Stabilization Effects of Natural Compounds and Polyhedral Oligomeric Silsesquioxane Nanoparticles on the Accelerated Degradation of Ethylene-Propylene-Diene Monomer

Abstract

:1. Introduction

2. Results

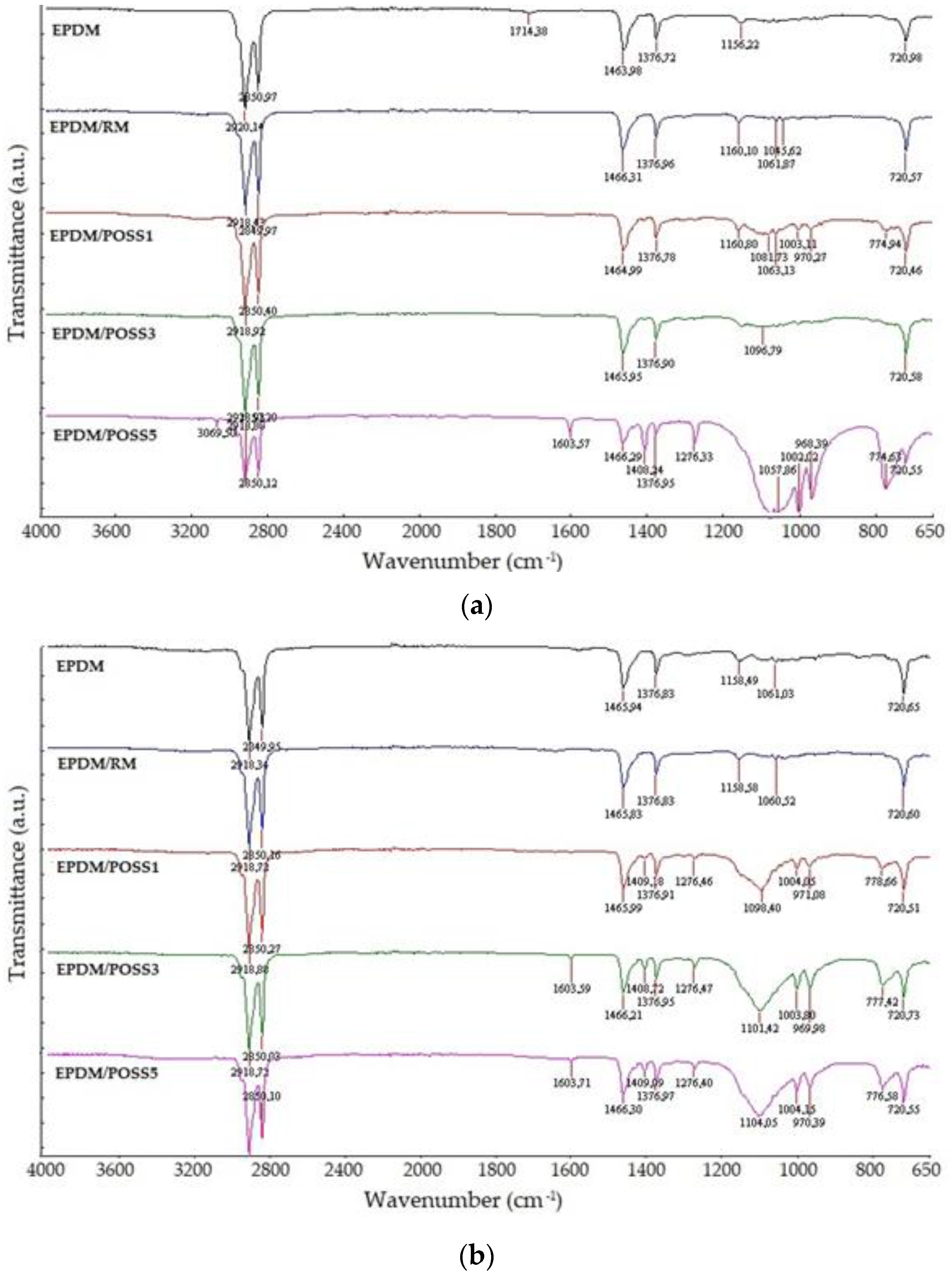

2.1. FTIR

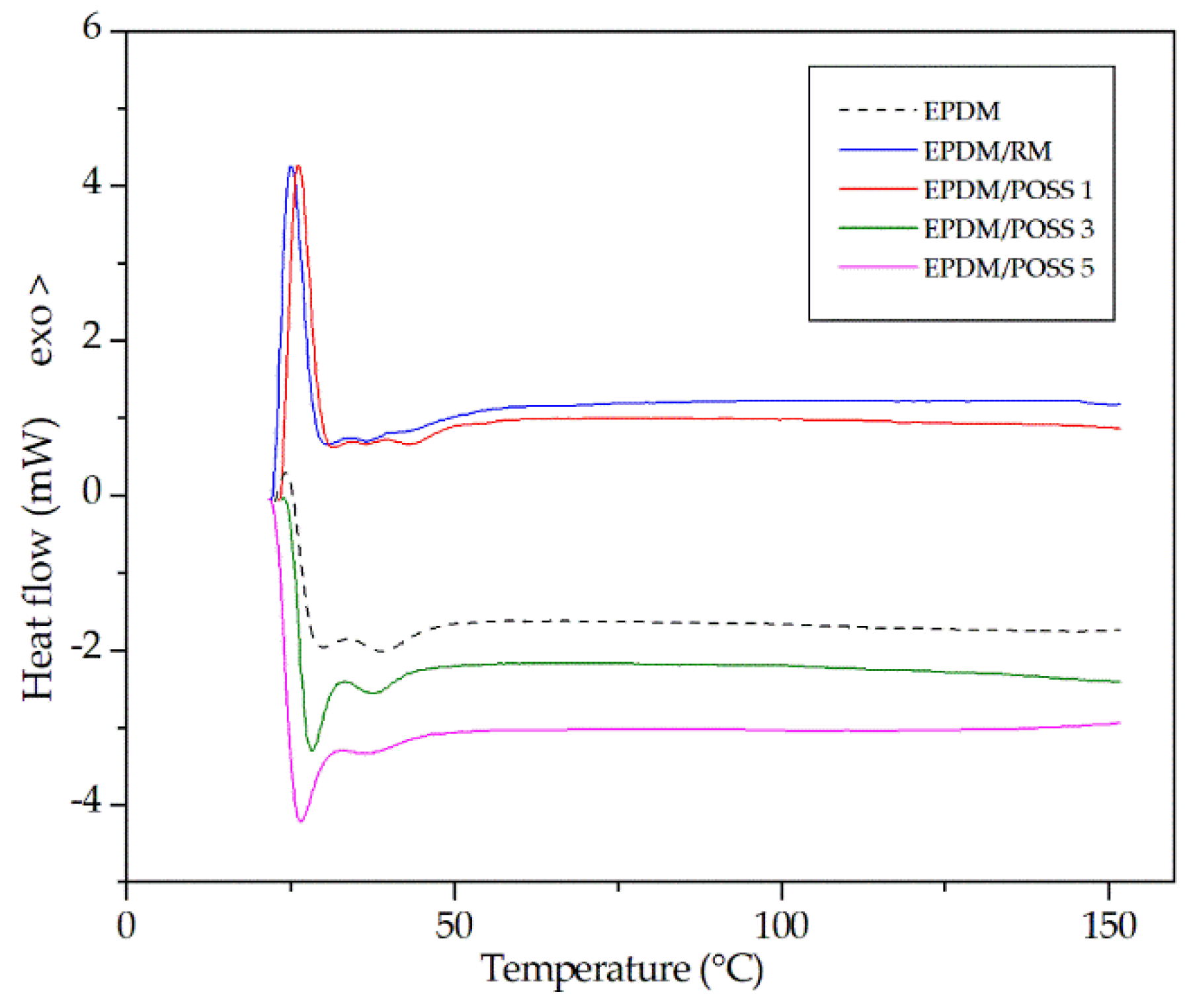

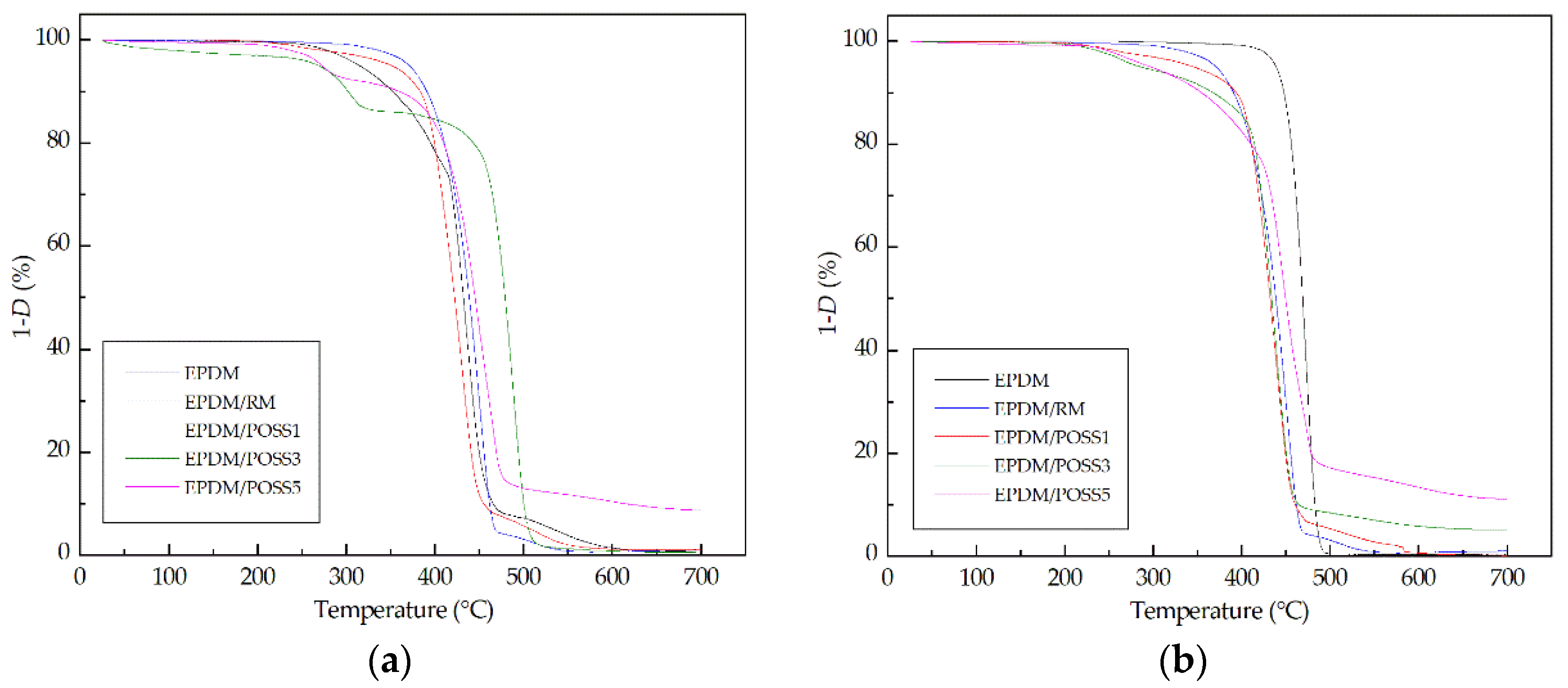

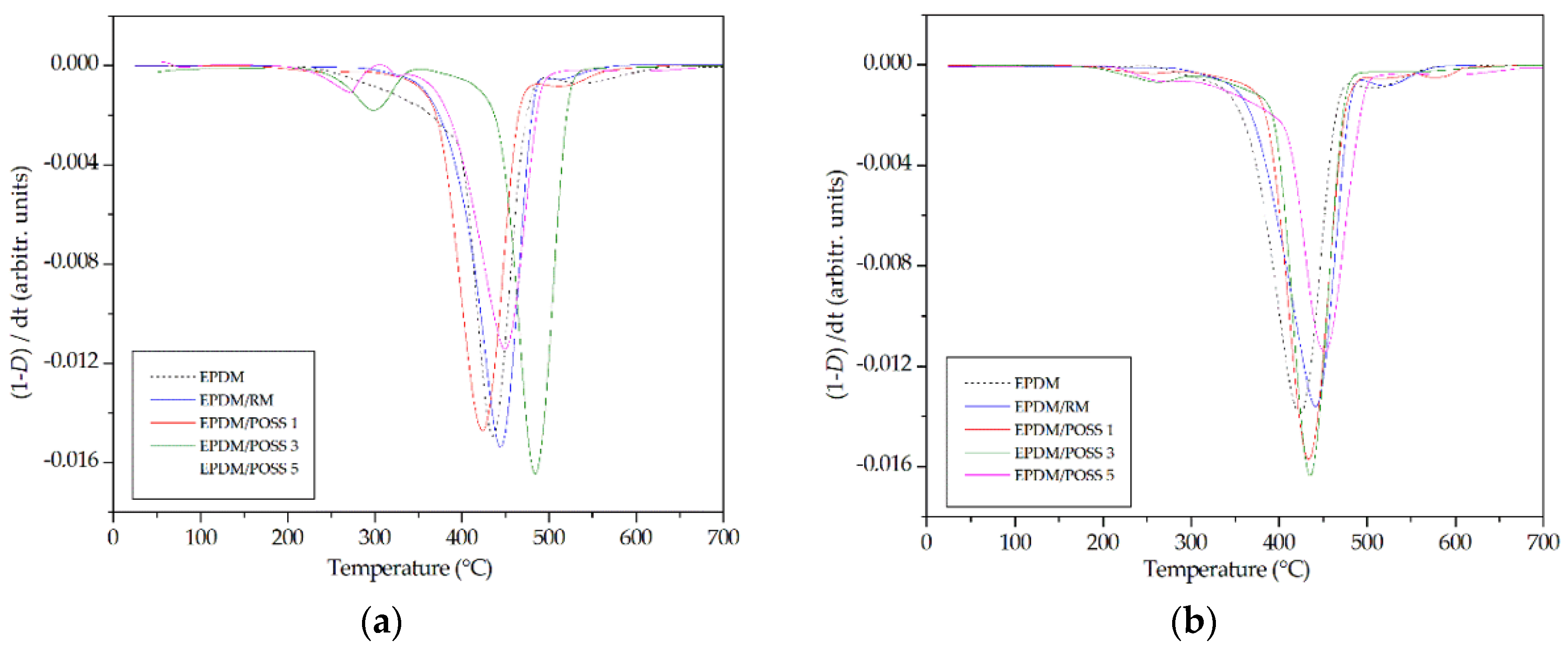

2.2. Thermal Behaviour

- The presence of rosemary and POSS at 1% enhances the resistance to the thermal degradation, as testified by the increase in T5% values, which was more pronounced for the non-irradiated samples (about 60 and 40 °C, respectively) than for irradiated ones (10 and 7 °C, respectively).

- On increasing the POSS amount in the composites a dramatic decrease in T5% was observed for the composites with POSS at 3 and 5 phr respectively, probably due to aggregation phenomena that reduce the ability to be dispersed in the matrix of POSS molecules.

- the EPDM composites with 3 and 5 phr of POSS presented at the end of TGA a solid residue at 700°C being increased as a function of the filler amount in the hybrid composite. FTIR analysis was carried out on the solid residue showing the typical band associated with the presence of silica [44,45]. The presence of this residue at the end of the experiment confirmed the poor interaction with the matrix as POSS content increases.

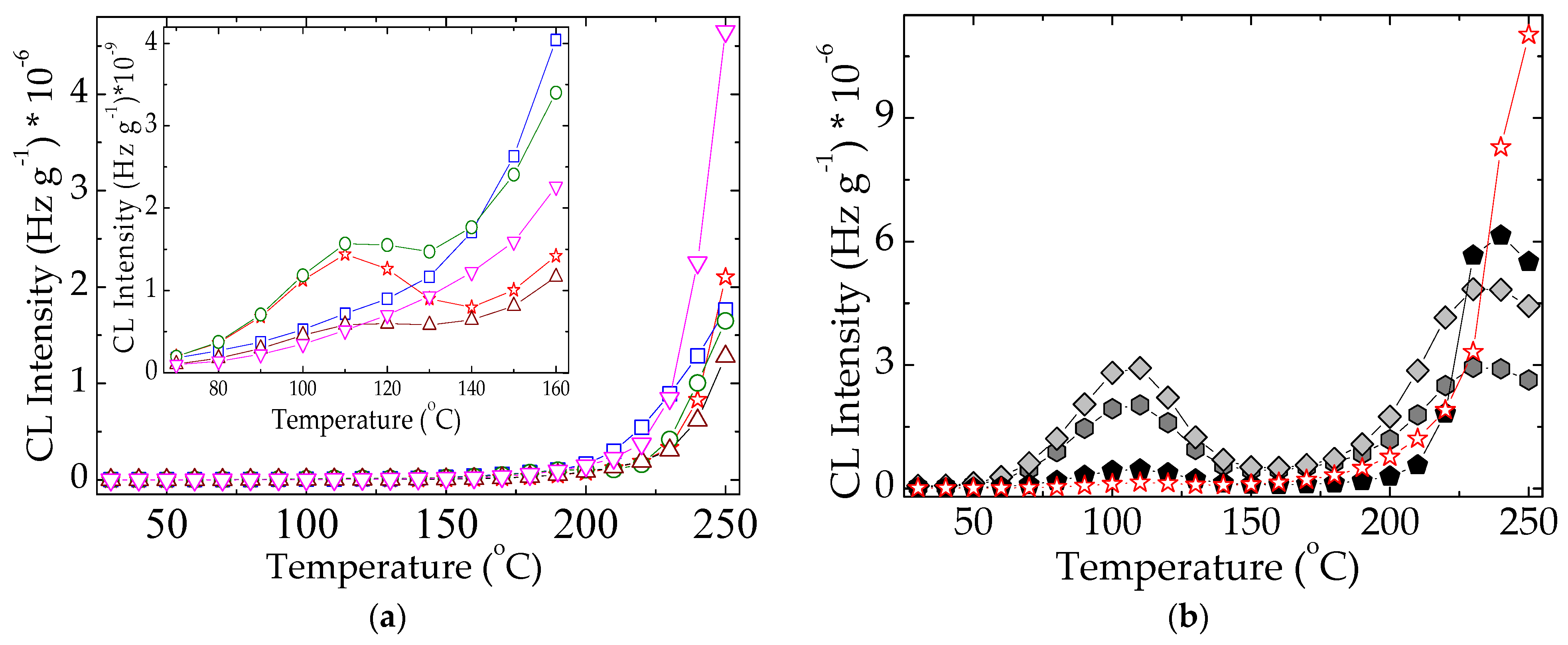

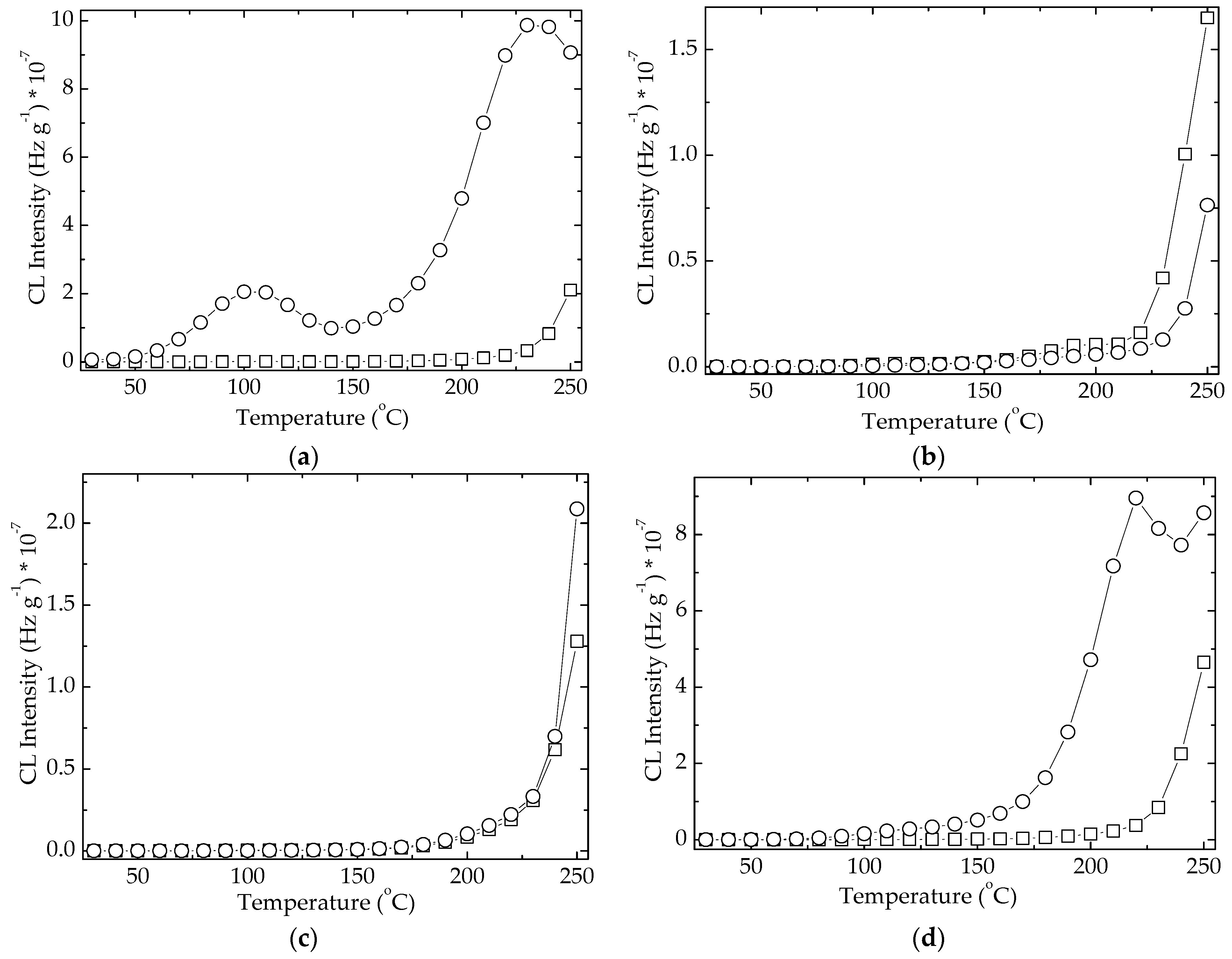

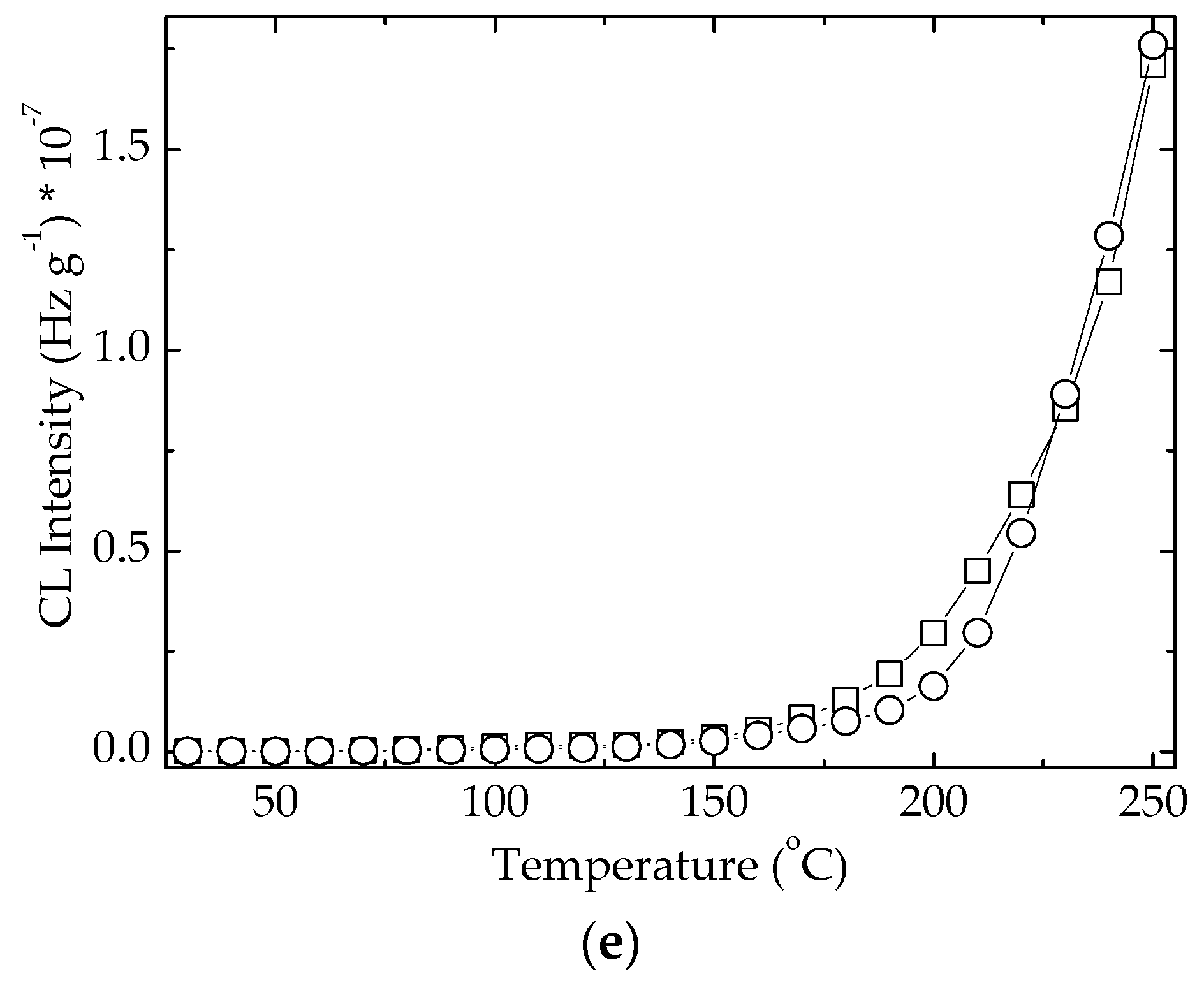

2.3. Chemiluminescence Investigation

Pristine EPDM Formulations

3. Discussion

4. Materials and Methods

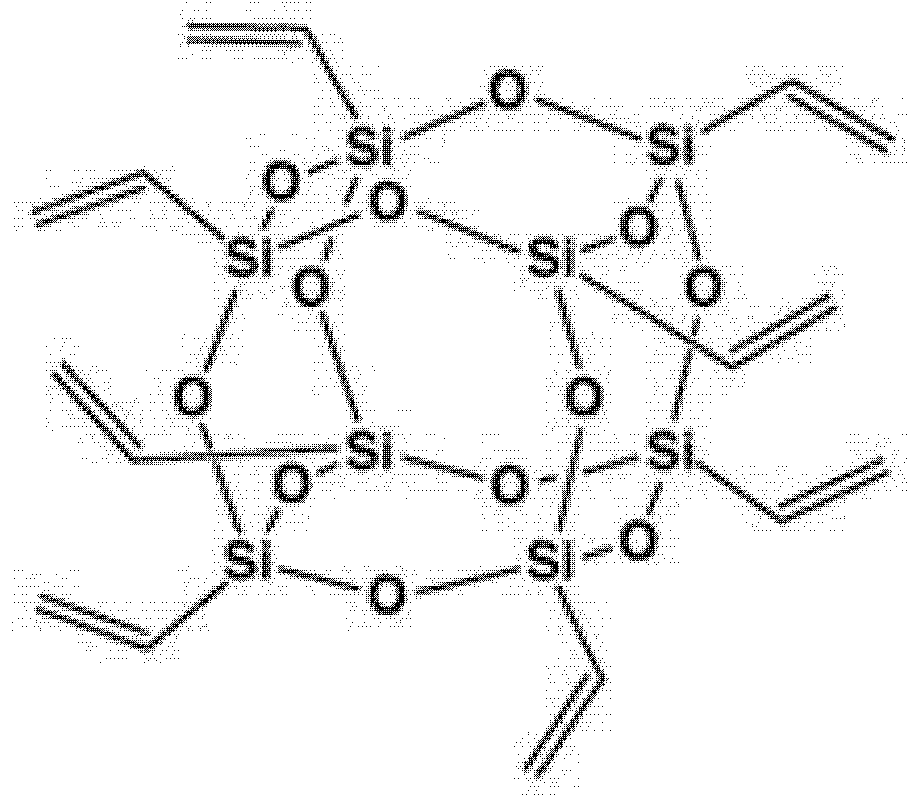

4.1. Materials

4.2. Sample Preparaton and Irradiation

4.3. FTIR Analysis

4.4. Differential Scanning Calorimetry (DSC)

4.5. Thermogravimetric Analysis (TGA)

4.6. Chemiluminescence (CL)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Sample Availability

References

- Xie, J.; VanAlstyne, V.; Uhlir, A.; Yang, X.Q. A review of rosemary as a natural antioxidative solution. Eur. J. Lipid Sci. Technol. 2017, 119, 1600439. [Google Scholar] [CrossRef]

- Munekata, P.E.S.; Alcántara, C.; Žugčić, T.; Abdelkebir, R.; Collado, M.C.; García-Pérez, J.V.; Reźek Jambrak, A.; Gavahian, M.; Barba, F.J.; Lorenzo, J.M. Impact of ultrasound-assisted extraction and solvent composition on bioactive compounds and in vitro biological activities of thyme and rosemary. Food Res. Int. 2020, 134, 109242. [Google Scholar] [CrossRef]

- Mariş, M.; Mariş, D.A.; Jipa, S.; Zaharescu, T.; Gorghiu, L.M. Radio-protective potential of rosemary (Rosmarinus officinalis) against effects of ionizing radiation. Rev. Chim. (Buchar.) 2010, 47, 281–292. [Google Scholar]

- Eskandarabadi, S.M.; Mahmoudian, M.; Farah, K.R.; Abdali, A.; Nozad, E.; Enayati, M. Active intelligent packaging film based on ethylene vinyl acetate nanocomposite containing extracted anthocyanin, rosemary extract and ZnO/Fe-MMT nanoparticles. Food Packag. Shelf Life 2019, 22, 100389. [Google Scholar] [CrossRef]

- Song, W.-C.; Canellas, E.; Wrona, M.; Becerril, R.; Nerin, C. Comparison of two antioxidant packaging based on rosemary oleoresin and green tea extract coated on polyethylene terephthalate for extending the shelf life of minced pork meat. Food Pack. Shelf Life 2020, 26, 100588. [Google Scholar] [CrossRef]

- Naiela, M.A.E.; Ismael, N.E.M.; Shehata, S.A. Ameliorative effect of diets supplemented with rosemary (Rosmarinus officinalis) on aflatoxin B1 toxicity in terms of the performances, liver histopathology, immunity and antioxidant activity of Nile Tilapia (Oreochromis niloticus). Aquaculture 2019, 511, 734264. [Google Scholar] [CrossRef]

- Petiwala, S.M.; Johnson, J.J. Diterpenes from rosemary (Rosmarinus officinalis): Defining their potential for anticancer activity. Cancer Lett. 2015, 367, 93–102. [Google Scholar] [CrossRef]

- Loto, T.R. Evaluation of the corrosive inhibition effect of the combined admixture of rosemary and cinnamon cassia oil on mild streel in weak acid electrolyte. Sustain. Chem. Pharm. 2020, 17, 100298. [Google Scholar] [CrossRef]

- Chendynski, L.L.; Cordeiro, T.; Messias, G.B.; Mantovani, A.C.G.; Spacilo, K.R.; Zeraik, M.L.; Borsato, D. Evaluation and application of extract of rosemary leaves, araçá pulp and peel of bacuri in the inhibition of the oxidation reaction of biodiesel. Fuel 2020, 261, 116379. [Google Scholar] [CrossRef]

- Jipa, S.; Zaharescu, T.; Setnescu, R.; Gorghiu, L.M.; Dumitrescu, C.; Santos, C.; Silva, A.M.; Gigante, B. Kinetic approach on stabilization of LDPE in the presence of carnosic acid and related compounds. I. Thermal investigation. J. Appl. Polym. Sci. 2005, 95, 1571–1577. [Google Scholar]

- Sánchez, M.D.; Castillo-Sánchez, J.; Morillas-Ruiz, J.M. Comparative study of rosemary extracts and several synthetic and natural foor antioxidants. Relevance of carnosic/carnosol ratio. Food Chem. 2020, 309, 125688. [Google Scholar] [CrossRef] [PubMed]

- Jipa, S.; Zaharescu, T.; Kappel, W.; Setnescu, R.; Lungulescu, M.; Olteanu, R. Vegetal polyphenols as antioxidants in polymers. J. Optoelectron. Adv. Mater. 2008, 10, 837–840. [Google Scholar]

- del Baño, M.J.; Lorente, J.; Castillo, J.; Benavente-García, O.; del Rio, J.A.; Ortoño, A.; Quirin, K.-W.; Gerard, D. Phenolic diterpenes, flavones and rosmarinic acid distribution during the development of leaves, flowers, stems, and roots of Rosmarinus officinalis. Antioxidant activities. J. Agric. Food Chem. 2003, 51, 4247–4253. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Rojo, S.; Visentin, A.; Maestri, D.; Cocero, M.J. Assisted extraction of rosemary antioxidants with green solvents. J. Food. Eng. 2012, 109, 98–103. [Google Scholar] [CrossRef] [Green Version]

- Kirschweng, B.; Tátraaljai, D.; Földes, E.; Pukánszky, B. Natural antioxidants as stabilizers for polymers. Polym. Degrad. Stab. 2017, 145, 25–40. [Google Scholar] [CrossRef] [Green Version]

- Nieto, G.; Ros, G.; Castillo, J. Antioxidant and antimicrobial properties of rosemary (Rosmarinus officinalis L.): A review. Medicines 2018, 5, 98. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Matejka, L.; Amici Kroutilová, I.; Lichtenhan, J.D.; Haddad, T.S. Structure ordering and reinforcement in POSS containing hybrids. Eur. Polym. J. 2014, 52, 117–126. [Google Scholar] [CrossRef]

- Ma, Y.; He, L. POSS-pendanted in epoxy chain inorganic-organic hybrid for highly thermo-mechanical, permeable and hydrothermal-resistant coatings. Mater. Phys. Chem. 2017, 201, 120–129. [Google Scholar] [CrossRef]

- Zhou, H.; Chua, M.H.; Xu, J.W. Functionalized POSS-based hybrid compositions. In Polymer Composites with Functionalized Nanoparticles. Synthesis, Properties, Applications, 1st ed.; Pielichowski, K., Majka, T., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 179–210. [Google Scholar]

- Pagacz, J.; Hebda, E.; Michałowski, S.; Ozimek, J.; Sternik, D.; Pielichovski, K. Polyurethane foams chemically reinforced with POSS—Thermal degradation study. Thermochim. Acta 2016, 642, 95–104. [Google Scholar] [CrossRef]

- Liu, S.; Guo, R.; Li, C.; Lu, C.; Yang, G.; Wang, F.; Nie, J.; Ma, C.; Gao, M. POSS hybrid hydrogels: A brief review of synthesis, properties and applications. Eur. Polym. J. 2021, 142, 110180. [Google Scholar] [CrossRef]

- Zha, G.; Gong, X.; Wei, G.; Liu, Q.; Guang, S.; Zhang, F.; Kea, F.; Xu, H. Facile preparation and properties of polyhedral oligomeric silsesquioxane (POSS) nano-hybrid materials with disaggregation effect. Mater. Sci. Eng. B 2019, 246, 136–142. [Google Scholar] [CrossRef]

- Hao, T.; Liu, X.; Hu, G.-H.; Jiang, T.; Zhang, Q. Preparation and characterization of polyurethane/POSS hybrid aqueous dispersions from mono-amino substituted POSS. Polym. Bull. 2017, 74, 517–529. [Google Scholar] [CrossRef]

- Kalia, S.; Pielichowski, K. (Eds.) Polymer/POSS Nanocomposites and Hybrid Materials. Preparation, Properties, Applications; Springer: New York, NY, USA, 2018. [Google Scholar]

- Lungu, A.; Ghitman, J.; Cernencu, I.A.; Serafim, A.; Florea, M.; Vasile, E.; Iovu, H. POSS containing hybrid nanomaterials based on thiol-epoxy click reaction. Polymer 2018, 145, 324–333. [Google Scholar] [CrossRef]

- Groch, P.; Dziubek, K.; Czaja, K.; Grzymek, M. Investigation of thermal stability of ethylene copolymers with POSS—Study under static and dynamic conditions. Polym. Degrad. Stab. 2018, 156, 218–227. [Google Scholar] [CrossRef]

- Zaharescu, T.; Blanco, I.; Bottino, F.A. Surface antioxidant activity of modified particles in POSS/EPDM Hybrids. Appl. Surf. Sci. 2020, 509, 144702. [Google Scholar] [CrossRef]

- Gamlin, C.D.; Dutta, N.K.; Choudhury, N.R. Mechanism and kinetics of the isothermal thermodegradation of ethylene-propylene-diene (EPDM) elastomers. Polym. Degrad. Stab. 2003, 80, 525–531. [Google Scholar] [CrossRef]

- Snijders, E.A.; Boersma, A.; van Baarle, B.; Noordermeer, J. Effect of third monomer type and content on the UV stability. Polym. Degrad. Stab. 2005, 89, 200–207. [Google Scholar] [CrossRef]

- Rivaton, A.; Cambon, S.; Gardette, J.-L. Radiochemical ageing of ethylene-propylene-diene elastomers. 4. Evaluation of some anti-oxidants. Polym. Degrad. Stab. 2006, 91, 136–143. [Google Scholar] [CrossRef] [Green Version]

- Ning, N.; Ma, Q.; Zhang, Y.; Zhang, L.; Wu, H.; Tian, M. Enhanced thermo-oxidative ageing of EPDM at high temperature by using synergistic antioxidants. Polym. Degrad. Stab. 2014, 102, 1–8. [Google Scholar] [CrossRef]

- Sivakanthan, S.; Rajendran, S.; Gamage, A.; Madhujith, T.; Mani, S. Antioxidant and antimicrobial applications of biopolymers; A review. Food. Res. Int. 2020, 136, 109327. [Google Scholar] [CrossRef]

- Bancuta, O.R.; Chilian, A.; Bancuta, I.; Ion, R.M.; Setnescu, R.; Setnescu, T.; Gheboianu, A.; Lungulescu, M. Ft-Ir and Uv-Vis characterization of grape extracts used as antioxidants in polymers. Rev. Roum. Chim. 2015, 60, 571–577. [Google Scholar]

- McDonnell, D.; Balfe, N.; O’Donnell, G.E. Analysis of the effects of chemical ageing of ethylene-propylene diene monomer by chemical, spectroscopic, and thermal means. Polym. Test. 2018, 65, 116–124. [Google Scholar] [CrossRef]

- Park, E.S.; Ro, H.W.; Nguyen, C.V.; Jaffe, R.L.; Yoon, D.Y. Infrared spectroscopy study of microstructures of poly(silsesquioxane)s. Chem. Mater. 2008, 20, 1548–1554. [Google Scholar] [CrossRef]

- Blanco, I.; Bottino, F.A.; Cicala, G.; Ognibene, G.; Tosto, C. Design, Preparation and Thermal Characterization of Polystyrene Composites Reinforced with Novel Three-Cages POSS Molecules. Molecules 2020, 25, 2967. [Google Scholar] [CrossRef] [PubMed]

- Taşdemir, M.; Topsakaloğlu, M. Dynamically Vulcanized EPDM/PP (40/60) Blends. Int. J. Polym. Mater. Polym. Biomater. 2006, 55, 1065–1073. [Google Scholar] [CrossRef]

- Lee, C.S.; Yoo, S.H.; Jho, J.Y. Mechanical properties of ultra-high molecular weight polyethylene irradiated with gamma rays. Macromol. Res. 2004, 12, 112–118. [Google Scholar] [CrossRef]

- Sreekanth, P.S.R.; Kanagaraj, S. Influence of MWCNTs and gamma irradiation on thermal characteristics of medical grade UHMWPE. Bull. Mater. Sci. 2014, 37, 347–356. [Google Scholar] [CrossRef] [Green Version]

- Stephens, C.P.; Benson, R.S.; Martinez-Pardo, M.E.; Barker, E.D.; Walker, J.B.; Stephens, T.P. The effect of dose rate on the crystalline lamellar thickness distribution in gamma-radiation of UHMWPE. Nucl. Instr. Meth. Phys. Res. B 2005, 236, 540–545. [Google Scholar] [CrossRef]

- Medel, F.J.; Garcıa-Alvarez, F.; Gomez-Barrena, E.; Puertolas, J.A. Microstructure changes of extruded ultra high molecular weight polyethylene after gamma irradiation and shelf-aging. Polym. Degrad. Stabil. 2005, 88, 435–443. [Google Scholar] [CrossRef]

- Blanco, I.; Bottino, F.A.; Cicala, G.; Cozzo, G.; Latteri, A.; Recca, A. Synthesis and thermal characterization of new dumbbell shaped POSS/PS nanocomposites: Influence of the symmetrical structure of the nanoparticles on the dispersion/aggregation in the polymer matrix. Polym. Compos. 2015, 36, 1394–1400. [Google Scholar] [CrossRef]

- Abate, L.; Blanco, I.; Cicala, G.; Mamo, A.; Recca, G.; Scamporrino, A. The influence of chain rigidity on the thermal properties of some novel random copolyethersulfones. Polym. Degrad. Stabil. 2010, 95, 798–802. [Google Scholar] [CrossRef]

- Fina, A.; Tabuani, D.; Carniato, F.; Frache, A.; Boccaleri, E.; Camino, G. Polyhedral oligomeric silsesquioxanes. (POSS) thermal degradation. Thermochim. Acta 2006, 440, 36. [Google Scholar] [CrossRef]

- Blanco, I.; Bottino, F.A. Kinetics of degradation and thermal behaviour of branched hepta phenyl POSS/PS nanocomposites. Polym. Degrad. Stabil. 2016, 129, 374–379. [Google Scholar] [CrossRef]

- Pospíšil, I.; Nešpůrek, S. Chain-breaking stabilizers in polymers: The current status. Polym. Degrad. Stab. 1995, 49, 99–110. [Google Scholar] [CrossRef]

- Dintcheva, N.T.; Morici, E.; Arrigo, R.; la Mantia, F.P.; Malatesta, V.; Schwab, J.J. UV-stabilization of polystyrene-based nanocomposites provided by polyhedral oligomeric silsesquioxanes (POSS). Polym. Degrad. Stab. 2012, 97, 2313–2322. [Google Scholar] [CrossRef]

- Lu, Y.; Foo, F.Y. Polyphenolics of salvia—A review. Phytochemistry 2002, 59, 117–140. [Google Scholar] [CrossRef]

- Gautier, M.R.; Senhorinho, G.N.A.; Scott, J.A. Microalgae under environmental stress as a source of antioxidants. Algal Res. 2020, 52, 102104. [Google Scholar] [CrossRef]

- Zaharescu, T.; Blanco, I.; Borbath, T.; Borbath, I.; Maris, M. Kinetic analysis on the stabilization effects of substituted POSS powders embedded in γ-radiolyzed polypropylene. J. Compos. Sci. 2021, 5, 124. [Google Scholar] [CrossRef]

- Aruoma, O.I.; Halliwell, B.; Aeschbach, R.; Löligers, J. Antioxidant and pro-oxidant properties of active rosemary constituents: Carnosol and carnosic acid. Xenobiotica 1992, 22, 257–268. [Google Scholar] [CrossRef]

- Lungulescu, M.; Zaharescu, T.; Jipa, S.; Setnescu, R.; Setnescu, T. Chemiluminescence study on gamma-irradiated EPDM/IIR blends. J. Optoelectron. Adv. Mater. 2008, 10, 834–836. [Google Scholar]

- Koutný, M.; Václavková, T.; Matisová-Rychlá, L.; Rychly, J. Characterization of oxidation progress by chemiluminescence. A study of polyethylene with pro-oxidant additives. Polym. Degrad. Stab. 2008, 93, 1515–1519. [Google Scholar] [CrossRef]

| Additive | Tm (°C) | T5% (°C) | Residue (%) |

|---|---|---|---|

| Irradiation dose: 0 kGy | |||

| free | 33.3 | 314.7 | 0 |

| rosemary | 34.3 | 370.7 | 0 |

| POSS 1% | 32.8 | 350.8 | 0.54 |

| POSS 3% | 33.4 | 268.7 | 1.10 |

| POSS 5% | 32.1 | 272.5 | 15.7 |

| Irradiation dose: 50 kGy | |||

| free | 34.9 | 339.5 | 0 |

| rosemary | 34.3 | 350.6 | 0 |

| POSS 1% | 34.4 | 345.7 | 0 |

| POSS 3% | 33.7 | 285.3 | 1.18 |

| POSS 5% | 33.4 | 296.8 | 12.6 |

| Additive | Testing Temperature (°C) | Oxidation Induction Time (min) | Relationship | Correlation Factor | Activation Energy (kJ mol−1) |

|---|---|---|---|---|---|

| free | 160 | 42 | y = −89.7 + 16.3x | 0.99729 | 135.5 |

| 170 | 20 | ||||

| 180 | 8 | ||||

| rosemary | 170 | 502 | y = −64.9 + 32.6x | 0.99961 | 271.0 |

| 180 | 98 | ||||

| 190 | 18 | ||||

| POSS 1 phr | 160 | 254 | y = −55.9 + 28.4x | 0.99888 | 236.1 |

| 170 | 65 | ||||

| 180 | 14 | ||||

| POSS 3 phr | 160 | 25 | y = −40.6 + 20.8x | 0.99584 | 172.9 |

| 170 | 10 | ||||

| 180 | 3 | ||||

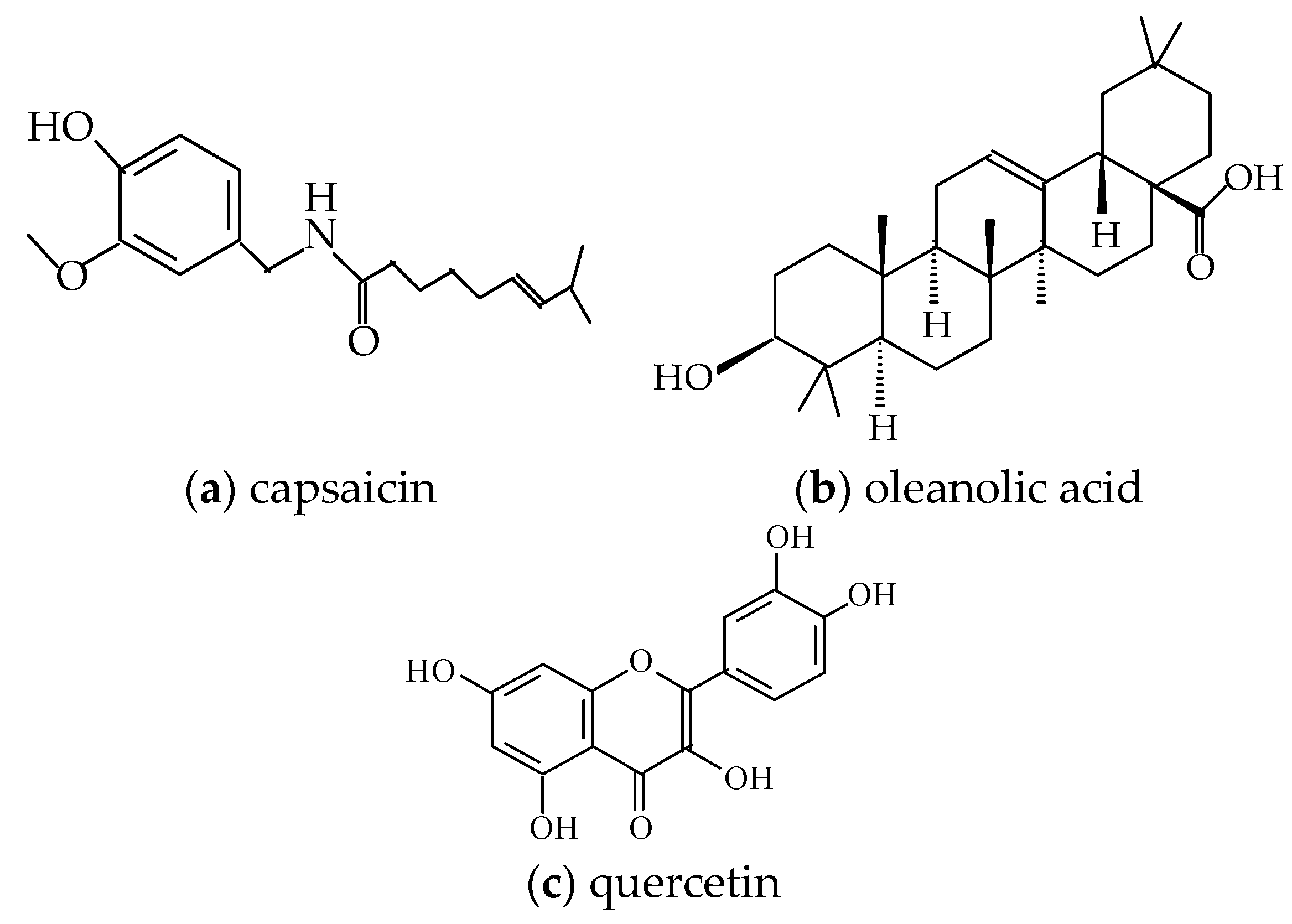

| quercetin | 170 | 710 | y = −47.2 + 25.7x | 0.99602 | 213.7 |

| 180 | 240 | ||||

| 190 | 58 | ||||

| capsaicin | 180 | 385 | y = −60.1 + 23.7x | 0.99614 | 197.0 |

| 190 | 110 | ||||

| 200 | 42 | ||||

| oleanolic acid | 160 | 50 | y = −40.1 + 20.6x | 0.99788 | 171.3 |

| 170 | 15 | ||||

| 180 | 6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaharescu, T.; Blanco, I. Stabilization Effects of Natural Compounds and Polyhedral Oligomeric Silsesquioxane Nanoparticles on the Accelerated Degradation of Ethylene-Propylene-Diene Monomer. Molecules 2021, 26, 4390. https://doi.org/10.3390/molecules26154390

Zaharescu T, Blanco I. Stabilization Effects of Natural Compounds and Polyhedral Oligomeric Silsesquioxane Nanoparticles on the Accelerated Degradation of Ethylene-Propylene-Diene Monomer. Molecules. 2021; 26(15):4390. https://doi.org/10.3390/molecules26154390

Chicago/Turabian StyleZaharescu, Traian, and Ignazio Blanco. 2021. "Stabilization Effects of Natural Compounds and Polyhedral Oligomeric Silsesquioxane Nanoparticles on the Accelerated Degradation of Ethylene-Propylene-Diene Monomer" Molecules 26, no. 15: 4390. https://doi.org/10.3390/molecules26154390

APA StyleZaharescu, T., & Blanco, I. (2021). Stabilization Effects of Natural Compounds and Polyhedral Oligomeric Silsesquioxane Nanoparticles on the Accelerated Degradation of Ethylene-Propylene-Diene Monomer. Molecules, 26(15), 4390. https://doi.org/10.3390/molecules26154390