Improvement of Impact Strength of Polylactide Blends with a Thermoplastic Elastomer Compatibilized with Biobased Maleinized Linseed Oil for Applications in Rigid Packaging

Abstract

:1. Introduction

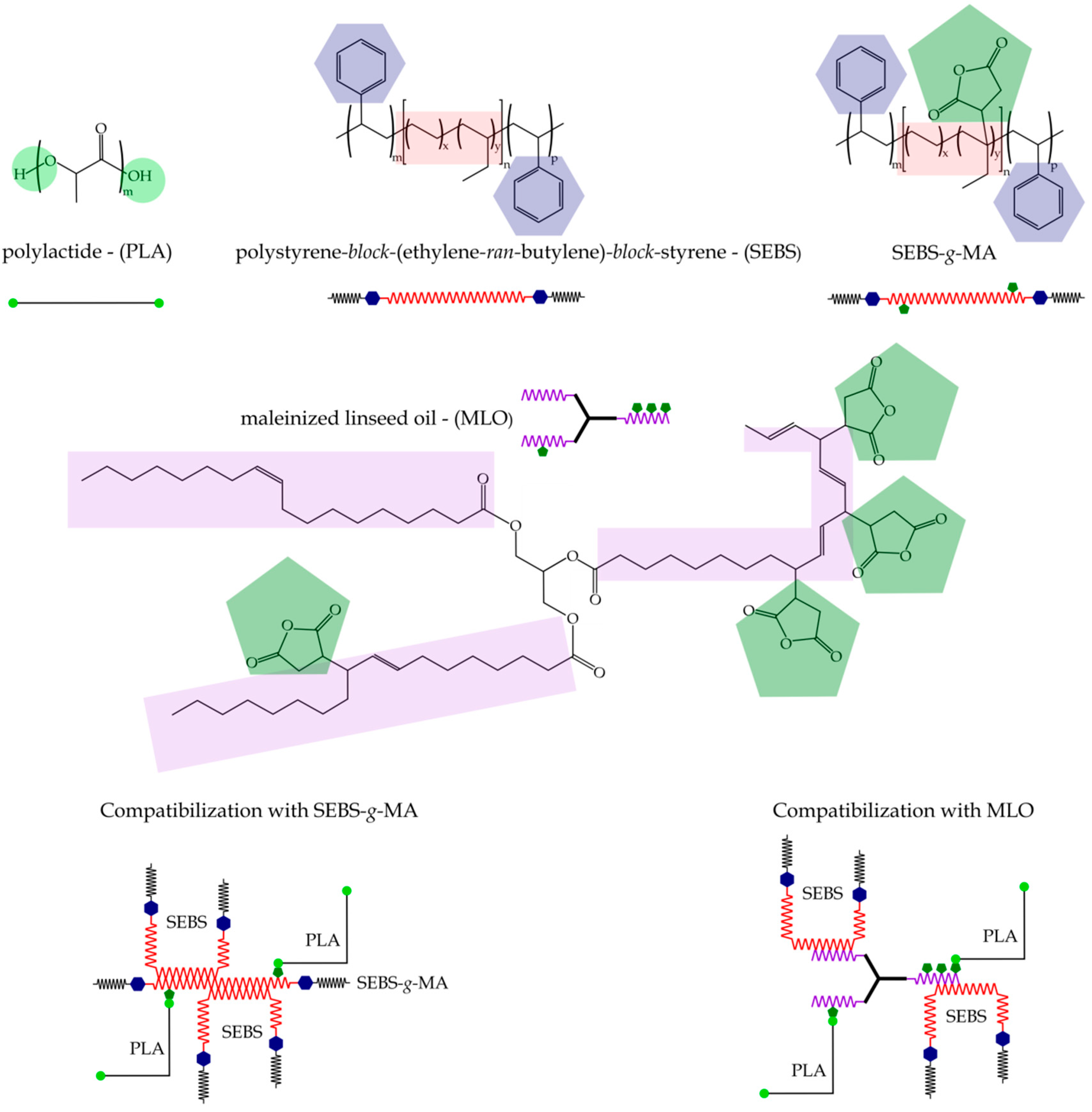

2. Results and Discussion

2.1. Mechanical Properties

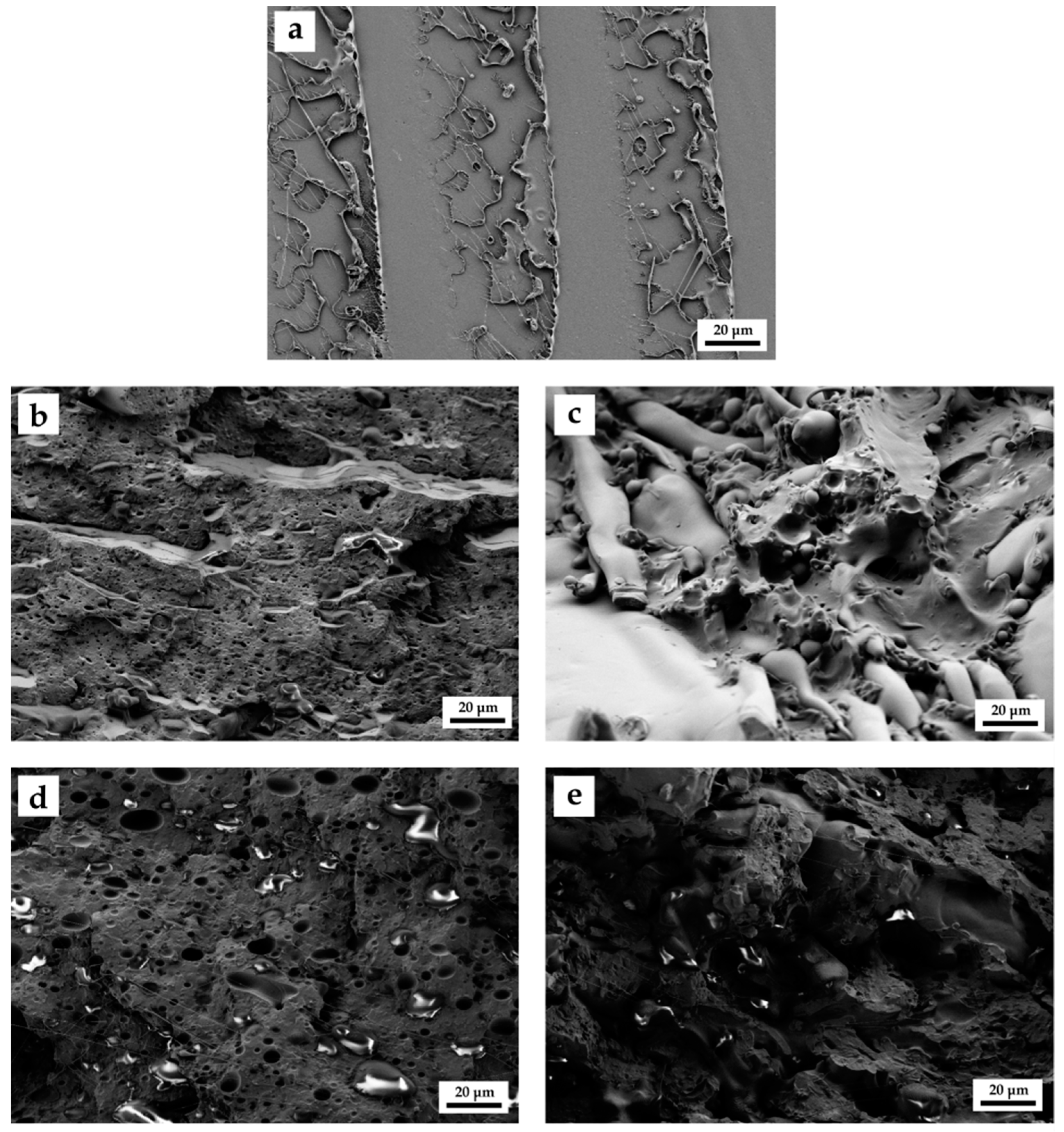

2.2. Morphology of PLA/SEBS Blends

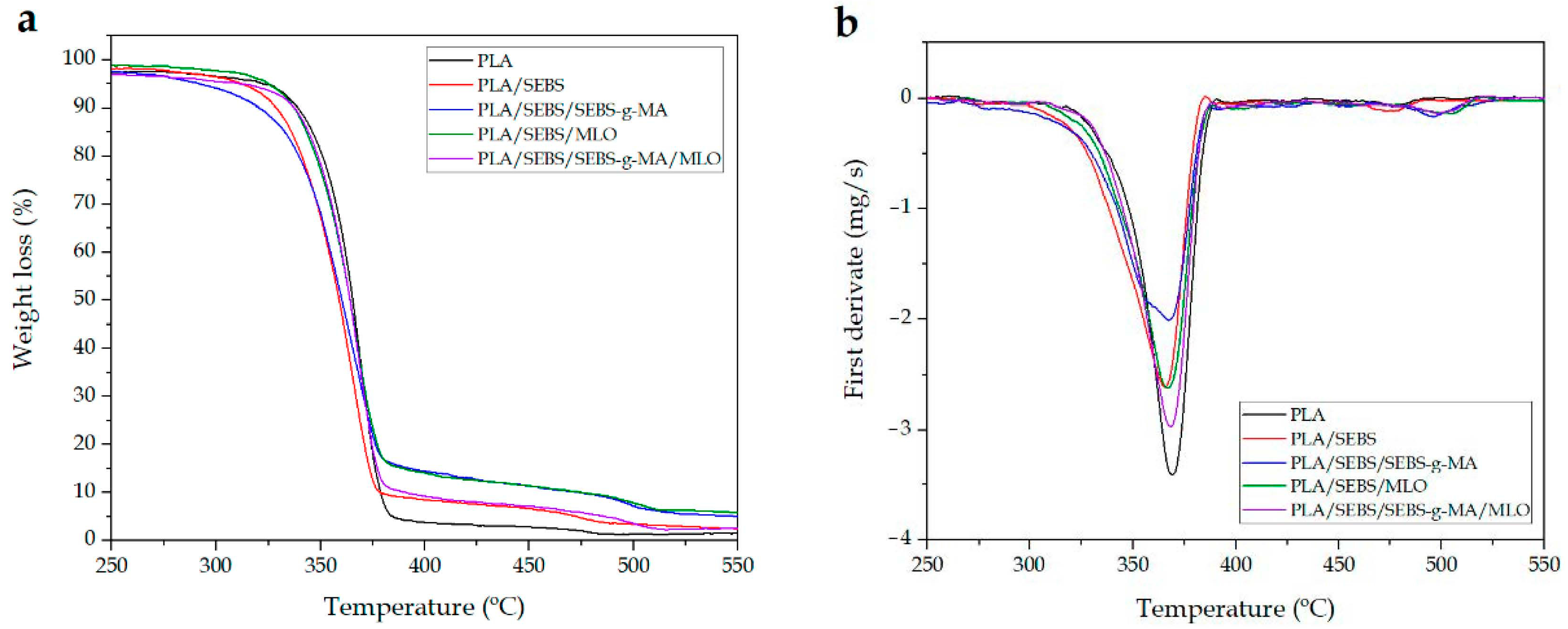

2.3. Thermal Properties of PLA/SEBS Blends

2.4. Dynamic-Mechanical Behaviour of PLA/SEBS Blends

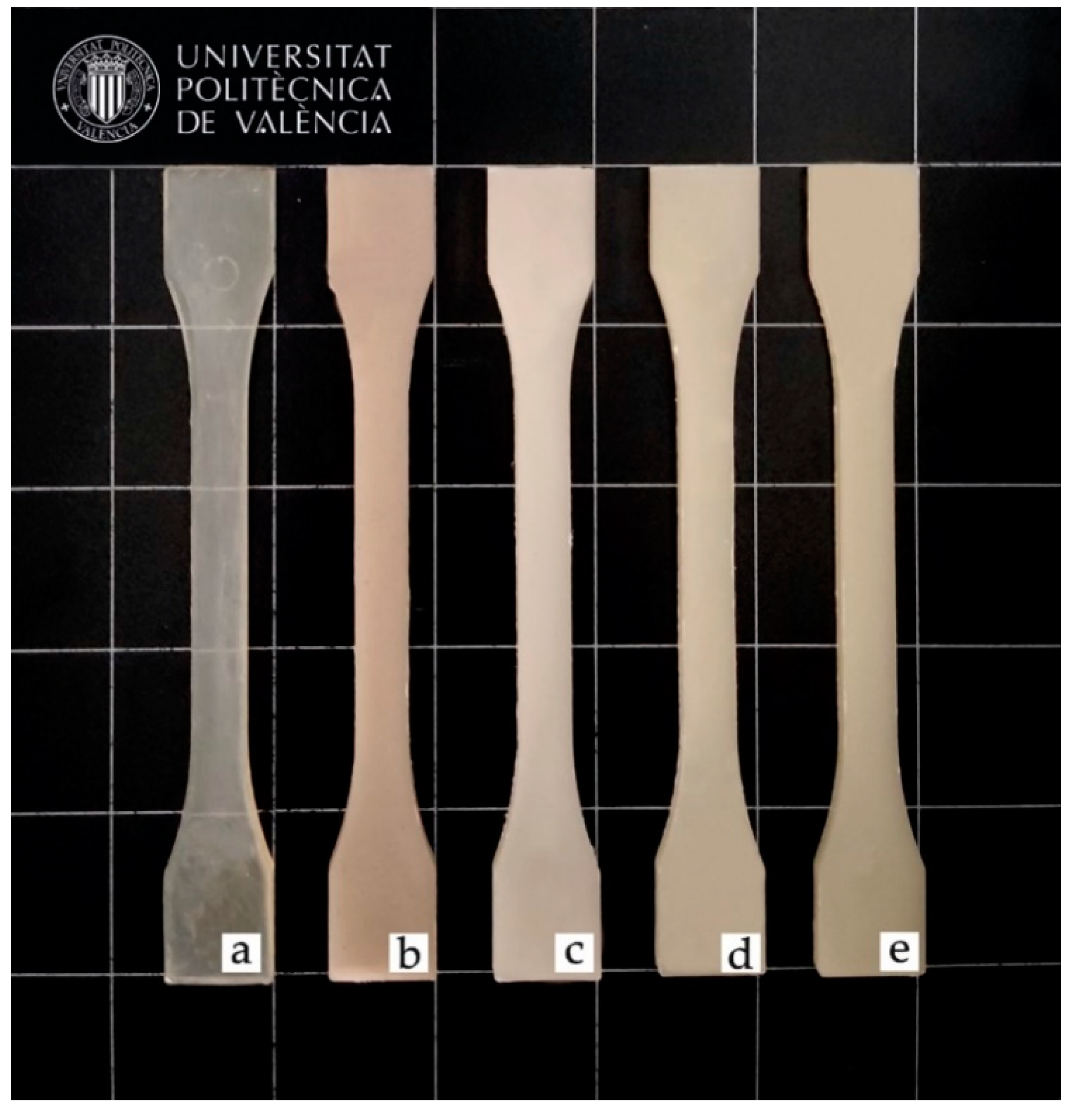

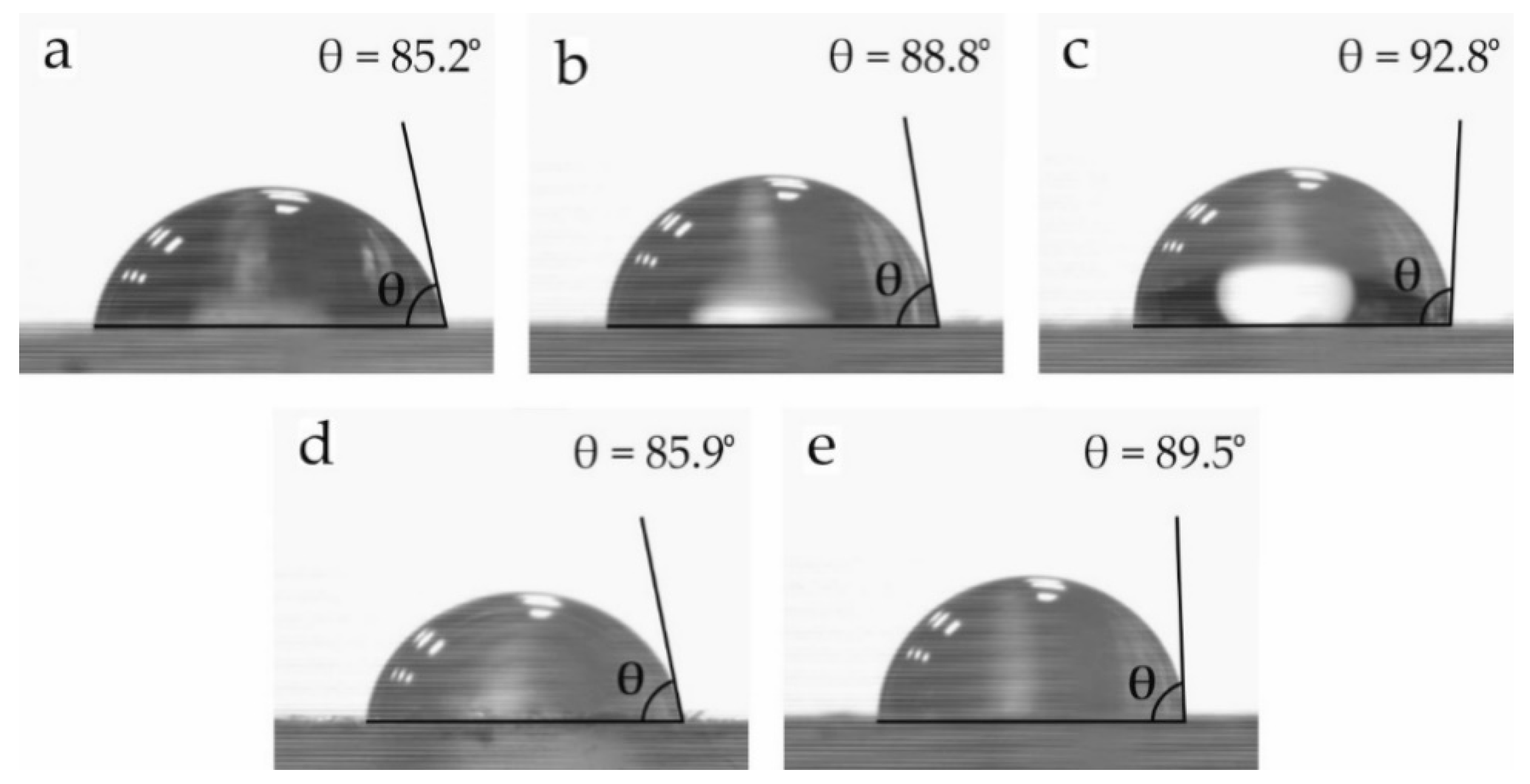

2.5. Colour Measurement and Wetting Properties of PLA/SEBS Blends

3. Materials and Methods

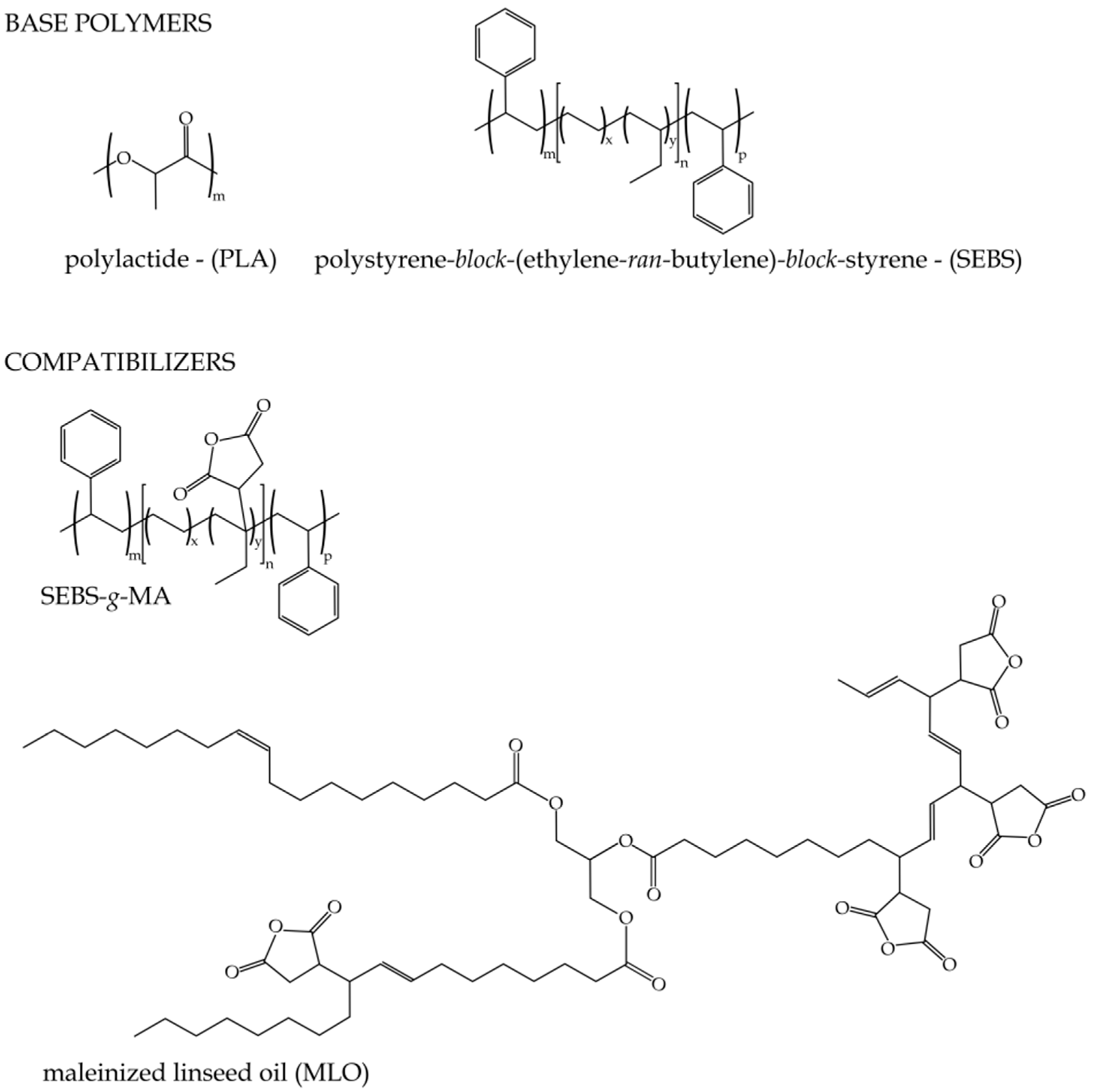

3.1. Materials

3.2. Preparation of PLA/SEBS Blends

3.3. Characterization of PLA/SEBS Blends

3.3.1. Mechanical Characterization

3.3.2. Morphology Characterization

3.3.3. Thermal Analysis

3.3.4. Dynamical–Mechanical Thermal Characterization

3.3.5. Colour and Wetting Characterization

3.3.6. Statistical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lascano, D.; Quiles-Carrillo, L.; Balart, R.; Boronat, T.; Montanes, N. Toughened poly (lactic acid)—PLA formulations by binary blends with poly (butylene succinate-co-adipate)—PBSA and their shape memory behaviour. Materials 2019, 12, 622. [Google Scholar] [CrossRef] [Green Version]

- Kabir, E.; Kaur, R.; Lee, J.; Kim, K.-H.; Kwon, E.E. Prospects of biopolymer technology as an alternative option for non-degradable plastics and sustainable management of plastic wastes. J. Clean. Prod. 2020, 258, 120536. [Google Scholar]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Tahir, N.; Bhatti, H.N.; Iqbal, M.; Noreen, S. Biopolymers composites with peanut hull waste biomass and application for Crystal Violet adsorption. Int. J. Biol. Macromol. 2017, 94, 210–220. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Lagaron, J.M.; Balart, R.; Torres-Giner, S. On the use of acrylated epoxidized soybean oil as a reactive compatibilizer in injection-molded compostable pieces consisting of polylactide filled with orange peel flour. Polymer International. 2018, 67, 1341–1351. [Google Scholar] [CrossRef]

- Barlow, C.; Morgan, D. Polymer film packaging for food: An environmental assessment. Resour. Conserv. Recycl. 2013, 78, 74–80. [Google Scholar] [CrossRef]

- Balart, J.F.; Garcia-Sanoguera, D.; Balart, R.; Boronat, T.; Sanchez-Nacher, L. Manufacturing and properties of biobased thermoplastic composites from poly(lactid acid) and hazelnut shell wastes. Polym. Compos. 2018, 39, 848–857. [Google Scholar] [CrossRef]

- Sun, J.Y.; Shen, J.J.; Chen, S.K.; Cooper, M.A.; Fu, H.B.; Wu, D.M.; Yang, Z.G. Nanofiller Reinforced Biodegradable PLA/PHA Composites: Current Status and Future Trends. Polymers 2018, 10, 22. [Google Scholar] [CrossRef] [Green Version]

- Meereboer, K.W.; Misra, M.; Mohanty, A.K. Review of recent advances in the biodegradability of polyhydroxyalkanoate (PHA) bioplastics and their composites. Green Chem. 2020, 22, 5519–5558. [Google Scholar] [CrossRef]

- Ciofu, C.; Mazurchevici, S.-N.; Maldonado-Cortes, D.; Pena-Paras, L.; Correa, D.I.Q.; Nedelcu, D. Tribological behavior of PLA biodegradable materials used in the automotive industry. Int. J. Mod. Manuf. Technol. 2019, 11, 83–88. [Google Scholar]

- Averous, L. Biodegradable multiphase systems based on plasticized starch: A review. J. Macromol. Sci. Polym. Rev. 2004, C44, 231–274. [Google Scholar] [CrossRef]

- Garcia-Campo, M.J.; Quiles-Carrillo, L.; Masia, J.; Reig-Pérez, M.J.; Montanes, N.; Balart, R. Environmentally friendly compatibilizers from soybean oil for ternary blends of poly (lactic acid)-PLA, poly (ε-caprolactone)-PCL and poly (3-hydroxybutyrate)-PHB. Materials 2017, 10, 1339. [Google Scholar]

- Abd Alsaheb, R.A.; Aladdin, A.; Othman, N.Z.; Abd Malek, R.; Leng, O.M.; Aziz, R.; El Enshasy, H.A. Recent applications of polylactic acid in pharmaceutical and medical industries. J. Chem. Pharm. Res. 2015, 7, 51–63. [Google Scholar]

- Leroy, A.; Ribeiro, S.; Grossiord, C.; Alves, A.; Vestberg, R.H.; Salles, V.; Brunon, C.; Gritsch, K.; Grosgogeat, B.; Bayon, Y. FTIR microscopy contribution for comprehension of degradation mechanisms in PLA-based implantable medical devices. J. Mater. Sci. Mater. Med. 2017, 28, 13. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misratt, M. Perspective on Polylactic Acid (PLA) based Sustainable Materials for Durable Applications: Focus on Toughness and Heat Resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Bouzouita, A.; Samuel, C.; Notta-Cuvier, D.; Odent, J.; Lauro, F.; Dubois, P.; Raquez, J.M. Design of highly tough poly(l-lactide)-based ternary blends for automotive applications. J. Appl. Polym. Sci. 2016, 133, 9. [Google Scholar] [CrossRef]

- Pappu, A.; Pickering, K.L.; Thakur, V.K. Manufacturing and characterization of sustainable hybrid composites using sisal and hemp fibres as reinforcement of poly (lactic acid) via injection moulding. Ind. Crop. Prod. 2019, 137, 260–269. [Google Scholar] [CrossRef]

- Spinelli, G.; Lamberti, P.; Tucci, V.; Ivanova, R.; Tabakova, S.; Ivanov, E.; Kotsilkova, R.; Cimmino, S.; Di Maio, R.; Silvestre, C. Rheological and electrical behaviour of nanocarbon/poly(lactic) acid for 3D printing applications. Compos. Part B Eng. 2019, 167, 467–476. [Google Scholar] [CrossRef]

- Cisneros-López, E.; Pal, A.; Rodriguez, A.; Wu, F.; Misra, M.; Mielewski, D.; Kiziltas, A.; Mohanty, A. Recycled poly (lactic acid)–based 3D printed sustainable biocomposites: A comparative study with injection molding. Mater. Today Sustain. 2020, 7, 100027. [Google Scholar]

- Burgos, N.; Armentano, I.; Fortunati, E.; Dominici, F.; Luzi, F.; Fiori, S.; Cristofaro, F.; Visai, L.; Jimenez, A.; Kenny, J.M. Functional Properties of Plasticized Bio-Based Poly(Lactic Acid)_Poly(Hydroxybutyrate) (PLA_PHB) Films for Active Food Packaging. Food Bioprocess Technol. 2017, 10, 770–780. [Google Scholar] [CrossRef] [Green Version]

- da Silva, T.F.; Menezes, F.; Montagna, L.S.; Lemes, A.P.; Passador, F.R. Preparation and characterization of antistatic packaging for electronic components based on poly(lactic acid)/carbon black composites. J. Appl. Polym. Sci. 2019, 136. [Google Scholar] [CrossRef]

- Wang, M.; Wu, Y.; Li, Y.D.; Zeng, J.B. Progress in Toughening Poly(Lactic Acid) with Renewable Polymers. Polym. Rev. 2017, 57, 557–593. [Google Scholar] [CrossRef]

- Tsouknidas, A.; Pantazopoulos, M.; Katsoulis, I.; Fasnakis, D.; Maropoulos, S.; Michailidis, N. Impact absorption capacity of 3D-printed components fabricated by fused deposition modelling. Mater. Des. 2016, 102, 41–44. [Google Scholar] [CrossRef]

- Darie-Nita, R.N.; Vasile, C.; Irimia, A.; Lipsa, R.; Rapa, M. Evaluation of some eco-friendly plasticizers for PLA films processing. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Burgos, N.; Martino, V.P.; Jimenez, A. Characterization and ageing study of poly(lactic acid) films plasticized with oligomeric lactic acid. Polym. Degrad. Stab. 2013, 98, 651–658. [Google Scholar] [CrossRef]

- Rapa, M.; Nita, R.N.D.; Vasile, C. Influence of Plasticizers over Some Physico-chemical Properties of PLA. Mater. Plast. 2017, 54, 73–78. [Google Scholar]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing Polylactic acid (PLA). Polimeros-Cienc. E Tecnol. 2015, 25, 581–590. [Google Scholar] [CrossRef]

- Yang, X.; Xu, H.; Odelius, K.; Hakkarainen, M. Poly(lactide)-g-poly(butylene succinate-co-adipate) with High Crystallization Capacity and Migration Resistance. Materials 2016, 9, 313. [Google Scholar] [CrossRef] [Green Version]

- Garcia, D.; Balart, R.; Sanchez, L.; Lopez, J. Compatibility of recycled PVC/ABS blends. Effect of previous degradation. Polym. Eng. Sci. 2007, 47, 789–796. [Google Scholar] [CrossRef]

- Juarez, D.; Ferrand, S.; Fenollar, O.; Fombuena, V.; Balart, R. Improvement of thermal inertia of styrene-ethylene/butylene-styrene (SEBS) polymers by addition of microencapsulated phase change materials (PCMs). Eur. Polym. J. 2011, 47, 153–161. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Garcia, D.; Crespo-Amoros, J.E.; Parres, F.; Samper, M.D. Influence of Ultraviolet Radiation Exposure Time on Styrene-Ethylene-Butadiene-Styrene (SEBS) Copolymer. Polymers 2020, 12, 862. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Z.X.; Dai, X.R.; Zou, L.; Wen, S.B.; Sinha, T.K.; Li, H. A developed, eco-friendly, and flexible thermoplastic elastomeric foam from SEBS for footwear application. Express Polym. Lett. 2019, 13, 948–958. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Joseph, G.; Shinu, K.; Jose, S.; Salim, N.V.; Hameed, N. Development of hybrid composites for automotive applications: Effect of addition of SEBS on the morphology, mechanical, viscoelastic, crystallization and thermal degradation properties of PP/PS–x GnP composites. RSC Adv. 2015, 5, 25634–25641. [Google Scholar]

- Parameswaranpillai, J.; Jose, S.; Siengchin, S.; Hameed, N. Phase morphology, mechanical, dynamic mechanical, crystallization, and thermal degradation properties of PP and PP/PS blends modified with SEBS elastomer. Int. J. Plast. Technol. 2017, 21, 79–95. [Google Scholar] [CrossRef]

- Parameswaranpillai, J.; Joseph, G.; Shinu, K.P.; Sreejesh, P.R.; Jose, S.; Salim, N.V.; Hameed, N. The role of SEBS in tailoring the interface between the polymer matrix and exfoliated graphene nanoplatelets in hybrid composites. Mater. Chem. Phys. 2015, 163, 182–189. [Google Scholar] [CrossRef]

- De Carvalho, A.P.A.; Sirqueira, A.D. Effect of compatibilization in situ on PA/SEBS blends. Polimeros-Cienc. E Tecnol. 2016, 26, 123–128. [Google Scholar] [CrossRef] [Green Version]

- Finotti, P.F.; Costa, L.C.; Capote, T.S.; Scarel-Caminaga, R.M.; Chinelatto, M.A. Immiscible poly (lactic acid)/poly (ε-caprolactone) for temporary implants: Compatibility and cytotoxicity. J. Mech. Behav. Biomed. Mater. 2017, 68, 155–162. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Garcia, D.; Ferri, J.; Boronat, T.; López-Martínez, J.; Balart, R. Processing and characterization of binary poly (hydroxybutyrate)(PHB) and poly (caprolactone)(PCL) blends with improved impact properties. Polym. Bull. 2016, 73, 3333–3350. [Google Scholar] [CrossRef] [Green Version]

- Mhlabeni, T.; Pillai, S.K.; Ray, S.S. Effect of organically modified layered double hydroxides on the properties of poly(lactic acid)/poly (butylene succinate)-co-adipate immiscible blends. J. Appl. Polym. Sci. 2020, 137. [Google Scholar] [CrossRef]

- Wang, W.Q.; Ying, J.; Wang, J.K. The reactive compatibilization effect of copolymer macroactivator for immiscible anionic polyamide 6/polystyrene blends via in situ polymerization. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Aguilar-Bolados, H.; Quijada, R.; Yazdani-Pedram, M.; Maldonado-Magnere, S.; Verdejo, R.; Lopez-Manchado, M.A. SEBS-Grafted Itaconic Acid as Compatibilizer for Elastomer Nanocomposites Based on BaTiO3 Particles. Polymers 2020, 12, 643. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhan, Z.M.; He, H.Z.; Zhu, Z.W.; Xue, B.; Wang, G.Z.; Chen, M.; Xiong, C.T. Blends of rABS and SEBS: Influence of In-Situ Compatibilization on the Mechanical Properties. Materials 2019, 12, 2352. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mengual, A.; Juarez, D.; Balart, R.; Ferrandiz, S. PE-g-MA, PP-g-MA and SEBS-g-MA compatibilizers used in material blends. Procedia Manuf. 2017, 13, 321–326. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Montanes, N.; Boronat, T.; Quiles-Carrillo, L.; Balart, R. Melt grafting of sepiolite nanoclay onto poly (3-hydroxybutyrate-co-4-hydroxybutyrate) by reactive extrusion with multi-functional epoxy-based styrene-acrylic oligomer. Eur. Polym. J. 2016, 84, 693–707. [Google Scholar] [CrossRef]

- Raquez, J.M.; Degee, P.; Nabar, Y.; Narayan, R.; Dubois, P. Biodegradable materials by reactive extrusion: From catalyzed polymerization to functionalization and blend compatibilization. Comptes Rendus Chim. 2006, 9, 1370–1379. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Duart, S.; Montanes, N.; Torres-Giner, S.; Balart, R. Enhancement of the mechanical and thermal properties of injection-molded polylactide parts by the addition of acrylated epoxidized soybean oil. Mater. Des. 2018, 140, 54–63. [Google Scholar] [CrossRef]

- Fombuena, V.; Sánchez-Nácher, L.; Samper, M.; Juarez, D.; Balart, R. Study of the properties of thermoset materials derived from epoxidized soybean oil and protein fillers. J. Am. Oil Chem. Soc. 2013, 90, 449–457. [Google Scholar] [CrossRef] [Green Version]

- Balart, J.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sánchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar]

- Garcia-Garcia, D.; Ferri, J.M.; Montanes, N.; Lopez-Martinez, J.; Balart, R. Plasticization effects of epoxidized vegetable oils on mechanical properties of poly (3-hydroxybutyrate). Polym. Int. 2016, 65, 1157–1164. [Google Scholar] [CrossRef]

- Sarwono, A.; Man, Z.; Bustam, M.A. Blending of epoxidised palm oil with epoxy resin: The effect on morphology, thermal and mechanical properties. J. Polym. Environ. 2012, 20, 540–549. [Google Scholar]

- Liminana, P.; Quiles-Carrillo, L.; Boronat, T.; Balart, R.; Montanes, N. The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly (Butylene Succinate (PBS) Matrix Compatibilized with Maleinized Linseed Oil (MLO). Materials 2018, 11, 2179. [Google Scholar] [CrossRef] [Green Version]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crop. Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [Green Version]

- Lima, J.C.C.; Araujo, E.A.G.; Agrawal, P.; Melo, T.J.A. PLA/SEBS Bioblends: Influence of SEBS Content and of Thermal Treatment on the Impact Strength and Morphology. Macromol. Symp. 2019, 383. [Google Scholar] [CrossRef] [Green Version]

- Nehra, R.; Maiti, S.N.; Jacob, J. Analytical interpretations of static and dynamic mechanical properties of thermoplastic elastomer toughened PLA blends. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Tjong, S.C.; Xu, S.A.; Li, R.K.Y.; Mai, Y.W. Mechanical behavior and fracture toughness evaluation of maleic anhydride compatibilized short glass fiber/SEBS/polypropylene hybrid composites. Compos. Sci. Technol. 2002, 62, 831–840. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (MLO) on mechanical performance of poly(lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef]

- Kaczmarek, H.; Nowicki, M.; Vuković-Kwiatkowska, I.; Nowakowska, S. Crosslinked blends of poly (lactic acid) and polyacrylates: AFM, DSC and XRD studies. J. Polym. Res. 2013, 20, 91. [Google Scholar] [CrossRef] [Green Version]

- Luyt, A.S.; Kelnar, I. Effect of blend ratio and nanofiller localization on the thermal degradation of graphite nanoplatelets-modified PLA/PCL. J. Therm. Anal. Calorim. 2019, 136, 2373–2382. [Google Scholar] [CrossRef]

- Chow, W.S.; Tham, W.L.; Poh, B.T.; Ishak, Z.A.M. Mechanical and Thermal Oxidation Behavior of Poly(Lactic Acid)/Halloysite Nanotube Nanocomposites Containing N,N’-Ethylenebis(Stearamide) and SEBS-g-MA. J. Polym. Environ. 2018, 26, 2973–2982. [Google Scholar] [CrossRef]

- Yu, X.; Wang, X.; Zhang, Z.; Peng, S.; Chen, H.; Zhao, X. High-performance fully bio-based poly (lactic acid)/polyamide11 (PLA/PA11) blends by reactive blending with multi-functionalized epoxy. Polym. Test. 2019, 78, 105980. [Google Scholar] [CrossRef]

- Silverajah, V.; Ibrahim, N.A.; Yunus, W.M.Z.W.; Hassan, H.A.; Woei, C.B. A comparative study on the mechanical, thermal and morphological characterization of poly (lactic acid)/epoxidized palm oil blend. Int. J. Mol. Sci. 2012, 13, 5878–5898. [Google Scholar] [CrossRef] [Green Version]

- Lascano, D.; Moraga, G.; Ivorra-Martinez, J.; Rojas-Lema, S.; Torres-Giner, S.; Balart, R.; Boronat, T.; Quiles-Carrillo, L. Development of injection-molded polylactide pieces with high toughness by the addition of lactic acid oligomer and characterization of their shape memory behavior. Polymers 2019, 11, 2099. [Google Scholar] [CrossRef] [Green Version]

- Guo, Q.; Li, X.; Li, W.; Yao, Z. The balanced insulating performance and mechanical property of PP by introducing PP-g-PS graft copolymer and SEBS elastomer. Ind. Eng. Chem. Res. 2018, 57, 6696–6704. [Google Scholar] [CrossRef]

- Qiu, Z.; Yang, W. Crystallization kinetics and morphology of poly (butylene succinate)/poly (vinyl phenol) blend. Polymer 2006, 47, 6429–6437. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Jorda-Vilaplana, A.; Balart, R.; Torres-Giner, S. A comparative study on the effect of different reactive compatibilizers on injection-molded pieces of bio-based high-density polyethylene/polylactide blends. J. Appl. Polym. Sci. 2019, 136, 47396. [Google Scholar] [CrossRef]

- Harris, A.M.; Lee, E.C. Improving mechanical performance of injection molded PLA by controlling crystallinity. J. Appl. Polym. Sci. 2008, 107, 2246–2255. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Fenollar, O.; Balart, R.; Torres-Giner, S.; Rallini, M.; Dominici, F.; Torre, L. A comparative study on the reactive compatibilization of melt-processed polyamide 1010/polylactide blends by multi-functionalized additives derived from linseed oil and petroleum. eXPRESS Polym. Lett. 2020, 14, 586–604. [Google Scholar] [CrossRef]

- Gonçalves, L.M.G.; Rigolin, T.R.; Frenhe, B.M.; Bettini, S.H.P. On the Recycling of a Biodegradable Polymer: Multiple Extrusion of Poly (Lactic Acid). Mater. Res. 2020, 23. [Google Scholar] [CrossRef]

- Ge, F.; Ding, Y.; Yang, L.; Huang, Y.; Jiang, L.; Dan, Y. Effect of the content and distribution of ultraviolet absorbing groups on the UV protection and degradation of polylactide films. RSC Adv. 2015, 5, 70473–70481. [Google Scholar] [CrossRef]

- Luna, C.B.B.; Gomes, F.B.C.; Ferreira, E.D.S.B.; Araújo, E.M.; Ferreira, R.D.S.B.; Wellen, R.M.R. Photo-degradation of PS/SBRr blends compatibilized with SEBS. Mater. Res. Express 2019, 6, 095327. [Google Scholar] [CrossRef]

- Vogler, E.A. Structure and reactivity of water at biomaterial surfaces. Adv. Colloid Interface Sci. 1998, 74, 69–117. [Google Scholar] [CrossRef]

- Fang, Q.; Ye, F.; Yang, X. Influence of hydrolysis of polyvinyl alcohol on its lubrication for styrene-ethylene-butylene-styrene block copolymer. Tribol. Int. 2019, 134, 408–416. [Google Scholar] [CrossRef]

| Code | E (MPa) | σmax (MPa) | εb (%) | Shore D Hardness | Impact Strength (kJ/m2) |

|---|---|---|---|---|---|

| PLA | 2977 ± 27 a | 35.8 ± 2.6 a | 7.4 ± 0.8 a | 80.0 ± 0.8 a | 1.3 ± 0.1 a |

| PLA/SEBS | 1419 ± 32 b | 6.3 ± 0.7 b | 7.8 ± 1.0 a | 63.0 ± 0.7 b | 4.8 ± 0.5 b |

| PLA/SEBS/SEBS-g-MA | 802 ± 39 c | 4.7 ± 0.6 c | 10.1 ± 1.1 b | 51.6 ± 1.1 c | 4.0 ± 0.1 b |

| PLA/SEBS/MLO | 1275 ± 61 b | 5.2 ± 0.6 c | 50.2 ± 4.3 c | 58.8 ± 0.4 b | 6.1 ± 0.6 c |

| PLA/SEBS/SEBS-g-MA/MLO | 897 ± 83 c | 5.9 ± 0.6 b | 23.0 ± 3.0 d | 58.2 ± 0.8 b | 3.5 ± 0.1 b |

| Code | Tg (°C) |

|---|---|

| PLA | 62.8 ± 0.5 |

| PLA/SEBS | 61.9 ± 0.3 |

| PLA/SEBS/SEBS-g-MA | 61.8 ± 0.4 |

| PLA/SEBS/MLO | 59.8 ± 0.2 |

| PLA/SEBS/SEBS-g-MA-MLO | 60.9 ± 0.1 |

| Code | T5% (°C) | Tdeg (°C) | Residual Weight (%) |

|---|---|---|---|

| PLA | 322.8 ± 1.5 | 368.9 ± 2.2 | 0.3 ± 0.1 |

| PLA/SEBS | 312.3 ± 1.2 | 365.3 ± 1.7 | 0.4 ± 0.1 |

| PLA/SEBS/SEBS-g-MA | 291.8 ± 1.1 | 367.1 ± 1.5 | 0.6 ± 0.2 |

| PLA/SEBS/MLO | 324.8 ± 1.5 | 366.8 ± 1.8 | 0.3 ± 0.2 |

| PLA/SEBS/SEBS-g-MA/MLO | 312.4 ± 1.1 | 368.1 ± 0.9 | 0.2 ± 0.1 |

| Parts | E’ (MPa) at −100 °C | E’ (MPa) at 25 °C | E’ (MPa) at 100 °C | Tg PLA (°C) * |

|---|---|---|---|---|

| PLA | 2110 ± 28 | 1720 ± 14 | 35.3 ± 1.1 | 68.5 ± 0.8 |

| PLA/SEBS | 1815 ± 17 | 427 ± 8 | 4.9 ± 0.3 | 69.3 ± 0.9 |

| PLA/SEBS/SEBS-g-MA | 2030 ± 30 | 260 ± 7 | 3.1 ± 0.2 | 70.0 ± 0.8 |

| PLA/SEBS/MLO | 1780 ± 17 | 875 ± 10 | 5.9 ± 0.6 | 63.8 ± 0.8 |

| PLA/SEBS/SEBS-g-MA/MLO | 1780 ± 25 | 265± 12 | 8.1 ± 0.3 | 63.7 ± 1.1 |

| Code | L* | a* | b* | Yellowness Index (YI) |

|---|---|---|---|---|

| PLA | 40.7 ± 0.3 | −0.45 ± 0.03 | 4.71 ± 0.13 | 21.3 ± 0.3 |

| PLA/SEBS | 53.2 ± 0.1 | 1.42 ± 0.01 | 6.76 ± 0.06 | 26.3 ± 0.1 |

| PLA/SEBS/SEBS-g-MA | 59.3 ± 0.1 | −0.82 ± 0.02 | 5.57 ± 0.10 | 19.3 ± 0.1 |

| PLA/SEBS/MLO | 58.4 ± 0.3 | −2.36 ± 0.02 | 8.69 ± 0.18 | 25.2 ± 0.3 |

| PLA/SEBS/SEBS-g-MA-MLO | 61.1 ± 0.1 | −1.74 ± 0.01 | 9.94 ± 0.02 | 28.1 ± 0.1 |

| Code | PLA (wt.%) | SEBS (wt.%) | SEBS-g-MA (wt.%) | MLO (phr) |

|---|---|---|---|---|

| PLA | 100 | 0 | 0 | 0 |

| PLA/SEBS | 80 | 20 | 0 | 0 |

| PLA/SEBS/SEBS-g-MA | 80 | 18 | 2 | 0 |

| PLA/SEBS/MLO | 80 | 20 | 0 | 5 |

| PLA/SEBS/SEBS-g-MA/MLO | 80 | 19 | 1 | 2.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tejada-Oliveros, R.; Balart, R.; Ivorra-Martinez, J.; Gomez-Caturla, J.; Montanes, N.; Quiles-Carrillo, L. Improvement of Impact Strength of Polylactide Blends with a Thermoplastic Elastomer Compatibilized with Biobased Maleinized Linseed Oil for Applications in Rigid Packaging. Molecules 2021, 26, 240. https://doi.org/10.3390/molecules26010240

Tejada-Oliveros R, Balart R, Ivorra-Martinez J, Gomez-Caturla J, Montanes N, Quiles-Carrillo L. Improvement of Impact Strength of Polylactide Blends with a Thermoplastic Elastomer Compatibilized with Biobased Maleinized Linseed Oil for Applications in Rigid Packaging. Molecules. 2021; 26(1):240. https://doi.org/10.3390/molecules26010240

Chicago/Turabian StyleTejada-Oliveros, Ramon, Rafael Balart, Juan Ivorra-Martinez, Jaume Gomez-Caturla, Nestor Montanes, and Luis Quiles-Carrillo. 2021. "Improvement of Impact Strength of Polylactide Blends with a Thermoplastic Elastomer Compatibilized with Biobased Maleinized Linseed Oil for Applications in Rigid Packaging" Molecules 26, no. 1: 240. https://doi.org/10.3390/molecules26010240