Effect of Acetylation on Physicochemical and Functional Properties of Commercial Pumpkin Protein Concentrate

Abstract

1. Introduction

2. Results and Discussion

2.1. Chemical Composition

2.2. Amino Acid Composition

2.3. Degree of Acetylation and In Vitro Digestibility

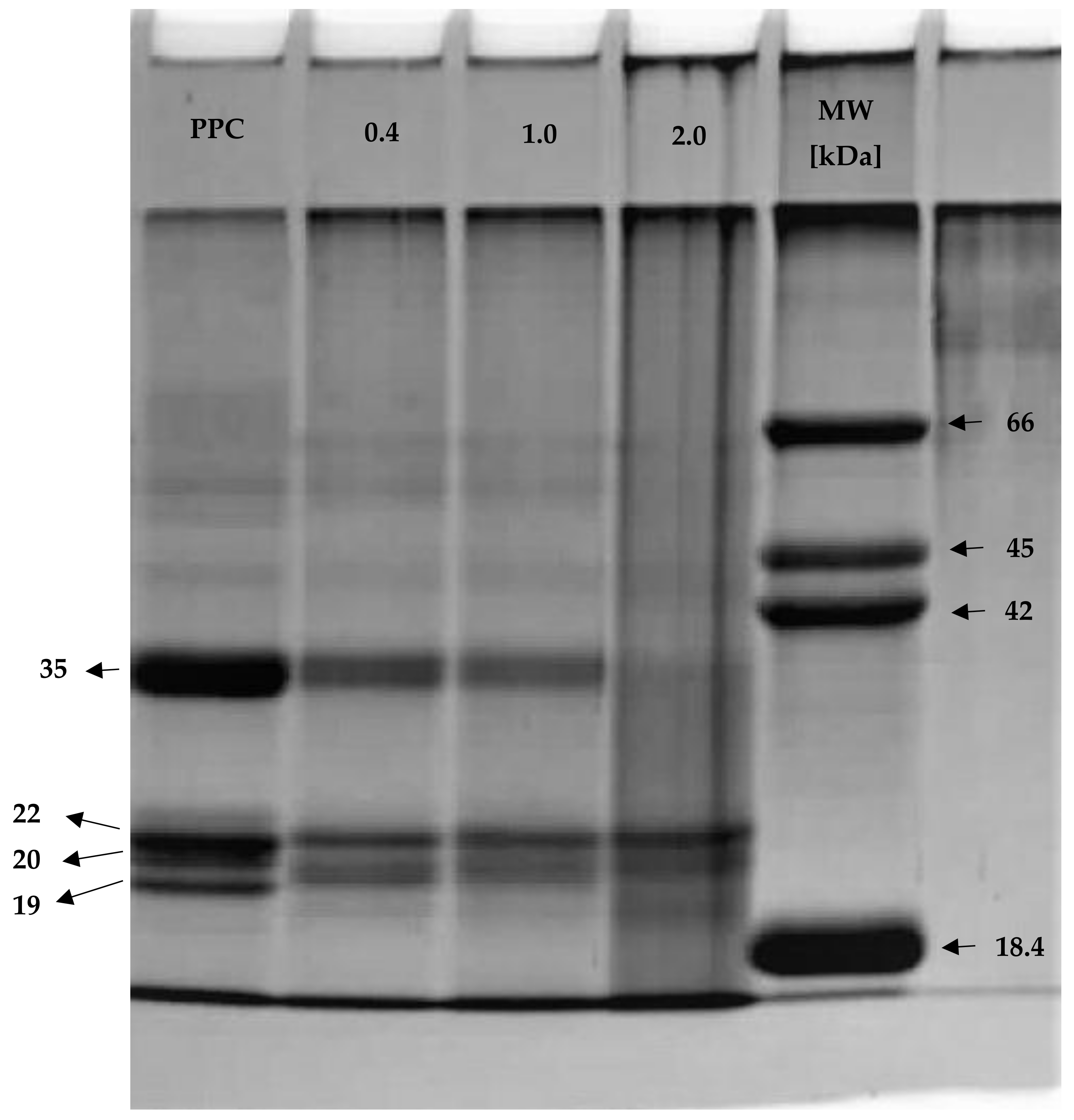

2.4. SDS-PAGE

2.5. Functional Properties

2.5.1. Protein Solubility Index

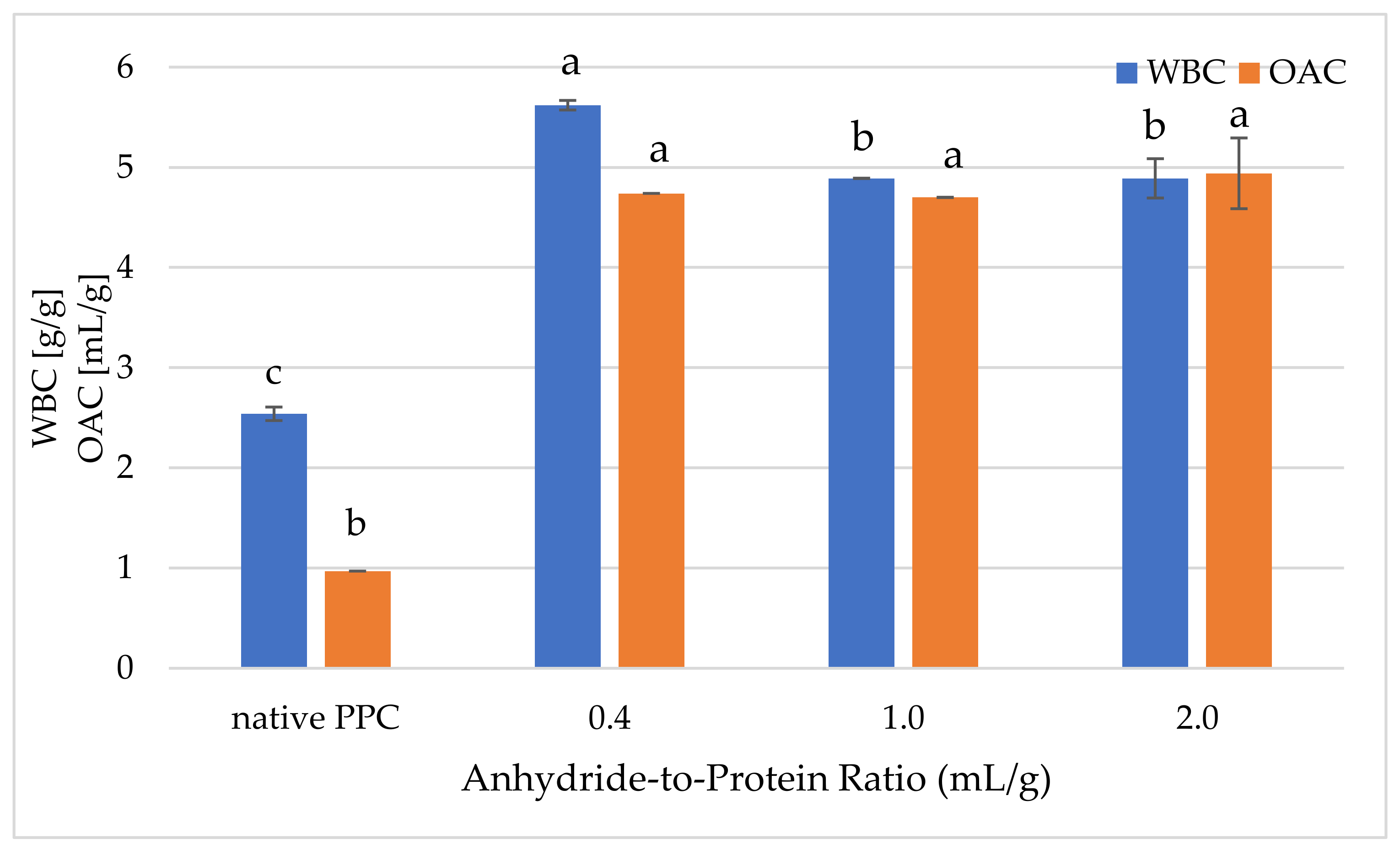

2.5.2. Water-Binding Capacity and Oil-Absorption Capacity

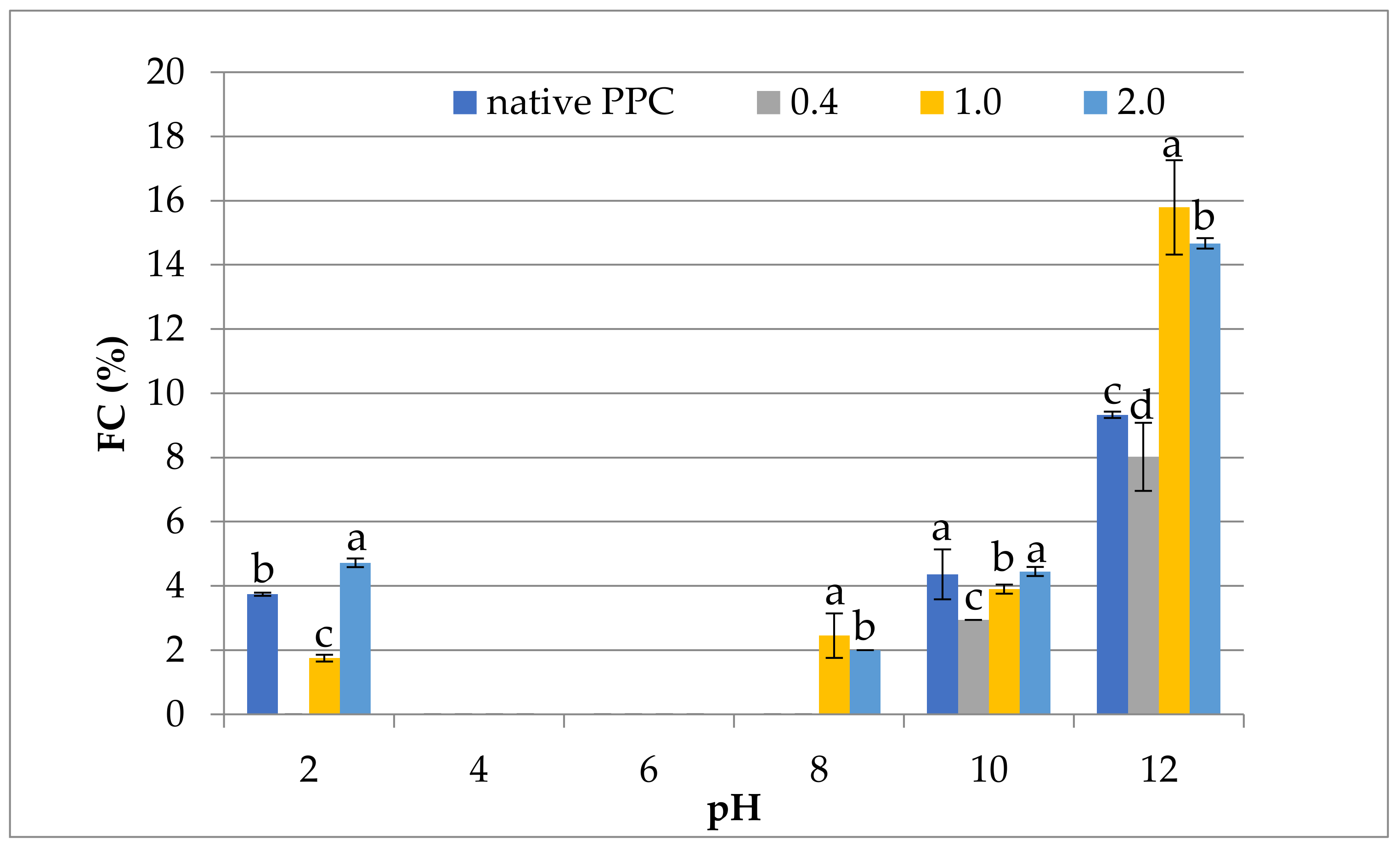

2.5.3. Foaming Properties

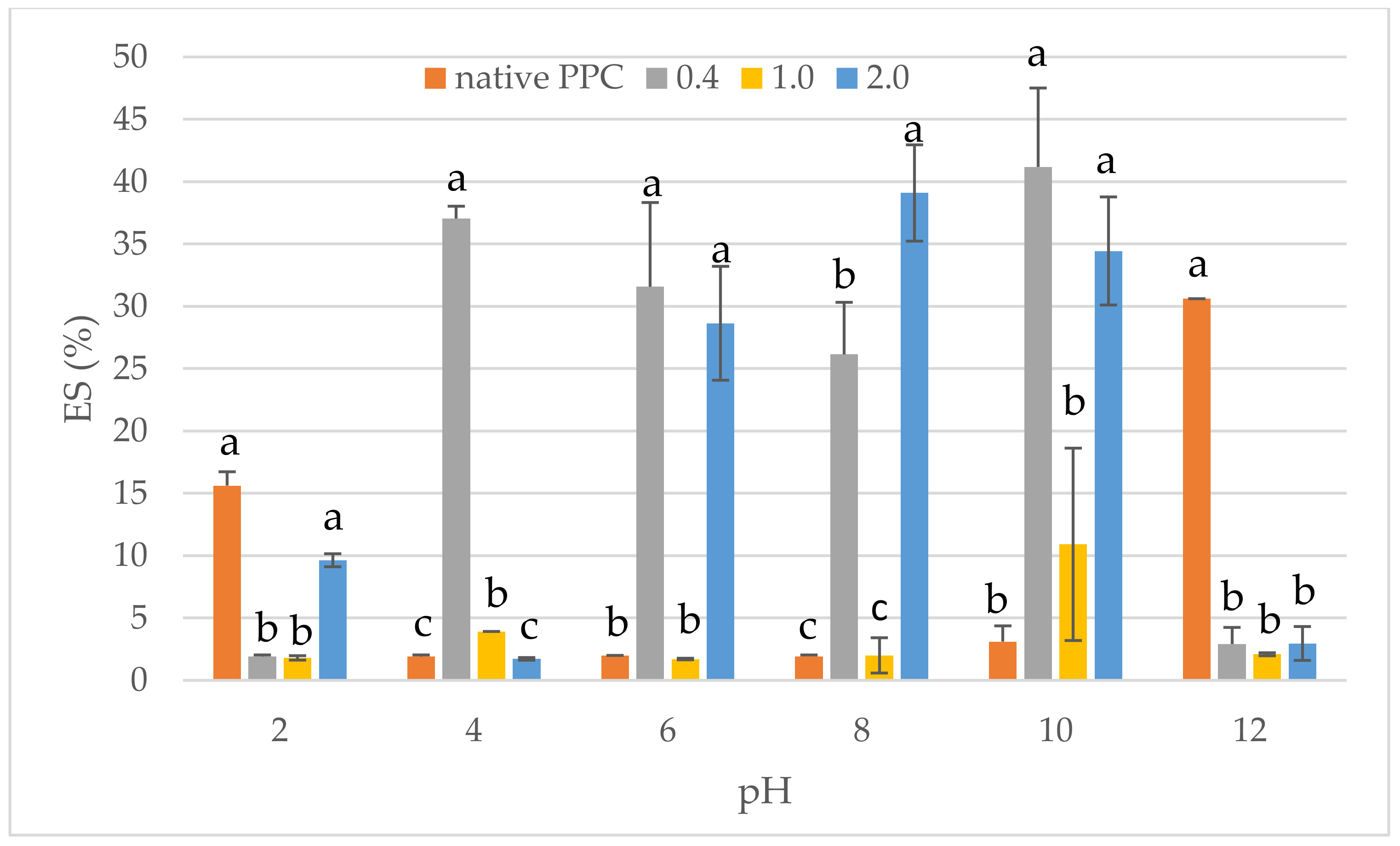

2.5.4. Emulsifying Properties

3. Materials and Methods

3.1. Materials and Chemicals

3.2. Acetylation of PPC

3.3. Basic Chemical Composition

3.4. Amino Acid Composition

3.5. Measurement of Degree of N-Acylation

3.6. Digestibility of Protein Preparations

3.7. Sodium Dodecyl Sulfate–Polyacrylamide Gel Electrophoresis (SDS-PAGE)

3.8. Determination of Functional Properties

3.8.1. Effect of pH on Protein Solubility

3.8.2. Water-Binding Capacity and Oil-Absorption Capacity

3.8.3. Effect of pH on Foaming Capacity and Stability

3.8.4. Effect of pH on Emulsifying Properties

3.9. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Antoniewska, A.; Adamska, A.; Rutkowska, J.; Zielińska, M. Olej z nasion dyni jako źródło cennych składników w diecie człowieka. Probl. Hig. Epidemiol. 2017, 98, 17–22. (In Polish) [Google Scholar]

- Murkovic, M. Pumpkin seed oil. In Gourmet and Health—Promoting Specialty Oils, 1st ed.; Moreau, R.A., Kamal-Eldin, A., Eds.; Academic Press: Cambridge, MA, USA; AOCS Press: Urbana, IL, USA, 2009; pp. 345–358. [Google Scholar]

- Peričin, D.; Radulović-Popović, L.; Vaštag, Ž.; Mađarev-Popović, S.; Trivić, S. Enymatic hydrolysis of protein isolate from hull-less pumpkin oil cake: Application of response surface methodology. Food Chem. 2009, 115, 753–757. [Google Scholar] [CrossRef]

- Vaštag, Ž.; Popović, L.; Popović, S.; Krimer, V.; Peričin, D. Production of enzymatic hydrolysates with antioxidant and angiotensin-I converting enzyme inhibitory activity from pumpkin oil cake protein isolate. Food Chem. 2011, 124, 1316–1321. [Google Scholar] [CrossRef]

- Ozuna, C.; León-Galván, M.F. Cucurbitaceae seed protein hydrolysates as a potential source of bioactive peptides with functional properties. Biomed. Res. Int. 2017, 2107, 2121878. [Google Scholar] [CrossRef] [PubMed]

- Chan, W.M.; Ma, C.Y. Acid modification of proteins from soymilk residue (okara). Food Res. Int. 1999, 32, 119–127. [Google Scholar] [CrossRef]

- Majzoobi, M.; Abedi, E.; Farahnaky, A.; Aminlari, M. Functional properties of acetylated glutenin and gliadin at varying pH values. Food Chem. 2012, 133, 1402–1407. [Google Scholar] [CrossRef]

- Franzen, K.J.; Kinsella, J.E. Functional properties of succinylated and acetylated leaf protein. J. Agric. Food Chem. 1976, 24, 914–919. [Google Scholar] [CrossRef]

- Beuchat, L.R. Functional and electrophoretic characteristics of succinylated peanut flour protein. J. Agric. Food Chem. 1977, 25, 258–261. [Google Scholar] [CrossRef]

- Kabirrulah, M.; Wills, R.B.H. Functional properties of acetylated and succinylated sunflower protein isolate. J. Food Technol. 1982, 17, 235–249. [Google Scholar] [CrossRef]

- Gruener, L.; Ismond, A.H. Effects of acetylation and siccinylation on the pysicochemical properties of the canola 12S globulin. Part I. Food Chem. 1997, 60, 357–363. [Google Scholar] [CrossRef]

- Melnychyn, P.; Stapley, R.B. Acylated Soybean Protein for Coffee Whiteners. U.S. Patent 3,764,711, 9 October 1973. [Google Scholar]

- Mosher, A. Flavouring Agent and Process for Preparaing Same. U.S. Patent 3,840,674, 8 October 1974. [Google Scholar]

- Creamer, L.K.; Roeper, J.; Lohrey, E.H. Preparation and evaluation of some acid soluble casein derivatives. N. Z. J. Dairy Sci. Technol. 1971, 6, 107–114. [Google Scholar]

- Liu, L.L.; Wang, H.; Ren, G.Y.; Duan, X.; Li, D.; Yin, G.J. Effects of freeze-drying and spray drying processes on functional properties of phosphorylation of egg white protein. Int. J. Agric. Biol. Eng. 2015, 8, 116–123. [Google Scholar]

- Zhao, C.-B.; Zhang, H.; Xu, X.-Y.; Cao, Y.; Zheng, M.-Z.; Liu, J.-S.; Wu, F. Effect of acetylation and succinylation on physicochemical properties and structural characteristics of oat protein isolate. Process. Biochem. 2017, 57, 117–123. [Google Scholar] [CrossRef]

- Fan, M.; Huang, Q.; Zhong, S.; Li, X.; Xiong, S.; Xie, J.; Yin, T.; Zhang, B.; Zhao, S. Gel properties of myofibrillar protein as affected by gelatinization and retrogradation behaviors of modified starches with different crosslinking and acetylation degress. Food Hydrocoll. 2019, 96, 604–616. [Google Scholar] [CrossRef]

- Acetic Anhydride. CAS No.: 108-24-7. Available online: http://www.eeaa.gov.eg/cmuic/cmuic_pdfs/generalpub/Acetic%20Anhydride.PDF (accessed on 23 February 2021).

- Rutkowski, A.; Kozłowska, H. Preparaty Żywnościowe z Białka Roślinnego, 1st ed.; Wydawnictwo Naukowo-Techniczne: Warsaw, Poland, 1981; p. 370. (In Polish) [Google Scholar]

- Moure, A.; Sineiro, J.; Domínquez, H.; Parajó, J.C. Functionality of oilseed protein products: A review. Food Res. Int. 2006, 39, 945–963. [Google Scholar] [CrossRef]

- El-Adawy, T.A. Functional properties and nutritional quality of acetylated and succinylated mung bean protein isolate. Food Chem. 2000, 70, 83–91. [Google Scholar] [CrossRef]

- Lawal, O.S.; Adebowale, K.O. The acetylated protein derivatives of Canavalia ensiformis (jack bean): A study of functional characteristics. Food Sci. Technol. LWT 2006, 39, 918–929. [Google Scholar] [CrossRef]

- Lawal, O.S.; Adebowale, K.O.; Adebowale, Y.A. Functional properties of native and chemically modified protein concentrates from bambarra groundnut. Food Res. Int. 2007, 40, 1003–1011. [Google Scholar] [CrossRef]

- Miedzianka, A.; Pęksa, A.; Aniołowska, M. Properties of acetylated potato protein preparations. Food Chem. 2012, 133, 1283–1291. [Google Scholar] [CrossRef]

- Khader, A.E.; Salem, O.M.; Zedan, M.A.; Mahmoud, S.F. Impact of substituting non-fat dry milk with acetylated whey protein concentrates the quality of chocolate ice milk. Egypt. J. Dairy Sci. 2001, 29, 299–312. [Google Scholar]

- Zedan, M.A.; Zedan, A.N.; Mahmoud, S.F. Effect of fortification of cow milk with acetylated whey protein concentrates on the quality of set yoghurt. Egypt. J. Dairy Sci. 2001, 29, 285–297. [Google Scholar]

- Zduńczyk, Z.; Minakowski, D.; Frejnagel, S.; Flis, M. Skład chemiczny i wartość pokarmowa makuchu z dyni. Rośliny Oleiste 1998, 19, 205–209. (In Polish) [Google Scholar]

- Nakai, S. Structure-functiona relationships of food proteins: With an emphasis on the importance of protein hydrophobicity. J. Agric. Food Chem. 1983, 31, 676–683. [Google Scholar] [CrossRef]

- Kotecka-Majchrzak, K.; Sumara, A.; Fornal, E.; Montowska, M. Proteomic analysis of oilseed cake: A comparative study of species-specific proteins and peptides extracted from ten seed species. J. Sci. Food Agric. 2021, 101, 297–306. [Google Scholar] [CrossRef] [PubMed]

- Fernández-Quintela, A.; Macarulla, M.T.; Del Barrio, A.S.; Martínez, J.A. Composion and functional properties of protein isolates obtained from commercial legumes grown in northern Spain. Plant Foods Hum. Nutr. 1997, 51, 331–342. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.Y.; Wood, D.F. Functional properties of oat proteins modified by acylation, trypsyn hydrolysis or linoleate treatment. J. Am. Oil Chem. Soc. 1987, 64, 1726–1731. [Google Scholar] [CrossRef]

- Lawal, O.S.; Dawodu, M.O. Maleic anhydride derivatives of a protein isolate: Preparation and functional evaluation. Eur. Food Res. Technol. 2007, 226, 187–198. [Google Scholar] [CrossRef]

- Achouri, A.; Zhang, W. Effect of succinylation on the physicochemical properties of soy protein hydrolysate. Food Res. Int. 2001, 34, 507–514. [Google Scholar] [CrossRef]

- Polzonetti, V.; Natalini, P.; Vincenzetti, S.; Vita, A.; Pucciarelli, S. Olives and Olive Oil in Health and Disease Prevention. In Modulatory Effect of Oleuropeinon Digestive Enzymes, 1st ed.; Preedy, V.R., Watson, R.R., Eds.; Academic Press: San Diego, CA, USA, 2010; pp. 1327–1333. [Google Scholar]

- Shukla, T.P. Chemical modification of food protein. In Food Protein Deterioration: Mechanism and Functionality, 1st ed.; Chery, J.P., Ed.; American Chemical Society ACS: Washington, DC, USA, 1982; p. 275. [Google Scholar]

- Salgó, A.; Ganzler, K.; Jécsai, J. Simple Enzymic Methods for Prediction of Plant Protein Digestibility. In Amino Acid Composition and Biological Value of Cereal Proteins, 1st ed.; Lásztity, R., Hidvégi, M., Eds.; Springer: Dordrecht, The Netherlands, 1985; pp. 311–321. [Google Scholar]

- Bergner, H.; Seidler, W.; Simon, O.; Schmandke, H. Digestibility and dietary quality of nonacetylated and acetylated Vicia faba proteins in maintenance: Studies on 15N-labelled adult rats. Ann. Nutr. Metab. 1984, 28, 156–163. [Google Scholar] [CrossRef]

- Osborne, T.B. The Vegetable Proteins, 2nd ed.; Longmans, Green and Co.: London, UK, 1924. [Google Scholar]

- Colman, P.; Suzuki, E.; Van Donkelaar, A. The structure of cucurbitin: Subunit symmetry and organization in situ. Eur. J. Biochem. 1980, 103, 585–588. [Google Scholar] [CrossRef] [PubMed]

- Popović, L.M.; Peričin, M.; Vaštag, Ž.G.; Popović, S.Z. Optimalization of transglutaminase cross-linking of pumpkin oil cake globulin; Improvement of the solubility and gelation properties. Food Bioprocess Technol. 2013, 6, 1105–1111. [Google Scholar] [CrossRef]

- Bučko, S.D.; Katona, J.M.; Popovič, L.M.; Vaštag, Ž.; Petrovič, L.B. Functional properties of pumpkin (Cucurbita pepo) seed protein isolate and hydrolysate. J. Serb. Chem. Soc. 2016, 81, 35–46. [Google Scholar] [CrossRef]

- Marcone, F.M.; Kakuda, Y.; Yada, R.Y. Salt-soluble seed globulins of various dicotyledonous and monocotyledonous plants. I. Isolation—Purification and characterization. Food Chem. 1997, 62, 27–47. [Google Scholar] [CrossRef]

- Vassiliou, A.G.; Neumann, G.M.; Condron, R.; Poly, G.M. Purification and mass spectrometry-assisted sequencing of basic antifungal proteins from seeds of pumpkin (Cucurbita maxima). Plant Sci. 1998, 134, 141–162. [Google Scholar] [CrossRef]

- Fang, E.F.; Wong, J.H.; Lin, P.; Ng, T.B. Biochemical characterization of the RNA-hydrolytic activity of a pumpkin 2S albumin. FEBS Lett. 2010, 584, 4089–4096. [Google Scholar] [CrossRef] [PubMed]

- Fruhwirth, G.O.; Hermetter, A. Seeds and oil of the Styrian oil pumpkin: Components and biological activities. Eur. J. Lipid Sci. Technol. 2007, 109, 1128–1140. [Google Scholar] [CrossRef]

- Rezig, L.; Rianblanc, A.; Chonaibi, M.; Guegen, J.; Handi, S. Functional properties of protein fractions obtained from pumpkin (Cucurbita Maxima) seed. Int. J. Food Prop. 2015, 19, 172–186. [Google Scholar] [CrossRef]

- Pham, T.T.; Tran, T.T.T.; Ton, N.M.N.; Le, V.V.M. Effects of pH and salt concentration on functional properties of pumpkin seed protein fractions. J. Food Process. Preserv. 2016, 41, 13–73. [Google Scholar] [CrossRef]

- Zayas, J.F. Functionality of Proteins in Food, 1st ed.; Springer: Berlin, Germany, 1997; p. 390. [Google Scholar]

- El-Adawy, T.E.; Taha, K.M. Characteristics and composition of different seed oils and flours. Food Chem. 2001, 74, 47–54. [Google Scholar] [CrossRef]

- Rodrigues, I.M.; Coelho, J.F.J.; Carvalho, M.G. Isolation and valorisation of vegetable proteins from oilseed plants: Methods, limitations and potential. J. Food Eng. 2012, 109, 337–346. [Google Scholar] [CrossRef]

- Liu, L.H.; Hung, T.V. Functional properties of acetylated chickpea proteins. J. Food Sci. 1998, 63, 331–337. [Google Scholar] [CrossRef]

- Dua, S.; Mahajan, A.; Mahajan, A. Improvement of functional properties of rapeseed (Brassica campestris Var. Toria) preparations by chemical modification. J. Agric. Food Chem. 1996, 44, 706–710. [Google Scholar] [CrossRef]

- Bora, P.S. Short communication. Effect of acetyltion on the functional properties of lentil (Lens culinaris) globulin. J. Sci. Food Agric. 2003, 83, 139–141. [Google Scholar] [CrossRef]

- Kinsella, J.E. Functional properties of soy proteins. J. Am. Oil Chem. Soc. 1979, 56, 242–258. [Google Scholar] [CrossRef]

- Sathe, S.K.; Desphande, S.S.; Salunkhe, D.K. Functional properties of winged bean (Psophocarpus tetragonolobus L.) proteins. J. Food Sci. 1982, 47, 503–509. [Google Scholar] [CrossRef]

- Krause, J.-P. Comparison of the effect of acylation and phosphorylation on surface pressure, surface potaential and foaming properties of protein isolates from rapeseed (Brasica napus). Ind. Crops Prod. 2002, 15, 221–228. [Google Scholar] [CrossRef]

- Wani, A.A.; Sogi, D.S.; Singh, P.; Wani, I.A. Characterisation and functional properties of watermelon (Citrullus lanatus) seeds proteins. J. Sci. Food Agric. 2011, 91, 113–121. [Google Scholar] [CrossRef]

- Barac, M.; Cabrilo, S.; Pesic, M.; Stanojevic, S.; Ristic, N. Profile and functional properties of seed proteins from six pea (Pisum sativum) genotypes. Int. J. Mol. Sci. 2010, 11, 4973–4990. [Google Scholar] [CrossRef]

- Atuonwu, A.C.; Akobundu, E.N.T. Nutritional and sensory quality of cookies supplemented with deffated pumpkin (Cucurbita pepo) seed flour. Pak. J. Nutr. 2010, 9, 672–677. [Google Scholar] [CrossRef]

- Shilpashree, B.G.; Arora, S.; Chawla, P.; Tomar, S.K. Effect of succinylation on physicochemical and functional properties of milk protein concentrate. Food Res. Int. 2015, 72, 223–230. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2005. [Google Scholar]

- AOAC. Official Methods of Analysis of AOAC International, 16th ed.; AOAC: Gaithersburg, MD, USA, 1996. [Google Scholar]

- Mariotti, F.; Tomé, D.; Mirand, P. Converting nitrogen into protein—Beyond 6.25 and Jones’ factors. Crit. Rev. Food Sci. Nutr. 2008, 48, 177–184. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis of AOAC, 16th ed.; AOAC: Washington, DC, USA, 1995. [Google Scholar]

- Habeeb, A.F.S.A. Determination of free amino groups in proteins by trinitrobenzenesulfonic acid. Anal. Biochem. 1966, 14, 328–336. [Google Scholar] [CrossRef]

- Kowalczewski, P.Ł.; Olejnik, A.; Białas, W.; Rybicka, I.; Zielińska-Dawidziak, M.; Siger, A.; Kubiak, P.; Lewandowicz, G. The nutritional value and biological activity of concentrated protein fraction of potato juice. Nutrients 2019, 11, 1523. [Google Scholar] [CrossRef]

- Zielińska-Dawidziak, M.; Tomczak, A.; Burzyńska, M.; Rokosik, E.; Dwiecki, K.; Piasecka-Kwiatkowska, D. Comparison of Lupinus angustifolius protein digestibility in dependence on protein, amino acids, trypsin inhibitors and polyphenolic compounds content. Int. J. Food Sci. Technol. 2020, 55, 2029–2040. [Google Scholar] [CrossRef]

- ISO 1871:2009: Food and Feed Products—General Guidelines for the Determination of Nitrogen by the Kjeldahl Method; ISO: Geneva, Switzerland, 2009.

- Laemmli, U.K. Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 1970, 227, 680–685. [Google Scholar] [CrossRef]

- Achouri, A.; Nail, V.; Boye, J.I. Sesame protein isolate: Fractionation, secondary structure and functional properties. Food Res. Int. 2012, 46, 360–369. [Google Scholar] [CrossRef]

- Jeżowski, P.; Polcyn, K.; Tomkowiak, A.; Rybicka, I.; Radzikowska, D. Technological and antioxidant properties of proteins obtained from waste potato juice. Open Life Sci. 2020, 15, 379–388. [Google Scholar] [CrossRef]

- Wu, H.; Wang, Q.; Ma, T.; Ren, J. Comparative studies on the functional properties of various protein concentrate preparations of peanut protein. Food Res. Int. 2009, 42, 343–348. [Google Scholar] [CrossRef]

| Anhydride-to-Protein Ratio (mL/g) | Dry Matter | Protein Content | Fat | Ash |

|---|---|---|---|---|

| (g/100g) | ||||

| Native PPC | 97.49 ± 0.39 b | 65.11 ± 0.76 a | 9.17 ± 0.17 a | 8.36 ± 0.01 b |

| 0.4 | 94.90 ± 0.01 c | 63.24 ± 2.68 a | 8.91 ± 0.15 b | 8.68 ± 0.02 a |

| 1.0 | 99.01 ± 0.24 a | 53.52 ± 0.88 b | 8.88 ± 0.13 b | 7.99 ± 0.02 c |

| 2.0 | 98.80 ± 0.01 a | 62.24 ± 2.99 a | 8.89 ± 0.09 b | 5.49 ± 0.01 d |

| Amino Acids | Native PPC | Anhydride-to-Protein Ratio (mL/g) | ||

|---|---|---|---|---|

| 0.4 | 1.0 | 2.0 | ||

| IAA * | ||||

| Leucine | 6.67 ± 2.43 a | 6.56 ± 1.01 b | 6.13 ± 1.00 c | 6.60 ± 0.72 ab |

| Isoleucine | 4.15 ± 0.34 a | 3.80 ± 1.07 b | 3.55 ± 0.32 c | 3.88 ± 0.42 b |

| Methionine | 1.62 ± 0.51 a | 1.27 ± 1.21 b | 0.97 ± 0.48 d | 1.16 ± 0.85 c |

| Cysteine | 0.42 ± 0.88 a | 0.32 ± 0.44 b | 0.23 ± 0.01 d | 0.27 ± 0.25 c |

| Phenyloalanine | 4.51 ± 2.26 a | 3.40 ± 1.56 b | 2.95 ± 0.18 d | 3.05 ± 0.87 c |

| Threonine | 1.99 ± 0.07 a | 1.97 ± 2.19 b | 0.84 ± 0.34 d | 1.14 ± 0.26 c |

| Lysine | 3.32 ± 0.34 a | 2.69 ± 1.76 b | 2.02 ± 0.86 c | 1.89 ± 0.69 d |

| Tyrosine | 1.70 ± 0.26 a | 1.21 ± 0.45 b | 0.75 ± 0.51 d | 1.13 ± 0.30 c |

| Valine | 4.10 ± 0.86 a | 3.15 ± 0.86 b | 2.72 ± 0.30 c | 2.56 ± 0.52 c |

| DAA ** | ||||

| Aspartic acid | 7.04 ± 0.72 a | 6.15 ± 0.72 d | 6.29 ± 0.79 b | 6.18 ± 0.95 c |

| Glutamic acid | 21.03 ± 4.26 a | 19.28 ± 2.81 c | 19.78 ± 0.93 b | 18.05 ± 1.58 d |

| Serine | 3.86 ± 1.07 a | 3.81 ± 1.27 b | 3.56 ± 0.23 d | 3.68 ± 1.92 c |

| Glycine | 2.83 ± 2.14 a | 2.44 ± 0.72 b | 1.73 ± 0.52 d | 2.07 ± 1.92 c |

| Alanine | 3.64 ± 0.57 d | 4.07 ± 0.57 a | 3.89 ± 0.38 b | 3.84 ± 0.33 c |

| Histidine | 1.72 ± 1.31 a | 1.61 ± 1.31 b | 1.49 ± 0.21 c | 1.60 ± 0.19 b |

| Arginine | 16.69 ± 0.51 a | 16.08 ± 0.91 c | 16.30 ± 2.83 b | 15.90 ± 0.17 d |

| Proline | 3.46 ± 1.90 b | 3.55 ± 2.24 a | 3.21 ± 0.97 d | 3.35 ± 1.05 c |

| Total amino acids | 88.63 ± 1.20 a | 85.98 ± 1.24 a | 81.07 ± 1.26 b | 79.88 ± 0.82 b |

| Dose of Acetic Anhydride | Degree of N-Acylation | Amount of Protein Released into the Intestinal Fluid in Two-Step Digestion |

|---|---|---|

| (mL/g) | (%) | (%) |

| Native PPC | - | 23.27 ± 0.01 b |

| 0.4 | 54.89 ± 0.20 c | 21.04 ± 0.01 c |

| 1.0 | 62.77 ± 0.33 b | 25.31 ± 0.01 a |

| 2.0 | 78.67 ± 0.12 a | 23.09 ± 0.01 b |

| Foam Stability (%) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Type of Preparation | Time | pH | ||||||

| 2 | 4 | 6 | 8 | 10 | 12 | |||

| Native PPC | 5 min | 1.9 | 0 | 0 | 0 | 4.5 | 8.0 | |

| 10 min | 1.9 | 0 | 0 | 0 | 4.5 | 3.7 | ||

| 30 min | 1.4 | 0 | 0 | 0 | 3.0 | 1.9 | ||

| 60 min | 1.4 | 0 | 0 | 0 | 2.0 | 1.9 | ||

| Anhydride-to-Protein Ratio (mL/g) | 0.4 | 5 min | 0 | 0 | 0 | 0 | 0 | 5.8 |

| 10 min | 0 | 0 | 0 | 0 | 0 | 3.6 | ||

| 30 min | 0 | 0 | 0 | 0 | 0 | 2.2 | ||

| 60 min | 0 | 0 | 0 | 0 | 0 | 1.7 | ||

| 1.0 | 5 min | 0 | 0 | 0 | 0 | 0 | 4.3 | |

| 10 min | 0 | 0 | 0 | 0 | 0 | 3.5 | ||

| 30 min | 0 | 0 | 0 | 0 | 0 | 3.5 | ||

| 60 min | 0 | 0 | 0 | 0 | 0 | 3.5 | ||

| 2.0 | 5 min | 0 | 0 | 0 | 0 | 0 | 8.7 | |

| 10 min | 0 | 0 | 0 | 0 | 0 | 8.6 | ||

| 30 min | 0 | 0 | 0 | 0 | 0 | 0 | ||

| 60 min | 0 | 0 | 0 | 0 | 0 | 0 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miedzianka, J.; Zambrowicz, A.; Zielińska-Dawidziak, M.; Drożdż, W.; Nemś, A. Effect of Acetylation on Physicochemical and Functional Properties of Commercial Pumpkin Protein Concentrate. Molecules 2021, 26, 1575. https://doi.org/10.3390/molecules26061575

Miedzianka J, Zambrowicz A, Zielińska-Dawidziak M, Drożdż W, Nemś A. Effect of Acetylation on Physicochemical and Functional Properties of Commercial Pumpkin Protein Concentrate. Molecules. 2021; 26(6):1575. https://doi.org/10.3390/molecules26061575

Chicago/Turabian StyleMiedzianka, Joanna, Aleksandra Zambrowicz, Magdalena Zielińska-Dawidziak, Wioletta Drożdż, and Agnieszka Nemś. 2021. "Effect of Acetylation on Physicochemical and Functional Properties of Commercial Pumpkin Protein Concentrate" Molecules 26, no. 6: 1575. https://doi.org/10.3390/molecules26061575

APA StyleMiedzianka, J., Zambrowicz, A., Zielińska-Dawidziak, M., Drożdż, W., & Nemś, A. (2021). Effect of Acetylation on Physicochemical and Functional Properties of Commercial Pumpkin Protein Concentrate. Molecules, 26(6), 1575. https://doi.org/10.3390/molecules26061575