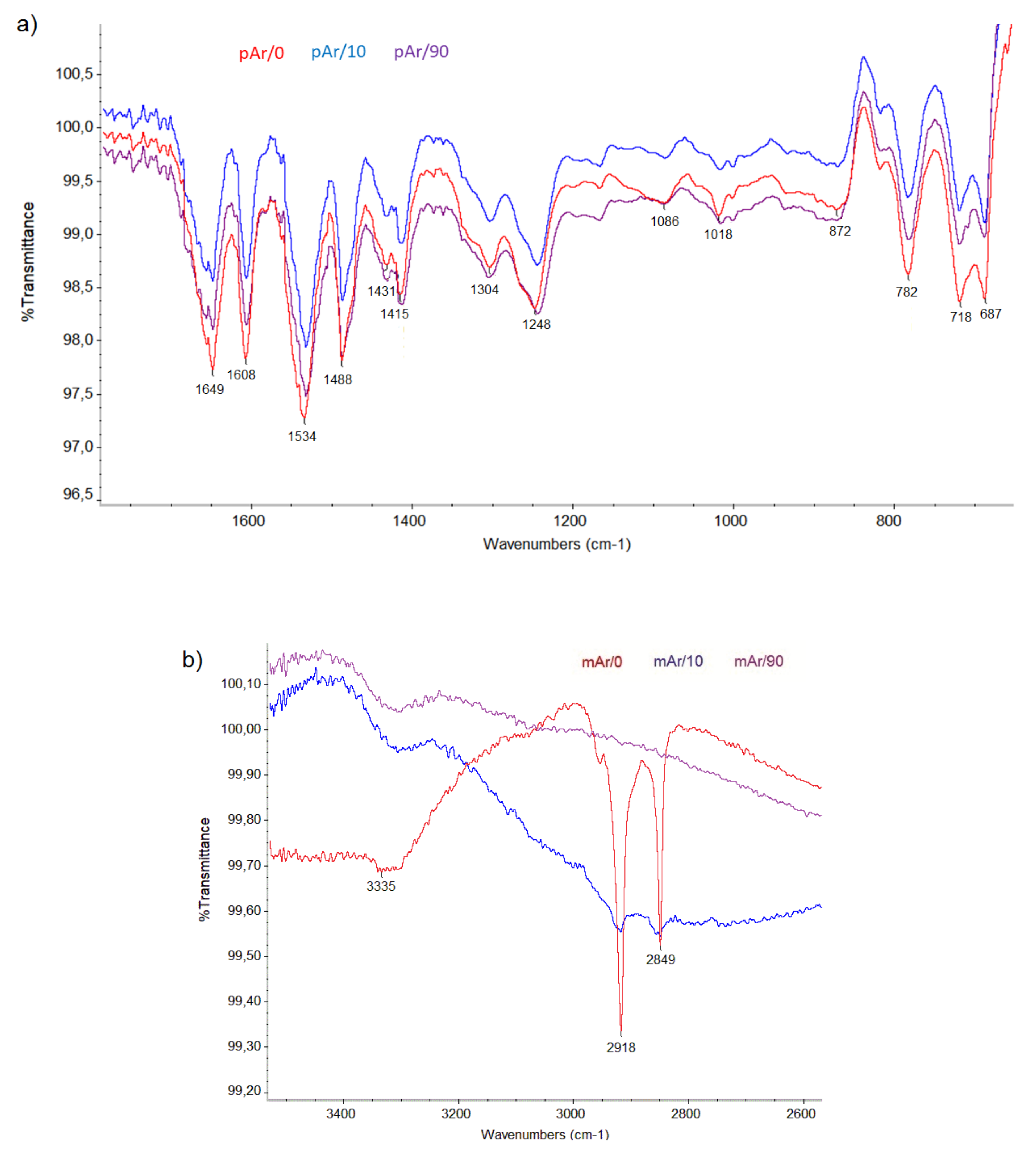

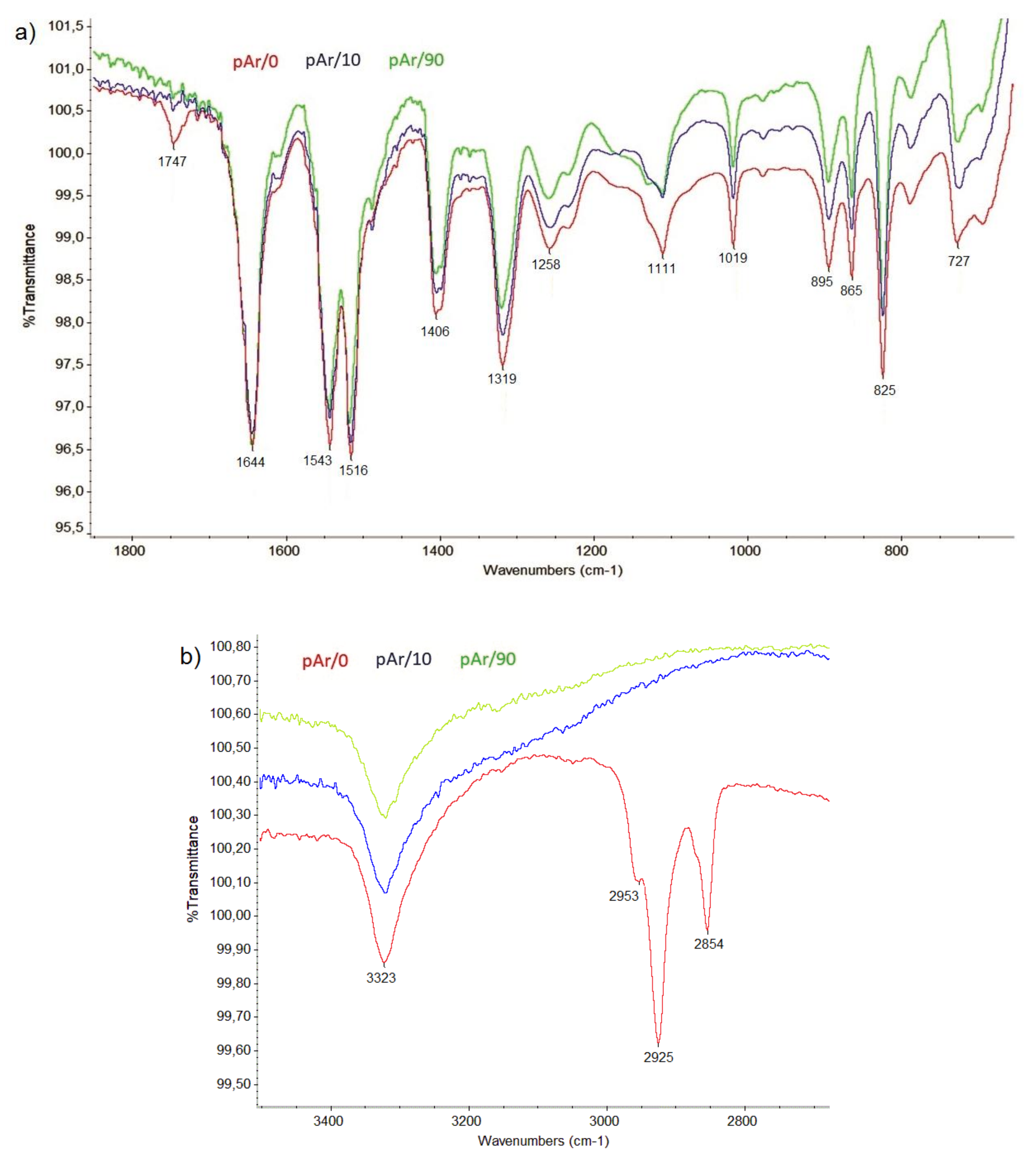

2.1. SEM/EDS Analysis

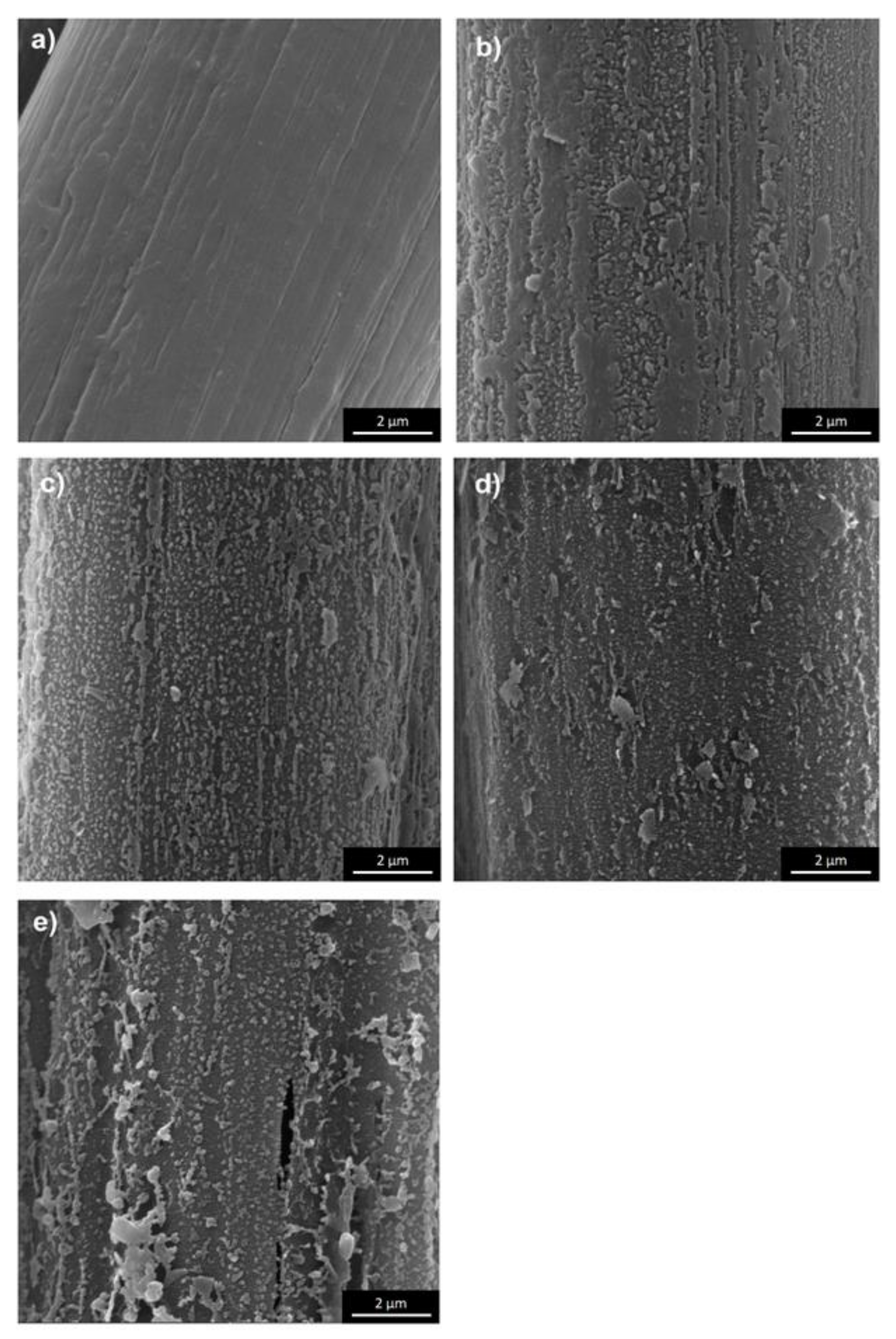

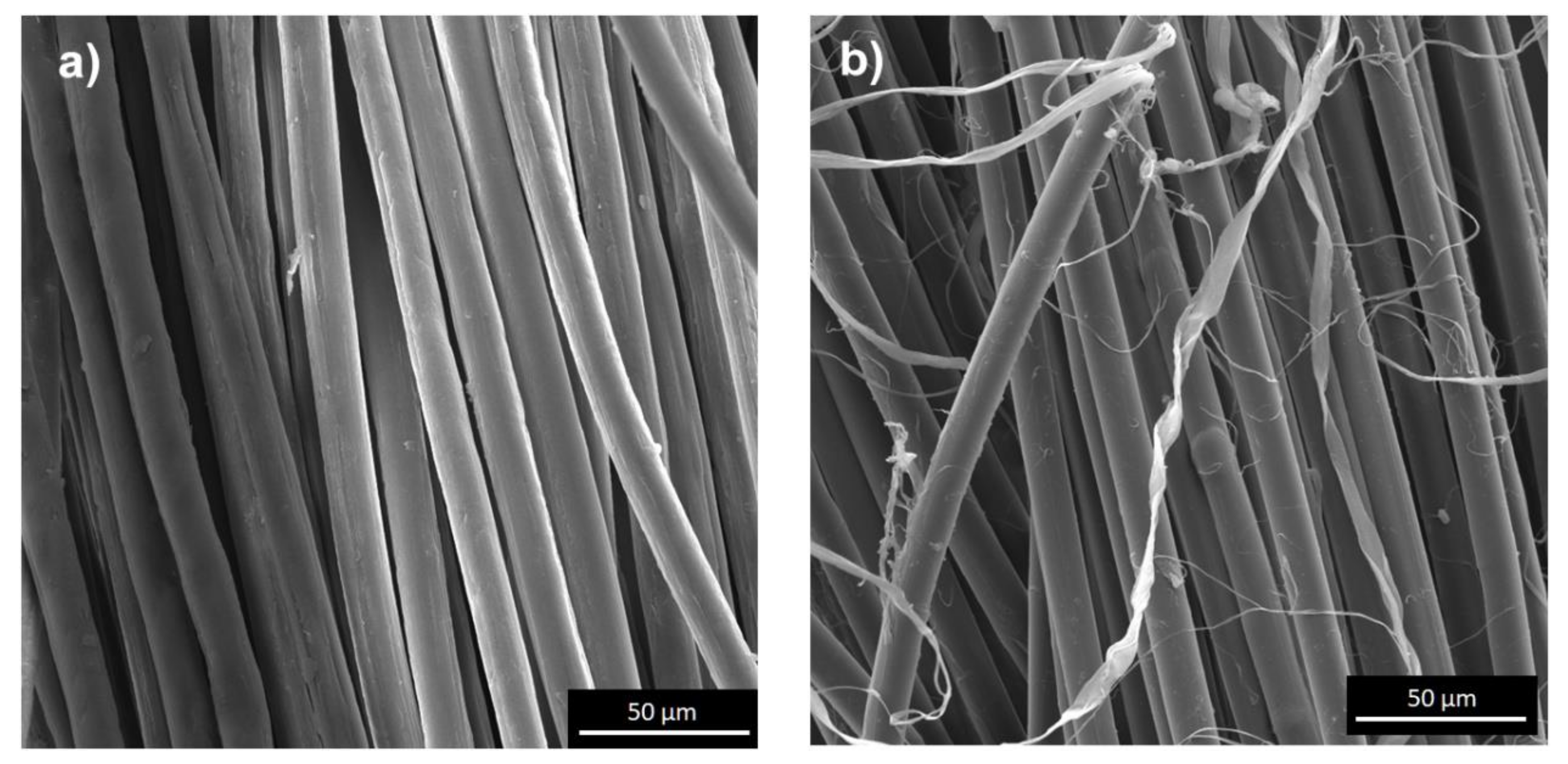

The fibers surface of unmodified meta-aramid (mAr/0) and para-aramid (pAr/0) yarns are smooth with visible longitudinal cracks and fibrils [

6,

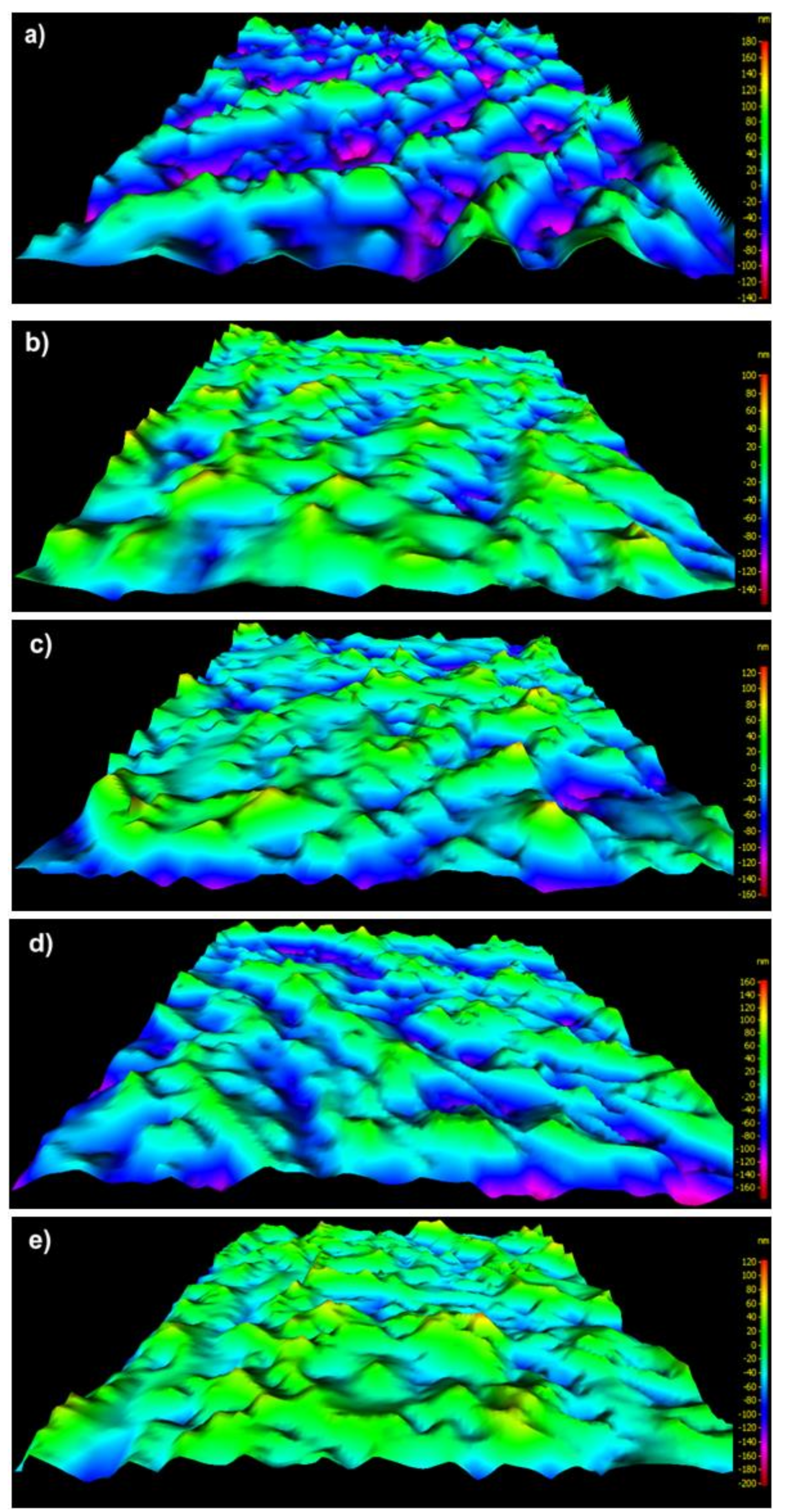

15]. Activation in the plasma caused changes in surface topography, increased unevenness and roughness, as evidenced by SEM three-dimensional (3D) images and stereometric parameters (

Figure 1,

Figure 2,

Figure 3 and

Figure 4). The parameter of the surface topography; the average height of the selected area (S

a), the maximum depth of the valley of the selected area (S

v), and the maximum height of the selected surface area (S

z) for mAr/0 yarn are 23 nm, 133 nm, and 245 nm, respectively. The surface area development factor (S

dr) is 18%. An increase in the value of S

a, S

v by 50%, S

z by 45%, and S

dr by about 7% is observed for mAr yarn after 60 min of plasma activation (mAr/60) (

Figure 2d). After 90 min of activation, the S

v value increased to 203nm, and the values of S

a, S

z and S

dr decreased by 17%, 5% and 14%, respectively, in relation to mAr/60. It can be caused by too much energy and removal of the top layer on which there were areas with the developed surface. This is evidenced by the protruding fragments on the fiber surface (

Figure 2e).

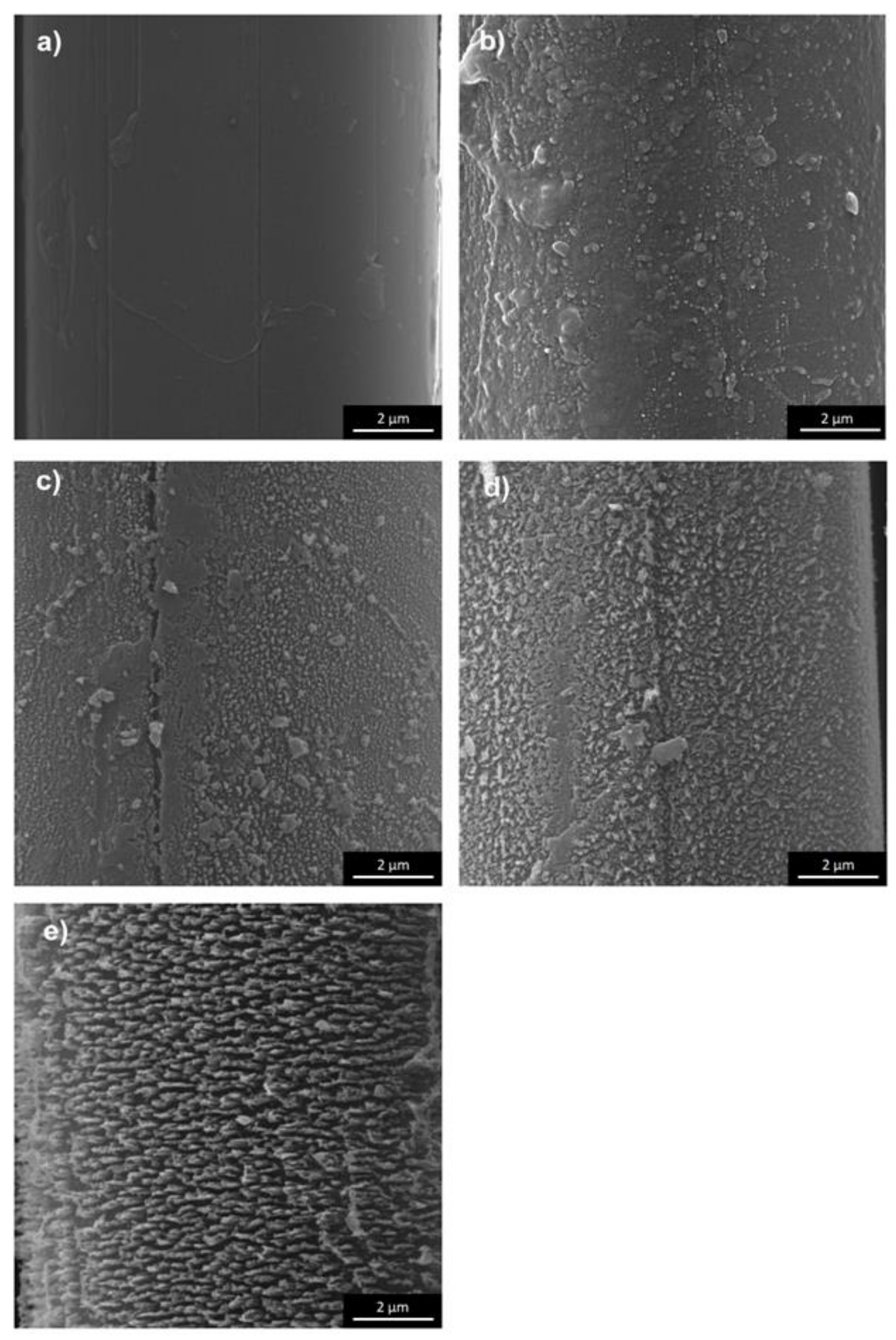

The values of S

a, S

v, and S

z of pAr/0 yarn are 23 nm, 152 nm, and 317 nm, respectively (

Figure 4a). Longitudinal cracks on the surface are deeper than for mAr/0. The S

dr for pAr/0 is 12% and is 30% lower compared to mAr/0. After 10 min of activation, there was an increase in S

a value of about 26% compared to pAr/0 (

Figure 4b). After 30 and 60 min (

Figure 4c–d), the S

a value does not change further, but after 90 min decreases by 10% compared to pAr/60 (

Figure 4e). The value of S

v after 10 and 30 min of activation is lower by 10% and 5%, respectively, and after 60 and 90 min is higher by 30% and 60%, respectively, in relation to pAr/0. The S

z value after 10 min and 30 min activation is lower by 12% and 18%, respectively, compared to pAr/0. After 60 min, an increase in S

z value by about 18% was recorded, relative to pAr/30. The highest value of S

z is observed after 90 min of activation and it is 364 nm. The S

dr increases by approximately 133%, 116%, and 141% for pAr/10, pAr/30, and pAr/60 yarns, respectively, compared to pAr/0. For pAr/90, the S

dr value decreases by 28% compared to pAr/60.

It can be seen that there is a clear difference in the surface morphology of unmodified yarns and both types of aramid fibers after plasma treatment. On the relatively smooth surface covered with longitudinal cavities and microfibrils, no protruding fragments are visible. Still, on the rough surface of aramid fibers after activation, numerous cavities, and fiber fragments are resulting from plasma etching. Plasma treatment causes the polymer degradation due to ion, electron, and free radical bombardment. The results of surface roughness analysis are shown in

Figure 2 and

Figure 4. The trends of surface roughness changes were in line with the trends visible on the SEM and 3D SEM images. As the plasma treatment time increased, more and larger fragments were evenly distributed over a much rougher surface. When the plasma treatment time increased to 90 min, the surface roughness of both types of aramid decreased, which can be attributed to the continuous etching or ablation process.

This corresponds with Wang et al. [

19] results who modified para-aramid yarn using plasma-induced vapor phase graft polymerization (PIVPGP) in the atmosphere of O

2, N

2, and Ar (100 W, 5, 10, 15, 20 min). An increase in porosity and furrows on the surface of the meta-aramid fibers treated by the microwave plasma (200 W) was observed by Ji et al. [

14]. Influence an atmospheric pressure plasma of Diffuse Surface Coplanar Barrier Discharge (DSCBD) on changes of roughness for meta- and para-aramid (300 W, 30 sec, 2 min, and 5 min) studied Stepankova et al. [

6]. They found an increase in the roughness of the meta-aramid fibers, and no changes for the para-aramid fibers, as in the study of Biro et al. (50–60 W,200 s) [

10]. Teams [

4,

7,

20] using plasma: NH

3, O

2 and H

2O (30 W, 10 min) [

4], atmospheric dielectric barrier discharge (DBD) plasma (143.5 W, 12 s) [

7], atmospheric pressure plasma and He/air mixture as working gas (5, 30, 60 s) [

20] found no change in the topography of para-aramid fibers surface. Poncil et al. [

21] observed surface smoothing and fading of fibrils on the surface of para-aramid yarn fibers, using atmospheric plasma (60 W, 3 min) and nitrogen as a working gas. In turn, Sheu et al. [

22] modifying para-aramid yarn with NH

3, O

2, H

2O plasma (100 W, 10 min) noted an increase in roughness and unevenness on the surface for all three types of gases. Biswas et al. [

9] observed an increase in the roughness of para-aramid fibers with time of activation at atmospheric pressure plasma (4 kW, 30 s, 1 min, 2 min, 3 min). Brown et al. [

23], by treating the para-aramid fabric with NH

3 plasma (100 W from 0.25–20 min) observed an increase in surface fibrillation. Chen et al. [

24] investigated the effect of atmospheric pressure plasma (720 W) on surface topography changes of para-aramid 3D fabric subsequent layers. They noticed a significant increase in the surface roughness mainly on the fibers surfaceof the first layer of 3D fabric and a decrease in the roughness of deeper fabric layers. Chen et al. [

13], by examining the effect of oxygen plasma (200 W, 5, 10, 15, 20 min) found an increase in roughness of para-aramid yarn with the activation time. Gu et al. [

11] observed an increase in the unevenness of the surface of para-aramid fibers after treating with a dielectric barrier discharge (DBD) argon plasma (300 W, 60 s). Lange et al. [

12] found an increase in the porosity of the surface of para-aramid fibers using atmospheric plasma (400 W, 0.1 s) and air and nitrogen. An increase in fibrillation on the surface of para-aramid fabric was observed by Guo et al. [

25] after air plasma (50 W, 25 min), similarly as Jia et al. [

8],after treating para-aramid fibers with DBD atmospheric plasma (143.5 W, 18 s).

SEM/EDS analysis of mAr/0 and pAr/0 yarns shows the presence of C, N, and O and trace amounts of Na and S (only for pAr) (

Table 1). The presence of sodium and sulfur is due to the aramid fibers producing technology. Form Ar the Na content indicate from the reaction of two comonomers in tetrahydrofuran. The slurry of an oligomer is formed which has been contacted with sodium carbonate and the polymer is formed [

26]. During plasma treatment, organic preparation is removed from the surface of the fibers, hence the reduction of C and N content. The O content increase with the activation time. The Na content amounts 0.1 wt.% and does not change after 30 min. For a longer time no Na content is observed what can be because of the tearing off fiber fragments what is observed on SEM and 3D SEM images. The pAris produced from the condensation of 1,4-diaminobenzene and terephthaloyl chloride. The formed pAr is immersed in sulfuric acid and then sodium hydroxide is added to neutralize it. The product of neutralization is sodium sulfate [

26]. As for mAr yarn, plasma treatment causes the removal of organic preparation and the reduction of carbon and nitrogen content. Sodium sulfate remains on the surface. Hence, the increase in oxygen content and a slight increase in Na (from 0.5 wt.% to 0.8 wt.%) and S (from 0.5 wt.% to 0.8 wt.%) content after 60 min of plasma treatment. For 90 min activation time the decrease of Na and S is observed, which proves the detachment of macromolecular fragments, what is visible on the SEM and 3D SEM images. To verify that changes in the percentages of elements after plasma modification are statistically significant, an analysis of significant differences was performed using the t-Student’s test. Experimental values of t (

Table 2) are calculated for p = 0.05 and t (0.05, 3) = 2.78 (t values from statistical tables) for the mean values of percentage C, N, O (

Table 1).

The oxygen content on the surface of both fibers types increases with increasing plasma activation time.

In the case of meta-aramid yarn, the largest and statistically significant increase in O content is observed after 60 and 90 min of activation (

Table 2) by 1.4 wt.% and 1.6 wt.%, respectively in relation to mAr/0. Activation causes a slight decrease in the content of C and N. These changes are not statistically significant. After 10 and 30 min, the Na content has not changed, and after 60 min there is no Na observed. Similarly, Stepankova et al. [

6] found an increase in O content, a decrease in C content and no change in the N content for meta-aramid fibers.

For pAr yarn, a statistically significant increase in O content is observed for all activation times and the highest of 2.4 wt.% is for 90 min. The increase in time causes a statistically significant reduction in carbon content after 10, 30, and 60 min. The reduction of N content is statistically significant after 90 min. Much higher increase of O content and decrease of C and N content observed Jia et al. [

7], Wu et al. [

27], and Wang et al. [

16] in comparison to our research. In addition, Lange et al. [

12] observed high increase in O content. Contrary to us, Jia et al. [

28] shown a decrease in O and an increase in C content. In turn, Gu et al. [

11] noted a decrease in O, C and N content. Biswas et al. [

9] found a slight decrease in the O and N content and increase in the C content. Changes in the percentage of elements on the surface of aramid textile materials result from the use of different types of plasma, plasma treatment conditions, and the residue of spinning preparations.

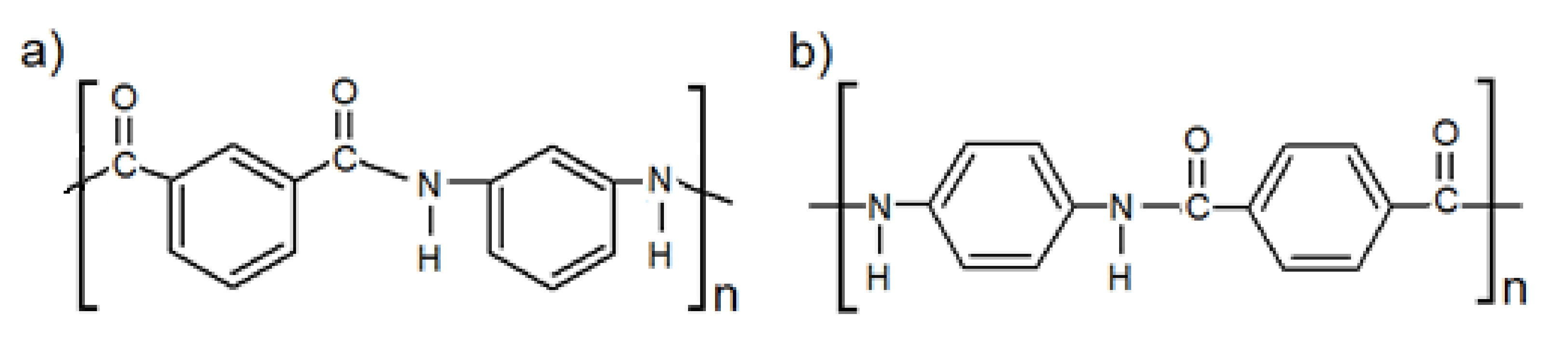

For pAr yarn, the O content before and after plasma modification is higher than for mAr yarn. These differences result from the molecular chain configuration and substitution of aromatic groups. Para-aramid consists of long molecular chains that are highly oriented and show strong intermolecular bonds in the para position. The hydrogen bonds formed from the para-substituted skeleton connect adjacent chains to form stacked sheets that curl into “microfibrils” and combine to form a fiber. This hierarchical structure allows the para-aramid to have a more even crystal structure. In the meta-aramid, the amine functional group is located in the meta orientation on the phenyl ring in the monomer. This slight difference in the molecular structure changes the optimal binding angles of phenyl-nitrogen and phenyl-carbon, causing a “crumpled” chain structure that cannot crystallize into stacked sheets. This causes it to take on a disordered structure with randomly arranged polymer chains, which results in lower crystallinity than para-aramid [

15,

29]. The difference in the arrangement of the structure of both aramids affects the availability of individual functional groups. Due to the hierarchical structure of para-aramid, the carbonyl, amino groups and the phenyl ring are better available compared to the meta-aramid, which is disordered, and the carbonyl and amino groups in the “crumpled” structure may hide between the phenyl ring and limit their availability and hence the lower oxygen content [

15].

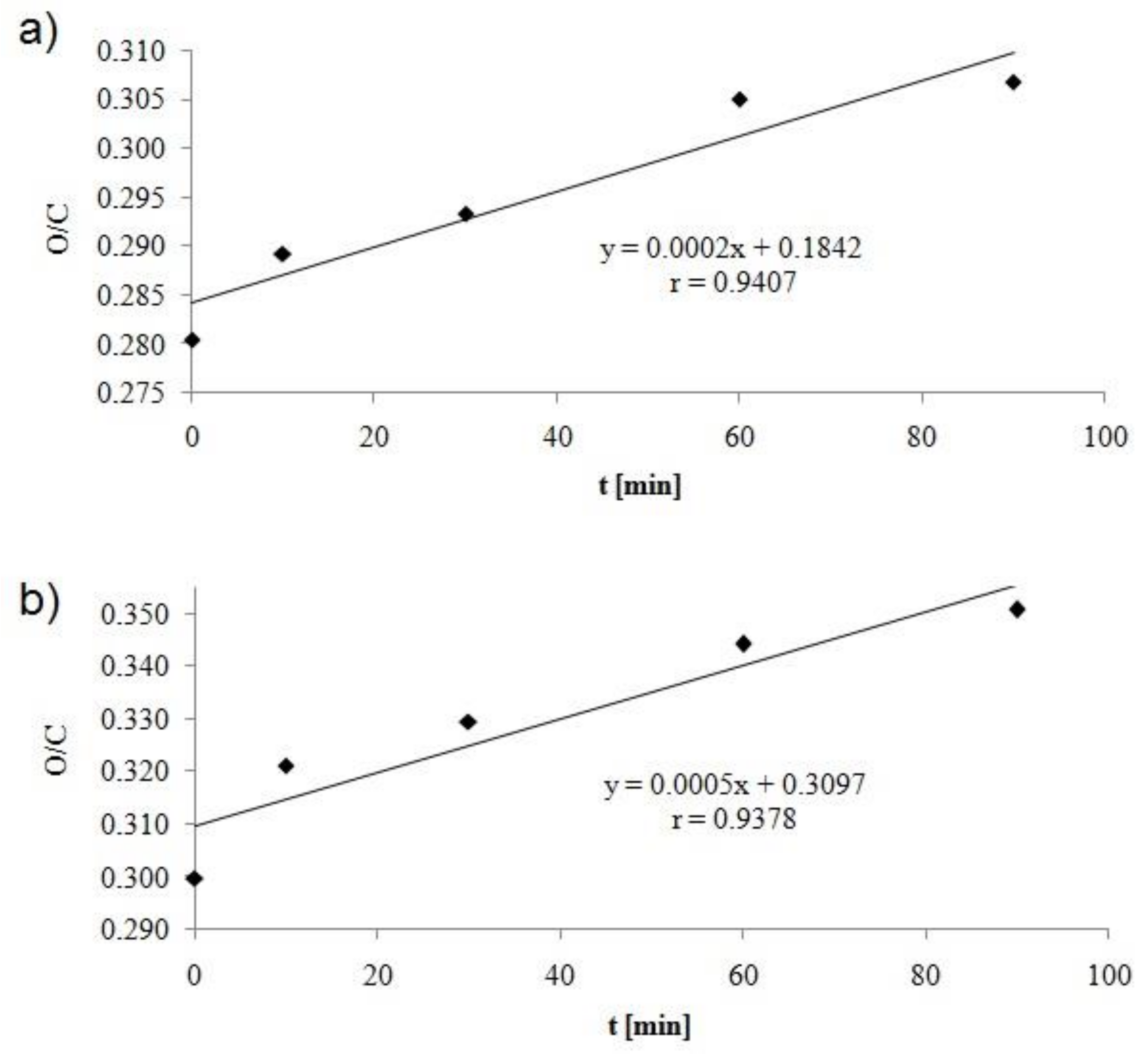

Figure 5 shows the effect of activation time on changes in O/C ratio on the fiber surface. For both yarns, the O/C value increases linearly as the activation time increases, but they are higher for pAr yarns.For 90 min, the increase in the O/C ratio is 10% and 17% for mAr yarn and pAr, respectively. An increase in O/C was also observed in the earlier work of the authors after corona discharge modification of the meta- and para-aramid fabric [

15].

An increase of O/C was found by Wu et al. [

27], Wang et al. [

16], Hwang et al. [

20], and Jia et al. [

28] for para-aramid fibers and Guo et al. [

25] for para-aramid fabric. A decrease in the O/C value for para-aramid yarn was observed by Jia et al. [

8], Inagaki et al. [

29], and Chen et al. [

24].

2.2. Goniometric Analysis

Table 3 summarizes the values of contact angle for yarns before and after activation in plasma for water (θ

W), θformamide (θ

F) and diiodomethane (θ

DIM). The values of θ

W, θ

F, and θ

DIM decrease with the increase of activation time. The value of θ

W form Ar/0 is 65.4 deg. For subsequent activation times it decreases by 16%, 30%, 35% after 10, 30 and 60 min, respectively. For mAr/90, the θ

W value stays at the same level as for mAr/60. The value of θ

F decreases by 4%, 17%, 24%, and 36% compared to 53.9 deg for mAr/0. The value of θ

DIM decreases by 16%, 20%, 30% after 10, 30, and 60 min compared to 60.2 deg for mAr/0. For mAr/90, the θ

DIM value does not change in comparison with mAr/60.

For pAr/0, the value of θW is 69.9 deg. After subsequent activation times, it decreases by 19%, 32%, 39% and 43%, respectively. The θF for pAr/0 amounts 64.2 deg and decreases by 10%, 20%, and 27% after 10, 30, and 90 min, respectively. After 60 min, the θF value is close to the value after 30 min. In turn, the θDIM value decreases respectively by 3%, 7%, 9%, and 20%, compared to the pAr/0 (56.9 deg).

Sheu et al. [

22] and Wang et al. [

16] obtained a similar value of water contact angle for para-aramid yarn. They noted higher decrease of its value after plasma treatment than we obtained. Wang et al. [

16] found the higher decrease of the diiodomethane contact angle for para aramid fibers. Jia et al. [

7] and Biswas et al. [

9] obtained lower decrease for the water contact angle for para-aramid fibers and in contrast to us, no changes for diiodomethane. Ren et al. [

30] found similar to us decrease of the water contact angle value for para-aramid fibers.

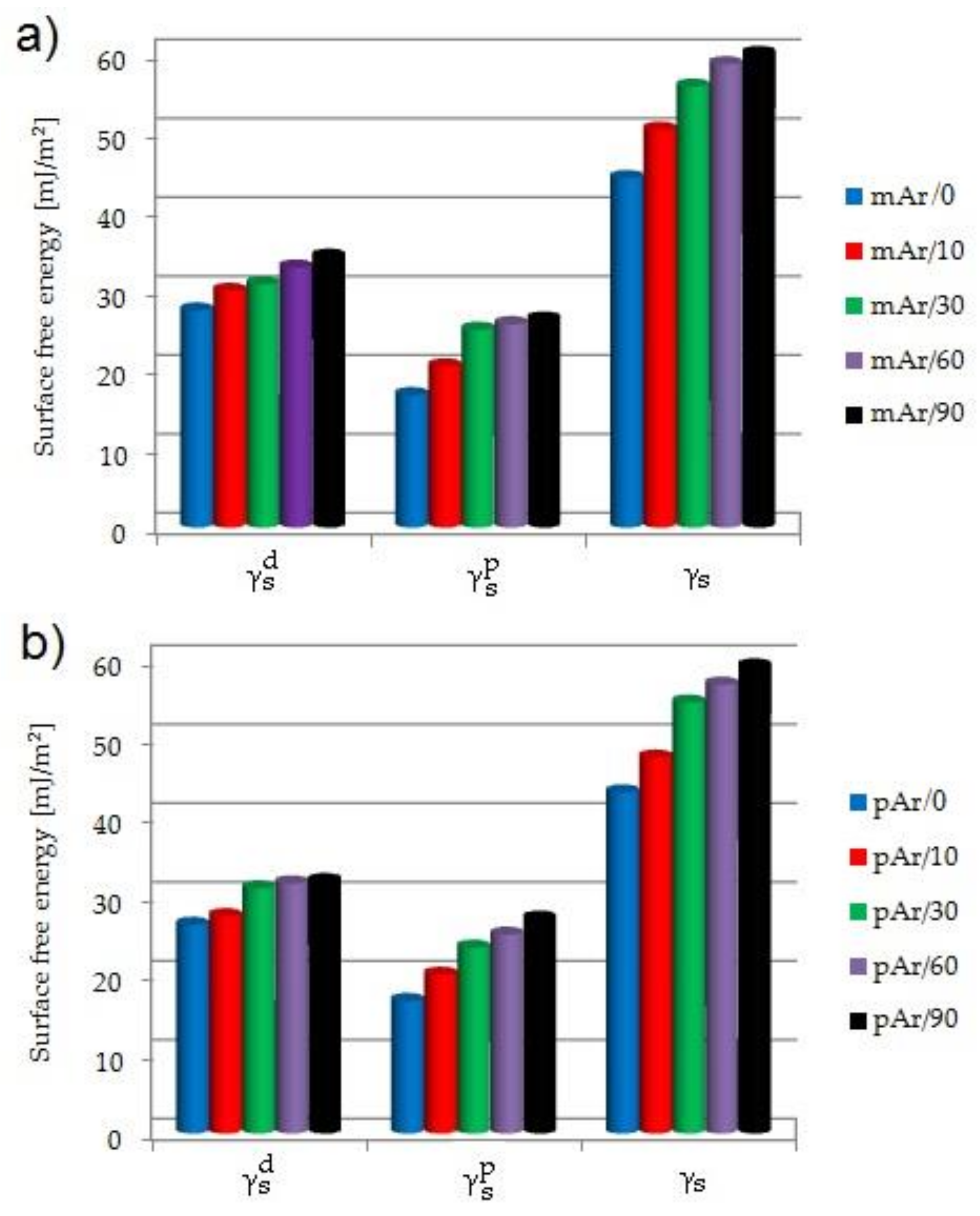

For mAr/0, the γ

s value is 44.3 mJ/m

2 (

Figure 6a). After 10 min, the γ

s value increases by 13%. For subsequent times, the increase by 26%, 33%, and 37% is observed. Low-pressure RF plasma is generated in the residue air. In this condition, oxygen and water can be the source of ozone, atomic oxygen, and hydroxyl radicals that initiate the processes of oxidation and hydrolysis on the surface of fibers. The amide groups in the aramid chains are attacked, and the amide bond breaks. These phenomena, together with the generated high energy of UV radiation, opens the possibility of some crosslinking between the chains. After breaking the amide bonds in the chain of aramid fibers, radicals are formed that react with oxygen. Then the created peroxides decompose, which results in the formation of carboxylic acid and nitroso groups [

26]. The formation of new functional groups on the surface of aramid fibers, e.g., hydroxyl, nitroso or carboxyl groups, make the fibers more hydrophilic, as evidenced by the decrease in water contact angle (

Table 3) and an increase in the polar component value (γ

sp) (

Figure 6a), which for mAr/0 amounts 16.8 mJ/m

2. A significant increase in the γ

sp value by 22% and 49% is observed especially after 10 and 30 min of activation, respectively. For longer times, the γ

sp value stays at the same level as for mAr/30. The dispersion component (γ

sd) (

Figure 6a) also increases with increasing activation time. For mAr/0, the γ

sd value is 27.5 mJ/m

2. The γ

sd value increases by 9% after 10 min. For mAr/30, the γ

sd value does not change in comparison with mAr/10 and for mAr/60 and mAr/90, the γ

sd value increases by 20% and 25%, respectively. The increase in γ

sd value is associated with significant changes in the fiber surface topography (

Figure 1,

Figure 2). As the activation time increases, the surface roughness and unevenness increases, and the values of stereometric parameters increase, which indicates greater surface development.

Ji et al. [

14], according to the Fowkes model, obtained the lower γ

s and γ

sp values for meta-aramid yarn and both values increased less than in our work, respectively by 10% and 15% after activation in the plasma.

The γ

s value of pAr/0 and mAr/0 are comparable (

Figure 6b). For pAr/10, the γ

s value increases by 10% compared to pAr/0. After 30 min, a 26% increase in γ

s value is observed. For subsequent times a slight increase by4% and 8% for pAr/60 and pAr/90, respectively, are observed. As for mAr yarns, for pAr yarns the formation of new functional groups on the surface of the fibers, e.g., hydroxyl, nitroso or carboxyl groups, has led to an increase in the hydrophilic nature of the fibers, as evidenced by the decrease in the water contact angle (

Table 3) and an increase in the component polar (γ

sp) (

Figure 6b). The γ

sp value of pAr/0 is 16.8 mJ/m

2. After subsequent activation times, an increase of 20%, 40%, 50%, and 62%, respectively, is observed. The dispersion component (γ

sd) (

Figure 6b) also increases with increasing activation time. For pAr/0, the γ

sd amounts 26.4 mJ/m

2. After 10 min of activation, a slight increase of 4% is observed. A much larger increase by 18% is found for pAr/30. For subsequent times the γ

sd value stays at the level similar to pAr/30. Wang et al. [

16], according to the Owens-Wendt formula, found the higher γ

s value and lower γ

sp and γ

sd values for para-aramid yarn. Similarly to us, after activation, they observed an increase in the γ

s and γ

sp values, and in contrary to us, the decrease in γ

sd value. Jia et al. [

7] observed the higher γ

s and γ

sd values and lower γ

sp value for para-aramid fibers than we obtained. After activation, they found an increase of the γ

s and γ

sp value and a decrease of the γ

sd value (calculated according to the Owens-Wendt formula).

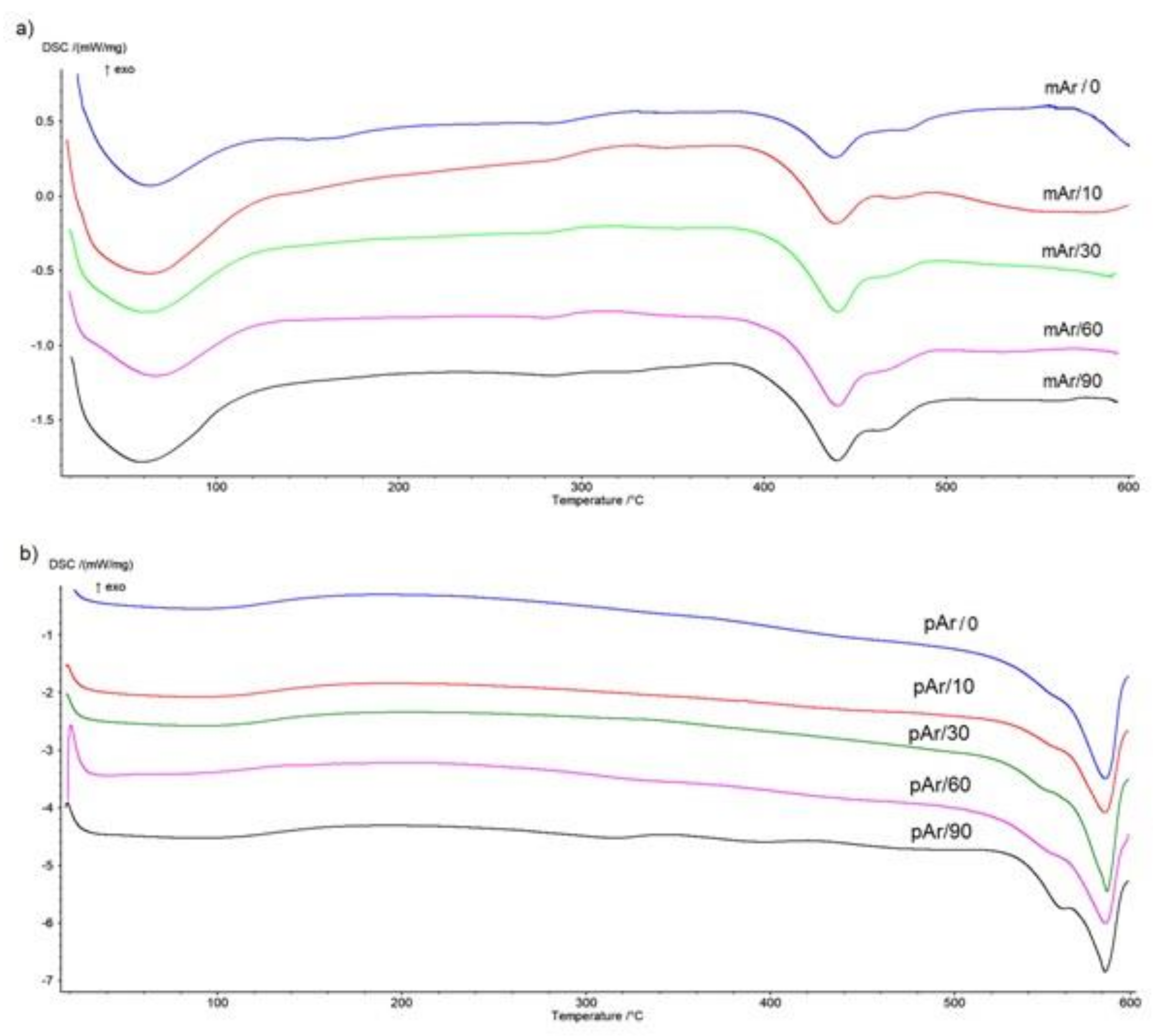

2.5. TG/DTG Analysis

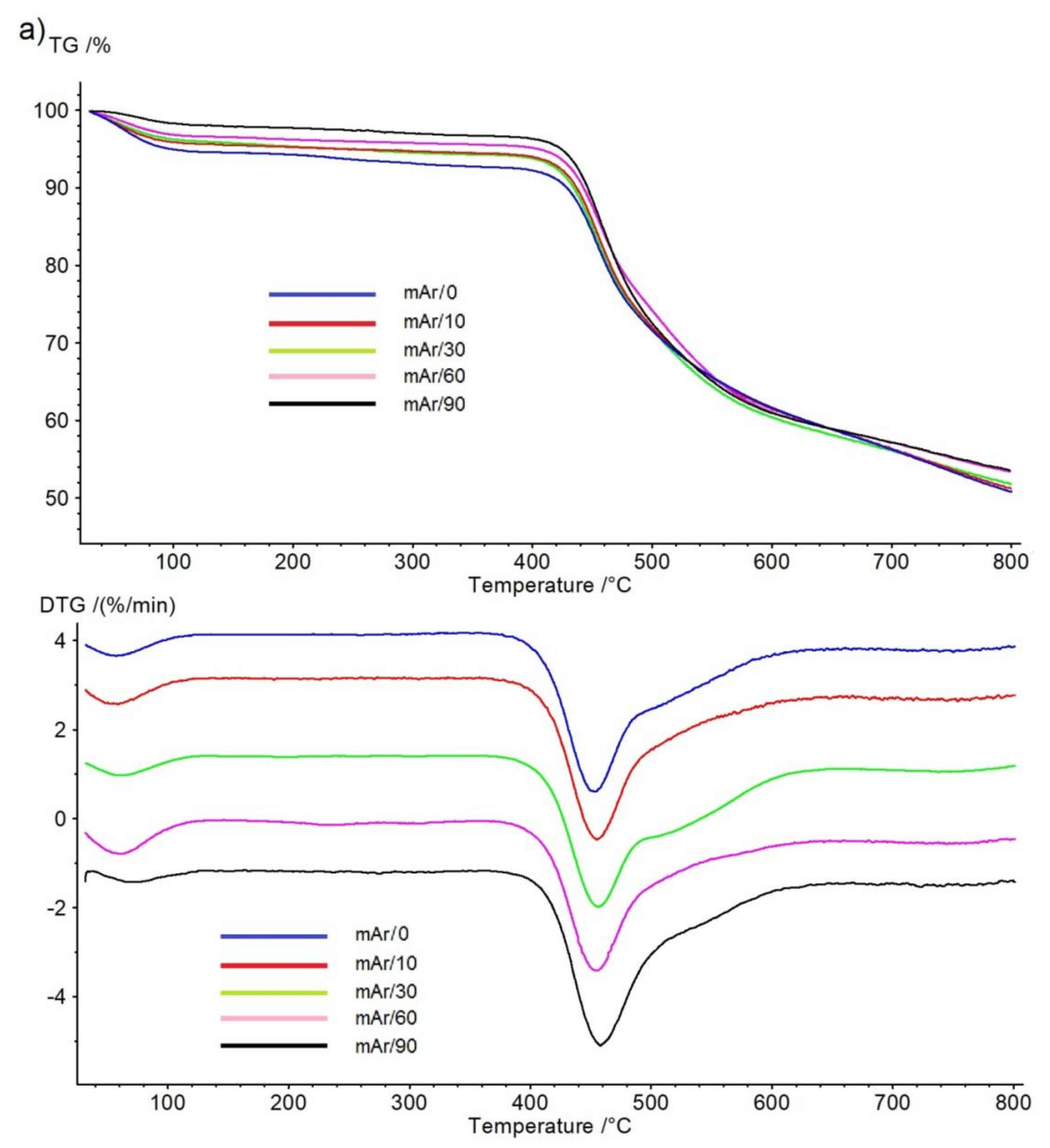

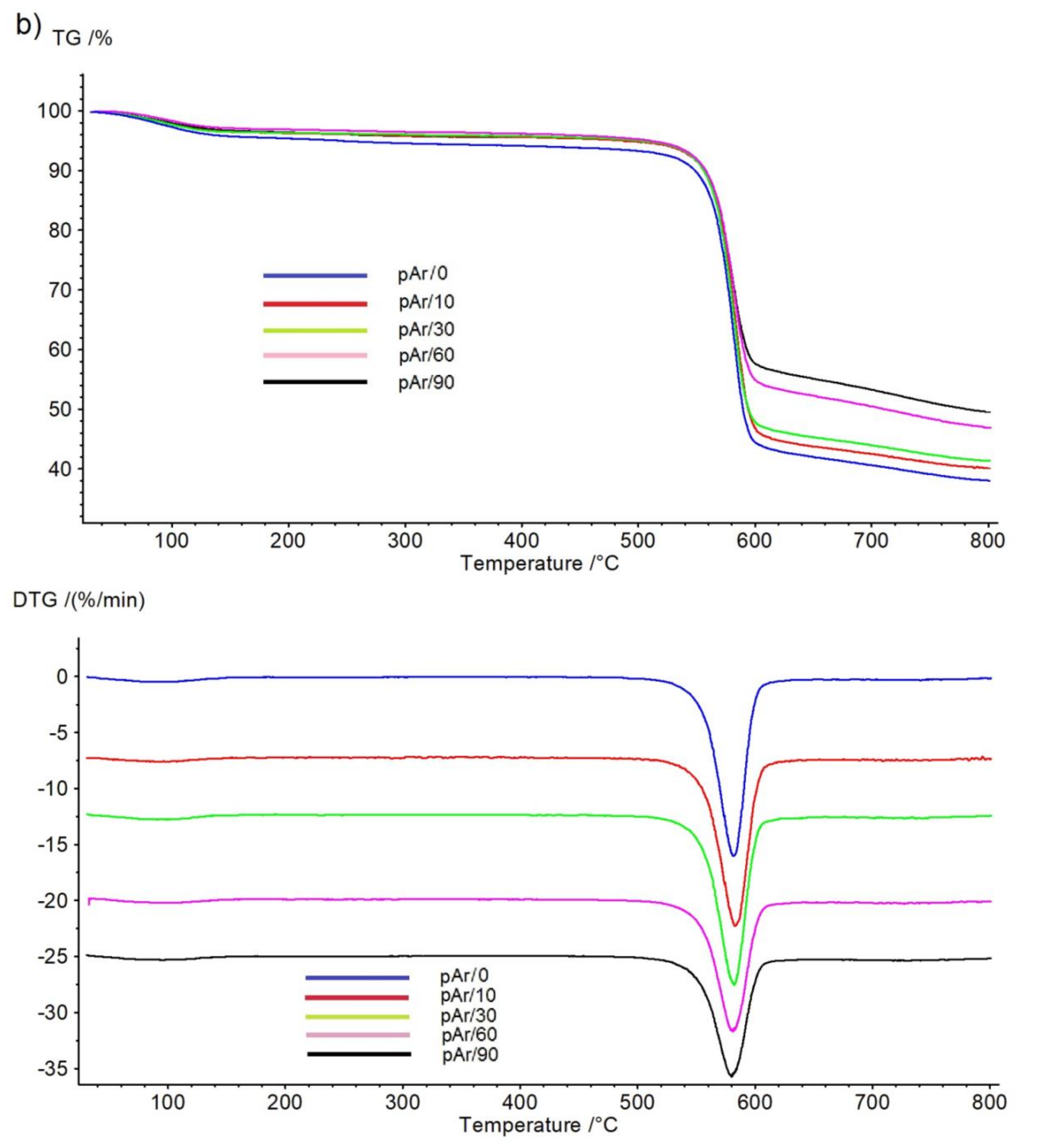

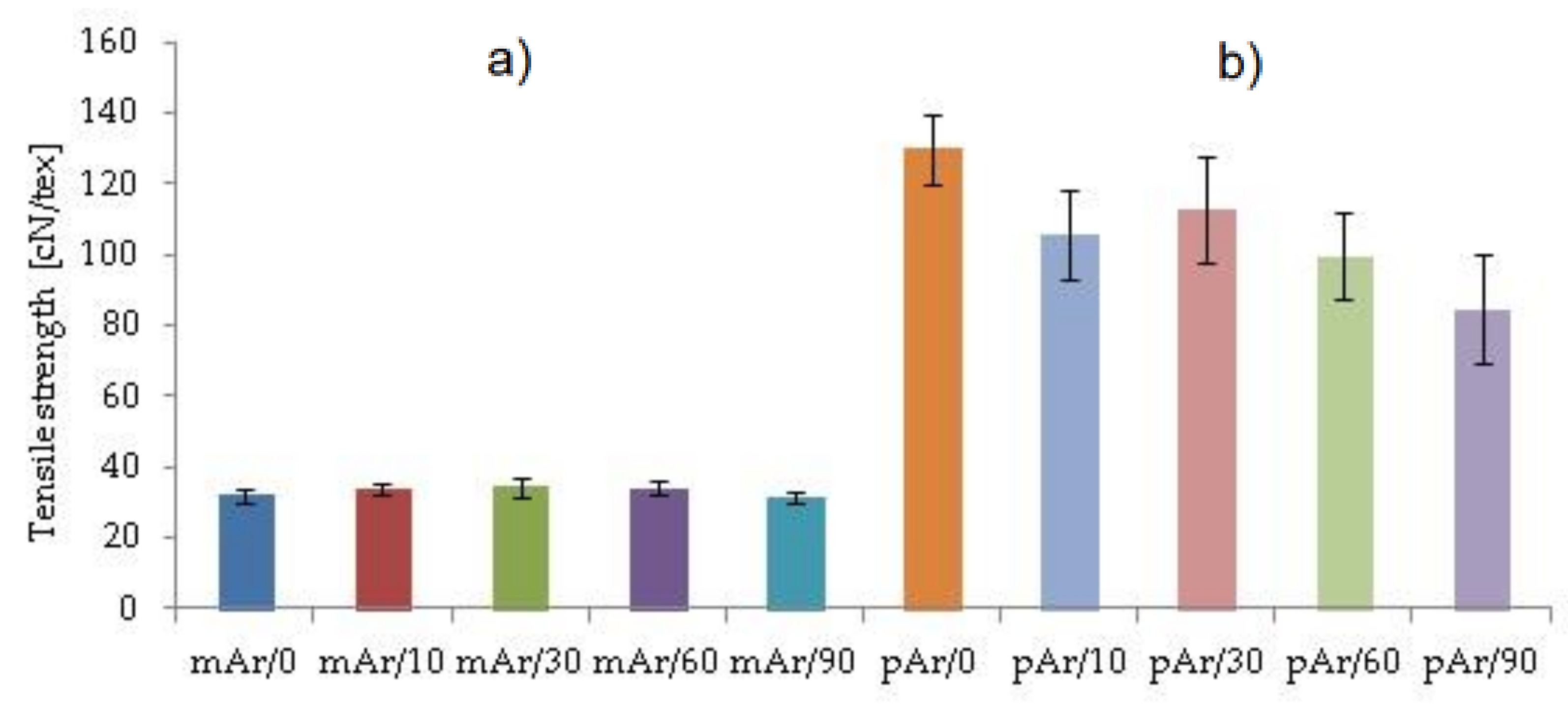

On the TG curve for mAr/0 yarn (

Figure 10a) a slight weight loss is observed in the range of 30–120 °C, which corresponds to the water desorption peak on the DTG curve. The thermal decomposition process occurs in two stages in the temperature range of 414–583 °C with a maxima at 455 °C and 521 °C for peak 1 and peak 2, respectively (

Table 6). Weight loss at 800 °C is 49%. Activation of the yarn does not cause significant changes in the initial temperatures, and the final temperature increases by 9 °C, 13 °C, 19 °C, and 21 °C after 10, 30, 60, and 90 min of activation, respectively. The temperature in the peak 1 maximum for yarn mAr/10, mAr/30, mAr/60 stays at the same level, and for yarn mAr/90, there is a temperature increase in peak 1 by 3 °C. The temperature at the maximum of peak 2 increases by 4 °C for mAr/10, similar to mAr/30. For mAr/60 and mAr/90, an increase in temperature of 9 °C and 21 °C is observed. Weight loss decreases by 0.4%, 1%, 3%, and 3% after 10, 30, 60, and 90 min of activation, respectively.

For pAr/0 yarn, the TG curve (

Figure 10b) shows a weight loss in the range of 30–120 °C, which corresponds to the water desorption peak on the DTG curve. The thermal decomposition process takes place in one-step at a temperature range of 560–599 °C with a maximum at 581 °C. The weight loss of pAr/0 at 800 °C is 62%. An increase in the activation time causes a slight increase in the value of the initial temperatures. After 90 min, the initial temperature increases by 4 °C. The final and maximum peak temperatures do not change with increasing activation time. Weight loss decreases by 3%, 5%, 14%, and 19%.

Sun et al. [

35] also observed a reduction in a weight loss of para-aramid fibers by about 2% after activation in an oxygen plasma (300 V). In our previous work [

15], we also found a decrease in weight loss for meta- and para-aramid fabric.

Differences in thermal properties and changes as a result of low-pressure air RF plasma modification are associated with differences in the production method and physicochemical properties of both fibers. The mAr fiber is made by spinning in a chemical solution called the wet spinning method. This semi-crystalline fiber is made up of a molecular chain partially oriented along the fiber axis. Its average moisture recovery is 4.5% in a standard atmosphere [

15,

36,

37,

38,

39].

The pAr fibers are formed by the dry-jet, wet spinning method. The presence of an amide bond in the polymer chain promotes the formation of a long chain, helping to form liquid crystals. The pAr fiber consists of fully stretched liquid crystal chains formed along the fiber axis with a very high degree of crystallinity and very high orientation. In a normal atmosphere, its average moisture recovery is about 4.3%. Due to the difference in the degree of crystallinity, the pAr density is 1.44 g/cm

3, and mAr 1.38 g/cm

3 [

15,

39].

Oxidation by air plasma treatment causes changes on the surface of the aramid fibers, without significantly affecting the thermal properties and cause slight changes in degradation temperatures. The used treatment time influences on the water content of both yarns (

Figure 7a,b). We observe a decrease in water weight loss from about 6% to about 2% for mAr yarns and from about 5% to about 3% for pAr yarns.