Highly Efficient Micro-Scale Liquid-Liquid In-Flow Extraction of 99mTc from Molybdenum

Abstract

:1. Introduction

2. Results and Discussion

3. Material and Methods

3.1. Materials

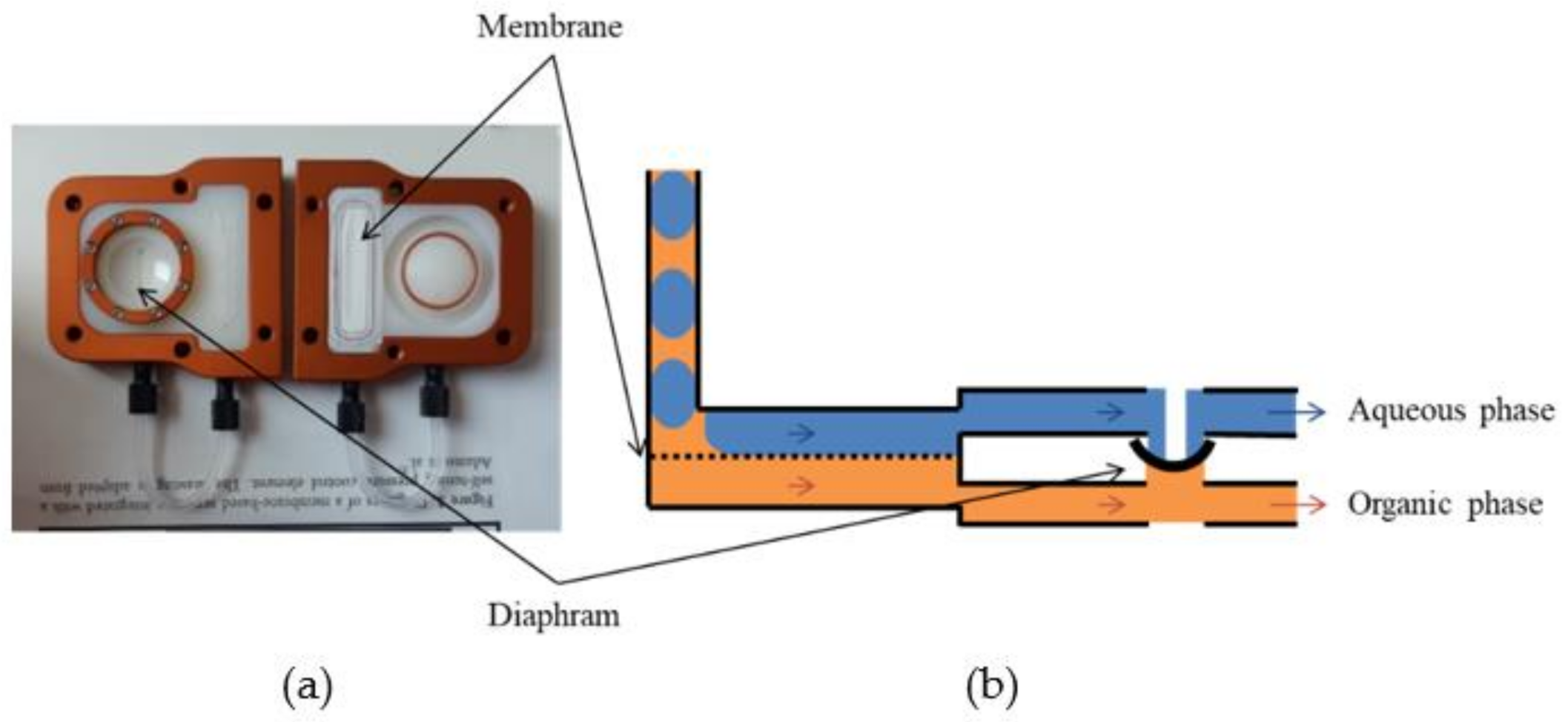

- a Zaiput SEP-10 device (purchased by ZAIPUT Flow Technologies company, Cambridge, MA, USA) mounting an OB-100 hydrophobic membrane, supplied with the device;

- two WPX1-U1/16S2-J8-CP peristaltic pumps (WELCO, Tokyo, Japan), flow rate of 0.5 mL/min at 6 V;

- two power supplies;

- a teflon T-junction;

- an ETFE capillary loop (1/8 “, length = 106 cm; internal diameter 1.59 mm; internal volume about 2.1 mL);

- ETFE tubes (1/8 “, internal diameter = 1.59 mm) and connectors.

3.2. Procedure

3.3. Quality Controls

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Boschi, A.; Uccelli, L.; Martini, P. A Picture of Modern Tc-99m Radiopharmaceuticals: Production, Chemistry, and Applications in Molecular Imaging. Appl. Sci. 2019, 9, 2526. [Google Scholar] [CrossRef] [Green Version]

- Qaim, S.M. Nuclear data for medical radionuclides. J. Radioanal. Nucl. Chem. 2015, 305, 233–245. [Google Scholar] [CrossRef]

- Scholten, B.; Lambrecht, R.M.; Cogneau, M.; Ruiz, H.V.; Qaim, S.M. Excitation functions for the cyclotron production of 99mTc and 99Mo. Appl. Radiat. Isot. 1999, 51, 69–80. [Google Scholar] [CrossRef]

- Uzunov, N.M.; Melendez-Alafort, L.; Bello, M.; Cicoria, G.; Zagni, F.; De Nardo, L.; Selva, A.; Mou, L.; Rossi-Alvarez, C.; Pupillo, G.; et al. Radioisotopic purity and imaging properties of cyclotron-produced 99mTc using direct 100Mo(p,2n) reaction. Phys. Med. Biol. 2018, 63, 1–30. [Google Scholar] [CrossRef]

- Bénard, F.; Buckley, K.R.; Ruth, T.J.; Zeisler, S.K.; Klug, J.; Hanemaayer, V.; Vuckovic, M.; Hou, X.; Celler, A.; Appiah, J.-P.; et al. Implementation of Multi-Curie Production of (99m)Tc by Conventional Medical Cyclotrons. J. Nucl. Med. 2014, 55, 1017–1022. [Google Scholar] [CrossRef] [Green Version]

- Schaffer, P.; Buckley, K.; Celler, A.; Klug, J.; Kovacs, M.; Prato, F.; Valliant, J.; Zeisler, S.; Ruth, T.; Benard, F. A tale of three targets: Direct, multi-Curie production of 99mTc on three different cyclotrons. J. Nucl. Med. 2015, 56, 164. [Google Scholar]

- Schaffer, P.; Bénard, F.; Bernstein, A.; Buckley, K.; Celler, A.; Cockburn, N.; Corsaut, J.; Dodd, M.; Economou, C.; Eriksson, T.; et al. Direct Production of 99mTc via 100Mo(p,2n) on Small Medical Cyclotrons. Phys. Procedia 2015, 66, 383–395. [Google Scholar] [CrossRef] [Green Version]

- Martini, P.; Boschi, A.; Cicoria, G.; Uccelli, L.; Pasquali, M.; Duatti, A.; Pupillo, G.; Marengo, M.; Loriggiola, M.; Esposito, J. A solvent-extraction module for cyclotron production of high-purity technetium-99m. Appl. Radiat. Isot. 2016, 118, 302–307. [Google Scholar] [CrossRef]

- Martini, P.; Boschi, A.; Cicoria, G.; Zagni, F.; Corazza, A.; Uccelli, L.; Pasquali, M.; Pupillo, G.; Marengo, M.; Loriggiola, M.; et al. In-house cyclotron production of high-purity Tc-99m and Tc-99m radiopharmaceuticals. Appl. Radiat. Isot. 2018, 139, 325–331. [Google Scholar] [CrossRef]

- Beaver, J.E.; Hupf, H.B. Production of 99mTc on a medical cyclotron: A feasibility study. J. Nucl. Med. 1971, 12, 739–741. [Google Scholar]

- Pillai, M.R.A.; Dash, A.; Knapp, F.F.R.J. Sustained availability of 99mTc: Possible paths forward. J. Nucl. Med. 2013, 54, 313–323. [Google Scholar] [CrossRef] [Green Version]

- Boschi, A.; Martini, P.; Pasquali, M.; Uccelli, L. Recent achievements in Tc-99m radiopharmaceutical direct production by medical cyclotrons. Drug Dev. Ind. Pharm. 2017, 43, 1402–1412. [Google Scholar] [CrossRef]

- Esposito, J.; Vecchi, G.; Pupillo, G.; Taibi, A.; Uccelli, L.; Boschi, A.; Gambaccini, M. Evaluation of 99Mo and 99m Tc productions based on a high-performance cyclotron. Sci. Technol. Nucl. Install. 2013. [Google Scholar] [CrossRef]

- IAEA. IAEA Nuclear Energy Series Non-HEU Production Technologies for Molybdenum-99 and Technetium-99m. IAEA Nucl. Energy Ser. 2013, 1–75. Available online: https://www-pub.iaea.org/MTCD/Publications/PDF/Pub1589_web.pdf (accessed on 19 September 2021).

- Capogni, M.; Pietropaolo, A.; Quintieri, L.; Angelone, M.; Boschi, A.; Capone, M.; Cherubini, N.; De Felice, P.; Dodaro, A.; Duatti, A.; et al. 14 MeV neutrons for 99Mo/99mTc production: Experiments, simulations and perspectives. Molecules 2018, 23, 1872. [Google Scholar] [CrossRef] [Green Version]

- Chattopadhyay, S.; Saha Das, S.; Barua, L.; Pal, A.K.; Kumar, U.; Madhusmita; Alam, M.N.; Hudait, A.K.; Banerjee, S. A compact solvent extraction based 99Mo/99mTc generator for hospital radiopharmacy. Appl. Radiat. Isot. 2019, 143, 41–46. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Das, S.S.; Das, M.K.; Goomer, N.C. Recovery of 99mTc from Na2[99Mo]MoO4 solution obtained from reactor-produced (n,γ) 99Mo using a tiny Dowex-1 column in tandem with a small alumina column. Appl. Radiat. Isot. 2008, 66, 1814–1817. [Google Scholar] [CrossRef]

- Uccelli, L.; Boschi, A.; Pasquali, M.; Duatti, A.; Di Domenico, G.; Pupillo, G.; Esposito, J.; Giganti, M.; Taibi, A.; Gambaccini, M. Influence of the generator in-growth time on the final radiochemical purity and stability of 99mTc radiopharmaceuticals. Sci. Technol. Nucl. Install. 2013. [Google Scholar] [CrossRef]

- Esposito, J.; Bettoni, D.; Boschi, A.; Calderolla, M.; Cisternino, S.; Fiorentini, G.; Keppel, G.; Martini, P.; Maggiore, M.; Mou, L.; et al. Laramed: A laboratory for radioisotopes of medical interest. Molecules 2019, 24, 20. [Google Scholar] [CrossRef] [Green Version]

- Kralj, J.G.; Sahoo, H.R.; Jensen, K.F. Integrated continuous microfluidic liquid–liquid extraction. Lab. Chip 2007, 7, 256–263. [Google Scholar] [CrossRef]

- Mariet, C.; Vansteene, A.; Losno, M.; Pellé, J.; Jasmin, J.P.; Bruchet, A.; Hellé, G. Microfluidics devices applied to radionuclides separation in acidic media for the nuclear fuel cycle. Micro Nano Eng. 2019, 3, 7–14. [Google Scholar] [CrossRef]

- Wang, J.; van Dam, R.M. High-Efficiency Production of Radiopharmaceuticals via Droplet Radiochemistry: A Review of Recent Progress. Mol. Imaging 2020, 19, 1536012120973099. [Google Scholar] [CrossRef]

- Pedersen, K.S.; Imbrogno, J.; Fonslet, J.; Lusardi, M.; Jensen, K.F.; Zhuravlev, F. Liquid–liquid extraction in flow of the radioisotope titanium-45 for positron emission tomography applications. React. Chem. Eng. 2018, 3, 898–904. [Google Scholar] [CrossRef] [Green Version]

- Rensch, C.; Jackson, A.; Lindner, S.; Salvamoser, R.; Samper, V.; Riese, S.; Bartenstein, P.; Wängler, C.; Wängler, B. Microfluidics: A groundbreaking technology for PET tracer production? Molecules 2013, 18, 7930–7956. [Google Scholar] [CrossRef] [Green Version]

- Maurice, A.; Theisen, J.; Gabriel, J.C.P. Microfluidic lab-on-chip advances for liquid–liquid extraction process studies. Curr. Opin. Colloid Interface Sci. 2020, 46, 20–35. [Google Scholar] [CrossRef]

- Farahani, A.; Rahbar-Kelishami, A.; Shayesteh, H. Microfluidic solvent extraction of Cd(II) in parallel flow pattern: Optimization, ion exchange, and mass transfer study. Sep. Purif. Technol. 2021, 258, 118031. [Google Scholar] [CrossRef]

- Priest, C.; Zhou, J.; Sedev, R.; Ralston, J.; Aota, A.; Mawatari, K.; Kitamori, T. Microfluidic extraction of copper from particle-laden solutions. Int. J. Miner. Process. 2011, 98, 168–173. [Google Scholar] [CrossRef]

- Zhang, L.; Hessel, V.; Peng, J.; Wang, Q.; Zhang, L. Co and Ni extraction and separation in segmented micro-flow using a coiled flow inverter. Chem. Eng. J. 2017, 307, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Hellé, G.; Mariet, C.; Cote, G. Microfluidic Tools for the Liquid-liquid Extraction of Radionuclides in Analytical Procedures. Procedia Chem. 2012, 7, 679–684. [Google Scholar] [CrossRef] [Green Version]

- Ban, Y.; Kikutani, Y.; Tokeshi, M.; Morita, Y. Extraction of Am(III) at the Interface of Organic-Aqueous Two-Layer Flow in a Microchannel. J. Nucl. Sci. Technol. 2011, 48, 1313–1318. [Google Scholar] [CrossRef]

- Martini, P.; Adamo, A.; Syna, N.; Boschi, A.; Uccelli, L.; Weeranoppanant, N.; Markham, J.; Pascali, G. Perspectives on the use of liquid extraction for radioisotope purification. Molecules 2019, 24, 334. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Adamo, A.; Heider, P.L.; Weeranoppanant, N.; Jensen, K.F. Membrane-based, liquid-liquid separator with integrated pressure control. Ind. Eng. Chem. Res. 2013, 52, 10802–10808. [Google Scholar] [CrossRef] [Green Version]

- Kashid, M.N.; Harshe, Y.M.; Agar, D.W. Liquid-liquid slug flow in a capillary: An alternative to suspended drop or film contactors. Ind. Eng. Chem. Res. 2007, 46, 8420–8430. [Google Scholar] [CrossRef]

- Ghaini, A.; Kashid, M.N.; Agar, D.W. Effective interfacial area for mass transfer in the liquid–liquid slug flow capillary microreactors. Chem. Eng. Process. Process. Intensif. 2010, 49, 358–366. [Google Scholar] [CrossRef]

- Woitalka, A.; Kuhn, S.; Jensen, K.F. Scalability of mass transfer in liquid–liquid flow. Chem. Eng. Sci. 2014, 116, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Holbach, A.; Kockmann, N. Counter-current arrangement of microfluidic liquid-liquid droplet flow contactors. Green Process. Synth. 2013, 2, 157–167. [Google Scholar] [CrossRef]

- Chattopadhyay, S.; Das, S.S.; Barua, L. A simple and rapid technique for recovery of 99mTc from low specific activity (n,γ)99Mo based on solvent extraction and column chromatography. Appl. Radiat. Isot. 2010, 68, 1–4. [Google Scholar] [CrossRef]

- Dessimoz, A.-L.; Cavin, L.; Renken, A.; Kiwi-Minsker, L. Liquid–liquid two-phase flow patterns and mass transfer characteristics in rectangular glass microreactors. Chem. Eng. Sci. 2008, 63, 4035–4044. [Google Scholar] [CrossRef] [Green Version]

- Jovanović, J.; Rebrov, E.V.; Nijhuis, T.A.; Kreutzer, M.T.; Hessel, V.; Schouten, J.C. Liquid-liquid flow in a capillary microreactor: Hydrodynamic flow patterns and extraction performance. Ind. Eng. Chem. Res. 2012, 51, 1015–1026. [Google Scholar] [CrossRef]

- Kashid, M.N.; Gerlach, I.; Goetz, S.; Franzke, J.; Acker, J.F.; Platte, F.; Agar, D.W.; Turek, S. Internal circulation within the liquid slugs of a liquid-liquid slug-flow capillary microreactor. Ind. Eng. Chem. Res. 2005, 44, 5003–5010. [Google Scholar] [CrossRef]

- Tsaoulidis, D.; Angeli, P. Effect of channel size on mass transfer during liquid–liquid plug flow in small scale extractors. Chem. Eng. J. 2015, 262, 785–793. [Google Scholar] [CrossRef] [Green Version]

- Sodium pertechnetate (99mTc) injection (Accelator- Produced). In EU Pharmacopoeia 9.3; EDQM (Ed.) European Directorate for the Quality of Medicines & HealthCare Council of Europe: Strasbourg, France, 2018; pp. 4801–4803. [Google Scholar]

- Sodium pertechnetate (99mTc) injection (FISSION). In EU Pharmacopoeia 8.0; EDQM (Ed.) European Directorate for the Quality of Medicines & HealthCare Council of Europe: Strasbourg, France, 2014; pp. 1090–1091. [Google Scholar]

- Sodium pertechnetate (99mTc) injection (NON-FISSION). In EU Pharmacopoeia 8.0; EDQM (Ed.) European Directorate for the Quality of Medicines & HealthCare Council of Europe: Strasbourg, France, 2014. [Google Scholar]

- Solvents with low toxic potential. In EU Pharmacopoeia 8.0; EDQM (Ed.) European Directorate for the Quality of Medicines & HealthCare Council of Europe: Strasbourg, France, 2014; p. 642. [Google Scholar]

- Skliarova, H.; Cisternino, S.; Cicoria, G.; Cazzola, E.; Gorgoni, G.; Marengo, M.; Esposito, J. Cyclotron solid targets preparation for medical radionuclides production in the framework of LARAMED project. J. Phys. Conf. Ser. 2020, 1548, 012022. [Google Scholar] [CrossRef]

| Sample | Volume [mL] | 99mTc % |

|---|---|---|

| Sample vial | empty | 3.3 ± 0.7 |

| ORG OUT 1 | 4 | - |

| AQ OUT 1 | 5 | - |

| ORG OUT 2 | 8.5 | 91.0 ± 1.8 |

| AQ OUT 2 | 7 | 2.1 ± 0.6 |

| ORG OUT 3 | 2.5 | 2.2 ± 1.4 |

| AQ OUT 3 | 3 | 1.5 ± 2.1 |

| H2O washing | 5 | - |

| MEK washing | 5 | - |

| Parameters | This Work | EU Phar. * [42,43,44,45] | Other SE-Based Techniques [16,37] | Generator Eluate | |

|---|---|---|---|---|---|

| CP | pH | 5 | 4–8 | 6–7 | 6 |

| Mo | <5 ppm | <10 ppm | - | ||

| Al | <5 ppm | <5 ppm | <10 ppm | <5 ppm | |

| MEK | <0.0006% (v/v) | <0.5% (v/v) | <0.1% (v/v) | - | |

| RCP | 99mTcO4− | >98% | ≥95% | >99% | >99% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martini, P.; Uccelli, L.; Duatti, A.; Marvelli, L.; Esposito, J.; Boschi, A. Highly Efficient Micro-Scale Liquid-Liquid In-Flow Extraction of 99mTc from Molybdenum. Molecules 2021, 26, 5699. https://doi.org/10.3390/molecules26185699

Martini P, Uccelli L, Duatti A, Marvelli L, Esposito J, Boschi A. Highly Efficient Micro-Scale Liquid-Liquid In-Flow Extraction of 99mTc from Molybdenum. Molecules. 2021; 26(18):5699. https://doi.org/10.3390/molecules26185699

Chicago/Turabian StyleMartini, Petra, Licia Uccelli, Adriano Duatti, Lorenza Marvelli, Juan Esposito, and Alessandra Boschi. 2021. "Highly Efficient Micro-Scale Liquid-Liquid In-Flow Extraction of 99mTc from Molybdenum" Molecules 26, no. 18: 5699. https://doi.org/10.3390/molecules26185699

APA StyleMartini, P., Uccelli, L., Duatti, A., Marvelli, L., Esposito, J., & Boschi, A. (2021). Highly Efficient Micro-Scale Liquid-Liquid In-Flow Extraction of 99mTc from Molybdenum. Molecules, 26(18), 5699. https://doi.org/10.3390/molecules26185699