Comparative Study of Microstructure and Mechanical Properties of Two TiAl-Based Alloys Reinforced with Carbide Particles

Abstract

1. Introduction

2. Results and Discussion

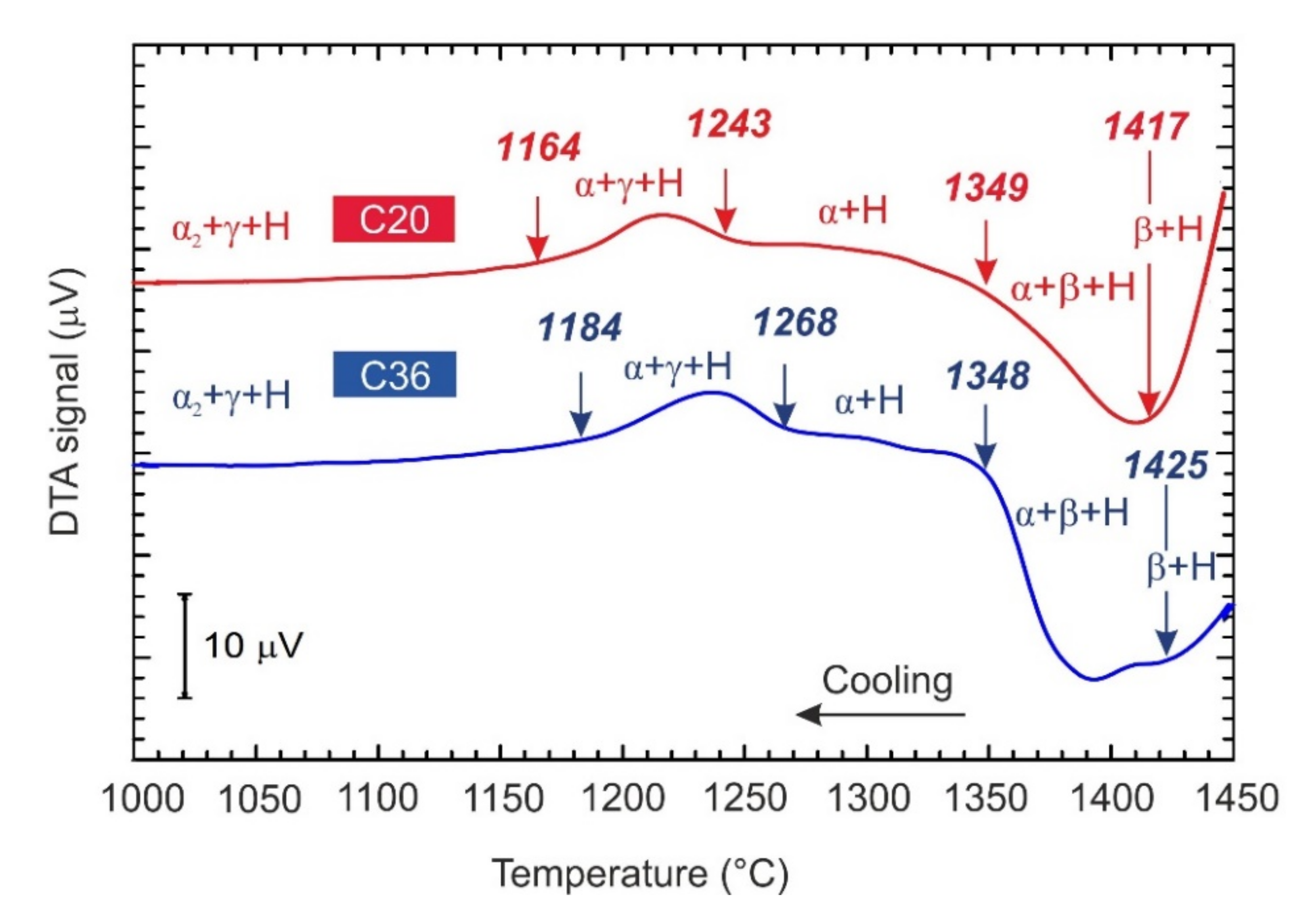

2.1. Solid-State Phase Transformations

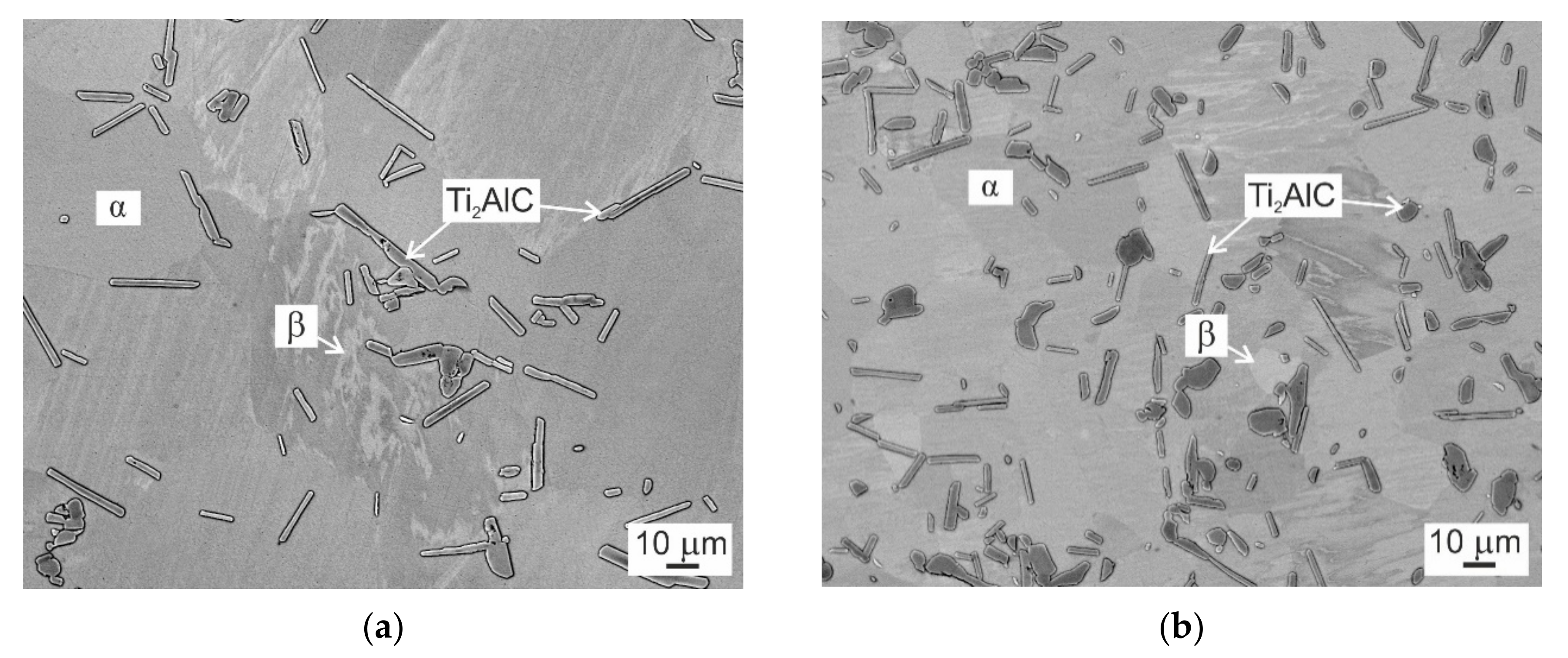

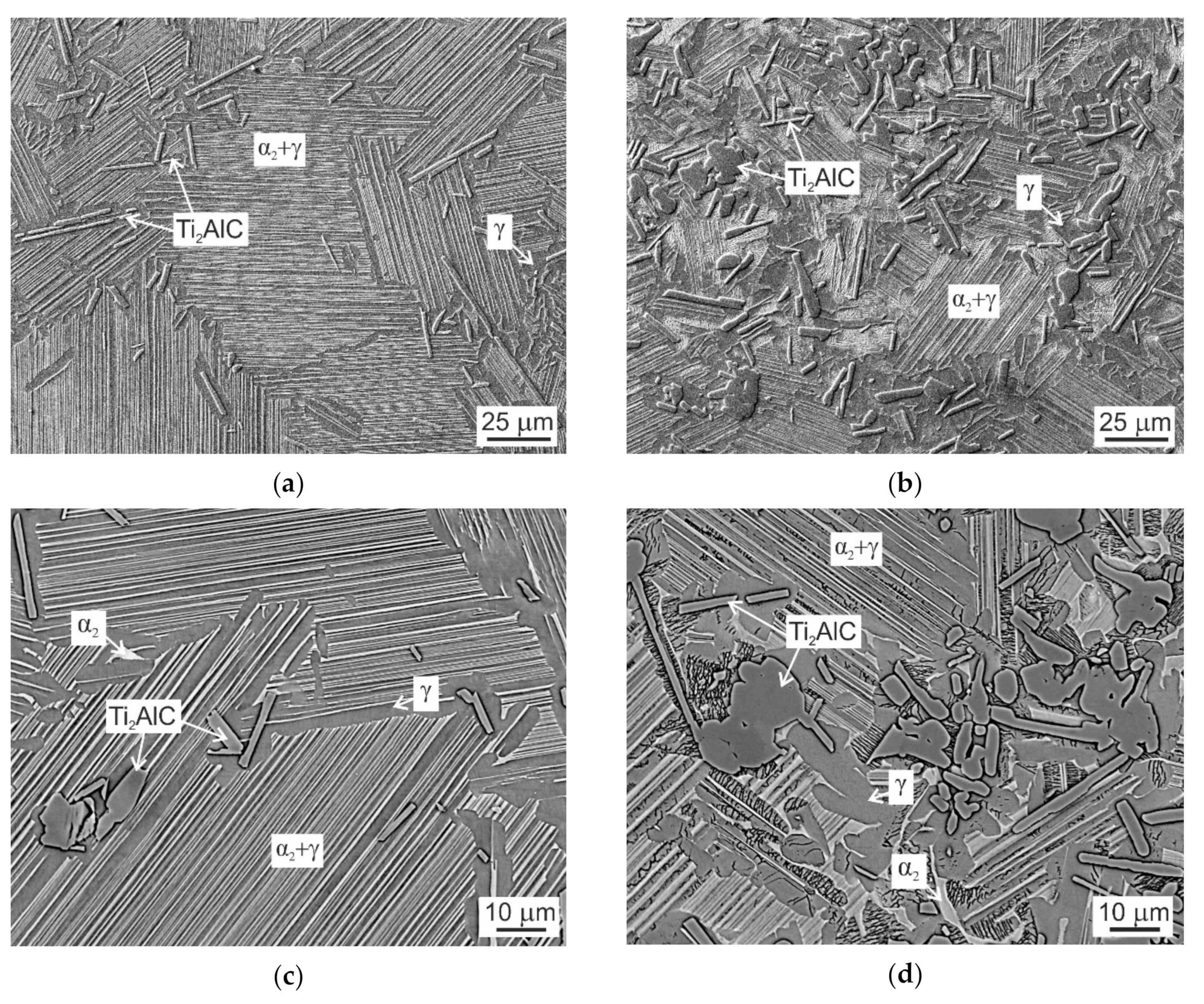

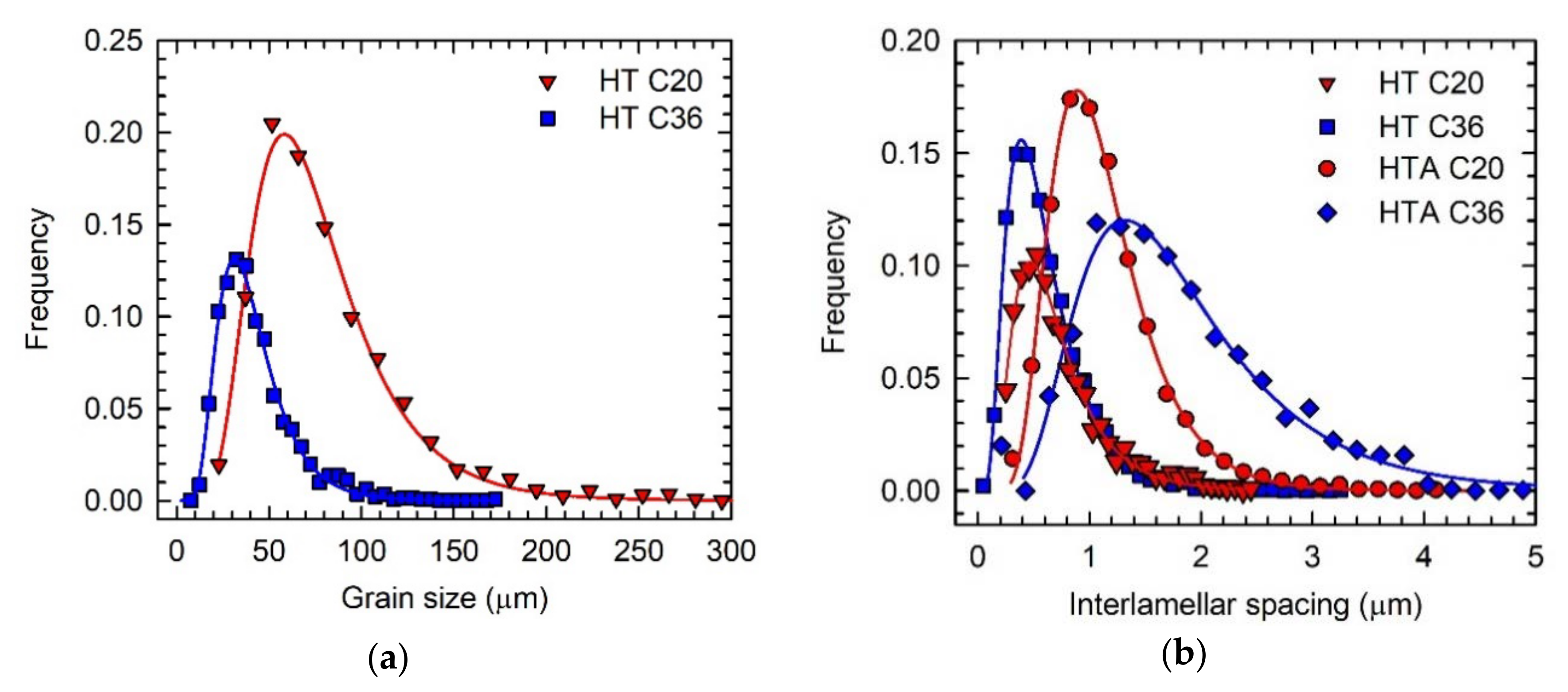

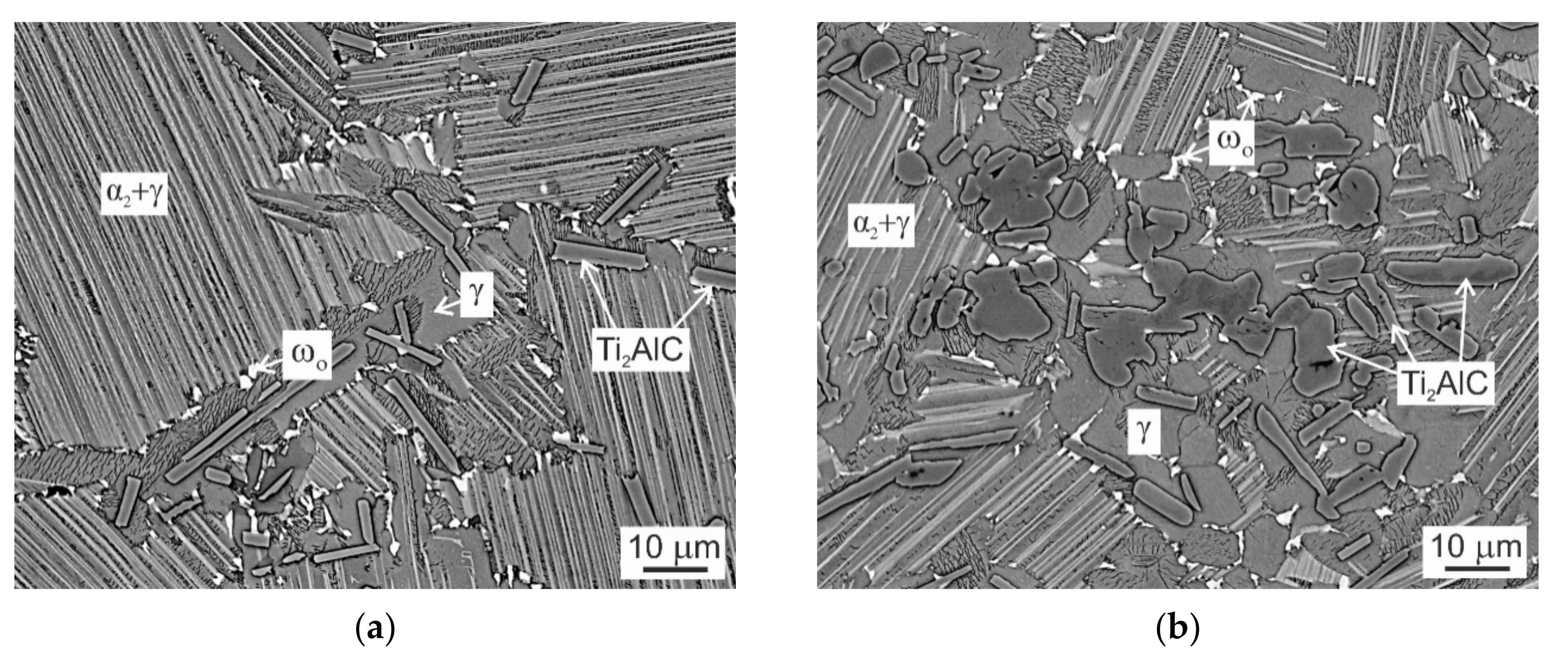

2.2. Effect of Heat Treatment on Microstructure

2.3. Effect of Ageing on Microstructure Stability

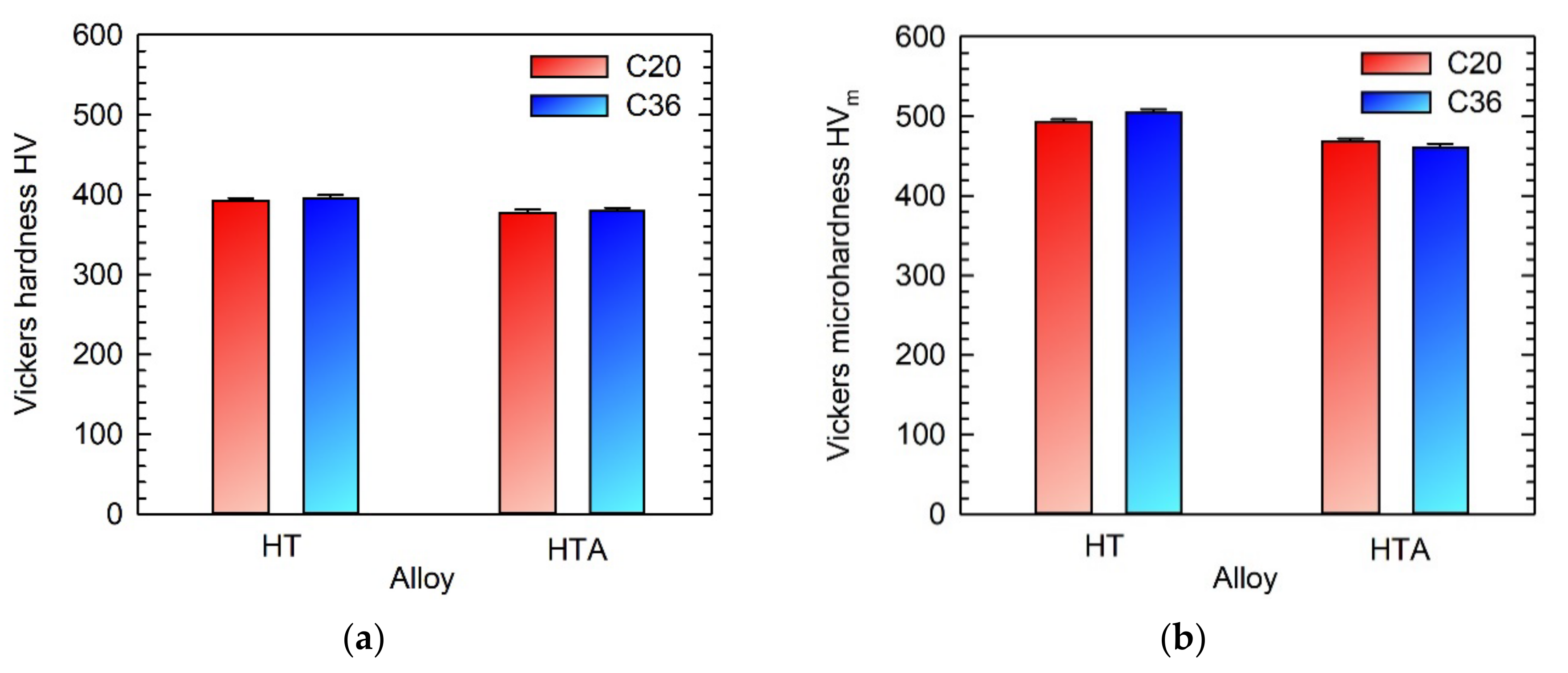

2.4. Vickers Hardness and Elastic Modulus

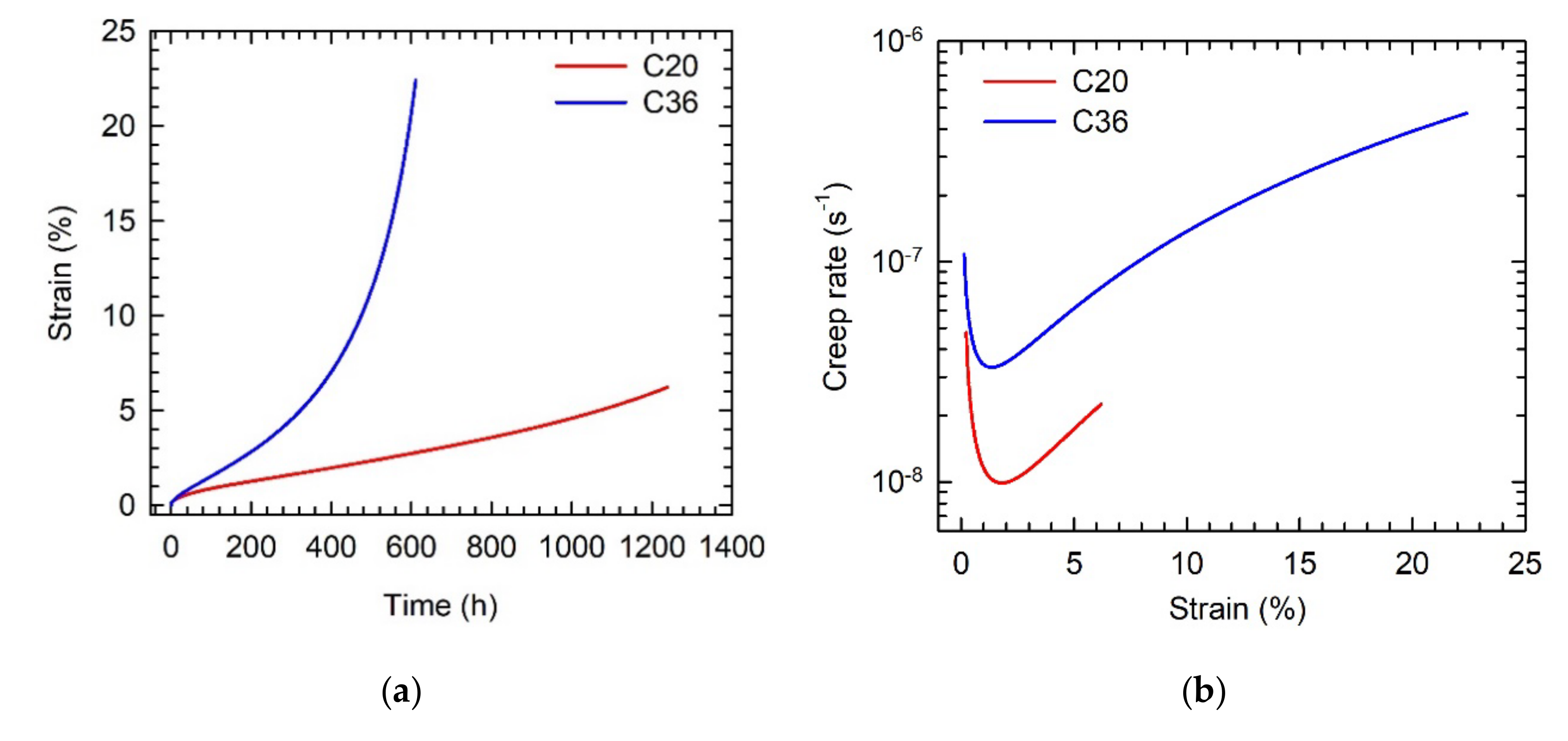

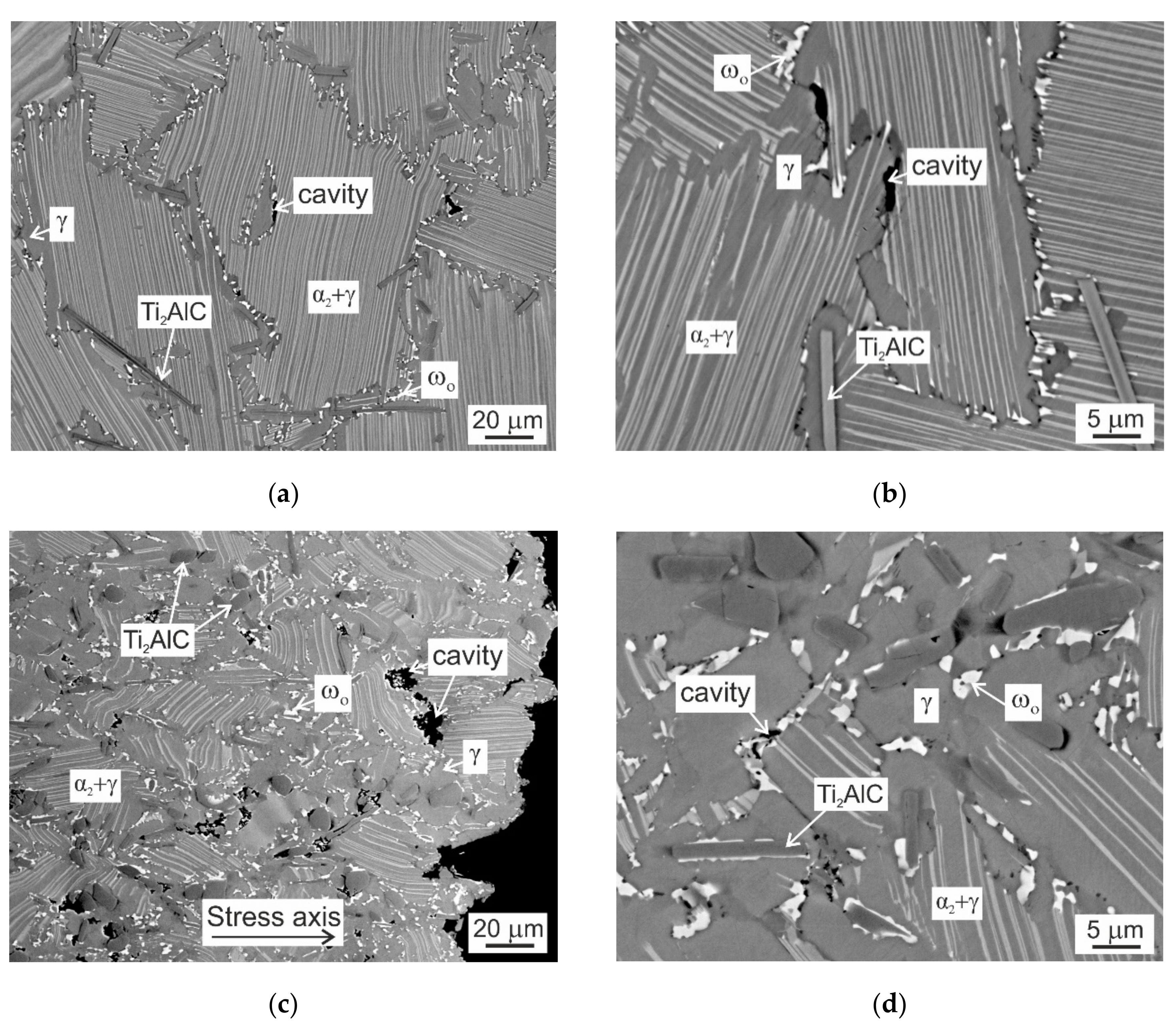

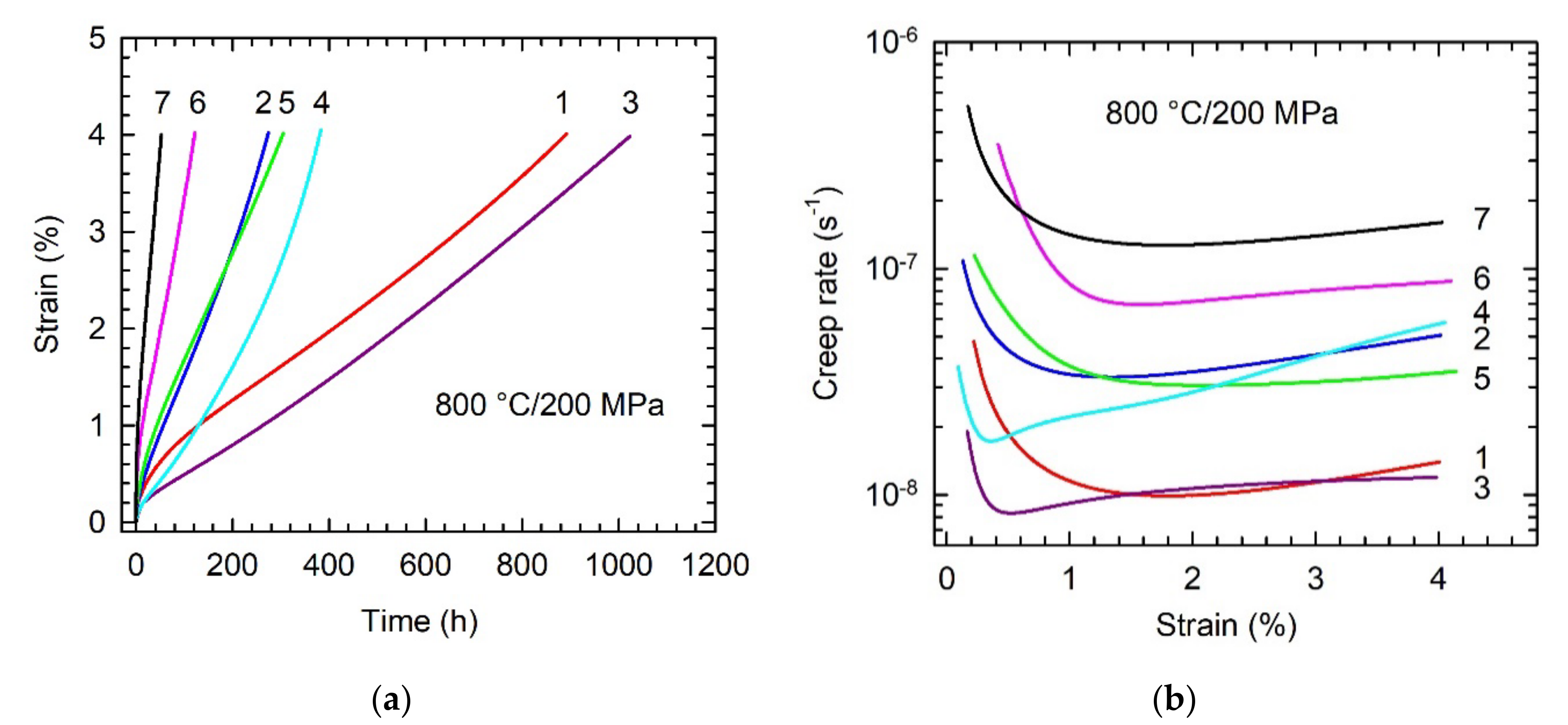

2.5. Creep Behaviour

3. Materials and Methods

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, Y.W.; Kim, S.L. Advances in gammalloy materials-processes-application technology: Successes, dilemmas, and future. JOM 2018, 70, 553–560. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Nag, S.; Suzuki, A.; Weimer, M.J. TiAl alloys in commercial aircraft engines. Mater. High. Temp. 2016, 33, 549–559. [Google Scholar] [CrossRef]

- Appel, F.; Paul, J.D.H.; Oehring, M. Gamma Titanium Aluminide aLloys: Science and Technology; Wiley-VCH Verlag & Co. KGaA: Weinheim, Germany, 2011. [Google Scholar]

- Kamyshnykova, K.; Lapin, J. Grain refinement of cast peritectic TiAl-based alloy by solid-state phase transformations. Kov. Mater. 2018, 56, 277–287. [Google Scholar] [CrossRef]

- Lapin, J.; Kamyshnykova, K. Processing, microstructure and mechanical properties of in-situ Ti3Al+TiAl matrix composite reinforced with Ti2AlC particles prepared by centrifugal casting. Intermetallics 2018, 98, 34–44. [Google Scholar] [CrossRef]

- Kim, Y.W. Strength and ductility in TiAl alloys. Intermetallics 1998, 6, 623–628. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, R.; Yang, Y.; Wu, S.; Guo, J.; Ding, H.; Su, Y.; Fu, H. Effects of lamellar spacing on microstructural stability and creep properties in β-solidifying γ-TiAl alloy by directional solidification. Mater. Sci. Eng. A 2018, 711, 508–514. [Google Scholar] [CrossRef]

- Klein, T.; Usategui, L.; Rashkova, B.; Nó, M.L.; San Juan, J.; Clemens, H.; Mayer, S. Mechanical behavior and related microstructural aspects of a nano-lamellar TiAl alloy at elevated temperatures. Acta. Mater. 2017, 128, 440–450. [Google Scholar] [CrossRef]

- Liu, Z.C.; Lin, J.P.; Li, S.J.; Chen, G.L. Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys. Intermetallics 2002, 10, 653–659. [Google Scholar] [CrossRef]

- Lapin, J.; Pelachová, T.; Dománková, M. Long-term creep behaviour of cast TiAl-Ta alloy. Intermetallics 2018, 95, 24–32. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Klein, T.; Clemens, H.; Mayer, S. Tailoring microstructure and chemical composition of advanced γ-TiAl based alloys for improved creep resistance. Intermetallics 2018, 97, 27–33. [Google Scholar] [CrossRef]

- Song, L.; Hu, X.; Wang, L.; Stark, A.; Lazurenko, D.; Lorenz, U.; Lin, J.; Pyczak, F.; Zhang, T. Microstructure evolution and enhanced creep property of a high Nb containing TiAl alloy with carbon addition. J. Alloy. Compd. 2019, 807, 151649. [Google Scholar] [CrossRef]

- Lapin, J. Comparative study of creep of cast Ti-46Al-2W-0.5Si and Ti-45Al-2W-0.6Si-0.7B alloys. Kov. Mater. 2006, 44, 57–64. [Google Scholar]

- Gabrisch, H.; Stark, A.; Schimansky, F.P.; Wang, L.; Schell, N.; Lorenz, U.; Pyczak, F. Investigation of carbides in Ti-45Al-5Nb-xC alloys (0 ≤ x ≤ 1) by transmission electron microscopy and high energy-XRD. Intermetallics 2013, 33, 44–53. [Google Scholar] [CrossRef]

- Wang, L.; Oehring, M.; Lorenz, U.; Stark, A.; Pyczak, F. New insights into perovskite-Ti3AlC precipitate splitting in a Ti-45Al-5Nb-0.75C alloy by transmission electron microscopy. Intermetallics 2018, 100, 70–76. [Google Scholar] [CrossRef]

- Cegan, T.; Szurman, I. Thermal stability and precipitation strengthening of fully lamellar Ti-45Al-5Nb-0.2B-0.75C alloy. Kov. Mater. 2017, 55, 421–430. [Google Scholar] [CrossRef]

- Lapin, J.; Klimová, A.; Gabalcová, Z.; Pelachová, T.; Bajana, O.; Štamborská, M. Microstructure and mechanical properties of cast in-situ TiAl matrix composites reinforced with (Ti,Nb)2AlC particles. Mater. Des. 2017, 133, 404–415. [Google Scholar] [CrossRef]

- Lapin, J.; Klimová, A. Vacuum induction melting and casting of TiAl-based matrix in-situ composites reinforced by carbide particles using graphite crucibles and moulds. Vacuum 2019, 169, 108930. [Google Scholar] [CrossRef]

- Lapin, J.; Štamborská, M.; Kamyshnykova, K.; Pelachová, T.; Klimová, A.; Bajana, O. Room temperature mechanical behaviour of cast in-situ TiAl matrix composite reinforced with carbide particles. Intermetallics 2019, 105, 113–123. [Google Scholar] [CrossRef]

- Chen, R.; Fang, H.; Chen, X.; Su, Y.; Ding, H.; Guo, J.; Fu, H. Formation of TiC/Ti2AlC and α2 + γ in in-situ TiAl composites with different solidification paths. Intermetallics 2017, 81, 9–15. [Google Scholar] [CrossRef]

- Chen, R.; Tan, Y.; Fang, H.; Luo, L.; Ding, H.; Su, Y.; Guo, J.; Fu, H. Macro/microstructure evolution and mechanical properties of Ti33.3Al alloys by adding WC particles. Mater. Sci. Eng. A 2018, 725, 171–180. [Google Scholar] [CrossRef]

- Barsoum, M.W.; Ali, M.; El-Raghy, T. Processing and characterization of Ti2AlC, Ti2AlN, and Ti2AlC0.5N0.5. Met. Mater. Trans. A 2000, 31, 1857–1865. [Google Scholar] [CrossRef]

- Klimová, A.; Lapin, J. Effects of C and N additions on primary MAX phase particles in intermetallic Ti-Al-Nb-Mo matrix in-situ composites prepared by vacuum induction melting. Kov. Mater. 2019, 57, 151–157. [Google Scholar] [CrossRef]

- Klimová, A.; Lapin, J. Effect of Al content on microstructure of Ti-Al-Nb-C-Mo composites reinforced with carbide particles. Kov. Mater. 2019, 57, 377–387. [Google Scholar] [CrossRef]

- Štamborská, M.; Lapin, J.; Bajana, O. Effect of carbon on the room temperature compressive behaviour of Ti-44.5Al-8Nb-0.8Mo-xC alloys prepared by vacuum induction melting. Kov. Mater. 2018, 56, 349–356. [Google Scholar] [CrossRef]

- Lapin, J.; Štamborská, M.; Pelachová, T.; Bajana, O. Fracture behaviour of cast in-situ TiAl matrix composite reinforced with carbide particles. Mater. Sci. Eng. A 2018, 721, 1–7. [Google Scholar] [CrossRef]

- Lapin, J.; Pelachová, T.; Bajana, O. High temperature deformation behaviour and microstructure of cast in-situ TiAl matrix composite reinforced with carbide particles. J. Alloy. Compd. 2019, 797, 754–765. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Rashkova, B.; Clemens, H.; Mayer, S. Enhancement of creep properties and microstructural stability of intermetallic β-solidifying γ-TiAl based alloys. Intermetallics 2015, 63, 19–26. [Google Scholar] [CrossRef]

- Kastenhuber, M.; Rashkova, B.; Clemens, H.; Mayer, S. Effect of microstructural instability on the creep resistance of an advanced intermetallic γ-TiAl based alloy. Intermetallics 2017, 80, 1–9. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Hallstedt, B.; Bondar, A.A.; Hecht, U.; Sleptsov, S.V.; Velikanova, T.Y. Thermodynamic description of the Al-C-Ti system. J. Alloy. Compd. 2015, 623, 480–496. [Google Scholar] [CrossRef]

- Yang, G.; Yang, X.; Wang, Y.; Cheng, L.; Kou, H.; Liu, Y.; Li, Y.; Wang, P.; Ren, W. Phase precipitation behavior of a quenched β-solidifying TiAl alloy with a fully-B2 microstructure during annealing at 800 °C. J. Alloy. Compd. 2020, 812, 152118. [Google Scholar] [CrossRef]

- Song, L.; Lin, J.; Li, J. Phase transformation mechanisms in a quenched Ti-45Al-8.5Nb-0.2W-0.2B-0.02Y alloy after subsequent annealing at 800 °C. J. Alloy. Compd. 2017, 691, 60–66. [Google Scholar] [CrossRef]

- Wang, L.; Zenk, C.; Stark, A.; Felfer, P.; Gabrisch, H.; Göken, M.; Lorenz, U.; Pyczak, F. Morphology evolution of Ti3AlC carbide precipitates in high Nb containing TiAl alloys. Acta Mater. 2017, 137, 36–44. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Bondar, A.A.; Hecht, U.; Velikanova, T.Y. The Al-B-Nb-Ti system. IV. Experimental study and thermodynamic re-evaluation of the binary Al-Nb and ternary Al-Nb-Ti systems. J. Alloy. Compd. 2009, 472, 133–161. [Google Scholar] [CrossRef]

- Wang, X.; Yang, J.; Song, L.; Kou, H.; Li, J.; Fu, H. Evolution of B2(ω) region in high-Nb containing TiAl alloy in intermediate temperature range. Intermetallics 2017, 82, 32–39. [Google Scholar] [CrossRef]

- Berglund, I.S.; Bryan, Z.L.; Manuel, M.V. Kinetic modeling of the γ phase in Ti-Al-Nb alloys. J. Alloy. Compd. 2017, 729, 688–694. [Google Scholar] [CrossRef]

- Karadge, M.; Gouma, P.I. A structural aspect of α(α2) → lamellar α2 + γ transformation in γ-TiAl. Philos. Mag. Lett. 2004, 84, 451–459. [Google Scholar] [CrossRef]

- Denquin, A.; Naka, S. Phase transformation mechanisms involved in two-phase TiAl-based alloys-I. Lamellar structure formation. Acta Mater. 1996, 44, 343–352. [Google Scholar] [CrossRef]

- Cabibbo, M. Carbon content driven high temperature γ-α2 interface modifications and stability in Ti–46Al–4Nb intermetallic alloy. Intermetallics 2020, 119, 106718. [Google Scholar] [CrossRef]

- Lapin, J. Effect of lamellar structure on microhardness and yield stress of directionally solidified intermetallic Ti-46Al-2W-0.5Si alloy. J. Mater. Sci. Lett. 2003, 22, 747–749. [Google Scholar] [CrossRef]

- Klein, T.; Schachermayer, M.; Mendez-Martin, F.; Schöberl, T.; Rashkova, B.; Clemens, H.; Mayer, S. Carbon distribution in multi-phase γ-TiAl based alloys and its influence on mechanical properties and phase formation. Acta. Mater. 2015, 94, 205–213. [Google Scholar] [CrossRef]

- Schloffer, M.; Rashkova, B.; Schöberl, T.; Schwaighofer, E.; Zhang, Z.; Clemens, H.; Mayer, S. Evolution of the ωo phase in a β-stabilized multi-phase TiAl alloy and its effect on hardness. Acta. Mater. 2014, 64, 241–252. [Google Scholar] [CrossRef]

- Velasco, B.; Gordo, E.; Hu, L.; Radovic, M.; Tsipas, S.A. Influence of porosity on elastic properties of Ti2AlC and Ti3SiC2 MAX phase foams. J. Alloy. Compd. 2018, 764, 24–35. [Google Scholar] [CrossRef]

- Kim, H.Y.; Maruyama, K. Parallel twinning during creep deformation in soft orientation PST crystal of TiAl alloy. Acta. Mater. 2001, 49, 2635–2643. [Google Scholar] [CrossRef]

- Du, X.W.; Zhu, J.; Kim, Y.W. Microstructural characterization of creep cavitation in a fully-lamellar TiAl alloy. Intermetallics 2001, 9, 137–146. [Google Scholar] [CrossRef]

- Du, X.W.; Zhu, J.; Zhang, X.; Cheng, Z.Y.; Kim, Y.W. Creep induced α2 → β phase transformation in a fully-lamellar TiAl alloy. Scr. Mater. 2000, 43, 597–602. [Google Scholar] [CrossRef]

- Lapin, J.; Pelachová, T.; Dománková, M. Creep behaviour of a new air-hardenable intermetallic Ti-46Al-8Ta alloy. Intermetallics 2011, 19, 814–819. [Google Scholar] [CrossRef]

- Lapin, J.; Nazmy, M. Microstructure and creep properties of a cast intermetallic Ti-46Al-2W-0.5Si alloy for gas turbine applications. Mater. Sci. Eng. A 2004, 380, 298–307. [Google Scholar] [CrossRef]

- Schwaighofer, E.; Rashkova, B.; Clemens, H.; Stark, A.; Mayer, S. Effect of carbon addition on solidification behavior, phase evolution and creep properties of an intermetallic β-stabilized γ-TiAl based alloy. Intermetallics 2014, 46, 173–184. [Google Scholar] [CrossRef]

- Maruyama, K.; Yamamoto, R.; Nakakuki, H.; Fujitsuna, N. Effects of lamellar spacing, volume fraction and grain size on creep strength of fully lamellar TiAl alloys. Mater. Sci. Eng. A 1997, 239–240, 419–428. [Google Scholar] [CrossRef]

- Kim, Y.W.; Kim, S.L. Effects of microstructure and C and Si additions on elevated temperature creep and fatigue of gamma TiAl alloys. Intermetallics 2014, 53, 92–101. [Google Scholar] [CrossRef]

- Kamyshnykova, K.; Lapin, J. Vacuum induction melting and solidification of TiAl-based alloy in graphite crucibles. Vacuum 2018, 154, 218–226. [Google Scholar] [CrossRef]

- Lapin, J.; Ondrúš, L.; Nazmy, M. Directional solidification of intermetallic Ti-46Al-2W-0.5Si alloy in alumina moulds. Intermetallics 2002, 10, 1019–1031. [Google Scholar] [CrossRef]

Sample Availability: Samples of Ti-42.6Al-8.7Nb-0.3Ta-2C and Ti-41Al-8.7Nb-0.3Ta-3.6C (in at.%) alloys are available from the authors. |

| Alloy | Ti | Al | Nb | Ta | C | O | N |

|---|---|---|---|---|---|---|---|

| C20 | 46.4 ± 0.4 | 42.6 ± 0.4 | 8.7 ± 0.1 | 0.3 ± 0.1 | 2.0 ± 0.1 | 775 ± 25 | 84 ± 15 |

| C36 | 46.3 ± 0.3 | 41.1 ± 0.4 | 8.7 ± 0.1 | 0.3 ± 0.1 | 3.6 ± 0.1 | 760 ± 30 | 76 ± 15 |

| Alloy | Phases | Ti | Al | Nb | Ta | C |

|---|---|---|---|---|---|---|

| C20 | γ | 44.5 ± 0.3 | 46.7 ± 04 | 8.7 ± 0.1 | 0.10 ± 0.05 | - |

| α2 | 55.1 ± 0.3 | 35.6 ± 0.4 | 9.2 ± 0.2 | 0.10 ± 0.05 | - | |

| α2 + γ | 47.1 ± 0.3 | 43.8 ± 0.4 | 9.0 ± 0.2 | 0.10 ± 0.05 | - | |

| Ti2AlC | 40.8 ± 0.5 | 24.7 ± 0.5 | 5.9 ± 0.2 | 0.60 ± 0.10 | 28.0 ± 0.4 | |

| C36 | γ | 44.5 ± 0.3 | 46.9 ± 0.4 | 8.5 ± 0.2 | 0.10 ± 0.05 | - |

| α2 | 54.6 ± 0.4 | 35.9 ± 0.4 | 9.3 ± 0.2 | 0.20 ± 0.05 | - | |

| α2 + γ | 47.0 ± 0.3 | 43.9 ± 0.4 | 9.0 ± 0.2 | 0.10 ± 0.05 | - | |

| Ti2AlC | 41.5 ± 0.4 | 24.5 ± 0.4 | 6.1 ± 0.2 | 0.60 ± 0.10 | 27.3 ± 0.4 |

| Alloy | Grain Size d (μm) | Interlamellar Spacing λ (μm) | Major Axis of Carbides L (μm) | Volume Fraction Vlg/Vgb (vol.%) | Volume Fraction VCgb (vol.%) | Average Volume Fraction VC (vol.%) | |

|---|---|---|---|---|---|---|---|

| C20 | HT | 70.6 ± 0.8 | 0.62 ± 0.02 | 10.8 ± 0.2 | 72/28 | 3.4 ± 0.2 | 4.1 ± 0.2 |

| HTA | 69.2 ± 0.9 | 1.04 ± 0.02 | 10.7 ± 0.2 | 68/32 | 3.7 ± 0.2 | 4.2 ± 0.2 | |

| C36 | HT | 37.7 ± 0.6 | 0.54 ± 0.03 | 9.5 ± 0.4 | 48/52 | 13.9 ± 0.4 | 14.1 ± 0.4 |

| HTA | 36.4 ± 0.9 | 1.66 ± 0.03 | 9.7 ± 0.4 | 39/61 | 14.0 ± 0.4 | 14.2 ± 0.4 | |

| Alloy | Phases | Ti | Al | Nb | Ta | C |

|---|---|---|---|---|---|---|

| HTA C20 | γ | 44.6 ± 0.3 | 46.9 ± 0.3 | 8.5 ± 0.2 | 0.10 ± 0.05 | - |

| ωo | 50.5 ± 0.3 | 37.0 ± 0.3 | 12.3 ± 0.2 | 0.20 ± 0.10 | - | |

| α2 + γ | 47.1 ± 0.3 | 44.1 ± 0.4 | 8.7 ± 0.3 | 0.10 ± 0.05 | - | |

| Ti2AlC | 40.6 ± 0.4 | 24.7 ± 0.6 | 5.9 ± 0.2 | 0.60 ± 0.10 | 28.2 ± 0.4 | |

| HTA C36 | γ | 44.4 ± 0.3 | 46.9 ± 0.4 | 8.6 ± 0.2 | 0.10 ± 0.05 | - |

| ωo | 50.4 ± 0.3 | 37.1 ± 0.4 | 12.3 ± 0.2 | 0.20 ± 0.10 | - | |

| α2 + γ | 47.0 ± 0.3 | 44.2 ± 0.4 | 8.7 ± 0.3 | 0.10 ± 0.05 | - | |

| Ti2AlC | 40.8 ± 0.4 | 24.6 ± 0.5 | 6.0 ± 0.2 | 0.60 ± 0.10 | 28.0 ± 0.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lapin, J.; Kamyshnykova, K.; Klimova, A. Comparative Study of Microstructure and Mechanical Properties of Two TiAl-Based Alloys Reinforced with Carbide Particles. Molecules 2020, 25, 3423. https://doi.org/10.3390/molecules25153423

Lapin J, Kamyshnykova K, Klimova A. Comparative Study of Microstructure and Mechanical Properties of Two TiAl-Based Alloys Reinforced with Carbide Particles. Molecules. 2020; 25(15):3423. https://doi.org/10.3390/molecules25153423

Chicago/Turabian StyleLapin, Juraj, Kateryna Kamyshnykova, and Alena Klimova. 2020. "Comparative Study of Microstructure and Mechanical Properties of Two TiAl-Based Alloys Reinforced with Carbide Particles" Molecules 25, no. 15: 3423. https://doi.org/10.3390/molecules25153423

APA StyleLapin, J., Kamyshnykova, K., & Klimova, A. (2020). Comparative Study of Microstructure and Mechanical Properties of Two TiAl-Based Alloys Reinforced with Carbide Particles. Molecules, 25(15), 3423. https://doi.org/10.3390/molecules25153423