Finger-Temperature-Detecting Liquid Crystal Composite Film for Anti-Counterfeiting Labels

Abstract

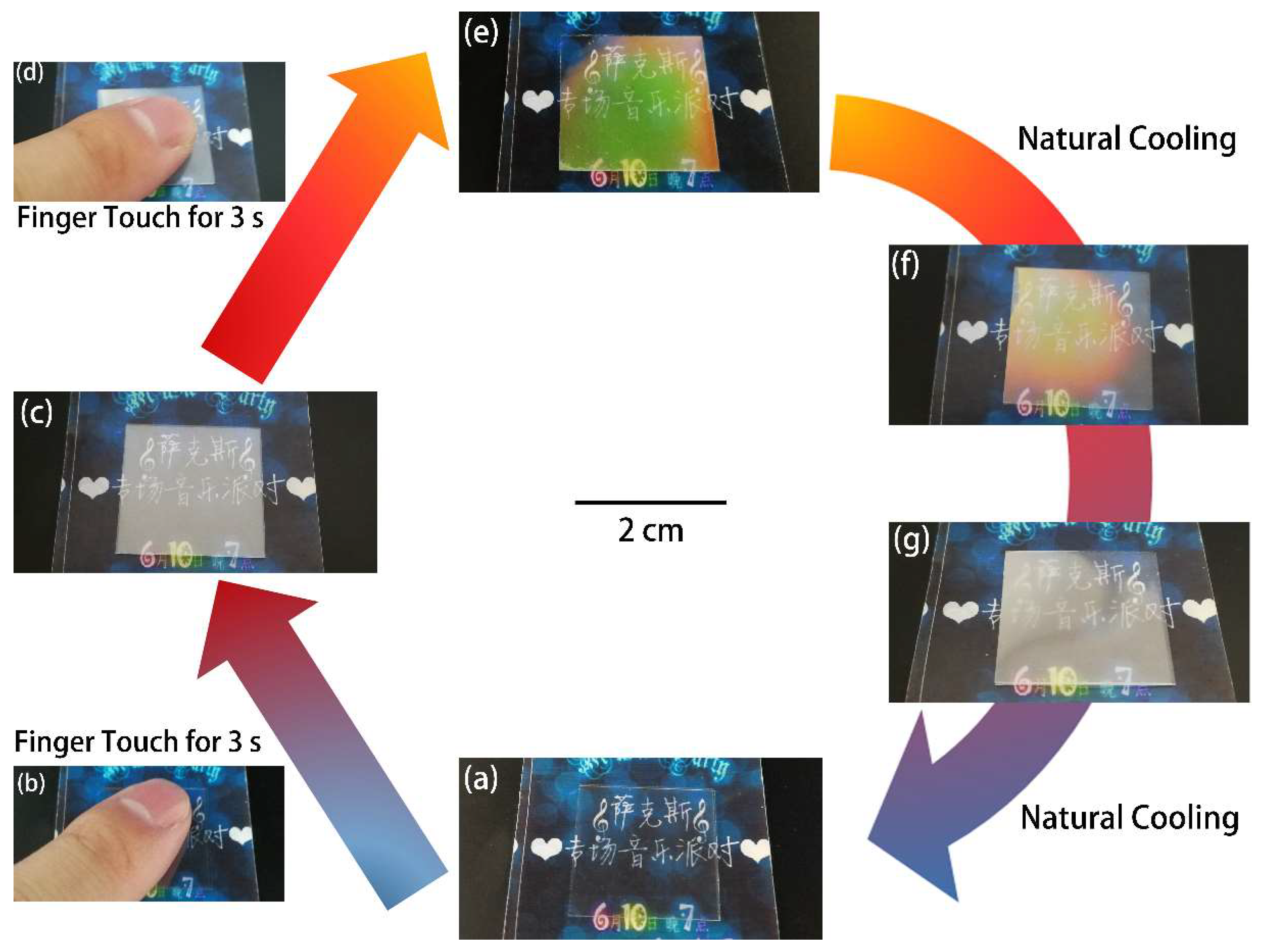

1. Introduction

2. Results and Discussion

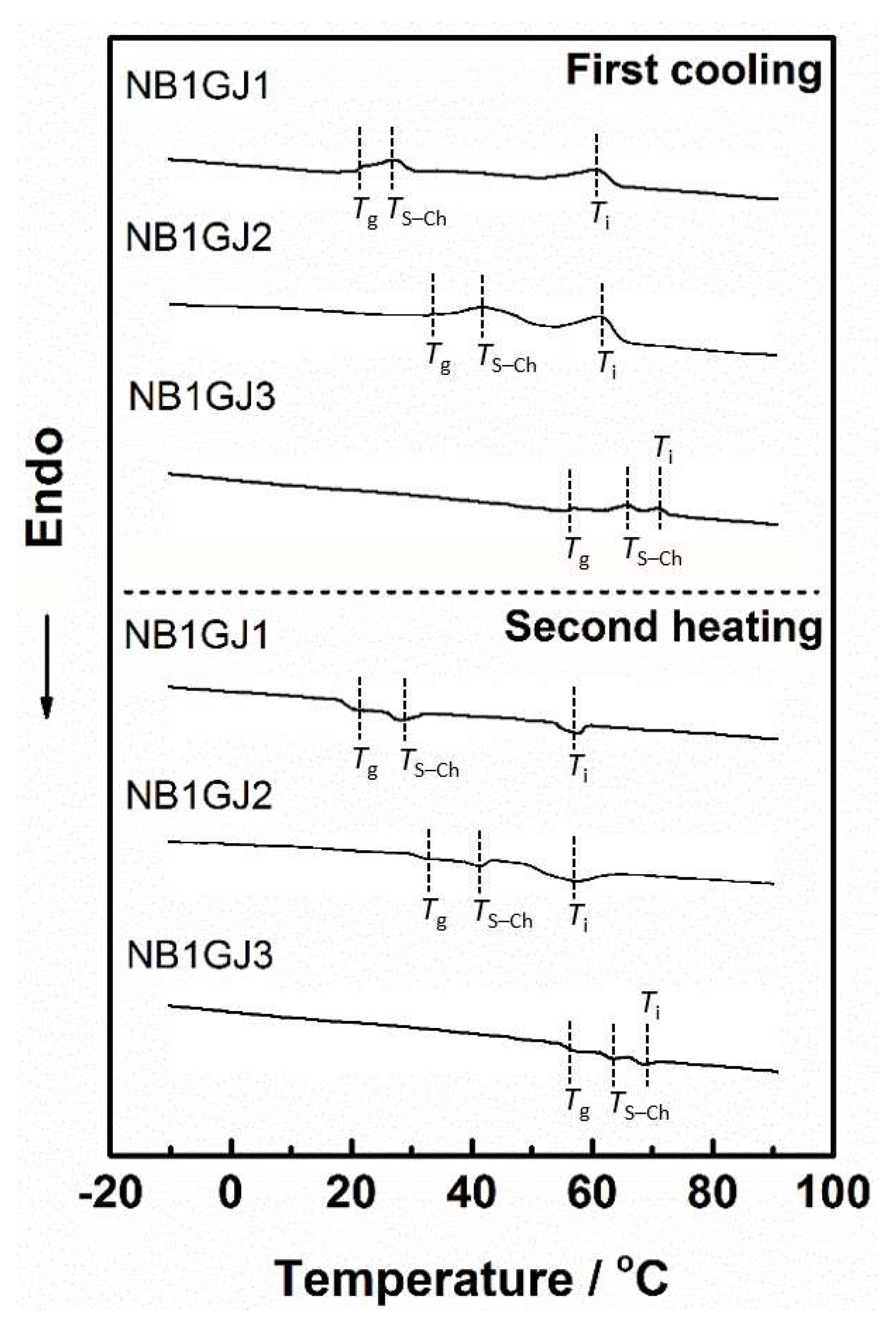

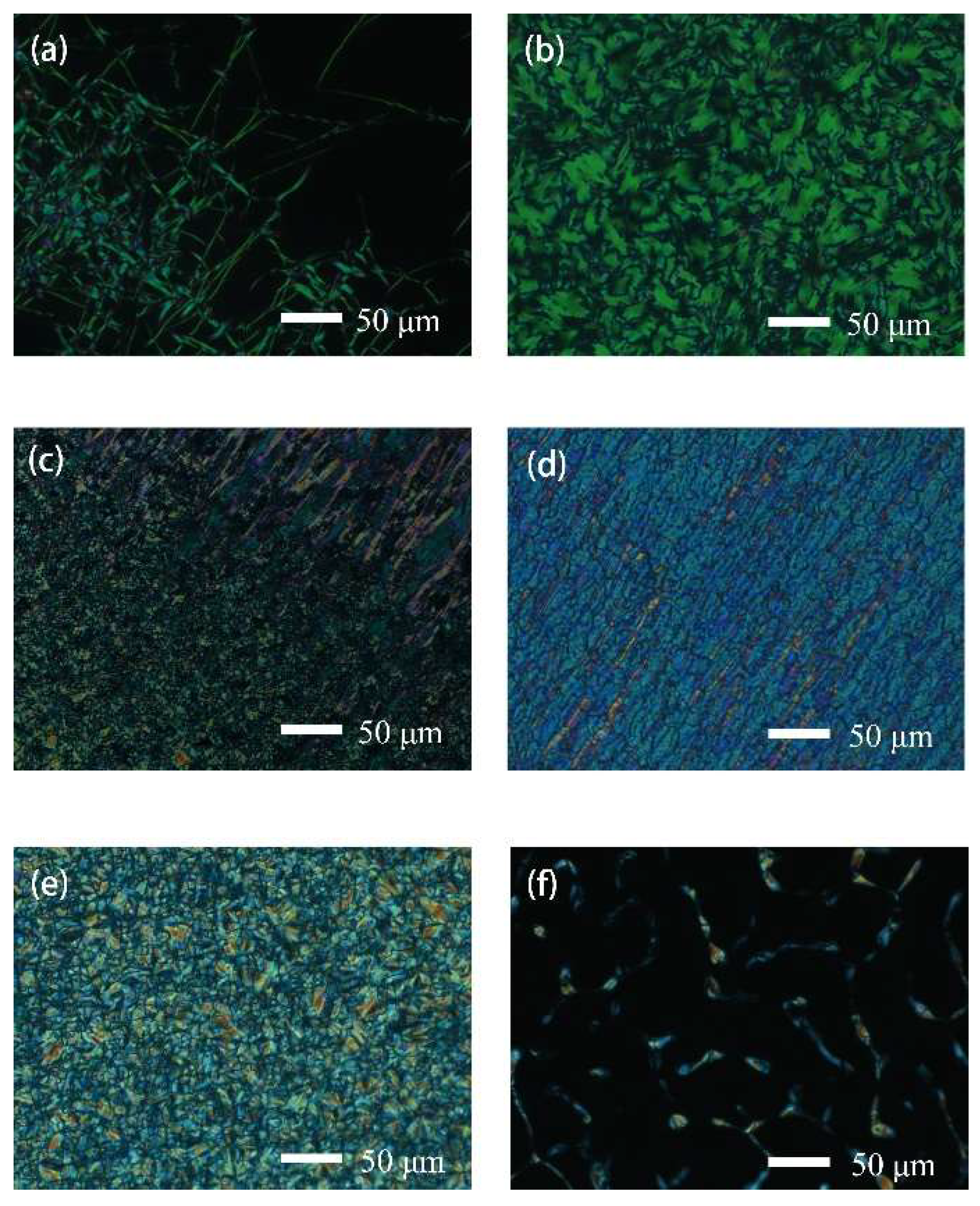

2.1. Phase Behaviors and Phase Structures of the LC Mixtures

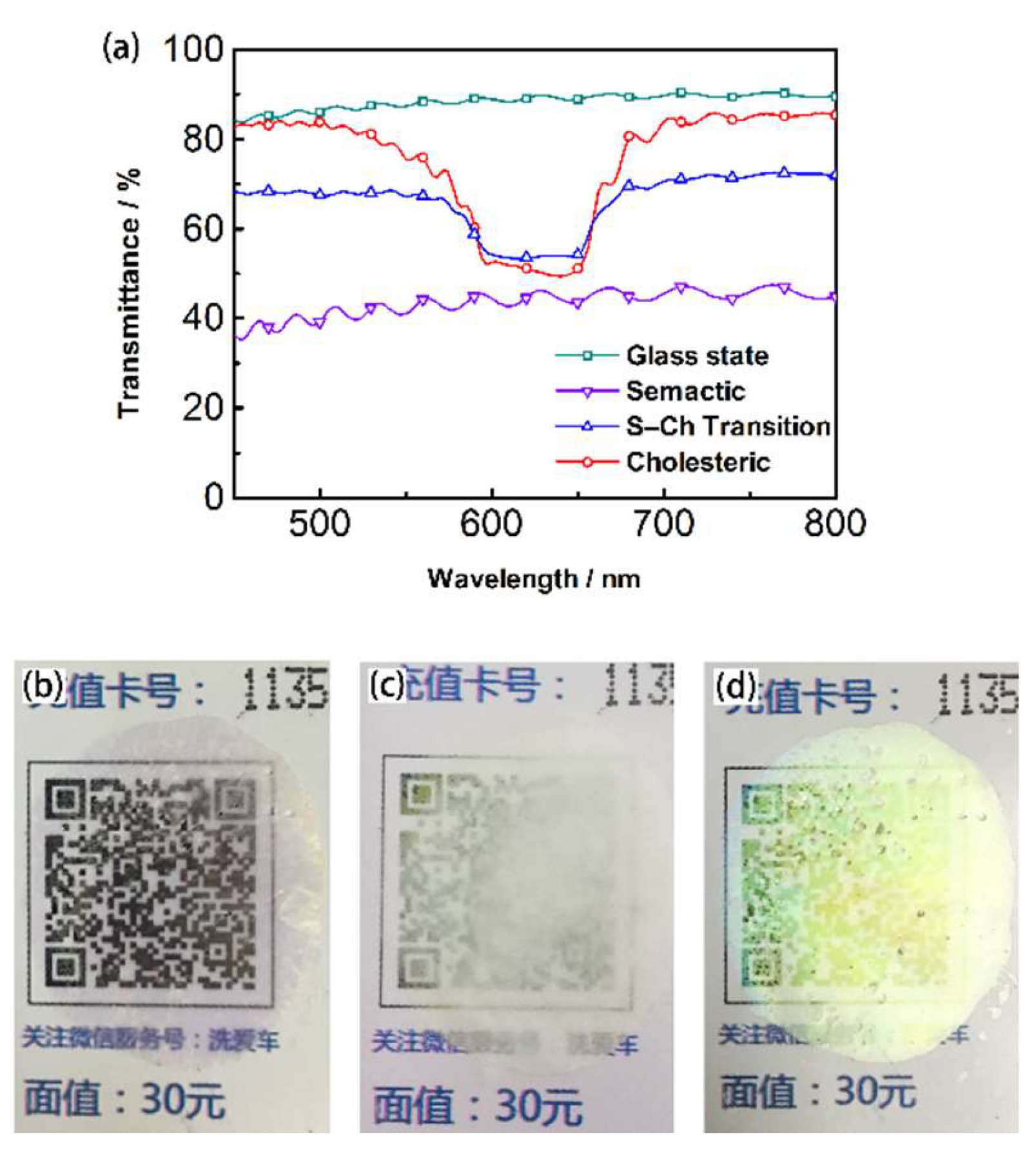

2.2. Optical Properties of the LC Mixture Film

3. Experimental Section

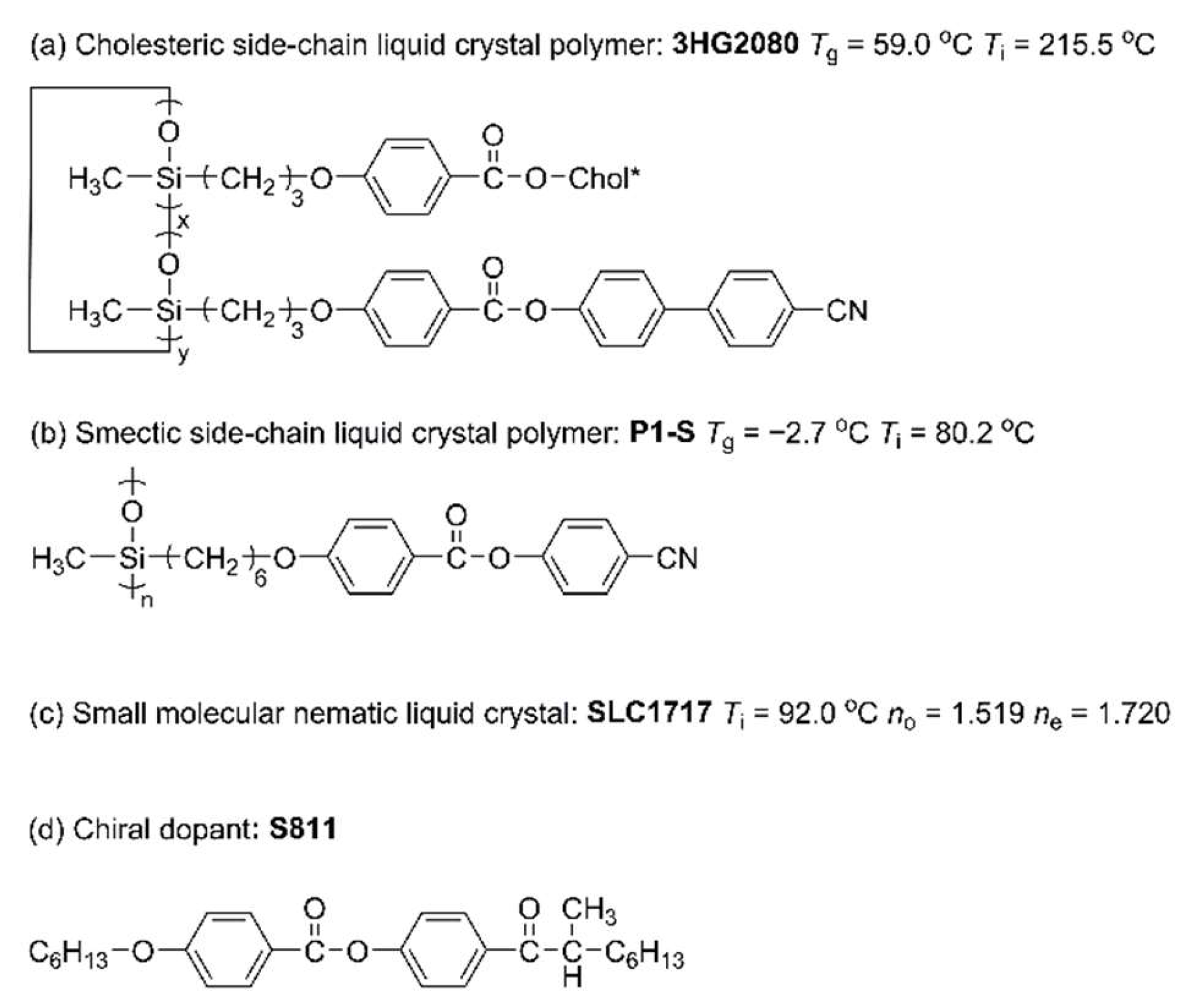

3.1. Materials

3.2. Measurements

3.3. Preparation of the LC Composite Film for Anti-Fake Labels

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Berman, B. Should your firm adopt a mass customization strategy? Bus. Horiz. 2008, 51, 191. [Google Scholar] [CrossRef]

- Mullard, A. The anticounterfeiter's technological tool kit. Nat. Med. 2010, 16, 361. [Google Scholar] [CrossRef]

- Ramjiawan, B.; Ramjiawan, A.; Tappia, P.; Pierce, G. Environmental and Food Safety and Security for South-East Europe and Ukraine. Springer 2012, 203. [Google Scholar]

- Lu, Y.T.; Chi, S. Compact, reliable asymmetric optical configuration for cost-effective fabrication of multiplex dot matrix hologram in anti-counterfeiting applications. Optik 2003, 114, 161–167. [Google Scholar] [CrossRef]

- Huang, S.; Wu, J.K. Optical Watermarking for Printed Document Authentication. IEEE T. INF. FOREN. SEC. 2007, 2, 164–173. [Google Scholar] [CrossRef]

- Hida, M.; Mitsui, T.; Minami, Y. Forensic investigation of counterfeit coins. Forensic Sci. Int. 1997, 89, 21–26. [Google Scholar] [CrossRef]

- Jiang, G.; Wang, S.; Yuan, W.; Zhao, Z.; Duan, A.; Xu, C.; Jiang, L.; Song, Y.; Zhu, D. Photo- and Proton-Dual-Responsive Fluorescence Switch Based on a Bisthienylethene-Bridged Naphthalimide Dimer and Its Application in Security Data Storage. Eur. J. Org. Chem. 2007, 2064–2067. [Google Scholar] [CrossRef]

- Xuan, R.; Ge, J. Invisible photonic prints shown by water. J. Mater. Chem. 2012, 22, 367–372. [Google Scholar] [CrossRef]

- Boudeta, B.; Binet, C.; Mitov, M.; Bourgerette, C.; Boucher, E. Microstructure of variable pitch cholesteric films and its relationship with the optical properties. Eur. Phys. J. E. 2000, 2, 247–253. [Google Scholar] [CrossRef]

- Broer, D.J. Deformed chiral-nematic networks obtained by polarized excitation of a dichroic photoinitiator. Curr. Opin. Solid St. M. 2002, 6, 553–561. [Google Scholar] [CrossRef]

- Bartolino, R.; Scaramuzza, N.; Lucchetta, D.E.; Barna, E.S.; Ionescu, A.T.; Blinov, L.M. Polarity sensitive electrooptical response in a nematic liquid crystal-polymer mixture. J. Appl. Phys. 1999, 85, 2870–2874. [Google Scholar] [CrossRef]

- Zschieschang, U.; Yamamoto, T.; Takimiya, K.; Kuwabara, H.; Ikeda, M.; Sekitani, T.; Someya, T.; Klauk, H. Organic electronics on banknotes. Adv. Mater. 2011, 23, 654. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.A.; Bhansali, U.S.; Alshareef, H.N. High-performance non-volatile organic ferroelectric memory on banknotes. Adv. Mater., 2012, 24. [Google Scholar] [CrossRef] [PubMed]

- Ifa, D.R.; Gumaelius, L.M.; Eberlin, L.S.; Manicke, N.E.; Cooks, R.G. Forensic analysis of inks by imaging desorption electrospray ionization (DESI) mass spectrometry. Analyst 2007, 132, 461–467. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Ma, X.; Lin, Z.; He, M.; Han, G.; Yang, C.; Xing, Z.; Zhang, S.; Zhang, X. Imaging Mass Spectrometry with a Low-Temperature Plasma Probe for the Analysis of Works of Art. Angew. Chem. Int. Ed., 2010, 49, 4435–4437. [Google Scholar] [CrossRef] [PubMed]

- Kobatake, S.; Imagawa, H.; Nakatani, H.; Nakashima, S. The irreversible thermo-bleaching function of a photochromic diarylethene having trimethylsilyl groups. New J. Chem. 2009, 33, 1362–1367. [Google Scholar] [CrossRef]

- Nakayama, K.; Ohtsubo, J. Optical security device providing fingerprint and designed pattern indicator using fingerprint texture in liquid crystal. Opt. Eng. 2012, 51, 0506. [Google Scholar] [CrossRef]

- Li, W.S.; Shen, Y.; Chen, Z.J.; Cui, Q.; Li, S.S.; Chen, L.J. Demonstration of patterned polymer-stabilized cholesteric liquid crystal textures for anti-counterfeiting two-dimensional barcodes. Appl. Optics 2017, 56, 601–606. [Google Scholar] [CrossRef]

- Nakayama, K.; Ohtsubo, J. Optical security devices using nonuniform schlieren texture of UV-curable nematic liquid crystal. Appl. Optics 2016, 55, 1012–1016. [Google Scholar] [CrossRef]

- Cheng, Z.H.; Cao, H.; Zhao, D.Y.; Hu, W.; He, W.L.; Yuan, X.T.; Xiao, J.M.; Zhang, H.Q.; Yang, H. Chiral nematic liquid crystals with helix inversion from (R)-1,1′-binaphthyl and cholesteryl ester moieties. Liq. Cryst. 2011, 38, 9–15. [Google Scholar] [CrossRef]

- Yao, W.H.; Gao, Y.Z.; Yuan, X.; He, B.F.; Yu, H.F.; Zhang, L.Y.; Zhi, Z.H.; He, W.L.; Yang, Z.; Yang, H.; et al. Synthesis and self-assembly behaviours of side-chain smectic thiol–ene polymers based on the polysiloxane backbone. J. Mater. Chem. C 2016, 4, 1425. [Google Scholar] [CrossRef]

- Gao, Y.Z.; Yao, W.H.; Sun, J.; Zhang, H.; Wang, Z.; Wang, L.; Yang, D.K.; Zhang, L.Y.; Yang, H. A novel soft matter composite material for energy-saving smart windows: From preparation to device application. J. Mater. Chem. A 2015, 3, 10738. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| Sample | SLC1717/S811/P1-S/3HG2080 [weight%] | Tga [°C] | TS‒Ch a [°C] | Tia [°C] |

|---|---|---|---|---|

| NB1GJ1 | 53.80/24.40/15.10/6.70 | 21.12 | 29.17 | 58.48 |

| NB1GJ2 | 50.42/22.87/14.15/12.56 | 33.52 | 39.37 | 61.81 |

| NB1GJ3 | 36.62/16.61/10.28/36.49 | 57.60 | 66.84 | 72.42 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, Y.; Feng, K.; Zhang, J.; Zhang, L. Finger-Temperature-Detecting Liquid Crystal Composite Film for Anti-Counterfeiting Labels. Molecules 2020, 25, 521. https://doi.org/10.3390/molecules25030521

Gao Y, Feng K, Zhang J, Zhang L. Finger-Temperature-Detecting Liquid Crystal Composite Film for Anti-Counterfeiting Labels. Molecules. 2020; 25(3):521. https://doi.org/10.3390/molecules25030521

Chicago/Turabian StyleGao, Yanzi, Ke Feng, Jin Zhang, and Lanying Zhang. 2020. "Finger-Temperature-Detecting Liquid Crystal Composite Film for Anti-Counterfeiting Labels" Molecules 25, no. 3: 521. https://doi.org/10.3390/molecules25030521

APA StyleGao, Y., Feng, K., Zhang, J., & Zhang, L. (2020). Finger-Temperature-Detecting Liquid Crystal Composite Film for Anti-Counterfeiting Labels. Molecules, 25(3), 521. https://doi.org/10.3390/molecules25030521