Tea Bags for Fmoc Solid-Phase Peptide Synthesis: An Example of Circular Economy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Important Issues (Process Generalities)

2.1.1. Quality Practices in Basic Biomedical Research (QPBR)

2.1.2. Security Measures

2.1.3. Waste Disposal

2.1.4. Reaction Flasks and Labeling

2.2. Reagents and Materials for Synthesis

- Polypropylene mesh sheets (catalog number F7221030-72. www.lumiteinc.com (accessed on 25 June 2021)).

- Resin: Fmoc-Rink Amide AM resin (0.55 meq/g).

- Fmoc-Amino Acids: Fmoc-L-Ala-OH. Fmoc-L-Arg(Pbf)-OH. Fmoc-L-Asn(Trt)-OH. Fmoc-L-Asp(OtBu)-OH. Fmoc-L-Cys(Trt)-OH. Fmoc-L-Gln(Trt)-OH. Fmoc-L-Glu(tBu)-OH. Fmoc-L-Gly-OH. Fmoc-L-His(Trt)-OH. Fmoc-L-Ile-OH. Fmoc-L-Leu-OH. Fmoc-L-Lys(Boc)-OH. Fmoc-Met-OH. Fmoc-L-Phe-OH. Fmoc-L-Pro-OH. Fmoc-L-Ser(tBu)-OH. Fmoc-L-Thr(tBu)-OH. Fmoc-L-Trp(Boc)-OH. Fmoc-L-Tyr(tBu)-OH. Fmoc-L-Val-OH.

- Activating reagents: N-[(1H-benzotriazol-1-yl)-(dimethylamino)methylene]-N-methylmethanaminium hexafluorophosphate N-oxide (HBTU). N-[6-chloro(1H-benzotriazol-1-yl)-(dimethylamino)methylene]-N-methylmethanaminium hexafluorophosphate N-oxide (HCTU). N,N′-diisopropylcarbodiimide (DIC) and OxymaPure®.

- Solvents: N,N-dimethylformamide (DMF), 2-propanol (IPA) and dichloromethane (DCM) diethyl ether synthesis grade. Methanol, acetonitrile, ethanol HPLC grade.

- Deprotecting reagent: 4-methylpiperidine (4MP).

- Cleavage Cocktail: trifluoroacetic acid (TFA), triisopropylsilane (TIS), 2.2′-(ethylenedioxy) diethanethiol (DOT); solvents, deprotecting and cleavage reagents were purchased from Merck KGaA (Darmstadt, Germany).

2.3. Required Documentation

2.4. Simultaneous Multiple-Peptide Synthesis “Mise en Place”

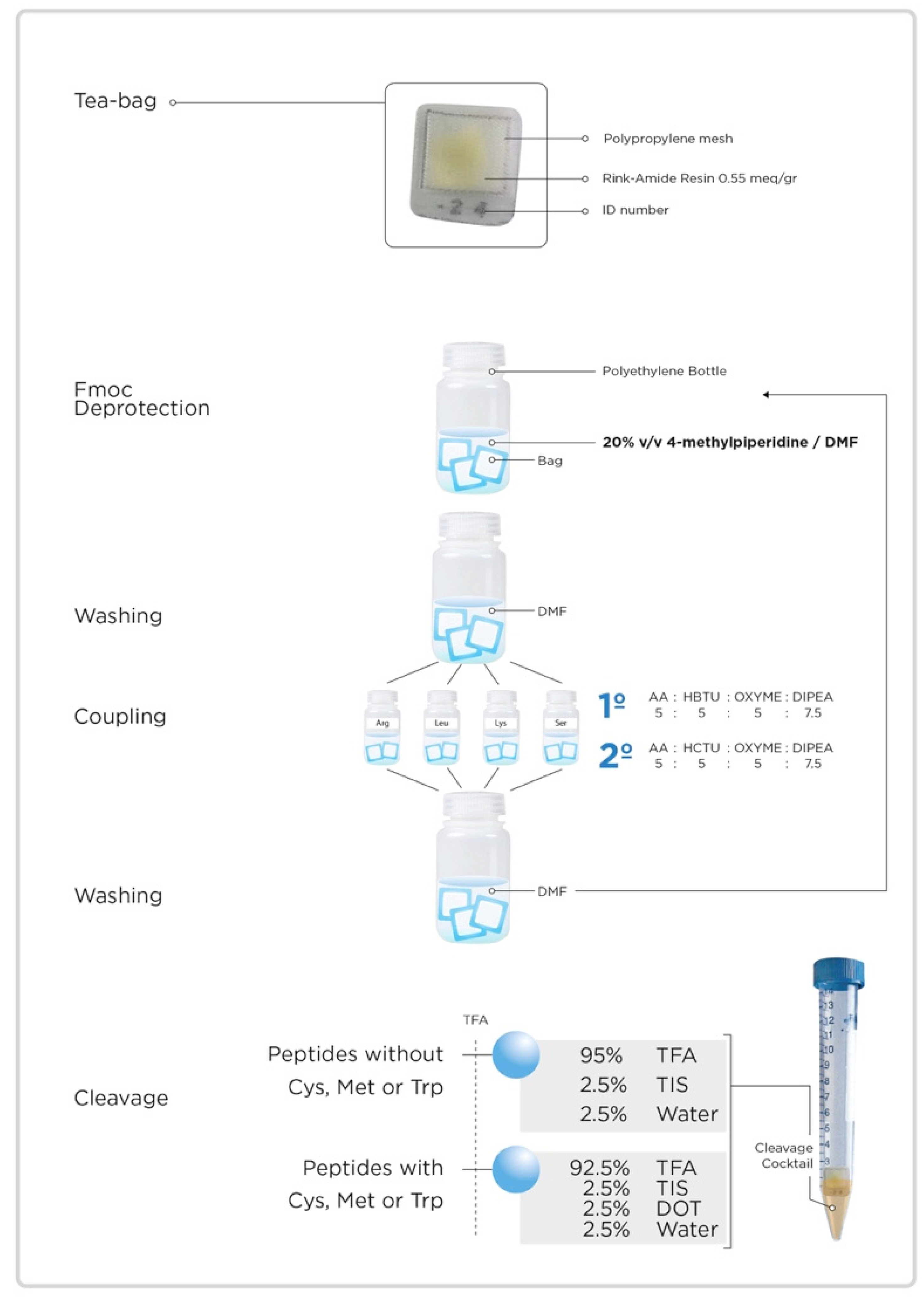

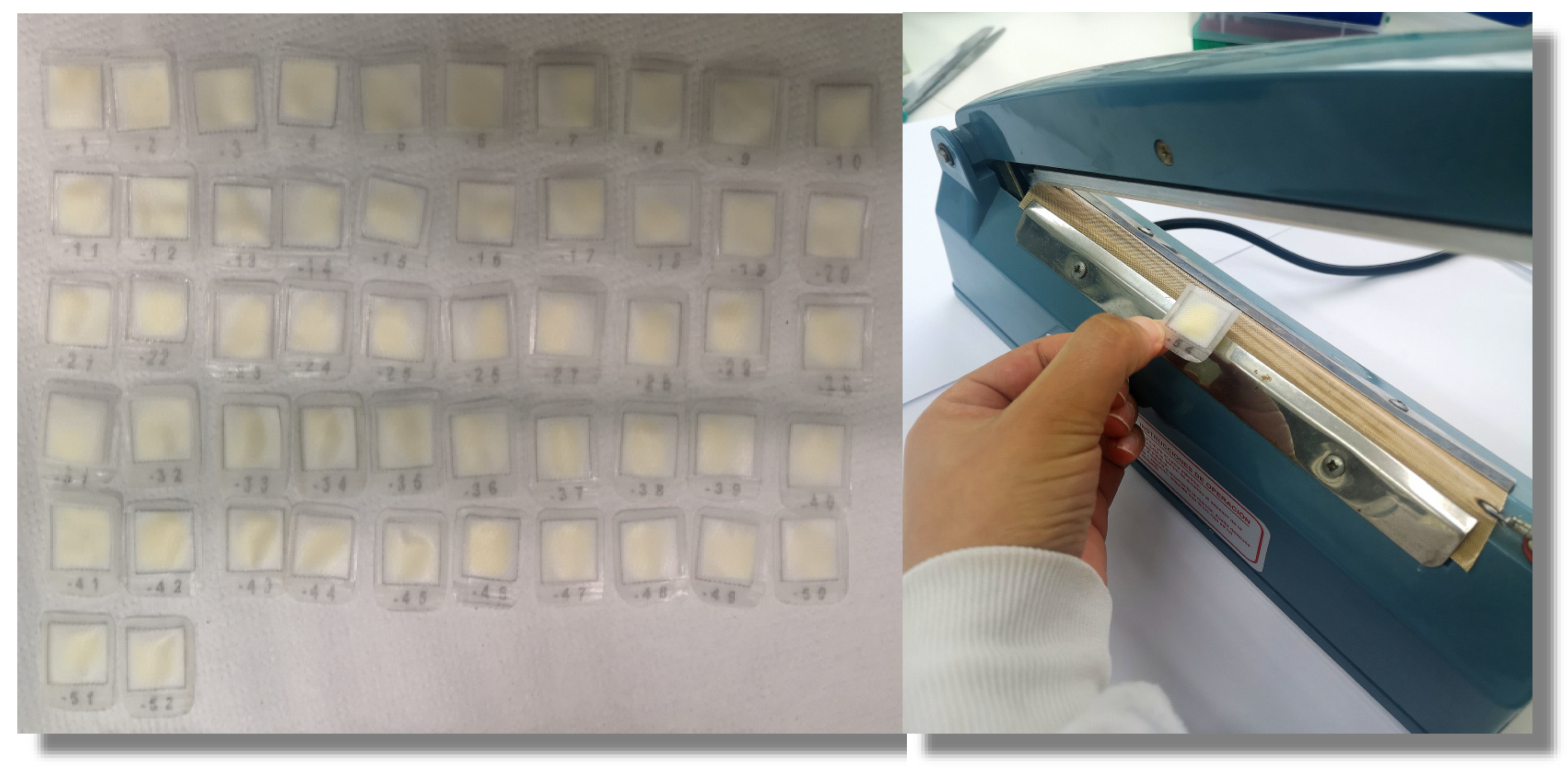

2.4.1. Preparation of Tea Bags

2.4.2. Working Document

2.4.3. Stock Solutions

Stock Amino Acid Solutions

Stock Activator Solutions (HBTU, HCTU)

Deprotection Reagent (4MP)

Coupling Indicator (BMP)

2.5. Synthesis Protocol

2.5.1. Resin Swelling

2.5.2. Initial Deprotection

2.5.3. Coupling Cycle

Deprotection

Single Coupling

Double Coupling

Colorimetric Test

Washing

2.5.4. Final Deprotection and Cleavage

Label and Preparation of the Bags

Preparation of Cleavage Solutions

Cleavage

Peptide Precipitation

2.6. Characterization

2.6.1. Reversed Phase High-Performance Liquid Chromatography (HPLC)

2.6.2. Electrospray Ionization-Mass Spectrometry (ESI-MS)

2.7. Purification

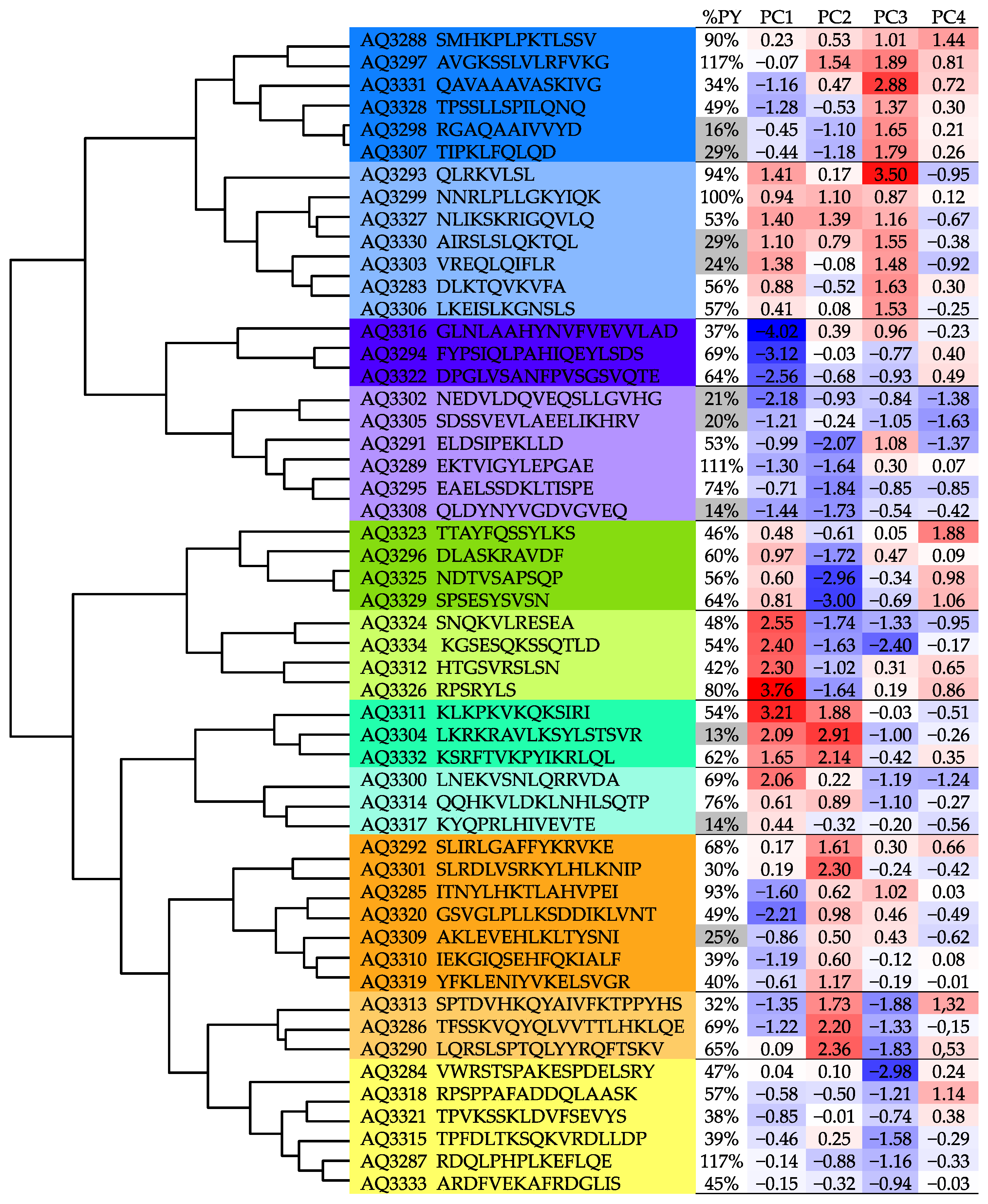

3. Results

3.1. Yield and Purity

3.2. Electrospray Ionization-Mass Spectrometry (ESI-MS)

3.3. Recycling and Reagent Usage

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| 4MP | 4-methylpiperidine |

| ALA | alanine |

| ARG | arginine |

| ASN | asparagine |

| ASP | aspartic acid |

| Boc | tert-butyloxycarbonyl |

| BPB | bromophenol blue |

| Bzl | benzyl |

| CYS | cysteine |

| DCM | dichloromethane |

| DIC | N.N′-diisopropylcarbodiimide |

| DIPEA | N-ethyldiisopropylamine |

| DMF | N.N-dimethylformamide |

| DOT | 2.2′-(ethylenedioxy) diethanethiol |

| ESI-MS | Electrospray Ionization-Mass Spectrometry |

| Fmoc | fluorenylmethoxycarbonyl |

| GLN | glutamine |

| GLU | glutamic acid |

| GLY | glycine |

| QPBR | Quality Practices in Basic Biomedical Research |

| HBTU | N-[(1H-benzotriazol-1-yl)-(dimethylamino)methylene]- N-methylmethanaminium hexafluorophosphate N-oxide |

| HCTU | N-[6-chloro(1H-benzotriazol-1-yl)-(dimethylamino)methylene]- N-methylmethanaminium hexafluorophosphate N-oxide |

| HIS | histidine |

| ILE | isoleucine |

| IPA | 2-propanol |

| LEU | leucine |

| LYS | lysine |

| MET | methionine |

| PHE | phenylalanine |

| PRO | proline |

| PY | peptide yield |

| RP-HPLC | Reversed Phase-High Performance Liquid Chromatography |

| RY | raw peptide yield |

| SER | serine |

| SOPs | Standard Operating Procedures |

| SPPS | solid-phase peptide synthesis |

| tBu | tert-butyl |

| TFA | trifluoroacetic acid |

| THR | threonine |

| TIS | triisopropylsilane |

| TRP | tryptophan |

| Trt | trityl |

| TY | Theoretical yield |

| TYR | tyrosine |

| VAL | valine |

References

- Merrifield, R.B. Solid Phase Peptide Synthesis. I. The Synthesis of a Tetrapeptide. J. Am. Chem. Soc. 1963, 14, 2149–2154. [Google Scholar] [CrossRef]

- Singh, S.K.; Collins, J.M. New Developments in Microwave-Assisted Solid Phase Peptide Synthesis. In Peptide Synthesis; Humana: New York, NY, USA, 2020; pp. 95–109. [Google Scholar]

- Houghten, R.A.; Pinilla, C.; Blondelle, S.E.; Appel, J.R.; Dooley, C.T.; Cuervo, J.H. Generation and use of synthetic peptide combinatorial libraries for basic research and drug discovery. Nature 1991, 354, 84–86. [Google Scholar] [CrossRef]

- Lam, K.S.; Salmon, S.E.; Hersh, E.M.; Hruby, V.J.; Kazmierski, W.M.; Knapp, R.J. A new type of synthetic peptide library for identifying ligand-binding activity. Nature 1991, 354, 82–84. [Google Scholar] [CrossRef] [PubMed]

- Geysen, M.H.; Melent, R.H.; Bartelingt, S.J. Use of peptide synthesis to probe viral antigens for epitopes to a resolution of a single amino acid (antigenic determinant/foot-and-mouth disease virus). Proc. Natl. Acad. Sci. USA 1984, 81, 3998–4002. [Google Scholar] [CrossRef] [Green Version]

- Frank, R.; Doring, R. Simultaneous multiple peptide synthesis under continuous flow conditions on cellulose paper discs as segmental solid supports. Tetrahedron 1988, 44, 6031–6040. [Google Scholar] [CrossRef]

- Houghten, R.A. General method for the rapid solid-phase synthesis of large numbers of peptides: Specificity of antigen-antibody interaction at the level of individual amino acids. Proc. Natl. Acad. Sci. USA 1985, 82, 5131–5135. [Google Scholar] [CrossRef] [Green Version]

- Mueller, L.K.; Baumruck, A.C.; Zhdanova, H.; Tietze, A.A. Challenges and Perspectives in Chemical Synthesis of Highly Hydrophobic Peptides. Front. Bioeng. Biotechnol. 2020, 8, 162. [Google Scholar] [CrossRef] [Green Version]

- Paradís-Bas, M.; Tulla-Puche, J.; Albericio, F. The road to the synthesis of “difficult peptides”. Chem. Soc. Rev. 2016, 45, 631–654. [Google Scholar] [CrossRef]

- Guzmán, F.; Gauna, A.; Luna, O.; Román, T.; Álvarez, C.; Albericio, F.; Cárdenas, C. The tea-bag protocol for comparison of Fmoc removal reagents in solid-phase peptide synthesis. Amino Acids 2020, 52, 1201–1205. [Google Scholar] [CrossRef] [PubMed]

- For Research, U.B.S.P.; in Tropical Diseases, T.; on Quality Practices in Basic Biomedical Research, S.W.G. Handbook : Quality practices in basic biomedical research / prepared for TDR by the Scientific Working Group on Quality Practices in Basic Biomedical Research 2006, TDR/PDE/QPR/05.1. Available online: https://www.who.int/tdr/publications/training-guideline-publications/handbook-quality-practices-biomedical-research/en/ (accessed on 1 August 2021).

- Bakken, S.S.; Suraski, Z.; Schmid, E. PHP Manual: Volume 1; iUniverse: Bloomington, IN, USA, 2000. [Google Scholar]

- El-Faham, A.; Albericio, F. Peptide Coupling Reagents, More than a Letter Soup. Chem. Rev. 2011, 111, 6557–6602. [Google Scholar] [CrossRef] [PubMed]

- Krchňák, V.; Vágner, J.; Lebl, M. Noninvasive continuous monitoring of solid-phase peptide synthesis by acid-base indicator. Int. J. Pept. Protein Res. 2009, 32, 415–416. [Google Scholar] [CrossRef]

- Flegel, M.; Sheppard, R.C. A sensitive, general method for quantitative monitoring of continuous flow solid phase peptide synthesis. J. Chem. Soc. Chem. Commun. 1990, 7, 536–538. [Google Scholar] [CrossRef]

- Osorio, D.; Rondon-Villareal, P.; Torres, R. Peptides: A package for data mining of antimicrobial peptides. R J. 2015, 7, 4–14. [Google Scholar] [CrossRef]

- Rstudio Team RStudio: Integrated Development Environment for R. 2020. RStudio, PBC, Boston, MA. Available online: http://www.rstudio.com/ (accessed on 1 August 2021).

- Intiquilla, A.; Jiménez-Aliaga, K.; Guzmán, F.; Alvarez, C.A.; Zavaleta, A.I.; Izaguirre, V.; Hernández-Ledesma, B. Novel antioxidant peptides obtained by alcalase hydrolysis of Erythrina edulis (pajuro) protein. J. Sci. Food Agric. 2019, 99, 2420–2427. [Google Scholar] [CrossRef] [PubMed]

- Matos, G.; Schmitt, P.; Barreto, C.; Farias, N.; Toledo-Silva, G.; Guzmán, F.; Destoumieux-Garzón, D.; Perazzolo, L.; Rosa, R. Massive Gene Expansion and Sequence Diversification Is Associated with Diverse Tissue Distribution, Regulation and Antimicrobial Properties of Anti-Lipopolysaccharide Factors in Shrimp. Mar. Drugs 2018, 16, 381. [Google Scholar] [CrossRef] [Green Version]

- Guzmán, F.; Wong, G.; Román, T.; Cárdenas, C.; Alvárez, C.; Schmitt, P.; Albericio, F.; Rojas, V. Identification of antimicrobial peptides from the microalgae Tetraselmis suecica (Kylin) Butcher and bactericidal activity improvement. Mar. Drugs 2019, 17, 453. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Carvajal-Rondanelli, P.; Aróstica, M.; Álvarez, C.A.; Ojeda, C.; Albericio, F.; Aguilar, L.F.; Marshall, S.H.; Guzmán, F. Understanding the antimicrobial properties/activity of an 11-residue Lys homopeptide by alanine and proline scan. Amino Acids 2018, 50, 557–568. [Google Scholar] [CrossRef]

- Barrera, N.; Melgarejo, L.; Cruz-Gallego, M.; Cortés, L.; Guzmán, F.; Calvo, J. Conformationally Restricted Peptides from Rice Proteins Elicit Antibodies That Recognize the Corresponding Native Protein in ELISA Assays. Molecules 2018, 23, 2262. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bethke, J.; Rojas, V.; Berendsen, J.; Cárdenas, C.; Guzmán, F.; Gallardo, J.A.; Mercado, L. Development of a new antibody for detecting natural killer enhancing factor (NKEF)-like protein in infected salmonids. J. Fish Dis. 2012, 35, 379–388. [Google Scholar] [CrossRef] [PubMed]

- Álvarez, C.A.; Barriga, A.; Albericio, F.; Romero, M.S.; Guzmán, F. Identification of Peptides in Flowers of Sambucus nigra with Antimicrobial Activity against Aquaculture Pathogens. Molecules 2018, 23, 1033. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Álvarez, C.; Santana, P.; Luna, O.; Cárdenas, C.; Albericio, F.; Romero, M.; Guzmán, F. Chemical Synthesis and Functional Analysis of VarvA Cyclotide. Molecules 2018, 23, 952. [Google Scholar] [CrossRef] [Green Version]

- Al Musaimi, O.; Al Shaer, D.; de la Torre, B.G.; Albericio, F. Green Circular Economy Applied to Peptide Synthesis. Chem. Today 2021, 39, 18–21. [Google Scholar]

| Amino Acid | Reagent | MW (g/mol) | 1 meq (mg) | 5-Fold Excess (mg) | 10-Fold Excess (mg) |

|---|---|---|---|---|---|

| ALA | A | 311.3 | 6.8 | 34.2 | 68.5 |

| ARG | R (Pbf) | 648.8 | 14.3 | 71.4 | 142.7 |

| ASN | N (Trt) | 596.7 | 13.1 | 65.6 | 131.3 |

| ASP | D (tBu) | 411.5 | 9.1 | 45.3 | 90.5 |

| CYS | C (Trt) | 585.7 | 12.9 | 64.4 | 128.9 |

| PHE | F | 387.4 | 8.5 | 42.6 | 85.2 |

| GLY | G | 297.3 | 6.5 | 32.7 | 65.4 |

| GLU | E (tBu) | 443.5 | 9.8 | 48.8 | 97.6 |

| GLN | Q (Trt) | 610.7 | 13.4 | 67.2 | 134.4 |

| HIS | H (Trt) | 619.7 | 13.6 | 68.2 | 136.3 |

| ILE | I | 353.4 | 7.8 | 38.9 | 77.7 |

| LEU | L | 353.4 | 7.8 | 38.9 | 77.7 |

| LYS | K (Boc) | 468.5 | 10.3 | 51.5 | 103.1 |

| MET | M | 371.5 | 8.2 | 40.9 | 81.7 |

| PRO | P | 337.4 | 7.4 | 37.1 | 74.2 |

| SER | S (tBu) | 383.4 | 8.4 | 42.2 | 84.3 |

| TYR | Y (tBu) | 459.6 | 10.1 | 50.6 | 101.1 |

| THR | T (tBu) | 397.5 | 8.7 | 43.7 | 87.5 |

| TRP | W (Boc) | 526.6 | 11.6 | 57.9 | 115.9 |

| VAL | V | 339.4 | 7.5 | 37.3 | 74.7 |

| HBTU | 379.3 | 8.3 | 41.7 | 83.4 | |

| HCTU | 413.69 | 9.1 | 45.5 | 91.0 | |

| TBTU | 321.1 | 7.1 | 35.3 | 70.6 | |

| TCTU | 355.5 | 7.8 | 39.1 | 78.2 | |

| OxymaPure | 142.11 | 3.1 | 15.6 | 31.26 | |

| DIPEA | 129 | 5.7 | 28.7 | 57.37 | |

| DIC | 126.2 | 3.4 | 16.9 | 33.9 | |

| Loading Capacity (LC) | 0.022 | ||||

| Resin Subst. (RS) | 0.55 | (Solid reagents) | |||

| Resin, g | 0.04 | (DIPEA) | |||

| (Liquid reagents) | |||||

| Label | Bag | Sequence | #Residues | MW | Mass Spectrometry Analysis | HLPC Purity | Theoretical Yield (mg) | Experimental Yield (mg) | %RY | %PY | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1+ | M2+ | M3+ | M4+ | M5+ | |||||||||||

| AQ3283 | 1 | DLKTQVKVFA | 10 | 1147.6 | ok | 1148.6 | 575.3 | 383.9 | 288.2 | 230.7 | 77.4 | 27.5 | 19.9 | 72 | 56 |

| AQ3284 | 2 | VWRSTSPAKESPDELSRY | 18 | 2107.3 | ok | 2108.3 | 1055.2 | 703.8 | 528.1 | 422.7 | 56.4 | 50.6 | 42.2 | 83 | 47 |

| AQ3285 | 3 | ITNYLHKTLAHVPEI | 15 | 1748.1 | ok | 1749.1 | 875.55 | 584.0 | 438.3 | 350.8 | 96.6 | 42.0 | 40.4 | 96 | 93 |

| AQ3286 | 4 | TFSSKVQYQLVVTTLHKLQE | 20 | 2348.7 | ok | 2349.7 | 1175.9 | 784.2 | 588.4 | 470.9 | 67.4 | 56.4 | 57.5 | 102 | 69 |

| AQ3287 | 5 | RDQLPHPLKEFLQE | 14 | 1749.0 | ok | 1750.0 | 876.0 | 584.3 | 438.5 | 351,0 | 95.2 | 42.0 | 51.4 | 122 | 117 |

| AQ3288 | 6 | SMHKPLPKTLSSV | 13 | 1423.7 | ok | 1424.7 | 713.35 | 475.9 | 357.2 | 285.9 | 94.9 | 34.2 | 32.6 | 95 | 90 |

| AQ3289 | 7 | EKTVIGYLEPGAE | 13 | 1404.6 | ok | 1405.6 | 703.8 | 469.5 | 352.4 | 282.1 | 83.4 | 33.7 | 45.1 | 134 | 111 |

| AQ3290 | 8 | LQRSLSPTQLYYRQFTSKV | 19 | 2314.7 | ok | 2315.7 | 1158.9 | 772.9 | 579.9 | 464.1 | 73.8 | 55.6 | 49.1 | 88 | 65 |

| AQ3291 | 9 | ELDSIPEKLLD | 11 | 1270.4 | ok | 1271.4 | 636.7 | 424.8 | 318.9 | 255.3 | 48.1 | 30.5 | 33.5 | 110 | 53 |

| AQ3292 | 10 | SLIRLGAFFYKRVKE | 15 | 1826.2 | ok | 1827.2 | 914.6 | 610.1 | 457.8 | 366.4 | 62.2 | 43.8 | 47.8 | 109 | 68 |

| AQ3293 | 11 | QLRKVLSL | 8 | 955.2 | ok | 956.2 | 479.1 | 319.7 | 240.1 | 192.2 | 58.8 | 22.9 | 18.4 | 80 | 47 |

| AQ3294 | 12 | FYPSIQLPAHIQEYLSDS | 18 | 2107.3 | ok | 2108.3 | 1055.2 | 703.8 | 528.1 | 422.8 | 77.2 | 50.6 | 45.3 | 90 | 69 |

| AQ3295 | 13 | EAELSSDKLTISPE | 14 | 1517.6 | ok | 1518.6 | 760.3 | 507.2 | 380.7 | 304.7 | 85.3 | 36.4 | 31.5 | 87 | 74 |

| AQ3296 | 14 | DLASKRAVDF | 10 | 1120.3 | ok | 1121.3 | 561.7 | 374.8 | 281.3 | 225.3 | 49.9 | 26.9 | 32.1 | 120 | 60 |

| AQ3297 | 15 | AVGKSSLVLRFVKG | 14 | 1459.8 | ok | 1460.8 | 731.4 | 487.9 | 366.2 | 293.2 | 97.4 | 35.0 | 41.9 | 120 | 117 |

| AQ3298 | 16 | RGAQAAIVVYD | 11 | 1161.3 | ok | 1162.3 | 582.2 | 388.4 | 291.6 | 233.5 | 19.1 | 27.9 | 23.5 | 84 | 16 |

| AQ3299 | 17 | NNRLPLLGKYIQK | 13 | 1555.9 | ok | 1556.9 | 779.5 | 520.0 | 390.2 | 312.4 | 78.8 | 37.3 | 47.5 | 127 | 100 |

| AQ3300 | 18 | LNEKVSNLQRRVDA | 14 | 1640.8 | ok | 1641.8 | 821.9 | 548.3 | 411.5 | 329.4 | 69.7 | 39.4 | 38.7 | 98 | 69 |

| AQ3301 | 19 | SLRDLVSRKYLHLKNIP | 18 | 2051.5 | ok | 2052.5 | 1027.3 | 685.2 | 514.1 | 411.5 | 52.5 | 49.2 | 28.3 | 57 | 30 |

| AQ3302 | 20 | NEDVLDQVEQSLLGVHG | 17 | 1851.0 | ok | 1852.0 | 927.0 | 618.3 | 464.0 | 371.4 | 64.0 | 44.4 | 14.3 | 32 | 21 |

| AQ3303 | 21 | VREQLQIFLR | 10 | 1300.6 | ok | 1301.6 | 651.8 | 434.9 | 326.4 | 261.3 | 50.1 | 31.2 | 14.9 | 48 | 24 |

| AQ3304 | 22 | LKRKRAVLKSYLSTSVR | 17 | 2004.4 | ok | 2005.4 | 1003.7 | 669.5 | 502.4 | 402.1 | 38.5 | 48.1 | 16.2 | 34 | 13 |

| AQ3305 | 23 | SDSSVEVLAEELIKHRV | 17 | 1910.1 | ok | 1911.1 | 956.6 | 638.0 | 478.8 | 383.2 | 72.5 | 45.8 | 12.7 | 28 | 20 |

| AQ3306 | 24 | LKEISLKGNSLS | 12 | 1287.5 | ok | 1288.5 | 645.3 | 430.5 | 323.1 | 258.7 | 81.9 | 30.9 | 21.4 | 69 | 57 |

| AQ3307 | 25 | TIPKLFQLQD | 10 | 1204.4 | ok | 1205.4 | 603.7 | 402.8 | 302.4 | 242.1 | 57.3 | 28.9 | 14.7 | 51 | 29 |

| AQ3308 | 26 | QLDYNYVGDVGVEQ | 14 | 1597.7 | ok | 1598.7 | 800.4 | 533.9 | 400.7 | 320.8 | 30.9 | 38.3 | 16.9 | 44 | 14 |

| AQ3309 | 27 | AKLEVEHLKLTYSNI | 15 | 1758.0 | ok | 1759.0 | 880.5 | 587.3 | 440.8 | 352.8 | 46.1 | 37.8 | 20.6 | 55 | 25 |

| AQ3310 | 28 | IEKGIQSEHFQKIALF | 16 | 1887.2 | ok | 1888.2 | 945.1 | 630.4 | 473.1 | 378.7 | 83.4 | 45.3 | 21.0 | 46 | 39 |

| AQ3311 | 29 | KLKPKVKQKSIRI | 13 | 1565.0 | ok | 1566.0 | 784.0 | 523.0 | 392.5 | 314.2 | 95.0 | 37.6 | 21.5 | 57 | 54 |

| AQ3312 | 30 | HTGSVRSLSN | 10 | 1056.3 | ok | 1057.3 | 529.7 | 353.4 | 265.3 | 212.5 | 48.3 | 25.4 | 22.1 | 87 | 42 |

| AQ3313 | 31 | SPTDVHKQYAIVFKTPPYHS | 20 | 2401.8 | ok | 2402.8 | 1202.4 | 801.9 | 601.7 | 481.6 | 78.7 | 55.6 | 22.3 | 40 | 32 |

| AQ3314 | 32 | QQHKVLDKLNHLSQTP | 16 | 1590.0 | ok | 1591.0 | 796.5 | 531.3 | 398.8 | 319.2 | 97.5 | 45.2 | 35.5 | 78 | 76 |

| AQ3315 | 33 | TPFDLTKSQKVRDLLDP | 17 | 1972.3 | ok | 1973.3 | 987.7 | 658.8 | 494.3 | 395.7 | 75.5 | 47.3 | 24.4 | 52 | 39 |

| AQ3316 | 34 | GLNLAAHYNVFVEVVLAD | 18 | 1943.2 | No * | 1944.2 | 973.1 | 649.1 | 487.1 | 389.8 | 87.0 | 46.6 | 19.8 | 42 | 37 |

| AQ3317 | 35 | KYQPRLHIVEVTE | 13 | 1610.9 | No ** | 1611.9 | 806.9 | 538.3 | 404.0 | 323.4 | 37.2 | 38.7 | 14.7 | 38 | 14 |

| AQ3318 | 36 | RPSPPAFADDQLAASK | 16 | 1669.8 | ok | 1670.8 | 836.4 | 557.9 | 418.7 | 335.2 | 72.8 | 40.1 | 31.4 | 78 | 57 |

| AQ3319 | 37 | YFKLENIYVKELSVGR | 16 | 1958.5 | ok | 1959.5 | 980.8 | 654,2 | 490.9 | 392.9 | 40.4 | 47.0 | 46.9 | 100 | 40 |

| AQ3320 | 38 | GSVGLPLLKSDDIKLVNT | 18 | 1869.5 | ok | 1870.5 | 936.3 | 624.5 | 468.6 | 375.1 | 46.8 | 44.9 | 46.9 | 105 | 49 |

| AQ3321 | 39 | TPVKSSKLDVFSEVYS | 16 | 1786.1 | ok | 1787.1 | 894.6 | 596.7 | 447.8 | 358.4 | 55.1 | 42.9 | 29.4 | 68 | 38 |

| AQ3322 | 40 | DPGLVSANFPVSGSVQTE | 18 | 1801.8 | ok | 1802.8 | 902.4 | 601.9 | 451.7 | 361.6 | 98.8 | 43.2 | 28.2 | 65 | 64 |

| AQ3323 | 41 | TTAYFQSSYLKS | 12 | 1394.6 | ok | 1395.6 | 698.8 | 466.2 | 349.9 | 280.1 | 68.2 | 33.5 | 22.4 | 67 | 46 |

| AQ3324 | 42 | SNQKVLRESEA | 11 | 1259.6 | ok | 1260.6 | 631.3 | 421.2 | 316.2 | 253.1 | 56.4 | 30.2 | 25.8 | 85 | 48 |

| AQ3325 | 43 | NDTVSAPSQP | 10 | 1014.5 | ok | 1015.5 | 508.8 | 339.5 | 254.9 | 204.1 | 68.7 | 24.3 | 19.9 | 82 | 56 |

| AQ3326 | 44 | RPSRYLS | 7 | 877.5 | ok | 878.5 | 440.3 | 293.8 | 220.6 | 176.7 | 90.2 | 21.1 | 18.8 | 89 | 80 |

| AQ3327 | 45 | NLIKSKRIGQVLQ | 13 | 1495.9 | ok | 1496.9 | 749.5 | 500.0 | 375.2 | 300.4 | 92.4 | 35.9 | 20.5 | 57 | 53 |

| AQ3328 | 46 | TPSSLLSPILQNQ | 13 | 1396.7 | ok | 1397.7 | 699.9 | 466.9 | 350.4 | 280.5 | 71.3 | 33.5 | 22.8 | 68 | 49 |

| AQ3329 | 47 | SPSESYSVSN | 10 | 1055.4 | ok | 1056.4 | 529.2 | 353.1 | 265.1 | 212.3 | 81.0 | 25.3 | 20.0 | 79 | 64 |

| AQ3330 | 48 | AIRSLSLQKTQL | 12 | 1356.8 | ok | 1357.8 | 679.9 | 453.6 | 340.5 | 272.6 | 33.4 | 32.6 | 28.0 | 86 | 29 |

| AQ3331 | 49 | QAVAAAVASKIVG | 13 | 1183.7 | ok | 1184.7 | 593.4 | 395.9 | 297.2 | 237.9 | 45.2 | 28.4 | 21.3 | 75 | 34 |

| AQ3332 | 50 | KSRFTVKPYIKRLQL | 15 | 1876.1 | ok | 1877.1 | 939.5 | 626.7 | 470.3 | 376.4 | 53.1 | 45.0 | 52.6 | 117 | 62 |

| AQ3333 | 51 | ARDFVEKAFRDGLIS | 15 | 1722.9 | ok | 1723.9 | 862.9 | 575.6 | 432.0 | 345.8 | 63.3 | 41.3 | 29.2 | 71 | 45 |

| AQ3334 | 52 | KGSESQKSSQTLD | 13 | 1393.7 | ok | 1394.7 | 698.4 | 465.9 | 349.7 | 279.9 | 54.4 | 33.4 | 33.5 | 100 | 54 |

| Cluster | PC | Original Variable |

|---|---|---|

| 1 | PC3 | Hidrophobicity/Boman |

| 2 | PC3–PC1 | Aliphatic index |

| 3 | PC1 | Hidrophobicity/Aliphatic index |

| 4 | PC1–PC2 | Charge/pI |

| 5 | PC1–PC2 | Charge/Aliphatic Index |

| 6 | PC1 | Hidrophobicity |

| 7 | PC1 | Charge/Hidrophobicity |

| 8 | PC1–PC3 | Boman/Hidrophobicity |

| 9 | PC1–PC2 | pI/Charge |

| 10 | PC2–PC3 | Size |

| 11 | PC3 | Aliphatic index |

| Item | Tea Bag Recycling | Tea Bag No Recycling | Individual Reactor |

|---|---|---|---|

| mL | mL | mL | |

| DMF | 5000 | 9000 | 6240 |

| DCM | 1000 | 2000 | 2500 |

| IPA | 1000 | 1000 | 1250 |

| 4MP | 140 | 280 | 750 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guzmán, F.; Gauna, A.; Roman, T.; Luna, O.; Álvarez, C.; Pareja-Barrueto, C.; Mercado, L.; Albericio, F.; Cárdenas, C. Tea Bags for Fmoc Solid-Phase Peptide Synthesis: An Example of Circular Economy. Molecules 2021, 26, 5035. https://doi.org/10.3390/molecules26165035

Guzmán F, Gauna A, Roman T, Luna O, Álvarez C, Pareja-Barrueto C, Mercado L, Albericio F, Cárdenas C. Tea Bags for Fmoc Solid-Phase Peptide Synthesis: An Example of Circular Economy. Molecules. 2021; 26(16):5035. https://doi.org/10.3390/molecules26165035

Chicago/Turabian StyleGuzmán, Fanny, Adriana Gauna, Tanya Roman, Omar Luna, Claudio Álvarez, Claudia Pareja-Barrueto, Luis Mercado, Fernando Albericio, and Constanza Cárdenas. 2021. "Tea Bags for Fmoc Solid-Phase Peptide Synthesis: An Example of Circular Economy" Molecules 26, no. 16: 5035. https://doi.org/10.3390/molecules26165035

APA StyleGuzmán, F., Gauna, A., Roman, T., Luna, O., Álvarez, C., Pareja-Barrueto, C., Mercado, L., Albericio, F., & Cárdenas, C. (2021). Tea Bags for Fmoc Solid-Phase Peptide Synthesis: An Example of Circular Economy. Molecules, 26(16), 5035. https://doi.org/10.3390/molecules26165035