The Art of Framework Construction: Core–Shell Structured Micro-Energetic Materials

Abstract

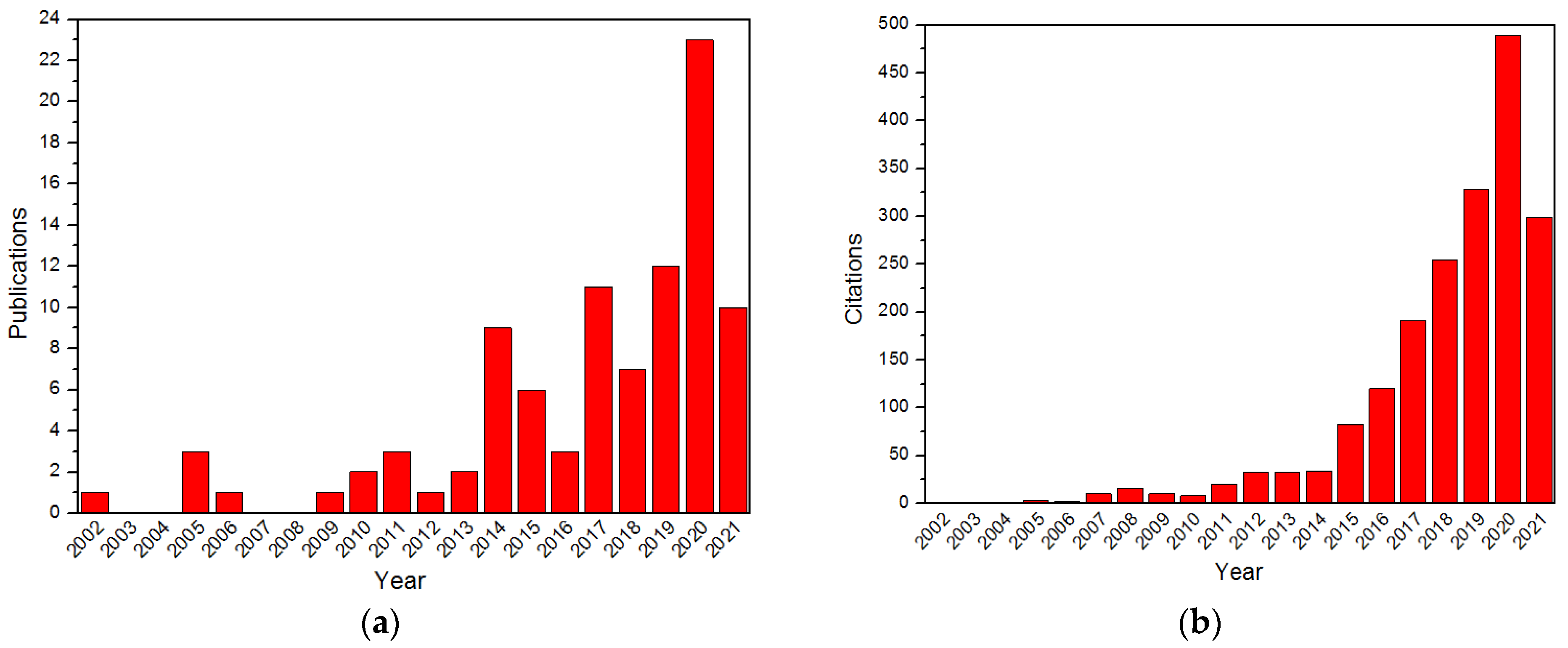

:1. Introduction

2. Preparation Methods for CSEs

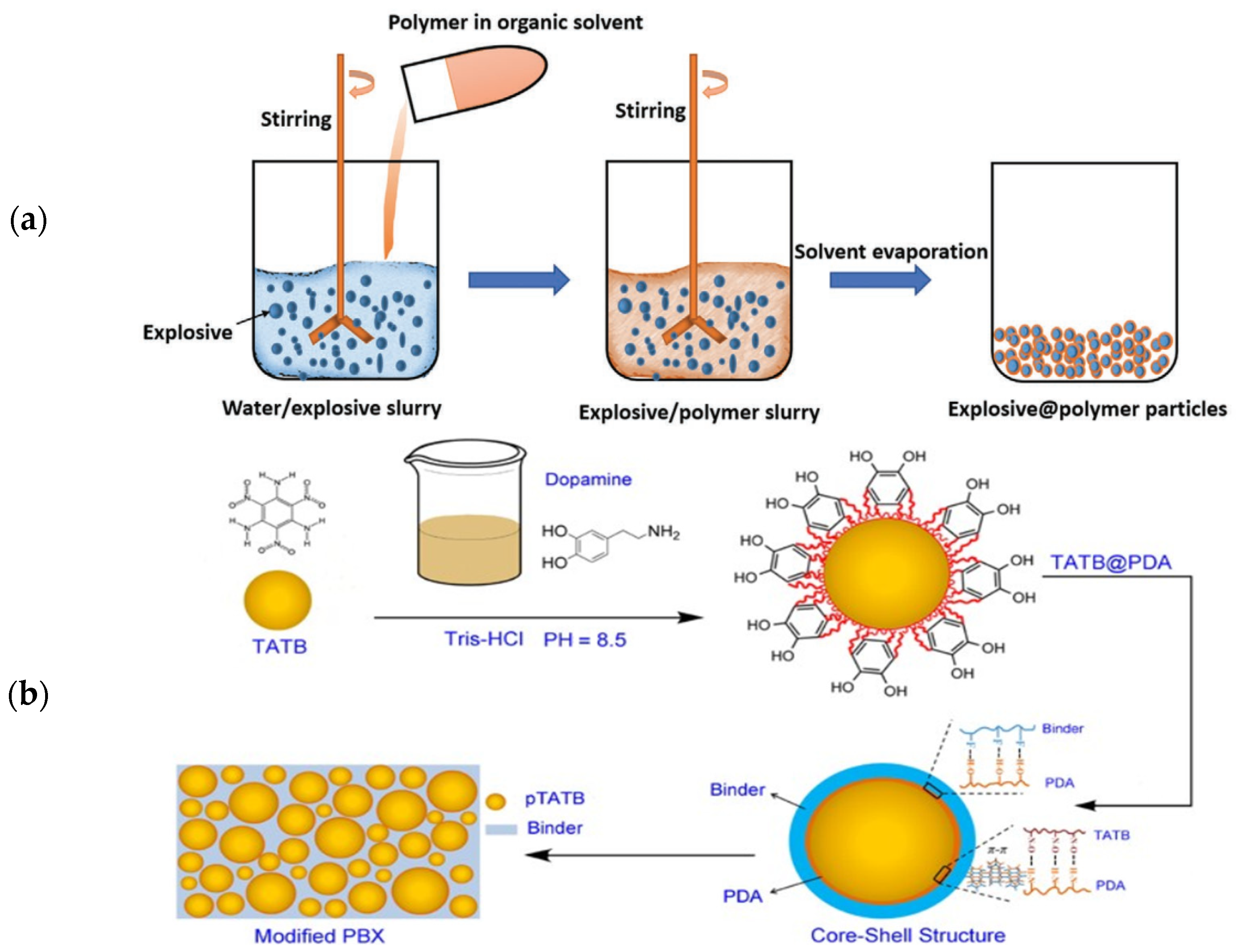

2.1. Water Suspension Method

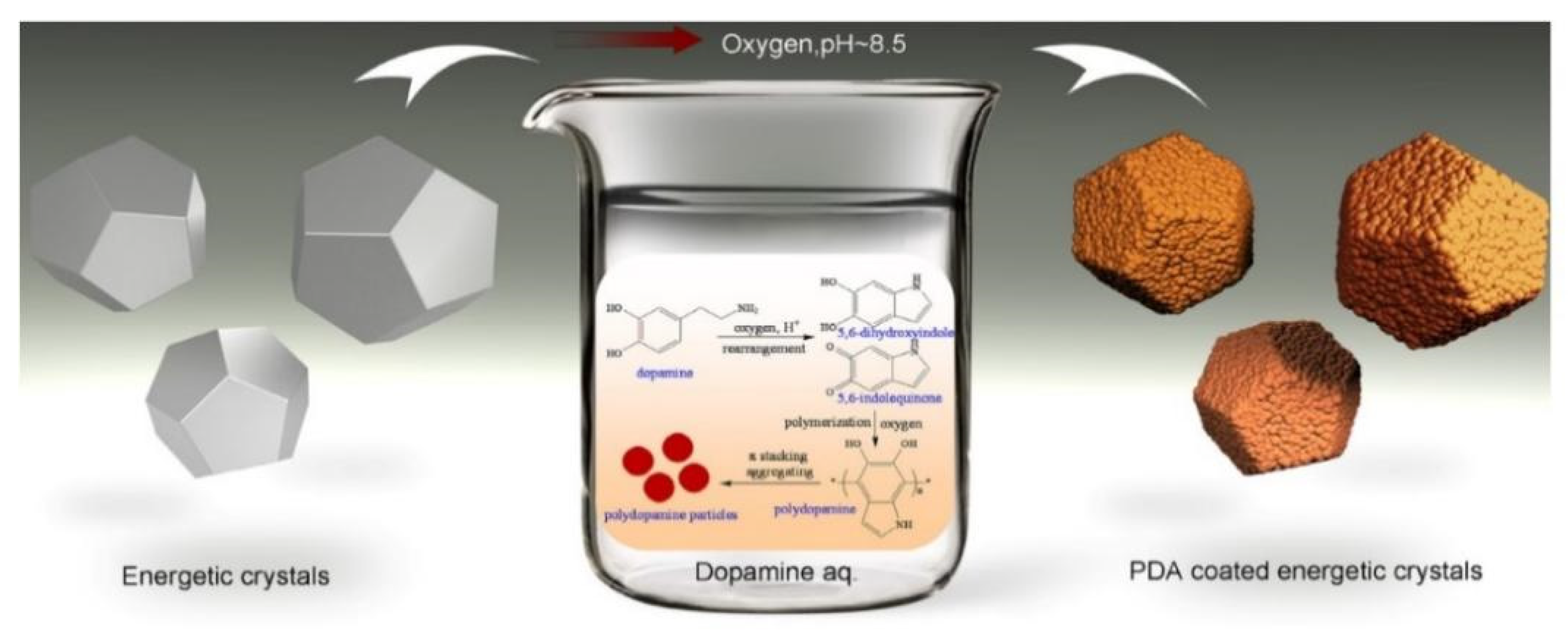

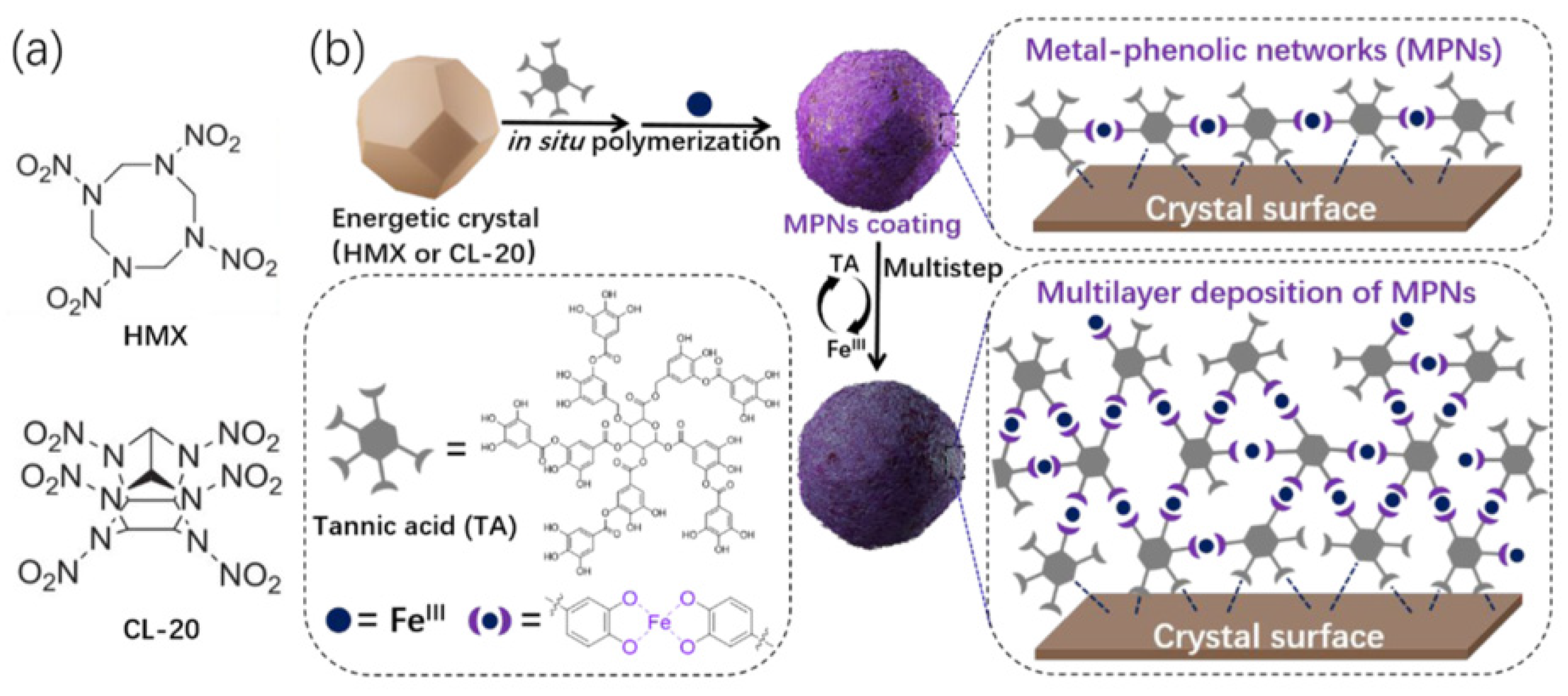

2.2. In Situ Polymerization

| Product | Size of Core [Diameter, μm] | Thickness of Shell [nm] | Shell Content [wt%] | Degree of Coverage | Feature | Comments | Contributor |

|---|---|---|---|---|---|---|---|

| TATB@PDA | 14 | NA | 1.5 | Close to 100% | Homogeneous PDA coating, coupled with obvious surface color change. | [52] | |

| HMX(HNIW)@UF resin | 20 (5–40) | NA | 4.8 (4.3) | 98.1% (95.3%) | Compact coating, without shrinks or bubbles. | [61] | |

| TATB@HBP | 20 | NA | 1.5 | NA | Intact coating, rough surface. | [55] | |

| CL-20/HMX/RDX@MF resin | 120/120/60 | 1–2 μm | 3.0 | 99.2%/98.7%/93.1% | Compact and uniform coating, slight agglomeration. | The reaction time should be well controlled to reduce self-agglomeration of shell material. | [60] |

| HMX@PDA | 22 | 100 | 2.1 | NA | Dense coating with PDA depositing layer-by-layer on the HMX crystal. | [64] | |

| HMX@MPNs 1 | 91 | 50 | 3.4 | NA | The composite particles have more textured surface with negligible wrinkles or holes. | Increasing the coating times may be an effective way to improve the compactness and mechanical strength through sequential layer deposition. | [65] |

| HMX@HPW 1@PDA | 47 | NA | NA | NA | A novel litchi-like core@double shell structure. | [66] | |

| ε-CL-20@PDA | 60 | NA | 1.6 | NA | The composite particles have polyhedron shapes with uniform and compact coating. | [57] | |

| HMX@BAMO-THF | 23 | NA | 1.5 | NA | The particle size distribution was relatively uniform, and the crystal quality greatly improved after coating. | [67] | |

| HMX/rGO/G 1 | 10 | NA | 2.0 | NA | Spherical morphology of the composite, different from angular HMX. | [43] | |

| HMX@TATB@PDA | 149.1 | 50–80 | NA | NA | Uniform and porous surface. | [35] | |

| LLM-105@PDA@HBPU 1 | 50,20,5 | NA | 1.0 | NA | A layer of plicate characteristics with nanoscale protuberances on the shell. | [12] | |

| HMX@PANI | 5–40 | NA | 3.1 | NA | Compact coating, few agglomerations and larger roughness after coating. | [63] | |

| CL-20/HMX/RDX@MUF resin | 10 | NA | 5.0 | NA | Spheroidized structure with dense and smooth surface. | Core–shell structured composites with high quality can be achieved. | [62] |

| HMX@TATB | <250 | NA | 42.5 | NA | HMX core has been jacketed with a layer of TATB particles. | [68] | |

| CL-20@TATB | 98 | NA | NA | NA | Uniform coating. | [69] | |

| NBTTP 1@PDA/GO | 5–15 | NA | 2.0 | NA | Regular color and particle size of all the samples. | [70] | |

| HMX@Polyurethane | 25.59 | NA | NA | NA | More uniform, complete and smooth surface than virgin HMX particles. | [71] | |

| HMX@HTPB/GAP/BAMO-THF | NA | NA | 5.0 | NA | Almost uniform coating. | [72] |

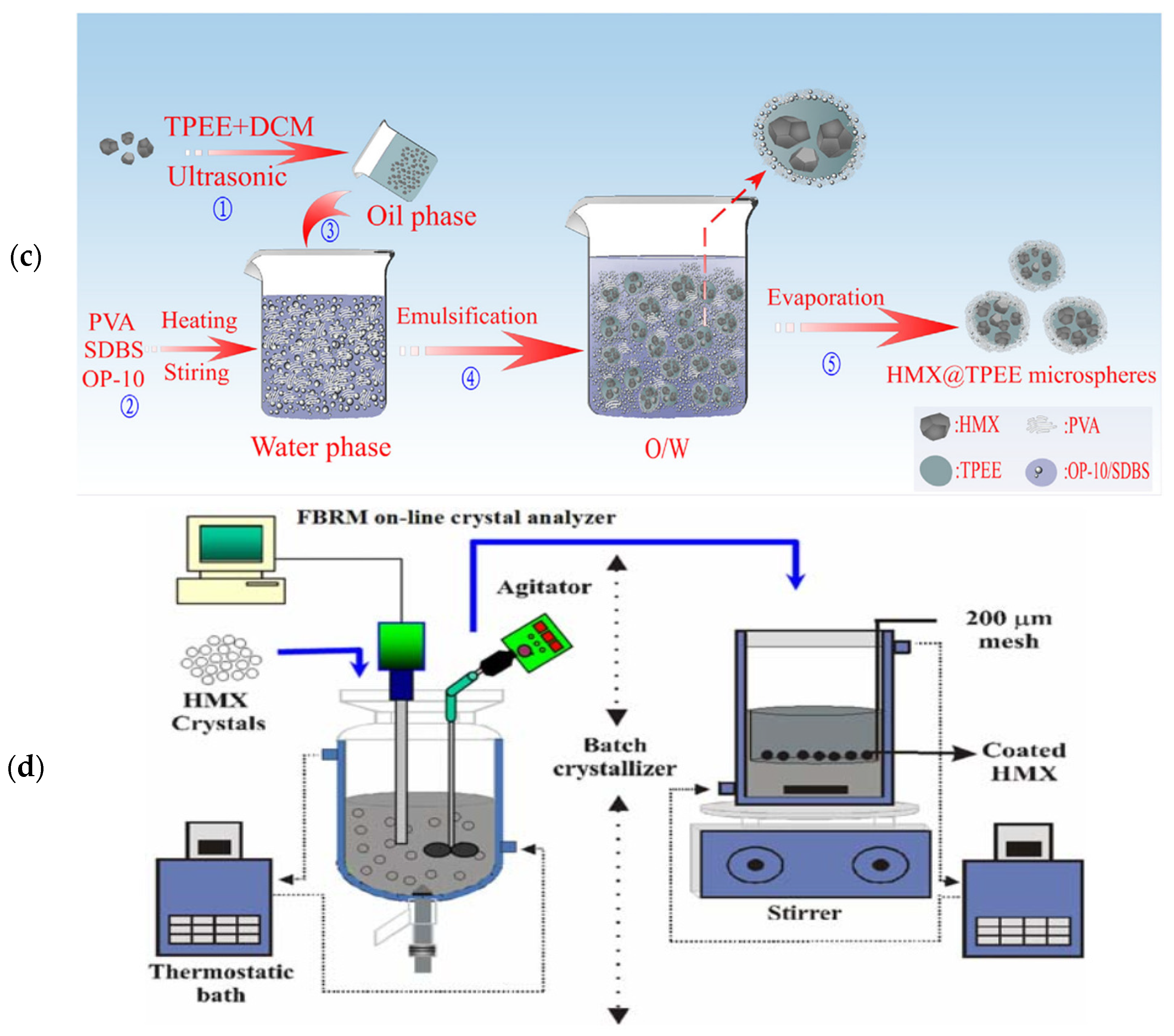

2.3. Emulsion Method

2.4. Crystallization Coating Method

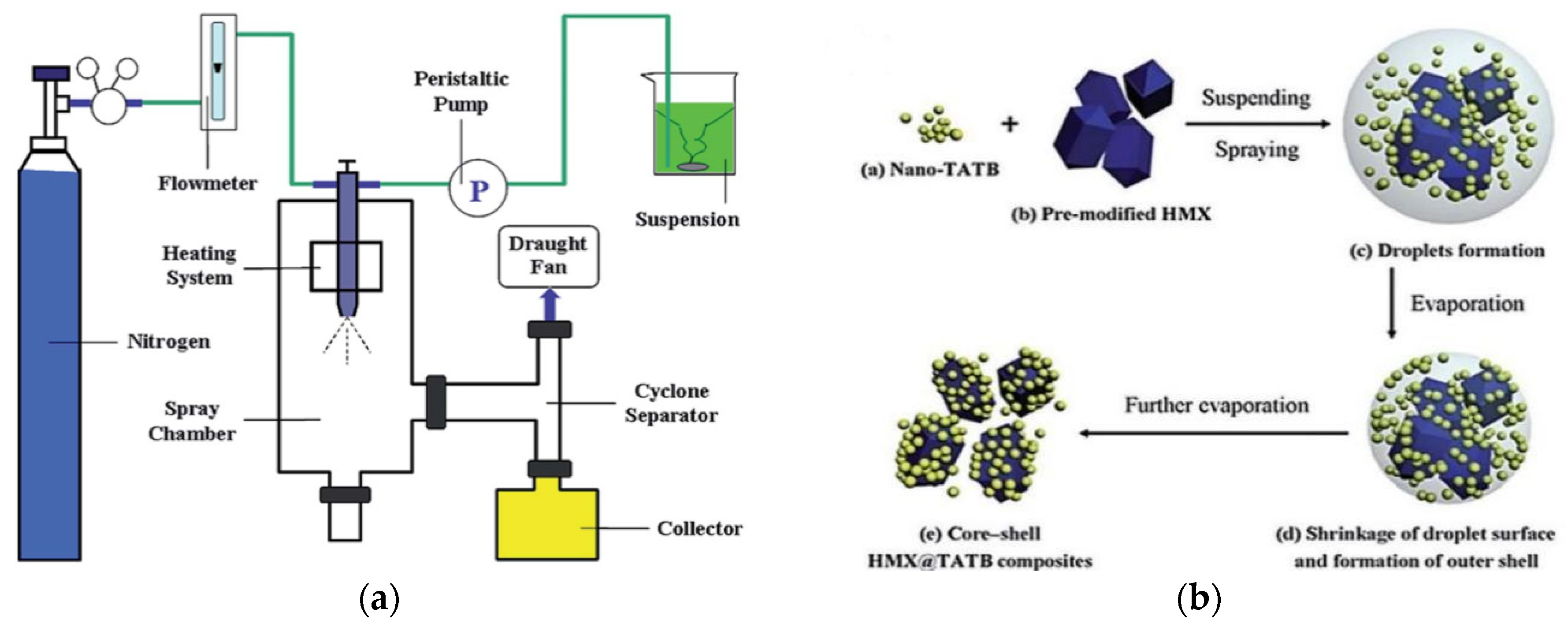

2.5. Spray Drying Method

2.6. Other Fabrication Techniques

2.6.1. Ultrasonic

2.6.2. Supercritical Encapsulation Method

2.6.3. Vapor Deposition Method

2.7. Comments on the Above-Mentioned Methods

3. Compositions and Characteristics of CSEs

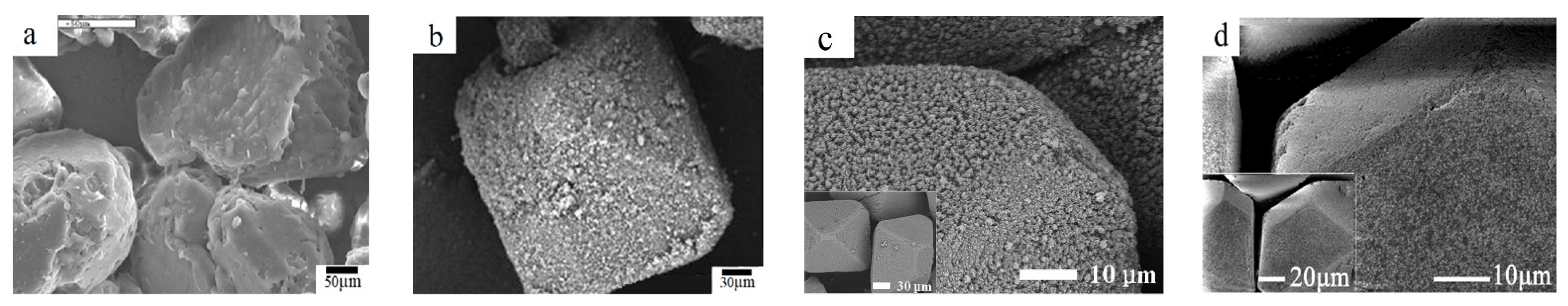

3.1. CSEs with Polymer as Shell

3.1.1. HMX-Based CSEs

3.1.2. TATB-Based CSEs

3.1.3. CSEs Based on Other Explosives

3.2. CSEs with Explosive as Shell

3.3. CSEs with Novel Materials as Shell

3.4. Challenges and Prospects

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Elbeih, A.; Zeman, S.; Jungová, M.; Vávra, P. Attractive nitramines and related PBXs. Propellants Explos. Pyrotech. 2013, 38, 379–385. [Google Scholar] [CrossRef]

- Sikder, A.K.; Sikder, N. A review of advanced high performance, insensitive and thermally stable energetic materials emerging for military and space applications. J. Hazard. Mater. 2004, 112, 1–15. [Google Scholar] [CrossRef]

- Duan, B.H.; Liu, N.; Wang, B.Z.; Lu, X.M.; Mo, H.C. Comparative theoretical studies on a series of novel energetic salts composed of 4,8-dihydrodifurazano[3,4-b,e]pyrazine-based anions and ammonium-based cations. Molecules 2019, 24, 3213. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yao, Y.Y.; Lin, Q.H.; Zhou, X.L.; Lu, M. Recent research on the synthesis pentazolate anion cyclo-N5−. FirePhysChem 2021, 1, 33–45. [Google Scholar] [CrossRef]

- Zhao, X.; Li, Z.; Zhang, J.; Gong, F.; Huang, B.; Zhang, Q.; Yan, Q.L.; Yang, Z. Regulating safety and energy release of energetic materials by manipulation of molybdenum disulfide phase. Chem. Eng. J. 2021, 411, 128603. [Google Scholar] [CrossRef]

- Hoffman, D.M.; Caley, L.E. Polymer blends as high explosive binders. Polym. Eng. Sci. 1986, 26, 1489–1499. [Google Scholar] [CrossRef]

- Manning, T.G.; Strauss, B. Reduction of Energetic Filler Sensitivity in Propellants through Coating. U.S. Patent 6524706, 25 February 2003. [Google Scholar]

- Antoine, E.D.M.; Richard, H.B. Crystallization and characterization of RDX, HMX, and CL-20. Cryst. Growth Des. 2004, 4, 999–1007. [Google Scholar]

- Hunt, E.M.; Jackson, M. Coating and characterization of energetic materials. In Proceedings of the ASME 2010 International Mechanical Engineering Congress and Exposition, Vancouver, BC, Canada, 12–18 November 2010; pp. 55–60. [Google Scholar]

- Zhang, J.; Shreeve, J.M. Time for pairing: Cocrystals as advanced energetic materials. CrystEngComm 2016, 18, 6124–6133. [Google Scholar] [CrossRef]

- Misasi, J.M.; Jin, Q.; Knauer, K.M.; Morgan, S.E.; Wiggins, J.S. Hybrid POSS-hyperbranched polymer additives for simultaneous reinforcement and toughness improvements in epoxy networks. Polymer 2017, 117, 54–63. [Google Scholar] [CrossRef]

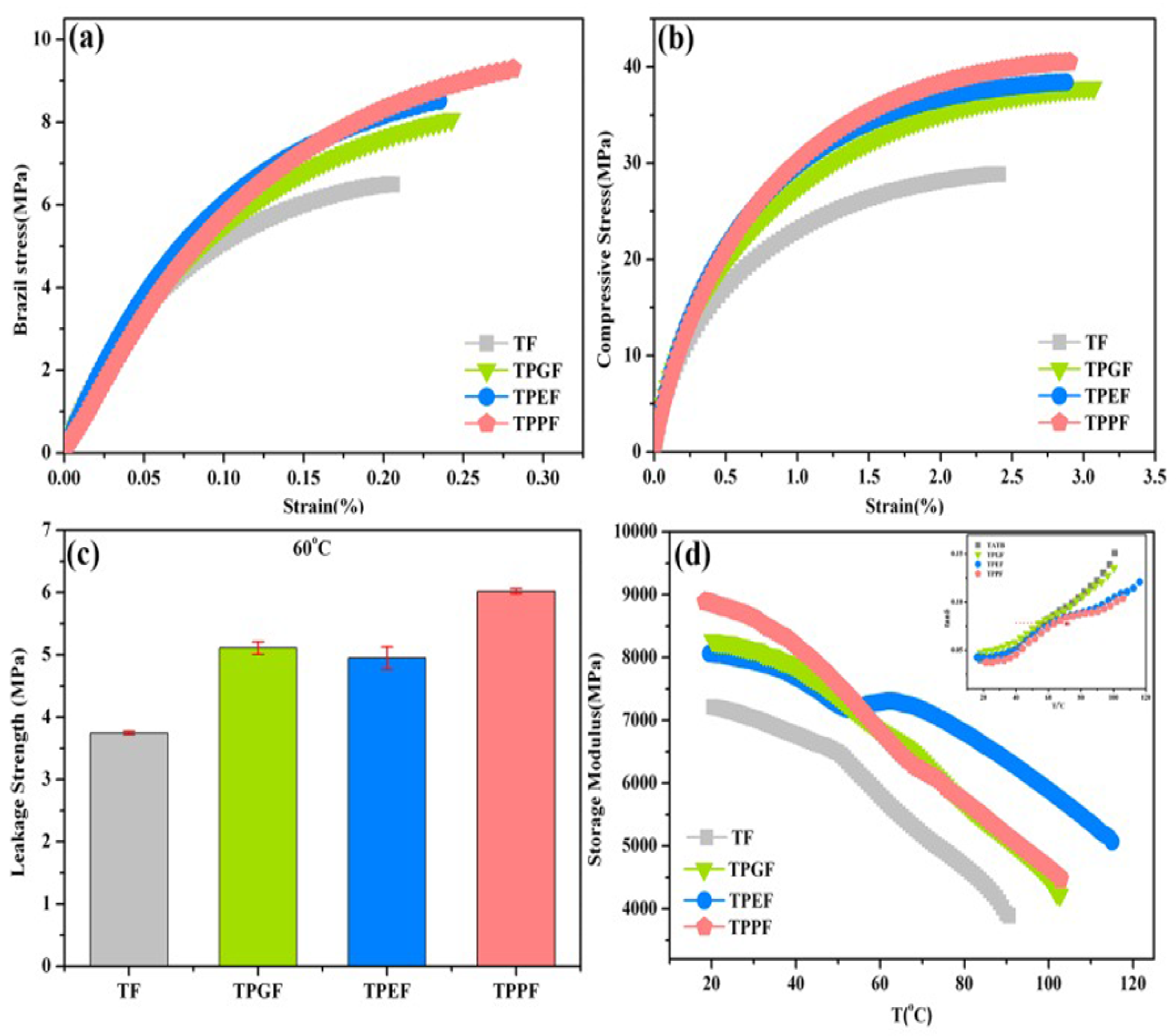

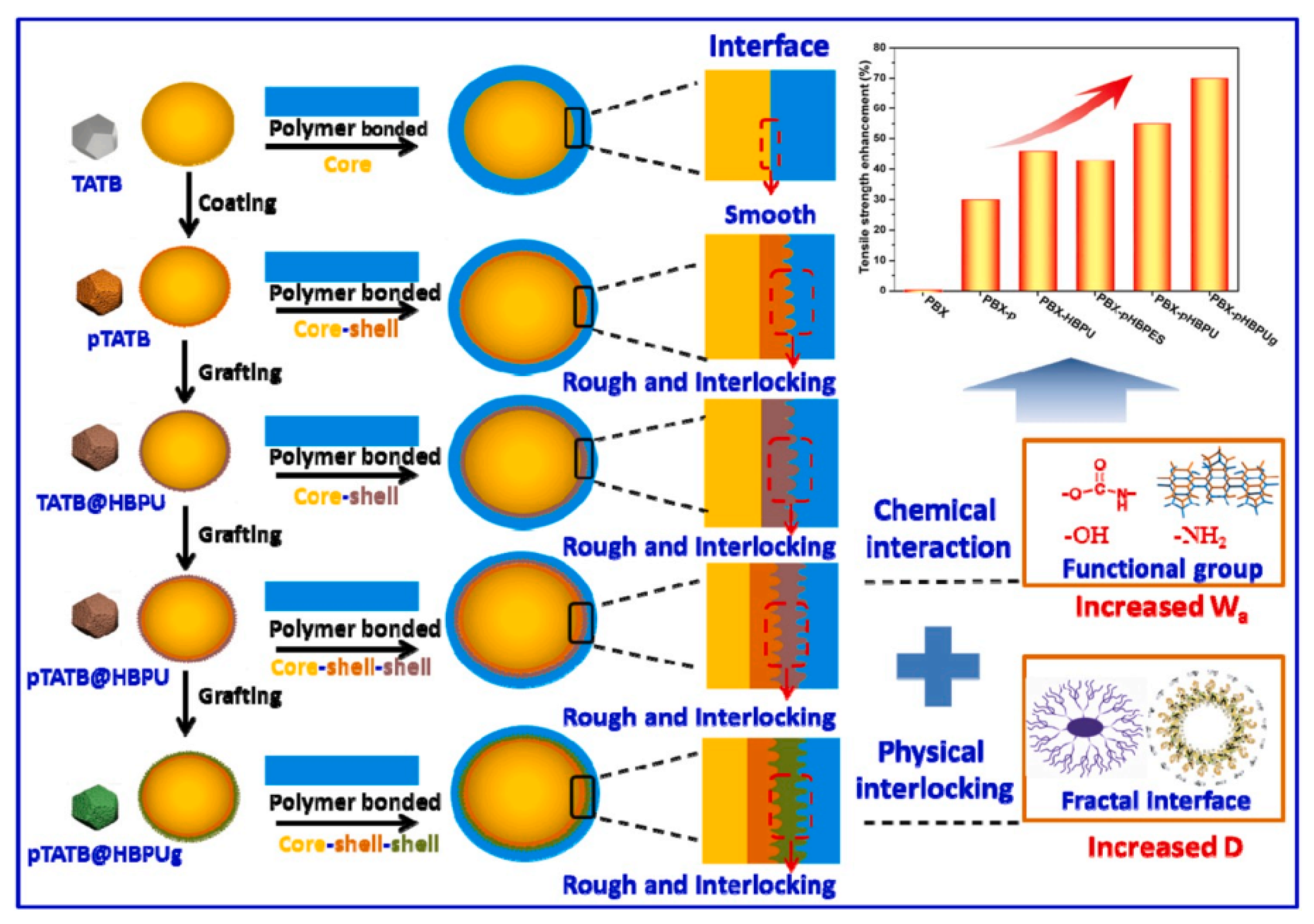

- He, G.; Li, X.; Jiang, Y.; Dai, Y.; Xu, R.; Zeng, C.; Tu, X.; Yang, Z. Bioinspired hierarchical interface design for improved mechanical and safety properties in energetic polymer composites. J. Mater. Sci. 2020, 55, 15726–15740. [Google Scholar] [CrossRef]

- Liu, Z.W.; Xie, H.M.; Li, K.X.; Chen, P.W.; Huang, F.L. Fracture behavior of PBX simulation subject to combined thermal and mechanical loads. Polym. Test. 2009, 28, 627–635. [Google Scholar] [CrossRef]

- Yang, G.S.; Zhou, Z.J.; Zhang, X.Y.; Pan, J.H.; Liu, L.P. Polymer bonded explosives (PBXs) with reduced thermal stress and sensitivity by thermal conductivity enhancement with graphene nanoplatelets. Compos. Sci. Technol. 2016, 131, 22–31. [Google Scholar]

- Lin, C.; Tian, Q.; Chen, K.; He, G.; Zhang, J.; Liu, S.; Almasy, L. Polymer bonded explosives with highly tunable creep resistance based on segmented polyurethane copolymers with different hard segment contents. Compos. Sci. Technol. 2017, 146, 10–19. [Google Scholar] [CrossRef]

- Liu, Y.; Peng, L.; Su, Z. Core-shell attapulgite@polyaniline composite particles via in situ oxidative polymerization. Synth. Met. 2007, 157, 585–591. [Google Scholar] [CrossRef]

- Ma, X.; Li, Y.; Hussain, I.; Shen, R.; Yang, G.; Zhang, K. Core-shell structured nanoenergetic materials: Preparation and fundamental properties. Adv. Mater. 2020, 32, 2001291. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Xue, Z.; Fu, X.; Yan, Q.L. Advanced crystalline energetic materials modified by coating/intercalation techniques. Chem. Eng. J. 2021, 417, 128044. [Google Scholar] [CrossRef]

- Zuo, C.; Wang, L.; Tong, Y.; Shi, L.; Ding, W.; Li, W. Co-deposition of pyrogallol/polyethyleneimine on polymer membranes for highly efficient treatment of oil-in-water emulsion. Sep. Purif. Technol. 2021, 267, 118660. [Google Scholar] [CrossRef]

- Jiang, J.; Zhu, L.; Zhu, L.; Zhu, B.; Xu, Y. Surface characteristics of a self-polymerized dopamine coating deposited on hydrophobic polymer films. Langmuir ACS J. Surf. Colloids 2011, 27, 14180–14187. [Google Scholar] [CrossRef] [PubMed]

- Gong, Q.H.; Gao, T.T.; Hu, T.T.; Zhou, G.W. Synthesis and electrochemical energy storage applications of micro/nanostructured spherical materials. Nanomaterials 2019, 9, 1207. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, J.; Du, Y.; Dong, K.; Su, H.; Zhang, S.; Li, S.; Pang, S. Taming dinitramide anions within an energetic metal–organic framework: A new strategy for synthesis and tunable properties of high energy materials. Chem. Mater. 2016, 28, 1472–1480. [Google Scholar] [CrossRef]

- Xiao, Z.; He, W.; Ying, S.; Zhou, W.; Xu, F. Current trends in energetic thermoplastic elastomers as binders in high energy insensitive propellants in China. Sci. Technol. Energ. Mater. 2014, 75, 37–43. [Google Scholar]

- Liu, W.; Wang, Y.; Wang, P.; Li, Y.; Jiang, Q.; Hu, X.; Wei, Y.; Qiu, Y.; Shahabadi, S.; Lu, X. A biomimetic approach to improve the dispersibility, interfacial interactions and toughening effects of carbon nanofibers in epoxy composites. Compos. Part B Eng. 2017, 113, 197–205. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, J.; Zhou, J.; Zhang, D.; Zhang, A. Dramatic toughness enhancement of benzoxazine/epoxy thermosets with a novel hyperbranched polymeric ionic liquid. Chem. Eng. J. 2018, 334, 1371–1382. [Google Scholar] [CrossRef]

- He, G.; Li, X.; Dai, Y.; Yang, Z.; Zeng, C.; Lin, C.; He, S. Constructing bioinspired hierarchical structure in polymer based energetic composites with superior thermal conductivity. Compos. Part B Eng. 2019, 162, 678–684. [Google Scholar] [CrossRef]

- Yang, Z.; Lin, C.; Gong, F.; Zeng, C.; Zhang, J.; Huang, F. Effects of crystal quality and morphology on the mechanical performance of LLM-105 based PBXs. Propellants Explos. Pyrotech. 2019, 44, 1219–1225. [Google Scholar] [CrossRef]

- Zhang, J.; Hwang, J.; Antonietti, M.; Schmidt, B. Water-in-water pickering emulsion stabilized by polydopamine particles and cross-linking. Biomacromolecules 2019, 20, 204–211. [Google Scholar] [CrossRef] [PubMed]

- He, W.; Li, Z.H.; Chen, S.; Yang, G.; Yang, Z.; Liu, P.J.; Yan, Q.L. Energetic metastable n-Al@PVDF/EMOF composite nanofibers with improved combustion performances. Chem. Eng. J. 2020, 383, 123146. [Google Scholar] [CrossRef]

- Gong, Q.H.; Wang, H.Q.; Song, W.H.; Sun, B.; Cao, P.; Gu, S.N.; Sun, X.F.; Zhou, G.W. Tunable synthesis of hierarchical yolk/double-shelled SiOx@TiO2@C nanospheres for high-performance lithium-ion batteries. Chem.-Eur. J. 2021, 27, 2654–2661. [Google Scholar] [CrossRef]

- Zhang, P.; Hu, W.; Wu, M.; Gong, L.; Tang, A.; Xiang, L.; Zhu, B.; Zhu, L.; Zeng, H. Cost-effective strategy for surface modification via complexation of disassembled polydopamine with Fe(III) ions. Langmuir ACS J. Surf. Colloids 2019, 35, 4101–4109. [Google Scholar] [CrossRef]

- Chen, L.; Liu, J.; He, W. Bio-inspired fabrication of energetic crystals@cellulose nanofibers core-shell composites with improved stability and reduced sensitivity. Compos. Commun. 2021, 27, 100868. [Google Scholar] [CrossRef]

- He, G.; Yang, Z.; Pan, L.; Zhang, J.; Liu, S.; Yan, Q.L. Bioinspired interfacial reinforcement of polymer-based energetic composites with a high loading of solid explosive crystals. J. Mater. Chem. A 2017, 5, 13499–13510. [Google Scholar] [CrossRef]

- Liu, J.H.; Yang, Z.J.; Liu, S.J.; Zhang, J.H.; Liu, Y.G. Effects of fluoropolymer binders on the mechanical properties of TATB-based PBX. Propellants Explos. Pyrotech. 2018, 43, 664–670. [Google Scholar] [CrossRef]

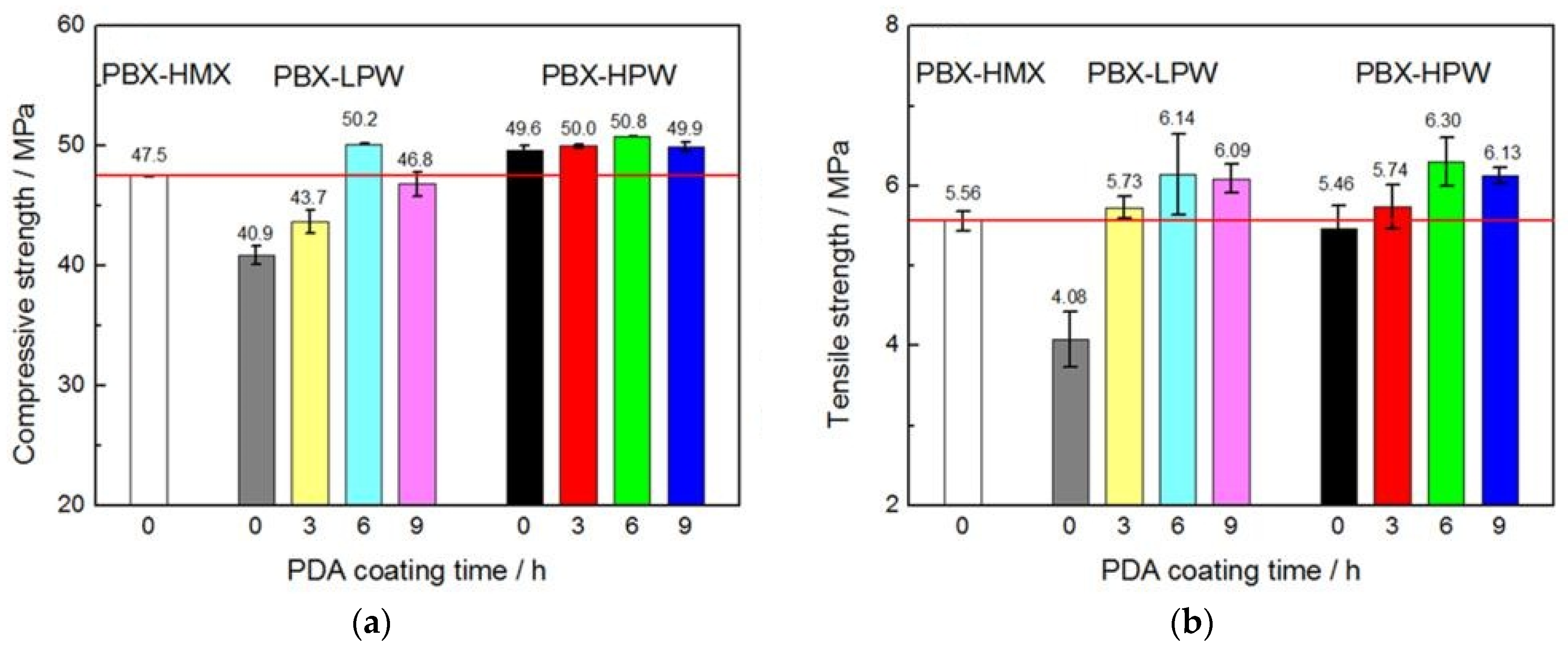

- Lin, C.; Huang, B.; Gong, F.; Yang, Z.; Liu, J.; Zhang, J.; Zeng, C.; Li, Y.; Li, J.; Guo, S. Core@double-shell structured energetic composites with reduced sensitivity and enhanced mechanical properties. ACS Appl. Mater. Interfaces 2019, 11, 30341–30351. [Google Scholar] [CrossRef]

- An, C.W.; Guo, X.D.; Song, X.L.; Wang, Y.; Li, F.S. Preparation and safety of well-dispersed RDX particles coated with cured HTPB. J. Energ. Mater. 2009, 27, 118–132. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, X.; Wu, F.; Yan, T. Preparation of HMX/TATB composite particles using a mechanochemical approach. Propellants Explos. Pyrotech. 2016, 41, 327–333. [Google Scholar] [CrossRef]

- Akiki, M.; Menon, S. A model for hot spot formation in shocked energetic materials. Combust. Flame 2015, 162, 1759–1771. [Google Scholar] [CrossRef]

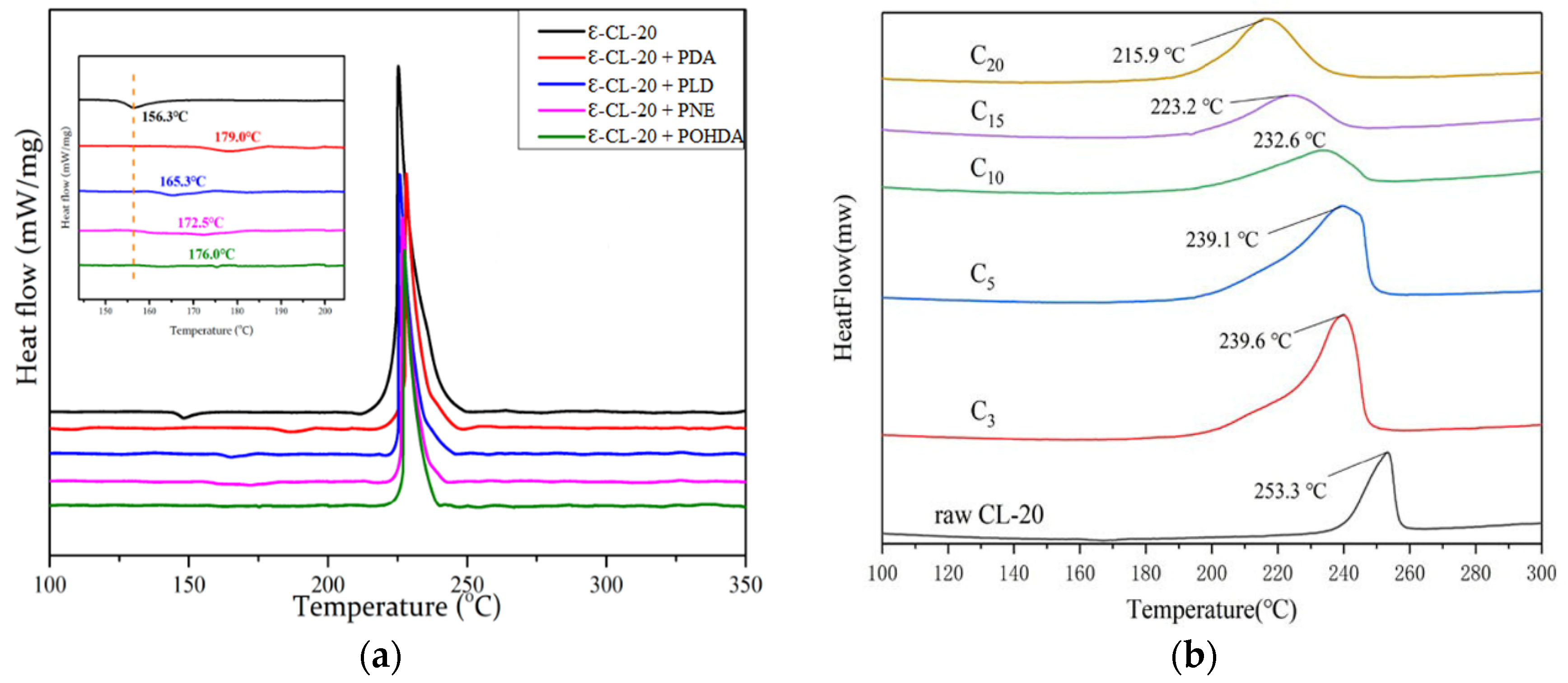

- Huang, B.; Xue, Z.; Chen, S.; Chen, J.; Li, X.; Xu, K.; Yan, Q.L. Stabilization of ε-CL-20 crystals by a minor interfacial doping of polydopamine-coated graphene oxide. Appl. Surf. Sci. 2020, 510, 145454. [Google Scholar] [CrossRef]

- Li, H.; Luo, Y.; Yu, F.; Zhang, H. In-situ construction of MOFs-based superhydrophobic/superoleophilic coating on filter paper with self-cleaning and antibacterial activity for efficient oil/water separation. Colloids Surf. A Physicochem. Eng. Asp. 2021, 625, 126976. [Google Scholar] [CrossRef]

- Mishima, K.; Matsuyama, K.; Tanabe, D.; Yamauchi, S.; Young, T.J.; Johnston, K.P. Microencapsulation of proteins by rapid expansion of supercritical solution with a nonsolvent. AIChE J. 2000, 46, 857–865. [Google Scholar]

- Zhu, W.; Ren, J.; Wang, Z.; Han, D.; Yang, H.; Guo, X. Synthesis of “brain-like” hierarchical porous microspheres by emulsion-solvent evaporation. Mater. Lett. 2015, 155, 130–133. [Google Scholar] [CrossRef]

- Niu, C.; Jin, B.; Peng, R.; Shang, Y.; Liu, Q. Preparation and characterization of insensitive HMX/rGO/G composites via in situ reduction of graphene oxide. RSC Adv. 2017, 7, 32275–32281. [Google Scholar] [CrossRef] [Green Version]

- Rahim, M.A.; Kristufek, S.L.; Pan, S.; Richardson, J.J.; Caruso, F. Phenolic building blocks for the assembly of functional materials. Angew. Chem. Int. Ed. 2019, 58, 1904–1927. [Google Scholar] [CrossRef]

- Yu, Q.; Zhao, C.; Zhu, Q.; Sui, H.; Yin, Y.; Li, J. Influence of polydopamine coating on the thermal stability of 2,6-diamino-3,5-dinitropyrazine-1-oxide explosive under different heating conditions. Thermochim. Acta 2020, 686, 178530. [Google Scholar] [CrossRef]

- Chen, J.; Wang, J.Y.; Wang, B.G.; Huang, H. Study on preparation process of ε-HNIW booster explosive by water slurry method. Chin. J. Explos. Propellants 2009, 32, 28–31. [Google Scholar]

- An, C.; Wang, J.; Xu, W.; Li, F. Preparation and properties of HMX coated with a composite of TNT/energetic material. Propellants Explos. Pyrotech. 2010, 35, 365–372. [Google Scholar] [CrossRef]

- Wang, J.; Ye, B.; An, C.; Wu, B.; Li, H.; Wei, Y. Preparation and properties of surface-coated HMX with viton and graphene oxide. J. Energ. Mater. 2016, 34, 235–245. [Google Scholar] [CrossRef]

- Kasprzyk, D.J.; Bell, D.A.; Flesner, R.L.; Larson, S.A. Characterization of a slurry process used to make a plastic-bonded explosive. Propellants Explos. Pyrotech. 2015, 24, 333–338. [Google Scholar] [CrossRef]

- An, C.W.; Li, F.S.; Song, X.L.; Wang, Y.; Guo, X.D. Surface coating of RDX with a composite of TNT and an energetic-polymer and its safety investigation. Propellants Explos. Pyrotech. 2009, 34, 400–405. [Google Scholar] [CrossRef]

- Yang, Z.; Li, J.; Huang, B.; Liu, S.; Huang, Z.; Nie, F. Preparation and properties study of core-shell CL-20/TATB composites. Propellants Explos. Pyrotech. 2014, 39, 51–58. [Google Scholar] [CrossRef]

- Lin, C.; Gong, F.; Yang, Z.; Pan, L.; Liu, S.; Li, J.; Guo, S. Bio-inspired fabrication of core@shell structured TATB/polydopamine microparticles via in situ polymerization with tunable mechanical properties. Polym. Test. 2018, 68, 126–134. [Google Scholar] [CrossRef]

- Gong, Q.H.; Li, Y.J.; Huang, H.; Zhang, J.; Gao, T.T.; Zhou, G.W. Shape-controlled synthesis of Ni-CeO2@PANI nanocomposites and their synergetic effects on supercapacitors. Chem. Eng. J. 2018, 344, 290–298. [Google Scholar] [CrossRef]

- Lin, C.; Gong, F.; Yang, Z.; Zhao, X.; Li, Y.; Zeng, C.; Li, J.; Guo, S. Core-shell structured HMX@polydopamine energetic microspheres: Synergistically enhanced mechanical, thermal, and safety performances. Polymers 2019, 11, 568. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- He, G.; Li, X.; Bai, L.; Meng, L.; Dai, Y.; Sun, Y.; Zeng, C.; Yang, Z.; Yang, G. Multilevel core-shell strategies for improving mechanical properties of energetic polymeric composites by the “grafting-from” route. Compos. Part B Eng. 2020, 191, 107967. [Google Scholar] [CrossRef]

- Postma, A.; Yan, Y.; Wang, Y.; Zelikin, A.N.; Tjipto, E.; Caruso, F. Self-polymerization of dopamine as a versatile and robust technique to prepare polymer capsules. Chem. Mater. 2009, 21, 3042–3044. [Google Scholar] [CrossRef]

- Zhang, H.; Jiao, Q.; Zhao, W.; Guo, X.; Li, D.; Sun, X. Enhanced crystal stabilities of ε-CL-20 via core-shell structured energetic composites. Appl. Sci. 2020, 10, 2663. [Google Scholar] [CrossRef] [Green Version]

- Zeng, C.; Yang, Z.; Zhang, J.; Li, Y.; Lin, C.; He, G.; Zhao, X.; Liu, S.; Gong, F. Enhanced interfacial and mechanical properties of PBX composites via surface modification on energetic crystals. Polymers 2019, 11, 1308. [Google Scholar] [CrossRef] [Green Version]

- Salaün, F.; Devaux, E.; Bourbigot, S.; Rumeau, P. Influence of process parameters on microcapsules loaded with n-hexadecane prepared by in situ polymerization. Chem. Eng. J. 2009, 155, 457–465. [Google Scholar] [CrossRef]

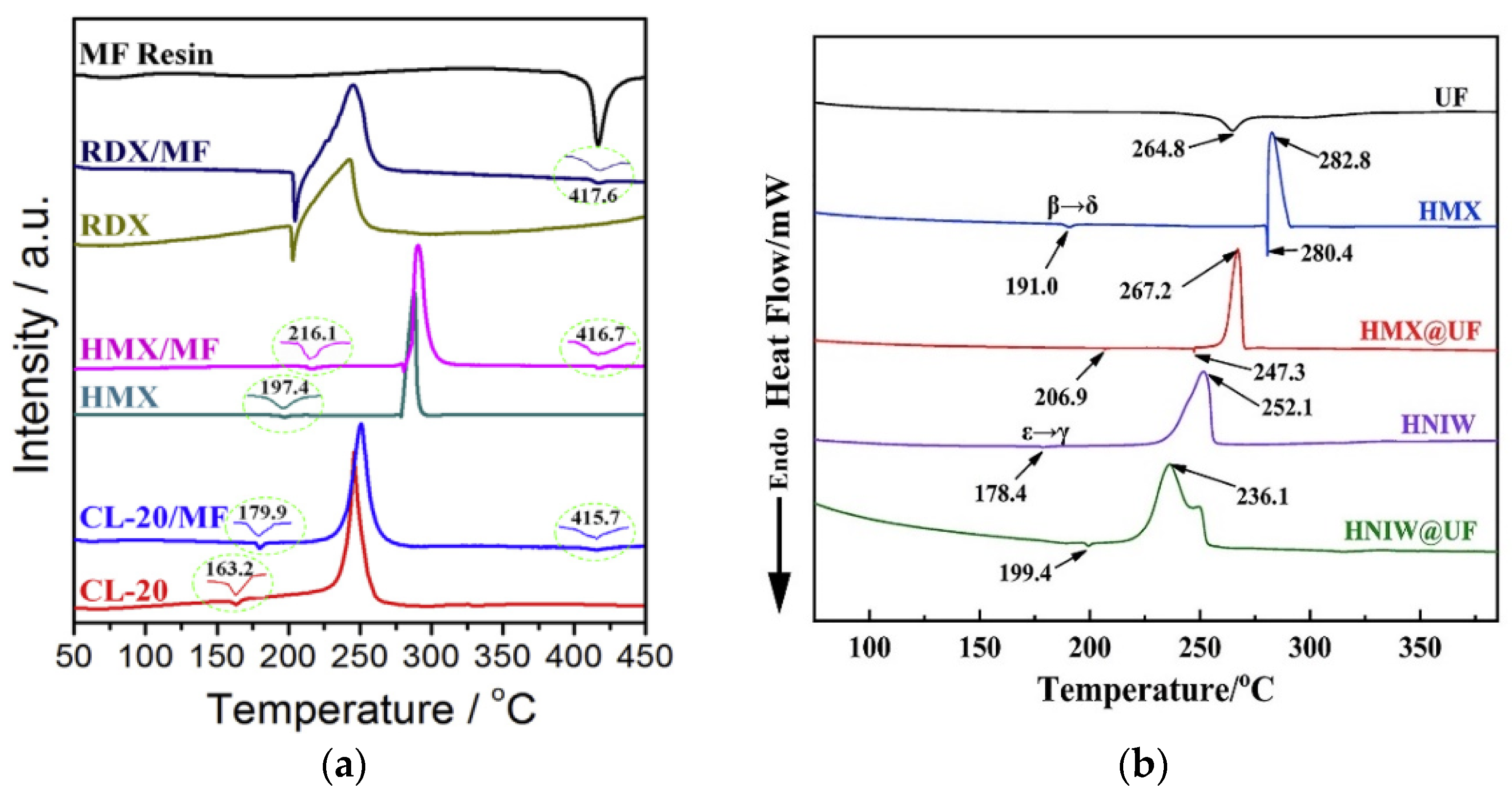

- Yang, Z.; Ding, L.; Wu, P.; Liu, Y.; Nie, F.; Huang, F. Fabrication of RDX, HMX and CL-20 based microcapsules via in situ polymerization of melamine–formaldehyde resins with reduced sensitivity. Chem. Eng. J. 2015, 268, 60–66. [Google Scholar] [CrossRef]

- Zhang, S.; Kou, K.; Zhang, J.; Jia, Q.; Xu, Y. Compact energetic crystals@urea-formaldehyde resin micro-composites with evident insensitivity. Compos. Commun. 2019, 15, 103–107. [Google Scholar] [CrossRef]

- Jia, X.; Wang, J.; Hou, C.; Tan, Y.; Zhang, Y. Effective insensitiveness of melamine urea-formaldehyde resin via interfacial polymerization on nitramine explosives. Nanoscale Res. Lett. 2018, 13, 402. [Google Scholar] [CrossRef] [Green Version]

- Zhang, S.; Gao, Z.; Jia, Q.; Liu, N.; Zhang, J.; Kou, K. Fabrication and characterization of surface modified HMX@PANI core-shell composites with enhanced thermal properties and desensitization via in situ polymerization. Appl. Surf. Sci. 2020, 515, 146042. [Google Scholar] [CrossRef]

- Gong, F.; Zhang, J.; Ding, L.; Yang, Z.; Liu, X. Mussel-inspired coating of energetic crystals: A compact core–shell structure with highly enhanced thermal stability. Chem. Eng. J. 2017, 309, 140–150. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, X.; Gong, F.; Lin, C.; Liu, Y.; Yang, Z.; Nie, F. Multilayer deposition of metal–phenolic networks for coating of energetic crystals: Modulated surface structures and highly enhanced thermal stability. ACS Appl. Energy Mater. 2020, 3, 11091–11098. [Google Scholar] [CrossRef]

- Lin, C.; Zeng, C.; Wen, Y.; Gong, F.; He, G.; Li, Y.; Yang, Z.; Ding, L.; Li, J.; Guo, S. Litchi-like core-shell HMX@HPW@PDA microparticles for polymer-bonded energetic composites with low sensitivity and high mechanical properties. ACS Appl. Mater. Interfaces 2020, 12, 4002–4013. [Google Scholar] [CrossRef] [PubMed]

- Bian, G.Z.; Guo, X.D.; Liu, K.W.; Li, F.S. In-situ crystallization coating HMX by BAMO-THF copolyether. Chin. J. Explos. Propellants 2014, 37, 35–38. [Google Scholar]

- Nandi, A.K.; Ghosh, M. Surface coating of cyclotetramethylenetetranitramine (HMX) crystals with the insensitive high explosive 1,3,5-triamino-2,4,6-trinitrobenzene (TATB). Cent. Eur. J. Energ. Mater. 2012, 2012, 119–130. [Google Scholar]

- Dong, L.Y.; Sheng, D.L.; Chen, L.K.; Zhu, Y.H.; Wang, P.Y.; Liu, L.J. In-situ coating of TATB on CL-20. Initiat. Pyrotech. 2016, 1, 41–44. [Google Scholar]

- Tan, L.; Lu, X.; Liu, N.; Yan, Q.L. Further enhancing thermal stability of thermostable energetic derivatives of dibenzotetraazapentene by polydopamine/graphene oxide coating. Appl. Surf. Sci. 2021, 543, 148825. [Google Scholar] [CrossRef]

- Zeng, G.Y.; Nie, F.D.; Liu, L.; Chen, J.; Huang, H. In-situ crystallization coating HMX by polyurethane. Chin. J. Energ. Mater. 2011, 19, 138–141. [Google Scholar]

- Huang, H.J.; Yang, P.; Huang, H.; Li, J.S. Study on HMX coated by in-situ polymerization. Chin. J. Explos. Propellants 2007, 30, 40–44. [Google Scholar]

- Blank, W.J.; Layman, R.E. Surfactant-Free Polymer Emulsion Coating Composition and Method for Preparing Same. U.S. Patent 4151143, 24 April 1979. [Google Scholar]

- Bayat, Y.; Zarandi, M.; Zarei, M.A.; Soleyman, R.; Zeynali, V. A novel approach for preparation of CL-20 nanoparticles by microemulsion method. J. Mol. Liq. 2014, 193, 83–86. [Google Scholar] [CrossRef]

- Guo, Z.L.; Liu, J.; Li, Y.Y.; Lin, H.F.; Wang, H.; Tam, K.C.; Liu, G.Y. Effects of dispersion techniques on the emulsion polymerization of methyl methacrylate. Colloid Polym. Sci. 2021, 299, 1147–1159. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Z.; Zhang, J.; Pan, L.; Ding, L.; Tian, X.; Zheng, X.; Gong, F. Fabrication and characterization of HMX@TPEE energetic microspheres with reduced sensitivity and superior toughness properties. Compos. Sci. Technol. 2017, 142, 253–263. [Google Scholar] [CrossRef]

- Liao, S.R.; Luo, Y.J.; Sun, J.; Tan, H.M. Preparation of WPU-g-SAN and its coating on HNIW. Chin. J. Energ. Mater. 2012, 20, 155–160. [Google Scholar]

- Wang, J.; An, C.; Ye, B.; Xu, R.; Liu, Q.; Wang, J.; Dong, J. CL-20/CAB energetic composite microspheres prepared by premix membrane emulsification. AIP Adv. 2020, 10, 125005. [Google Scholar] [CrossRef]

- Jia, X.; Xu, L.; Hu, Y.; Li, C.; Geng, X.; Guo, H.; Liu, X.; Tan, Y.; Wang, J. Preparation of agglomeration-free composite energetic microspheres taking PMMA-PVA with honeycomb structure as template via the molecular collaborative self-assembly. J. Energ. Mater. 2020, 39, 182–196. [Google Scholar] [CrossRef]

- Kim, K.J.; Kim, H.S. Coating of energetic materials using crystallization. Chem. Eng. Technol. 2005, 28, 946–951. [Google Scholar] [CrossRef]

- Kim, K.J.; Jung, J.W. Effect of supersaturation on the morphology of coated surface in coating by solution crystallization. Ind. Eng. Chem. Res. 2011, 50, 3475–3482. [Google Scholar]

- Kim, K.J.; Kim, H.S. Agglomeration of NTO on the surface of HMX particles in water-NMP solvent. Cryst. Res. Technol. 2008, 43, 87–92. [Google Scholar] [CrossRef]

- Reinhard, V.; Willard, R.F.; David, L.B. Particle formation in spray drying. J. Aerosol Sci. 2007, 38, 728–746. [Google Scholar]

- Huang, C.; Liu, J.; Ding, L.; Wang, D.; Yang, Z.; Nie, F. Facile fabrication of nanoparticles stacked 2,6-diamino-3,5-dinitropyrazine-1-oxide (LLM-105) sub-microspheres via electrospray deposition. Propellants Explos. Pyrotech. 2017, 43, 188–193. [Google Scholar] [CrossRef]

- Ye, B.Y.; An, C.W.; Wang, J.Y.; Geng, X.H. Formation and properties of HMX-based microspheres via spray drying. RSC Adv. 2017, 7, 35411–35416. [Google Scholar] [CrossRef] [Green Version]

- Qiu, H.; Stepanov, V.; Di Stasio, A.R.; Chou, T.; Lee, W.Y. RDX-based nanocomposite microparticles for significantly reduced shock sensitivity. J. Hazard. Mater. 2011, 185, 489–493. [Google Scholar] [CrossRef]

- Zhang, X.X.; Yang, Z.J.; Nie, F.; Yan, Q.L. Recent advances on the crystallization engineering of energetic materials. Energetic Mater. Front. 2020, 1, 141–156. [Google Scholar] [CrossRef]

- Ma, Z.; Gao, B.; Wu, P.; Shi, J.; Qiao, Z.; Yang, Z.; Yang, G.; Huang, B.; Nie, F. Facile, continuous and large-scale production of core–shell HMX@TATB composites with superior mechanical properties by a spray-drying process. RSC Adv. 2015, 5, 21042–21049. [Google Scholar] [CrossRef]

- Yang, Y.; Li, X.; Zhao, Y.; Han, Y.; Sun, Y.; Wang, J. Preparation and characterization of core–shell structured FOX-7/F2602 PBX with improved thermal stability and reduced sensitivity. AIP Adv. 2021, 11, 025323. [Google Scholar] [CrossRef]

- Lobry, E.; Berthe, J.E.; Hübner, J.; Schnell, F.; Spitzer, D. Tuning the oxygen balance of energetic composites: Crystallization of ADN/secondary explosives mixtures by spray flash evaporation. Propellants Explos. Pyrotech. 2021, 46, 398–412. [Google Scholar] [CrossRef]

- He, G.; Liu, J.; Gong, F.; Lin, C.; Yang, Z. Bioinspired mechanical and thermal conductivity reinforcement of highly explosive-filled polymer composites. Compos. Part A Appl. Sci. Manuf. 2018, 107, 1–9. [Google Scholar] [CrossRef]

- Hou, C.; Zhang, Y.; Chen, Y.; Jia, X.; Tan, Y. Fabrication of ultra-fine TATB/HMX cocrystal using a compound solvent. Propellants Explos. Pyrotech. 2018, 43, 916–922. [Google Scholar] [CrossRef]

- Huang, B.; Hao, X.; Zhang, H.; Yang, Z.; Ma, Z.; Li, H.; Nie, F.; Huang, H. Ultrasonic approach to the synthesis of HMX@TATB core-shell microparticles with improved mechanical sensitivity. Ultrason. Sonochem. 2014, 21, 1349–1357. [Google Scholar] [CrossRef] [PubMed]

- Cocero, M.J.; Martín, Á.; Mattea, F.; Varona, S. Encapsulation and co-precipitation processes with supercritical fluids: Fundamentals and applications. J. Supercrit. Fluids 2009, 47, 546–555. [Google Scholar] [CrossRef]

- He, B.; Stepanov, V.; Qiu, H.; Krasnoperov, L.N. Production and characterization of composite Nano-RDX by RESS co-precipitation. Propellants Explos. Pyrotech. 2015, 40, 659–664. [Google Scholar] [CrossRef]

- He, W.; Liu, P.J.; He, G.Q.; Gozin, M.; Yan, Q.L. Highly reactive metastable intermixed composites (MICs): Preparation and characterization. Adv. Mater. 2018, 30, 1706293. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Y.; Zhou, X.; Xu, J.; Ma, X.; Ye, Y.; Yang, G.; Zhang, K. In situ preparation of explosive embedded CuO/Al/CL-20 nanoenergetic composite with enhanced reactivity. Chem. Eng. J. 2018, 354, 885–895. [Google Scholar] [CrossRef]

- He, W.; Tao, B.; Yang, Z.; Yang, G.; Guo, X.; Liu, P.J.; Yan, Q.L. Mussel-inspired polydopamine-directed crystal growth of core-shell n-Al@PDA@CuO metastable intermixed composites. Chem. Eng. J. 2019, 369, 1093–1101. [Google Scholar] [CrossRef]

- Zhou, X.; Zhu, Y.; Cheng, Z.P.; Ke, X.; Shi, K.W.; Zhang, K.L. Preparation of cyclotrimethylenetrinitramine-copper oxide core-shell particles and their thermal decomposition kinetics. Propellants Explos. Pyrotech. 2019, 44, 1368–1374. [Google Scholar] [CrossRef]

- Wharton, R.K.; Harding, J.A. A study of some factors that affect the impact sensitiveness of liquids determined using the BAM Fall hammer apparatus. J. Hazard. Mater. 1994, 37, 265–276. [Google Scholar] [CrossRef]

- Peterson, P.D.; Idar, D.J. Microstructural differences between virgin and recycled lots of PBX 9502. Propellants Explos. Pyrotech. 2005, 30, 88–94. [Google Scholar] [CrossRef]

- Gao, H.; Hou, X.T.; Ke, X.; Liu, J.; Hao, J.; Xiao, L.; Chen, T.; Zuo, Y.Y.; Jiang, W. Effects of nano-HMX on the properties of RDX-CMDB propellant: Higher energy and lower sensitivity. Def. Technol. 2017, 13, 323–326. [Google Scholar]

- Liu, T.; Geng, C.; Zheng, B.; Li, S.; Luo, G. Encapsulation of cyclotetramethylenetetranitramine (HMX) by electrostatically self-assembled graphene oxide for desensitization. Propellants Explos. Pyrotech. 2017, 42, 1057–1065. [Google Scholar] [CrossRef]

- Willey, T.M.; Lauderbach, L.; Gagliardi, F.; Van Buuren, T.; Glascoe, E.A.; Tringe, J.W.; Lee, J.R.I.; Springer, H.K.; Ilavsky, J. Mesoscale evolution of voids and microstructural changes in HMX-based explosives during heating through the β-δ phase transition. J. Appl. Phys. 2015, 118, 055901. [Google Scholar] [CrossRef]

- Gong, F.; Yang, Z.; Qian, W.; Liu, Y.; Zhang, J.; Ding, L.; Lin, C.; Zeng, C.; Yan, Q. Kinetics for inhibited polymorphic transition of HMX crystal after strong surface confinement. J. Phys. Chem. C 2019, 123, 11011–11019. [Google Scholar] [CrossRef]

- Kubat, J.; Rigdahl, M.; Welander, M. Characterization of interfacial interactions in high density polyethylene filled with glass spheres using dynamic-mechanical analysis. J. Appl. Polym. Sci. 1990, 39, 1527–1539. [Google Scholar] [CrossRef]

- Boddu, V.M.; Viswanath, R.S.; Ghosh, R.K.; Damavarapu, R. 2,4,6-Triamino-1,3,5-trinitrobenzene (TATB) and TATB-based formulations—A review. J. Hazard. Mater. 2010, 181, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Lin, C.; Liu, J.; Huang, Z.; Gong, F.; Li, Y.; Pan, L.; Zhang, J.; Liu, S. Enhancement of creep properties of TATB-based polymer-bonded explosive using styrene copolymer. Propellants Explos. Pyrotech. 2015, 40, 189–196. [Google Scholar] [CrossRef]

- Palmas, P.; Botzanowski, T.; Guerain, M.; Forzy, A.; Bruneton, E.; Delrio, G. Size determination of porosity inclusions in an organic solid material by (1)H NMR diffusion and SEM-FIB experiments: The TATB case. J. Phys. Chem. B 2016, 120, 4152–4159. [Google Scholar] [CrossRef] [PubMed]

- Zeng, C.; Lin, C.; Zhang, J.; Liu, J.; He, G.; Li, Y.; Liu, S.; Gong, F.; Yang, Z. Grafting hyperbranched polyester on the energetic crystals: Enhanced mechanical properties in highly-loaded polymer based composites. Compos. Sci. Technol. 2019, 184, 107842. [Google Scholar] [CrossRef]

- Simpson, R.L.; Urtiew, P.A.; Ornellas, D.L.; Moody, G.L.; Scribner, K.J.; Hoffman, D.M. CL-20 performance exceeds that of HMX and its sensitivity is moderate. Propellants Explos. Pyrotech. 1997, 22, 249–255. [Google Scholar] [CrossRef]

- Li, J.; Brill, T.B. Kinetics of solid polymorphic phase transitions of CL-20. Propellants Explos. Pyrotech. 2007, 32, 326–330. [Google Scholar] [CrossRef]

- Ghosh, M.; Venkatesan, V.; Mandave, S.; Banerjee, S.; Sikder, N.; Sikder, A.K.; Bhattacharya, B. Probing crystal growth of ε- and α-CL-20 polymorphs via metastable phase transition using microscopy and vibrational spectroscopy. Cryst. Growth Des. 2014, 14, 5053–5063. [Google Scholar] [CrossRef]

- Zhang, P.; Xu, J.J.; Guo, X.Y.; Jiao, Q.J.; Zhang, J.Y. Effect of addictives on polymorphic transition of ε-CL-20 in castable systems. J. Therm. Anal. Calorim. 2014, 117, 1001–1008. [Google Scholar] [CrossRef]

- Zheng, X.; Yu, S.; Wen, W.; Wen, Y.; Wang, P.; Lan, L.; Dai, X.; Han, Y.; Li, J.; Li, Y. Sensitivity and phase transition of heated ϵ-CL-20 in drop-weight impact test. Propellants Explos. Pyrotech. 2018, 43, 1164–1170. [Google Scholar] [CrossRef]

- Pan, Q.; Zhang, H.L.; Guo, X.Y.; Zhao, W.J.; Fan, X.K. Effects of different coatings on the crystal transformation of β-HNIW. J. Cryst. Growth 2021, 566–567, 126175. [Google Scholar] [CrossRef]

- Wang, Y.Q.; Li, X.; Chen, S.S.; Ma, X.; Yu, Z.Y.; Jin, S.H.; Li, L.J.; Chen, Y. Preparation and characterization of cyclotrimethylenetrinitramine (RDX) with reduced sensitivity. Materials 2017, 10, 974. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jia, X.; Cao, Q.; Guo, W.; Li, C.; Shen, J.; Geng, X.; Wang, J.; Hou, C. Synthesis, thermolysis, and solid spherical of RDX/PMMA energetic composite materials. J. Mater. Sci. Mater. Electron. 2019, 30, 20166–20173. [Google Scholar] [CrossRef]

- Sun, J.; Huang, H.; Zhang, Y.; Zheng, M.X.; Liu, J.L. In-situ coating of TATB on HMX. Chin. J. Energ. Mater. 2006, 14, 330–332. [Google Scholar]

- Yan, Q.L.; Gozin, M.; Zhao, F.Q.; Cohen, A.; Pang, S.P. High energetic compositions based on functionalized carbon nanomaterials. Nanoscale 2016, 8, 4799–4851. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.; Yang, Z.; Liu, J.; Lin, C.; Zhang, J.; Zheng, X. Enhancing fracture toughness of polymer-based functional energetic composites by filling nano-graphene in matrix. Polym. Compos. 2019, 40, 1151–1161. [Google Scholar] [CrossRef]

| Product | Preparation Methods | Size of Core [Diameter, μm] | Feature | Comments | Contributor |

|---|---|---|---|---|---|

| RDX@TNT/HP-1 | Water suspension | 70 | A coarse and continuous film coating over RDX surface. | Rough surface and nice coating structure could be achieved. Sometimes aggregations exist. | [50] |

| LLM-105@fluoropolymer | Water suspension | 60 | Spherical morphology, rough surface and few agglomerates. | [27] | |

| HMX@TPEE | Emulsion solvent evaporation | 25 | Compact and coherent spherical particles with many tiny holes. | The use of emulsifiers has significant influence on the morphology of microspheres. | [76] |

| CL-20@CAB | Premix membrane emulsification | 78 | Dumbbell-shaped composites with two balls sticking together. | [78] | |

| HMX@TATB | Spray drying | 10–25 | The surface of core–shell composites presented a coarse and continuous morphology. | A highly efficient one-step process to produce core–shell micro-particles. | [88] |

| FOX-7@F2602 | Spray drying | 20–69 | The particle size decreased significantly after coating with the thickness of shell layer about 10–20 nm. | [89] | |

| HMX@NTO | Crystallization coating | 200–300 | NTO crystallized onto the surface of HMX as the nucleation center homogeneously. | The specific crystal morphology and narrow crystal size distribution can be achieved. | [80] |

| HMX@TATB | Ultrasonic | 90–120 | Rough surface and homogeneous coating. | A mild and suitable process to prepare micro-CSEs. Dispersant is commonly used to avoid aggregation. | [93] |

| RDX@VDF-HFP22 | Supercritical encapsulation | Smooth and homogeneous thin film was obtained. | Green production process with high preparation efficiency but few aggregates. | [95] | |

| RDX@CuO | RF magnetron sputtering | CuO covered the RDX particle intimately and uniformly. | [99] |

| Product | Preparation Methods | Shell Content/% | Increment of Phase Transition Temperature/°C | Increment of Peak Decomposition Temperature/°C | Improvement Percentage of H50/% | Improvement Percentage of E50/% | Contributor |

|---|---|---|---|---|---|---|---|

| HMX@PDA | In situ polymerization | 0.5 | 26 | 0.2 | 0 | [64] | |

| HMX@MF | In situ polymerization | 2.9 | 18.7 | 3.2 | 83 | [60] | |

| HMX@UF | In situ polymerization | 4.3 | 15.9 | −15.6 | 246 | [61] | |

| HMX@MUF | In situ polymerization | 5.0 | NA | NA | 240 | [62] | |

| HMX@PANI | In situ polymerization | 3.1 | 17.2 | −2.4 | 189 | [63] | |

| HMX@TPEE | Emulsion solvent evaporation | 5.0 | NA | −1.4 | 57 | [76] | |

| HMX@HPW@PDA | Water suspension and in situ polymerization | 2.0 | 11.3 | 0 | 117 | [66] | |

| RDX@MF | In situ polymerization | 3.0 | 2.7 | 85 | [60] | ||

| RDX@PVAc | Spray drying | 17.0 | NA | 60 (Shock sensitivity) | [86] | ||

| RDX@VMCC | Spray drying | 17.0 | NA | 32 (Shock sensitivity) | [86] | ||

| RDX@PMMA | Water suspension | 3.0 | 0.37 | 35 | [118] | ||

| RDX@PMMA | Emulsion polymerization | 3.0 | 2.38 | 63 | [118] | ||

| CL-20@MF | In situ polymerization | 3.0 | 16.7 | 6.1 | 163 | [60] | |

| CL-20@PDA | In situ polymerization | 1.6 | 22.7 | NA | 0 | [57] | |

| CL-20@UF | In situ polymerization | 3.9 | NA | −16 | 350 | [61] | |

| CL-20@CAB | Premix membrane emulsification | 3.0 | NA | −13.7 | 102 | [78] | |

| HMX@NTO | Crystallization coating | 6.0 | NA | NA | 78 | [80] | |

| RDX@TNT/HP-1 | Water suspension | 2.5/0.5 | 0.6 | 57 | [50] | ||

| HMX@TATB | Ultrasonic | 15 | NA | NA | >348 | [93] | |

| HMX@TATB | Spray drying | 8.0 | NA | NA | >239 | [88] | |

| HMX@TATB | In situ coating | 10.0 | NA | NA | 75 | [119] | |

| CL-20@TATB | Water suspension | 5.0 | NA | NA | 210 | [51] | |

| 35.0 | 10.4 | 0.5 | 272 | ||||

| CL-20@rGO | In situ reduction | 2.0 | 18.48 | 0.5 | 171 | [39] | |

| HMX@Viton | Water suspension | 5.0 | NA | 0.8 | 143 | [48] | |

| HMX@Viton/GO | Water suspension | 4/1 | NA | −0.2 | 237 | [48] | |

| HMX@rGO/G | In situ reduction | 2.0 | NA | −0.2 | 92 | [43] | |

| HMX@MPNs | In situ polymerization | 1.8 | 42.3 | NA | [65] | ||

| RDX@CuO | Vapor deposition | 54 | −24.8 | [99] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duan, B.; Li, J.; Mo, H.; Lu, X.; Xu, M.; Wang, B.; Liu, N. The Art of Framework Construction: Core–Shell Structured Micro-Energetic Materials. Molecules 2021, 26, 5650. https://doi.org/10.3390/molecules26185650

Duan B, Li J, Mo H, Lu X, Xu M, Wang B, Liu N. The Art of Framework Construction: Core–Shell Structured Micro-Energetic Materials. Molecules. 2021; 26(18):5650. https://doi.org/10.3390/molecules26185650

Chicago/Turabian StyleDuan, Binghui, Jiankang Li, Hongchang Mo, Xianming Lu, Minghui Xu, Bozhou Wang, and Ning Liu. 2021. "The Art of Framework Construction: Core–Shell Structured Micro-Energetic Materials" Molecules 26, no. 18: 5650. https://doi.org/10.3390/molecules26185650

APA StyleDuan, B., Li, J., Mo, H., Lu, X., Xu, M., Wang, B., & Liu, N. (2021). The Art of Framework Construction: Core–Shell Structured Micro-Energetic Materials. Molecules, 26(18), 5650. https://doi.org/10.3390/molecules26185650