Processing Methodologies of Wet Microalga Biomass Toward Oil Separation: An Overview

Abstract

1. Introduction

1.1. Lipids and Fatty Acids

1.2. Lipids Recovered

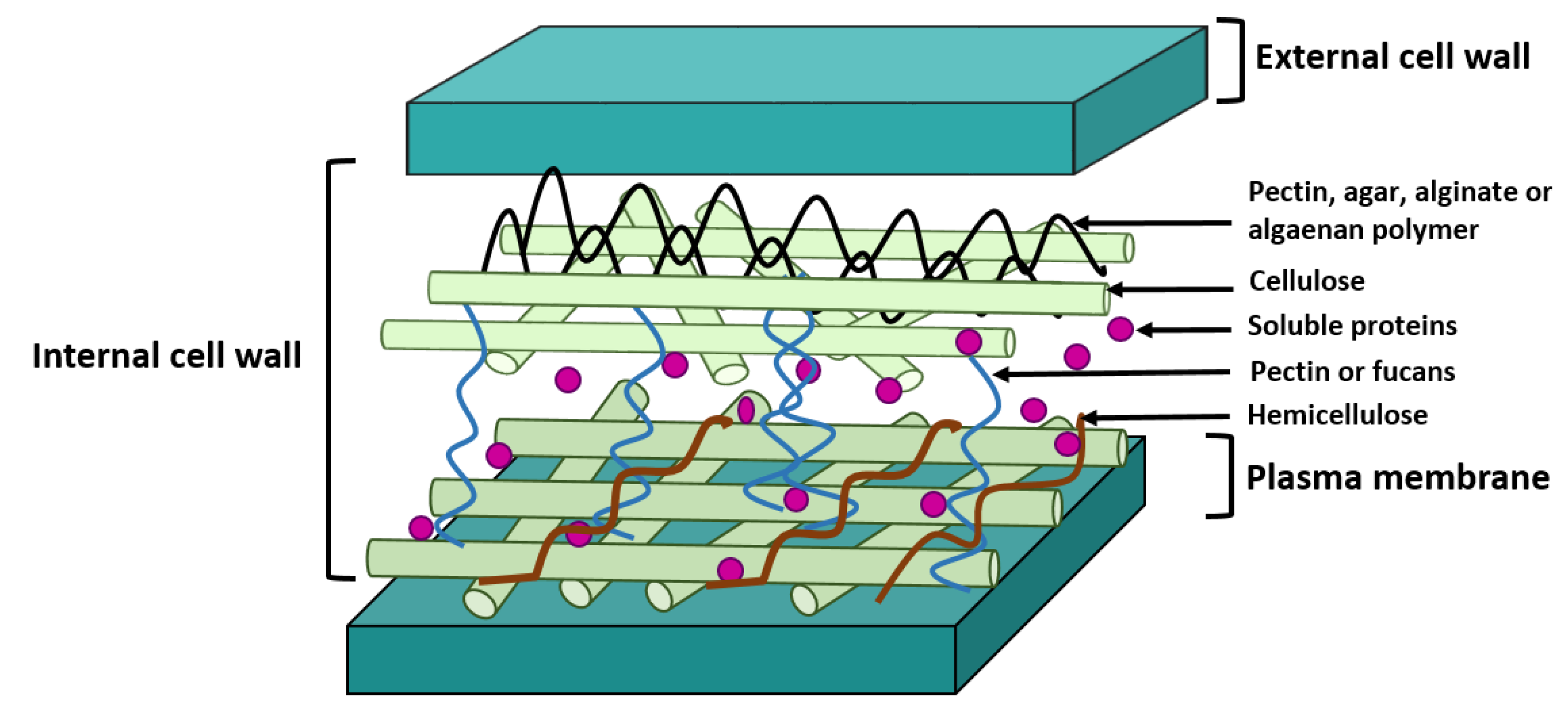

1.3. Microalgae Cell Wall

2. Biomass Pretreatments for Lipid Extraction Applied to Wet Biomass

2.1. Microwaves

2.2. Ultrasound

2.3. Bead Milling

2.4. Osmotic Shock

2.5. Enzymatic Hydrolysis

2.6. Acid Hydrolysis

2.7. Ionic Liquids

2.8. Patented Processes

3. Microalgae Integrated Processes

3.1. Microalgae-Based Processes

3.2. Process Integration Strategies

3.3. Environmental and Economic Considerations

4. Concluding Remarks

Funding

Conflicts of Interest

References

- Mahlia, T.M.I.; Syazmi, Z.A.H.S.; Mofijur, M.; Abas, A.E.P.; Bilad, M.R.; Ong, H.C.; Silitonga, A.S. Patent landscape review on biodiesel production: Technology updates. Renew. Sustain. Energy Rev. 2020, 118, 109–526. [Google Scholar] [CrossRef]

- Lee, X.J.; Ong, H.C.; Gan, Y.Y.; Chen, W.H.; Mahlia, T.M.I. State of art review on conventional and advanced pyrolysis of macroalgae and microalgae for biochar, bio-oil and bio-syngas production. Energy Convers. Manag. 2020, 210, 112–707. [Google Scholar] [CrossRef]

- Schenk, P.M.; Thomas-Hall, S.R.; Stephens, E.; Marx, U.C.; Mussgnug, J.H.; Posten, C.; Kruse, O.; Hankamer, B. Second Generation Biofuels: High-Efficiency Microalgae for Biodiesel Production. BioEnergy Res. 2008, 1, 20–43. [Google Scholar] [CrossRef]

- Spolaore, P.; Joannis-Cassan, C.; Duran, E.; Isambert, A. Commercial applications of microalgae. J. Biosci. Bioeng. 2006, 101, 87–96. [Google Scholar] [CrossRef]

- Yamaguchi, K. Recent advances in microalgal bioscience in Japan, with special reference to utilization of biomass and metabolites: A review. J. Appl. Phycol. 1996, 8, 487–502. [Google Scholar] [CrossRef]

- M. U., N.; Mehar, J.G.; Mudliar, S.N.; Shekh, A.Y. Recent Advances in Microalgal Bioactives for Food, Feed, and Healthcare Products: Commercial Potential, Market Space, and Sustainability. Compr. Rev. Food Sci. Food Saf. 2019, 18, 1882–1897. [Google Scholar] [CrossRef]

- Roy, S.S.; Pal, R. Microalgae in Aquaculture: A Review with Special References to Nutritional Value and Fish Dietetics. Proc. Zool. Soc. 2015, 68, 1–8. [Google Scholar] [CrossRef]

- Wilhelm, C.; Jakob, T. From photons to biomass and biofuels: Evaluation of different strategies for the improvement of algal biotechnology based on comparative energy balances. Appl. Microbiol. Biotechnol. 2011, 92, 909–919. [Google Scholar] [CrossRef]

- Wells, M.L.; Potin, P.; Craigie, J.S.; Raven, J.A.; Merchant, S.S.; Helliwell, K.E.; Smith, A.G.; Camire, M.E.; Brawley, S.H. Algae as nutritional and functional food sources: Revisiting our understanding. J. Appl. Phycol. 2017, 29, 949–982. [Google Scholar] [CrossRef]

- Plaza, M.; Herrero, M.; Alejandro Cifuentes, A.; Ibáñez, E. Innovative natural functional ingredients from microalgae. J. Agric. Food Chem. 2009, 57, 7159–7170. [Google Scholar] [CrossRef]

- Ye, C.; Mu, D.; Horowitz, N.; Xue, Z.; Chen, J.; Xue, M.; Zhou, Y.; Klutts, M.; Zhou, W. Life cycle assessment of industrial scale production of spirulina tablets. Algal Res. 2018, 34, 154–163. [Google Scholar] [CrossRef]

- Kang, Z.; Kim, B.H.; Ramanan, R.; Choi, J.E.; Yang, J.W.; Oh, H.M.; Kim, H.S. A cost analysis of microalgal biomass and biodiesel production in open raceways treating municipal wastewater and under optimum light wavelength. J. Microbiol. Biotechnol. 2015, 25, 109–118. [Google Scholar] [CrossRef] [PubMed]

- Bai, F.W.; Anderson, W.A.; Moo-Young, M. Ethanol fermentation technologies from sugar and starch feedstocks. Biotechnol. Adv. 2008, 26, 89–105. [Google Scholar] [CrossRef]

- Malcata, F.X. Microalgae and biofuels: A promising partnership? Trends Biotechnol. 2011, 29, 542–549. [Google Scholar] [CrossRef] [PubMed]

- Escobar, J.C.; Lora, E.S.; Venturini, O.J.; Yáñez, E.E.; Castillo, E.F.; Almazan, O. Biofuels: Environment, technology and food security. Renew. Sustain. Energy Rev. 2009, 13, 1275–1287. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 294–306. [Google Scholar] [CrossRef]

- Mubarak, M.; Shaija, A.; Suchithra, T.V. A review on the extraction of lipid from microalgae for biodiesel production. Algal Res. 2015, 7, 117–123. [Google Scholar] [CrossRef]

- Wen, Z.Y.; Chen, F. Heterotrophic production of eicosapentaenoic acid by microalgae. Biotechnol. Adv. 2003, 21, 273–294. [Google Scholar] [CrossRef]

- Gardner, R.D.; Cooksey, K.E.; Mus, F.; Macur, R.; Moll, K.; Eustance, E.; Carlson, R.P.; Gerlach, R.; Fields, M.W.; Peyton, B.M. Use of sodium bicarbonate to stimulate triacylglycerol accumulation in the chlorophyte Scenedesmus sp. and the diatom Phaeodactylum tricornutum. J. Appl. Phycol. 2012, 24, 1311–1320. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Bermúdez, S.P.C.; Termote-Verhalle, R.; Bruneel, C.; Muylaert, K.; Parra-Saldivar, R.; Foubert, I. Influence of extraction solvent system on the extractability of lipid components from the biomass of Nannochloropsis gaditana. J. Appl. Phycol. 2014, 26, 1501–1510. [Google Scholar] [CrossRef]

- Calder, P.C. n-3 Polyunsaturated fatty acids, inflammation, and inflammatory diseases. Am. J. Clin. Nutr. 2006, 83, 1505–1519. [Google Scholar] [CrossRef]

- Ward, O.P.; Singh, A. Omega-3/6 fatty acids: Alternative sources of production. Process Biochem. 2005, 40, 3627–3652. [Google Scholar] [CrossRef]

- Strobel, C.; Jahreis, G.; Kuhnt, K. Survey of n-3 and n-6 polyunsaturated fatty acids in fish and fish products. Lipids Health Dis. 2012, 11, 1476–1511. [Google Scholar] [CrossRef]

- Swanson, D.; Block, R.; Mousa, S.A. Omega-3 fatty acids EPA and DHA: Health benefits throughout life. Adv. Nutr. 2012, 3, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Schüler, L.M.; Schulze, P.S.C.; Pereira, H.; Barreira, L.; León, R.; Varela, J. Trends and strategies to enhance triacylglycerols and high-value compounds in microalgae. Algal Res. 2017, 25, 263–273. [Google Scholar] [CrossRef]

- Rodolfi, L.; Zittelli, G.C.; Bassi, N.; Padovani, G.; Biondi, N.; Bonini, G.; Tredici, M.R. Microalgae for oil: Strain selection, induction of lipid synthesis and outdoor mass cultivation in a low-cost photobioreactor. Biotechnol. Bioeng. 2009, 102, 100–112. [Google Scholar] [CrossRef] [PubMed]

- Von Schacky, C. Omega-3 fatty acids: Anti-arrhythmic, pro-arrhythmic, or both? Front. Physiol. 2012, 3, 88. [Google Scholar] [CrossRef]

- Von Schacky, C.; Harris, W.S. Cardiovascular benefits of omega-3 fatty acids. Cardiovasc. Res. 2007, 73, 310–315. [Google Scholar]

- Guil-Guerrero, J.L. Stearidonic acid (18:4n-3): Metabolism, nutritional importance, medical uses and natural sources. Eur. J. Lipid Sci. Technol. 2007, 109, 1226–1236. [Google Scholar] [CrossRef]

- Simopoulos, A.P. Omega-3 fatty acids in inflammation and autoimmune diseases. J. Am. Coll. Nutr. 2002, 21, 495–505. [Google Scholar] [CrossRef]

- Bannenberg, G.; Mallon, C.; Edwards, H.; Yeadon, D.; Yan, K.; Johnson, H.; Ismail, A. Omega-3 Long-Chain Polyunsaturated Fatty Acid Content and Oxidation State of Fish Oil Supplements in New Zealand. Sci. Rep. 2017, 7, 1488. [Google Scholar] [CrossRef] [PubMed]

- Matsumoto, C.; Yoruk, A.; Wang, L.; Gaziano, J.M.; Sesso, H.D. Fish and omega-3 fatty acid consumption and risk of hypertension. J. Hypertens. 2019, 37, 1223–1229. [Google Scholar] [CrossRef] [PubMed]

- Gunstone, F.D. Fatty Acid and Lipid Chemistry; Springer: Boston, MA, USA, 1996. [Google Scholar]

- Whitehead, P.J.P. Clupeoid fishes of the World an Annotated and Illustrated Catalogue of the Herrings, Sardines, Pilchards, Sprats, Shads, United Nations Development Programme Food and Agriculture Organization of The United Nations Anchovies and Wolf-Herrings Part I-Chirocentridae, Clupeidae and Pristigasteridae (Suborder CLUPEOIDEI); FAO Fisheries Synopsis: London, UK, 1985. [Google Scholar]

- Dulvy, N.K.; Sadovy, Y.; Reynolds, J.D. Extinction vulnerability in marine populations. Fish Fish. 2003, 4, 25–64. [Google Scholar] [CrossRef]

- Barclay, W.R.; Meager, K.M.; Abril, J.R. Heterotrophic production of long chain omega-3 fatty acids utilizing algae and algae-like microorganisms. J. Appl. Phycol. 1994, 6, 123–129. [Google Scholar] [CrossRef]

- Ursin, V.M. Modification of Plant Lipids for Human Health: Development of Functional Land-Based Omega-3 Fatty Acids. J. Nutr. 2003, 133, 4271–4274. [Google Scholar] [CrossRef]

- Miller, M.R.; Nichols, P.D.; Carter, C.G. N-3 Oil sources for use in aquaculture alternatives to the unsustainable harvest of wild fish. Nutr. Res. Rev. 2008, 21, 85–96. [Google Scholar] [CrossRef]

- Kuhnt, K.; Degen, C.; Jaudszus, A.; Jahreis, G. Searching for health beneficial n-3 and n-6 fatty acids in plant seeds. Eur. J. Lipid Sci. Technol. 2012, 114, 153–160. [Google Scholar] [CrossRef]

- Bell, J.G.; Tocher, D.R.; Henderson, R.J.; Dick, J.R.; Crampton, V.O. Altered fatty acid compositions in Atlantic salmon (Salmo salar) fed diets containing linseed and rapeseed oils can be partially restored by a subsequent fish oil finishing diet. J. Nutr. 2003, 133, 2793–2801. [Google Scholar] [CrossRef]

- Torstensen, B.E.; Øyvind, L.; Frøyland, L. Lipid metabolism and tissue composition in Atlantic salmon (Salmo salar L.)—Effects of capelin oil, palm oil, and oleic acid-enriched sunflower oil as dietary lipid sources. Lipids 2000, 35, 653–664. [Google Scholar] [CrossRef]

- Halim, R.; Gladman, B.; Danquah, M.K.; Webley, P.A. Oil extraction from microalgae for biodiesel production. Bioresour. Technol. 2011, 102, 178–185. [Google Scholar] [CrossRef]

- Mahaffey, K.R.; Clickner, R.P.; Jeffries, R.A. Methylmercury and omega-3 fatty acids: Co-occurrence of dietary sources with emphasis on fish and shellfish. Environ. Res. 2008, 107, 20–29. [Google Scholar] [CrossRef] [PubMed]

- Bourdon, J.A.; Bazinet, T.M.; Arnason, T.T.; Kimpe, L.E.; Blais, J.M.; White, P.A. Polychlorinated biphenyls (PCBs) contamination and aryl hydrocarbon receptor (AhR) agonist activity of Omega-3 polyunsaturated fatty acid supplements: Implications for daily intake of dioxins and PCBs. Food Chem. Toxicol. 2010, 48, 3093–3097. [Google Scholar] [CrossRef] [PubMed]

- Manuell, A.L.; Beligni, M.V.; Elder, J.H.; Siefker, D.T.; Tran, M.; Weber, A.; McDonald, T.L.; Mayfield, S.P. Robust expression of a bioactive mammalian protein in Chlamydomonas chloroplast. Plant Biotechnol. J. 2007, 5, 402–412. [Google Scholar] [CrossRef]

- Li, Y.; Qin, J.; Moore, B.; Ball, A. Perspectives on marine phytoplankton as a source of nutrition and bioenergy. In Marine Phytoplankton; Oceanography and Ocean Engineering Series; Nova Science: Hauppage, NY, USA, 2009; pp. 187–202. [Google Scholar]

- Armenta, R.E.; Valentine, M.C. Single-cell oils as a source of omega-3 fatty acids: An overview of recent advances. JAOCS J. Am. Oil Chem. Soc. 2013, 90, 167–182. [Google Scholar] [CrossRef]

- Griffiths, M.J.; Harrison, S.T.L. Lipid productivity as a key characteristic for choosing algal species for biodiesel production. J. Appl. Phycol. 2009, 21, 493–507. [Google Scholar] [CrossRef]

- Miao, X.; Wu, Q. High yield bio-oil production from fast pyrolysis by metabolic controlling of Chlorella protothecoides. J. Biotechnol. 2004, 110, 85–93. [Google Scholar] [CrossRef]

- Adarme-Vega, T.C.; Lim, D.K.Y.; Timmins, M.; Vernen, F.; Li, Y.; Schenk, P.M. Microalgal biofactories: A promising approach towards sustainable omega-3 fatty acid production. Microb. Cell Fact. 2012, 11, 96. [Google Scholar] [CrossRef]

- Folch, J.; Lees, M.; Sloane Stanley, G.H. A simple method for the isolation and purification of total lipides from animal tissues. J. Biol. Chem. 1957, 226, 497–509. [Google Scholar] [CrossRef]

- Bligh, E.G.; Dyer, W.J. A rapid method of total lipid extraction and purification. Can. J. Biochem. Physiol. 1959, 37, 911–917. [Google Scholar] [CrossRef]

- Ryckebosch, E.; Muylaert, K.; Foubert, I. Optimization of an Analytical Procedure for Extraction of Lipids from Microalgae. J. Am. Oil Chem. Soc. 2012, 89, 189–198. [Google Scholar] [CrossRef]

- Sander, K.; Murthy, G.S. Life cycle analysis of algae biodiesel. Int. J. Life Cycle Assess. 2010, 15, 704–714. [Google Scholar] [CrossRef]

- Mohn, H. Improved technologies for harvesting and processing of microalgae and their impact on production costs. Arch. Hydrobiol. Beih. Ergeb. Limnol. 1978, 228, 228–253. [Google Scholar]

- Lardon, L.; Hélias, A.; Sialve, B.; Steyer, J.-P.; Bernard, O. Life-Cycle Assessment of Biodiesel Production from Microalgae. Environ. Sci. Technol. 2009, 43, 6475–6481. [Google Scholar] [CrossRef]

- Xu, L.; Brilman, D.W.F.; Withag, J.A.M.; Brem, G.; Kersten, S. Assessment of a dry and a wet route for the production of biofuels from microalgae: Energy balance analysis. Bioresour. Technol. 2011, 102, 5113–5122. [Google Scholar] [CrossRef]

- Uduman, N.; Qi, Y.; Danquah, M.K.; Forde, G.M.; Hoadley, A. Dewatering of microalgal cultures: A major bottleneck to algae-based fuels. J. Renew. Sustain. Energy 2010, 2, 012701. [Google Scholar] [CrossRef]

- De Boer, K.; Moheimani, N.R.; Borowitzka, M.A.; Bahri, P.A. Extraction and conversion pathways for microalgae to biodiesel: A review focused on energy consumption. J. Appl. Phycol. 2012, 24, 1681–1698. [Google Scholar] [CrossRef]

- Lee, B.; Park, S.Y.; Heo, Y.S.; Yea, S.S.; Kim, D.E. Efficient colorimetric assay of RNA polymerase activity using inorganic pyrophosphatase and ammonium molybdate. Bull. Korean Chem. Soc. 2009, 30, 2485–2488. [Google Scholar]

- Passell, H.; Dhaliwal, H.; Reno, M.; Wu, B.; Ben Amotz, A.; Ivry, E.; Gay, M.; Czartoski, T.; Laurin, L.; Ayer, N. Algae biodiesel life cycle assessment using current commercial data. J. Environ. Manag. 2013, 129, 103–111. [Google Scholar] [CrossRef]

- Torres, C.M.; Ríos, S.D.; Torras, C.; Salvadó, J.; Mateo-Sanz, J.M.; Jiménez, L. Microalgae-based biodiesel: A multicriteria analysis of the production process using realistic scenarios. Bioresour. Technol. 2013, 147, 7–16. [Google Scholar] [CrossRef]

- Yoo, G.; Park, W.-K.; Kim, C.W.; Choi, Y.-E.; Yang, J.-W. Direct lipid extraction from wet Chlamydomonas reinhardtii biomass using osmotic shock. Bioresour. Technol. 2012, 123, 717–722. [Google Scholar] [CrossRef]

- Dong, T.; Knoshaug, E.P.; Pienkos, P.T.; Laurens, L.M.L. Lipid recovery from wet oleaginous microbial biomass for biofuel production: A critical review. Appl. Energy 2016, 177, 879–895. [Google Scholar] [CrossRef]

- Cooney, M.; Young, G.; Nagle, N. Extraction of Bio-oils from Microalgae. Sep. Purif. Rev. 2009, 38, 291–325. [Google Scholar] [CrossRef]

- Subhadra, B. Grinson-George Algal biorefinery-based industry: An approach to address fuel and food insecurity for a carbon-smart world. J. Sci. Food Agric. 2011, 91, 2–13. [Google Scholar] [CrossRef]

- Pan, Y.; Alam, M.A.; Wang, Z.; Huang, D.; Hu, K.; Chen, H.; Yuan, Z. One-step production of biodiesel from wet and unbroken microalgae biomass using deep eutectic solvent. Bioresour. Technol. 2017, 238, 157–163. [Google Scholar] [CrossRef] [PubMed]

- Chew, K.W.; Yap, J.Y.; Show, P.L.; Suan, N.H.; Juan, J.C.; Ling, T.C.; Lee, D.J.; Chang, J.S. Microalgae biorefinery: High value products perspectives. Bioresour. Technol. 2017, 229, 53–62. [Google Scholar] [CrossRef]

- Severo, I.A.; Deprá, M.C.; Zepka, L.Q.; Jacob-Lopes, E. Photobioreactors and Oxycombustion: A Mini-Review on the Process Integration. J. Chem. Eng. Process Technol. 2016, 7, 7–9. [Google Scholar]

- Colling Klein, B.; Bonomi, A.; Maciel Filho, R. Integration of microalgae production with industrial biofuel facilities: A critical review. Renew. Sustain. Energy Rev. 2018, 82, 1376–1392. [Google Scholar] [CrossRef]

- Budzianowski, W.M.; Postawa, K. Total Chain Integration of sustainable biorefinery systems. Appl. Energy 2016, 184, 1432–1446. [Google Scholar] [CrossRef]

- Velazquez-Lucio, J.; Rodríguez-Jasso, R.M.; Colla, L.M.; Sáenz-Galindo, A.; Cervantes-Cisneros, D.E.; Aguilar, C.N.; Fernandes, B.D.; Ruiz, H.A.A. Microalgal biomass pretreatment for bioethanol production: A review Microalgal biomass pretreatment for bioethanol production: A review. Biofuel Res. J. 2018, 17, 780–791. [Google Scholar] [CrossRef]

- Günerken, E.; D’Hondt, E.; Eppink, M.H.M.; Garcia-Gonzalez, L.; Elst, K.; Wijffels, R.H. Cell disruption for microalgae biorefineries. Biotechnol. Adv. 2015, 33, 243–260. [Google Scholar] [CrossRef]

- Alhattab, M.; Kermanshahi-Pour, A.; Brooks, M.S.L. Microalgae disruption techniques for product recovery: Influence of cell wall composition. J. Appl. Phycol. 2019, 31, 61–88. [Google Scholar] [CrossRef]

- Safi, C.; Charton, M.; Pignolet, O.; Silvestre, F.; Vaca-Garcia, C.; Pontalier, P.Y. Influence of microalgae cell wall characteristics on protein extractability and determination of nitrogen-to-protein conversion factors. J. Appl. Phycol. 2013, 25, 523–529. [Google Scholar] [CrossRef]

- D’Hondt, E.; Martín-Juárez, J.; Bolado, S.; Kasperoviciene, J.; Koreiviene, J.; Sulcius, S.; Elst, K.; Bastiaens, L. Cell disruption technologies. In Microalgae-Based Biofuels and Bioproducts; Elsevier: Amsterdam, The Netherlands, 2017; pp. 133–154. [Google Scholar]

- Baudelet, P.-H.; Ricochon, G.; Linder, M.; Muniglia, L. A new insight into cell walls of Chlorophyta. Algal Res. 2017, 25, 333–371. [Google Scholar] [CrossRef]

- Ben-Amotz, A. Bioactive Compounds: Glycerol Production, Carotenoid Production, Fatty Acids Production. In The Alga Dunaliella; CRC Press: Boca Raton, FL, USA, 2019; pp. 189–208. [Google Scholar]

- Patel, A.; Matsakas, L.; Sartaj, K.; Chandra, R. Extraction of lipids from algae using supercritical carbon dioxide. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Elsevier: Amsterdam, The Netherlands, 2020; pp. 17–39. [Google Scholar]

- Mandal, V.; Mohan, Y.; Hemalatha, S. Microwave assisted extraction—An innovative and promising extraction tool for medicinal plant research. Pharmacogn. Rev. 2007, 1, 7–18. [Google Scholar]

- Amarni, F.; Kadi, H. Kinetics study of microwave-assisted solvent extraction of oil from olive cake using hexane. Innov. Food Sci. Emerg. Technol. 2010, 11, 322–327. [Google Scholar] [CrossRef]

- Lee, J.-Y.; Yoo, C.; Jun, S.-Y.; Ahn, C.-Y.; Oh, H.-M. Comparison of several methods for effective lipid extraction from microalgae. Bioresour. Technol. 2010, 101, S75–S77. [Google Scholar] [CrossRef]

- Biller, P.; Friedman, C.; Ross, A.B. Hydrothermal microwave processing of microalgae as a pre-treatment and extraction technique for bio-fuels and bio-products. Bioresour. Technol. 2013, 136, 188–195. [Google Scholar] [CrossRef]

- Cheng, J.; Yu, T.; Li, T.; Zhou, J.; Cen, K. Using wet microalgae for direct biodiesel production via microwave irradiation. Bioresour. Technol. 2013, 131, 531–535. [Google Scholar] [CrossRef]

- Cheng, J.; Huang, R.; Li, T.; Zhou, J.; Cen, K. Biodiesel from wet microalgae: Extraction with hexane after the microwave-assisted transesterification of lipids. Bioresour. Technol. 2014, 170, 69–75. [Google Scholar] [CrossRef]

- Wahidin, S.; Idris, A.; Shaleh, S.R.M. Rapid biodiesel production using wet microalgae via microwave irradiation. Energy Convers. Manag. 2014, 84, 227–233. [Google Scholar] [CrossRef]

- Bach, Q.-V.; Chen, W.-H.; Lin, S.-C.; Sheen, H.-K.; Chang, J.-S. Wet torrefaction of microalga Chlorella vulgaris ESP-31 with microwave-assisted heating. Energy Convers. Manag. 2017, 141, 163–170. [Google Scholar] [CrossRef]

- Martinez-Guerra, E.; Gude, V.G.; Mondala, A.; Holmes, W.; Hernandez, R. Microwave and ultrasound enhanced extractive-transesterification of algal lipids. Appl. Energy 2014, 129, 354–363. [Google Scholar] [CrossRef]

- Martinez-Guerra, E.; Howlader, M.S.; Shields-Menard, S.; French, W.T.; Gude, V.G. Optimization of wet microalgal FAME production from Nannochloropsis sp. under the synergistic microwave and ultrasound effect. Int. J. Energy Res. 2018, 42, 1934–1949. [Google Scholar] [CrossRef]

- Dai, M.; Xu, H.; Yu, Z.; Fang, S.; Chen, L.; Gu, W.; Ma, X. Microwave-assisted fast co-pyrolysis behaviors and products between microalgae and polyvinyl chloride. Appl. Therm. Eng. 2018, 136, 9–15. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, R.; Yin, R.; Mei, Y. Upgrading of bio-oil from biomass fast pyrolysis in China: A review. Renew. Sustain. Energy Rev. 2013, 24, 66–72. [Google Scholar] [CrossRef]

- Ali, M.; Watson, I.A. Microwave treatment of wet algal paste for enhanced solvent extraction of lipids for biodiesel production. Renew. Energy 2015, 76, 470–477. [Google Scholar] [CrossRef]

- Lee, A.K.; Lewis, D.M.; Ashman, P.J. Disruption of microalgal cells for the extraction of lipids for biofuels: Processes and specific energy requirements. Biomass Bioenergy 2012, 46, 89–101. [Google Scholar] [CrossRef]

- Luque, R.; Menéndez, J.A.; Arenillas, A.; Cot, J. Microwave-assisted pyrolysis of biomass feedstocks: The way forward? Energy Environ. Sci. 2012, 5, 5481–5488. [Google Scholar] [CrossRef]

- Mushtaq, F.; Mat, R.; Ani, F.N. A review on microwave assisted pyrolysis of coal and biomass for fuel production. Renew. Sustain. Energy Rev. 2014, 39, 555–574. [Google Scholar] [CrossRef]

- Motasemi, F.; Afzal, M.T. A review on the microwave-assisted pyrolysis technique. Renew. Sustain. Energy Rev. 2013, 28, 317–330. [Google Scholar] [CrossRef]

- Lam, S.S.; Chase, H.A. A Review on Waste to Energy Processes Using Microwave Pyrolysis. Energies 2012, 5, 4209–4232. [Google Scholar] [CrossRef]

- Mokhtar, N.M.; Omar, R.; Idris, A. Microwave Pyrolysis for Conversion of Materials to Energy: A Brief Review. Energy Sources Part A Recover. Util. Environ. Eff. 2012, 34, 2104–2122. [Google Scholar] [CrossRef]

- Yin, C. Microwave-assisted pyrolysis of biomass for liquid biofuels production. Bioresour. Technol. 2012, 120, 273–284. [Google Scholar] [CrossRef] [PubMed]

- Adam, F.; Abert-Vian, M.; Peltier, G.; Chemat, F. “Solvent-free” ultrasound-assisted extraction of lipids from fresh microalgae cells: A green, clean and scalable process. Bioresour. Technol. 2012, 114, 457–465. [Google Scholar] [CrossRef] [PubMed]

- Buttress, A.J.; Binner, E.; Yi, C.; Palade, P.; Robinson, J.P.; Kingman, S.W. Development and evaluation of a continuous microwave processing system for hydrocarbon removal from solids. Chem. Eng. J. 2016, 283, 215–222. [Google Scholar] [CrossRef]

- Esquivel-Hernández, D.A.; Ibarra-Garza, I.P.; Rodríguez-Rodríguez, J.; Cuéllar-Bermúdez, S.P.; de J. Rostro-Alanis, M.; Alemán-Nava, G.S.; García-Pérez, J.S.; Parra-Saldívar, R. Green extraction technologies for high-value metabolites from algae: A review. Biofuels Bioprod. Biorefining 2017, 11, 215–231. [Google Scholar]

- Suslick, K.S.; Flannigan, D.J. Inside a Collapsing Bubble: Sonoluminescence and the Conditions During Cavitation. Annu. Rev. Phys. Chem. 2008, 59, 659–683. [Google Scholar] [CrossRef]

- Harun, R.; Singh, M.; Forde, G.M.; Danquah, M.K. Bioprocess engineering of microalgae to produce a variety of consumer products. Renew. Sustain. Energy Rev. 2010, 14, 1037–1047. [Google Scholar] [CrossRef]

- Sung, M.; Han, J.-I. Ultrasound-assisted in-situ transesterification of wet Aurantiochytrium sp. KRS 101 using potassium carbonate. Bioresour. Technol. 2018, 261, 117–121. [Google Scholar] [CrossRef]

- Sankaran, R.; Manickam, S.; Yap, Y.J.; Ling, T.C.; Chang, J.-S.; Show, P.L. Extraction of proteins from microalgae using integrated method of sugaring-out assisted liquid biphasic flotation (LBF) and ultrasound. Ultrason. Sonochem. 2018, 48, 231–239. [Google Scholar] [CrossRef]

- Wang, M.; Yuan, W.; Jiang, X.; Jing, Y.; Wang, Z. Disruption of microalgal cells using high-frequency focused ultrasound. Bioresour. Technol. 2014, 153, 315–321. [Google Scholar] [CrossRef] [PubMed]

- Keris-Sen, U.D.; Sen, U.; Soydemir, G.; Gurol, M.D. An investigation of ultrasound effect on microalgal cell integrity and lipid extraction efficiency. Bioresour. Technol. 2014, 152, 407–413. [Google Scholar] [CrossRef] [PubMed]

- Halim, R.; Rupasinghe, T.W.T.; Tull, D.L.; Webley, P.A. Mechanical cell disruption for lipid extraction from microalgal biomass. Bioresour. Technol. 2013, 140, 53–63. [Google Scholar] [CrossRef] [PubMed]

- Gaikwad, S.G.; Pandit, A.B. Ultrasound emulsification: Effect of ultrasonic and physicochemical properties on dispersed phase volume and droplet size. Ultrason. Sonochem. 2008, 15, 554–563. [Google Scholar] [CrossRef]

- Wen, C.; Zhang, J.; Zhang, H.; Dzah, C.S.; Zandile, M.; Duan, Y.; Ma, H.; Luo, X. Advances in ultrasound assisted extraction of bioactive compounds from cash crops—A review. Ultrason. Sonochem. 2018, 48, 538–549. [Google Scholar] [CrossRef]

- Postma, P.R.; Suarez-Garcia, E.; Safi, C.; Yonathan, K.; Olivieri, G.; Barbosa, M.J.; Wijffels, R.H.; Eppink, M.H.M. Energy efficient bead milling of microalgae: Effect of bead size on disintegration and release of proteins and carbohydrates. Bioresour. Technol. 2017, 224, 670–679. [Google Scholar] [CrossRef]

- Middelberg, A.P.J. Process-scale disruption of microorganisms. Biotechnol. Adv. 1995, 13, 491–551. [Google Scholar] [CrossRef]

- Halim, R.; Harun, R.; Danquah, M.K.; Webley, P.A. Microalgal cell disruption for biofuel development. Appl. Energy 2012, 91, 116–121. [Google Scholar] [CrossRef]

- Postma, P.R.; Miron, T.L.; Olivieri, G.; Barbosa, M.J.; Wijffels, R.H.; Eppink, M.H.M. Mild disintegration of the green microalgae Chlorella vulgaris using bead milling. Bioresour. Technol. 2015, 184, 297–304. [Google Scholar] [CrossRef]

- Clavijo Rivera, E.; Montalescot, V.; Viau, M.; Drouin, D.; Bourseau, P.; Frappart, M.; Monteux, C.; Couallier, E. Mechanical cell disruption of Parachlorella kessleri microalgae: Impact on lipid fraction composition. Bioresour. Technol. 2018, 256, 77–85. [Google Scholar] [CrossRef]

- Doucha, J.; Lívanský, K. Influence of processing parameters on disintegration of Chlorella cells in various types of homogenizers. Appl. Microbiol. Biotechnol. 2008, 81, 431–440. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Pei, Z.; Yuan, W.; Mao, E. Effect of nitrogen and extraction method on algae lipid yield. Int. J. Agric. Biol. Eng. 2009, 2, 51–57. [Google Scholar]

- Chisti, Y.; Moo-Young, M. Disruption of microbial cells for intracellular products. Enzyme Microb. Technol. 1986, 8, 194–204. [Google Scholar] [CrossRef]

- Harrison, S.T.L. Cell Disruption. In Comprehensive Biotechnology; Pergamon: Oxford, UK, 2011; pp. 619–640. [Google Scholar]

- Prabakaran, P.; Ravindran, A.D. A comparative study on effective cell disruption methods for lipid extraction from microalgae. Lett. Appl. Microbiol. 2011, 53, 150–154. [Google Scholar] [CrossRef] [PubMed]

- Mercer, P.; Armenta, R.E. Developments in oil extraction from microalgae. Eur. J. Lipid Sci. Technol. 2011, 113, 539–547. [Google Scholar] [CrossRef]

- Asif, M.B.; Hai, F.I.; Jegatheesan, V.; Price, W.E.; Nghiem, L.D.; Yamamoto, K. Applications of Membrane Bioreactors in Biotechnology Processes; Elsevier Inc.: Amsterdam, The Netherlands, 2018; ISBN 9780128136065. [Google Scholar]

- Demuez, M.; Mahdy, A.; Tomás-Pejó, E.; González-Fernández, C.; Ballesteros, M. Enzymatic cell disruption of microalgae biomass in biorefinery processes. Biotechnol. Bioeng. 2015, 112, 1955–1966. [Google Scholar] [CrossRef]

- Singhania, R.R. Production of celluloytic enzymes for the hydrolysis of lignocellulosic biomass. In Biofuels; Elsevier Inc.: Amsterdam, The Netherlands, 2011; pp. 177–201. ISBN 9780123850997. [Google Scholar]

- Zhang, Y.; Kong, X.; Wang, Z.; Sun, Y.; Zhu, S.; Li, L.; Lv, P. Optimization of enzymatic hydrolysis for effective lipid extraction from microalgae Scenedesmus sp. Renew. Energy 2018, 125, 1049–1057. [Google Scholar] [CrossRef]

- Šoštarič, M.; Klinar, D.; Bricelj, M.; Golob, J.; Berovič, M.; Likozar, B. Growth, lipid extraction and thermal degradation of the microalga Chlorella vulgaris. N. Biotechnol. 2012, 29, 325–331. [Google Scholar] [CrossRef]

- Cho, H.-S.; Oh, Y.-K.; Park, S.-C.; Lee, J.-W.; Park, J.-Y. Effects of enzymatic hydrolysis on lipid extraction from Chlorella vulgaris. Renew. Energy 2013, 54, 156–160. [Google Scholar] [CrossRef]

- Liang, K.; Zhang, Q.; Cong, W. Enzyme-Assisted Aqueous Extraction of Lipid from Microalgae. J. Agric. Food Chem. 2012, 60, 11771–11776. [Google Scholar] [CrossRef]

- Cheng, Y.S.; Zheng, Y.; Labavitch, J.M.; Vandergheynst, J.S. The impact of cell wall carbohydrate composition on the chitosan flocculation of Chlorella. Process Biochem. 2011, 46, 1927–1933. [Google Scholar] [CrossRef]

- Agustini, N.W.S.; Hidhayati, N.; Wibisono, S.A. Effect of hydrolysis time and acid concentration on bioethanol production of microalga Scenedesmus sp. Effect of hydrolysis time and acid concentration on bioethanol production of microalga Scenedesmus sp. IOP Conf. Ser. Earth Environ. Sci. 2019, 308, 12029. [Google Scholar] [CrossRef]

- Shahidi, F. Extraction and Measurement of Total Lipids. Curr. Protoc. Food Anal. Chem. 2003, 7, D1.1.1–D1.1.11. [Google Scholar] [CrossRef]

- Yu, X.; Dong, T.; Zheng, Y.; Miao, C.; Shulin, C. Investigation of cell disruption methods for lipid extraction from oleaginous microorganisms. Eur. J. Lipid Sci. Technol. 2014, 117, 730–737. [Google Scholar] [CrossRef]

- Chatzifragkou, A.; Fakas, S.; Galiotou-Panayotou, M.; Komaitis, M.; Aggelis, G.; Papanikolaou, S. Commercial sugars as substrates for lipid accumulation in Cunninghamella echinulata and Mortierella isabellina fungi. Eur. J. Lipid Sci. Technol. 2010, 112, 1048–1057. [Google Scholar] [CrossRef]

- Xiao, L. Evaluation of Extraction Methods for Recovery of Fatty Acids from Marine Products. Master’s Thesis, University of Bergen, Bergen, Norway, February 2010. [Google Scholar]

- Lee, S.Y.; Cho, J.M.; Chang, Y.K.; Oh, Y.-K. Cell disruption and lipid extraction for microalgal biorefineries: A review. Bioresour. Technol. 2017, 244, 1317–1328. [Google Scholar] [CrossRef] [PubMed]

- Duongbia, N.; Chaiwongsar, S.; Chaichana, C.; Chaiklangmuang, S. Acidic hydrolysis performance and hydrolyzed lipid characterizations of wet Spirulina platensis. Biomass Convers. Biorefinery 2019, 9, 305–319. [Google Scholar] [CrossRef]

- Park, J.Y.; Oh, Y.K.; Lee, J.S.; Lee, K.; Jeong, M.J.; Choi, S.A. Acid-catalyzed hot-water extraction of lipids from Chlorella vulgaris. Bioresour. Technol. 2014, 153, 408–412. [Google Scholar] [CrossRef]

- Martins, L.B.; Soares, J.; da Silveira, W.B.; de Cássia Superbi Sousa, R. Dilute sulfuric acid hydrolysis of Chlorella vulgaris biomass improves the multistage liquid-liquid extraction of lipids. Biomass Convers. Biorefinery 2020, 1–13. [Google Scholar] [CrossRef]

- Markou, G.; Angelidaki, I.; Nerantzis, E.; Georgakakis, D. Bioethanol Production by Carbohydrate-Enriched Biomass of Arthrospira (Spirulina) platensis. Energies 2013, 6, 3937–3950. [Google Scholar] [CrossRef]

- Lee, I.; Park, J.Y.; Choi, S.A.; Oh, Y.K.; Han, J.I. Hydrothermal nitric acid treatment for effectual lipid extraction from wet microalgae biomass. Bioresour. Technol. 2014, 172, 138–142. [Google Scholar] [CrossRef] [PubMed]

- Laurens, L.M.L.; Nagle, N.; Davis, R.; Sweeney, N.; Van Wychen, S.; Lowell, A.; Pienkos, P.T. Acid-catalyzed algal biomass pretreatment for integrated lipid and carbohydrate-based biofuels production. Green Chem. 2015, 17, 1145–1158. [Google Scholar] [CrossRef]

- Orr, V.C.A.; Plechkova, N.V.; Seddon, K.R.; Rehmann, L. Disruption and Wet Extraction of the Microalgae Chlorella vulgaris Using Room-Temperature Ionic Liquids. ACS Sustain. Chem. Eng. 2016, 4, 591–600. [Google Scholar] [CrossRef]

- Chen, X.; Hu, L.; Xing, R.; Liu, S.; Yu, H.; Qin, Y.; Li, K.; Li, R.; Li, P. Ionic liquid-assisted subcritical water promotes the extraction of lipids from wet microalgae Scenedesmus sp. Eur. J. Lipid Sci. Technol. 2015, 117, 1192–1198. [Google Scholar] [CrossRef]

- Olkiewicz, M.; Caporgno, M.P.; Font, J.; Legrand, J.; Lepine, O.; Plechkova, N.V.; Pruvost, J.; Seddon, K.R.; Bengoa, C. A novel recovery process for lipids from microalgæ for biodiesel production using a hydrated phosphonium ionic liquid. Green Chem. 2015, 17, 2813–2824. [Google Scholar] [CrossRef]

- Pragya, N.; Pandey, K.K.; Sahoo, P.K. A review on harvesting, oil extraction and biofuels production technologies from microalgae. Renew. Sustain. Energy Rev. 2013, 24, 159–171. [Google Scholar] [CrossRef]

- Young, G.; Nippgen, F.; Titterbrandt, S.; Cooney, M.J. Lipid extraction from biomass using co-solvent mixtures of ionic liquids and polar covalent molecules. Sep. Purif. Technol. 2010, 72, 118–121. [Google Scholar] [CrossRef]

- Zhanyou, C.R.; Olan, Z. Method for extracting microalga oil under assistance of carbonate and absorbing carbon dioxide for circulated culture. Chinese Patent No. CN109055228, 21 December 2018. [Google Scholar]

- Jie, X.; Xuan, C.; Mingxing, W.; Jiaxiong, W.; Jinxuan, C.; Yalong, L.; Zhongyang, D.; Fan, L. Method for extracting mixed fatty acids from wet microalgae mud by using subcritical water. Chinese Patent No. CN108300565, 20 July 2018. [Google Scholar]

- Chunfeng, S.; Meilian, X.; Yawei, S.; Gingling, L.; Na, J.; Lianwen, F.; Hongwei, W. Joint treatment device based on integration of vapor recompression and heat exchange and applied to microalgae. Chinese Patent No. CN107057838, 28 May 2017. [Google Scholar]

- Wenzhou, X.; Fangfang, Y.; Tao, L.; Hualian, W.; Shikun, D.; Jiewei, F.; Dehai, L.; Shengjie, J.; Dengliang, Y.; Pingping, L.Q.G. Method for preparing microalgae oil and protein polysaccharide by adopting wet algae and one-step method. Chinese Patent No. CN106701311, 24 May 2017. [Google Scholar]

- Jun, C.; Kefa, C.; Jianzhong, L.; Junhu, Z.; Zhenyu, H.; Zhihua, W.; Weijuan, Y.; Yanwei, Z.; Zhijun, Z. Method of using ultrasonic wave to change wet alga cell fractal structure for improving grease extraction. Chinese Patent No. CN104549684, 29 April 2015. [Google Scholar]

- Teixeira, R. Process for the Extraction of Lipids from Microalgae Using Ionic Liquids. US Patent No. US20110217777, 8 September 2011. [Google Scholar]

- Aleksandrovich, N.S.; Mikhajlovich, D.V.; Vladimirovna, M.J.; Pavlovna, L.A. Method of extraction of lipids from biomass. Russian Patent No. RU0002555554, 10 July 2015. [Google Scholar]

- Dong, W.; Xianyuan, Y. Method for wet extraction of purified microalgae oil. Chinese Patent No. CN104059773, 24 September 2014. [Google Scholar]

- Severo, I.A.; Siqueira, S.F.; Deprá, M.C.; Maroneze, M.M.; Zepka, L.Q.; Jacob-Lopes, E. Biodiesel facilities: What can we address to make biorefineries commercially competitive? Renew. Sustain. Energy Rev. 2019, 112, 686–705. [Google Scholar] [CrossRef]

- Gaignard, C.; Gargouch, N.; Dubessay, P.; Delattre, C.; Pierre, G.; Laroche, C.; Fendri, I.; Abdelkafi, S.; Michaud, P. New horizons in culture and valorization of red microalgae. Biotechnol. Adv. 2019, 37, 193–222. [Google Scholar] [CrossRef]

- Khanra, S.; Mondal, M.; Halder, G.; Tiwari, O.N.; Gayen, K.; Bhowmick, T.K. Downstream processing of microalgae for pigments, protein and carbohydrate in industrial application: A review. Food Bioprod. Process. 2018, 110, 60–84. [Google Scholar] [CrossRef]

- Gifuni, I.; Pollio, A.; Safi, C.; Marzocchella, A.; Olivieri, G. Current Bottlenecks and Challenges of the Microalgal Biorefinery. Trends Biotechnol. 2019, 37, 242–252. [Google Scholar] [CrossRef] [PubMed]

- ’t Lam, G.P.; Vermuë, M.H.; Eppink, M.H.M.; Wijffels, R.H.; van den Berg, C. Multi-Product Microalgae Biorefineries: From Concept Towards Reality. Trends Biotechnol. 2018, 36, 216–227. [Google Scholar] [CrossRef] [PubMed]

- Klemeš, J.J.; Varbanov, P.S.; Wan Alwi, S.R.; Manan, Z.A. Sustainable Process Integration and Intensification; De Gruyter: Berlin, Germany, 2018; ISBN 9783110535365. [Google Scholar]

- Walmsley, T.G.; Ong, B.H.Y.; Klemeš, J.J.; Tan, R.R.; Varbanov, P.S. Circular Integration of processes, industries, and economies. Renew. Sustain. Energy Rev. 2019, 107, 507–515. [Google Scholar] [CrossRef]

- Aziz, M.; Oda, T.; Kashiwagi, T. Integration of energy-efficient drying in microalgae utilization based on enhanced process integration. Energy 2014, 70, 307–316. [Google Scholar] [CrossRef]

- Luo, J.; Fang, Z.; Smith, R.L. Ultrasound-enhanced conversion of biomass to biofuels. Prog. Energy Combust. Sci. 2014, 41, 56–93. [Google Scholar] [CrossRef]

- Moncada, J.; Tamayo, J.A.; Cardona, C.A. Integrating first, second, and third generation biorefineries: Incorporating microalgae into the sugarcane biorefinery. Chem. Eng. Sci. 2014, 118, 126–140. [Google Scholar] [CrossRef]

- Moncada, J.; Cardona, C.A.; Rincón, L.E. Design and analysis of a second and third generation biorefinery: The case of castorbean and microalgae. Bioresour. Technol. 2015, 198, 836–843. [Google Scholar] [CrossRef]

- Zhu, L.D.; Hiltunen, E. Application of livestock waste compost to cultivate microalgae for bioproducts production: A feasible framework. Renew. Sustain. Energy Rev. 2016, 54, 1285–1290. [Google Scholar] [CrossRef]

- Di Chen, Y.; Li, S.; Ho, S.H.; Wang, C.; Lin, Y.C.; Nagarajan, D.; Chang, J.S.; Ren, N. qi Integration of sludge digestion and microalgae cultivation for enhancing bioenergy and biorefinery. Renew. Sustain. Energy Rev. 2018, 96, 76–90. [Google Scholar] [CrossRef]

- Zahedi, S.; Icaran, P.; Yuan, Z.; Pijuan, M. Assessment of free nitrous acid pre-treatment on a mixture of primary sludge and waste activated sludge: Effect of exposure time and concentration. Bioresour. Technol. 2016, 216, 870–875. [Google Scholar] [CrossRef]

- Cheng, J.; Xu, J.; Huang, Y.; Li, Y.; Zhou, J.; Cen, K. Growth optimisation of microalga mutant at high CO2 concentration to purify undiluted anaerobic digestion effluent of swine manure. Bioresour. Technol. 2015, 177, 240–246. [Google Scholar] [CrossRef] [PubMed]

- Kao, C.Y.; Chiu, S.Y.; Huang, T.T.; Dai, L.; Hsu, L.K.; Lin, C.S. Ability of a mutant strain of the microalga Chlorella sp. to capture carbon dioxide for biogas upgrading. Appl. Energy 2012, 93, 176–183. [Google Scholar] [CrossRef]

- Zhou, K.; Zhang, Y.; Jia, X. Co-cultivation of fungal-microalgal strains in biogas slurry and biogas purification under different initial CO2 concentrations. Sci. Rep. 2018, 8, 1–12. [Google Scholar] [CrossRef] [PubMed]

| Patent Name/Invention | Pretreatment Applied to Extract Lipids | Technology to Separate Microalgae Residues | Advantages | Year | Reference |

|---|---|---|---|---|---|

| Method for extracting microalgal oil assisted by carbonate and absorbing carbon dioxide in circulated culture | (1) Wall breaking treatment—sodium carbonate + ionic liquid (DBU) + heat (2) Salting-out extraction—methanol (3) CO2 introduction (into the aqueous phase) | N/A | Reduces energy consumption cost; Allows water recycling. | 2018 | [148] |

| Method for extracting mixed fatty acids from wet microalgae mud by using subcritical water | Subcritical water extraction | N/A | Fast and efficient oil extraction; Environmentally friendly; Uses water as extraction medium and hydrolysis reaction agent (thus avoiding use of organic solvents); Saves energy; High fatty acid extraction rate, simple separation, easy scale-up. | 2018 | [149] |

| Joint treatment device based on the integration of vapor recompression and heat exchange and applied to microalgae | Joint treatment device which comprises (a) microalgae drying system; (b) grease extraction system; (c) solvent recovery system. | N/A | Uses dry and wet microalgae; Energy-efficient; Joint device has simple structure and is easy to perform; The whole process reduces operating costs. | 2017 | [150] |

| Method for preparing microalgae oil and protein-polysaccharide by adopting wet algae and one-step method | Extraction with solvents–ethyl alcohol | Filtration method, and standing layering or centrifugal layering | Strong fat solubility of ethyl alcohol; Pollution-free to human body and environment; Keeps activity of high value-added active substances; Short treatment time; Simple to operate; High extraction efficiency; Possibility of application to large-scale. | 2017 | [151] |

| Method of using ultrasonic wave to change wet alga cell fractal structure for improving grease extraction | Solvent extraction (chloroform-methanol), with previous treatment by ultrasound waves | Centrifugation | Avoids dewatering and drying steps; Reduces cell wall thickness. | 2015 | [152] |

| Process for extraction of lipids from microalgae using ionic liquids | Several ionic liquids, individually and in combination, were tested | Chemical forces, magnetic forces, and separation based on density differences were tested | Green technology. | 2011 | [153] |

| Method of extraction of lipids from biomass | Cell membranes destruction in vortex-electromagnetic field with ferromagnetic particles | Organic solvent superposition pulse-cavitation | Reduces extraction time; Increases output of lipid fraction. | 2015 | [154] |

| Method for wet extraction of purified microalgal oil | Solvent extraction (hexane) | Centrifugation | Easy operation; Low power consumption. | 2014 | [155] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pôjo, V.; Tavares, T.; Malcata, F.X. Processing Methodologies of Wet Microalga Biomass Toward Oil Separation: An Overview. Molecules 2021, 26, 641. https://doi.org/10.3390/molecules26030641

Pôjo V, Tavares T, Malcata FX. Processing Methodologies of Wet Microalga Biomass Toward Oil Separation: An Overview. Molecules. 2021; 26(3):641. https://doi.org/10.3390/molecules26030641

Chicago/Turabian StylePôjo, Vânia, Tânia Tavares, and Francisco Xavier Malcata. 2021. "Processing Methodologies of Wet Microalga Biomass Toward Oil Separation: An Overview" Molecules 26, no. 3: 641. https://doi.org/10.3390/molecules26030641

APA StylePôjo, V., Tavares, T., & Malcata, F. X. (2021). Processing Methodologies of Wet Microalga Biomass Toward Oil Separation: An Overview. Molecules, 26(3), 641. https://doi.org/10.3390/molecules26030641