

| MoS2 | 2-MBT | 1.52 | 14.76 | 120 | 22 | - | |||

| Adsorption | ||||||

| MoS2-Based Composite | Contaminant | Contact Time (min) | Removal 1st Cycle (%) | Number of Cycles | Removal after Last Cycle (%) | Ref. |

| Au/Fe3O4/MoS2CAs | Hg(II) | 30 | 95–100 | 10 | >95 | [109] |

| MoS2/Fe3O4 | Hg(II) | - | 100–95 | 5 | identical | [111] |

| MoS2-kaolin | Hg(II) | 50 | 99 | 5 | 77 | [98] |

| MoS2-rGO | Hg(II) | 7 | 100 | 6 | 85–90 | [110] |

| MoS2/MTT | Hg(II) | - | 100 | 4 | 85.2 | [99] |

| MoS2/Fe3O4 | Pb(II) | - | 100–95 | 5 | identical | [111] |

| MoS2/LDC | Cr(VI) | 30 | 99 | 4 | 90 | [112] |

| chitosan-coated MoS2 1:2 | Au(III) | - | 98.9 | 4 | 86.4 | [28] |

| MoS2-rGO | Ofloxacin | - | 92 | 8 | 4 | [7] |

| Photocatalysis | ||||||

| MoS2-Based Catalyst | Contaminant | Irradiation Time (min) | Removal 1st Cycle (%) | Number of Cycles | Removal after Last Cycle (%) | Ref. |

| α-Fe2O3/MoS2QDs | MB | 1 120 | 83 91 | 3 | 1min 65 120 min 75 | [92] |

| MZO (MoS2/ZnO) | MB | 40 | 97 | 5 | 89.10 | [121] |

| ZnO/MoS2 8 h | MB | 37.5 | 85 | 5 | 65 | [124] |

| CM12 (Cu2O/MoS2) | MO | 30 | 90 | 5 | 40 | [126] |

| CoO/meso-CN/MoS2(1%) (S6) | MO | 60 | 84 | 5 | 80 | [118] |

| Ni foam with ZnO/MoS2 | MO | 10 | 92.7 | 4 | 86.9 | [120] |

| 5% MoS2/ZnO | RhB | 50 | 95 | 5 | 87 | [93] |

| CTAB-MoS2-P25 | RhB | 120 | 91 | 4 | 76 | [130] |

| 1.9% MoS2/g-C3N4/PAN | RhB | 120 | 48 | 4 | 43 | [125] |

| BiOI/MoS2 (BMS-8) | RhB | 90 | 100 | 6 | >90 | [3] |

| g-C3N4/MoS2/GO (AT3G15) | RhB | 60 | 99 | 5 | 92 | [131] |

| CoO/meso-CN/MoS2(1%) (S6) | Methyl red | 60 | 96 | 5 | 90 | [118] |

| CoO/meso-CN/MoS2(1%) (S6) | Congo red | 60 | 95 | 5 | 88 | [118] |

| MoS2-ZnS | Crystal violet | 40 | 98.5 | 4 | 90.5 | [132] |

| MoS2/g-C3N4/TiO2 | Malachite green | 60 | 86 | 4 | 70 | [133] |

| MoS2/BiOBr/CF | TC | 120 | 89.0 | 4 | 80.7 | [134] |

| Fe3O4/MoS2/BiVO4 (FMB3) | TC | 120 | 86.1 | 5 | >80 | [135] |

| MoS2/Z-50 | TC | 120 | 96.8 | 5 | 87.2 | [136] |

| 20 wt% MS/BEuCN | TC | 50 | 99 | 3 | identical | [120] |

| MoS2/TiO2/graphene (MTG-48) | TC | 60 | 92 | 5 | 85 | [137] |

| MoS2/ZnO QDs | TC | 80 | 96 | 5 | 89 | [138] |

| CdS/MoS2/ZnO(CMZ) | Ofloxacin | 90 | 89 | 4 | 70–75 | [139] |

| UiO-66/MoS2 (UMS-0.15) | Lomefloxacin | 90 | 87 | 4 | 79 | [113] |

| MXene-Ti3C2/MoS2 (MT-4) | Ranitidine | 60 | 88.4 | 80 | [140] | |

| RGO10%/ZnO20%/MoS2 | Aniline | 120 | 100 | 5 | 100 | [141] |

| MoS2/CuO-25% | 2-MBT | 120 | 96 | 5 | 91 | [142] |

| MoS2/BiOBr/CF | Cr(VI) | 120 | 84.7 | 4 | 76.6 | [134] |

| MoS2/TiO2/graphene (MTG-48) | Pb(II) | 60 | 88 | 6 | 80 | [137] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amaral, L.O.; Daniel-da-Silva, A.L. MoS2 and MoS2 Nanocomposites for Adsorption and Photodegradation of Water Pollutants: A Review. Molecules 2022, 27, 6782. https://doi.org/10.3390/molecules27206782

Amaral LO, Daniel-da-Silva AL. MoS2 and MoS2 Nanocomposites for Adsorption and Photodegradation of Water Pollutants: A Review. Molecules. 2022; 27(20):6782. https://doi.org/10.3390/molecules27206782

Chicago/Turabian StyleAmaral, Leonardo O., and Ana L. Daniel-da-Silva. 2022. "MoS2 and MoS2 Nanocomposites for Adsorption and Photodegradation of Water Pollutants: A Review" Molecules 27, no. 20: 6782. https://doi.org/10.3390/molecules27206782

APA StyleAmaral, L. O., & Daniel-da-Silva, A. L. (2022). MoS2 and MoS2 Nanocomposites for Adsorption and Photodegradation of Water Pollutants: A Review. Molecules, 27(20), 6782. https://doi.org/10.3390/molecules27206782