Flexible Polymer–Organic Solar Cells Based on P3HT:PCBM Bulk Heterojunction Active Layer Constructed under Environmental Conditions

Abstract

1. Introduction

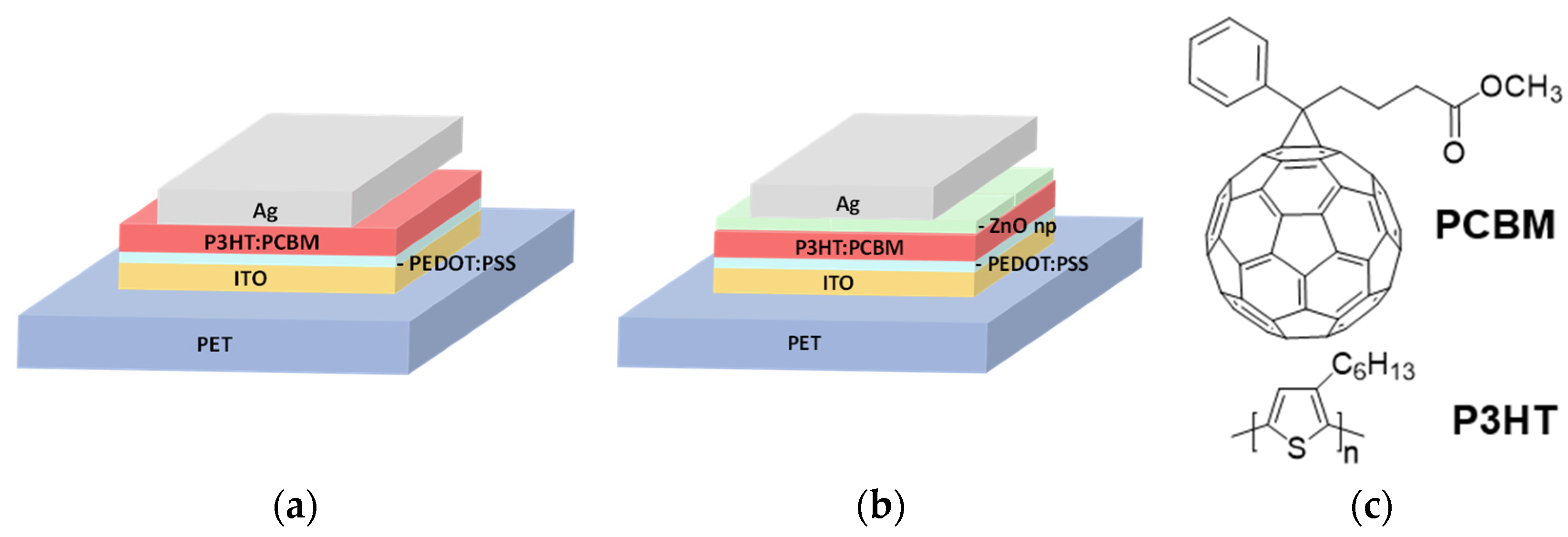

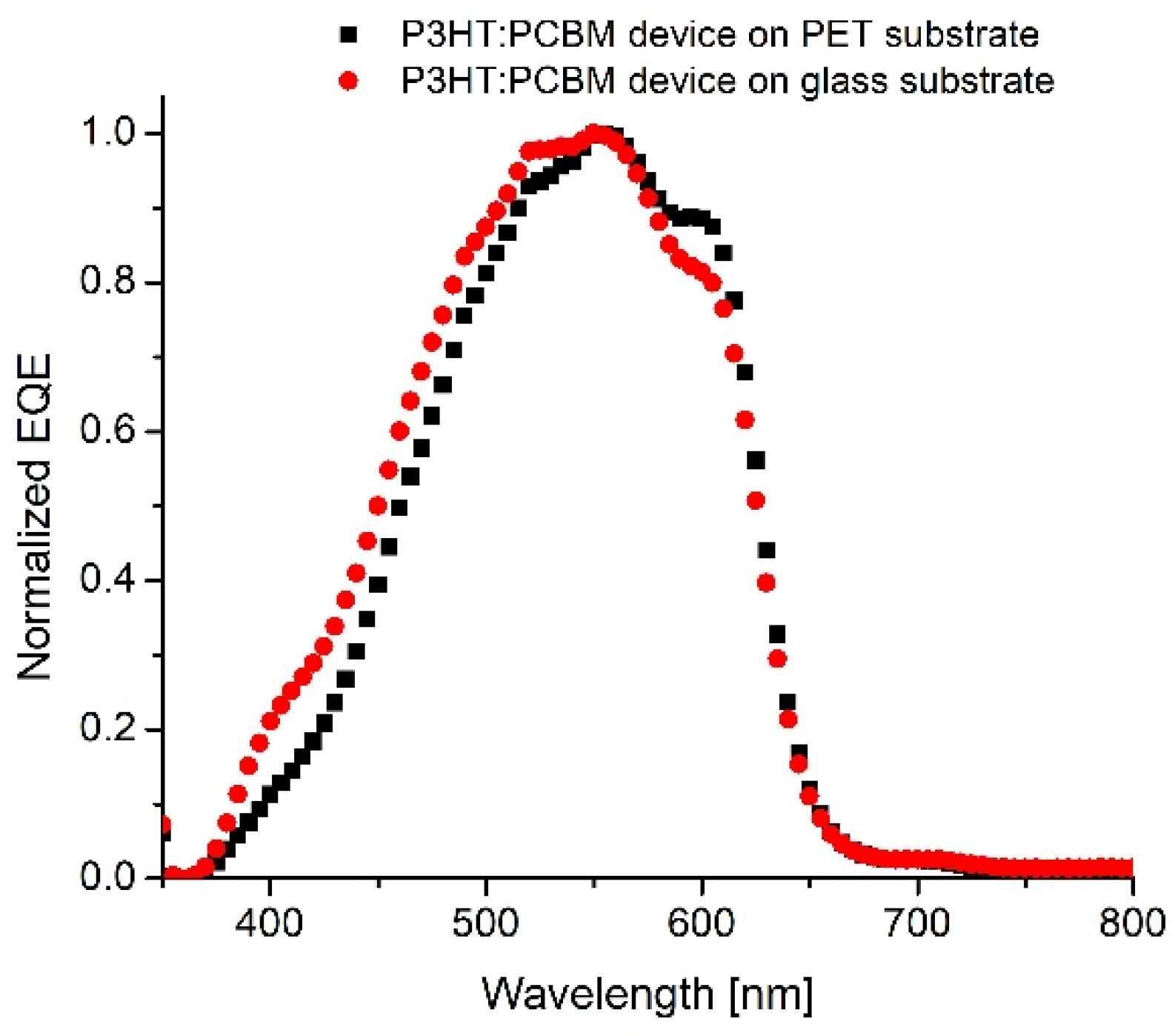

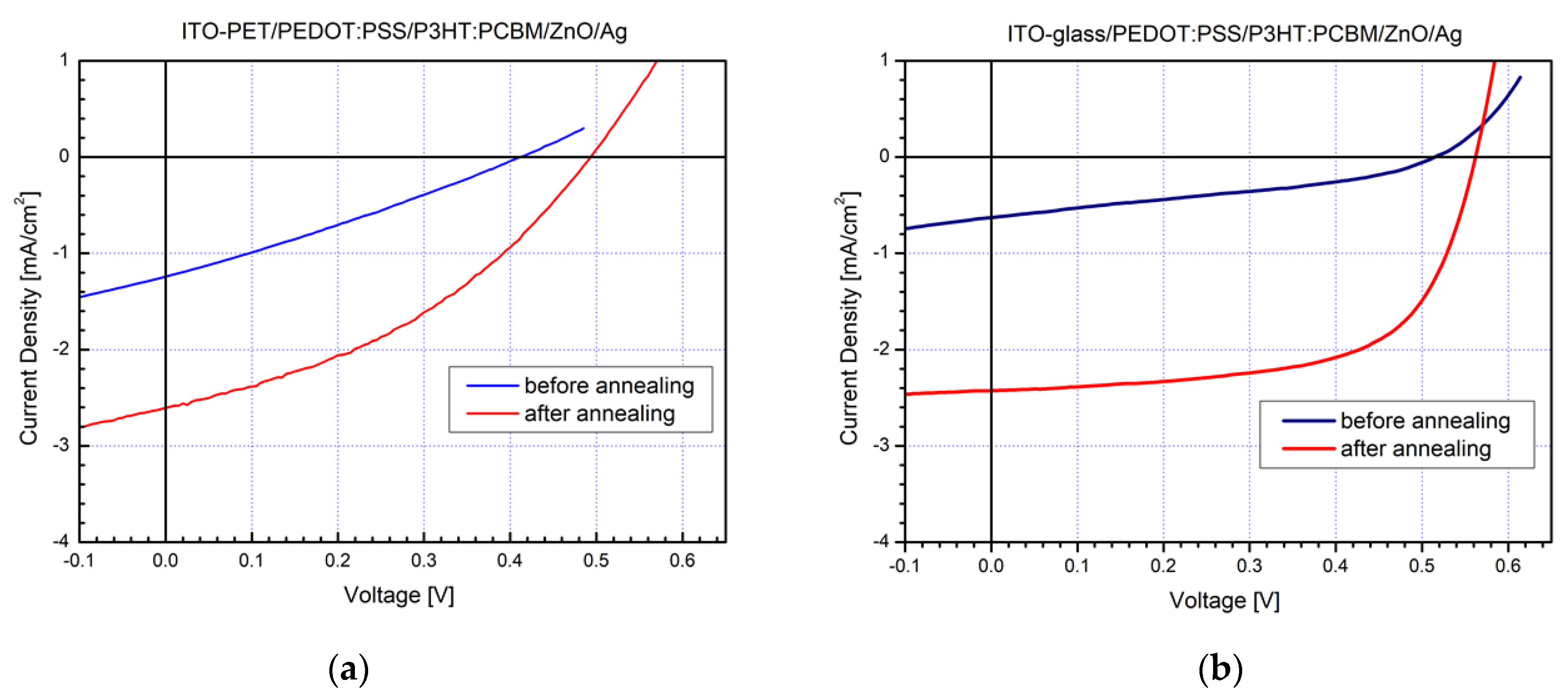

2. Results and Discussion

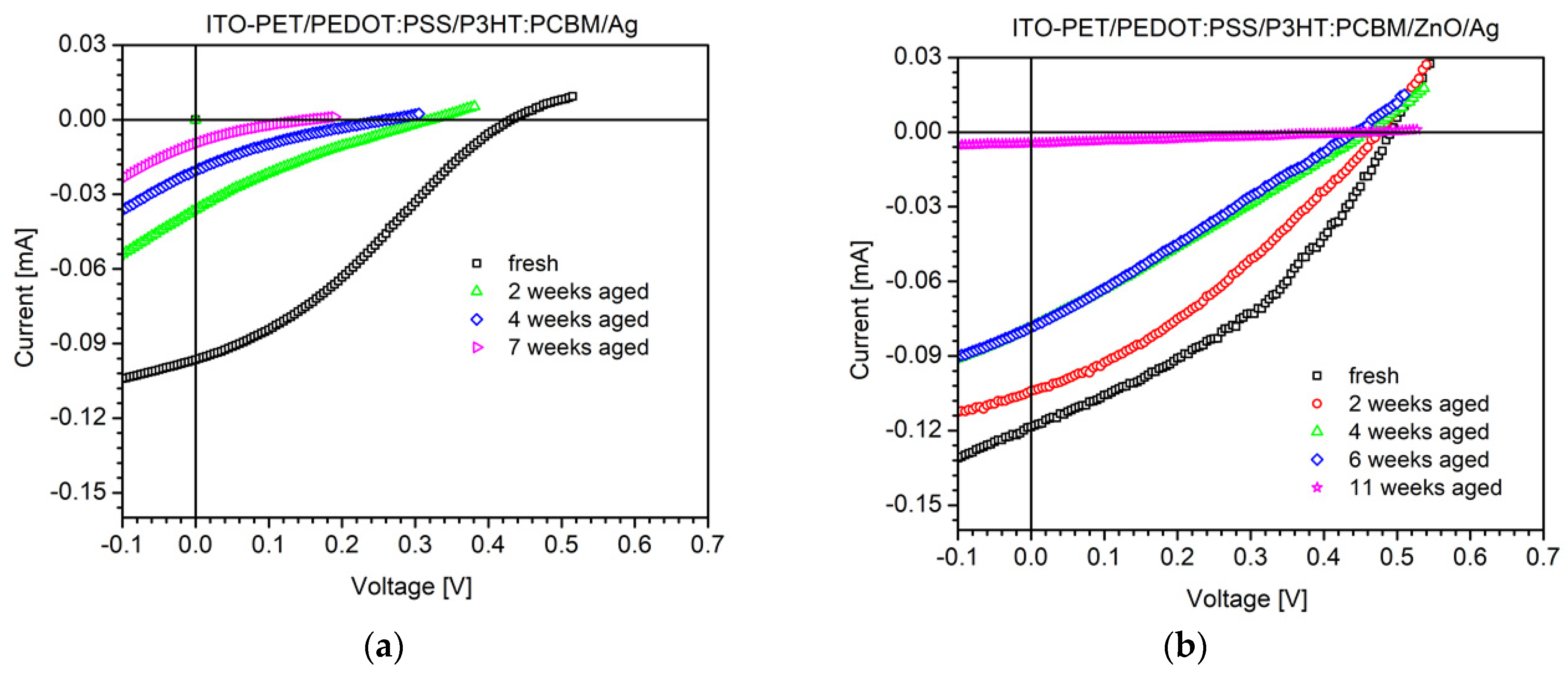

2.1. Current–Voltage Measurements

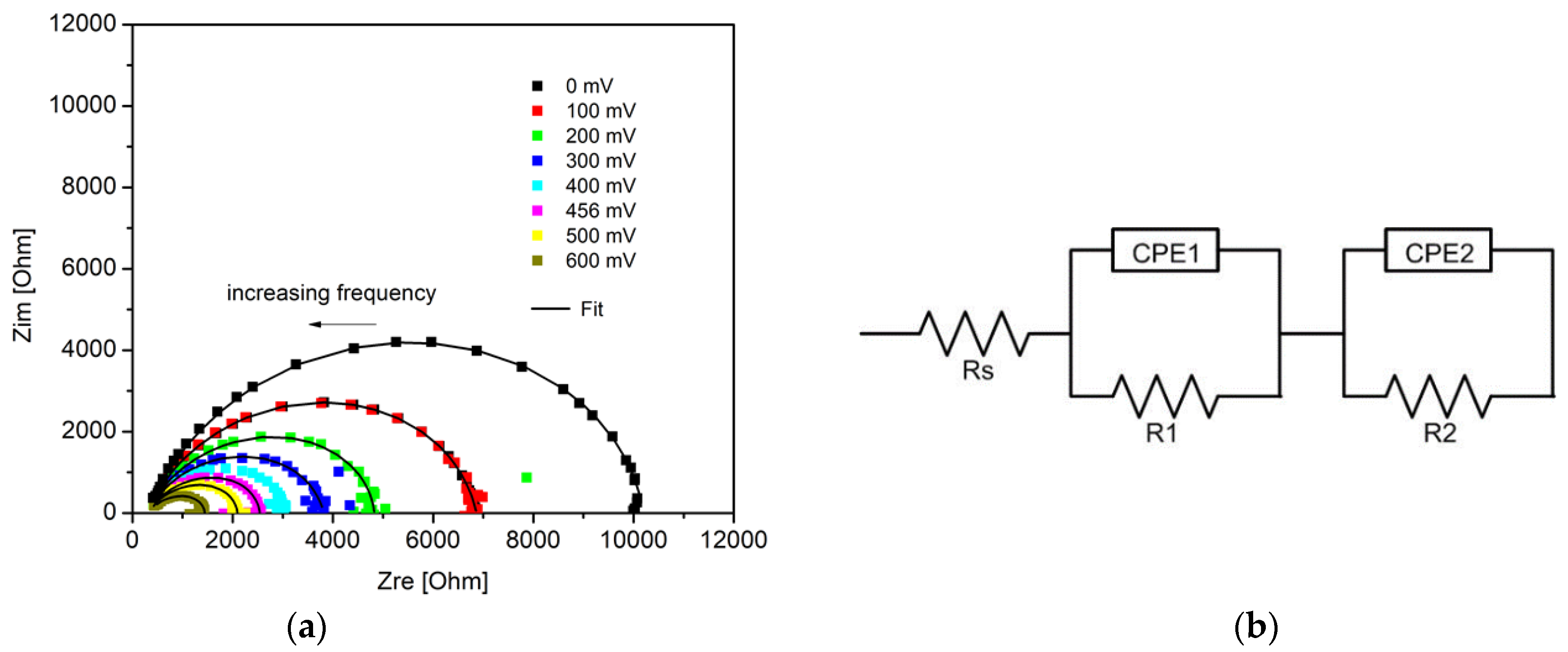

2.2. Impedance Spectroscopy Measurements

2.3. Device Stability Characterization

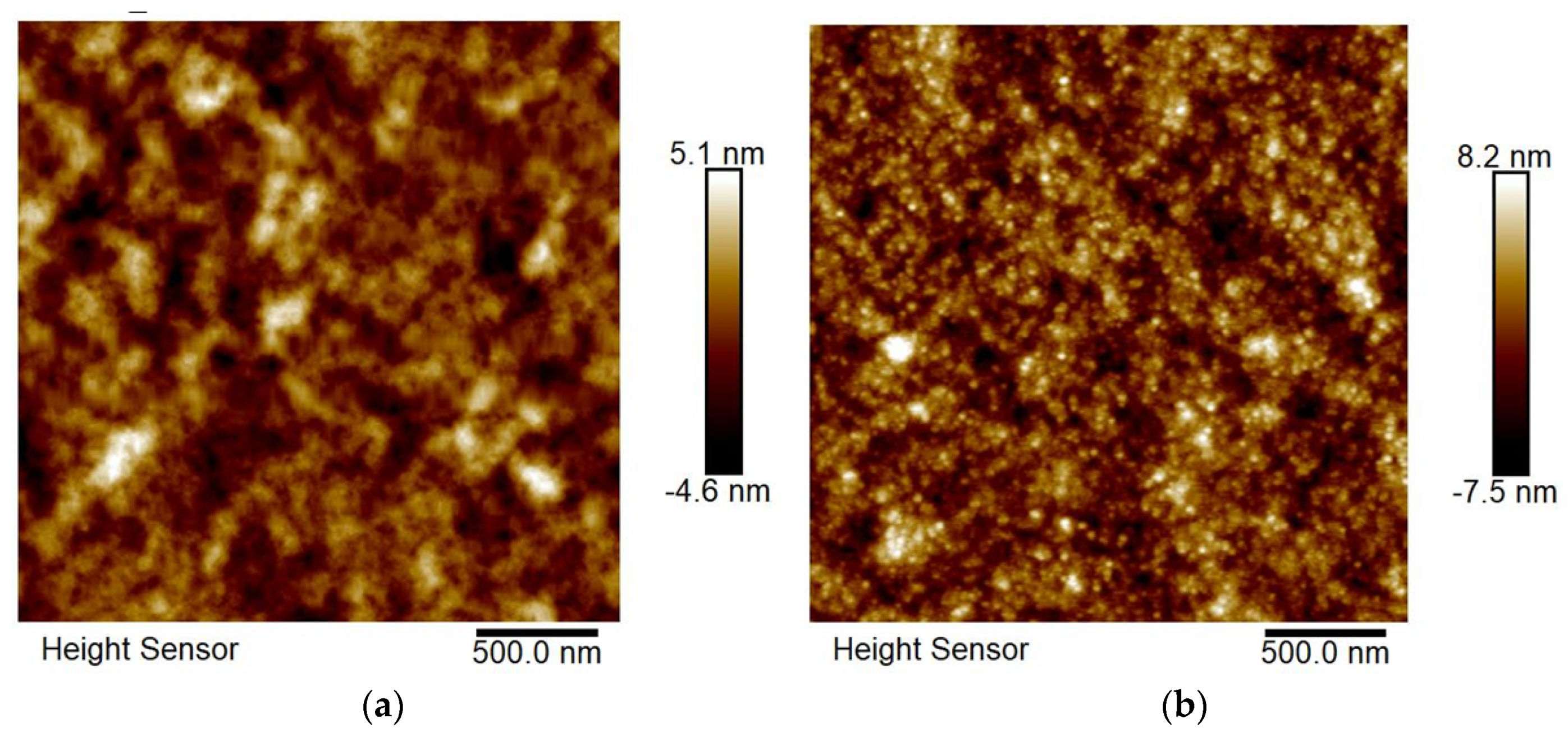

2.4. AFM Surface Characterization

3. Materials and Methods

3.1. Materials

3.2. Device Fabrication

3.3. Characterization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Krebs, F.C. Fabrication and processing of polymer solar cells: A review of printing and coating techniques. Sol. Energy Mater. Sol. Cells 2009, 93, 394–412. [Google Scholar] [CrossRef]

- Park, H.J.; Kang, M.-G.; Ahn, S.H.; Guo, L.J. A facile route to polymer solar cells with optimum morphology readily applicable to a roll-to-roll process without sacrificing high device performance. Adv. Mater. 2010, 22, E247–E252. [Google Scholar] [CrossRef] [PubMed]

- Krebs, F.C.; Jørgensen, M.; Norrman, K.; Hagemann, O.; Alstrup, J.; Nielsen, T.D.; Fyenbo, J.; Larsen, K.; Kristensen, J. A complete process for production of flexible large area polymer solar cells entirely using screenprinting—First public demonstration. J. Sol. Energy Mater. Sol. Cells 2009, 93, 422–441. [Google Scholar] [CrossRef]

- Youn, H.; Park, H.J.; Guo, L.J. Organic photovoltaic cells: From performance improvement to manufacturing processes. Small 2015, 11, 2228–2246. [Google Scholar] [CrossRef]

- Berny, S.; Blouin, N.; Distler, A.; Egelhaaf, H.-J.; Krompiec, M.; Lohr, A.; Lozman, O.R.; Morse, G.E.; Nanson, L.; Pron, A.; et al. Solar trees: First large-scale demonstration of fully solution coated, semitransparent, flexible organic photovoltaic modules. Adv. Sci. 2016, 3, 1500342. [Google Scholar] [CrossRef]

- Hashemi, S.A.; Ramakrishna, S.; Aberle, A.G. Recent progress in flexible-wearable solar cells for self-powered electronic devices. Energy Environ. Sci. 2020, 13, 685–742. [Google Scholar] [CrossRef]

- Choi, S.; Lee, H.; Ghaffari, R.; Hyeon, T.; Kim, D.-H. Recent advances in flexible and stretchable bio-electronic devices integrated with nanomaterials. Adv. Mater. 2016, 28, 4203–4218. [Google Scholar] [CrossRef] [PubMed]

- Woo, S.; Lyu, H.-K.; Han, Y.S.; Kim, Y. Effects of hole-collecting buffer layers and electrodes on the performance of flexible plastic organic photovoltaics. Int. J. Photoenergy 2013, 2013, 398912. [Google Scholar] [CrossRef]

- Xu, X.; Fukuda, K.; Karki, A.; Park, S.; Kimura, H.; Jinno, H.; Watanabe, N.; Yamamoto, S.; Shimomura, S.; Kitazawa, D.; et al. Thermally stable, highly efficient, ultraflexible organic photovoltaics. Proc. Natl. Acad. Sci. USA 2018, 115, 4589–4594. [Google Scholar] [CrossRef]

- Lam, J.-Y.; Shih, C.-C.; Lee, W.-Y.; Chueh, C.-C.; Jang, G.-W.; Huang, C.-J.; Tung, S.-H.; Chen, W.-C. Bio-based transparent conductive film consisting of polyethylene furanoate and silver nanowires for flexible optoelectronic devices. Macromol. Rapid Commun. 2018, 39, 1800271. [Google Scholar] [CrossRef] [PubMed]

- Heo, S.-W.; Lee, J.-Y.; Song, H.-J.; Ku, J.-R.; Moon, D.-K. Patternable brush painting process for fabrication of flexible polymer solar cells. Sol. Energy Mater. Sol. Cells 2011, 95, 3041–3046. [Google Scholar] [CrossRef]

- Jung, S.; Sou, A.; Banger, K.; Ko, D.-H.; Chow, P.C.Y.; McNeill, C.R.; Sirringhaus, H. All-inkjet-printed, all-air-processed solar cells. Adv. Energy Mater. 2014, 4, 1400432. [Google Scholar] [CrossRef]

- Ganesan, S.; Gollu, S.R.; Alam khan, J.; Kushwaha, A.; Gupta, D. Inkjet printing of zinc oxide and P3HT:ICBA in ambient conditions for inverted bulk heterojunction solar cells. Opt. Mater. 2019, 94, 430–435. [Google Scholar] [CrossRef]

- Gereanu, A.-G.; Sartorio, C.; Bonasera, A.; Giuliano, G.; Cataldo, S.; Scopelliti, M.; Arrabito, G.; Pignataro, B. Pseudo-planar organic heterojunctions by sequential printing of quasi-miscible inks. Coatings 2021, 11, 586. [Google Scholar] [CrossRef]

- Kaduwal, D.; Schleiermacher, H.-F.; Schulz-Gericke, J.; Kroyer, T.; Zimmermann, B.; Würfel, U. ITO-free organic solar cells with roll-to-roll coated organic functional layers from non-halogenated solvents. Sol. Energy Mater. Sol. Cells 2014, 124, 92–97. [Google Scholar] [CrossRef]

- Cheng, P.; Lin, Y.; Zawacka, N.K.; Andersen, T.R.; Liu, W.; Bundgaard, E.; Jørgensen, M.; Chen, H.; Krebs, F.C.; Zhan, X. Comparison of additive amount used in spincoated and roll-coated organic solar cells. J. Mater. Chem. A 2014, 2, 19542–19549. [Google Scholar] [CrossRef]

- Laventure, A.; Harding, C.; Cieplechowicz, E.; Li, Z.; Wang, J.; Zou, Y.; Welch, G.C. Screening quinoxaline-type donor polymers for roll-to-roll processing compatible organic photovoltaics. ACS Appl. Polym. Mater. 2019, 1, 2168–2176. [Google Scholar] [CrossRef]

- Kapnopoulos, C.; Mekeridis, E.D.; Tzounis, L.; Polyzoidis, C.; Zachariadis, A.; Tsimikli, S.; Gravalidis, C.; Laskarakis, A.; Vouroutzis, N.; Logothetidis, S. Fully gravure printed organic photovoltaic modules: A straightforward process with a high potential for large scale production. Sol. Energy Mater. Sol. Cells 2016, 144, 724–731. [Google Scholar] [CrossRef]

- Carlé, J.E.; Andersen, T.R.; Helgesen, M.; Bundgaard, E.; Jørgensen, M.; Krebs, F.C. A laboratory scale approach to polymer solar cells using one coating/printing machine, flexible substrates, no ITO, no vacuum and no spincoating. Sol. Energy Mater. Sol. Cells 2013, 108, 126–128. [Google Scholar] [CrossRef]

- Andersen, T.R.; Dam, H.F.; Burkhart, B.; Angmo, D.; Corazza, M.; Thompson, B.C.; Krebs, F.C. Medium area, flexible single and tandem junction solar cells based on roll coated semi-random copolymers. J. Mater. Chem. C 2014, 2, 9412–9415. [Google Scholar] [CrossRef]

- Andersen, T.R.; Cooling, N.A.; Almyahi, F.; Hart, A.S.; Nicolaidis, N.C.; Feron, K.; Noori, M.; Vaughan, B.; Griffith, M.J.; Belcher, W.J.; et al. Fully roll-to-roll prepared organic solar cells in normal geometry with a sputter-coated aluminium top-electrode. Sol. Energy Mater. Sol. Cells 2016, 149, 103–109. [Google Scholar] [CrossRef]

- Kaltenbrunner, M.; White, M.S.; Głowacki, E.D.; Sekitani, T.; Someya, T.; Sariciftci, N.S.; Bauer, S. Ultrathin and lightweight organic solar cells with high flexibility. Nat. Commun. 2012, 3, 770. [Google Scholar] [CrossRef] [PubMed]

- Hansen, R.M.D.O.; Liu, Y.; Madsen, M.; Rubahn, H.-G. Flexible organic solar cells including efficiency enhancing grating structures. Nanotechnology 2013, 24, 145301. [Google Scholar] [CrossRef]

- Guo, F.; Li, N.; Radmilovic, V.V.; Radmilovic, V.R.; Turbiez, M.; Spiecker, E.; Forberich, K.; Brabec, C.J. Fully printed organic tandem solar cells using solution-processed silver nanowires and opaque silver as charge collecting electrodes. Energy Environ. Sci. 2015, 8, 1690–1697. [Google Scholar] [CrossRef]

- Galagan, Y.; Andriessen, R. Organic photovoltaics: Technologies and manufacturing. In Third Generation Photovoltaics; Fthenakis, V., Ed.; InTech: London, UK, 2012. [Google Scholar] [CrossRef]

- Hösel, M.; Søndergaard, R.R.; Jørgensen, M.; Krebs, F.C. Fast inline roll-to-roll printing for indium-tin-oxide-free polymer solar cells using automatic registration. Energy Technol. 2013, 1, 102–107. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, T.; Zhou, H.; Price, S.C.; Wiley, B.J.; You, W. Solution-processed flexible polymer solar cells with silver nanowire electrodes. ACS Appl. Mater. Interfaces 2011, 3, 4075–4084. [Google Scholar] [CrossRef] [PubMed]

- Ajuria, J.; Ugarte, I.; Cambarau, W.; Etxebarria, I.; Tena-Zaera, R.; Pacios, R. Insights on the working principles of flexible and efficient ITO-free organic solar cells based on solution processed Ag nanowire electrodes. Sol. Energy Mater. Sol. Cells 2012, 102, 148–152. [Google Scholar] [CrossRef]

- Nickel, F.; Haas, T.; Wegner, E.; Bahro, D.; Salehin, S.; Kraft, O.; Gruber, P.A.; Colsmann, A. Mechanically robust, ITO-free, 4.8% efficient, all-solution processed organic solar cells on flexible PET foil. Sol. Energy Mater. Sol. Cells 2014, 130, 317–321. [Google Scholar] [CrossRef]

- Park, Y.; Bormann, L.; Müller-Meskamp, L.; Vandewal, K.; Leo, K. Efficient flexible organic photovoltaics using silver nanowires and polymer based transparent electrodes. Org. Electron. 2016, 36, 68–72. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, C.; Chen, D.; Tang, S.; Zhang, J.; Wang, Y.; Han, G.; Xu, S.; Hao, Y. Flexible ITO-free organic solar cells based on MoO3/Ag anodes. IEEE Photonics J. 2015, 7, 8400109. [Google Scholar] [CrossRef]

- Yin, Z.; Sun, S.; Salim, T.; Wu, S.; Huang, X.; He, Q.; Lam, Y.M.; Zhang, H. Organic photovoltaic devices using highly flexible reduced graphene oxide films as transparent electrodes. ACS Nano 2010, 4, 5263–5268. [Google Scholar] [CrossRef] [PubMed]

- Kymakis, E.; Savva, K.; Stylianakis, M.M.; Fotakis, C.; Stratakis, E. Flexible organic photovoltaic cells with in situ nonthermal photoreduction of spin-coated graphene oxide electrodes. Adv. Funct. Mater. 2013, 23, 2742–2749. [Google Scholar] [CrossRef]

- Espinosa, N.; Garcia-Valverde, R.; Urbina, A.; Lenzmann, F.; Manceau, M.; Angmo, D.; Krebs, F.C. Life cycle assessment of ITO-free flexible polymer solar cells prepared by roll-to-roll coating and printing. Sol. Energy Mater. Sol. Cells 2012, 97, 3–13. [Google Scholar] [CrossRef]

- Hambsch, M.; Jin, H.; Clulow, A.J.; Nelson, A.; Yamada, N.L.; Velusamy, M.; Yang, Q.; Zhu, F.; Burn, P.L.; Gentle, I.R.; et al. Improved stability of non-ITO stacked electrodes for large area flexible organic solar cells. Sol. Energy Mater. Sol. Cells 2014, 130, 182–190. [Google Scholar] [CrossRef]

- Cao, W.; Zheng, Y.; Li, Z.; Wrzesniewski, E.; Hammond, W.T.; Xue, J. Flexible organic solar cells using an oxide/metal/oxide trilayer as transparent electrode. Org. Electron. 2012, 13, 2221–2228. [Google Scholar] [CrossRef]

- Espinosa, N.; Dam, H.F.; Tanenbaum, D.M.; Andreasen, J.W.; Jørgensen, M.; Krebs, F.C. Roll-to-roll processing of inverted polymer solar cells using hydrated vanadium(V)oxide as a PEDOT:PSS replacement. Materials 2011, 4, 169–182. [Google Scholar] [CrossRef]

- Oseni, S.O.; Mola, G.T. Properties of functional layers in inverted thin film organic solar cells. Sol. Energy Mater. Sol. Cells 2017, 160, 241–256. [Google Scholar] [CrossRef]

- Zhang, H.; Tan, W.-Y.; Fladischer, S.; Ke, L.; Ameri, T.; Li, N.; Turbiez, M.; Spiecker, E.; Zhu, X.-H.; Cao, Y.; et al. Roll to roll compatible fabrication of inverted organic solar cells with a self-organized charge selective cathode interfacial layer. J. Mater. Chem. A 2016, 4, 5032–5038. [Google Scholar] [CrossRef]

- Jouane, Y.; Colis, S.; Schmerber, G.; Dinia, A.; Leveque, P.; Heiser, T.; Chapuis, Y.-A. Influence of flexible substrates on inverted organic solar cells using sputtered ZnO as cathode interfacial layer. Org. Electron. 2013, 14, 1861–1868. [Google Scholar] [CrossRef]

- Polyzoidis, C.A.; Kapnopoulos, C.; Mekeridis, E.D.; Tzounis, L.; Tsimikli, S.; Gravalidis, C.; Laskarakis, A.; Logothetidis, S. Improvement of inverted OPV performance by enhancement of ZnO layer properties as an electron transfer layer. Mater. Today Proc. 2016, 3, 758–771. [Google Scholar] [CrossRef]

- Cha, H.-C.; Huang, Y.-C.; Hsu, F.-H.; Chuang, C.-M.; Lu, D.-H.; Chou, C.-W.; Chen, C.-Y.; Tsao, C.-S. Performance improvement of large-area roll-to-roll slot-die-coated inverted polymer solar cell by tailoring electron transport layer. Sol. Energy Mater. Sol. Cells 2014, 130, 191–198. [Google Scholar] [CrossRef]

- Böttiger, A.P.L.; Jørgensen, M.; Menzel, A.; Krebs, F.C.; Andreasen, J.W. High-throughput roll-to-roll X-ray characterization of polymer solar cell active layers. J. Mater. Chem. 2012, 22, 22501–22509. [Google Scholar] [CrossRef]

- Park, Y.; Berger, J.; Tang, Z.; Müller-Meskamp, L.; Lasagni, A.F.; Vandewal, K.; Leo, K. Flexible, light trapping substrates for organic photovoltaics. Appl. Phys. Lett. 2016, 109, 093301. [Google Scholar] [CrossRef]

- Bundgaard, E.; Hagemann, O.; Manceau, M.; Jørgensen, M.; Krebs, F.C. Low band gap polymers for roll-to-roll coated polymer solar cells. Macromolecules 2010, 43, 8115–8120. [Google Scholar] [CrossRef]

- Wu, F.-C.; Huang, Y.-C.; Cheng, H.-L.; Chou, W.-Y.; Tang, F.-C. Importance of disordered polymer segments to microstructure-dependent photovoltaic properties of polymer-fullerene bulk heterojunction solar cells. J. Phys. Chem. C 2011, 115, 15057–15066. [Google Scholar] [CrossRef]

- Bonasera, A.; Giuliano, G.; Arrabito, G.; Pignataro, B. Tackling performance challenges in organic photovoltaics: An overview about compatibilizers. Molecules 2020, 25, 2200. [Google Scholar] [CrossRef]

- Glatthaar, M.; Riede, M.; Keegan, N.; Sylvester-Hvid, K.; Zimmermann, B.; Niggemann, M.; Hinsch, A.; Gombert, A. Efficiency limiting factors of organic bulk heterojunction solar cells identified by electrical impedance spectroscopy. Sol. Energ. Mat. Sol. Cells 2007, 91, 390–393. [Google Scholar] [CrossRef]

- Kumar, P.; Jain, S.C.; Kumar, V.; Chand, S.; Tandon, R.P. A model for the current–voltage characteristics of organic bulk heterojunction solar cells. J. Phys. D Appl. Phys. 2009, 42, 055102. [Google Scholar] [CrossRef]

- Tress, W.; Petrich, A.; Hummert, M.; Hein, M.; Leo, K.; Riede, M. Imbalanced mobilities causing S-shaped IV curves in planar heterojunction organic solar cells. Appl. Phys. Lett. 2011, 98, 063301. [Google Scholar] [CrossRef]

- Garcia-Belmonte, G.; Boix, P.P.; Bisquert, J.; Sessolo, M.; Bolink, H. Simultaneous determination of carrier lifetime and electron density-of-states in P3HT:PCBM organic solar cells under illumination by impedance spectroscopy. J. Sol. Energ. Mat. Sol. C 2010, 94, 366–375. [Google Scholar] [CrossRef]

- Garcia-Belmonte, G.; Munar, A.; Barea, E.M.; Bisquert, J.; Ugarte, I.; Pacios, R. Charge carrier mobility and lifetime of organic bulk heterojunctions analyzed by impedance spectroscopy. Org. Electron. 2008, 9, 847–851. [Google Scholar] [CrossRef]

- Khelifi, S.; Decock, K.; Lauwaert, J.; Vrielinck, H.; Spoltore, D.; Piersimoni, F.; Manca, J.; Belghachi, A.; Burgelman, M. Investigation of defects by admittance spectroscopy measurements in poly (3-hexylthiophene):(6,6)-phenyl C61-butyric acid methyl ester organic solar cells degraded under air exposure. J. Appl. Phys. 2011, 110, 094509. [Google Scholar] [CrossRef]

- Sendova-Vassileva, M.; Popkirov, G.; Vitanov, P.; Dikov, C.; Gancheva, V.; Tsocheva, D.; Mokreva, P. Influence of the type of metal contact and post-deposition treatment on the performance of P3HT:PCBM organic solar cells. J. Phys. Conf. Ser. 2012, 398, 012049. [Google Scholar] [CrossRef]

- Oklobia, O.; Komilian, S.; Sadat-Shafai, T. Impedance spectroscopy and capacitance—voltage measurements analysis: Impact of charge carrier lifetimes and mapping vertical segregation in bulk heterojunction P3HT: PCBM solar cells. Org. Electron. 2018, 61, 276–281. [Google Scholar] [CrossRef]

- Gergova, R.; Sendova-Vassileva, M.; Popkirov, G.; Dikov, H.; Atanasova, M.-D.; Grancharov, G. Influence of ZnO nanoparticles as electron transport material on the performance and stability of organic solar cells with sputtered Ag back electrodes. J. Phys. Conf. Ser. 2021, 1762, 012039. [Google Scholar] [CrossRef]

- Reese, M.O.; Gevorgyan, S.A.; Jørgensen, M.; Bundgaard, E.; Kurtz, S.R.; Ginley, D.S.; Olson, D.C.; Lloyd, M.T.; Morvillo, P.; Katz, E.A.; et al. Consensus stability testing protocols for organic photovoltaic materials and devices. Sol. Energy Mater. Sol. Cells 2011, 95, 1253–1267. [Google Scholar] [CrossRef]

| Type of Photoelement | Voc, V | Jsc, mA/cm2 | FF, % | PCE, % |

|---|---|---|---|---|

| ITO-PET/HTL/active layer/Ag | 0.434 | 2.74 | 27 | 0.34 |

| ITO-glass/HTL/active layer/Ag | 0.451 | 2.52 | 36 | 0.42 |

| ITO-PET/HTL/active layer/ETL/Ag | 0.496 | 2.60 | 38 | 0.49 |

| ITO-glass/HTL/active layer/ETL/Ag | 0.561 | 2.49 | 61 | 0.86 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grancharov, G.; Atanasova, M.-D.; Kalinova, R.; Gergova, R.; Popkirov, G.; Dikov, C.; Sendova-Vassileva, M. Flexible Polymer–Organic Solar Cells Based on P3HT:PCBM Bulk Heterojunction Active Layer Constructed under Environmental Conditions. Molecules 2021, 26, 6890. https://doi.org/10.3390/molecules26226890

Grancharov G, Atanasova M-D, Kalinova R, Gergova R, Popkirov G, Dikov C, Sendova-Vassileva M. Flexible Polymer–Organic Solar Cells Based on P3HT:PCBM Bulk Heterojunction Active Layer Constructed under Environmental Conditions. Molecules. 2021; 26(22):6890. https://doi.org/10.3390/molecules26226890

Chicago/Turabian StyleGrancharov, Georgy, Mariya-Desislava Atanasova, Radostina Kalinova, Rositsa Gergova, Georgi Popkirov, Christosko Dikov, and Marushka Sendova-Vassileva. 2021. "Flexible Polymer–Organic Solar Cells Based on P3HT:PCBM Bulk Heterojunction Active Layer Constructed under Environmental Conditions" Molecules 26, no. 22: 6890. https://doi.org/10.3390/molecules26226890

APA StyleGrancharov, G., Atanasova, M.-D., Kalinova, R., Gergova, R., Popkirov, G., Dikov, C., & Sendova-Vassileva, M. (2021). Flexible Polymer–Organic Solar Cells Based on P3HT:PCBM Bulk Heterojunction Active Layer Constructed under Environmental Conditions. Molecules, 26(22), 6890. https://doi.org/10.3390/molecules26226890