Recent Advances in The Polymer Dispersed Liquid Crystal Composite and Its Applications

Abstract

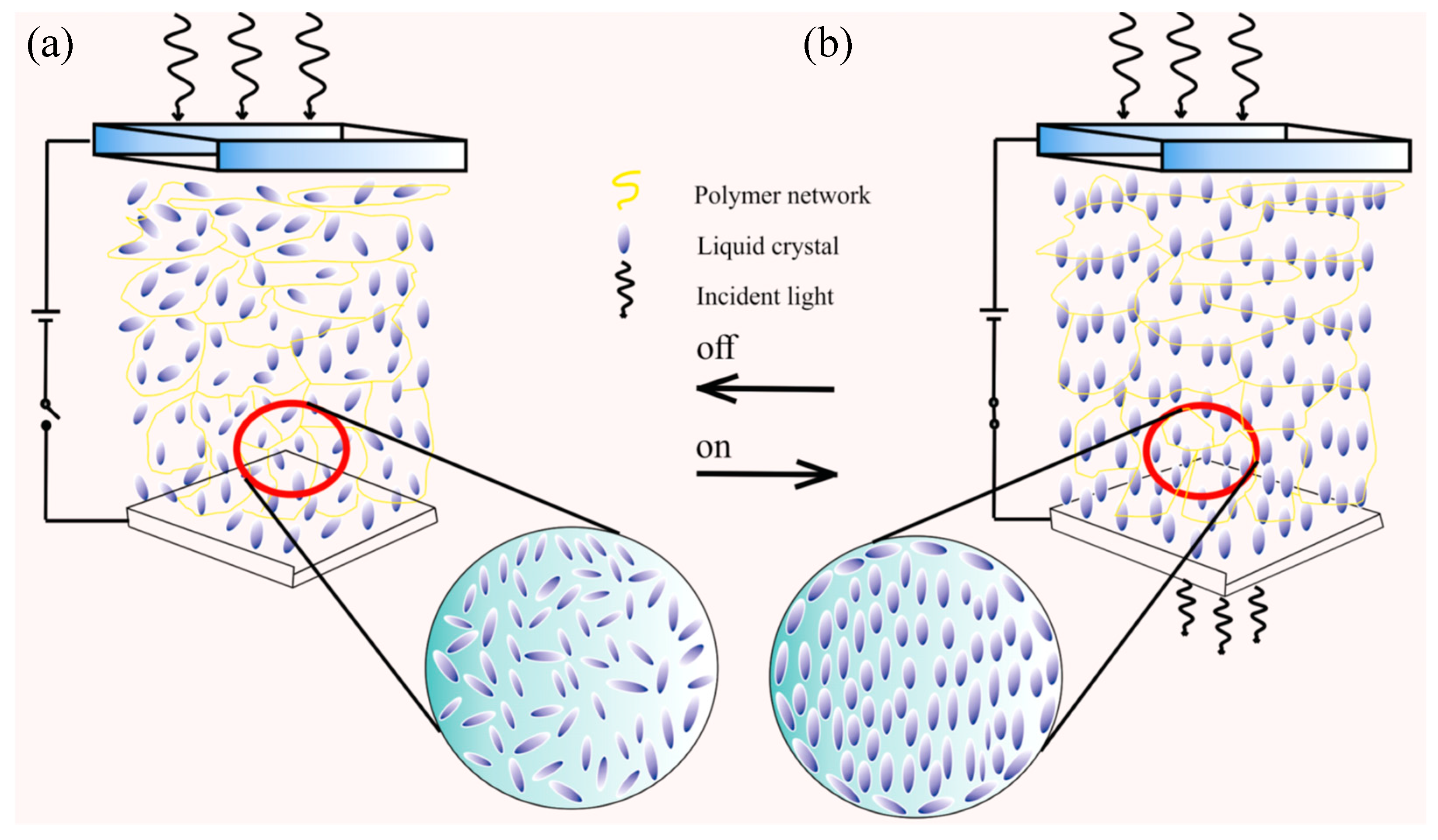

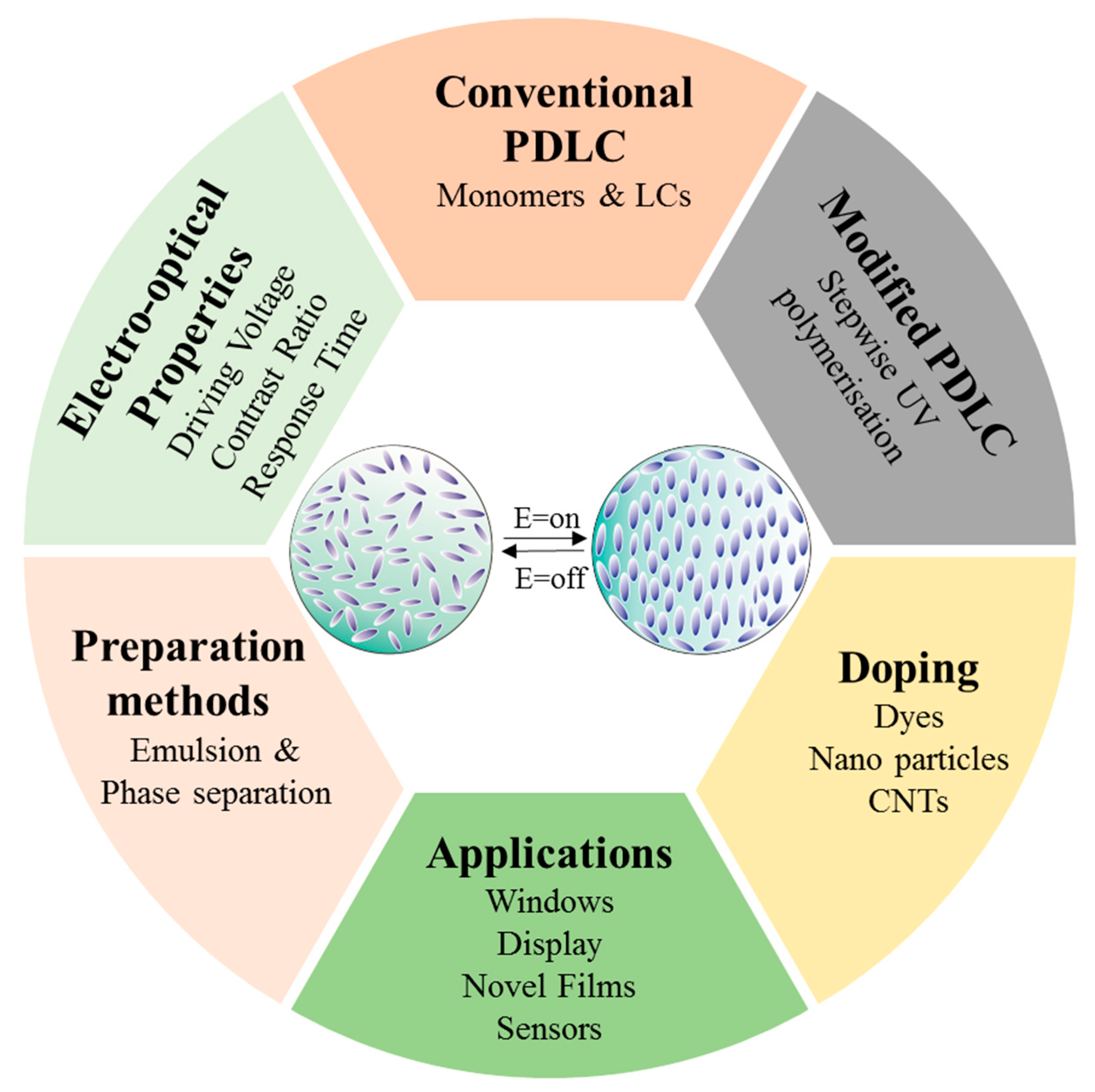

:1. Introduction

2. Preparation of Conventional PDLC Composite Film

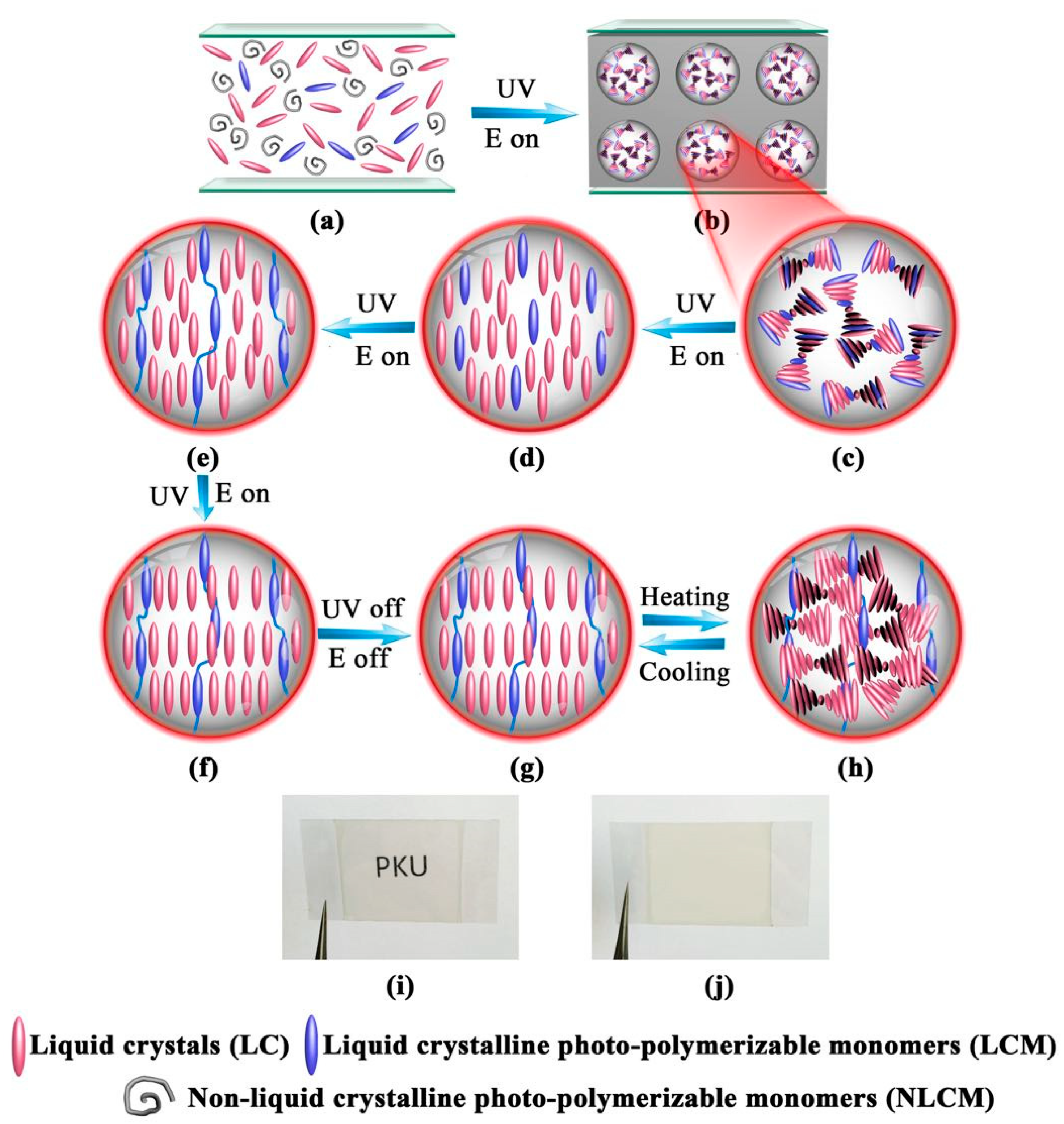

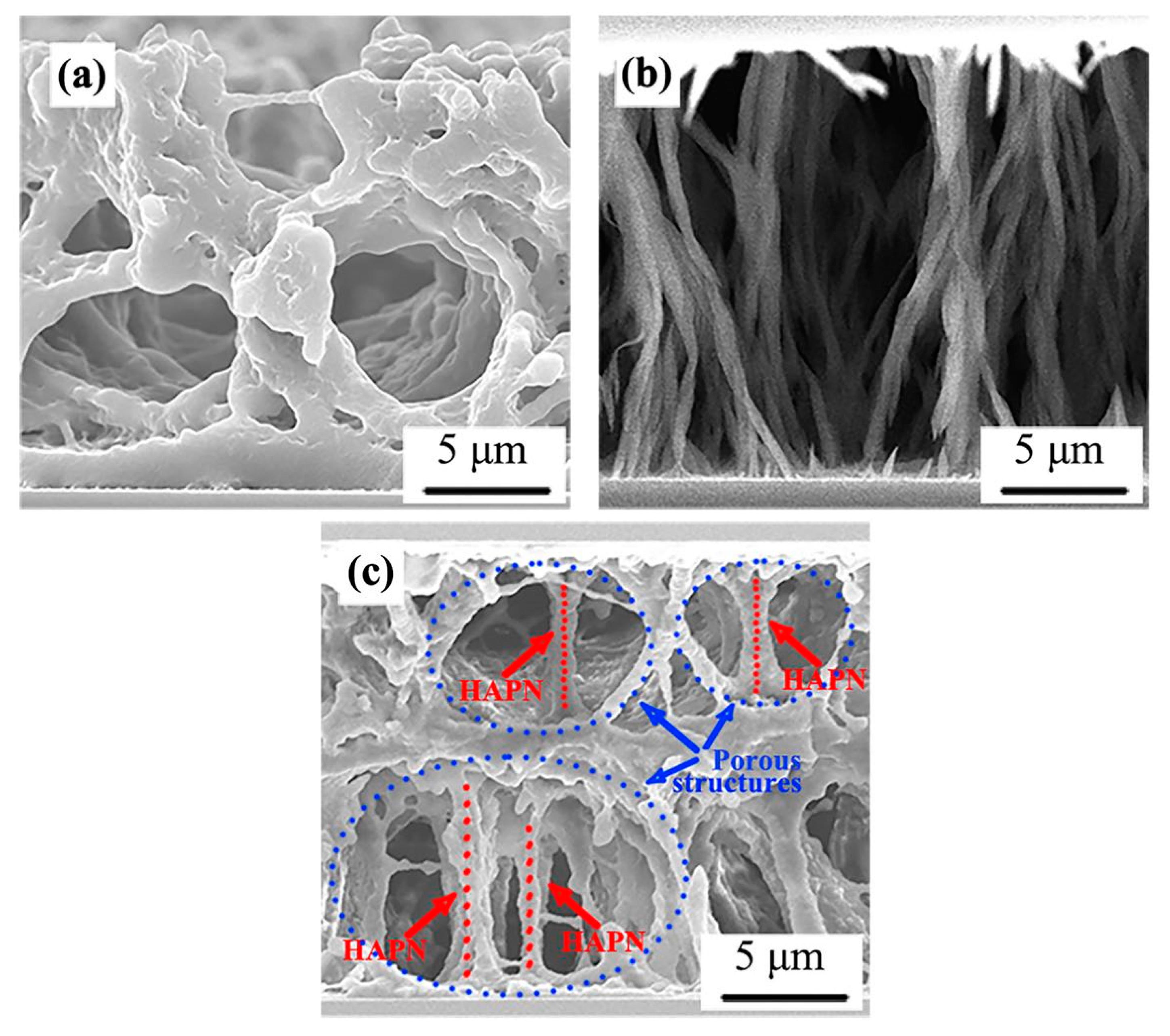

3. Preparation of Modified PDLC Composite Film

4. Preparation of Nanoparticles Doped PDLC Composite Film

5. Preparation of Dye-Doped PDLC Composite Film

6. Preparation of Carbon Nanofillers-doped PDLC Composite Film

7. Applications

7.1. Traditional Applications

7.2. HPDLC

7.3. Novel Films

7.4. Device Components

7.5. Others

8. Conclusions

Funding

Conflicts of Interest

References

- Zhong, T.; Mandle, R.J.; Goodby, J.W.; Zhang, L.; Zhang, C. Comparative studies of polymer-dispersed liquid crystal films via a thiol-ene click reaction. Polym. Adv. Technol. 2019, 30, 2781–2789. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Zhong, T.; Chen, G.; Li, C.; Chen, M.; Zhang, C.; Zhang, L.; Li, K.; Yang, Z.; et al. Electrically switchable light transmittance of epoxy-mercaptan polymer/nematic liquid crystal composites with controllable microstructures. Polymer 2019, 160, 53–64. [Google Scholar] [CrossRef]

- Hu, G.; Chen, H.; Liu, Z.; Zhang, S.; Zhou, Y.; Zhu, B.; Gu, H. Tailoring structure and properties of polymer-dispersed liquid crystal by quenching process. Liq. Cryst. 2020, 46, 1–9. [Google Scholar] [CrossRef]

- Li, C.; Chen, M.; Shen, W.; Chen, G.; Zhang, L.; Yang, H. A study on the polymer structures and electro-optical properties of epoxy-mercaptan-based polymer dispersed liquid crystal films. Liq. Cryst. 2019, 46, 1718–1726. [Google Scholar] [CrossRef]

- Ghosh, A.; Sundaram, S.; Mallick, T.K.; Mallick, T.K. Evaluation of thermal performance for a smart switchable adaptive polymer dispersed liquid crystal (PDLC) glazing. Sol. Energy 2020, 195, 185–193. [Google Scholar] [CrossRef]

- Fahad, M.; Ye, H.; Jeon, S.; Hong, J.-H.; Hong, S.-K. Enhancement of Reflective Optical Properties Using Photoluminescence-Polymer-Dispersed Liquid Crystal with Added Chiral Dopant. Sci. Adv. Mater. 2016, 8, 1745–1751. [Google Scholar] [CrossRef]

- Zhou, L.; Chen, G.; Shen, W.; Zhang, C.; Lanying, Z. Effect of functionality of thiol on the optical properties of liquid crystals/polymer composite films. Liq. Cryst. 2020, 5, 1–9. [Google Scholar] [CrossRef]

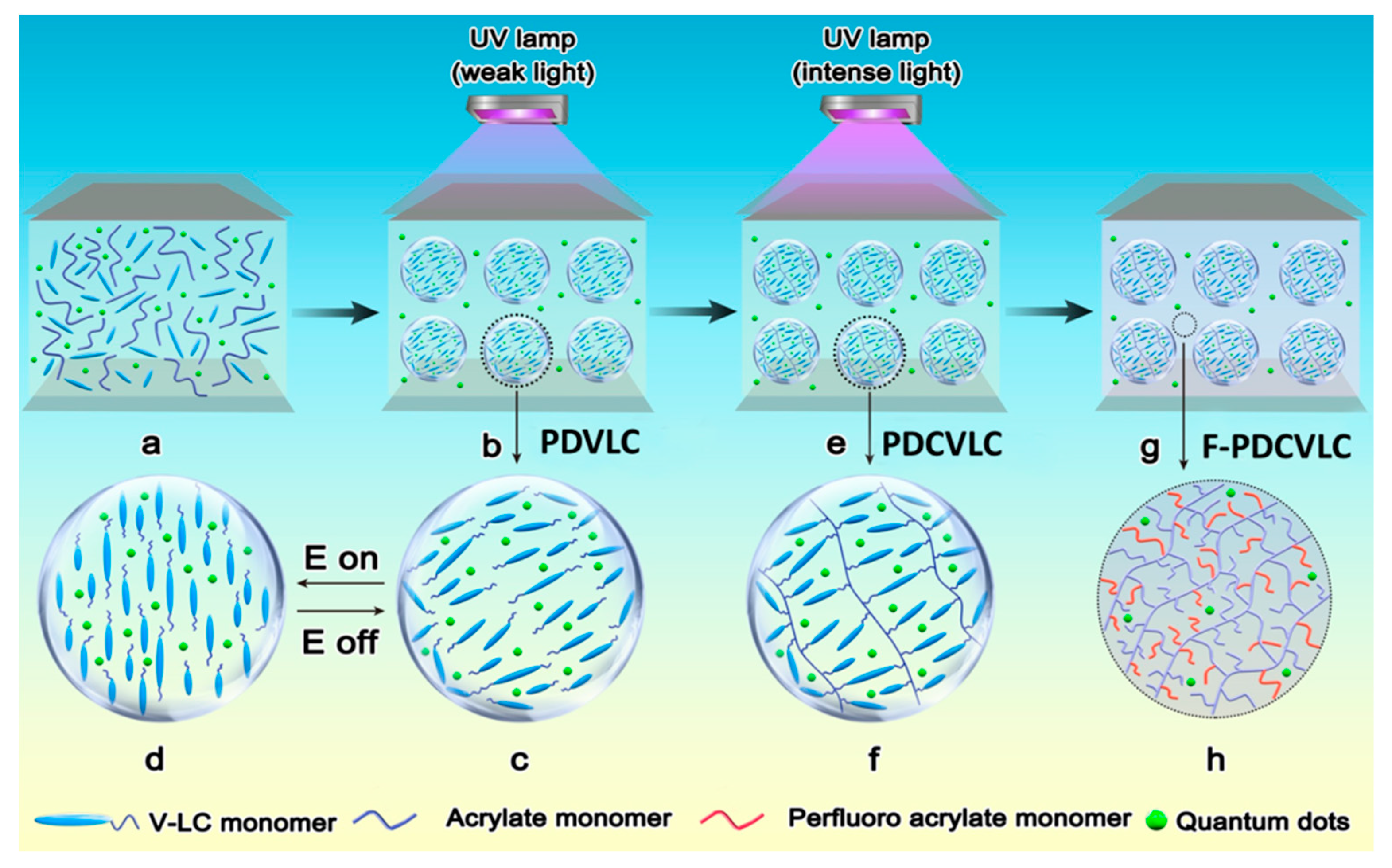

- Zhang, S.; Li, C.; Wang, Q.; Zhou, L.; Saeed, M.H.; Wang, X.; Zhang, L.; Yang, Z.; Yang, H. Fluorescence enhancement and encapsulation of quantum dots via a novel crosslinked vinyl-ether liquid crystals/polymer composite film. Polymer 2020, 207, 122834. [Google Scholar] [CrossRef]

- Jiang, J.; McGraw, G.; Ma, R.; Brown, J.; Yang, D.-K. Selective scattering polymer dispersed liquid crystal film for light enhancement of organic light emitting diode. Opt. Express 2017, 25, 3327–3335. [Google Scholar] [CrossRef]

- Seo, J.; Nam, S.; Jeong, J.; Lee, C.; Kim, H.; Kim, Y. Liquid Crystal-Gated-Organic Field-Effect Transistors with In-Plane Drain–Source–Gate Electrode Structure. ACS Appl. Mater. Interfaces 2014, 7, 504–510. [Google Scholar] [CrossRef]

- Labeeb, A.M.; Ibrahim, S.A.; Ward, A.A.; Abd-El-Messieh, S.L. Polymer/liquid crystal nanocomposites for energy storage applications. Polym. Eng. Sci. 2020, 12, 1–12. [Google Scholar] [CrossRef]

- Nasir, N.; Hong, H.; Rehman, M.A.; Kumar, S.; Seo, Y. Polymer-dispersed liquid-crystal-based switchable glazing fabricated via vacuum glass coupling. RSC Adv. 2020, 10, 32225–32231. [Google Scholar] [CrossRef]

- Chen, C.P.; Kim, D.S.; Jhun, C.G. Electro-Optical Effects of a Color Polymer-Dispersed Liquid Crystal Device by Micro-Encapsulation with a Pigment-Doped Shell. Crystals 2019, 9, 364. [Google Scholar] [CrossRef] [Green Version]

- De Filpo, G.; Armentano, K.; Pantuso, E.; Mashin, A.I.; Chidichimo, G.; Nicoletta, F.P. Polymer Membranes Dispersed Liquid Crystal (PMDLC): A new electro-optical device. Liq. Cryst. 2019, 46, 986–993. [Google Scholar] [CrossRef]

- Li, K.; Jiang, H.; Cheng, M.; Li, Y.; Yin, Z.; Luo, D.; Sun, X.W.; Liu, Y.J. Controlling morphological and electro-optical properties via the phase separation in polymer/liquid-crystal composite materials. Liq. Cryst. 2020, 47, 238–247. [Google Scholar] [CrossRef]

- Zhong, T.; Mandle, R.J.; Goodby, J.W.; Zhang, C.; Zhang, L. Thiol-ene reaction based polymer dispersed liquid crystal composite films with low driving voltage and high contrast ratio. Liq. Cryst. 2019, 1–13. [Google Scholar] [CrossRef]

- Chen, M.; Liang, X.; Hu, W.; Zhang, L.; Zhang, C.; Yang, H. A polymer microsphere-filled cholesteric-liquid crystal film with bistable electro-optical characteristics. Mater. Des. 2018, 157, 151–158. [Google Scholar] [CrossRef]

- Shao, L.; Li, J.; Zhang, Y.; Gong, S.; Wang, Y. Effect of macro-RAFT agent on the morphology of polymer dispersed liquid crystals. Liq. Cryst. 2014, 41, 652–661. [Google Scholar] [CrossRef]

- Li, C.; Chen, M.; Zhang, L.; Shen, W.; Liang, X.; Wang, X.; Yang, H. An electrically light-transmittance-switchable film with a low driving voltage based on liquid crystal/polymer composites. Liq. Cryst. 2019, 47, 1–8. [Google Scholar] [CrossRef]

- Chen, M.; Hu, W.; Liang, X.; Zhang, H.; Zhang, C.; Song, P.; Zhang, L.; Li, F.; Chen, F.; Yang, H. The regulation of polymer structures and electro-optical properties of epoxy-mercaptan-based phase separated liquid crystals/polymer composites. Polymer 2017, 127, 1–7. [Google Scholar] [CrossRef]

- Kim, J.; Han, J.I. Effect of UV intensity on the electro-optical properties of polymer dispersed liquid crystal lens for smart electronic glasses. Electron. Mater. Lett. 2014, 10, 665–669. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, J.; Zhou, L.; Gao, Y.; Hai, M.; Zhang, L.; Li, F.; Zhou, G.; Li, X.; Zhang, C.; et al. Preparation of polymer-dispersed liquid crystal doped with indium tin oxide nanoparticles. Liq. Cryst. 2017, 45, 1068–1077. [Google Scholar] [CrossRef]

- Jain, A.K.; Deshmukh, R. An Overview of Polymer-Dispersed Liquid Crystals Composite Films and Their Applications. Liq. Cryst. Disp. Technol. 2020, 1–68. [Google Scholar] [CrossRef]

- Egamov, M.H.; Gerasimov, V.P.; Krakhalev, M.N.; Prishchepa, O.O.; Zyryanov, V.Y.; Loiko, V.A. Polarizing properties of a stretched film of a polymer-dispersed liquid crystal with a surfactant dopant. J. Opt. Technol. 2014, 81, 414–417. [Google Scholar] [CrossRef]

- Krakhalev, M.N.; Prishchepa, O.O.; Sutormin, V.S.; Zyryanov, V.Y. Polymer dispersed nematic liquid crystal films with conical boundary conditions for electrically controllable polarizers. Opt. Mater. 2019, 89, 1–4. [Google Scholar] [CrossRef] [Green Version]

- Cui, Y.; Zola, R.S.; Yang, D.-K.; Yang, Y.-C. P-142: Improvement of PDLC Performance by Changing Surface Anchoring Strength. SID Symp. Dig. Tech. Pap. 2011, 42, 1641–1644. [Google Scholar] [CrossRef]

- Rudyak, V.Y.; Krakhalev, M.N.; Prishchepa, O.O.; Sutormin, V.S.; Emelyanenko, A.V.; Zyryanov, V.Y. Orientational structures in nematic droplets with conical boundary conditions. JETP Lett. 2017, 106, 384–389. [Google Scholar] [CrossRef] [Green Version]

- Deshmukh, R.; Jain, A.K. Effect of anti-parallel and twisted alignment techniques on various properties of polymer stabilised liquid crystal (PSLC) films. Liq. Cryst. 2017, 43, 436–447. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamil, M.; Jeon, Y.J. The effect of voltage controlled orientation order of liquid crystals in non-acrylic polymer dispersed liquid crystals films. J. Dispers. Sci. Technol. 2017, 39, 1115–1120. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamil, M.; Lee, J.W.; Jee, K.E.; Jeon, Y.J. Transitions of bipolar to radial orientation of liquid crystal droplets in amphiphilic system of PDLC film. J. Dispers. Sci. Technol. 2017, 38, 1325–1329. [Google Scholar] [CrossRef]

- Deshmukh, R.; Katariya-Jain, A. Novel techniques of PDLC film preparation furnishing manifold properties in a single device. Liq. Cryst. 2015, 43, 256–267. [Google Scholar] [CrossRef]

- Rumi, M.; Bunning, T.J.; Sio, L.D.E. Polymer dispersed liquid crystals. Soft Mater. Ser. 2019, 8, 61–104. [Google Scholar] [CrossRef]

- Singh, S.; Srivastava, J.K.; Singh, R.K. Polymer dispersed liquid crystals. Liq. Cryst. Polym. 2016, 7, 195–250. [Google Scholar]

- Bronnikov, S.; Kostromin, S.; Zuev, V. Polymer-Dispersed Liquid Crystals: Progress in Preparation, Investigation, and Application. J. Macromol. Sci. Part B 2013, 52, 1718–1735. [Google Scholar] [CrossRef]

- Ahmad, F.; Jeon, Y.J.; Jamil, M. Graphene-based polymer dispersed liquid crystals display—An overview. Mol. Cryst. Liq. Cryst. 2018, 669, 46–60. [Google Scholar] [CrossRef]

- Jamil, M.; Ahmad, F.; Rhee, J. Nanoparticle-doped polymer-dispersed liquid crystal display. Curr. Sci. 2011, 101, 1544–1552. [Google Scholar]

- Yang, D.; Wu, S. Liquid Crystal/Polymer Composites. In Fundamentals of Liquid Crystal Devices; John Wiley & Sons: Hoboken, NJ, USA, 2014; Volume 11, pp. 363–412. [Google Scholar] [CrossRef]

- Higgins, D.A. Probing the Mesoscopic Chemical and Physical Properties of Polymer-Dispersed Liquid Crystals. Adv. Mater. 2000, 12, 251–264. [Google Scholar] [CrossRef]

- Liu, J.; Liu, X.; Zhen, Z. Effects of chiral additives on the electro-optical properties of polymer dispersed liquid crystal. Mater. Lett. 2016, 163, 142–145. [Google Scholar] [CrossRef]

- Li, W.; Cao, H.; Kashima, M.; Liu, F.; Cheng, Z.; Yang, Z.; Zhu, S.; Yang, H. Control of the microstructure of polymer network and effects of the microstructures on light scattering properties of UV-cured polymer-dispersed liquid crystal films. J. Polym. Sci. Part B Polym. Phys. 2008, 46, 2090–2099. [Google Scholar] [CrossRef]

- Ellahi, M.; Liu, F.; Song, P.; Gao, Y.; Rafique, M.Y.; Khan, D.F.; Cao, H.; Yang, H. Characterization and morphology of polymer-dispersed liquid crystal films. Soft Mater. 2014, 12, 339–345. [Google Scholar] [CrossRef]

- Li, W.; Yu, L.; He, W.; Yuan, X.; Zhao, N.; Huang, W.; Cao, H.; Yang, Z.; Yang, H. Effect of a Photopolymerizable Monomer Containing a Hydrogen Bond on Near-Infrared Radiation Transmittance of Nematic Liquid Crystal/Monomers Composites. J. Phys. Chem. C 2008, 112, 13739–13743. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamil, M.; Jeon, Y.J.; Woo, L.J.; Jung, J.E.; Jang, J.E.; Lee, G.H.; Park, J. Comparative study on the electrooptical properties of polymer-dispersed liquid crystal films with different mixtures of monomers and liquid crystals. J. Appl. Polym. Sci. 2011, 121, 1424–1430. [Google Scholar] [CrossRef]

- Manda, R.; Pagidi, S.; Kim, M.; Park, C.H.; Yoo, H.S.; Sandeep, K.; Lim, Y.J.; Lee, S.H. Effect of monomer concentration and functionality on electro-optical properties of polymer-stabilised optically isotropic liquid crystals. Liq. Cryst. 2017, 45, 736–745. [Google Scholar] [CrossRef]

- Mouquinho, A.; Figueirinhas, J.; Sotomayor, J. Digital optical memory devices based on polymer-dispersed liquid crystals films: Appropriate polymer matrix morphology. Liq. Cryst. 2019, 47, 636–649. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, D.; Cao, H.; Song, P.; Yang, C.; Yang, H.; Hu, G.-H. Preparation and electro-optical properties of polymer dispersed liquid crystal films with relatively low liquid crystal content. Polym. Adv. Technol. 2013, 24, 453–459. [Google Scholar] [CrossRef]

- Kizhakidathazhath, R.; Nishikawa, H.; Okumura, Y.; Higuchi, H.; Kikuchi, H. High-Performance Polymer Dispersed Liquid Crystal Enabled by Uniquely Designed Acrylate Monomer. Polymers 2020, 12, 1625. [Google Scholar] [CrossRef]

- Saeed, M.H.; Zhang, S.; Zhou, L.; Chen, G.; Wang, M.; Zhang, L.; Yang, D.; Yang, H. Effects of rigid structures containing (meth)acrylate monomers and crosslinking agents with different chain length on the morphology and electro-optical properties of polymer-dispersed liquid crystal films. J. Mod. Opt. 2020, 67, 682–691. [Google Scholar] [CrossRef]

- Lin, H.; Zhang, S.; Saeed, M.H.; Zhou, L.; Gao, H.; Huang, J.; Zhang, L.; Yang, H.; Xiao, J.; Gao, Y. Effects of the methacrylate monomers with different end groups on the morphologies, electro-optical and mechanical properties of polymer dispersed liquid crystals composite films. Liq. Cryst. 2020, 1–13. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Chen, G.; Li, C.; Han, C.; Zhang, J.; Zhang, J.; Zhang, L.; Yang, H. Effects of polymer micro-structures on the thermo-optical properties of a flexible soft-mater film based on liquid crystals/polymer composite. Polymer 2018, 146, 161–168. [Google Scholar] [CrossRef]

- Gao, H.; Zhang, S.; Saeed, M.H.; Chen, G.; Lin, H.; Huang, J.; Zhang, L.; Wang, Q.; Cao, H. Study on the morphologies and electro-optical properties of cyano-phenyl-ester liquid crystals/polymer composite films prepared by a stepwise polymerisation. Liq. Cryst. 2020, 1–10. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, C.; Zhou, L.; Fang, H.; Huang, J.; Ma, H.; Zhang, Y.; Yang, J.; Zhang, L.; Song, P.; et al. Effect of a Polymercaptan Material on the Electro-Optical Properties of Polymer-Dispersed Liquid Crystal Films. Molecules 2016, 22, 43. [Google Scholar] [CrossRef] [Green Version]

- Yang, J.; Zhang, Y.; Zhang, C.; Lanying, Z.; Li, C.; Zhang, S.; Li, C.; Zhang, J.; Zhang, D.; Sun, Y.; et al. Regulating content of thiol/LC and UV intensity to optimize morphology and electro-optical performance of polymer-dispersed liquid crystal. Liq. Cryst. 2018, 45, 1–8. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, Y.; Zhou, L.; Huang, J.; Fang, H.; Ma, H.; Zhang, Y.; Yang, J.; Song, P.; Zhang, C.; et al. A Study on the Electro-Optical Properties of Thiol-Ene Polymer Dispersed Cholesteric Liquid Crystal (PDChLC) Films. Molecules 2017, 22, 317. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, L.; Shi, Z.; He, T.; Liu, Y.; Wang, Y. Effects of the chain length of crosslinking agent and dye-doped amount on the electro-optical properties of polymer-dispersed liquid crystal films prepared by nucleophile-initiated thiol-ene click reaction. Liq. Cryst. 2019, 47, 42–53. [Google Scholar] [CrossRef]

- Shi, Z.; Shao, L.; Wang, F.; Deng, F.; Liu, Y.; Wang, Y. Fabrication of dye-doped polymer-dispersed liquid crystals with low driving voltage based on nucleophile-initiated thiol-ene click reaction. Liq. Cryst. 2017, 45, 579–585. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, Y.; Wang, Y. Effects of thiol monomers on the electro-optical properties of polymer-dispersed liquid crystal films prepared by nucleophile-initiated thiol-ene click reaction. Liq. Cryst. 2018, 45, 1746–1752. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, Y.; Shi, Z.; He, T.; Gong, X.; Geng, P.; Gao, Z.; Wang, Y. Effects of alkyl chain length of monomer and dye-doped type on the electro-optical properties of polymer-dispersed liquid crystal films prepared by nucleophile-initiated thiol-ene click reaction. Liq. Cryst. 2019, 47, 658–672. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, L.; Yang, J.; Zhang, J.; Hai, M.; Zhang, L.; Li, F.; Zhang, C.; Yang, Z.; Yang, H.; et al. Effects of crosslinking agent/diluents/thiol on morphology of the polymer matrix and electro-optical properties of polymer-dispersed liquid crystal. Liq. Cryst. 2017, 45, 728–735. [Google Scholar] [CrossRef]

- Sun, Y.; Zhang, C.; Cao, H.; Gao, Y.; Ding, H.; Li, F.; Yu, H.; Yang, Z.; Yang, H. Effects of functionality of thiol monomer on electro-optical properties of polymer-dispersed liquid crystal films. Liq. Cryst. 2016, 44, 1086–1092. [Google Scholar] [CrossRef]

- Zhang, H.; Zhong, T.; Chen, M.; Zhang, L.; Liu, X.; Cao, H.; Yang, H.; Zhu, S. The physical properties of alkene-terminated liquid crystal molecules/E8 mixture and the electro-optical properties as they doped in polymer-dispersed liquid crystal systems. Liq. Cryst. 2017, 45, 1118–1128. [Google Scholar] [CrossRef]

- Zhang, H.; Cao, H.; Chen, M.; Zhang, L.; Jiang, T.; Chen, H.; Li, F.; Zhu, S.; Yang, H. Effects of the fluorinated liquid crystal molecules on the electro-optical properties of polymer dispersed liquid crystal films. Liq. Cryst. 2017, 44, 2301–2310. [Google Scholar] [CrossRef]

- Zhang, H.; Chen, M.; Jiang, T.; Chen, H.; Zhang, D.; Sun, Y.; Zhang, L.; Zhu, S.; Yang, H. Cyano terminated tolane compounds for polymer dispersed liquid crystal application: Relationship between cyano terminated tolane based molecular structures and electro-optical properties. Liq. Cryst. 2018, 45, 1771–1782. [Google Scholar] [CrossRef]

- Chidichimo, G.; De Filpo, G.; Manfredi, S.; Mormile, S.; Tortora, L.; Gallucci, C.; Cassano, R. High Contrast Reverse Mode PDLC Films: A Morphologic and Electro-Optical Analysis. Mol. Cryst. Liq. Cryst. 2009, 500, 10–22. [Google Scholar] [CrossRef]

- Wang, H.; Wang, L.; Chen, M.; Li, T.; Cao, H.; Yang, D.; Yang, Z.; Yang, H.; Zhu, S. Bistable polymer-dispersed cholesteric liquid crystal thin film enabled by a stepwise polymerization. RSC Adv. 2015, 5, 58959–58965. [Google Scholar] [CrossRef]

- Guo, S.-M.; Liang, X.; Zhang, C.-H.; Chen, M.; Shen, C.; Zhang, L.; Yuan, X.; He, B.-F.; Yang, H. Preparation of a Thermally Light-Transmittance-Controllable Film from a Coexistent System of Polymer-Dispersed and Polymer-Stabilized Liquid Crystals. ACS Appl. Mater. Interfaces 2017, 9, 2942–2947. [Google Scholar] [CrossRef]

- Guo, S.; Liang, X.; Zhang, H.; Shen, W.; Li, C.; Wang, X.; Zhang, C.; Zhang, L.; Yang, H. An electrically light-transmittance-controllable film with a low-driving voltage from a coexistent system of polymer-dispersed and polymer-stabilised cholesteric liquid crystals. Liq. Cryst. 2018, 45, 1854–1860. [Google Scholar] [CrossRef]

- Li, C.-Y.; Wang, X.; Liang, X.; Sun, J.; Li, C.-X.; Zhang, S.-F.; Zhang, L.; Zhang, H.; Yang, H. Electro-Optical Properties of a Polymer Dispersed and Stabilized Cholesteric Liquid Crystals System Constructed by a Stepwise UV-Initiated Radical/Cationic Polymerization. Crystals 2019, 9, 282. [Google Scholar] [CrossRef] [Green Version]

- Shen, W.; Wang, L.; Chen, G.; Li, C.; Zhang, L.; Yang, Z.; Yang, H. A facile route towards controllable electric-optical performance of polymer-dispersed liquid crystal via the implantation of liquid crystalline epoxy network in conventional resin. Polymer 2019, 167, 67–77. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Wang, Q.; Guo, S.; Zhang, L.; Yang, H. Active and passive modulation of solar light transmittance in a hybrid thermochromic soft-matter system for energy-saving smart window applications. J. Mater. Chem. C 2018, 6, 7054–7062. [Google Scholar] [CrossRef]

- Wu, Q.; Wang, Y. Low driving voltage ITO doped polymer-dispersed liquid crystal film and reverse voltage pulse driving method. Appl. Opt. 2017, 56, 8159. [Google Scholar] [CrossRef]

- Zhang, C.; Ge, Y.; Huo, X.; Xue, J.; Li, K.; Zhang, Y.; Miao, Z. Studies on electro-optical properties of polymer matrix/LC/ITO nanoparticles composites. Polym. Adv. Technol. 2019, 31, 544–552. [Google Scholar] [CrossRef]

- Niu, X.; Liu, J.; Liu, W.; Zhu, S. Flexible free-standing films morphology characterization: PVA/silica polymer network dispersed cholesteric liquid crystals films by sol-gel method. Liq. Cryst. 2019, 46, 1396–1402. [Google Scholar] [CrossRef]

- Jayoti, D.; Malik, P.; Singh, A. Analysis of morphological behaviour and electro-optical properties of silica nanoparticles doped polymer dispersed liquid crystal composites. J. Mol. Liq. 2017, 225, 456–461. [Google Scholar] [CrossRef]

- Beroguiaa, D.; Abdoune, F.Z.; Belaid, Z.H.; Méchernène, L. Influence of SiO2 nanoparticles on electro-optical and thermophysical properties of polyacrylate/liquid crystal composites. Liq. Cryst. 2019, 47, 799–809. [Google Scholar] [CrossRef]

- Mishra, K.K.; Dubey, S.K.; Mani, S.A. Optical characterization of inorganic nanoparticles doped in polymer dispersed liquid crystal. Mol. Cryst. Liq. Cryst. 2017, 647, 244–252. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, J.; Jiang, Z.; Zhu, Q.; Chen, Q.; Zhuang, S. Optical and dielectric analysis of ZnO nanorods doped polymer dispersed liquid crystal and ethanol gas sensing investigation. Liq. Cryst. 2020, 1–10. [Google Scholar] [CrossRef]

- He, T.; Yang, B.; Zhang, L.; Shi, Z.; Gong, X.; Geng, P.; Gao, Z.; Wang, Y. A study on electro-optical properties of polymer dispersed liquid crystal films doped with barium titanate nanoparticles prepared by nucleophile-initiated thiol-ene click reaction. Liq. Cryst. 2019, 47, 1004–1018. [Google Scholar] [CrossRef]

- Hsu, C.-C.; Chen, Y.-X.; Li, H.-W.; Hsu, J.-S. Low switching voltage ZnO quantum dots doped polymer-dispersed liquid crystal film. Opt. Express 2016, 24, 7063–7068. [Google Scholar] [CrossRef]

- Kumari, A.; Sinha, A. Role of BaTiO3 nanoparticles on electro-optic performance of epoxy-resin-based PDLC devices. Liq. Cryst. 2020, 1–12. [Google Scholar] [CrossRef]

- Shim, H.; Lyu, H.-K.; Allabergenov, B.; Garbovskiy, Y.; Glushchenko, A.; Choi, B. Enhancement of frequency modulation response time for polymer-dispersed liquid crystal. Liq. Cryst. 2016, 43, 1390–1396. [Google Scholar] [CrossRef]

- Kocakülah, G.; Balci, S.; Köysal, O. Determination of Phase Transition and Electro-Optical Behaviors of Quantum Dot Doped Polymer Dispersed Liquid Crystal. J. Electron. Mater. 2020, 49, 3427–3434. [Google Scholar] [CrossRef]

- John, V.N.; Varanakkottu, S.N.; Varghese, S. Flexible, ferroelectric nanoparticle doped polymer dispersed liquid crystal devices for lower switching voltage and nanoenergy generation. Opt. Mater. 2018, 80, 233–240. [Google Scholar] [CrossRef]

- Jayoti, D.; Malik, P. Dielectric Study of Gold Nanoparticle Doped Polymer Dispersed Liquid Crystal. In Proceedings of the 2nd International Conference On Condensed Matter and Applied Physics (ICC 2017), Bikaner, India, 24–25 November 2017; Volume 1953. [Google Scholar] [CrossRef]

- Ji, Y.-Y.; Fan, F.; Zhang, X.; Cheng, J.-R.; Chang, S.-J. Terahertz birefringence anisotropy and relaxation effects in polymer-dispersed liquid crystal doped with gold nanoparticles. Opt. Express 2020, 28, 17253–17265. [Google Scholar] [CrossRef]

- Chan, C.-H.; Wu, T.-Y.; Yen, M.-H.; Lin, C.-E.; Cheng, K.-T.; Chen, C.C. Low power consumption and high-contrast light scattering based on polymer-dispersed liquid crystals doped with silver-coated polystyrene microspheres. Opt. Express. 2016, 24, 29963. [Google Scholar] [CrossRef] [PubMed]

- Önsal, G.; Kocakülah, G.; Kahyaoğlu, A.; Köysal, O. Influence of azo dye concentration on dielectric response in polymer dispersed liquid crystal composites. J. Mol. Liq. 2019, 284, 607–615. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, V.; Jaggi, C.; Raina, K. Dye-dependent studies on droplet pattern and electro-optic behaviour of polymer dispersed liquid crystal. Liq. Cryst. 2016, 44, 757–767. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, V.; Chinky, J.; Jayoti, D.; Raina, K.; Malik, P. Impact of dye on the switching responses of polymer dispersed ferroelectric liquid crystal. Mol. Cryst. Liq. Cryst. 2017, 647, 385–394. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamil, M.; Jeon, Y.J. Advancement trends in dye-doped polymer dispersed liquid crystals—A survey review. Mol. Cryst. Liq. Cryst. 2017, 648, 88–113. [Google Scholar] [CrossRef]

- Kim, M.; Park, K.J.; Seok, S.; Ok, J.M.; Jung, H.-T.; Choe, J.; Kim, D.H. Fabrication of Microcapsules for Dye-Doped Polymer-Dispersed Liquid Crystal-Based Smart Windows. ACS Appl. Mater. Interfaces 2015, 7, 17904–17909. [Google Scholar] [CrossRef]

- Cheng, Z.; Wang, T.; Li, X.; Zhang, Y.; Yu, H. NIR–Vis–UV Light-Responsive Actuator Films of Polymer-Dispersed Liquid Crystal/Graphene Oxide Nanocomposites. ACS Appl. Mater. Interfaces 2015, 7, 27494–27501. [Google Scholar] [CrossRef]

- Kumar, P.; Sharma, V.; Jaggi, C.; Malik, P.; Raina, K. Orientational control of liquid crystal molecules via carbon nanotubes and dichroic dye in polymer dispersed liquid crystal. Liq. Cryst. 2016, 44, 843–853. [Google Scholar] [CrossRef]

- Deshmukh, R.; Jain, A.K. The complete morphological, electro-optical and dielectric study of dichroic dye-doped polymer-dispersed liquid crystal. Liq. Cryst. 2014, 41, 960–975. [Google Scholar] [CrossRef]

- Jain, A.K.; Deshmukh, R. Influence of a guest dichroic azo dye on a host liquid crystal dispersed in polymer matrix. Int. J. ChemTech Res. 2014, 6, 1813–1816. [Google Scholar]

- Kocakülah, G.; Önsal, G.; Köysal, O. Electro-optical and dielectric performance analysis: The influence of azo dye on polymer/LC composite structures. Appl. Phys. A 2018, 125. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, P.; Sharma, A.; Chinky, J.; Raina, K. Droplet configuration control with orange azo dichroic dye in polymer dispersed liquid crystal for advanced electro-optic characteristics. J. Mol. Liq. 2017, 233, 122–130. [Google Scholar] [CrossRef]

- Sharma, V.; Kumar, P. Studies of absorption coefficient cum electro-optic performance of polymer dispersed liquid crystal doped with CNT and dichroic dye. Phys. B Condens. Matter 2017, 524, 118–122. [Google Scholar] [CrossRef]

- Jain, A.K.; Deshmukh, R. Electro-optical and dielectric study of multi-walled carbon nanotube doped polymer dispersed liquid crystal films. Liq. Cryst. 2018, 46, 1191–1202. [Google Scholar] [CrossRef]

- Wu, Y.; Cao, H.; Duan, M.; Li, E.; Wang, H.; Yang, Z.; Wang, D.; He, W.-L. Effects of a chemically modified multiwall carbon nanotubes on electro-optical properties of PDLC films. Liq. Cryst. 2017, 45, 1023–1031. [Google Scholar] [CrossRef]

- Liang, X.; Guo, C.; Chen, M.; Guo, S.; Lanying, Z.; Li, F.; Guo, S.; Yang, H. A roll-to-roll process for multi-responsive soft-matter composite films containing Cs: X WO 3 nanorods for energy-efficient smart window applications. Nanoscale Horizons 2017, 2, 319–325. [Google Scholar] [CrossRef]

- Liang, X.; Guo, S.; Chen, M.; Li, C.; Wang, Q.; Zou, C.; Zhang, C.; Zhang, L.; Guo, S.; Yang, H. A temperature and electric field-responsive flexible smart film with full broadband optical modulation. Mater. Horizons 2017, 4, 878–884. [Google Scholar] [CrossRef]

- Liang, X.; Chen, M.; Guo, S.-M.; Zhang, L.; Li, F.; Yang, H. Dual-Band Modulation of Visible and Near-Infrared Light Transmittance in an All-Solution-Processed Hybrid Micro–Nano Composite Film. ACS Appl. Mater. Interfaces 2017, 9, 40810–40819. [Google Scholar] [CrossRef]

- Kumar, S.; Hong, H.; Choi, W.; Akhtar, I.; Rehman, M.A.; Seo, Y. Acrylate-assisted fractal nanostructured polymer dispersed liquid crystal droplet based vibrant colored smart-windows. RSC Adv. 2019, 9, 12645–12655. [Google Scholar] [CrossRef] [Green Version]

- Murray, J.; Ma, D.; Munday, J.N. Electrically Controllable Light Trapping for Self-Powered Switchable Solar Windows. ACS Photonics 2016, 4, 1–7. [Google Scholar] [CrossRef]

- Chung, S.-H.; Noh, H.Y. Polymer-dispersed liquid crystal devices with graphene electrodes. Opt. Express 2015, 23, 32149–32157. [Google Scholar] [CrossRef] [PubMed]

- Huh, J.-W.; Yu, B.-H.; Heo, J.; Yoon, T.-H. Double-layered light shutter using long-pitch cholesteric liquid crystal cells. Appl. Opt. 2015, 54, 3792–3795. [Google Scholar] [CrossRef]

- Oh, S.-W.; Baek, J.-M.; Heo, J.; Yoon, T.-H. Dye-doped cholesteric liquid crystal light shutter with a polymer-dispersed liquid crystal film. Dye. Pigment. 2016, 134, 36–40. [Google Scholar] [CrossRef]

- Dierking, I. Polymer-Modified Liquid Crystals; Royal Society of Chemistry: London, UK, 2019. [Google Scholar]

- Li, H.; Qi, Y.; Guo, C.; Malallah, R.; Sheridan, J.T. Holographic characterization of diffraction grating modulation in photopolymers. Appl. Opt. 2018, 57, E107–E117. [Google Scholar] [CrossRef]

- Neipp, C.; Taleb, S.I.; Francés, J.; Fernández, R.; Puerto, D.; Calzado, E.M.; Gallego, S.; Belendez, A. Analysis of the Imaging Characteristics of Holographic Waveguides Recorded in Photopolymers. Polymers 2020, 12, 1485. [Google Scholar] [CrossRef]

- Fuh, A.Y.-G.; Tsai, Y.-L.; Yang, C.-H.; Wu, S.T. Fabrication of optical vortex lattices based on holographic polymer-dispersed liquid crystal films. Opt. Lett. 2017, 43, 154–157. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, K.; Gao, H.; Lu, F.; Sun, L.; Zhuang, S. Multi-wavelength sensitive holographic polymer dispersed liquid crystal grating applied within image splitter for autostereoscopic display. In Proceedings of the Photonic Fiber and Crystal Devices: Advances in Materials and Innovations in Device Applications X, San Diego, CA, USA, 28 August–1 September 2016; Volume 9958, p. 995818. [Google Scholar] [CrossRef]

- Wang, K.; Zheng, J.; Liu, Y.; Gao, H.; Zhuang, S. Electrically tunable two-dimensional holographic polymer-dispersed liquid crystal grating with variable period. Opt. Commun. 2017, 392, 128–134. [Google Scholar] [CrossRef]

- Fuh, A.Y.-G.; Chen, W.-K.; Cheng, K.-T.; Liu, Y.-C.; Liu, C.-K.; Chen, Y.-D. Formation of holographic gratings in polymer-dispersed liquid crystals using off-resonant light. Opt. Mater. Express 2015, 5, 774. [Google Scholar] [CrossRef]

- Fernandez, R.; Gallego, S.; Márquez, A.; Francés, J.; Martínez, F.; Gallego, S.; Belendez, A. Analysis of holographic polymer-dispersed liquid crystals (HPDLCs) for tunable low frequency diffractive optical elements recording. Opt. Mater. 2018, 76, 295–301. [Google Scholar] [CrossRef] [Green Version]

- Liu, L.; Kong, X.; Wang, Q.; Liu, Y.; Xuan, L.; Liu, Y. High pump efficiency of a second-order distributed feedback laser based on holographic polymer dispersed liquid crystals with preferred liquid crystal molecular orientation. J. Mater. Chem. C 2018, 6, 9517–9522. [Google Scholar] [CrossRef]

- De Sio, L.; Lloyd, P.F.; Tabiryan, N.V.; Bunning, T.J.; Tabriyan, N.V. Hidden Gratings in Holographic Liquid Crystal Polymer-Dispersed Liquid Crystal Films. ACS Appl. Mater. Interfaces 2018, 10, 13107–13112. [Google Scholar] [CrossRef]

- Manda, R.; Pagidi, S. Fast response and transparent optically isotropic liquid crystal diffraction grating Fast response and transparent optically isotropic liquid crystal diffraction grating. Opt. Express. 2017, 25, 24033–24043. [Google Scholar] [CrossRef]

- Peng, H.; Chen, G.; Ni, M.; Yan, Y.; Zhuang, J.; Roy, V.A.L.; Li, R.K.Y.; Xie, X. Classical photopolymerization kinetics, exceptional gelation, improved diffraction efficiency and driving voltage in scaffolding morphological H-PDLCs afforded by photoinitibitor. Polym. Chem. 2015, 9, 1–11. [Google Scholar] [CrossRef]

- Ni, M.; Chen, G.; Sun, H.; Xie, X.; Yang, Z.; Liao, Y.; Ye, Y.S.; Yang, Y.; Xie, X. Well-structured holographic polymer dispersed liquid crystals by employing acrylamide and doping ZnS nanoparticles. Mater. Chem. Front. 2017, 1, 294–303. [Google Scholar] [CrossRef]

- Chen, G.; Ni, M.; Xie, X.; Huang, F.; Liao, Y.; Wang, M.; Zhu, J.; Roy, V.A.L.; Xie, X. Photoinitiation and Inhibition under Monochromatic Green Light for Storage of Colored 3D Images in Holographic Polymer-Dispersed Liquid Crystals. ACS Appl. Mater. Interfaces 2017, 9, 1810–1819. [Google Scholar] [CrossRef]

- Ma, H.; Zhou, L.; Han, C.; Zhang, C.; Zhang, L. The fabrication of novel optical diffusers based on UV-cured polymer dispersed liquid crystals. Liq. Cryst. 2018, 46, 138–144. [Google Scholar] [CrossRef]

- Zhou, L.; Ma, H.; Han, C.; Hu, W.; Zhang, S.; Zhang, L.; Yang, H. A novel light diffuser based on the combined morphology of polymer networks and polymer balls in a polymer dispersed liquid crystals film. RSC Adv. 2018, 8, 21690–21698. [Google Scholar] [CrossRef] [Green Version]

- Zhou, L.; Han, C.; Saeed, M.H.; Zhang, C.; Zhang, L. A switchable optical diffuser based on a polymer/nematic liquid crystal composite film with transient polymer balls-networks microstructure. Liq. Cryst. 2019, 46, 2213–2222. [Google Scholar] [CrossRef]

- Zhou, L.; Saeed, M.H.; Zhang, L. Optical diffusers based on uniform nano-sized polymer balls/nematic liquid crystals composite films. Liq. Cryst. 2019, 47, 785–798. [Google Scholar] [CrossRef]

- Zhou, L.; He, Z.; Han, C.; Zhang, L.; Yang, H. Switchable anti-peeping film for liquid crystal displays from polymer dispersed liquid crystals. Liq. Cryst. 2018, 46, 718–724. [Google Scholar] [CrossRef]

- Han, C.; Zhou, L.; Ma, H.; Li, C.; Zhang, S.; Cao, H.; Zhang, L.; Yang, H. Fabrication of a controllable anti-peeping device with a laminated structure of microlouver and polymer dispersed liquid crystals film. Liq. Cryst. 2019, 46, 2235–2244. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, Q.; Li, C.; Shi, G.; Zhang, L.; Wang, X.; Yang, Z.; Yang, H. Fluorescence enhancement of quantum dots from the titanium dioxide/liquid crystals/polymer composite films. Liq. Cryst. 2020, 1–14. [Google Scholar] [CrossRef]

- Ailincai, D.; Marin, L. Eco-friendly PDLC composites based on chitosan and cholesteryl acetate. J. Mol. Liq. 2020, 114466, 114466. [Google Scholar] [CrossRef]

- He, Z.; Yin, K.; Hsiang, E.-L.; Wu, S.-T. Volumetric light-shaping polymer-dispersed liquid crystal films for mini-LED backlights. Liq. Cryst. 2020, 1–6. [Google Scholar] [CrossRef]

- Cong, S.; Cao, Y.; Fang, X.; Wang, Y.-F.; Liu, Q.; Gui, H.; Shen, C.; Cao, X.; Kim, E.S.; Zhou, C. Carbon Nanotube Macroelectronics for Active Matrix Polymer-Dispersed Liquid Crystal Displays. ACS Nano 2016, 10, 10068–10074. [Google Scholar] [CrossRef]

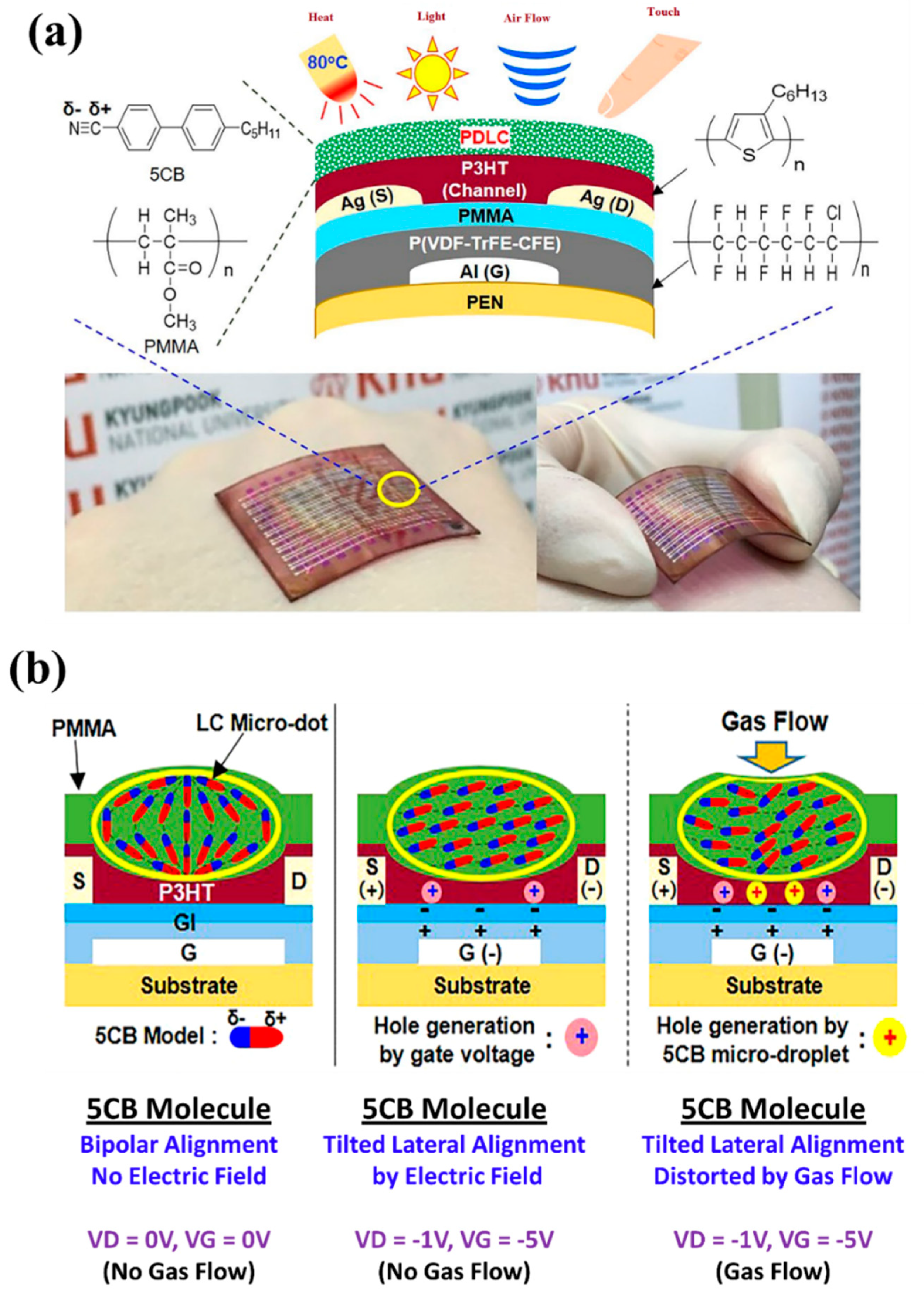

- Song, M.; Seo, J.; Kim, H.; Kim, Y. Ultrasensitive Multi-Functional Flexible Sensors Based on Organic Field-Effect Transistors with Polymer-Dispersed Liquid Crystal Sensing Layers. Sci. Rep. 2017, 7, 1–11. [Google Scholar] [CrossRef]

- Mateen, F.; Ali, M.; Oh, H.; Hong, S.-K. Nitrogen-doped carbon quantum dot based luminescent solar concentrator coupled with polymer dispersed liquid crystal device for smart management of solar spectrum. Sol. Energy 2019, 178, 48–55. [Google Scholar] [CrossRef]

- Mateen, F.; Oh, H.; Jung, W.; Lee, S.Y.; Kikuchi, H.; Hong, S.-K. Polymer dispersed liquid crystal device with integrated luminescent solar concentrator. Liq. Cryst. 2017, 45, 498–506. [Google Scholar] [CrossRef]

- Mateen, F.; Oh, H.; Jung, W.; Binns, M.; Hong, S.-K. Metal nanoparticles based stack structured plasmonic luminescent solar concentrator. Sol. Energy 2017, 155, 934–941. [Google Scholar] [CrossRef]

- Vasiliev, M.; Nur-E-Alam, M.; Alameh, K. Recent Developments in Solar Energy-Harvesting Technologies for Building Integration and Distributed Energy Generation. Energies 2019, 12, 1080. [Google Scholar] [CrossRef] [Green Version]

- Khlifi, S.; Bigeon, J.; Cortes, M.A.; Dumait, N.; Loas, G.; Cordier, S.; Molard, Y. Switchable Two-Dimensional Waveguiding Abilities of Luminescent Hybrid Nanocomposites for Active Solar Concentrators. ACS Appl. Mater. Interfaces 2020, 12, 14400–14407. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Wang, X. Odor Modulates Hand Movements in a Reach-to-Grasp Task. Front. Neurosci. 2020, 14, 560. [Google Scholar] [CrossRef]

- Esteves, C.; Ramou, E.; Porteira, A.R.P.; Barbosa, A.J.M.; Roque, A.C.A. Seeing the Unseen: The Role of Liquid Crystals in Gas-Sensing Technologies. Adv. Opt. Mater. 2020, 8, 1902117. [Google Scholar] [CrossRef]

- Ailincai, D.; Farcau, C.; Paslaru, E.; Marin, L. PDLC composites based on polyvinyl boric acid matrix—A promising pathway towards biomedical engineering. Liq. Cryst. 2016, 43, 1973–1985. [Google Scholar] [CrossRef]

- Ailincai, D.; Pamfil, D.; Marin, L. Multiple bio-responsive polymer dispersed liquid crystal composites for sensing applications. J. Mol. Liq. 2018, 272, 572–582. [Google Scholar] [CrossRef]

- Perju, E.; Stoleru, E.; Marin, L. Polymer-dispersed liquid crystal composites for bio-applications: Thermotropic, surface and optical properties. Liq. Cryst. 2015, 42, 370–382. [Google Scholar] [CrossRef]

- Edwards, R.S.; Ward, J.; Zhou, L.Q.; Trushkevych, O. The interaction of polymer dispersed liquid crystal sensors with ultrasound. Appl. Phys. Lett. 2020, 116, 044104. [Google Scholar] [CrossRef] [Green Version]

- Hassanfiroozi, A.; Huang, Y.-P. Effect of Noncovalent Interaction of a Polymer-Dispersed Liquid Crystal for Interferometric Applications over a Range of Low Frequencies. ACS Appl. Polym. Mater. 2019, 1, 2840–2845. [Google Scholar] [CrossRef]

- Pagidi, S.; Manda, R.; Bhattacharyya, S.S.; Lee, S.G.; Song, S.M.; Lim, Y.J.; Lee, S.H.; Lee, S.H. Fast Switchable Micro-Lenticular Lens Arrays Using Highly Transparent Nano-Polymer Dispersed Liquid Crystals. Adv. Mater. Interfaces 2019, 6, 1–7. [Google Scholar] [CrossRef]

- Yu, J.H.; Chen, H.-S.; Chen, P.-J.; Song, K.H.; Noh, S.C.; Lee, J.M.; Ren, H.; Lin, Y.-H.; Lee, S.H. Electrically tunable microlens arrays based on polarization-independent optical phase of nano liquid crystal droplets dispersed in polymer matrix. Opt. Express 2015, 23, 17337–17344. [Google Scholar] [CrossRef] [PubMed]

| No. | Monomers | Chemical Structure | Reference |

|---|---|---|---|

| 1 | Lauryl acrylate |  | [48] |

| 2 | Lauryl methacrylate |  | [50] |

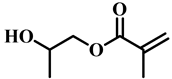

| 3 | Hydroxypropyl methacrylate |  | [49,50] |

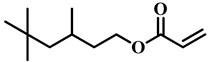

| 4 | 3, 5, 5-trimethelhexyl acrylate |  | [51] |

| 5 | Glycidyl methacrylate |  | [49] |

| 6 | Tetrahydrofurfuryl acrylate |  | [48] |

| 7 | Tetrahydrofurfuryl methacrylate |  | [48,49] |

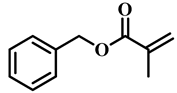

| 8 | Benzyl methacrylate |  | [48,49] |

| 9 | Cyclohexyl methacrylate |  | [48,49] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saeed, M.H.; Zhang, S.; Cao, Y.; Zhou, L.; Hu, J.; Muhammad, I.; Xiao, J.; Zhang, L.; Yang, H. Recent Advances in The Polymer Dispersed Liquid Crystal Composite and Its Applications. Molecules 2020, 25, 5510. https://doi.org/10.3390/molecules25235510

Saeed MH, Zhang S, Cao Y, Zhou L, Hu J, Muhammad I, Xiao J, Zhang L, Yang H. Recent Advances in The Polymer Dispersed Liquid Crystal Composite and Its Applications. Molecules. 2020; 25(23):5510. https://doi.org/10.3390/molecules25235510

Chicago/Turabian StyleSaeed, Mohsin Hassan, Shuaifeng Zhang, Yaping Cao, Le Zhou, Junmei Hu, Imran Muhammad, Jiumei Xiao, Lanying Zhang, and Huai Yang. 2020. "Recent Advances in The Polymer Dispersed Liquid Crystal Composite and Its Applications" Molecules 25, no. 23: 5510. https://doi.org/10.3390/molecules25235510