Recent Achievements in Dyes Removal Focused on Advanced Oxidation Processes Integrated with Biological Methods

Abstract

1. Introduction

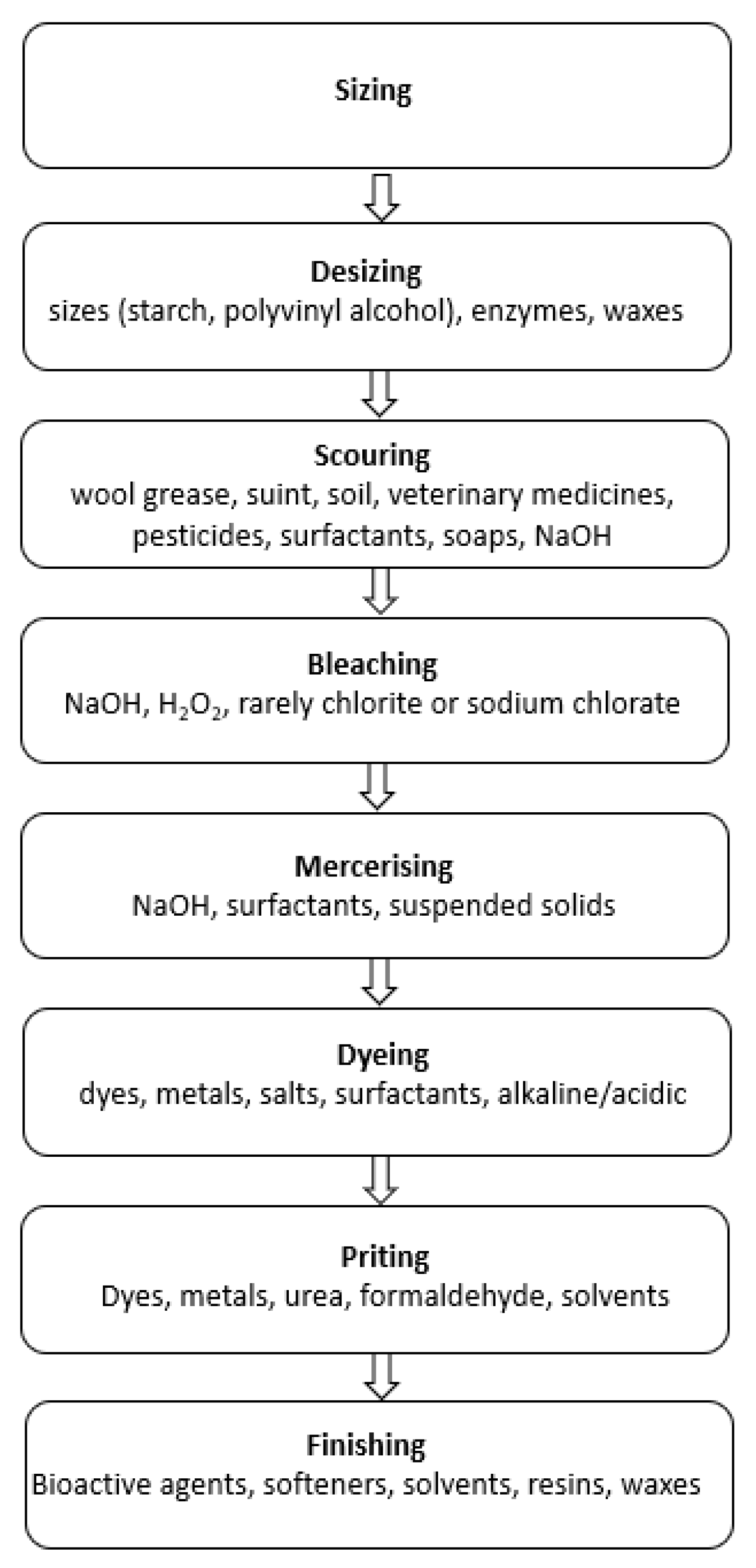

2. Classifications of Dyestuffs and Characteristics of Textile Wastewater

3. Processes Used in the Textile Dyes Removal

4. Mechanism and Kinetics of AOPs

- Formation of ·OH;

- Initial attacks on target molecules by ·OH and their breakdown into fragments;

- Subsequent attacks by ·OH until ultimate mineralization.

4.1. Ozone-Based AOPs

4.2. Fenton Reaction

5. Biological Processes

5.1. Enzymes and Microbial Community Action in Dye Degradation

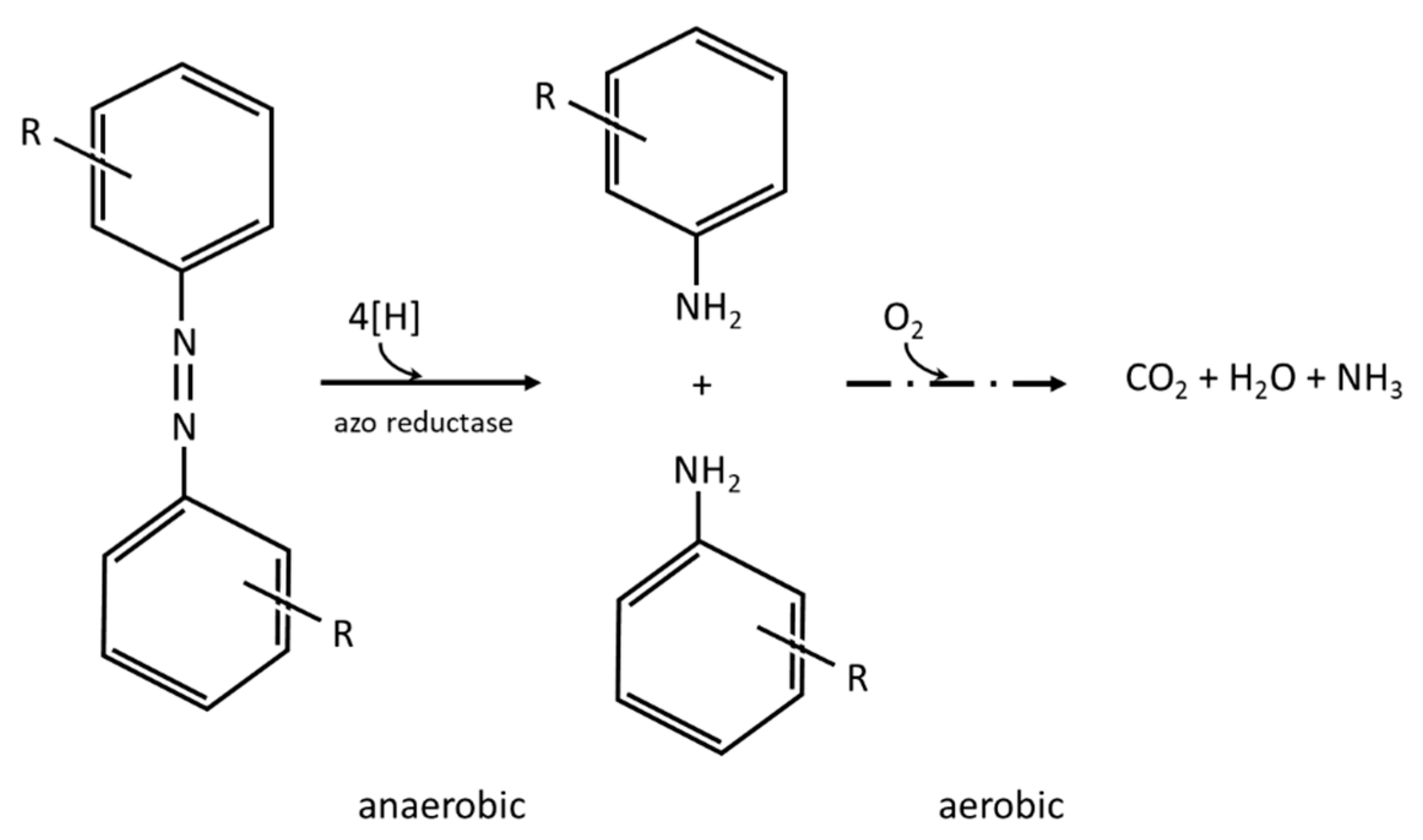

5.2. Anaerobic Treatment

5.3. Aerobic Treatment

5.4. Combined Anaerobic and Aerobic Treatment

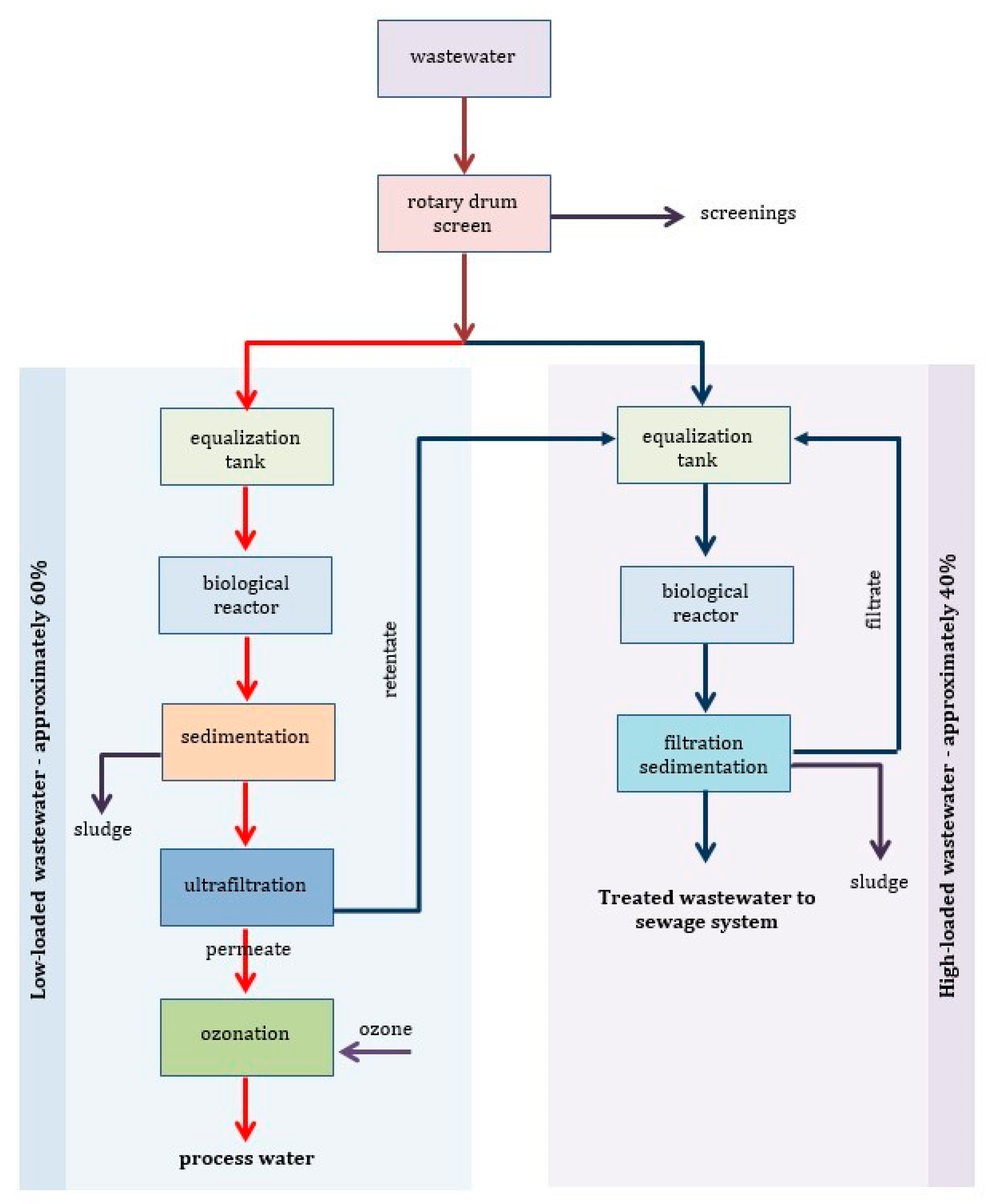

6. Integrated AOPs and Biological Methods

- chemical post-treatment after biodegradation;

- chemical pretreatment before biodegradation;

- biodegradation before and after chemical oxidation, possible more than one cycle or integrated system [14].

6.1. Chemical Post-Treatment

6.2. Chemical Pre-Treatment

6.3. Influence of AOPs Pre-Treatment on Biodegradation Kinetics

6.4. Pilot and Industrial Plants

7. Conclusions and Future Perspectives

Funding

Conflicts of Interest

References

- Gupta, V.K. Fundamentals of Natural Dyes and Its Application on Textile Substrates. In Chemistry and Technology of Natural and Synthetic Dyes and Pigments; Samanta, A.K., Awwad, N.S., Algarni, H.M., Eds.; IntechOpen: London, UK, 2020; ISBN 978-1-78985-998-0. [Google Scholar]

- Dyes And Pigments Market Size; Industry Report 2020–2027; Mordor Intelligence: Hyderabad, India, 2020; Volume 130.

- Benkhaya, S.; M’ rabet, S.; El Harfi, A. A review on classifications, recent synthesis and applications of textile dyes. Inorg. Chem. Commun. 2020, 115, 107891. [Google Scholar] [CrossRef]

- Yuan, H.; Chen, L.; Cao, Z.; Hong, F.F. Enhanced decolourization efficiency of textile dye Reactive Blue 19 in a horizontal rotating reactor using strips of BNC-immobilized laccase: Optimization of conditions and comparison of decolourization efficiency. Biochem. Eng. J. 2020, 156, 107501. [Google Scholar] [CrossRef]

- Albahnasawi, A.; Yüksel, E.; Gürbulak, E.; Duyum, F. Fate of aromatic amines through decolorization of real textile wastewater under anoxic-aerobic membrane bioreactor. J. Environ. Chem. Eng. 2020, 8, 104226. [Google Scholar] [CrossRef]

- Kant, R. Textile dyeing industry an environmental hazard. Nat. Sci. 2012, 4, 22–26. [Google Scholar] [CrossRef]

- Ghaly, A.E.; Ananthashankar, R.; Alhattab, M.; Ramakrishnan, V. Production, Characterization and Treatment of Textile Effluents: A Critical Review. J. Chem. Eng. Process. Technol. 2014, 5, 1–18. [Google Scholar]

- Pal, P. Industry—Specific Water Treatment: Case Studies. In Industrial Water Treatment Process Technology; Butterworth-Heinemann: Oxford, UK, 2017; pp. 243–511. [Google Scholar]

- Abiri, F.; Fallah, N.; Bonakdarpour, B. Sequential anaerobic-aerobic biological treatment of colored wastewaters: Case study of a textile dyeing factory wastewater. Water Sci. Technol. 2017, 75, 1261–1269. [Google Scholar] [CrossRef]

- Chao, C.; Guan, H.; Zhang, J.; Liu, Y.; Zhao, Y.; Zhang, B. Immobilization of laccase onto porous polyvinyl alcohol/halloysite hybrid beads for dye removal. Water Sci. Technol. 2018, 77, 809–818. [Google Scholar] [CrossRef] [PubMed]

- Miklos, D.B.; Remy, C.; Jekel, M.; Linden, K.G.; Drewes, J.E.; Hübner, U. Evaluation of advanced oxidation processes for water and wastewater treatment—A critical review. Water Res. 2018, 139, 118–131. [Google Scholar] [CrossRef]

- Fast, S.A.; Gude, V.G.; Truax, D.D.; Martin, J.; Magbanua, B.S. A Critical Evaluation of Advanced Oxidation Processes for Emerging Contaminants Removal. Environ. Process. 2017, 4, 283–302. [Google Scholar] [CrossRef]

- Oller, I.; Malato, S.; Sánchez-pérez, J.A. Combination of Advanced Oxidation Processes and biological treatments for wastewater decontamination—A review. Sci. Total Environ. 2011, 409, 4141–4166. [Google Scholar] [CrossRef] [PubMed]

- Paździor, K.; Bilińska, L.; Ledakowicz, S. A review of the existing and emerging technologies in the combination of AOPs and biological processes in industrial textile wastewater treatment. Chem. Eng. J. 2019, 376, 120597. [Google Scholar] [CrossRef]

- Prasad, A.; Rao, B. Physico Chemical Characterization of Textile Effluent and Screening for Dye Decolorizing Bacteria. Glob. J. Biotechnol. Biochem. 2010, 5, 80–86. [Google Scholar]

- Chequer, F.D.; de Oliveira, G.A.R.; Ferraz, E.A.; Cardoso, J.C.; Zanoni, M.B.; de Oliveira, D.P. Textile dyes: Dyeing process and environmental impact. In Eco-Friendly Textile Dyeing and Finishing; Gunay, M., Ed.; IntechOpen: London, UK, 2013; pp. 151–176. [Google Scholar]

- Gürses, A.; Açıkyıldız, M.; Güneş, K.; Gürses, M.S. Classification of Dye and Pigments. In Dyes and Pigments; Springer: Berlin, Germany, 2016; pp. 31–45. [Google Scholar]

- dos Santos, A.B.; Cervantes, F.J.; van Lier, J.B. Review paper on current technologies for decolourisation of textile wastewaters: Perspectives for anaerobic biotechnology. Bioresour. Technol. 2007, 98, 2369–2385. [Google Scholar] [CrossRef] [PubMed]

- Benkhaya, S.; M’rabet, S.; El Harfi, A. Classifications, properties, recent synthesis and applications of azo dyes. Heliyon 2020, 6, e03271. [Google Scholar] [CrossRef]

- Yu, B.; Wan, L.; Wan, G.; Gao, X.; Cai, Z. Reusing salt of reactive dyeing wastewater for reactive dyeing. In Proceedings of the 2017 3rd International Forum on Energy, Environment Science and Materials (IFEESM 2017), Shenzhen, China, 25–26 November 2017; Volume 120, pp. 1237–1242. [Google Scholar]

- Holkar, C.R.; Jadhav, A.J.; Pinjari, D.V.; Mahamuni, N.M.; Pandit, A.B. A critical review on textile wastewater treatments: Possible approaches. J. Environ. Manag. 2016, 182, 351–366. [Google Scholar] [CrossRef] [PubMed]

- Bhatia, D.; Sharma, N.R.; Singh, J.; Kanwar, R.S. Biological methods for textile dye removal from wastewater: A review. Crit. Rev. Environ. Sci. Technol. 2017, 47, 1836–1876. [Google Scholar] [CrossRef]

- Gottschalk, C.; Libra, J.A.; Saupe, A. Ozonation of water and waste water: A Practical Guide to Understanding Ozone and Its Applications; Wiley-VCH: Weinheim, Germany, 2010; ISBN 9783527628926. [Google Scholar]

- Sarria, V.; Kenfack, S.; Guillod, O.; Pulgarin, C. An innovative coupled solar-biological system at field pilot scale for the treatment of biorecalcitrant pollutants. J. Photochem. Photobiol. A Chem. 2003, 159, 89–99. [Google Scholar] [CrossRef]

- Manivanan, R. Recycling of Industrial Effluents; New India Publishing Agency: New Delhi, India, 2006; ISBN 9788189422127. [Google Scholar]

- Yaseen, D.A.; Scholz, M. Textile Dye Wastewater Characteristics and Constituents of Synthetic Effluents: A Critical Review; Springer: Berlin/Heidelberg, Germany, 2019; Volume 16, ISBN 0123456789. [Google Scholar]

- Bilińska, L.; Gmurek, M.; Ledakowicz, S. Comparison between industrial and simulated textile wastewater treatment by AOPs—Biodegradability, toxicity and cost assessment. Chem. Eng. J. 2016, 306, 550–559. [Google Scholar] [CrossRef]

- Wrebiak, J.; Bilińska, L.; Paździor, K.; Ledakowicz, S. Biodegradability assessment of wastewater streams from textile dye house (Ocena biodegradowalności wyodrębnionych strumieni ścieków z farbiarni). Przegląd Włókienniczy—WłóknoOdzieżSkóra 2014, 46–49. [Google Scholar]

- The European Commission. Integrated Pollution Prevention and Control. Reference Document on Best Available Techniques for the Textiles Industr; The European Commission: Brussels, Belgium, 2003; p. 626. [Google Scholar]

- European Commission. European IPPC Bureau Review of the Best Available Techniques (BAT) Reference Document for the Textiles Industry; European Commission: Bruseels, Belgium, 2019; Volume 1, pp. 2–32. [Google Scholar]

- Shawaqfah, M.; Al Momani, F.A.; Al-Anber, Z.A. Ozone treatment of aqueous solutions containing commercial dyes. Afinidad 2012, 69, 229–234. [Google Scholar]

- Hu, C.; Wang, Y. Decolorization and biodegradability of photocatalytic treated azo dyes and wool textile wastewater. Chemosphere 1999, 39, 2107–2115. [Google Scholar] [PubMed]

- Bae, J.S.; Freeman, H.S. Aquatic toxicity evaluation of copper-complexed direct dyes to the Daphnia magna. Dye. Pigment. 2007, 73, 126–132. [Google Scholar] [CrossRef]

- Blánquez, A.; Rodríguez, J.; Brissos, V.; Mendes, S.; Martins, L.O.; Ball, A.S.; Arias, M.E.; Hernández, M. Decolorization and detoxification of textile dyes using a versatile Streptomyces laccase-natural mediator system. Saudi J. Biol. Sci. 2019, 26, 913–920. [Google Scholar] [CrossRef]

- Dias, N.C.; Alves, T.L.M.; Azevedo, D.A.; Bassin, J.P.; Dezotti, M. Metabolization of by-products formed by ozonation of the azo dye Reactive Red 239 in moving-bed biofilm reactors in series. Braz. J. Chem. Eng. 2020, 37, 495–504. [Google Scholar] [CrossRef]

- Sarayu, K.; Sandhya, S. Current technologies for biological treatment of textile wastewater-A review. Appl. Biochem. Biotechnol. 2012, 167, 645–661. [Google Scholar] [CrossRef] [PubMed]

- Al, G.; Özdemir, U.; Aksoy, Ö. Cytotoxic effects of Reactive Blue 33 on Allium cepa determined using Taguchi’s L8 orthogonal array. Ecotoxicol. Environ. Saf. 2013, 98, 36–40. [Google Scholar] [CrossRef]

- Sonwani, R.K.; Swain, G.; Giri, B.S.; Singh, R.S.; Rai, B.N. Biodegradation of Congo red dye in a moving bed biofilm reactor: Performance evaluation and kinetic modeling. Bioresour. Technol. 2020, 302, 122811. [Google Scholar] [CrossRef] [PubMed]

- Hussein, F.H. Chemical properties of treated textile dyeing wastewater. Asian J. Chem. 2013, 25, 9393–9400. [Google Scholar] [CrossRef]

- Heratizadeh, A.; Geier, J.; Molin, S.; Werfel, T. Contact sensitization in patients with suspected textile allergy. Data of the Information Network of Departments of Dermatology (IVDK) 2007–2014. Contact Dermat. 2017, 77, 143–150. [Google Scholar] [CrossRef]

- Paździor, K.; Wrębiak, J.; Klepacz-Smółka, A.; Gmurek, M.; Bilińska, L.; Kos, L.; Sójka-Ledakowicz, J.; Ledakowicz, S. Influence of ozonation and biodegradation on toxicity of industrial textile wastewater. J. Environ. Manag. 2017, 195, 166–173. [Google Scholar] [CrossRef]

- Zhang, S.; Zhong, L.; Wang, J.; Tang, A.; Yang, H. Porous carbon-based MgAlF5·1.5H2O composites derived from carbon-coated clay presenting super high adsorption capacity for Congo Red. Chem. Eng. J. 2021, 406, 126784. [Google Scholar] [CrossRef]

- Bonetto, L.R.; Crespo, J.S.; Guégan, R.; Esteves, V.I.; Giovanela, M. Removal of methylene blue from aqueous solutions using a solid residue of the apple juice industry: Full factorial design, equilibrium, thermodynamics and kinetics aspects. J. Mol. Struct. 2021, 1224, 129296. [Google Scholar] [CrossRef]

- Zhou, S.; Fu, Z.; Xia, L.; Mao, Y.; Zhao, W.; Wang, A.; Zhang, C.; Ding, C.; Xu, W. In situ synthesis of ternary hybrid nanocomposites on natural Juncus effusus fiber for adsorption and photodegradation of organic dyes. Sep. Purif. Technol. 2021, 255, 117671. [Google Scholar] [CrossRef]

- Maruthanayagam, A.; Mani, P.; Kaliappan, K.; Chinnappan, S. In vitro and In silico Studies on the Removal of Methyl Orange from Aqueous Solution Using Oedogonium subplagiostomum AP1. Water. Air. Soil Pollut. 2020, 231, 1–21. [Google Scholar] [CrossRef]

- Radwan, E.K.; Abdel-Aty, A.M.; El-Wakeel, S.T.; Abdel Ghafar, H.H. Bioremediation of potentially toxic metal and reactive dye-contaminated water by pristine and modified Chlorella vulgaris. Environ. Sci. Pollut. Res. 2020, 27, 21777–21789. [Google Scholar] [CrossRef] [PubMed]

- Kristianto, H.; Tanuarto, M.Y.; Prasetyo, S.; Sugih, A.K. Magnetically assisted coagulation using iron oxide nanoparticles-Leucaena leucocephala seeds’ extract to treat synthetic Congo red wastewater. Int. J. Environ. Sci. Technol. 2020, 17, 3561–3570. [Google Scholar] [CrossRef]

- Mateus, G.A.P.; dos Santos, T.R.T.; Sanches, I.S.; Silva, M.F.; de Andrade, M.B.; Paludo, M.P.; Gomes, R.G.; Bergamasco, R. Evaluation of a magnetic coagulant based on Fe3O4 nanoparticles and Moringa oleifera extract on tartrazine removal: Coagulation-adsorption and kinetics studies. Environ. Technol. 2020, 41, 1648–1663. [Google Scholar] [CrossRef]

- Reck, I.M.; Baptista, A.T.A.; Paixão, R.M.; Bergamasco, R.; Vieira, M.F.; Vieira, A.M.S. Application of magnetic coagulant based on fractionated protein of Moringa oleifera Lam. seeds for aqueous solutions treatment containing synthetic dyes. Environ. Sci. Pollut. Res. 2020, 27, 12192–12201. [Google Scholar] [CrossRef] [PubMed]

- Padhiyar, H.; Thanki, A.; Kumar Singh, N.; Pandey, S.; Yadav, M.; Chand Yadav, T. Parametric and kinetic investigations on segregated and mixed textile effluent streams using Moringa oleifera seed powders of different sizes. J. Water Process. Eng. 2020, 34, 101159. [Google Scholar] [CrossRef]

- Puteri, R.D.; Hadisoebroto, R.; Kusumadewi, R.A. Effects of mixing speed on turbidity and dyes removal from wastewater with tiger shrimp shells as biocoagulant. Int. J. Sci. Technol. Res. 2020, 9, 2089–2095. [Google Scholar]

- Garvasis, J.; Prasad, A.R.; Shamsheera, K.O.; Jaseela, P.K.; Joseph, A. Efficient removal of Congo red from aqueous solutions using phytogenic aluminum sulfate nano coagulant. Mater. Chem. Phys. 2020, 251, 123040. [Google Scholar] [CrossRef]

- Özyonar, F.; Gökkuş, Ö.; Sabuni, M. Removal of disperse and reactive dyes from aqueous solutions using ultrasound-assisted electrocoagulation. Chemosphere 2020, 258, 127325. [Google Scholar] [CrossRef]

- Akhtar, A.; Aslam, Z.; Asghar, A.; Bello, M.M.; Raman, A.A.A. Electrocoagulation of Congo Red dye-containing wastewater: Optimization of operational parameters and process mechanism. J. Environ. Chem. Eng. 2020, 8, 104055. [Google Scholar] [CrossRef]

- Fan, T.; Deng, W.; Feng, X.; Pan, F.; Li, Y. An integrated electrocoagulation—Electrocatalysis water treatment process using stainless steel cathodes coated with ultrathin TiO2 nanofilms. Chemosphere 2020, 254, 126776. [Google Scholar] [CrossRef] [PubMed]

- Phalakornkule, C.; Suandokmai, T.; Petchakan, S. A solar powered direct current electrocoagulation system with hydrogen recovery for wastewater treatment. Sep. Sci. Technol. 2020, 55, 2353–2361. [Google Scholar] [CrossRef]

- Rodrigues, A.R.; Seki, C.C.; Ramalho, L.S.; Argondizo, A.; Silva, A.P. Electrocoagulation in a fixed bed reactor—Color removal in batch and continuous mode. Sep. Purif. Technol. 2020, 253, 117481. [Google Scholar] [CrossRef]

- Criado, S.P.; Gonçalves, M.J.; Ballod Tavares, L.B.; Bertoli, S.L. Optimization of electrocoagulation process for disperse and reactive dyes using the response surface method with reuse application. J. Clean. Prod. 2020, 275, 122690. [Google Scholar] [CrossRef]

- dos Santos, A.J.; Brillas, E.; Cabot, P.L.; Sirés, I. Simultaneous persulfate activation by electrogenerated H2O2 and anodic oxidation at a boron-doped diamond anode for the treatment of dye solutions. Sci. Total Environ. 2020, 747, 141541. [Google Scholar] [CrossRef]

- Yang, H.; Bi, Y.; Wang, M.; Chen, C.; Xu, Z.; Chen, K.; Zhou, Y.; Zhang, J.; Niu, Q.J. β-FeOOH self-supporting electrode for efficient electrochemical anodic oxidation process. Chemosphere 2020, 261, 127674. [Google Scholar] [CrossRef]

- Lu, J.; Chen, Z.; Ayele, B.A.; Liu, X.; Chen, Q. Electrocatalytic activities of engineered carbonaceous cathodes for generation of hydrogen peroxide and oxidation of recalcitrant reactive dye. J. Electroanal. Chem. 2020, 878, 114579. [Google Scholar] [CrossRef]

- Ghalebizade, M.; Ayati, B. Investigating electrode arrangement and anode role on dye removal efficiency of electro-peroxone as an environmental friendly technology. Sep. Purif. Technol. 2020, 251, 117350. [Google Scholar] [CrossRef]

- Di, J.; Zhu, M.; Jamakanga, R.; Gai, X.; Li, Y.; Yang, R. Electrochemical activation combined with advanced oxidation on NiCo2O4 nanoarray electrode for decomposition of Rhodamine, B.J. Water Process. Eng. 2020, 37, 101386. [Google Scholar] [CrossRef]

- Qaseem, S.; Dlamini, D.S.; Zikalala, S.A.; Tesha, J.M.; Husain, M.D.; Wang, C.; Jiang, Y.; Wei, X.; Vilakati, G.D.; Li, J. Electro-catalytic membrane anode for dye removal from wastewater. Colloids Surf. A Physicochem. Eng. Asp. 2020, 603, 125270. [Google Scholar] [CrossRef]

- Nawaz, H.; Umar, M.; Ullah, A.; Razzaq, H.; Zia, K.M.; Liu, X. Polyvinylidene fluoride nanocomposite super hydrophilic membrane integrated with Polyaniline-Graphene oxide nano fillers for treatment of textile effluents. J. Hazard. Mater. 2021, 403, 123587. [Google Scholar] [CrossRef]

- Zhang, M.Y.; Wang, X.P.; Lin, R.; Liu, Y.; Chen, F.S.; Cui, L.S.; Meng, X.M.; Hou, J. Improving the hydrostability of ZIF-8 membrane by biomolecule towards enhanced nanofiltration performance for dye removal. J. Memb. Sci. 2021, 618, 118630. [Google Scholar] [CrossRef]

- Meng, J.; Xie, Y.; Gu, Y.H.; Yan, X.; Chen, Y.; Guo, X.J.; Lang, W.Z. PVDF-CaAlg nanofiltration membranes with dual thin-film-composite (TFC) structure and high permeation flux for dye removal. Sep. Purif. Technol. 2021, 255, 117739. [Google Scholar] [CrossRef]

- Vatanpour, V.; Mousavi Khadem, S.S.; Dehqan, A.; Al-Naqshabandi, M.A.; Ganjali, M.R.; Sadegh Hassani, S.; Rashid, M.R.; Saeb, M.R.; Dizge, N. Efficient removal of dyes and proteins by nitrogen-doped porous graphene blended polyethersulfone nanocomposite membranes. Chemosphere 2021, 263, 127892. [Google Scholar] [CrossRef]

- Zeng, H.; Yu, Z.; Shao, L.; Li, X.; Zhu, M.; Liu, Y.; Feng, X.; Zhu, X. A novel strategy for enhancing the performance of membranes for dyes separation: Embedding PAA@UiO-66-NH2 between graphene oxide sheets. Chem. Eng. J. 2021, 403, 126281. [Google Scholar] [CrossRef]

- Mehrjo, F.; Pourkhabbaz, A.; Shahbazi, A. PMO synthesized and functionalized by p-phenylenediamine as new nanofiller in PES-nanofiltration membrane matrix for efficient treatment of organic dye, heavy metal, and salts from wastewater. Chemosphere 2021, 263, 128088. [Google Scholar] [CrossRef] [PubMed]

- Khataee, A.; Fazli, A.; Zakeri, F.; Joo, S.W. Synthesis of a high-performance Z-scheme 2D/2D WO3@CoFe-LDH nanocomposite for the synchronic degradation of the mixture azo dyes by sonocatalytic ozonation process. J. Ind. Eng. Chem. 2020, 89, 301–315. [Google Scholar] [CrossRef]

- Chokshi, N.P.; Ruparelia, J.P. Catalytic Ozonation of Reactive Black 5 Over Silver–Cobalt Composite Oxide Catalyst. J. Inst. Eng. Ser. A 2020, 101, 433–443. [Google Scholar] [CrossRef]

- Wang, J.; Chen, H.; Yuan, R.; Wang, F.; Ma, F.; Zhou, B. Intensified degradation of textile wastewater using a novel treatment of hydrodynamic cavitation with the combination of ozone. J. Environ. Chem. Eng. 2020, 8, 103959. [Google Scholar] [CrossRef]

- Muniyasamy, A.; Sivaporul, G.; Gopinath, A.; Lakshmanan, R.; Altaee, A.; Achary, A.; Velayudhaperumal Chellam, P. Process development for the degradation of textile azo dyes (mono-, di-, poly-) by advanced oxidation process—Ozonation: Experimental & partial derivative modelling approach. J. Environ. Manag. 2020, 265, 110397. [Google Scholar]

- Bilińska, L.; Blus, K.; Foszpańczyk, M.; Gmurek, M.; Ledakowicz, S. Catalytic ozonation of textile wastewater as a polishing step after industrial scale electrocoagulation. J. Environ. Manag. 2020, 265, 110502. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Li, K.; Sun, Z.; Wang, J. Enhanced mineralization of reactive brilliant red X-3B by UV driven photocatalytic membrane contact ozonation. J. Hazard. Mater. 2020, 391, 122194. [Google Scholar] [CrossRef]

- Sun, K.; Yuan, D.; Liu, Y.; Song, Y.; Sun, Z.; Liu, R. Study on the efficiency and mechanism of Direct Red 80 dye by conventional ozonation and peroxone (O3/H2O2) treatment. Sep. Sci. Technol. 2019, 55, 1–9. [Google Scholar] [CrossRef]

- Sadeghi Rad, T.; Khataee, A.; Pouran, S.R.; Joo, S.W. The key role of free radicals generated from activation of H2O2, S2O82− and ozone over chromium/cerium co-doped magnetite nanoparticles. Sep. Purif. Technol. 2020, 239, 116538. [Google Scholar] [CrossRef]

- Abdi, M.; Balagabri, M.; Karimi, H.; Hossini, H.; Rastegar, S.O. Degradation of crystal violet (CV) from aqueous solutions using ozone, peroxone, electroperoxone, and electrolysis processes: A comparison study. Appl. Water Sci. 2020, 10, 1–10. [Google Scholar] [CrossRef]

- Muneer, M.; Kanjal, M.I.; Saeed, M.; Javed, T.; Haq, A.U.; Ud Den, N.Z.; Jamal, M.A.; Ali, S.; Iqbal, M. High energy radiation induced degradation of reactive yellow 145 dye: A mechanistic study. Radiat. Phys. Chem. 2020, 177, 109115. [Google Scholar] [CrossRef]

- Emadi, Z.; Sadeghi, M.; Mohammadi-Moghadam, F.; Sadeghi, R.; Forouzandeh, S.; Sadeghi, R. Decolorization of reactive black-5 high concentration by vermicompost microflora and detoxification of by-products by UV-C/H2O2 post-treatment. Pollution 2020, 6, 503–511. [Google Scholar]

- Ding, X.; Gutierrez, L.; Croue, J.P.; Li, M.; Wang, L.; Wang, Y. Hydroxyl and sulfate radical-based oxidation of RhB dye in UV/H2O2 and UV/persulfate systems: Kinetics, mechanisms, and comparison. Chemosphere 2020, 253, 126655. [Google Scholar] [CrossRef]

- Murcia, M.D.; Gómez, M.; Gómez, E.; Gomez, J.L.; Hidalgo, A.M.; Murcia, S.; Campos, D. Comparison of two excilamps and two reactor configurations in the UV-H2O2 removal process of amaranth. J. Water Process. Eng. 2020, 33, 101051. [Google Scholar] [CrossRef]

- Aristizábal, A.; Perilla, G.; Lara-Borrero, J.A.; Diez, R. KrCl and XeCl excilamps and LP-Hg lamp for UV and UV/H2O2 decolourization of dyes in water. Environ. Technol. 2020, 41, 238–250. [Google Scholar] [CrossRef]

- Laftani, Y.; Chatib, B.; Boussaoud, A.; El Makhfouk, M.; Hachkar, M.; Khayar, M. Optimization of diazo dye disappearance by the UV/H2O2 process using the Box–Behnken design. Water Sci. Technol. 2019, 80, 1731–1739. [Google Scholar] [CrossRef]

- Fattahimoghaddam, H.; Mahvelati-Shamsabadi, T.; Lee, B.K. Efficient Photodegradation of Rhodamine B and Tetracycline over Robust and Green g-C3N4 Nanostructures: Supramolecular Design. J. Hazard. Mater. 2021, 403, 123703. [Google Scholar] [CrossRef]

- He, Z.; Liang, R.; Zhou, C.; Yan, G.; Wu, L. Carbon quantum dots (CQDs)/noble metal co-decorated MIL-53(Fe) as difunctional photocatalysts for the simultaneous removal of Cr(VI) and dyes. Sep. Purif. Technol. 2021, 255, 117725. [Google Scholar] [CrossRef]

- Hui, J.; Pestana, C.J.; Caux, M.; Gunaratne, H.Q.N.; Edwards, C.; Robertson, P.K.J.; Lawton, L.A.; Irvine, J.T.S. Graphitic-C3N4 coated floating glass beads for photocatalytic destruction of synthetic and natural organic compounds in water under UV light. J. Photochem. Photobiol. A Chem. 2021, 405, 112935. [Google Scholar] [CrossRef]

- Rambabu, K.; Bharath, G.; Banat, F.; Show, P.L. Green synthesis of zinc oxide nanoparticles using Phoenix dactylifera waste as bioreductant for effective dye degradation and antibacterial performance in wastewater treatment. J. Hazard. Mater. 2021, 402, 123560. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Jia, X.; Duan, P.; Xia, R.; Zhang, N.; Cheng, B.; Wang, Z.; Zhang, Y. V2O5/P-g-C3N4 Z-scheme enhanced heterogeneous photocatalytic removal of methyl orange from water under visible light irradiation. Colloids Surf. A Physicochem. Eng. Asp. 2020, 608, 125580. [Google Scholar] [CrossRef]

- Shi, J.; Wang, J.; Liang, L.; Xu, Z.; Chen, Y.; Chen, S.; Xu, M.; Wang, X.; Wang, S. Carbothermal synthesis of biochar-supported metallic silver for enhanced photocatalytic removal of methylene blue and antimicrobial efficacy. J. Hazard. Mater. 2021, 401, 123382. [Google Scholar] [CrossRef] [PubMed]

- Morshed, M.N.; Pervez, N.; Behary, N. Statistical modeling and optimization of heterogeneous Fenton ‑ like removal of organic pollutant using fibrous catalysts : A full factorial design. Sci. Rep. 2020, 10, 1–14. [Google Scholar] [CrossRef]

- Qian, H.; Hou, Q.; Yu, G.; Nie, Y.; Bai, C.; Bai, X.; Ju, M. Enhanced removal of dye from wastewater by Fenton process activated by core-shell NiCo2O4@FePc catalyst. J. Clean. Prod. 2020, 273, 123028. [Google Scholar] [CrossRef]

- Punathil, S.; Ghime, D.; Mohapatra, T.; Thakur, C.; Ghosh, P. Fixed Bed Reactor for Removal of Methylene Blue Dye Using Heterogeneous Fenton Catalyst. J. Hazard. ToxicRadioact. Waste 2020, 24, 5515. [Google Scholar]

- Kumar, J.E.; Mulai, T.; Kharmawphlang, W.; Sharan, R.N.; Sahoo, M.K. Decolourisation, mineralisation and detoxification of mixture of azo dyes using Fenton and Fenton-type advanced oxidation processes. Chem. Pap. 2020, 74, 3145–3159. [Google Scholar] [CrossRef]

- Nwanji, O.L.; Omorogie, M.O.; Olowoyo, J.O.; Babalola, J.O. Remediation of industrial dye by Fenton-activated biogenic waste. Surf. Interfaces 2020, 20, 100555. [Google Scholar] [CrossRef]

- Wu, Q.; Siddique, M.S.; Yu, W. Iron-nickel bimetallic metal-organic frameworks as bifunctional Fenton-like catalysts for enhanced adsorption and degradation of organic contaminants under visible light: Kinetics and mechanistic studies. J. Hazard. Mater. 2021, 401, 123261. [Google Scholar] [CrossRef]

- Mushtaq, F.; Zahid, M.; Mansha, A.; Bhatti, I.A.; Mustafa, G.; Nasir, S.; Yaseen, M. MnFe2O4/coal fly ash nanocomposite: A novel sunlight-active magnetic photocatalyst for dye degradation. Int. J. Environ. Sci. Technol. 2020, 17, 4233–4248. [Google Scholar] [CrossRef]

- Tan, W.; Ai, J.; Fan, Y.; Liu, X.; Xu, Y.; Zhang, H.; Huang, Y.H. Enhanced mineralization of Reactive Black 5 by waste iron oxide via photo-Fenton process. Res. Chem. Intermed. 2020, 46, 4423–4431. [Google Scholar] [CrossRef]

- Silva, E.D.N.; Brasileiro, I.L.O.; Madeira, V.S.; De Farias, B.A.; Ramalho, M.L.A.; Rodríguez-Aguado, E.; Rodríguez-Castellón, E. Reusable CuFe2O4-Fe2O3 catalyst synthesis and application for the heterogeneous photo-Fenton degradation of methylene blue in visible light. J. Environ. Chem. Eng. 2020, 8, 104132. [Google Scholar] [CrossRef]

- Chen, J.; Xing, Z.; Han, J.; Su, M.; Li, Y.; Lu, A. Enhanced degradation of dyes by Cu-Co-Ni nanoparticles loaded on amino-modified octahedral metal–organic framework. J. Alloy. Compd. 2020, 834, 155106. [Google Scholar] [CrossRef]

- Ain, Q.U.; Rasheed, U.; Yaseen, M.; Zhang, H.; Tong, Z. Superior dye degradation and adsorption capability of polydopamine modified Fe3O4-pillared bentonite composite. J. Hazard. Mater. 2020, 397, 122758. [Google Scholar] [CrossRef]

- Suhan, M.B.K.; Shuchi, S.B.; Anis, A.; Haque, Z.; Islam, M.S. Comparative degradation study of remazol black B dye using electro-coagulation and electro-Fenton process: Kinetics and cost analysis. Environ. Nanotechnol. Monit. Manag. 2020, 14, 100335. [Google Scholar] [CrossRef]

- Setayesh, S.R.; Nazari, P.; Maghbool, R. Engineered FeVO4/CeO2 nanocomposite as a two-way superior electro-Fenton catalyst for model and real wastewater treatment. J. Environ. Sci. 2020, 97, 110–119. [Google Scholar] [CrossRef] [PubMed]

- Márquez, A.A.; Sirés, I.; Brillas, E.; Nava, J.L. Mineralization of Methyl Orange azo dye by processes based on H2O2 electrogeneration at a 3D-like air-diffusion cathode. Chemosphere 2020, 259, 127466. [Google Scholar] [CrossRef] [PubMed]

- Zahrani, A.A.; Ayati, B. Improving Fe-based heterogeneous Electro-Fenton nano catalyst using transition metals in a novel orbiting electrodes reactor. Chemosphere 2020, 256, 127049. [Google Scholar] [CrossRef]

- Ergan, B.T.; Gengec, E. Dye degradation and kinetics of online Electro-Fenton system with thermally activated carbon fiber cathodes. J. Environ. Chem. Eng. 2020, 8, 104217. [Google Scholar] [CrossRef]

- Jiao, Y.; Ma, L.; Tian, Y.; Zhou, M. A flow-through electro-Fenton process using modified activated carbon fiber cathode for orange II removal. Chemosphere 2020, 252, 126483. [Google Scholar] [CrossRef]

- Ayed, L.; Ladhari, N.; Achour, S.; Chaieb, K. Decolorization of Reactive Yellow 174 dye in real textile wastewater by active consortium: Experimental factorial design for bioremediation process optimization. J. Text. Inst. 2020. [Google Scholar] [CrossRef]

- Guo, G.; Hao, J.; Tian, F.; Liu, C.; Ding, K.; Xu, J.; Zhou, W.; Guan, Z. Decolorization and detoxification of azo dye by halo-alkaliphilic bacterial consortium: Systematic investigations of performance, pathway and metagenome. Ecotoxicol. Environ. Saf. 2020, 204. [Google Scholar] [CrossRef]

- Dhaouefi, Z.; Toledo-Cervantes, A.; Ghedira, K.; Chekir-Ghedira, L.; Muñoz, R. Decolorization and phytotoxicity reduction in an innovative anaerobic/aerobic photobioreactor treating textile wastewater. Chemosphere 2019, 234, 356–364. [Google Scholar] [CrossRef]

- Louati, I.; Elloumi-Mseddi, J.; Cheikhrouhou, W.; Hadrich, B.; Nasri, M.; Aifa, S.; Woodward, S.; Mechichi, T. Simultaneous cleanup of Reactive Black 5 and cadmium by a desert soil bacterium. Ecotoxicol. Environ. Saf. 2020, 190, 110103. [Google Scholar] [CrossRef]

- Pandey, K.; Saha, P.; Rao, K.V.B. A study on the utility of immobilized cells of indigenous bacteria for biodegradation of reactive azo dyes. Prep. Biochem. Biotechnol. 2020, 50, 317–329. [Google Scholar] [CrossRef] [PubMed]

- Reddy, S.; Osborne, J.W. Biodegradation and biosorption of Reactive Red 120 dye by immobilized Pseudomonas guariconensis: Kinetic and toxicity study. Water Environ. Res. 2020, 92, 1230–1241. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, Z.; Xing, L.; Zhou, J.; Ren, J.; Ming, L.; Hua, Z.; Li, X.; Zhang, D. Ethanol as an efficient cosubstrate for the biodegradation of azo dyes by Providencia rettgeri: Mechanistic analysis based on kinetics, pathways and genomics. Bioresour. Technol. 2021, 31, 124117. [Google Scholar] [CrossRef]

- Chen, G.; An, X.; Feng, L.; Xia, X.; Zhang, Q. Genome and transcriptome analysis of a newly isolated azo dye degrading thermophilic strain Anoxybacillus sp. Ecotoxicol. Environ. Saf. 2020, 203, 111047. [Google Scholar] [CrossRef] [PubMed]

- Franca, R.D.G.; Vieira, A.; Carvalho, G.; Oehmen, A.; Pinheiro, H.M.; Barreto Crespo, M.T.; Lourenço, N.D. Oerskovia paurometabola can efficiently decolorize azo dye Acid Red 14 and remove its recalcitrant metabolite. Ecotoxicol. Environ. Saf. 2020, 191, 110007. [Google Scholar] [CrossRef]

- Thanavel, M.; Kadam, S.K.; Biradar, S.P.; Govindwar, S.P.; Jeon, B.-H.; Sadasivam, S.K. Combined biological and advanced oxidation process for decolorization of textile dyes. SN Appl. Sci. 2019, 1, 1–16. [Google Scholar] [CrossRef]

- Montañez‑Barragán, B.; Sanz-Martin, J.L.; Gutiérrez‑Macías, P.; Morato-Cerro, A.; Rodríguez‑Vázquez, R.; Barragán‑Huerta, B.E. Azo dyes decolorization under high alkalinity and salinity conditions by Halomonas sp. in batch and packed bed reactor. Extremophiles 2020, 20, 239–247. [Google Scholar] [CrossRef]

- Agrawal, K.; Verma, P. Myco-valorization approach using entrapped Myrothecium verrucaria ITCC-8447 on synthetic and natural support via column bioreactor for the detoxification and degradation of anthraquinone dyes. Int. Biodeterior. Biodegrad. 2020, 153, 105052. [Google Scholar] [CrossRef]

- Ali, S.S.; Sun, J.; Koutra, E.; El-Zawawy, N.; Elsamahy, T.; El-Shetehy, M. Construction of a novel cold-adapted oleaginous yeast consortium valued for textile azo dye wastewater processing and biorefinery. Fuel 2021, 285, 119050. [Google Scholar] [CrossRef]

- Zhao, J.; Wu, Q.X.; Cheng, X.D.; Su, T.; Wang, X.H.; Zhang, W.N.; Lu, Y.M.; Chen, Y. Biodegradation and detoxification of the triphenylmethane dye coomassie brilliant blue by the extracellular enzymes from mycelia of Lactarius deliciosus. Front. Chem. Sci. Eng. 2020, 1–16. [Google Scholar] [CrossRef]

- Gao, T.; Qin, D.; Zuo, S.; Peng, Y.; Xu, J.; Yu, B.; Song, H.; Dong, J. Decolorization and detoxification of triphenylmethane dyes by isolated endophytic fungus, Bjerkandera adusta SWUSI4 under non-nutritive conditions. Bioresour. Bioprocess. 2020, 7, 1–12. [Google Scholar] [CrossRef]

- Laraib, Q.; Shafique, M.; Jabeen, N.; Naz, S.A.; Nawaz, H.R.; Solangi, B.; Zubair, A.; Sohail, M. Luffa cylindrica immobilized with Aspergillus terreus QMS-1: An efficient and cost-effective strategy for the removal of congo red using stirred tank reactor. Pol. J. Microbiol. 2020, 69, 193–203. [Google Scholar] [CrossRef]

- Habeeb Mohamed, V.B.; Arunprasath, R.; Purusothaman, G. Biological treatment of azo dyes on effluent by Neurospora sp isolated and adopted from dye contaminated site. J. Text. Inst. 2020, 111, 1239–1245. [Google Scholar] [CrossRef]

- Noman, E.; Al-Gheethi, A.; Talip, B.A.; Mohamed, R.; Kassim, A.H. Decolourization of Dye Wastewater by A Malaysian isolate of Aspergillus iizukae 605EAN Strain: A Biokinetic, Mechanism and Microstructure Study. Int. J. Environ. Anal. Chem. 2020, 100, 1–24. [Google Scholar] [CrossRef]

- Al-Tohamy, R.; Sun, J.; Fareed, M.F.; Kenawy, E.R.; Ali, S.S. Ecofriendly biodegradation of Reactive Black 5 by newly isolated Sterigmatomyces halophilus SSA1575, valued for textile azo dye wastewater processing and detoxification. Sci. Rep. 2020, 10, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Chatterjee, S.; Dey, S.; Sarma, M.; Chaudhuri, P.; Das, S. Biodegradation of Congo Red by Manglicolous Filamentous Fungus Aspergillus flavus JKSC-7 Isolated from Indian Sundabaran Mangrove Ecosystem. Appl. Biochem. Microbiol. 2020, 56, 708–717. [Google Scholar] [CrossRef]

- Šlosarčíková, P.; Plachá, D.; Malachová, K.; Rybková, Z.; Novotný, Č. Biodegradation of Reactive Orange 16 azo dye by simultaneous action of Pleurotus ostreatus and the yeast Candida zeylanoides. Folia Microbiol. 2020, 65, 629–638. [Google Scholar] [CrossRef]

- Khan, S.A.; Mehmood, S.; Nabeela; Iqbal, A.; Hamayun, M. Industrial polluted soil borne fungi decolorize the recalcitrant azo dyes Synozol red HF–6BN and Synozol black B. Ecotoxicol. Environ. Saf. 2020, 206, 111381. [Google Scholar] [CrossRef]

- Sosa-Martínez, J.D.; Balagurusamy, N.; Montañez, J.; Peralta, R.M.R.A.; Moreira, R.d.F.P.M.; Bracht, A.; Peralta, R.M.R.A.; Morales-Oyervides, L. Synthetic dyes biodegradation by fungal ligninolytic enzymes: Process optimization, metabolites evaluation and toxicity assessment. J. Hazard. Mater. 2020, 400, 123254. [Google Scholar]

- Vineh, M.B.; Saboury, A.A.; Poostchi, A.A.; Ghasemi, A. Biodegradation of phenol and dyes with horseradish peroxidase covalently immobilized on functionalized RGO-SiO2 nanocomposite. Int. J. Biol. Macromol. 2020, 164, 4403–4414. [Google Scholar] [CrossRef] [PubMed]

- Xu, L.; Sun, K.; Wang, F.; Zhao, L.; Hu, J.; Ma, H.; Ding, Z. Laccase production by Trametes versicolor in solid-state fermentation using tea residues as substrate and its application in dye decolorization. J. Environ. Manag. 2020, 270, 110904. [Google Scholar] [CrossRef]

- Navas, L.E.; Carballo, R.; Levin, L.; Berretta, M.F. Fast decolorization of azo dyes in alkaline solutions by a thermostable metal-tolerant bacterial laccase and proposed degradation pathways. Extremophiles 2020, 24, 705–719. [Google Scholar] [CrossRef]

- Yin, Q.; Zhou, G.; Peng, C.; Zhang, Y.; Kües, U.; Liu, J.; Xiao, Y.; Fang, Z. The first fungal laccase with an alkaline pH optimum obtained by directed evolution and its application in indigo dye decolorization. AMB Express 2019, 9, 1–13. [Google Scholar] [CrossRef]

- Uber, T.M.; Buzzo, A.J.d.R.; Scaratti, G.; Amorim, S.M.; Helm, C.V.; Maciel, G.M.; Peralta, R.A.; Moreira, R.d.F.P.M.; Bracht, A.; Peralta, R.M. Comparative detoxification of Remazol Rrilliant Blue R by free and immobilized laccase of Oudemansiella canarii. Biocatal. Biotransform. 2020, 1–12. [Google Scholar] [CrossRef]

- Abou-El-Souod, G.; Hamouda, R.A.; El-Sheekh, M. Influence of heavy metal as co-contamination on biodegradation of dyes by free and immobilized Scenedesmus obliquus. Desalin. Water Treat. 2020, 182, 351–358. [Google Scholar] [CrossRef]

- Han, S.; Han, W.; Chen, J.; Sun, Y.; Dai, M.; Zhao, G. Bioremediation of malachite green by cyanobacterium Synechococcus elongatus PCC 7942 engineered with a triphenylmethane reductase gene. Appl. Microbiol. Biotechnol. 2020, 104, 3193–3204. [Google Scholar] [CrossRef]

- Mahajan, P.; Kaushal, J. Phytoremediation of azo dye methyl red by macroalgae Chara vulgaris L.: Kinetic and equilibrium studies. Environ. Sci. Pollut. Res. 2020, 27, 26406–26418. [Google Scholar] [CrossRef]

- Oyebamiji, O.O.; Boeing, W.J.; Holguin, F.O.; Ilori, O.; Amund, O. Green microalgae cultured in textile wastewater for biomass generation and biodetoxification of heavy metals and chromogenic substances. Bioresour. Technol. Rep. 2019, 7, 100247. [Google Scholar] [CrossRef]

- Behl, K.; Joshi, M.; Sharma, M.; Tandon, S.; Chaurasia, A.K.; Bhatnagar, A.; Nigam, S. Performance evaluation of isolated electrogenic microalga coupled with graphene oxide for decolorization of textile dye wastewater and subsequent lipid production. Chem. Eng. J. 2019, 375, 121950. [Google Scholar] [CrossRef]

- Zhu, Y.; Wang, W.; Ni, J.; Hu, B. Cultivation of granules containing anaerobic decolorization and aerobic degradation cultures for the complete mineralization of azo dyes in wastewater. Chemosphere 2020, 246, 125753. [Google Scholar] [CrossRef]

- Berkessa, Y.W.; Yan, B.; Li, T.; Jegatheesan, V.; Zhang, Y. Treatment of anthraquinone dye textile wastewater using anaerobic dynamic membrane bioreactor: Performance and microbial dynamics. Chemosphere 2020, 238, 124539. [Google Scholar] [CrossRef]

- Cai, J.; Pan, A.; Li, Y.; Xiao, Y.; Zhou, Y.; Chen, C.; Sun, F.; Su, X. A novel strategy for enhancing anaerobic biodegradation of an anthraquinone dye reactive blue 19 with resuscitation-promoting factors. Chemosphere 2021, 263, 127922. [Google Scholar] [CrossRef]

- Gadow, S.I.; Li, Y.Y. Development of an integrated anaerobic/aerobic bioreactor for biodegradation of recalcitrant azo dye and bioenergy recovery: HRT effects and functional resilience. Bioresour. Technol. Rep. 2020, 9, 100388. [Google Scholar] [CrossRef]

- Tang, W.; Zhou, B.; Xing, K.; Tan, L. Co-enhanced activated sludge system by static magnetic field and two halotolerant yeasts for azo dye treatment. Water Environ. Res. 2020, 1–10. [Google Scholar]

- Zhuang, H.; Shi, J.; Shan, S.; Ping, L.; Zhang, C. Enhanced anaerobic treatment of azo dye wastewater via direct interspecies electron transfer with Fe3O4/sludge carbon. Int. J. Hydrogen Energy 2020, 45, 28476–28487. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Watari, T.; Hatamoto, M.; Sutani, D.; Setiadi, T.; Yamaguchi, T. Evaluation of a combined anaerobic baffled reactor–downflow hanging sponge biosystem for treatment of synthetic dyeing wastewater. Environ. Technol. Innov. 2020, 19, 100913. [Google Scholar] [CrossRef]

- Shoukat, R.; Khan, S.J.; Jamal, Y. Hybrid anaerobic-aerobic biological treatment for real textile wastewater. J. Water Process. Eng. 2019, 29, 100804. [Google Scholar] [CrossRef]

- Carvalho, J.R.S.; Amaral, F.M.; Florencio, L.; Kato, M.T.; Delforno, T.P.; Gavazza, S. Microaerated UASB reactor treating textile wastewater: The core microbiome and removal of azo dye Direct Black 22. Chemosphere 2020, 242, 125157. [Google Scholar] [CrossRef]

- Hameed, B.B.; Ismail, Z.Z. Biodegradation of reactive yellow dye using mixed cells immobilized in different biocarriers by sequential anaerobic/aerobic biotreatment: Experimental and modelling study. Environ. Technol. (UK) 2020, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Hameed, B.B.; Ismail, Z.Z. New application of Orchis mascula as a biocarrier for immobilization of mixed cells for biodegradation and detoxification of reactive azo dyes. Environ. Sci. Pollut. Res. 2020, 27, 38732–38744. [Google Scholar] [CrossRef] [PubMed]

- Cui, M.H.; Sangeetha, T.; Gao, L.; Wang, A.J. Efficient azo dye wastewater treatment in a hybrid anaerobic reactor with a built-in integrated bioelectrochemical system and an aerobic biofilm reactor: Evaluation of the combined forms and reflux ratio. Bioresour. Technol. 2019, 292, 122001. [Google Scholar] [CrossRef] [PubMed]

- Ong, C.; Lee, K.; Chang, Y. Biodegradation of mono azo dye-Reactive Orange 16 by acclimatizing biomass systems under an integrated anoxic-aerobic REACT sequencing batch moving bed biofilm reactor. J. Water Process. Eng. 2020, 36, 101268. [Google Scholar] [CrossRef]

- Castro, F.D.; Bassin, J.P.; Alves, T.L.M.; Sant’Anna, G.L.; Dezotti, M. Reactive Orange 16 dye degradation in anaerobic and aerobic MBBR coupled with ozonation: Addressing pathways and performance. Int. J. Environ. Sci. Technol. 2020, 1–20. [Google Scholar] [CrossRef]

- Deng, D.; Lamssali, M.; Aryal, N.; Ofori-Boadu, A.; Jha, M.K.; Samuel, R.E. Textiles wastewater treatment technology: A review. Water Environ. Res. 2020, 92, 1805–1810. [Google Scholar] [CrossRef] [PubMed]

- Katheresan, V.; Kansedo, J.; Lau, S.Y. Efficiency of various recent wastewater dye removal methods: A review. J. Environ. Chem. Eng. 2018, 6, 4676–4697. [Google Scholar] [CrossRef]

- Glaze, W.H.; Kang, J.W.; Chapin, D.H. The chemistry of water treatment processes involving ozone, hydrogen peroxide and ultraviolet radiation. Ozone Sci. Eng. 1987, 9, 335–352. [Google Scholar] [CrossRef]

- Harvey, D.; Rutledge, N. Industrial Chemistry; Scientific e-Resources: New Delhi, India, 2019; ISBN 9781839471971. [Google Scholar]

- Bühler, R.E.; Staehelin, J.; Hoigné, J. Ozone decomposition in water studied by pulse radiolysis. 1. HO2/O2− and HO3/O3− as intermediates. J. Phys. Chem. 1984, 88, 2560–2564. [Google Scholar]

- Tomiyasu, H.; Fukutomi, H.; Gordon, G. Kinetics and Mechanism of Ozone Decomposition in Basic Aqueous Solution. Inorg. Chem. 1985, 24, 2962–2966. [Google Scholar] [CrossRef]

- Beltran, F.J. Ozone Reaction Kinetics for Water and Wastewater Systems; CRC Press: Boca Raton, FL, USA, 2004; ISBN 978-1-56670-629-2. [Google Scholar]

- Perkowski, J.; Kos, L.; Ledakowicz, S.; Zylla, R. Decomposition of anthraquinone dye acid blue 62 by the decoloration of textile wastewater by advanced oxidation process. Fibres Text. East. Eur. 2003, 11, 88–94. [Google Scholar]

- Perkowski, J.; Kos, L.; Zyłła, R.; Ledakowicz, S. A kinetic model of decoloration of water solution of anthraquinone dye initiated by generality hydroksyl radicals. Fibres Text. East. Eur. 2005, 13, 59–64. [Google Scholar]

- Hashimoto, S.; Miyata, T.; Suzuki, N.; Kawakami, W. Decoloration and degradation of an anthraquinone dye aqueous solution in flow system using an electron accelerator. Radiat. Phys. Chem. 1979, 13, 107–113. [Google Scholar] [CrossRef]

- Yang, D.; Yuan, J. COD and Color Removal from Real Dyeing Wastewater by Ozonation. Water Environ. Res. 2016, 88, 403–407. [Google Scholar] [CrossRef]

- Rekhate, C.V.; Shrivastava, J.K. Decolorization of Azo Dye Solution by Ozone Based Advanced Oxidation Processes: Optimization Using Response Surface Methodology and Neural Network. Ozone Sci. Eng. 2020, 00, 1–15. [Google Scholar] [CrossRef]

- Zhang, X.B.; Dong, W.Y.; Yang, W. Decolorization efficiency and kinetics of typical reactive azo dye RR2 in the homogeneous Fe(II) catalyzed ozonation process. Chem. Eng. J. 2013, 233, 14–23. [Google Scholar] [CrossRef]

- Bilińska, L.; Żyłła, R.; Smółka, K.; Gmurek, M.; Ledakowicz, S. Modeling of ozonation of C.I. reactive black 5 through a kinetic approach. Fibres Text. East. Eur. 2017, 25, 54–60. [Google Scholar] [CrossRef]

- Baffoun, A.; Ghali, A.E.; Hachani, I. Decolorization kinetics of acid azo dye and basic thiazine dye in aqueous solution by UV/H2O2 and UV/FENTON: Effects of operational parameters. Autex Res. J. 2017, 17, 85–94. [Google Scholar] [CrossRef]

- Castro, F.D.; Bassin, J.P.; Dezotti, M. Treatment of a simulated textile wastewater containing the Reactive Orange 16 azo dye by a combination of ozonation and moving-bed biofilm reactor: Evaluating the performance, toxicity, and oxidation by-products. Environ. Sci. Pollut. Res. 2017, 24, 6307–6316. [Google Scholar] [CrossRef]

- Kasprzyk-Hordern, B.; Ziółek, M.; Nawrocki, J. Catalytic ozonation and methods of enhancing molecular ozone reactions in water treatment. Appl. Catal. B Environ. 2003, 46, 639–669. [Google Scholar] [CrossRef]

- Nawrocki, J. Catalytic ozonation in water: Controversies and questions. Discussion paper. Appl. Catal. B Environ. 2013, 142–143, 465–471. [Google Scholar] [CrossRef]

- Asgari, G.; Faradmal, J.; Nasab, H.Z.; Ehsani, H. Catalytic ozonation of industrial textile wastewater using modified C-doped MgO eggshell membrane powder. Adv. Powder Technol. 2019, 30, 1297–1311. [Google Scholar] [CrossRef]

- Khamparia, S.; Jaspal, D.K. Adsorption in combination with ozonation for the treatment of textile waste water: A critical review. Front. Environ. Sci. Eng. 2017, 11, 1–18. [Google Scholar] [CrossRef]

- Nakhate, P.H.; Gadipelly, C.R.; Joshi, N.T.; Marathe, K.V. Engineering aspects of catalytic ozonation for purification of real textile industry wastewater at the pilot scale. J. Ind. Eng. Chem. 2018, 69, 77–89. [Google Scholar] [CrossRef]

- Merényi, G.; Lind, J.; Naumov, S.; Sonntag, C. Von Reaction of ozone with hydrogen peroxide (peroxone process): A revision of current mechanistic concepts based on thermokinetic and quantum-chemical considerations. Environ. Sci. Technol. 2010, 44, 3505–3507. [Google Scholar] [CrossRef] [PubMed]

- Rehman, M.S.U.; Muhammad, A.; Shafeeq, A.; Chughtai, M.A.; Ali, A.M.; Ahmad, F. Decolorization of Turquoise Blue Dye by Ozonation, O3/H2O2 and Fenton Processes. Res. J. Environ. Sci. 2008, 2, 310–315. [Google Scholar]

- Fenton, H. Oxidation of Tartaic Acid in presence of Iron. J. Chem. Soc. Trans. 1894, 65, 899–910. [Google Scholar] [CrossRef]

- Wang, S. A Comparative study of Fenton and Fenton-like reaction kinetics in decolourisation of wastewater. Dye. Pigment. 2008, 76, 714–720. [Google Scholar] [CrossRef]

- Ledakowicz, S.; Maciejewska, R.; Gȩbicka, L.; Perkowski, J. Kinetics of the decolorization by Fenton’s reagent. Ozone Sci. Eng. 2000, 22, 195–205. [Google Scholar] [CrossRef]

- Chen, Y.; Cheng, Y.; Guan, X.; Liu, Y.; Nie, J.; Li, C. A Rapid Fenton treatment of bio-treated dyeing and finishing wastewater at second-scale intervals: Kinetics by stopped-flow technique and application in a full-scale plant. Sci. Rep. 2019, 9, 1–11. [Google Scholar] [CrossRef]

- Giwa, A.R.A.; Bello, I.A.; Olabintan, A.B.; Bello, O.S.; Saleh, T.A. Kinetic and thermodynamic studies of fenton oxidative decolorization of methylene blue. Heliyon 2020, 6, 4–10. [Google Scholar] [CrossRef]

- Khan, J.; Sayed, M.; Ali, F.; Khan, H.M. Removal of Acid Yellow 17 Dye by Fenton Oxidation Process. Z. Fur Phys. Chem. 2018, 232, 507–525. [Google Scholar] [CrossRef]

- Hashemian, S. Fenton-like oxidation of malachite green solutions: Kinetic and thermodynamic study. J. Chem. 2013, 2013. [Google Scholar] [CrossRef]

- Argun, M.E.; Karatas, M. Application of Fenton Process for Decolorization of Reactive Black 5 from Sythetic Wastewater: Kinetics and Thermodynamics. Environ. Prog. Sustain. Energy 2010, 30, 540–548. [Google Scholar] [CrossRef]

- Ledakowicz, S.; Bilińska, L.; Żyłła, R. Application of Fenton’s Reagent in the Textile Wastewater Treatment Under Industrial Conditions. Ecol. Chem. Eng. S 2012, 19, 163–174. [Google Scholar] [CrossRef]

- Chen, H.; Motuzas, J.; Martens, W.; Diniz da Costa, J.C. Degradation of azo dye Orange II under dark ambient conditions by calcium strontium copper perovskite. Appl. Catal. B Environ. 2018, 221, 691–700. [Google Scholar] [CrossRef]

- He, J.; Yang, X.; Men, B.; Wang, D. Interfacial mechanisms of heterogeneous Fenton reactions catalyzed by iron-based materials: A review. J. Environ. Sci. 2016, 39, 97–109. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, A.; Ma, J.; Fu, M. Facile green synthesis of functional nanoscale zero-valent iron and studies of its activity toward ultrasound-enhanced decolorization of cationic dyes. Chemosphere 2017, 166, 80–88. [Google Scholar] [CrossRef] [PubMed]

- Thomas, N.; Dionysiou, D.D.; Pillai, S.C. Heterogeneous Fenton catalysts: A review of recent advances. J. Hazard. Mater. 2021, 404, 124082. [Google Scholar] [CrossRef] [PubMed]

- Kliś, S.; Thomas, M.; Barbusiński, K.; Golombek, K.; Krzeminski, Ł.; Chyc, M. Removal of azo dye acid red 27 from aqueous solutions using classical and modified fenton reagent with zero-valent iron. Fibres Text. East. Eur. 2019, 137, 100–106. [Google Scholar] [CrossRef]

- Muniyasamy, A.; Sivaporul, G.; Gopinath, A.; John, J.; Achary, A.; Chellam, P.V. Fractional factorial design modelling on degradation of Direct Red 81 dye by advanced oxidation process—ozonation: Reaction kinetics. Water Sci. Technol. 2019, 80, 2037–2046. [Google Scholar] [CrossRef]

- Venkatesh, S.; Venkatesh, K. Ozonation for Degradation of Acid Red 14: Effect of Buffer Solution. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2020, 90, 209–212. [Google Scholar] [CrossRef]

- Hien, N.T.; Nguyen, L.H.; Van, H.T.; Nguyen, T.D.; Nguyen, T.H.V.; Chu, T.H.H.; Nguyen, T.V.; Trinh, V.T.; Vu, X.H.; Aziz, K.H.H. Heterogeneous catalyst ozonation of Direct Black 22 from aqueous solution in the presence of metal slags originating from industrial solid wastes. Sep. Purif. Technol. 2020, 233, 115961. [Google Scholar] [CrossRef]

- Hu, E.; Shang, S.; Chiu, A.K.L. Removal of Reactive Dyes in Textile Effluents by Catalytic Ozonation Pursuing on-Site Effluent Recycling. Molecules 2019, 24, 2755. [Google Scholar] [CrossRef]

- El Hassani, K.; Kalnina, D.; Turks, M.; Beakou, B.H.; Anouar, A. Enhanced degradation of an azo dye by catalytic ozonation over Ni-containing layered double hydroxide nanocatalyst. Sep. Purif. Technol. 2019, 210, 764–774. [Google Scholar] [CrossRef]

- Bakht Shokouhi, S.; Dehghanzadeh, R.; Aslani, H.; Shahmahdi, N. Activated carbon catalyzed ozonation (ACCO) of Reactive Blue 194 azo dye in aqueous saline solution: Experimental parameters, kinetic and analysis of activated carbon properties. J. Water Process. Eng. 2020, 35, 101188. [Google Scholar] [CrossRef]

- Kamarehie, B.; Jafari, A.; Ghaderpoori, M.; Amin Karami, M.; Mousavi, K.; Ghaderpoury, A. Catalytic ozonation process using PAC/γ-Fe 2 O 3 to Alizarin Red S degradation from aqueous solutions: A batch study. Chem. Eng. Commun. 2019, 206, 898–908. [Google Scholar] [CrossRef]

- Yuan, M.; Fu, X.; Yu, J.; Xu, Y.; Huang, J.; Li, Q.; Sun, D. Green synthesized iron nanoparticles as highly efficient fenton-like catalyst for degradation of dyes. Chemosphere 2020, 261, 127618. [Google Scholar] [CrossRef]

- Verduzco, L.E.; Garcia-Díaz, R.; Martinez, A.I.; Salgado, R.A.; Méndez-Arriaga, F.; Lozano-Morales, S.A.; Avendaño-Alejo, M.; Padmasree, K.P. Degradation efficiency of methyl orange dye by La0.5Sr0.5CoO3 perovskite oxide under dark and UV irradiated conditions. Dye. Pigment. 2020, 183, 108743. [Google Scholar] [CrossRef]

- Mohamed, H.; Mohamed, H.; Mostefa, T.; Yabri, B.; Rachid, S. Simultaneous biodegradation of methylene blue and phenol by Trametes hirsuta in batch and packed bed reactors. Res. J. Chem. Environ. 2019, 23, 106–115. [Google Scholar]

- Alam, R.; Ardiati, F.C.; Solihat, N.N.; Alam, M.B.; Lee, S.H.; Yanto, D.H.Y.; Watanabe, T.; Kim, S. Biodegradation and metabolic pathway of anthraquinone dyes by Trametes hirsuta D7 immobilized in light expanded clay aggregate and cytotoxicity assessment. J. Hazard. Mater. 2020, 405, 124176. [Google Scholar] [CrossRef] [PubMed]

- Assadi, A.; Naderi, M.; Mehrasbi, M.R. Anaerobic–aerobic sequencing batch reactor treating azo dye containing wastewater: Effect of high nitrate ions and salt. J. Water Reuse Desalin. 2018, 8, 251–261. [Google Scholar] [CrossRef]

- Korenak, J.; Ploder, J.; Trček, J.; Hélix-Nielsen, C.; Petrinic, I. Decolourisations and biodegradations of model azo dye solutions using a sequence batch reactor, followed by ultrafiltration. Int. J. Environ. Sci. Technol. 2018, 15, 483–492. [Google Scholar] [CrossRef]

- Yan, L.K.Q.; Fung, K.Y.; Ng, K.M. Aerobic sludge granulation for simultaneous anaerobic decolorization and aerobic aromatic amines mineralization for azo dye wastewater treatment. Environ. Technol. 2018, 39, 1368–1375. [Google Scholar] [CrossRef] [PubMed]

- Bahia, M.; Passos, F.; Adarme, O.F.H.; Aquino, S.F.; Silva, S.Q. Anaerobic-Aerobic Combined System for the Biological Treatment of Azo Dye Solution using Residual Yeast. Water Environ. Res. 2018, 90, 729–737. [Google Scholar] [CrossRef]

- Li, H.H.; Wang, Y.T.; Wang, Y.T.; Wang, H.X.; Sun, K.K.; Lu, Z.M. Bacterial degradation of anthraquinone dyes. J. Zhejiang Univ. Sci. B 2019, 20, 528–540. [Google Scholar] [CrossRef]

- Goud, B.S.; Cha, H.L.; Koyyada, G.; Kim, J.H. Augmented Biodegradation of Textile Azo Dye Effluents by Plant Endophytes: A Sustainable, Eco-Friendly Alternative. Curr. Microbiol. 2020, 77, 3240–3255. [Google Scholar] [CrossRef] [PubMed]

- Durão, P.; Bento, I.; Fernandes, A.T.; Melo, E.P.; Lindley, P.F.; Martins, L.O. Perturbations of the T1 copper site in the CotA laccase from Bacillus subtilis: Structural, biochemical, enzymatic and stability studies. J. Biol. Inorg. Chem. 2006, 11, 514–526. [Google Scholar] [CrossRef] [PubMed]

- Husain, Q. Peroxidase mediated decolorization and remediation of wastewater containing industrial dyes: A review. Rev. Environ. Sci. Biotechnol. 2010, 9, 117–140. [Google Scholar] [CrossRef]

- Kalsoom, U.; Ashraf, S.S.; Meetani, M.A.; Rauf, M.A.; Bhatti, H.N. Mechanistic study of a diazo dye degradation by Soybean Peroxidase. Chem. Cent. J. 2013, 7, 1. [Google Scholar] [CrossRef]

- Klepacz-Smółka, A.; Paździor, K.; Ledakowicz, S.; Sójka-Ledakowicz, J.; Mrozińska, Z.; Zyłła, R. Kinetic Studies of Decolourisation of Concentrates From Nanofiltration Treatment of Real Textile Effluents in Anaerobic / Aerobic Sequencing. Environ. Prot. Eng. 2009, 35, 145–155. [Google Scholar]

- Selvaraj, V.; Swarna Karthika, T.; Mansiya, C.; Alagar, M. An over review on recently developed techniques, mechanisms and intermediate involved in the advanced azo dye degradation for industrial applications. J. Mol. Struct. 2021, 1224. [Google Scholar]

- Khandare, R.; Govindwar, S. Microbial Degradation Mechanism of Textile Dye and Its Metabolic Pathway for Environmental Safety. Environ. Waste Manag. 2015, 399–439. [Google Scholar]

- Sen, S.K.; Raut, S.S.; Bandyopadhyay, P.; Raut, S.S. Fungal decolouration and degradation of azo dyes: A review. Fungal Biol. Rev. 2016, 30, 112–133. [Google Scholar] [CrossRef]

- Vijaykumar, M.H.; Veeranagouda, Y.; Neelakanteshwar, K.; Karegoudar, T.B. Decolorization of 1:2 metal complex dye Acid blue 193 by a newly isolated fungus, Cladosporium cladosporioides. World J. Microbiol. Biotechnol. 2006, 22, 157–162. [Google Scholar] [CrossRef]

- Omar, H.H. Algal decolorization and degradation of monoazo and diazo dyes. Pak. J. Biol. Sci. 2008, 11, 1310–1316. [Google Scholar] [CrossRef]

- Fazal, T.; Mushtaq, A.; Rehman, F.; Ullah Khan, A.; Rashid, N.; Farooq, W.; Rehman, M.S.U.; Xu, J. Bioremediation of textile wastewater and successive biodiesel production using microalgae. Renew. Sustain. Energy Rev. 2018, 82, 3107–3126. [Google Scholar] [CrossRef]

- de Andrade, C.J.; de Andrade, L.M. Microalgae for bioremediation of textile wastewater: An overview. Moj Food Process. Technol. 2018, 6, 432–433. [Google Scholar] [CrossRef]

- Madoni, P.; Davoli, D.; Gibin, G. Survey of filamentous microorganisms from bulking and foaming activated- sludge plants in Italy. Water Res. 2000, 34, 1767–1772. [Google Scholar] [CrossRef]

- Modin, O.; Persson, F.; Wilén, B.M.; Hermansson, M. Nonoxidative removal of organics in the activated sludge process. Crit. Rev. Environ. Sci. Technol. 2016, 46, 635–672. [Google Scholar] [CrossRef]

- Eikelboom, D.H. Process. Control. of Activated Sludge Plants by Microscopic Investigation, 1st ed.; IWA Publishing: London, UK, 2000; ISBN 1-900222-29-9. [Google Scholar]

- Andreadakis, A.D. Physical and chemical properties of activated sludge flocs. Water Res. 1993, 27, 1707–1714. [Google Scholar] [CrossRef]

- Frijters, C.T.M.J.; Vos, R.H.; Scheffer, G.; Mulder, R. Decolorizing and detoxifying textile wastewater, containing both soluble and insoluble dyes, in a full scale combined anaerobic/aerobic system. Water Res. 2006, 40, 1249–1257. [Google Scholar] [CrossRef]

- Gupta, P.; Diwan, B. Bacterial Exopolysaccharide mediated heavy metal removal: A Review on biosynthesis, mechanism and remediation strategies. Biotechnol. Rep. 2017, 13, 58–71. [Google Scholar] [CrossRef] [PubMed]

- Mohapatra, R.K.; Behera, S.S.; Patra, J.K.; Thatoi, H.; Parhi, P.K. Potential application of bacterial biofilm for bioremediation of toxic heavy metals and dye-contaminated environments. New Futur. Dev. Microb. Biotechnol. Bioeng. Microb. Biofilms Curr. Res. Futur. Trends Microb. Biofilms 2019, 267–281. [Google Scholar]

- Sun, P.; Hui, C.; Wang, S.; Wan, L.; Zhang, X.; Zhao, Y. Bacillus amyloliquefaciens biofilm as a novel biosorbent for the removal of crystal violet from solution. Colloids Surf. B Biointerfaces 2016, 139, 164–170. [Google Scholar] [CrossRef]

- Misal, S.A.; Gawai, K.R. Azoreductase: A key player of xenobiotic metabolism. Bioresour. Bioprocess. 2018, 5. [Google Scholar] [CrossRef]

- Punzi, M.; Nilsson, F.; Anbalagan, A.; Svensson, B.M.; Jönsson, K.; Mattiasson, B.; Jonstrup, M. Combined anaerobic-ozonation process for treatment of textile wastewater: Removal of acute toxicity and mutagenicity. J. Hazard. Mater. 2015, 292, 52–60. [Google Scholar] [CrossRef]

- Legerská, B.; Chmelová, D.; Ondrejovič, M. Degradation of synthetic dyes by laccases—A mini-review. Nov. Biotechnol. Chim. 2016, 15, 90–106. [Google Scholar] [CrossRef]

- Klepacz-Smółka, A.; Sójka-Ledakowicz, J.; Paździor, K.; Ledakowicz, S. Application of anoxic fixed film and aerobic CSTR bioreactor in treatment of nanofiltration concentrate of real textile wastewater. Chem. Pap. 2010, 64, 230–236. [Google Scholar] [CrossRef]

- Paździor, K.; Klepacz-Smółka, A.; Ledakowicz, S.; Sójka-Ledakowicz, J.; Mrozińska, Z.; Zyłła, R. Integration of nanofiltration and biological degradation of textile wastewater containing azo dye. Chemosphere 2009, 75, 250–255. [Google Scholar] [CrossRef]

- Goswami, M.; Chaturvedi, P.; Kumar Sonwani, R.; Dutta Gupta, A.; Rani Singhania, R.; Shekher Giri, B.; Nath Rai, B.; Singh, H.; Yadav, S.; Sharan Singh, R. Application of Arjuna (Terminalia arjuna) seed biochar in hybrid treatment system for the bioremediation of Congo red dye. Bioresour. Technol. 2020, 307. [Google Scholar] [CrossRef]

- Brindha, R.; Muthuselvam, P.; Senthilkumar, S.; Rajaguru, P. Fe0 catalyzed photo-Fenton process to detoxify the biodegraded products of azo dye Mordant Yellow 10. Chemosphere 2018, 201, 77–95. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, K.; Xu, W.; Du, B.; Wei, Q.; Liu, B.; Wei, D. GO/PEDOT:NaPSS modified cathode as heterogeneous electro-Fenton pretreatment and subsequently aerobic granular sludge biological degradation for dye wastewater treatment. Sci. Total Environ. 2020, 700, 134536. [Google Scholar] [CrossRef]

- Shanmugam, B.K.; Easwaran, S.N.; Mohanakrishnan, A.S.; Kalyanaraman, C.; Mahadevan, S. Biodegradation of tannery dye effluent using Fenton’s reagent and bacterial consortium: A biocalorimetric investigation. J. Environ. Manag. 2019, 242, 106–113. [Google Scholar] [CrossRef]

- Ledakowicz, S.; Żyłła, R.; Paździor, K.; Wrębiak, J.; Sójka-Ledakowicz, J. Integration of Ozonation and Biological Treatment of Industrial Wastewater from Dyehouse. Ozone Sci. Eng. 2017, 39, 1–9. [Google Scholar] [CrossRef]

- Kanagaraj, J.; Mandal, A.B. Combined biodegradation and ozonation for removal of tannins and dyes for the reduction of pollution loads. Environ. Sci. Pollut. Res. 2012, 19, 42–52. [Google Scholar] [CrossRef]

- Wu, J.; Ma, L.; Chen, Y.; Cheng, Y.; Liu, Y.; Zha, X. Catalytic ozonation of organic pollutants from bio-treated dyeing and finishing wastewater using recycled waste iron shavings as a catalyst: Removal and pathways. Water Res. 2016, 92, 140–148. [Google Scholar] [CrossRef] [PubMed]

- Azizi, A.; Moghaddam, M.R.A.; Maknoon, R.; Kowsari, E. Innovative combined technique for high concentration of azo dye AR18 wastewater treatment using modified SBR and enhanced Fenton process as post treatment. Process. Saf. Environ. Prot. 2015, 95, 255–264. [Google Scholar] [CrossRef]

- Bae, W.; Won, H.; Hwang, B.; de Toledo, R.A.; Chung, J.; Kwon, K.; Shim, H. Characterization of refractory matters in dyeing wastewater during a full-scale Fenton process following pure-oxygen activated sludge treatment. J. Hazard. Mater. 2015, 287, 421–428. [Google Scholar] [CrossRef]

- Ribeiro, M.C.M.; Starling, M.C.V.M.; Leão, M.M.D.; Amorim, C.C. De Textile wastewater reuse after additional treatment by Fenton ’ s reagent. Environ. Sci. Pollut. Res. 2017, 24, 6165–6175. [Google Scholar] [CrossRef] [PubMed]

- Baba, Y.; Yatagai, T.; Harada, T.; Kawase, Y. Hydroxyl radical generation in the photo-fenton process: Effects of carboxylic acids on iron redox cycling. Chem. Eng. J. 2015, 277, 229–241. [Google Scholar] [CrossRef]

- Venkatesh, S.; Venkatesh, K.; Quaff, A.R. Dye decomposition by combined ozonation and anaerobic treatment: Cost effective technology. J. Appl. Res. Technol. 2017, 15, 340–345. [Google Scholar] [CrossRef]

- Fahmi, F.; Abidin, C.Z.A.; Rahmat, N.R. Multi-stage Ozonation and Biological Treatment for Removal of Azo Dye Industrial Effluent. Int. J. Environ. Sci. Dev. 2010, 1, 193–198. [Google Scholar] [CrossRef]

- Abidin, C.Z.A.; Ridwan, F.M. Characteristic of COD and Colour Removal of Azo Dye in Ozonation and Biological Treatment. In Proceedings of the 2011 National Postgraduate Conference: NPC 2011: Energy & Sustainability: Exploring the Innovative Minds, Seri Iskandar, Malaysia, 19–20 September 2011; Volume 18, pp. 13–18. [Google Scholar]

- Beltrán, F.J.; García-Araya, J.F.; Álvarez, P. Impact of chemical oxidation on biological treatment of a primary municipal wastewater. 2. Effects of ozonation on kinetics of biological oxidation. Ozone Sci. Eng. 1997, 19, 513–526. [Google Scholar] [CrossRef]

- Ledakowicz, S.; Solecka, M.; Zylla, R. Biodegradation, decolourisation and detoxification of textile wastewater enhanced by advanced oxidation processes. J. Biotechnol. 2001, 89, 175–184. [Google Scholar] [CrossRef]

- Karahan, O.; Dulkadiroglu, H.; Kabdasli, I.; Sozen, S.; Germirli Babuna, F.; Orhon, D. Effect of ozonation on the biological treatability of a textile mill effluent. Environ. Technol. 2002, 23, 1325–1336. [Google Scholar] [CrossRef]

- Scott, J.P.; Ollis, D.F. Integration of chemical and biological oxidation processes for water treatment: II Recent Illustrations and Experiences. J. Adv. Oxid. Technol. 1997, 2, 374–381. [Google Scholar] [CrossRef]

- Bilińska, L.; Blus, K.; Gmurek, M.; Ledakowicz, S. Brine recycling from industrial textilewastewater treated by ozone. By-products accumulation. Part 1: Multi recycling loop. Water 2019, 11. [Google Scholar]

- Ma, J.; Chen, Y.; Nie, J.; Ma, L.; Huang, Y.; Li, L.; Liu, Y.; Guo, Z. Pilot-scale study on catalytic ozonation of bio-treated dyeing and finishing wastewater using recycled waste iron shavings as a catalyst. Sci. Rep. 2018, 8, 7555. [Google Scholar] [CrossRef]

- Sen, S.K.; Patra, P.; Das, C.R.; Raut, S.; Raut, S. Pilot-scale evaluation of bio-decolorization and biodegradation of reactive textile wastewater: An impact on its use in irrigation of wheat crop. Water Resour. Ind. 2019, 21, 100106. [Google Scholar] [CrossRef]

- Sathya, U.; Keerthi; Nithya, M.; Balasubramanian, N. Evaluation of advanced oxidation processes (AOPs) integrated membrane bioreactor (MBR) for the real textile wastewater treatment. J. Environ. Manag. 2019, 246, 768–775. [Google Scholar] [CrossRef] [PubMed]

- Wastewater Plant Upgrades Ozone System. Available online: https://www.waterworld.com/home/article/16190017/wastewater-plant-upgrades-ozone-system (accessed on 1 December 2020).

- Bilińska, L.; Bemska, J.; Biliński, K.; Ledakowicz, S. Zintegrowana chemiczno-biologiczna oczyszczalnia ścieków włókienniczych. Inżynieria I Apar. Chem. 2012, 4, 95–97. [Google Scholar]

| Effluent | pH (−) | Conductivity (mS cm−1) | Cl− (g L−1) | COD (mgO2 L−1) | BOD5 (mgO2 L−1) | BOD5/ COD (−) | TN 1 (mg L−1) | TP 2 (mg L−1) |

|---|---|---|---|---|---|---|---|---|

| washing | 9.9–10.0 | 2.25–4.9 | 0.30–0.74 | 2080–2440 | 535–620 | 0.25–0.26 | 2.3–78 | 1.8–8.0 |

| acidification | 4.4–7.1 | 1.19–2.4 | 0.08–0.11 | 750–2300 | 200–250 | 0.11–0.27 | 1.0–38 | 0.4–9.4 |

| rinsing | 4.5–7.0 | 0.77–1.46 | 0.06–0.08 | 240–1280 | 80–95 | 0.07–0.33 | 0.5–17 | 0.1–6.9 |

| dyeing | 10.2–11.6 | 61.6–110 | 23.3–35.1 | 350–3710 | 25–75 | 0.02–0.07 | 22–25 | 0.5–8.5 |

| rinsing | 10.6–10.8 | 13.7–25.5 | 7.38–9.55 | 235–1075 | 30–40 | 0.04–0.13 | 8.8–10 | 0.1–3.0 |

| acidification | 3.6–8.7 | 2.69–11.3 | 2.58–3.29 | 360–1160 | 60–280 | 0.17–0.24 | 3.8–6.8 | 0.1 –4.0 |

| washing after dyeing | 5.5–8.8 | 0.30–5.45 | 0.80–1.46 | 505–965 | 40–400 | 0.08–0.40 | 3.6–11 | 0.4–0.9 |

| rinsing | 6.8–9.1 | 0.05–1.63 | 0.27–0.58 | 280–550 | 70–300 | 0.25–0.55 | 2.0–5.3 | 0.1–0.4 |

| rinsing | 7.6–8.7 | 0.03–1.35 | 0.12–0.39 | 155–185 | 50–130 | 0.32–0.71 | 1.4–2.2 | 0.02–0.2 |

| neutralisation | 5.4–7.9 | 0.06–1.07 | 0.06–0.13 | 120–470 | 35–200 | 0.29–0.43 | 0.5–1.2 | 0.21–0.49 |

| final mixed effluent | 9.6–9.9 | 12.4–12.6 | 3.6–4.9 | 960–970 | 170–240 | 0.25 | 5.5–18.7 | 0.5–4.5 |

| Process | Current Development | References |

|---|---|---|

| Adsorption | Synthesizing of new, efficient, nature-based, or waste-originating adsorbents, kinetic, equilibrium and thermodynamic studies on biosorption | [42,43,44,45,46] |

| Coagulation/flocculation | Synthesizing of new, efficient, nature-based, or waste-originating coagulants and acceleration of sedimentation by magnetic field | [47,48,49,50,51,52] |

| Electro-coagulation | Ultra-sound assistance, nanofilms on cathodes and solar power usage | [53,54,55,56,57,58] |

| Electrochemical oxidation | Air-diffusion cathodes, new materials and coatings of electrodes, membrane anode and electro-peroxone process | [59,60,61,62,63,64] |

| Membrane filtration | Novel membrane materials, with addition of graphene, stabilization of membranes by biomacromolecules | [65,66,67,68,69,70] |

| Ozonation | Catalyst addition, enhancement by ultrasound and hydrodynamic cavitation | [71,72,73,74,75] |

| O3/UV | Photocatalytic membranes | [76] |

| O3/H2O2 | Proposal of the degradation mechanism, enhancement by electrolysis, heterogenous catalyst addition | [77,78,79] |

| UV/H2O2 | Measurements of cytotoxicity, mutagenicity and phytotoxicity changes, proposal of degradation mechanism, comparison of different UV sources | [80,81,82,83,84,85] |

| Photocatalytic oxidation | Synthesizing nanoparticles, efficient under visible light or difunctional catalysts, green methods of catalyst synthesis | [86,87,88,89,90,91] |

| Fenton | Fenton-like heterogenous catalysts enabling dye degradation in a wide range of pH, among the others zero-valent iron catalysts, green or one-spot synthesis of catalysts, fixed bed reactor application, implementation of sulphate radical anions | [92,93,94,95,96] |

| Photo-Fenton | Fenton-like heterogenous catalysts enabling dye degradation under visible light, waste-originating catalysts, proposal of degradation mechanism | [97,98,99,100,101,102] |

| Electro-Fenton | Kinetics and cost analysis, synthesizing of nanocomposite electrodes, air-diffusion cathode, proposal of mechanism and degradation pathways, novel orbiting electrodes reactor and recirculation flow-through reactor | [103,104,105,106,107,108] |

| Bacterial treatment | Isolation of new strains or consortia from activated sludge, oxidation ditch, palm oil mill effluent or desert soil, alkali-, halo- and thermophilic strains implementation, consortium with algae, bacteria immobilization, co-substrate addition, proposal of mechanisms, pathways genome and transcriptome analysis | [109,110,111,112,113,114,115,116,117,118,119] |

| Fungal treatment | Implementation of microbial consortium (e.g., yeast consortium with ability of lignin valorization dye treatment and biodiesel production), fungi immobilization, isolation of new strains from plant roots or effluent site | [120,121,122,123,124,125,126,127,128,129,130] |

| Enzyme treatment | Optimization of enzyme production, enzyme immobilization, metabolites and toxicity assessment | [131,132,133,134,135,136] |

| Algal treatment | Immobilization, co-contaminant influence on dye biodegradation, genetic modification of algae and cyanobacteria, graphene oxide addition and lipid production | [137,138,139,140,141] |

| Activated sludge, anaerobic sludge | Granule formation (anaerobic core with aerobic shell), metagenomic analysis in anaerobic MBR, addition of resuscitation-promoting factors, integration of anaerobic and aerobic reactors, addition of halotolerant yeast and magnetic field | [142,143,144,145,146,147,148,149,150] |

| Biofilm | Application of new biocarriers, co-substrate addition, kinetic analysis and process optimization in moving bed biofilm reactor, biomass acclimatization and optimization of anoxic/aerobic sequencing batch moving bed bioreactors | [151,152,153,154,155] |

| Object | Catalyst | Conditions | Effectiveness | Reference |

|---|---|---|---|---|

| Ozonation | ||||

| Reactive Orange 16, Reactive Red 120, Direct Red 80 | none | Found as optimal: pH 11, time 10 min, initial dye concentration 2000 mg L−1 | 52–64% dye removal | [74] |

| Direct Red 81 | none | Found as optimal: pH 11, time 27 min, initial dye concentration 2000 mg L−1 | 61% dye removal | [193] |

| Acid Black 1 | none | Found as optimal: ozone concentration 70 mg L−1, pH 6, time 20 min, initial dye concentration 200 mg L−1 | 95.5% decolorization | [167] |

| Direct Red 80 | none | Ozone dosage 1.25 g L−1 min−1, pH 2–13.5 (optimal 12), initial dye concentration 100 mg L−1 | 99% decolorization, 27.4% COD removal | [77] |

| Reactive Red 239 | none | Ozone concentration 20 mg L−1, pH 7, time 20 min, ozone consumption 106.9 mgO3 L−1, initial dye concentration 50 mg L−1 | 100% decolorization, 62% COD and 35% DOC removals | [35] |

| Acid Red 14 | none | pH 10.7 (tested also 6.65), time 25 min, initial dye concentration 1500 mg L−1 | 93% decolorization | [194] |

| Crystal Violet | none | Ozone dose 2 mg L−1 min−1, pH 6.8, time 60 min, initial dye concentration 50 mg L−1 | 78% decolorization | [79] |

| Direct Black 22 | none | Ozone dose 5 g h−1, pH 3–11 (optimal 11), time 30 min | 55% COD removal | [195] |

| Rinsing effluents containing Reactive Blue 19, Reactive Red 239, Reactive Yellow 176 | none | Ozone concentration 20 mg L−1, gas flow rate 0.5 L min−1, pH 7 | 60% COD removal after 60 min | [196] |

| Effluents after electrocoagulation containing mainly Reactive Black 5 | none | Transferred ozone dose 600 mgO3 L−1, pH 11, time 30 min, | Above 90% decolorization | [75] |

| Catalytic Ozonation | ||||

| Methyl Orange | Ni-based layered double hydroxides (Ni-LDHs) nanomaterials 1–3 g L−1 | Ozone flow rate 109 mg h−1, pH 9, initial dye concentration 100–500 mg L−1 | 96% decolorization, 72% COD removal | [197] |

| Direct Black 22 | Zinc slag 0.125–1 g L−1 | Ozone dose 5 g h−1, pH 3–11 (optimal 11), time 30 min, 100 mg L−1 H2O2 addition | 69% COD removal, 76% COD removal with H2O2 | [195] |

| Reactive Blue 194 | Activated carbon | Ozone concentration 178.8 mg L−1, time 40 min, pH 5–12, 25–50 °C, NaCl addition 5–50 g L−1 | 100% decolorization, up to 90% COD removal | [198] |

| Reactive Black 5 | Silver-cobalt composite oxide 0.2–1 g L−1 | Gas flow rate 30 L h−1, pH 2.2–12, initial dye concentration 100–1000 ppm | Up to 99% TOC removal | [72] |

| Alizarin Red S | activated carbon powder/c-Fe2O3 nano-composite 0.2–2 g L−1 | Ozone dose 5 g h−1, pH 3–11, time 30 min, initial dye concentration 100–500 mg L−1 | Up to 95% dye removal, 40% mineralization | [199] |

| Rinsing effluents containing Reactive Blue 19, Reactive Red 239, Reactive Yellow 176 | MnFe2O4@CA 1 g L−1 | Ozone concentration 20 mg L−1, gas flow rate 0.5 L min−1, pH 7 | 100% decolorization after 15 min, 65% COD removal after 40 min | [196] |

| Effluents after electrocoagulation containing mainly Reactive Black 5 | Activated carbon 0.5 g L−1 | Transferred ozone dose 500 mgO3 L−1, pH 11, time 30 min, | Above 90% decolorization, toxicity decrease | [75] |

| Textile wastewater | Copper-doped zinc oxide 1–4 g L−1 | Ozone flow 10 to 40 g m−3, time 30 min, pH 3–11 (optimal 7) | Up to 90% COD removal | [176] |

| Peroxone | ||||

| Crystal Violet | none | Ozone dose 2 mg L−1 min−1, pH 3–9 (optimal 9), time 30 min, initial dye concentration 25–200 mg L−1 | 100% decolorization | [79] |

| Direct Red 80 | none | Ozone dose 1.25 g L−1 min−1, H2O2:O3 ratio equal to 1:10500, pH 2–13.5 (optimal 13), initial dye concentration 100 mg L−1 | 99% decolorization, 43% COD removal | [77] |

| Direct Black 22 | none | Ozone dose 5 g h−1, pH 3–11 (optimal 11), time 30 min, 100 mg L−1 H2O2 addition | 66% COD removal | [195] |

| Fenton Based | ||||

| Methylene Blue | iron (II) sulphate 2–5 mM | 10–80 mM H2O2, 20–40 °C, pH 2–7 (optimal 3), initial dye concentration 10–50 ppm, time 30 min | 98.8% decolorization, 85% COD removal | [183] |

| Acid Yellow 17 | iron (II) sulphate 0.04–0.07 mM | 0.50–1.1 mM H2O2, 25 °C, pH 2–8 (optimal 3), initial dye concentration 0.06–0.09 mM, time 60 min | 89% degradation | [184] |

| Acid Red 27 | iron (II) sulphate 60–100 mg L−1 | 20–100 mgH2O2 L−1, pH 2–5 (optimal 3.5), time 30 min, initial dye concentration 100 mg L−1 | 72% COD removal | [192] |

| Ponceau Xylidine, calconcarboxylic acid | iron (II) sulphate 1.7 mM | 7.3 mM H2O2 or Na2S2O8, | Decolorization: 94% (1 min), 100% (240 min), COD removal (240 min): 40% Fe/HP, 60% Fe/SPS | [95] |

| Methylene Blue | pulverized Malacantha alnifolia tree bark modified with iron (II) sulfate 0.5–1 g L−1 | Fe2+/H2O2 ratios: 10/10,000–100/10,000, pH 2–8, time 60 min | 97% dye removal | [96] |

| Acid Red 27 | Zero valent iron 60–100 mg L−1 | 20–100 mgH2O2 L−1, pH 2–5 (optimal 3), time 30 min, initial dye concentration 100 mg L−1 | 69% COD removal, toxicity decrease | [192] |

| Crystal Violet | zerovalent iron nanoparticles dispersed on polyester fabrics 5 g L−1 | 20–100 mLH2O2 L−1 (optimal 100), pH 5–9 (optimal 5) | 99% dye removal | [92] |

| Methyl Orange | iron (III) nanoparticles synthesised with Dimocarpus longan extract 0–18.5 mg L−1 | 0–46.8 mM H2O2, time 30 min, pH 2–10 (optimal 3), initial dye concentration 50–250 mg L−1 | 100% dye removal | [200] |

| Methylene Blue | iron (III) loaded on activated carbon (2–15 wt%) | Packed bed reactor, 0.0163–0.326 M H2O2, pH 2–9 (optimal 3.5), temperature 30–50 °C, initial dye concentration 100 mg L−1 | 70% dye removal | [94] |

| Eriochrome Black, Methylene Blue, Rhodamine B | core-shell nickel cobalt spinel coated with iron phthalocyanine 4–6 g L−1 | 40–60 mM H2O2, pH 4–6.7, initial dye concentration 5–20 mg L−1 | 100% dye removal, 90% TOC removal (Rhodamine B) | [93] |

| Orange II | calcium strontium copper loaded perovskite 1 g L−1 | Without H2O2, time 90 min, initial dye concentration 10–100 ppm | 95% degradation, 40% carbon removal | [188] |

| Methyl Orange | Perovskite 10–25 mg L−1 | Without H2O2, pH 2–10 (optimal 2.5), time 20 min, initial dye concentration 20 ppm | 90% degradation | [201] |

| Object | Catalyst | Conditions | Effectiveness | Reference |

|---|---|---|---|---|

| Bacteria | ||||

| Reactive Red 120 | Pseudomonas guariconensis | Inoculum: 2% (w/v) (2 g) of immobilized (alginate beads) effective isolate in MSM broth + 0.5% glucose, temperature 28 ± 2 °C, initial dye concentration 100 mg/L−1 | 91% dye uptake | [114] |

| Brilliant Crocein | Providencia rettgeri | Oligotrophic medium, 2% v/v inoculum, time 8 d, 500 mg L−1 ethanol, initial dye concentration 50 mg L−1 | 100% dye removal | [115] |

| Direct Black G | Anoxybacillus sp. PDR2 | 10% v/v inoculum, microaerobic conditions, time 48 h, initial dye concentration 100–600 mg L−1 | 82–98% decolorization | [116] |

| Reactive Black 5, Brilliant Violet 5R, Reactive Orange 16 | Halomonas sp | Shaken Erlenmeyer flasks, pH 6–11, 2 10% salinity, initial dye concentration 50 mg L−1 | Above 90% decolorization: RB5–24 h, RV5–13 h, RO16–3 h | [119] |

| Reactive Black 5 and cadmium | Pseudomonas aeruginosa strain Gb30 | LB medium, pH 8, 5% v/v inoculum, temperature 37 °C, initial concentrations: 0.629 mM Cd2+ and 50 mgRB5 L−1 | 100% decolorization | [112] |

| Reactive Orange 16, Reactive Blue 250 | Bacillus sp. VITAKB20 and Lysinibacillus sp. KPB6 | Different broths: LB, nutrient ZZ, MSM, temperature 37 °C, immobilization in alginate beads, shaking conditions | 97.5% RO16 and 98.2% RB 250 degradations | [113] |

| Reactive Yellow 174 added to industrial textile wastewater | Bacterial consortium: Sphingomonas paucimobilis, Pseudomonas putida and Lactobacillus acidophilus | 10% inoculum, temperature 35 °C, time 5 d, initial dye concentration 750 ppm | 86% COD removal, 90% decolorization | [109] |

| Methanil Yellow G | Bacterial consortium: Halomonas (49.8%), Marinobacter (30.7%) and Clostridiisalibacter (19.2%) | 1 g L−1 yeast extract, pH 10, 10% salinity, temperature 40 °C, time 16 h, initial dye concentration 100 mg L−1 | 93 % decolorization | [110] |

| Acid Red 14 | Oerskovia paurometabola | Synthetic textile wastewater containing Emsize E1 (sizing agent) and 1 g L−1 yeast extract, anaerobic conditions, temperature 30 °C, initial dye concentration 20–100 mg/L−1 | 91% decolorization | [117] |

| Reactive Black 5, Brilliant Violet 5R, Reactive Orange 16 | Halomonas sp | Aerobic PBR, volcanic rock filling, temperature 38 °C, HRT 9–11 h, initial dye concentration 50–150 mg/L−1 | 95% RO16, 79.5% RV5 and 81% RB5 removals | [119] |

| Congo Red | Bacillus sp. MH587030.1 | MBBR, polyurethane foam-polypropylene carrier, pH 5–9, carrier filling ratio 10–60% v/v initial dye concentration 10–100 mg/L−1 | Dye removal up to 95.7% | [38] |

| Fungi | ||||