The Effect of Simultaneous Si and Ti/Mo Alloying on High-Temperature Strength of Fe3Al-Based Iron Aluminides

Abstract

1. Introduction

2. Materials and Methods

2.1. Alloys Production

2.2. Experimental Methods

3. Results and Discussion

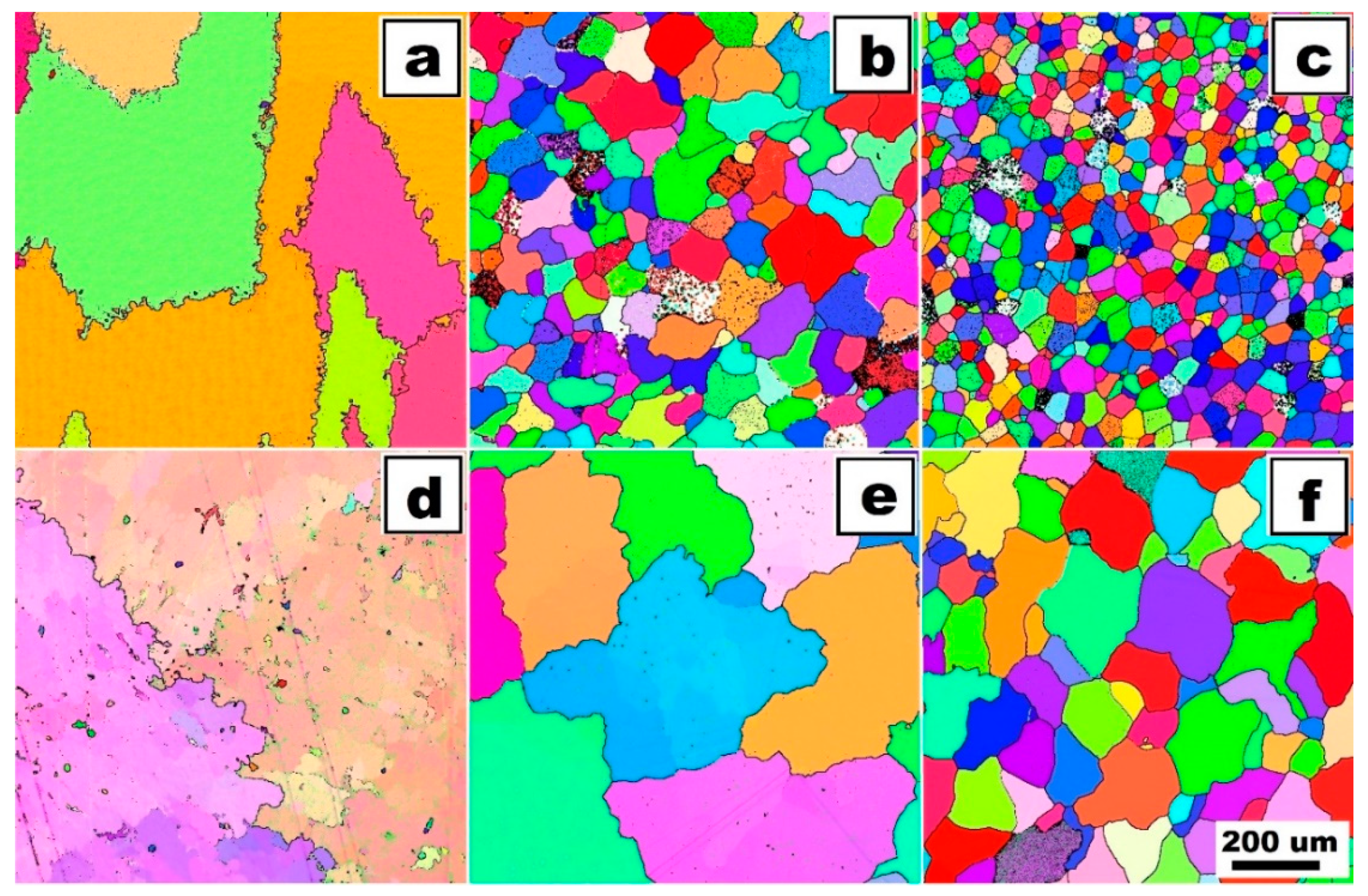

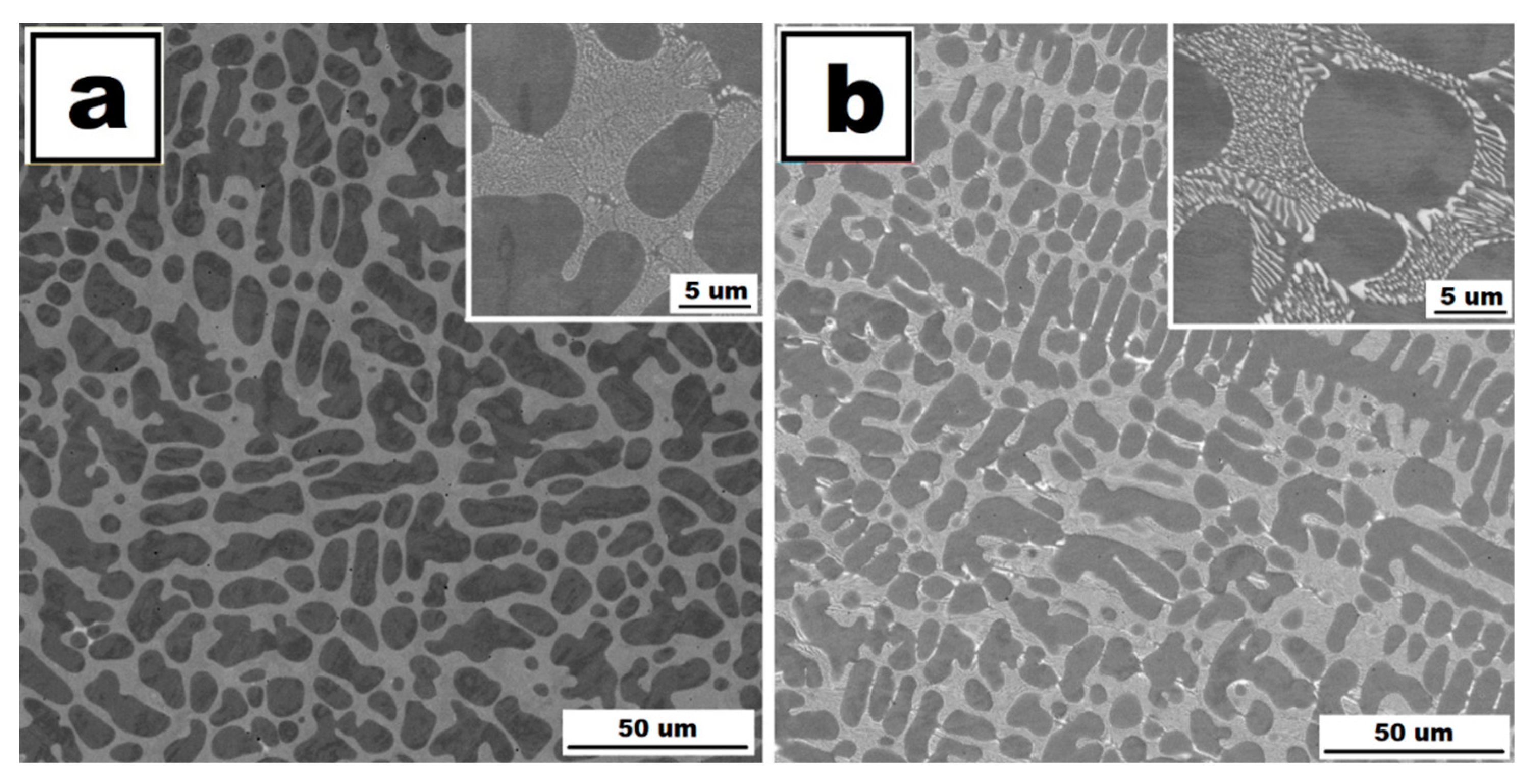

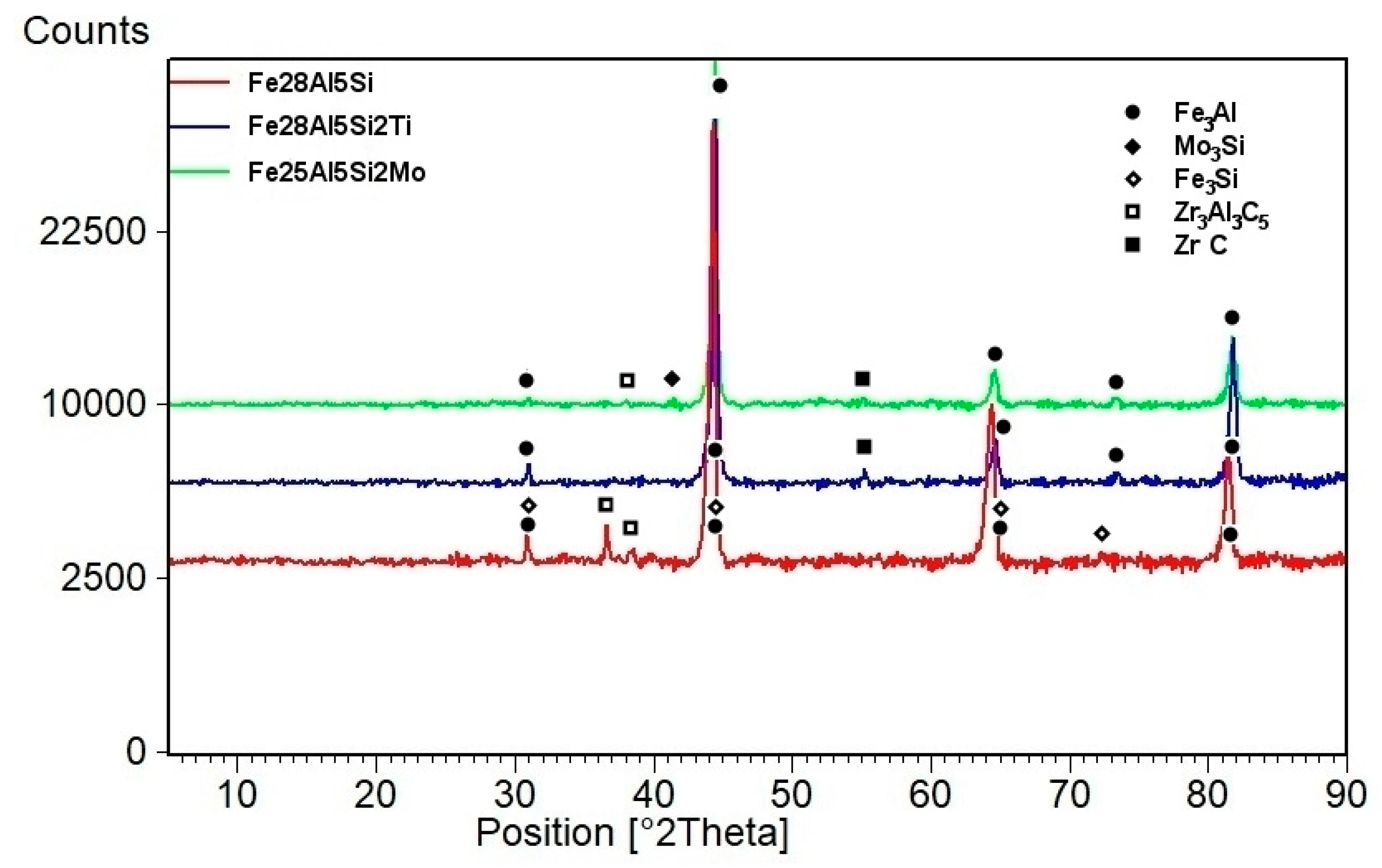

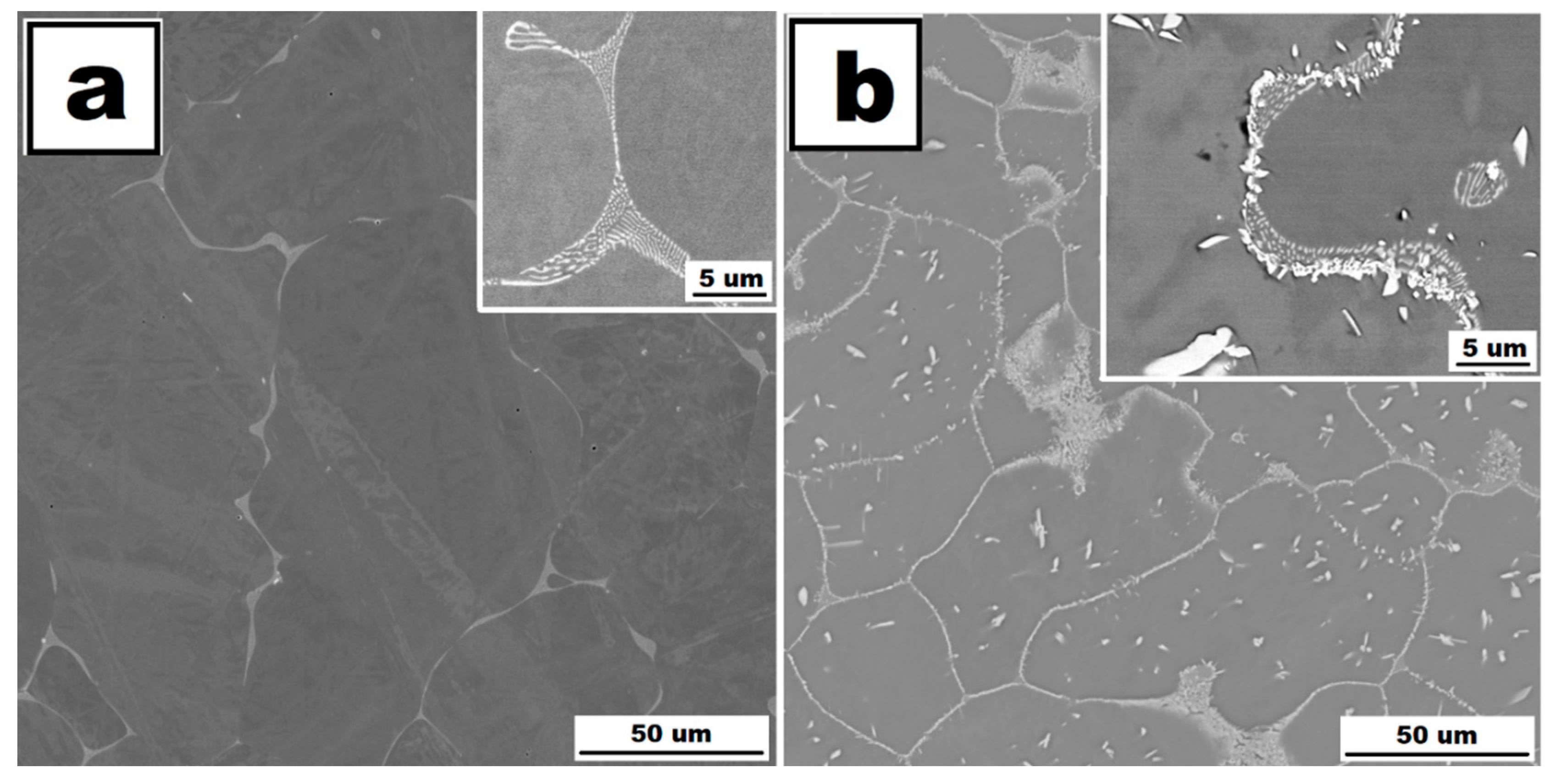

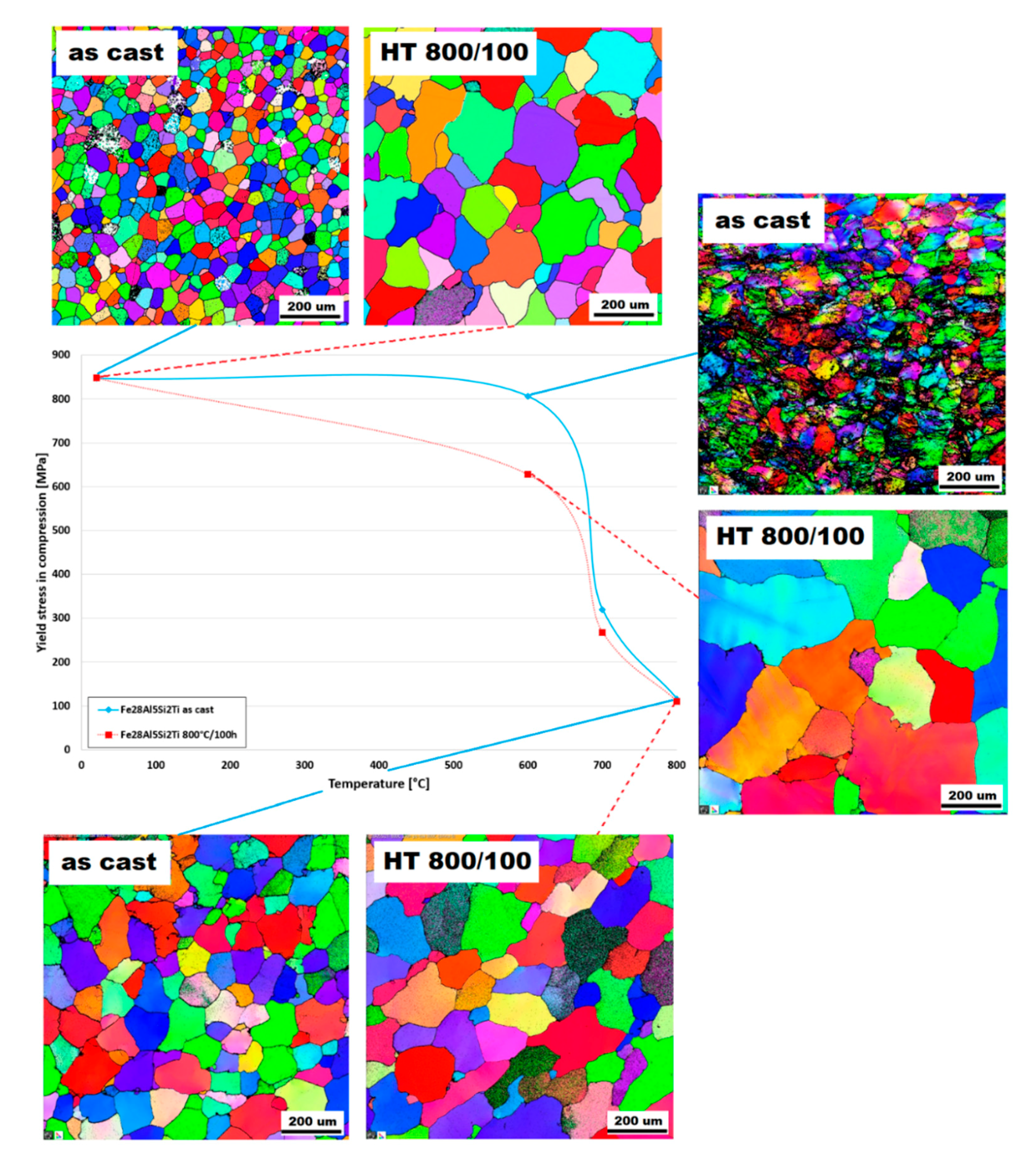

3.1. The Structure of Investigated Alloys

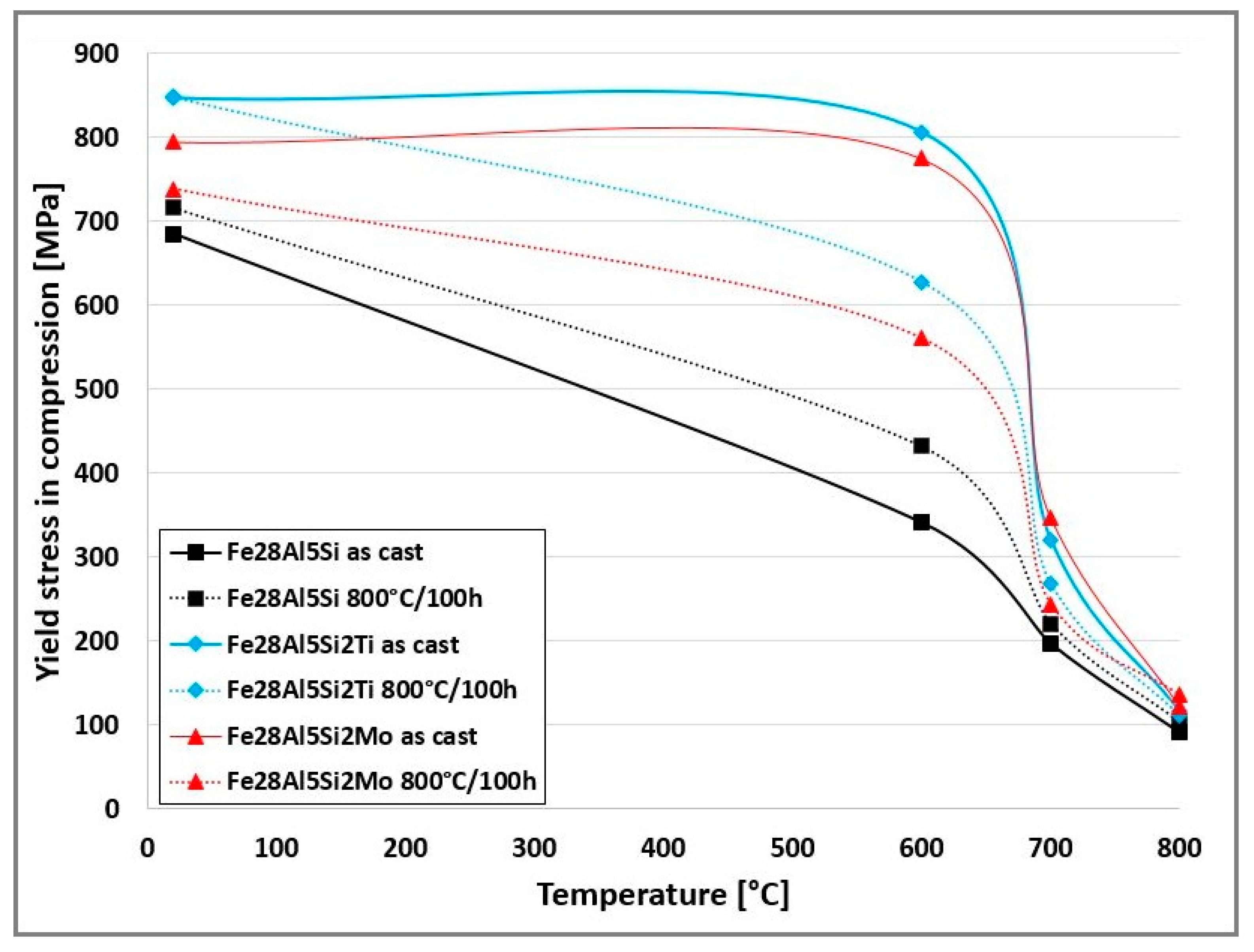

3.2. The High-Temperature Yield Stress in Compression of Investigated Alloys

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Palm, M. Concepts derived from phase diagram studies for the strengthening of Fe–Al-based alloys. Intermetallics 2005, 13, 1286–1295. [Google Scholar] [CrossRef]

- Marker, M.C.J.; Duarte, L.I.; Leinenbach, C.; Richter, K.W. Characterization of the Fe-rich corner of Al–Fe–Si–Ti. Intermetallics 2013, 39, 38–49. [Google Scholar] [CrossRef] [PubMed]

- Mc Kamey, C.G. Iron Aluminides. In Physical Metallurgy and Processing of Intermetallic Compounds; Stoloff, N.S., Sikka, V.K., Eds.; Chapman & Hall: New York, NY, USA, 1996; pp. 351–391. ISBN 9780412989711. [Google Scholar]

- Ghosh, G. Ternary Alloys; Petzow, G., Effenberg, G., Eds.; VCH Publisher: Weinheim, Germany, 1992; Volume 5, pp. 394–437. [Google Scholar]

- Ghosh, G. Aluminium—Iron—Silicon, light metal systems: Phase diagrams, crystallographic and thermodynamic data. Landolt e Börnstein 2005, 11A2, 359–409. [Google Scholar]

- Maitra, T.; Gupta, S.P. Intermetallic compound formation in Fe—Al—Si ternary system: Part II. Mater. Charact. 2003, 49, 293–311. [Google Scholar] [CrossRef]

- Marker, M.; Skolyszewska-Kühberger, B.; Effenberger, H.S.; Schmetterer, C.; Richter, K.W. Phase equilibria and structural investigations in the system Al-Fe-Si. Intermetallics 2011, 19, 1919–1929. [Google Scholar] [CrossRef] [PubMed]

- Eumann, M.; Sauthoff, G.; Palm, M. Phase equilibria in the Fe–Al–Mo system—Part I: Stability of the Laves phase Fe2Mo and isothermal section at 800 °C. Intermetallics 2008, 16, 706–716. [Google Scholar] [CrossRef]

- Eumann, M.; Sauthoff, G.; Palm, M. Phase equilibria in the Fe–Al–Mo system—Part II: Isothermal sections at 1000 and 1150 °C. Intermetallics 2008, 16, 834–846. [Google Scholar] [CrossRef]

- Yildirim, M.; Akdeniz, M.V.; Mekhrabov, A.O. Effect of Mo addition on microstructure, ordering, and room-temperature mechanical properties of Fe-50Al. Trans. Nonferrous Metals Soc. China 2018, 28, 1970–1979. [Google Scholar] [CrossRef]

- Maziasz, P.J.; McKamey, C.G. Microstructural characterization of precipitates formed during high temperature testing and processing of iron-aluminide alloys. Mater. Sci. Eng. A 1992, 152, 322–334. [Google Scholar] [CrossRef]

- Eumann, M.; Palm, M.; Sauthoff, G. Alloys based on Fe3Al or FeAl with strengthening Mo3Al precipitates. Intermetallics 2004, 12, 625–633. [Google Scholar] [CrossRef]

- Raghavan, V. Al-Fe-Ti (aluminum-iron-titanium). JPE 2002, 23, 367–374. [Google Scholar] [CrossRef]

- Palm, M.; Lacaze, J. Assessment of the Al–Fe–Ti system. Intermetallics 2006, 14, 1291–1303. [Google Scholar] [CrossRef]

- Ghosh, G. Al-Fe-Ti, Light metal systems. In Landolt-Börnstein—Group IV Physical Chemistry; Springer: Stuttgart, Germany, 2008; Volume 11D1, pp. 1–39. [Google Scholar]

- Palm, M.; Sauthoff, G. Deformation behaviour and oxidation resistance of single-phase and two-phase L21-ordered Fe–Al–Ti alloys. Intermetallics 2004, 12, 1345–1359. [Google Scholar] [CrossRef]

- Raghavan, V. Fe-Si-Ti (Iron-Silicon-Titanium). J. Phase Equilib. Diffus. 2009, 30, 393–396. [Google Scholar] [CrossRef]

- Schuster, J.C.; Weitzer, F.; Naka, M.; Stein, F.; Palm, M. On the reaction scheme and liquidus surface in the ternary system FeSiTi. Intermetallics 2008, 16, 273–282. [Google Scholar]

- Zakharov, A.M.; Gu’ldin, I.T.; Arnol’d, A.A.; Matsenko, Y.A. Phase equilibria in the aluminum-silicon-iron-titanium system in the concentration ranges of 10–14% silicon, 0–3% iron, and 0–0.6% titanium. Izvestiya Vysshikh Uchebnykh Zavedenii Tsvetnaya Metallurgiya 1988, 2, 94–96. [Google Scholar]

- Nová, K.; Novák, P.; Průša, F.; Kopeček, J.; Čech, J. Synthesis of Intermetallics in Fe-Al-Si System by Mechanical Alloying. Metals 2018, 9, 20. [Google Scholar] [CrossRef]

- Novák, P.; Nová, K. Oxidation Behavior of Fe–Al, Fe–Si and Fe–Al–Si Intermetallics. Materials 2019, 12, 1748. [Google Scholar] [CrossRef]

- Novák, P.; Vanka, T.; Nová, K.; Stoulil, J.; Průša, F.; Kopeček, J.; Haušild, P.; Laufek, F. Structure and Properties of Fe–Al–Si Alloy Prepared by Mechanical Alloying. Materials 2019, 12, 2463. [Google Scholar] [CrossRef] [PubMed]

- Pan, Y.; Wang, S.; Zhang, X.; Jia, L. First-principles investigation of new structure, mechanical and electronic properties of Mo-based silicides. Ceram. Int. 2018, 44, 1744–1750. [Google Scholar] [CrossRef]

- Stein, F. unpublished results in Palm, M. Concepts derived from phase diagram studies for the strengthening of Fe–Al-based alloys. Intermetallics 2005, 13, 1286–1295. [Google Scholar]

- Novák, P.; Barták, Z.; Nová, K.; Průša, F. Effect of Nickel and Titanium on Properties of Fe-Al-Si Alloy Prepared by Mechanical Alloying and Spark Plasma Sintering. Materials 2020, 13, 800. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are available from the authors. |

| Alloy | The Nominal Chemical Composition [at.%] | |||||

|---|---|---|---|---|---|---|

| Fe | Al | Si | Mo | Ti | Zr | |

| Fe28Al5Si | Bal. | 28.0 | 5.0 | − | − | 0.2 |

| Fe28Al5Si2Mo | Bal. | 28.0 | 5.0 | 2.0 | − | 0.2 |

| Fe28Al5Si2Ti | Bal. | 28.0 | 5.0 | − | 2.0 | 0.2 |

| Alloy | Matrix Hardness [HV0.01] | Eutectics Hardness [HV0.01] | fV of Eutectics [%] |

|---|---|---|---|

| Fe28Al5Si as-cast | 455 ± 6 | 750 ± 4 | 44 |

| Fe28Al5Si HT 800/100 | 549 ± 11 | 752 ± 9 | 34 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vodičková, V.; Švec, M.; Hanus, P.; Novák, P.; Záděra, A.; Keller, V.; Prokopčáková, P.P. The Effect of Simultaneous Si and Ti/Mo Alloying on High-Temperature Strength of Fe3Al-Based Iron Aluminides. Molecules 2020, 25, 4268. https://doi.org/10.3390/molecules25184268

Vodičková V, Švec M, Hanus P, Novák P, Záděra A, Keller V, Prokopčáková PP. The Effect of Simultaneous Si and Ti/Mo Alloying on High-Temperature Strength of Fe3Al-Based Iron Aluminides. Molecules. 2020; 25(18):4268. https://doi.org/10.3390/molecules25184268

Chicago/Turabian StyleVodičková, Věra, Martin Švec, Pavel Hanus, Pavel Novák, Antonín Záděra, Vojtěch Keller, and Petra Pazourková Prokopčáková. 2020. "The Effect of Simultaneous Si and Ti/Mo Alloying on High-Temperature Strength of Fe3Al-Based Iron Aluminides" Molecules 25, no. 18: 4268. https://doi.org/10.3390/molecules25184268

APA StyleVodičková, V., Švec, M., Hanus, P., Novák, P., Záděra, A., Keller, V., & Prokopčáková, P. P. (2020). The Effect of Simultaneous Si and Ti/Mo Alloying on High-Temperature Strength of Fe3Al-Based Iron Aluminides. Molecules, 25(18), 4268. https://doi.org/10.3390/molecules25184268