Scientometric Overview of Coffee By-Products and Their Applications

Abstract

1. Introduction

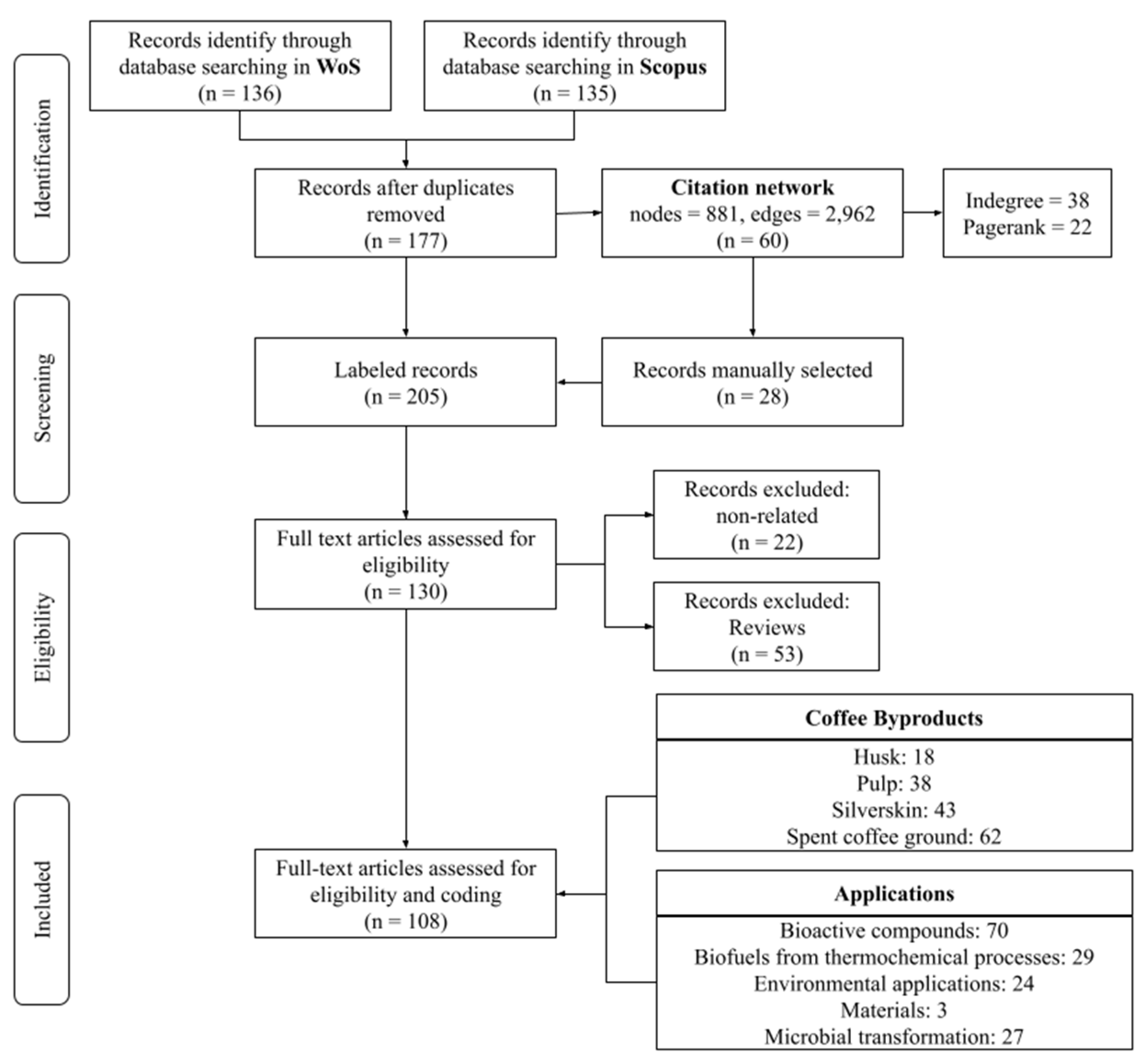

2. Methodology

2.1. Step 1: Scientometric Analysis

2.2. Step 2: Analysis of Coffee By-Product Applications

3. Results

3.1. Scientometric Analysis

3.1.1. Annual Scientific Production

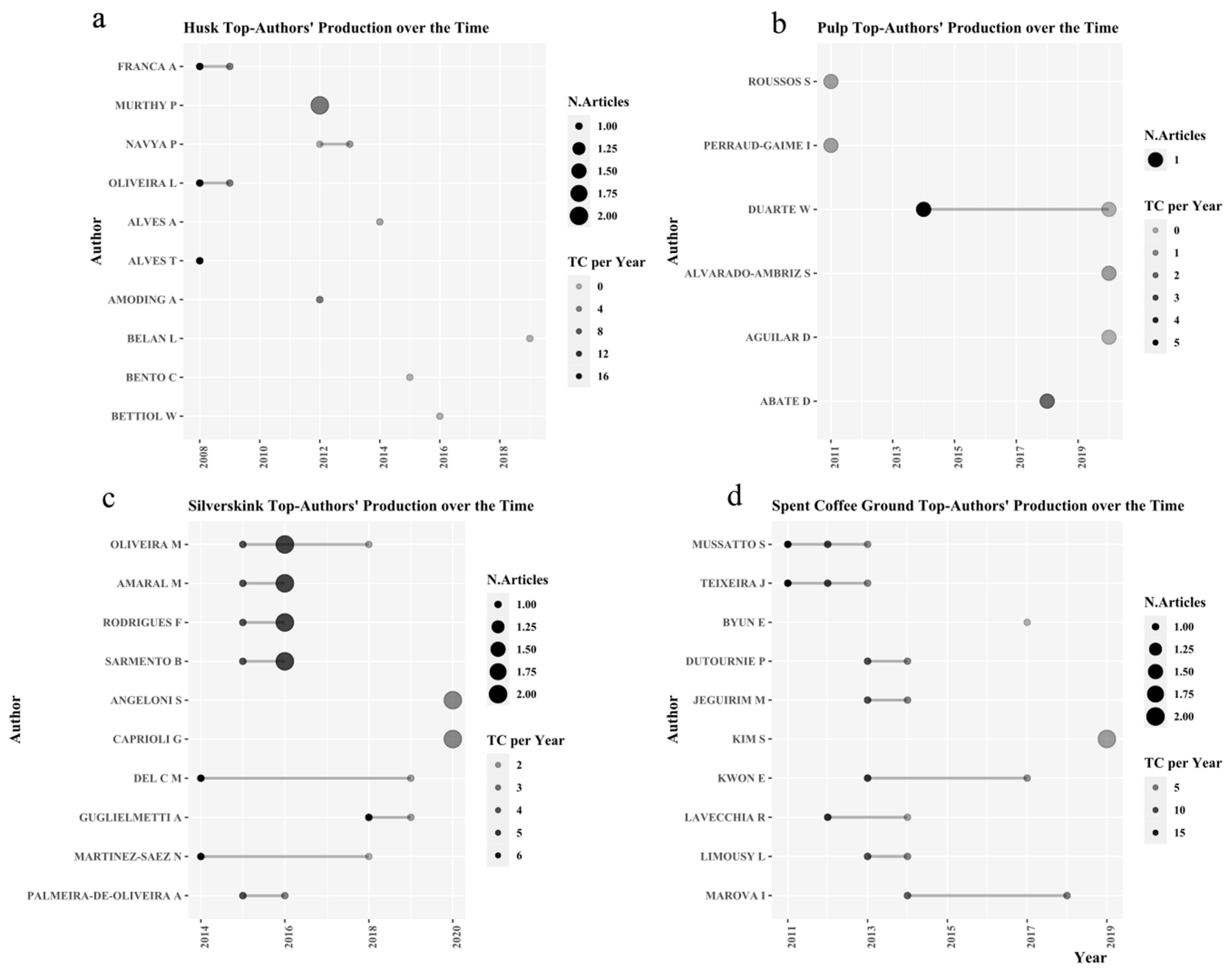

3.1.2. Authorship Analysis

3.1.3. Journal Analysis

3.2. Applications

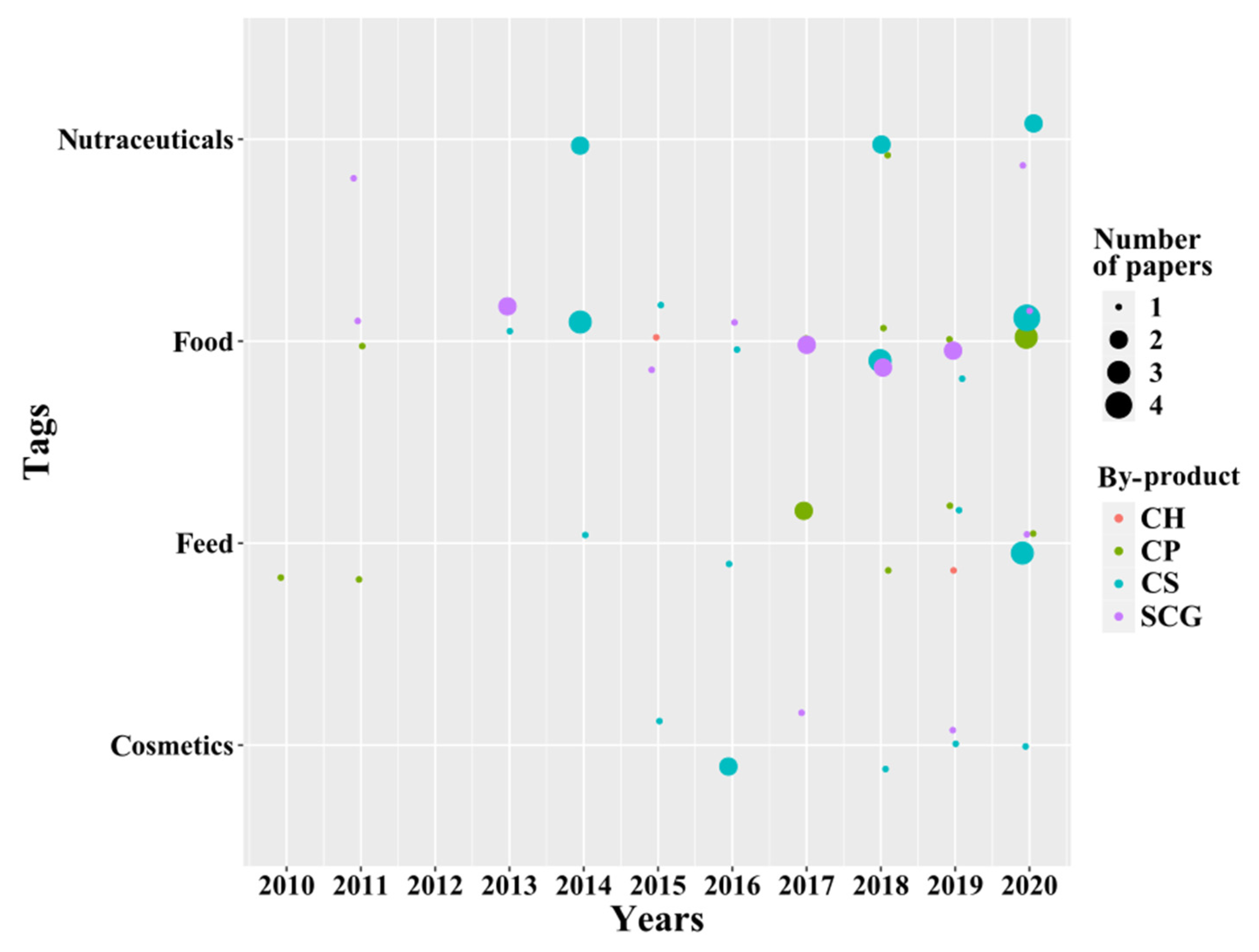

3.2.1. Bioactive Compounds

Nutraceuticals

Food

Feed

Cosmetics

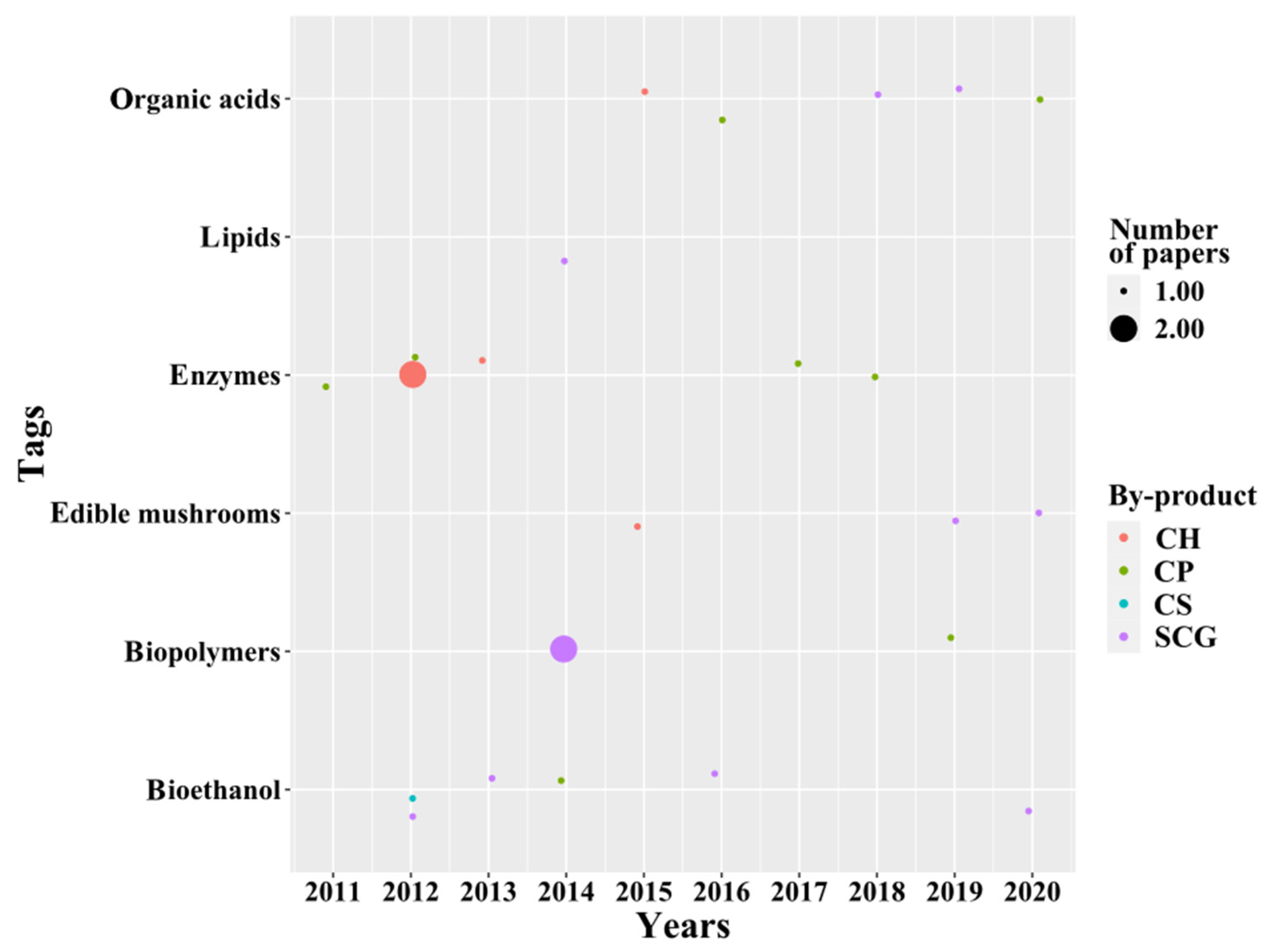

3.2.2. Microbial Transformations (and Other Biotechnological Applications)

Organic Acids

Lipids and Biopolymers

Enzymes

Edible Mushrooms

Bioethanol

3.2.3. Environmental Applications

Fertilizers

Composting

Biopesticides

Bioadsorbents and Biocatalysts

3.2.4. Biofuels from Thermochemical Processes

Biodiesel

Solid Fuels

Bio-Oil

Syngas

3.2.5. Materials and Others

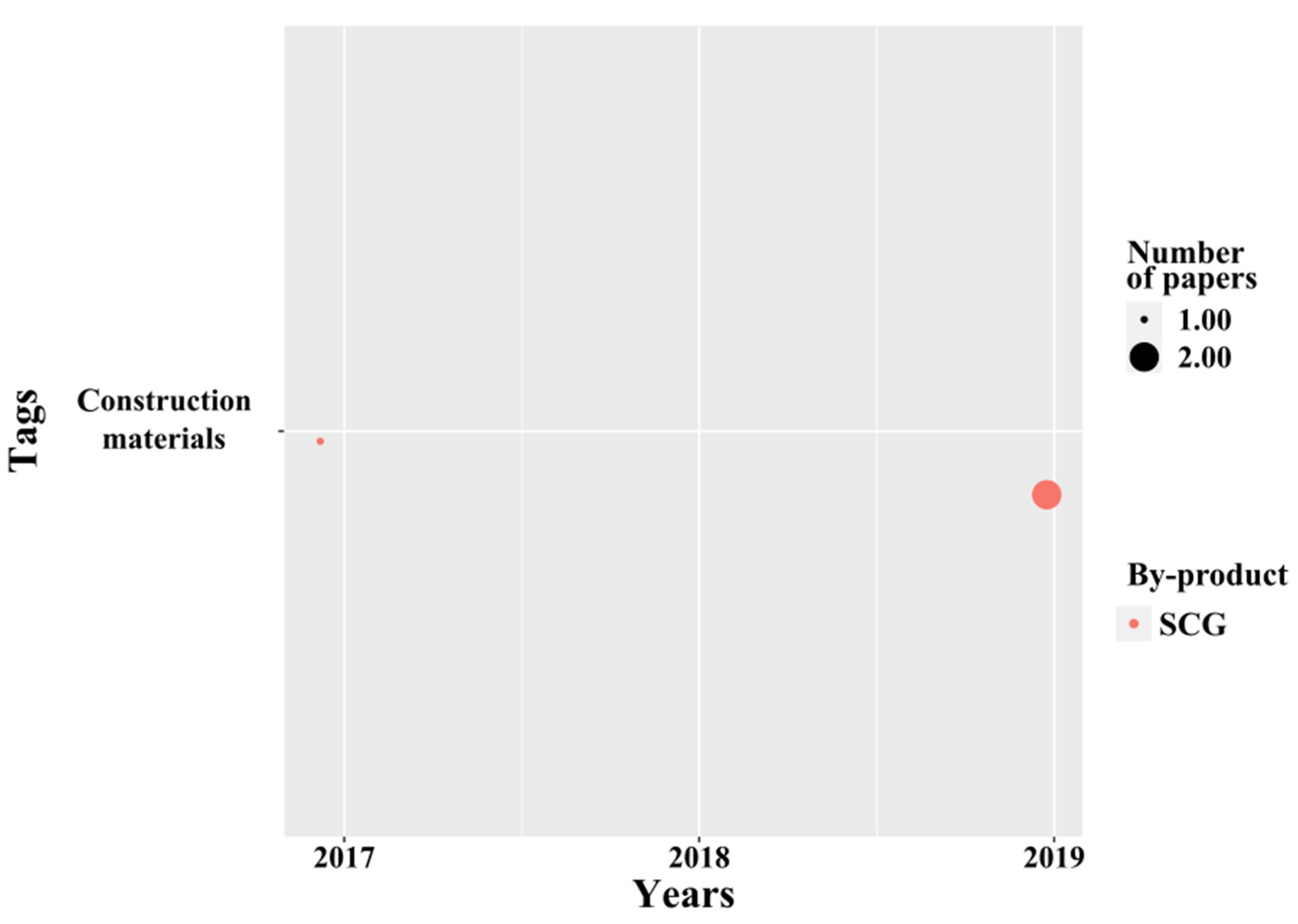

Construction Materials

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Sample Availability

References

- Angeloni, S.; Mustafa, A.M.; Abouelenein, D.; Alessandroni, L.; Acquaticci, L.; Nzekoue, F.K.; Petrelli, R.; Sagratini, G.; Vittori, S.; Torregiani, E.; et al. Characterization of the Aroma Profile and Main Key Odorants of Espresso Coffee. Molecules 2021, 26, 3856. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues da Silva, M.; Sanchez Bragagnolo, F.; Lajarim Carneiro, R.; de Oliveira Carvalho Pereira, I.; Aquino Ribeiro, J.A.; Martins Rodrigues, C.; Jelley, R.E.; Fedrizzi, B.; Soleo Funari, C. Metabolite Characterization of Fifteen by-products of the Coffee Production Chain: From Farm to Factory. Food Chem. 2022, 369, 130753. [Google Scholar] [CrossRef]

- Catalán, E.; Komilis, D.; Sánchez, A. Environmental Impact of Cellulase Production from Coffee Husks by Solid-State Fermentation: A Life-Cycle Assessment. J. Clean. Prod. 2019, 233, 954–962. [Google Scholar] [CrossRef]

- Gómez-Aguilar, D.L.; Rodríguez-Miranda, J.P.; Baracaldo-Guzmán, D.; Salcedo-Parra, O.J.; Esteban-Muñoz, J.A. Biosorption of Pb(II) Using Coffee Pulp as a Sustainable Alternative for Wastewater Treatment. Nato Adv. Sci. Inst. Ser. E Appl. Sci. 2021, 11, 6066. [Google Scholar] [CrossRef]

- Geeraert, L.; Berecha, G.; Honnay, O.; Aerts, R. Organoleptic Quality of Ethiopian Arabica Coffee Deteriorates with Increasing Intensity of Coffee Forest Management. J. Environ. Manag. 2019, 231, 282–288. [Google Scholar] [CrossRef]

- Sermyagina, E.; Mendoza Martinez, C.L.; Nikku, M.; Vakkilainen, E. Spent Coffee Grounds and Tea Leaf Residues: Characterization, Evaluation of Thermal Reactivity and Recovery of High-Value Compounds. Biomass Bioenergy 2021, 150, 106141. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Martins, S.; Teixeira, J.A. Production, Composition, and Application of Coffee and Its Industrial Residues. Food Bioprocess Technol. 2011, 4, 661–672. [Google Scholar] [CrossRef]

- Esquivel, P.; Jiménez, V.M. Functional Properties of Coffee and Coffee by-products. Food Res. Int. 2012, 46, 488–495. [Google Scholar] [CrossRef]

- Murthy, P.S.; Madhava Naidu, M. Sustainable Management of Coffee Industry by-products and Value Addition—A Review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Narita, Y.; Inouye, K. Review on Utilization and Composition of Coffee Silverskin. Food Res. Int. 2014, 61, 16–22. [Google Scholar] [CrossRef]

- Campos-Vega, R.; Loarca-Piña, G.; Vergara-Castañeda, H.A.; Oomah, B.D. Spent Coffee Grounds: A Review on Current Research and Future Prospects. Trends Food Sci. Technol. 2015, 45, 24–36. [Google Scholar] [CrossRef]

- Alves, R.C.; Rodrigues, F.; Antónia Nunes, M.; Vinha, A.F.; Oliveira, M.B.P.P. State of the art in coffee processing by-products. In Handbook of Coffee Processing By-Products; Elsevier: Amsterdam, The Netherlands, 2017; pp. 1–26. [Google Scholar] [CrossRef]

- Klingel, T.; Kremer, J.I.; Gottstein, V.; Rajcic de Rezende, T.; Schwarz, S.; Lachenmeier, D.W. A Review of Coffee By-products Including Leaf, Flower, Cherry, Husk, Silver Skin, and Spent Grounds as Novel Foods within the European Union. Foods 2020, 9, 665. [Google Scholar] [CrossRef]

- de Melo Pereira, G.V.; de Carvalho Neto, D.P.; Magalhães Júnior, A.I.; do Prado, F.G.; Pagnoncelli, M.G.B.; Karp, S.G.; Soccol, C.R. Chemical Composition and Health Properties of Coffee and Coffee by-products. Adv. Food Nutr. Res. 2020, 91, 65–96. [Google Scholar] [PubMed]

- Castaldo, L.; Narváez, A.; Izzo, L.; Graziani, G.; Ritieni, A. In Vitro Bioaccessibility and Antioxidant Activity of Coffee Silverskin Polyphenolic Extract and Characterization of Bioactive Compounds Using UHPLC-Q-Orbitrap HRMS. Molecules 2020, 25, 2132. [Google Scholar] [CrossRef]

- Kohn, K.C.; Gordon, L. Citation Analysis as a Tool for Collection Development and Instruction. Collect. Manag. 2014, 39, 275–296. [Google Scholar] [CrossRef]

- Lachenmeier, D.W.; Teipel, J.; Scharinger, A.; Kuballa, T.; Walch, S.G.; Grosch, F.; Bunzel, M.; Okaru, A.O.; Schwarz, S. Fully Automated Identification of Coffee Species and Simultaneous Quantification of Furfuryl Alcohol Using NMR Spectroscopy. J. AOAC Int. 2020, 103, 306–314. [Google Scholar] [CrossRef] [PubMed]

- Vinkler, P. Core Journals and Elite Subsets in Scientometrics. Scientometrics 2019, 121, 241–259. [Google Scholar] [CrossRef]

- Cabrera, L.C.; Caldarelli, C.E.; da Camara, M.R.G. Mapping Collaboration in International Coffee Certification Research. Scientometrics 2020, 124, 2597–2618. [Google Scholar] [CrossRef]

- Macías-Quiroga, I.F.; Henao-Aguirre, P.A.; Marín-Flórez, A.; Arredondo-López, S.M.; Sanabria-González, N.R. Bibliometric Analysis of Advanced Oxidation Processes (AOPs) in Wastewater Treatment: Global and Ibero-American Research Trends. Environ. Sci. Pollut. Res. Int. 2020, 28, 23791–23811. [Google Scholar] [CrossRef] [PubMed]

- Aria, M.; Cuccurullo, C. Bibliometrix: An R-Tool for Comprehensive Science Mapping Analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef]

- Robledo, S.; Grisales Aguirre, A.M.; Hughes, M.; Eggers, F. “Hasta La Vista, Baby’’—Will Machine Learning Terminate Human Literature Reviews in Entrepreneurship? J. Small Bus. Manag. 2021, 1–30. [Google Scholar] [CrossRef]

- Duque, P.; Meza, O.E.; Giraldo, D.; Barreto, K. Economía Social y Economía Solidaria: Un análisis bibliométrico y revisión de literatura. Revesco. Rev. De Estud. Coop. 2021, 138, e75566. [Google Scholar] [CrossRef]

- Rolz, C.; Menchú, J.F.; del Carmen de Arriola, M.; de Micheo, F. Pressing of Coffee Pulp. Agric. Wastes 1980, 2, 207–214. [Google Scholar] [CrossRef]

- Borrelli, R.C.; Esposito, F.; Napolitano, A.; Ritieni, A.; Fogliano, V. Characterization of a New Potential Functional Ingredient: Coffee Silverskin. J. Agric. Food Chem. 2004, 52, 1338–1343. [Google Scholar] [CrossRef] [PubMed]

- Givens, D.I.; Barber, W.P. In Vivo Evaluation of Spent Coffee Grounds as a Ruminant Feed. Agric. Wastes 1986, 18, 69–72. [Google Scholar] [CrossRef]

- Oliveira, L.S.; Franca, A.S.; Alves, T.M.; Rocha, S.D.F. Evaluation of Untreated Coffee Husks as Potential Biosorbents for Treatment of Dye Contaminated Waters. J. Hazard. Mater. 2008, 155, 507–512. [Google Scholar] [CrossRef] [PubMed]

- Bonilla-Hermosa, V.A.; Duarte, W.F.; Schwan, R.F. Utilization of Coffee by-products Obtained from Semi-Washed Process for Production of Value-Added Compounds. Bioresour. Technol. 2014, 166, 142–150. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, F.; Sarmento, B.; Amaral, M.H.; Oliveira, M.B.P.P. Exploring the Antioxidant Potentiality of Two Food by-products into a Topical Cream: Stability, in Vitro and in Vivo Evaluation. Drug Dev. Ind. Pharm. 2016, 42, 880–889. [Google Scholar] [CrossRef] [PubMed]

- Mussatto, S.I.; Ballesteros, L.F.; Martins, S.; Teixeira, J.A. Extraction of Antioxidant Phenolic Compounds from Spent Coffee Grounds. Sep. Purif. Technol. 2011, 83, 173–179. [Google Scholar] [CrossRef]

- Sampaio, A.; Dragone, G.; Vilanova, M.; Oliveira, J.M.; Teixeira, J.A.; Mussatto, S.I. Production, Chemical Characterization, and Sensory Profile of a Novel Spirit Elaborated from Spent Coffee Ground. LWT Food Sci. Technol. 2013, 54, 557–563. [Google Scholar] [CrossRef]

- Mussatto, S.I.; Machado, E.M.S.; Carneiro, L.M.; Teixeira, J.A. Sugars Metabolism and Ethanol Production by Different Yeast Strains from Coffee Industry Wastes Hydrolysates. Appl. Energy 2012, 92, 763–768. [Google Scholar] [CrossRef]

- Hurtado-Marín, V.A.; Agudelo-Giraldo, J.D.; Robledo, S.; Restrepo-Parra, E. Analysis of Dynamic Networks Based on the Ising Model for the Case of Study of Co-Authorship of Scientific Articles. Sci. Rep. 2021, 11, 5721. [Google Scholar] [CrossRef] [PubMed]

- Blondel, V.D.; Guillaume, J.-L.; Lambiotte, R.; Lefebvre, E. Fast Unfolding of Communities in Large Networks. J. Stat.Mech. Theory Exp. 2008, 2008, P10008. [Google Scholar] [CrossRef]

- Belan, L.; de Almeida Rego, F.C.; de Castro, F.A.B.; Serafim, C.C.; Gasparini, M.J.; Zundt, M.; Ludovico, A.; Castilho, C.; Filho, L.F.C.; Eleodoro, J.I. Replacing Oat Hay with Coffee Husk in the Feed of Finishing Lambs. Semin.-Cienc. Agrar. 2019, 40, 1653–1662. [Google Scholar] [CrossRef]

- Dadi, D.; Daba, G.; Beyene, A.; Luis, P.; Van der Bruggen, B. Composting and Co-Composting of Coffee Husk and Pulp with Source-Separated Municipal Solid Waste: A Breakthrough in Valorization of Coffee Waste. Int. J. Recycl. Org. Waste Agric. 2019, 8, 263–277. [Google Scholar] [CrossRef]

- Pleissner, D.; Neu, A.-K.; Mehlmann, K.; Schneider, R.; Puerta-Quintero, G.I.; Venus, J. Fermentative Lactic Acid Production from Coffee Pulp Hydrolysate Using Bacillus Coagulans at Laboratory and Pilot Scales. Bioresour. Technol. 2016, 218, 167–173. [Google Scholar] [CrossRef]

- Rodrigues, F.; Gaspar, C.; Palmeira-de-Oliveira, A.; Sarmento, B.; Helena Amaral, M.; Oliveira, M.B.P.P. Application of Coffee Silverskin in Cosmetic Formulations: Physical/antioxidant Stability Studies and Cytotoxicity Effects. Drug Dev. Ind. Pharm. 2016, 42, 99–106. [Google Scholar] [CrossRef] [PubMed]

- Lykoudi, A.; Frontistis, Z.; Vakros, J.; Manariotis, I.D.; Mantzavinos, D. Degradation of Sulfamethoxazole with Persulfate Using Spent Coffee Grounds Biochar as Activator. J. Env. Manag. 2020, 271, 111022. [Google Scholar] [CrossRef]

- Vega, A.; De León, J.A.; Reyes, S.M.; Miranda, S.Y. Componentes Bioactivos de Diferentes Marcas de Café Comerciales de Panamá. Relación Entre Ácidos Clorogénicos Y Cafeína. Inf. Tecnol. 2018, 29, 43–54. [Google Scholar] [CrossRef]

- Bessada, S.M.F.; Alves, R.C.; Costa, A.S.G.; Nunes, M.A.; Oliveira, M.B.P.P. Coffea Canephora Silverskin from Different Geographical Origins: A Comparative Study. Sci. Total Environ. 2018, 645, 1021–1028. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, F.; Palmeira-de-Oliveira, A.; das Neves, J.; Sarmento, B.; Helena Amaral, M.; Oliveira, M.B.P.P. Coffee Silverskin: A Possible Valuable Cosmetic Ingredient. Pharm. Biol. 2015, 53, 386–394. [Google Scholar] [CrossRef] [PubMed]

- Angeloni, S.; Scortichini, S.; Fiorini, D.; Sagratini, G.; Vittori, S.; Neiens, S.D.; Steinhaus, M.; Zheljazkov, V.D.; Maggi, F.; Caprioli, G. Characterization of Odor-Active Compounds, Polyphenols, and Fatty Acids in Coffee Silverskin. Molecules 2020, 25, 2993. [Google Scholar] [CrossRef] [PubMed]

- Pettinato, M.; Casazza, A.A.; Ferrari, P.F.; Palombo, D.; Perego, P. Eco-Sustainable Recovery of Antioxidants from Spent Coffee Grounds by Microwave-Assisted Extraction: Process Optimization, Kinetic Modeling and Biological Validation. Food Bioprod. Process. 2019, 114, 31–42. [Google Scholar] [CrossRef]

- Iriondo-Dehond, A.; Iriondo-Dehond, M.; Del Castillo, M.D. Applications of Compounds from Coffee Processing by-products. Biomolecules 2020, 10, 1219. [Google Scholar] [CrossRef] [PubMed]

- Nzekoue, F.K.; Angeloni, S.; Navarini, L.; Angeloni, C.; Freschi, M.; Hrelia, S.; Vitali, L.A.; Sagratini, G.; Vittori, S.; Caprioli, G. Coffee Silverskin Extracts: Quantification of 30 Bioactive Compounds by a New HPLC-MS/MS Method and Evaluation of Their Antioxidant and Antibacterial Activities. Food Res. Int. 2020, 133, 109128. [Google Scholar] [CrossRef]

- Jiménez-Zamora, A.; Pastoriza, S.; Rufián-Henares, J.A. Revalorization of Coffee by-products. Prebiotic, Antimicrobial and Antioxidant Properties. LWT—Food Sci. Technol. 2015, 61, 12–18. [Google Scholar] [CrossRef]

- Pourfarzad, A.; Mahdavian-Mehr, H.; Sedaghat, N. Coffee Silverskin as a Source of Dietary Fiber in Bread-Making: Optimization of Chemical Treatment Using Response Surface Methodology. LWT—Food Sci. Technol. 2013, 50, 599–606. [Google Scholar] [CrossRef]

- Guglielmetti, A.; Fernandez-Gomez, B.; Zeppa, G.; del Castillo, M. Nutritional Quality, Potential Health Promoting Properties and Sensory Perception of an Improved Gluten-Free Bread Formulation Containing Inulin, Rice Protein and Bioactive Compounds Extracted from Coffee Byproducts. Pol. J. Food Nutr. Sci. 2019, 69, 157–166. [Google Scholar] [CrossRef]

- Beltrán-Medina, E.A.; Guatemala-Morales, G.M.; Padilla-Camberos, E.; Corona-González, R.I.; Mondragón-Cortez, P.M.; Arriola-Guevara, E. Evaluation of the Use of a Coffee Industry By-product in a Cereal-Based Extruded Food Product. Foods 2020, 9, 1008. [Google Scholar] [CrossRef]

- Martinez-Saez, N.; Ullate, M.; Martin-Cabrejas, M.A.; Martorell, P.; Genovés, S.; Ramon, D.; del Castillo, M.D. A Novel Antioxidant Beverage for Body Weight Control Based on Coffee Silverskin. Food Chem. 2014, 150, 227–234. [Google Scholar] [CrossRef]

- Martinez-Saez, N.; Castillo, M.D. Development of Sustainable Novel Foods and Beverages Based on Coffee By-products for Chronic Diseases. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2019; pp. 307–315. ISBN 9780128126882. [Google Scholar]

- Fernanda Quijano-Aviles, M.; Lisbeth Franco-Agurto, G.; Belen Suarez-Quirumbay, K.; Delida Barragan-Lucas, A.; Isabel Manzano-Santana, P. Linear Programming Formulation of a Dairy Drink Made of Cocoa, Coffee and Orange by-products. Emir. J. Food Agric. 2016, 28, 554–559. [Google Scholar] [CrossRef]

- Burniol-Figols, A.; Cenian, K.; Skiadas, I.V.; Gavala, H.N. Integration of Chlorogenic Acid Recovery and Bioethanol Production from Spent Coffee Grounds. Biochem. Eng. J. 2016, 116, 54–64. [Google Scholar] [CrossRef]

- Getachew, A.T.; Cho, Y.J.; Chun, B.S. Effect of Pretreatments on Isolation of Bioactive Polysaccharides from Spent Coffee Grounds Using Subcritical Water. Int. J. Biol. Macromol. 2018, 109, 711–719. [Google Scholar] [CrossRef] [PubMed]

- Simões, J.; Nunes, F.M.; Domingues, M.R.; Coimbra, M.A. Extractability and Structure of Spent Coffee Ground Polysaccharides by Roasting Pre-Treatments. Carbohydr. Polym. 2013, 97, 81–89. [Google Scholar] [CrossRef] [PubMed]

- Martinez-Saez, N.; García, A.T.; Pérez, I.D.; Rebollo-Hernanz, M.; Mesías, M.; Morales, F.J.; Martín-Cabrejas, M.A.; del Castillo, M.D. Use of Spent Coffee Grounds as Food Ingredient in Bakery Products. Food Chem. 2017, 216, 114–122. [Google Scholar] [CrossRef] [PubMed]

- Aguilar-Raymundo, V.G.; Sánchez-Páez, R.; Gutiérrez-Salomón, A.L.; Barajas-Ramírez, J.A. Spent Coffee Grounds Cookies: Sensory and Texture Characteristics, Proximate Composition, Antioxidant Activity, and Total Phenolic Content. J. Food Process. Preserv. 2019, 43, e14223. [Google Scholar] [CrossRef]

- Nzekoue, F.K.; Khamitova, G.; Angeloni, S.; Sempere, A.N.; Tao, J.; Maggi, F.; Xiao, J.; Sagratini, G.; Vittori, S.; Caprioli, G. Spent Coffee Grounds: A Potential Commercial Source of Phytosterols. Food Chem. 2020, 325, 126836. [Google Scholar] [CrossRef] [PubMed]

- Lopes, A.C.A.; Andrade, R.P.; de Oliveira, L.C.C.; Lima, L.M.Z.; Santiago, W.D.; de Resende, M.L.V.; das Gracas Cardoso, M.; Duarte, W.F. Production and Characterization of a New Distillate Obtained from Fermentation of Wet Processing Coffee by-products. J. Food Sci. Technol.-Mysore 2020, 57, 4481–4491. [Google Scholar] [CrossRef] [PubMed]

- Navia, D.P.P.; de Velasco, R.J.M.; Hoyos, J.L.C. Production and Evaluation of Ethanol from Coffee Processing by-products [Obtención Y Evaluación de Etanol a Partir de Los Subproductos Del Beneficio de Café]. Vitae Scholast. 2011, 18, 287–294. [Google Scholar]

- Heeger, A.; Kosińska-Cagnazzo, A.; Cantergiani, E.; Andlauer, W. Bioactives of Coffee Cherry Pulp and Its Utilisation for Production of Cascara Beverage. Food Chem. 2017, 221, 969–975. [Google Scholar] [CrossRef] [PubMed]

- Delgado, S.R.; Arbelaez, A.F.A.; Rojano, B. Antioxidant Capacity, Bioactive Compounds in Coffee Pulp and Implementation in the Production of Infusions. Acta Sci. Pol. Technol. Aliment. 2019, 18, 235–248. [Google Scholar] [CrossRef]

- Kusumocahyo, S.P.; Wijaya, S.; Dewi, A.A.C.; Rahmawati, D.; Widiputri, D.I. Optimization of the Extraction Process of Coffee Pulp as a Source of Antioxidant. In Proceedings of the IOP Conference Series: Earth and Environmental Science; Institute of Physics Publishing: New York, NY, USA, 2020; Volume 443. [Google Scholar]

- Magoni, C.; Bruni, I.; Guzzetti, L.; Dell’Agli, M.; Sangiovanni, E.; Piazza, S.; Regonesi, M.E.; Maldini, M.; Spezzano, R.; Caruso, D.; et al. Valorizing Coffee Pulp by-products as Anti-Inflammatory Ingredient of Food Supplements Acting on IL-8 Release. Food Res. Int. 2018, 112, 129–135. [Google Scholar] [CrossRef]

- Alvarado-Ambriz, S.G.; Lobato-Calleros, C.; Hernandez-Rodriguez, L.; Vernon-Carter, E.J. Wet Processing Coffee Waste as an Alternative to Produce Extracts with Antifungal Activity: In Vitro and in Vivo Valorization. Rev. Mex. Ing. Quim. 2020, 19, 135–149. [Google Scholar] [CrossRef]

- Kasuya, M.C.M.; da Luz, J.M.; Nunes, M.D.; da Silva, M.D.C.S.; de Carvalho, D.R.; de Assunção, L.S.; de Almeida Paula, T.; Moura, C.; Bento, C.B.P. Production of Selenium-Enriched Mushrooms in Coffee Husks and Use of This Colonized Residue; Elsevier Inc.: Amsterdam, The Netherlands, 2015; pp. 301–309. [Google Scholar] [CrossRef]

- Moreau, Y.; Arredondo, J.-L.; Perraud-Gaime, I.; Roussos, S. Dietary Utilisation of Protein and Energy from Fresh and Ensiled Coffee Pulp by the Nile Tilapia, Oreochromis Niloticus. Braz. Arch. Biol. Technol. 2003, 46, 223–231. [Google Scholar] [CrossRef]

- Donkoh, A.; Atuahene, C.C.; Kese, A.G.; Mensah-Asante, B. The Nutritional Value of Dried Coffee Pulp (DCP) in Broiler Chickens’ Diets. Anim. Feed Sci. Technol. 1988, 22, 139–146. [Google Scholar] [CrossRef]

- Nurfeta, A. Feed Intake, Digestibility, Nitrogen Utilization, and Body Weight Change of Sheep Consuming Wheat Straw Supplemented with Local Agricultural and Agro-Industrial by-products. Trop. Anim. Health Prod. 2010, 42, 815–824. [Google Scholar] [CrossRef] [PubMed]

- de Otálora, X.D.; Ruiz, R.; Goiri, I.; Rey, J.; Atxaerandio, R.; San Martin, D.; Orive, M.; Iñarra, B.; Zufia, J.; Urkiza, J.; et al. Valorisation of Spent Coffee Grounds as Functional Feed Ingredient Improves Productive Performance of Latxa Dairy Ewes. Anim. Feed Sci. Technol. 2020, 264, 114461. [Google Scholar] [CrossRef]

- Truzzi, C.; Annibaldi, A.; Girolametti, F.; Giovannini, L.; Riolo, P.; Ruschioni, S.; Olivotto, I.; Illuminati, S. A Chemically Safe Way to Produce Insect Biomass for Possible Application in Feed and Food Production. Int. J. Environ. Res. Public Health 2020, 17, 2121. [Google Scholar] [CrossRef] [PubMed]

- Kusumocahyo, S.P.; Tangguh, P.; Annelies, C.D.; Sutanto, H. Utilization of Coffee Silverskin By-product from Coffee Roasting Industry through Extraction Process for the Development of Antioxidant Skin Gel. J. Cosmet. Sci. 2019, 70, 313–325. [Google Scholar] [PubMed]

- Oumer, O.J.; Abate, D. Screening and Molecular Identification of Pectinase Producing Microbes from Coffee Pulp. Biomed Res. Int. 2018, 2018, 2961767. [Google Scholar] [CrossRef] [PubMed]

- Nieter, A.; Kelle, S.; Linke, D.; Berger, R.G. A P-Coumaroyl Esterase from Rhizoctonia Solani with a Pronounced Chlorogenic Acid Esterase Activity. N. Biotechnol. 2017, 37, 153–161. [Google Scholar] [CrossRef] [PubMed]

- Hudeckova, H.; Neureiter, M.; Obruca, S.; Frühauf, S.; Marova, I. Biotechnological Conversion of Spent Coffee Grounds into Lactic Acid. Lett. Appl. Microbiol. 2018, 66, 306–312. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.-W.; Jang, J.H.; Yeo, H.J.; Seol, J.; Kim, S.R.; Jung, Y.H. Lactic Acid Production from a Whole Slurry of Acid-Pretreated Spent Coffee Grounds by Engineered Saccharomyces Cerevisiae. Appl. Biochem. Biotechnol. 2019, 189, 206–216. [Google Scholar] [CrossRef] [PubMed]

- Obruca, S.; Petrik, S.; Benesova, P.; Svoboda, Z.; Eremka, L.; Marova, I. Utilization of Oil Extracted from Spent Coffee Grounds for Sustainable Production of Polyhydroxyalkanoates. Appl. Microbiol. Biotechnol. 2014, 98, 5883–5890. [Google Scholar] [CrossRef] [PubMed]

- El Achaby, M.; Ruesgas-Ramon, M.; Fayoud, N.-E.H.; Figueroa-Espinoza, M.C.; Trabadelo, V.; Draoui, K.; Ben Youcef, H. Bio-Sourced Porous Cellulose Microfibrils from Coffee Pulp for Wastewater Treatment. Cellulose 2019, 26, 3873–3889. [Google Scholar] [CrossRef]

- Prieto, A.; Escapa, I.F.; Martínez, V.; Dinjaski, N.; Herencias, C.; de la Peña, F.; Tarazona, N.; Revelles, O. A Holistic View of Polyhydroxyalkanoate Metabolism in Pseudomonas Putida. Environ. Microbiol. 2016, 18, 341–357. [Google Scholar] [CrossRef] [PubMed]

- Tarazona, N.A.; Machatschek, R.; Lendlein, A. Influence of Depolymerases and Lipases on the Degradation of Polyhydroxyalkanoates Determined in Langmuir Degradation Studies. Adv. Mater. Interfaces 2020, 7, 2000872. [Google Scholar] [CrossRef]

- Benoit, I.; Navarro, D.; Marnet, N.; Rakotomanomana, N.; Lesage-Meessen, L.; Sigoillot, J.-C.; Asther, M.; Asther, M. Feruloyl Esterases as a Tool for the Release of Phenolic Compounds from Agro-Industrial by-products. Carbohydr. Res. 2006, 341, 1820–1827. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Morales, G.G.; Ramírez-Coronel, A.; Guzmán-López, O.; Cruz-Sosa, F.; Perraud-Gaime, I.; Roussos, S.; Saucedo-Castañeda, G.; Perez-Morales, G.G.; Ramirez-Coronel, A.; Guzman-Lopez, O.; et al. Feruloyl Esterase Activity from Coffee Pulp in Solid-State Fermentation. Food Technol. Biotechnol. 2011, 49, 352–358. [Google Scholar]

- Antier, P.; Minjares, A.; Roussos, S.; Viniegragonzález, G. New Approach for Selecting Pectinase Producing Mutants of Aspergillus Niger Well Adapted to Solid State Fermentation. Biotechnol. Adv. 1993, 11, 429–440. [Google Scholar] [CrossRef]

- Murthy, P.S.; Naidu, M.M. Production and Application of Xylanase from Penicillium Sp Utilizing Coffee By-products. Food Bioprocess Technol. 2012, 5, 657–664. [Google Scholar] [CrossRef]

- Navya, P.N.; Pushpa, S.M. Production, Statistical Optimization and Application of Endoglucanase from Rhizopus Stolonifer Utilizing Coffee Husk. Bioprocess Biosyst. Eng. 2013, 36, 1115–1123. [Google Scholar] [CrossRef] [PubMed]

- Navya, P.N.; Bhoite, R.N.; Murthy, P.S. Others Bioconversion of Coffee Husk Cellulose and Statistical Optimization of Process for Production of Exoglucanase by Rhizopus Stolonifer. World Appl. Sci. J. 2012, 20, 781–789. [Google Scholar] [CrossRef]

- Gąsecka, M.; Magdziak, Z.; Siwulski, M.; Jasińska, A.; Budzyńska, S.; Rzymski, P.; Kalač, P.; Niedzielski, P.; Pankiewicz, J.; Mleczek, M. Effect of Thymus vulgaris Post-extraction Waste and Spent Coffee Grounds on the Quality of Cultivated Pleurotus eryngii. J. Food Process. Preserv. 2020, 44, e14648. [Google Scholar] [CrossRef]

- Carrasco-Cabrera, C.P.; Bell, T.L.; Kertesz, M.A. Caffeine Metabolism during Cultivation of Oyster Mushroom (Pleurotus ostreatus) with Spent Coffee Grounds. Appl. Microbiol. Biotechnol. 2019, 103, 5831–5841. [Google Scholar] [CrossRef] [PubMed]

- Gouvea, B.M.; Torres, C.; Franca, A.S.; Oliveira, L.S.; Oliveira, E.S. Feasibility of Ethanol Production from Coffee Husks. Biotechnol. Lett. 2009, 31, 1315–1319. [Google Scholar] [CrossRef] [PubMed]

- Kwon, E.E.; Yi, H.; Jeon, Y.J. Sequential Co-Production of Biodiesel and Bioethanol with Spent Coffee Grounds. Bioresour. Technol. 2013, 136, 475–480. [Google Scholar] [CrossRef] [PubMed]

- Battista, F.; Barampouti, E.M.; Mai, S.; Bolzonella, D.; Malamis, D.; Moustakas, K.; Loizidou, M. Added-Value Molecules Recovery and Biofuels Production from Spent Coffee Grounds. Renew. Sustain. Energy Rev. 2020, 131. [Google Scholar] [CrossRef]

- Gómez Aguilar, D.L.; Rodríguez Miranda, J.P.; Baracaldo Guzmán, D.; Esteban Muñoz, J.A. Using Coffee Pulp as Bioadsorbent for the Removal of Manganese (Mn (II)) from Synthetic Wastewater. Water 2020, 12, 2500. [Google Scholar] [CrossRef]

- Caliskan, S.; Ozok, N.; Makineci, E. Utilization of Spent Coffee Grounds as Media for Stone Pine (Pinus pinea) Seedlings. J. Soil Sci. Plant Nutr. 2020, 20, 2014–2024. [Google Scholar] [CrossRef]

- Gammoudi, N.; Nagaz, K.; Ferchichi, A. Potential Use of Spent Coffee Grounds and Spent Tea Leaves Extracts in Priming Treatment to Promote In Vitro Early Growth of Salt-and Drought-Stressed Seedlings of Capsicum annuum L. Waste Biomass Valorization 2020, 12, 3341–3353. [Google Scholar] [CrossRef]

- Zoca, S.M.; Penn, C.J.; Rosolem, C.A.; Alves, A.R.; Neto, L.O.; Martins, M.M. Coffee Processing Residues as a Soil Potassium Amendment. Int. J. Recycl. Org. Waste Agric. 2014, 3, 155–165. [Google Scholar] [CrossRef]

- Deal, C.; Brewer, C.E.; Brown, R.C.; Okure, M.A.E.; Amoding, A. Comparison of Kiln-Derived and Gasifier-Derived Biochars as Soil Amendments in the Humid Tropics. Biomass Bioenergy 2012, 37, 161–168. [Google Scholar] [CrossRef]

- Berecha, G.; Lemessa, F.; Wakjira, M. Exploring the Suitability of Coffee Pulp Compost as Growth Media Substitute in Greenhouse Production. Int. J. Agric. Res. 2011, 6, 255–267. [Google Scholar] [CrossRef][Green Version]

- Higashikawa, F.S.; Silva, C.A.; Nunes, C.A.; Bettiol, W.; Guerreiro, M.C. Physico-Chemical Evaluation of Organic Wastes Compost-Based Substrates for Eucalyptus Seedlings Growth. Commun. Soil Sci. Plant Anal. 2016, 47, 581–592. [Google Scholar] [CrossRef]

- Kammoun, M.; Ghorbel, I.; Charfeddine, S.; Kamoun, L.; Gargouri-Bouzid, R.; Nouri-Ellouz, O. The Positive Effect of Phosphogypsum-Supplemented Composts on Potato Plant Growth in the Field and Tuber Yield. J. Environ. Manag. 2017, 200, 475–483. [Google Scholar] [CrossRef] [PubMed]

- Thligene, N.; Mezzapesa, G.N.; Mondelli, D.; Trani, A.; Veronico, P.; Melillo, M.T.; Dumontet, S.; Miano, T.; Sasanelli, N. Effect of Coffee Silver Skin and Brewers’ Spent Grain in the Control of Root-Knot Nematodes. Helminthologia 2019, 56, 30–41. [Google Scholar] [CrossRef] [PubMed]

- Franca, A.S.; Oliveira, L.S.; Ferreira, M.E. Kinetics and Equilibrium Studies of Methylene Blue Adsorption by Spent Coffee Grounds. Desalination 2009, 249, 267–272. [Google Scholar] [CrossRef]

- Zuorro, A.; Lavecchia, R. Spent Coffee Grounds as a Valuable Source of Phenolic Compounds and Bioenergy. J. Clean. Prod. 2012, 34, 49–56. [Google Scholar] [CrossRef]

- Boonamnuayvitaya, V.; Chaiya, C.; Tanthapanichakoon, W. The Preparation and Characterization of Activated Carbon from Coffee Residue. J. Chem. Eng. Jpn. 2004, 37, 1504–1512. [Google Scholar] [CrossRef]

- Santos Polidoro, A.; Scapin, E.; Lazzari, E.; Silva, A.N.; dos Santos, A.L.; Caramao, E.B.; Jacques, R.A. Valorization of Coffee Silverskin Industrial Waste by Pyrolysis: From Optimization of Bio-Oil Production to Chemical Characterization by GC X GC/qMS. J. Anal. Appl. Pyrolysis 2018, 129, 43–52. [Google Scholar] [CrossRef]

- Cho, D.-W.; Kwon, E.E.; Kwon, G.; Zhang, S.; Lee, S.-R.; Song, H. Co-Pyrolysis of Paper Mill Sludge and Spend Coffee Ground Using CO2 as Reaction Medium. J. CO2 Util. 2017, 21, 572–579. [Google Scholar] [CrossRef]

- Haile, M. Integrated Volarization of Spent Coffee Grounds to Biofuels. Biofuel Res. J. 2014, 1, 65–69. [Google Scholar] [CrossRef]

- Kookos, I.K. Technoeconomic and Environmental Assessment of a Process for Biodiesel Production from Spent Coffee Grounds (SCGs). Resour. Conserv. Recycl. 2018, 134, 156–164. [Google Scholar] [CrossRef]

- Rajesh Banu, J.; Kavitha, S.; Yukesh Kannah, R.; Dinesh Kumar, M.; Preethi; Atabani, A.E.; Kumar, G. Biorefinery of Spent Coffee Grounds Waste: Viable Pathway towards Circular Bioeconomy. Bioresour. Technol. 2020, 302, 122821. [Google Scholar] [CrossRef]

- Massaya, J.; Prates Pereira, A.; Mills-Lamptey, B.; Benjamin, J.; Chuck, C.J. Conceptualization of a Spent Coffee Grounds Biorefinery: A Review of Existing Valorisation Approaches. Food Bioprod. Process. 2019, 118, 149–166. [Google Scholar] [CrossRef]

- Tuntiwiwattanapun, N.; Monono, E.; Wiesenborn, D.; Tongcumpou, C. In-Situ Transesterification Process for Biodiesel Production Using Spent Coffee Grounds from the Instant Coffee Industry. Ind. Crop. Prod. 2017, 102, 23–31. [Google Scholar] [CrossRef]

- Le, P.T.K.; Vu, Q.T.H.; Nguyen, Q.T.V.; Tran, K.A.; Le, K.A. Spent Coffee Grounds as a Valuable Source of Bioactive Compounds and Bioenergy. Chem. Eng. Trans. 2017, 56, 37–42. [Google Scholar] [CrossRef]

- Del Pozo, C.; Bartrolí, J.; Puy, N.; Fàbregas, E. Converting Coffee Silverskin to Value-Added Products under a Biorefinery Approach. In Proceedings of the European Biomass Conference and Exhibition Proceedings; ETA-Florence Renewable Energies: Firenze, Italy, 2019; pp. 1292–1296. Available online: http://www.etaflorence.it/proceedings/?detail=16544 (accessed on 10 December 2021).

- Jeguirim, M.; Limousy, L.; Dutournie, P. Pyrolysis Kinetics and Physicochemical Properties of Agropellets Produced from Spent Ground Coffee Blended with Conventional Biomass. Chem. Eng. Res. Des. 2014, 92, 1876–1882. [Google Scholar] [CrossRef]

- Wei, R.; Li, H.; Chen, Y.; Hu, Y.; Long, H.; Li, J.; Xu, C.C. Environmental Issues Related to Bioenergy. Reference Module in Earth Systems and Environmental Sciences. 2020. Available online: http://scitechconnect.elsevier.com/resources/reference-module-earth-sciences-environmental-systems/# (accessed on 10 December 2021).

- Lazzari, E.; Arena, K.; Caramao, E.B.; Herrero, M. Quantitative Analysis of Aqueous Phases of Bio-Oils Resulting from Pyrolysis of Different Biomasses by Two-Dimensional Comprehensive Liquid Chromatography. J. Chromatogr. A 2019, 1602, 359–367. [Google Scholar] [CrossRef] [PubMed]

- Orosco, J.; Patiño, F.J.; Quintero, M.J.; Rodríguez, L. Residual Biomass Gasification on a Small Scale and Its Thermal Utilization for Coffee Drying. Livest. Res. Rural Dev. 2018, 30. Available online: http://www.lrrd.cipav.org.co/lrrd30/1/jair30005.html (accessed on 10 December 2021).

- Torres, C.; Urvina, L.; de Lasa, H. A Chemical Equilibrium Model for Biomass Gasification. Application to Costa Rican Coffee Pulp Transformation Unit. Biomass Bioenergy 2019, 123, 89–103. [Google Scholar] [CrossRef]

- Suksiripattanapong, C.; Kua, T.-A.; Arulrajah, A.; Maghool, F.; Horpibulsuk, S. Strength and Microstructure Properties of Spent Coffee Grounds Stabilized with Rice Husk Ash and Slag Geopolymers. Constr. Build. Mater. 2017, 146, 312–320. [Google Scholar] [CrossRef]

- Andreola, F.; Borghi, A.; Pedrazzi, S.; Allesina, G.; Tartarini, P.; Lancellotti, I.; Barbieri, L. Spent Coffee Grounds in the Production of Lightweight Clay Ceramic Aggregates in View of Urban and Agricultural Sustainable Development. Materials 2019, 12, 3581. [Google Scholar] [CrossRef] [PubMed]

- Yoo, J.; Chang, S.J.; Wi, S.; Kim, S. Spent Coffee Grounds as Supporting Materials to Produce Bio-Composite PCM with Natural Waxes. Chemosphere 2019, 235, 626–635. [Google Scholar] [CrossRef] [PubMed]

| Keyword Search | By-Product | WoS | Scopus | Results |

|---|---|---|---|---|

| Title = (byproduct* or by-product*) AND Title = (application* or utilizat* or commerc* or valorizat*) | Topic = (coffee pulp) | 26 | 33 | 36 |

| Topic = (coffee husk) | 16 | 21 | 25 | |

| Topic = (coffee “silver skin”) OR (silverskin) | 30 | 34 | 35 | |

| Topic = (spent coffee grounds) | 64 | 47 | 79 | |

| Total | 136 | 125 | 177 |

| Categories | Tags | Total Tags | Total Categories |

|---|---|---|---|

| Bioactive Compounds | Cosmetics | 8 (11%) | 72 (45%) |

| Feed | 18 (25%) | ||

| Food | 35 (49%) | ||

| Nutraceuticals | 11 (15%) | ||

| Microbial Transformation | Bioethanol | 7 (24%) | 29 (18%) |

| Biogas | 1 (3%) | ||

| Biopolymers | 3 (10%) | ||

| Edible mushrooms | 3 (10%) | ||

| Enzymes | 9 (31%) | ||

| Lipids | 1 (3%) | ||

| Organic acids | 5 (17%) | ||

| Environmental Applications | Bioadsorbents | 15 (58%) | 26 (16%) |

| Biocatalysts | 1 (4%) | ||

| Biopesticides | 1 (4%) | ||

| Fertilizers | 6 (23%) | ||

| Biofuels from Thermochemical Processes | Bio-oil | 3 (12%) | 31 (19%) |

| Biodiesel | 5 (16%) | ||

| Solid fuels | 10 (32%) | ||

| Syngas | 13 (42%) | ||

| Materials | Construction | 3 (10%) | 3 (2%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durán-Aranguren, D.D.; Robledo, S.; Gomez-Restrepo, E.; Arboleda Valencia, J.W.; Tarazona, N.A. Scientometric Overview of Coffee By-Products and Their Applications. Molecules 2021, 26, 7605. https://doi.org/10.3390/molecules26247605

Durán-Aranguren DD, Robledo S, Gomez-Restrepo E, Arboleda Valencia JW, Tarazona NA. Scientometric Overview of Coffee By-Products and Their Applications. Molecules. 2021; 26(24):7605. https://doi.org/10.3390/molecules26247605

Chicago/Turabian StyleDurán-Aranguren, Daniel D., Sebastian Robledo, Eduardo Gomez-Restrepo, Jorge W. Arboleda Valencia, and Natalia A. Tarazona. 2021. "Scientometric Overview of Coffee By-Products and Their Applications" Molecules 26, no. 24: 7605. https://doi.org/10.3390/molecules26247605

APA StyleDurán-Aranguren, D. D., Robledo, S., Gomez-Restrepo, E., Arboleda Valencia, J. W., & Tarazona, N. A. (2021). Scientometric Overview of Coffee By-Products and Their Applications. Molecules, 26(24), 7605. https://doi.org/10.3390/molecules26247605