Surface Characterization and Optical Properties of Reinforced Dental Glass-Ceramics Related to Artificial Aging

Abstract

1. Introduction

2. Results

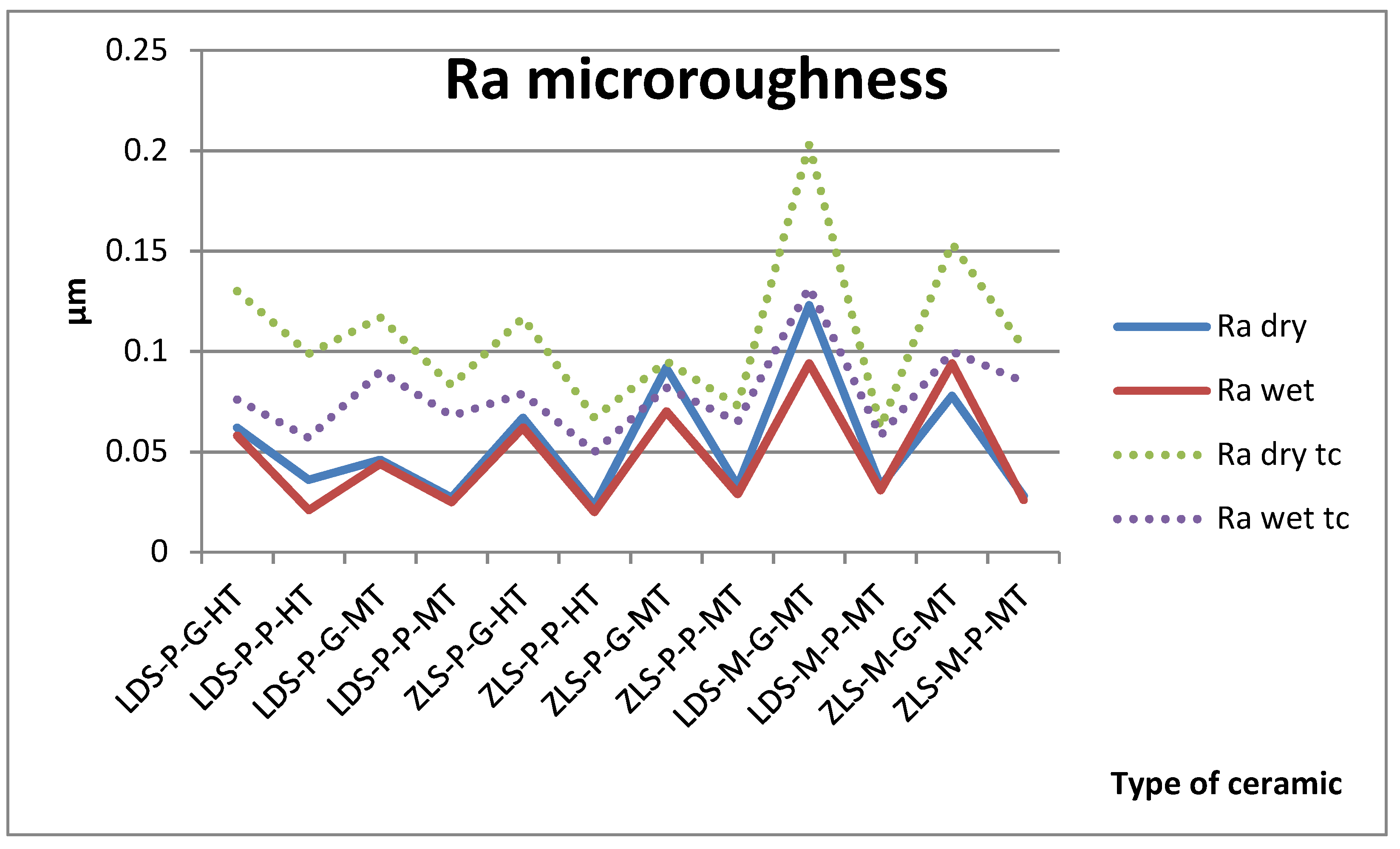

2.1. Surface Roughness

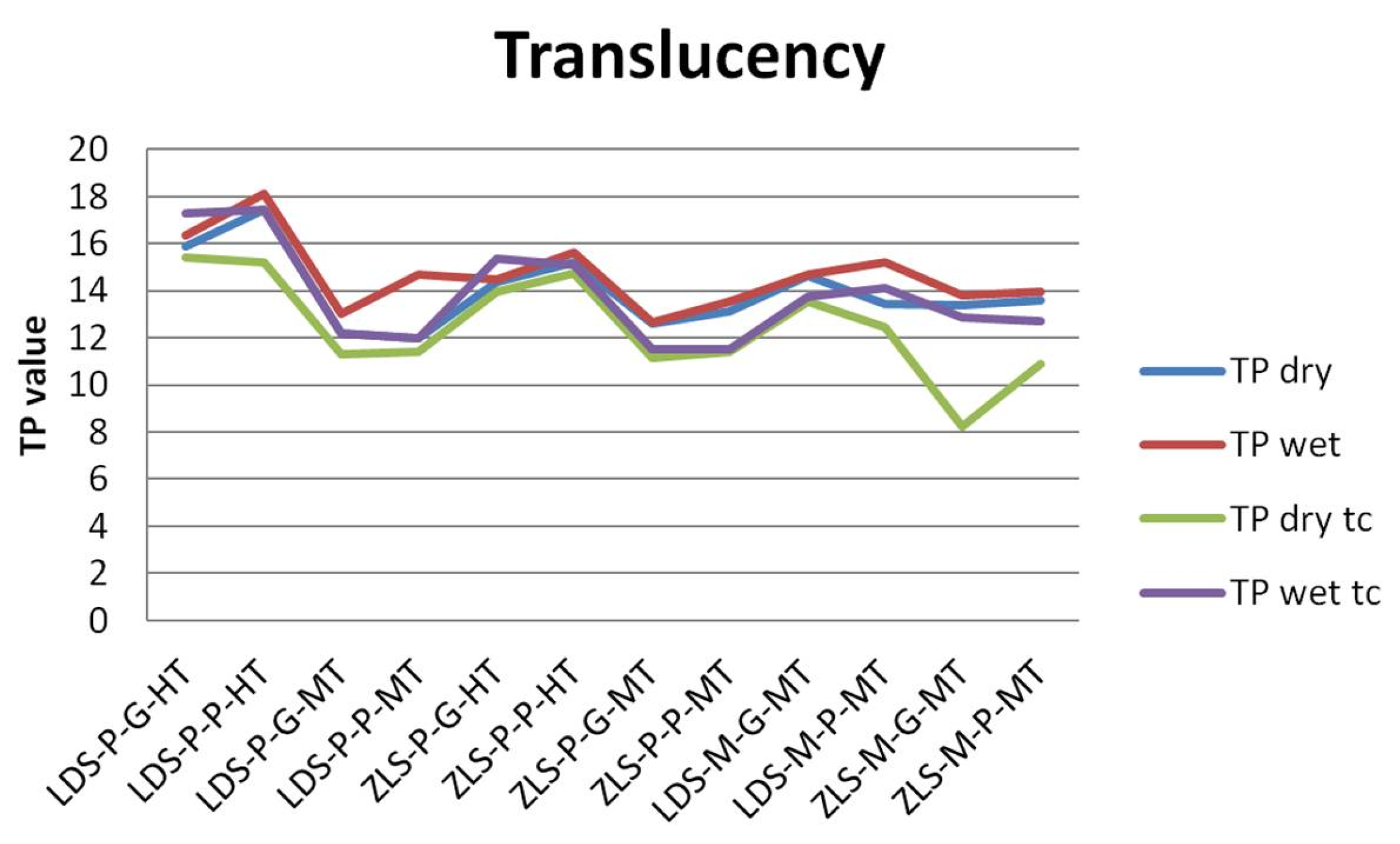

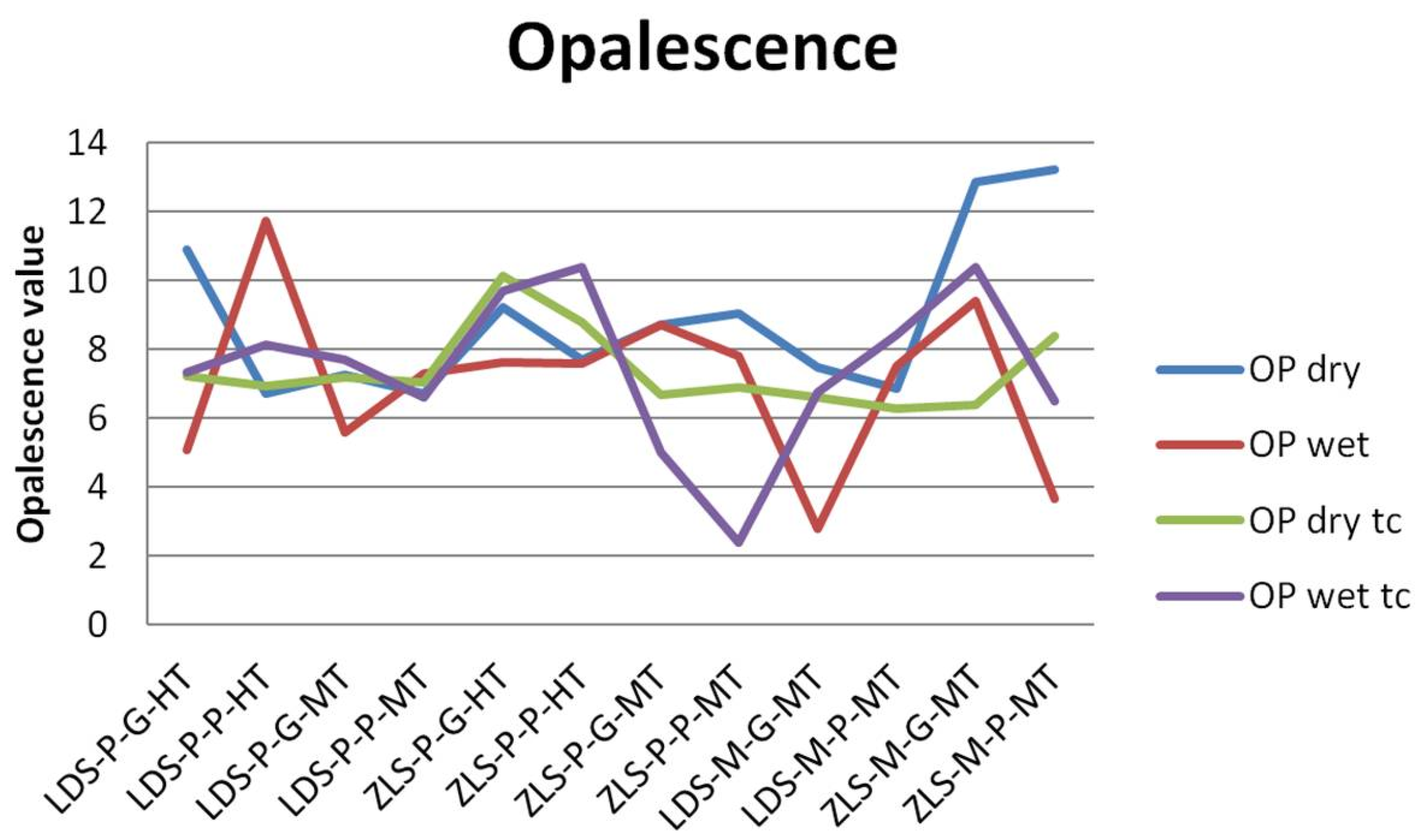

2.2. Optical Properties

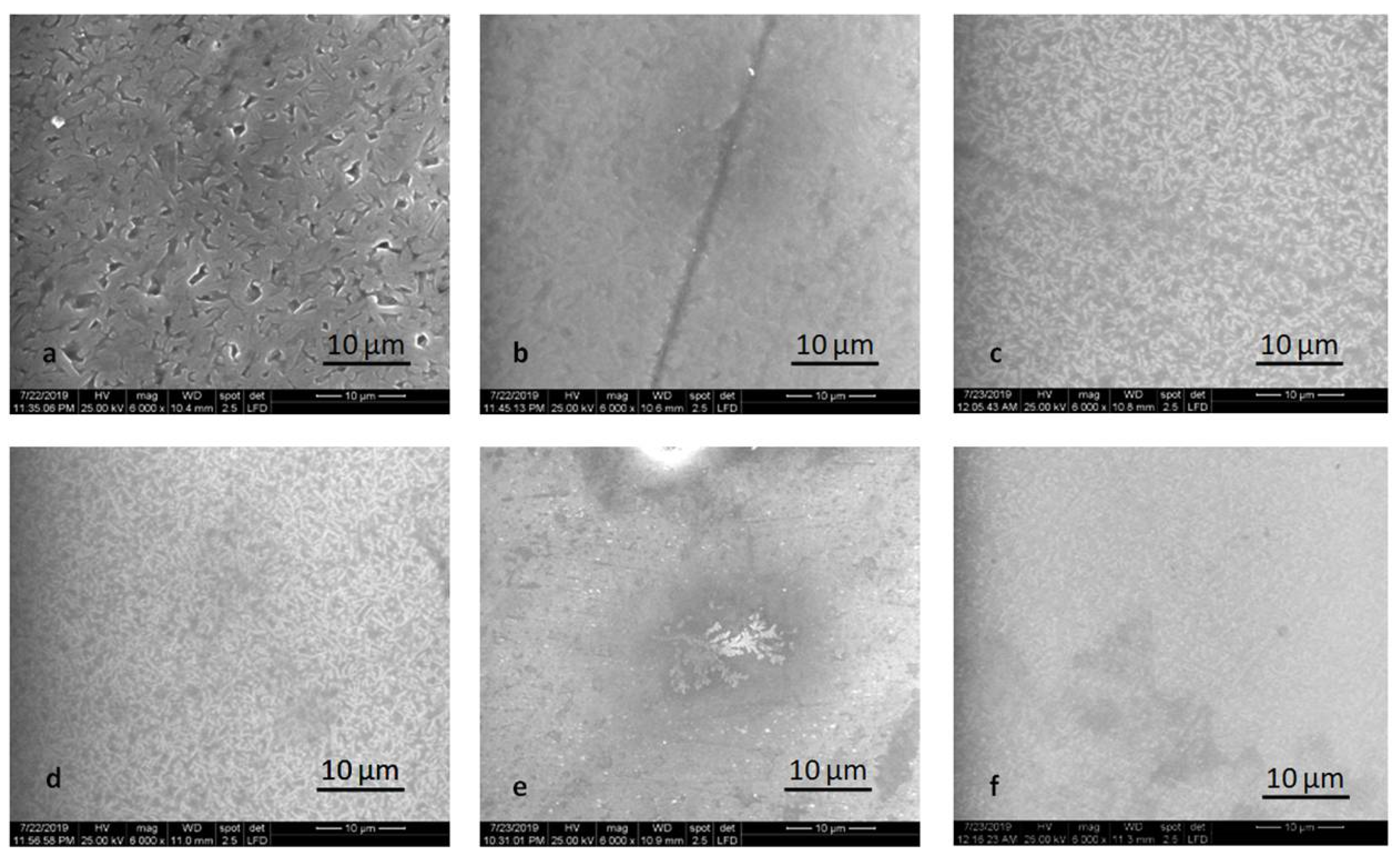

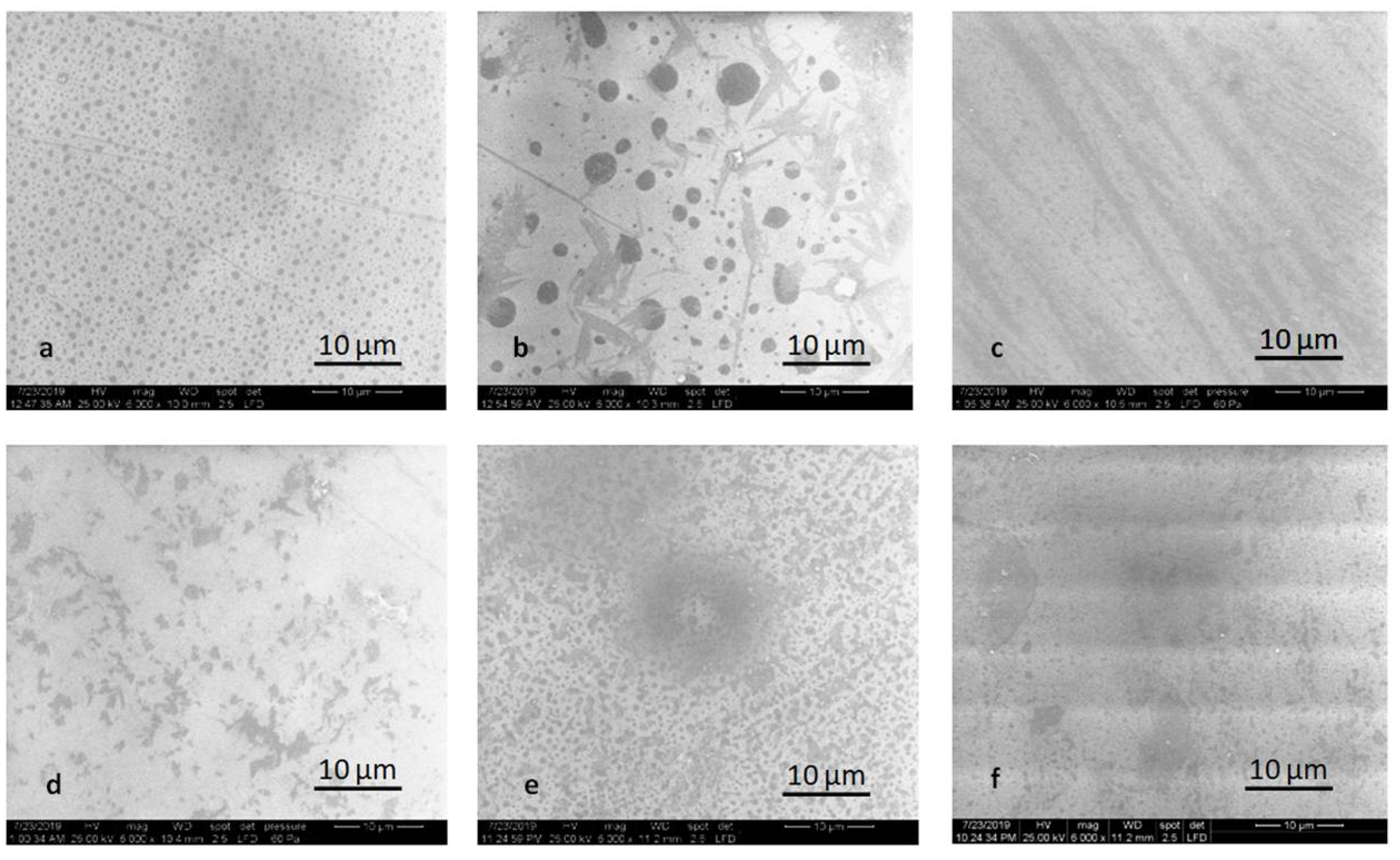

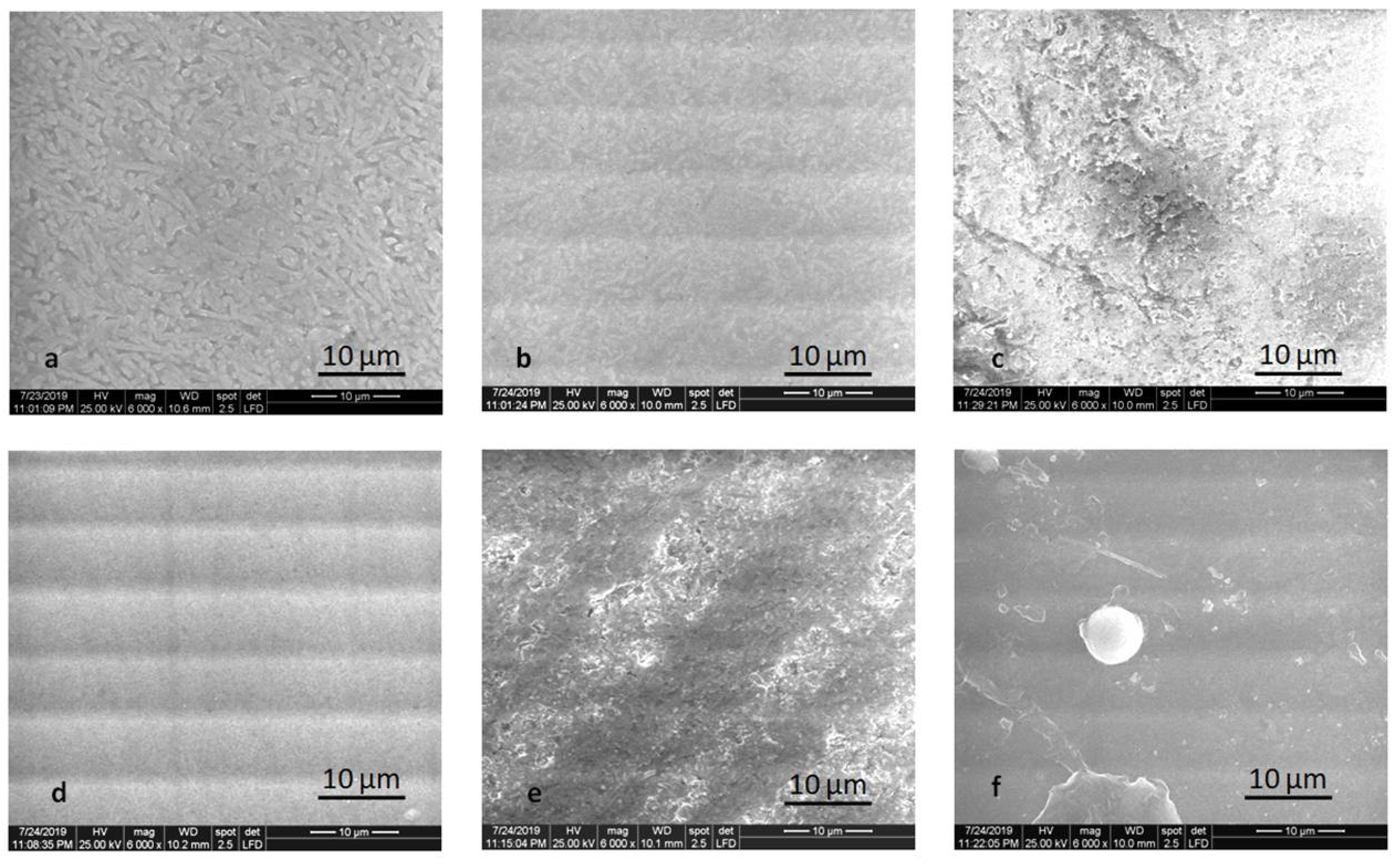

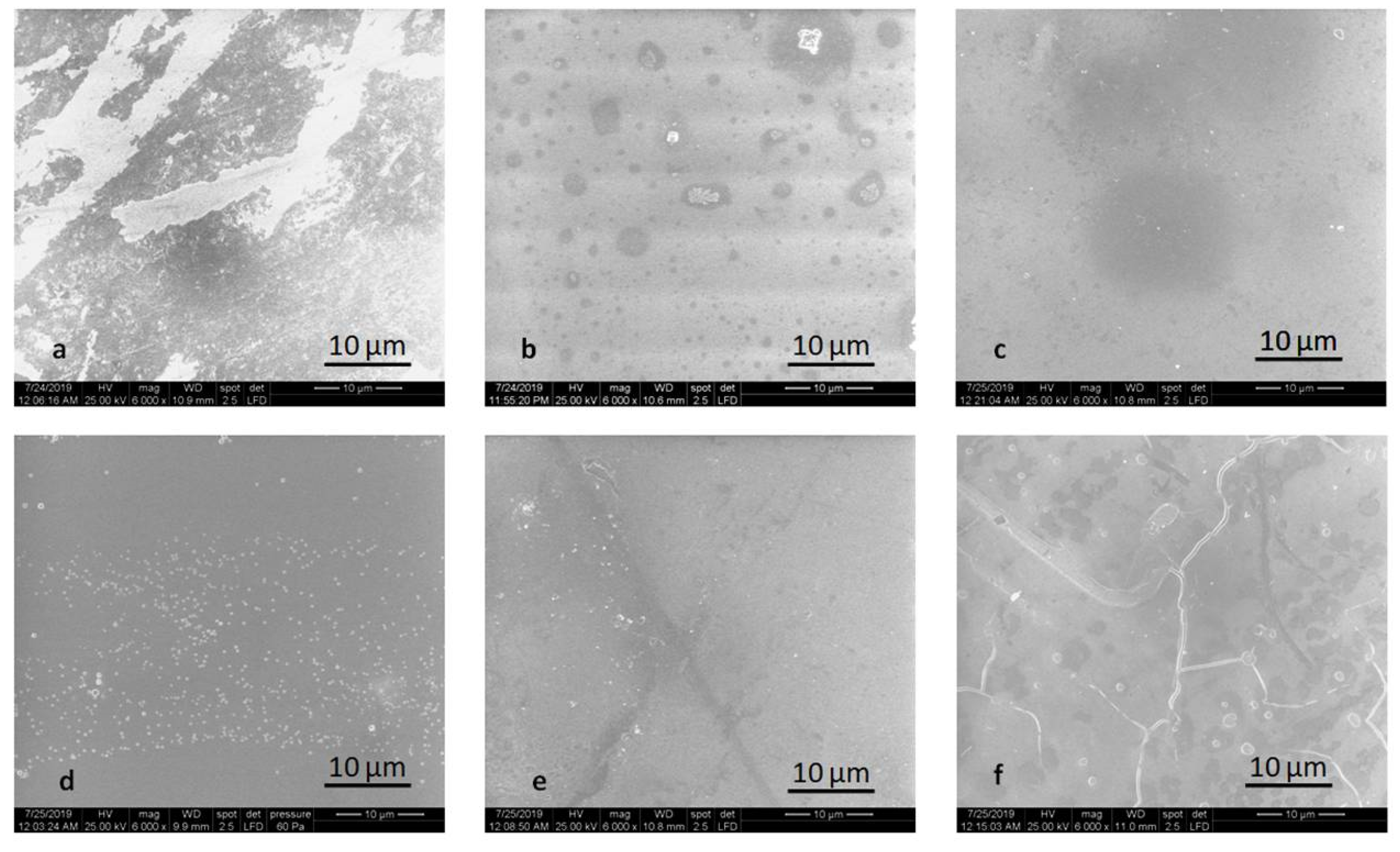

Scanning Electron Microscopy (SEM)

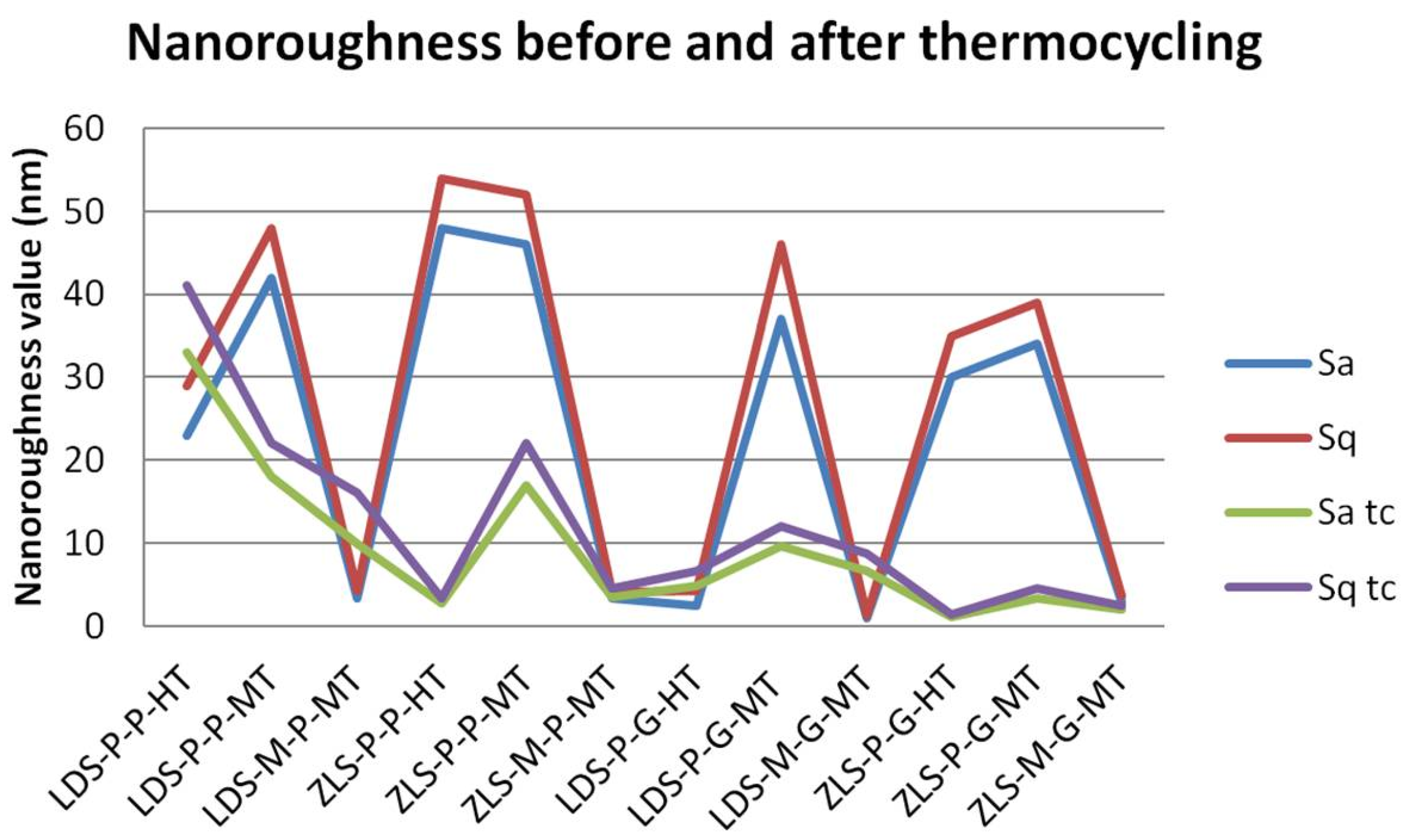

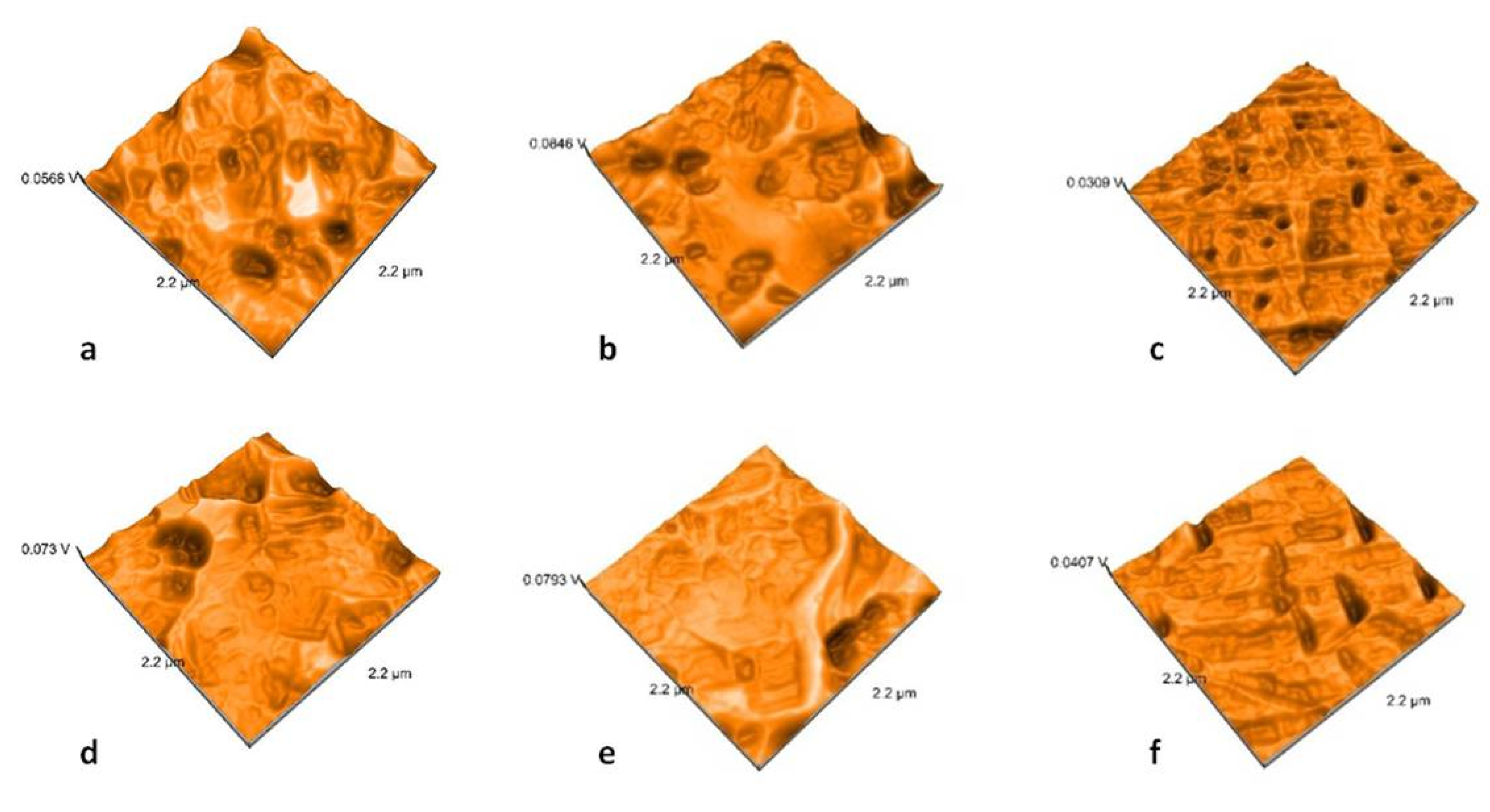

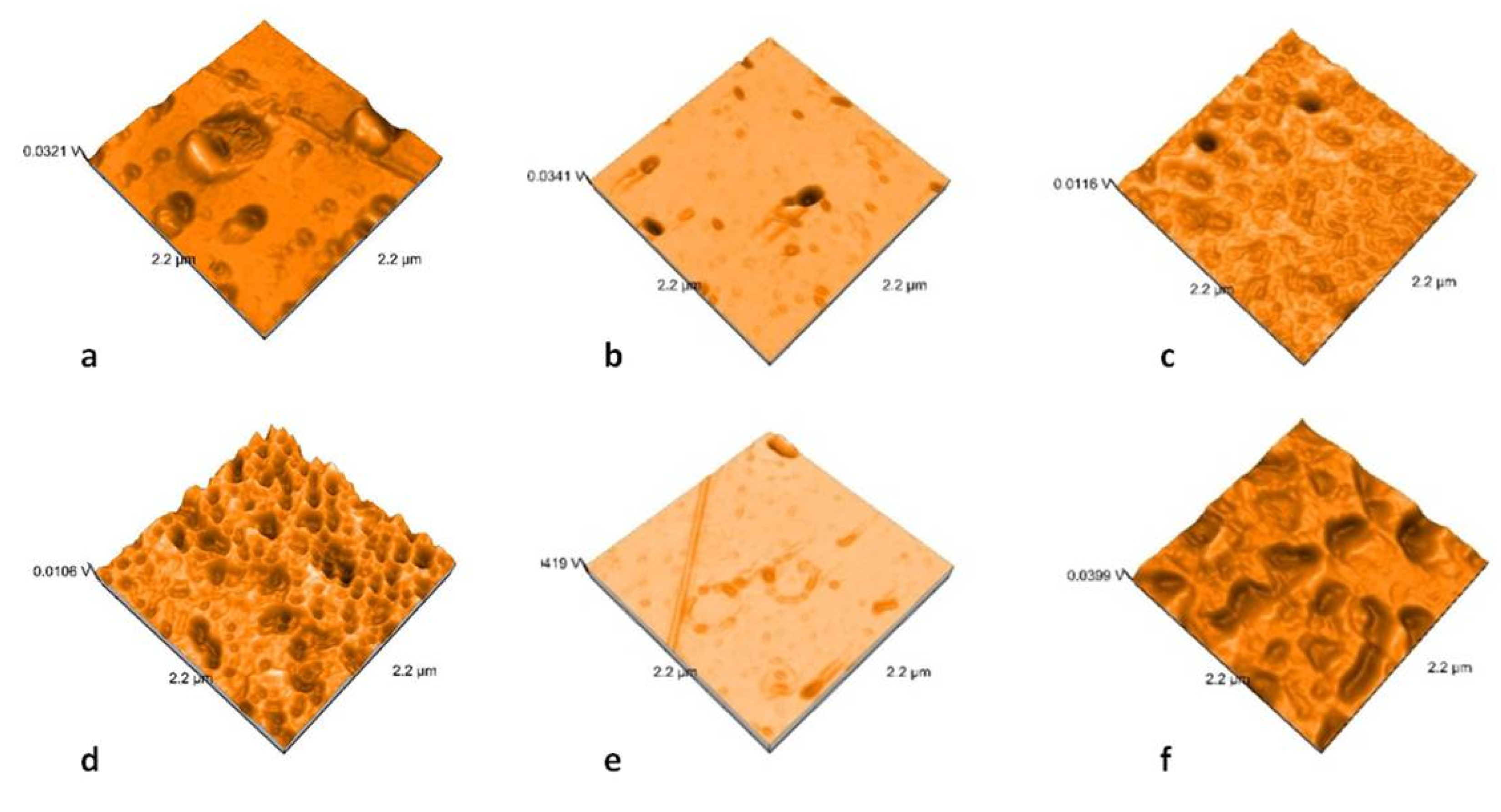

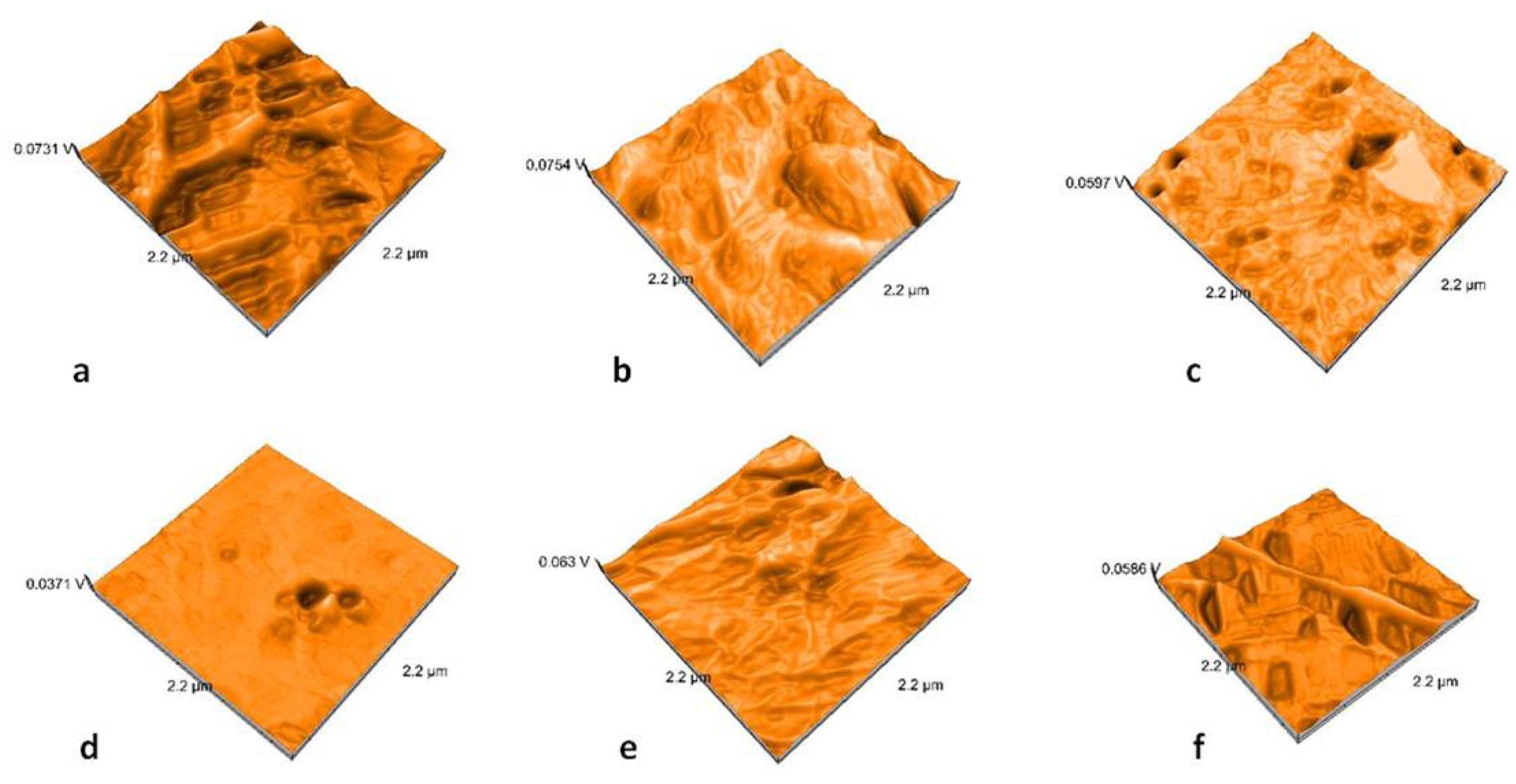

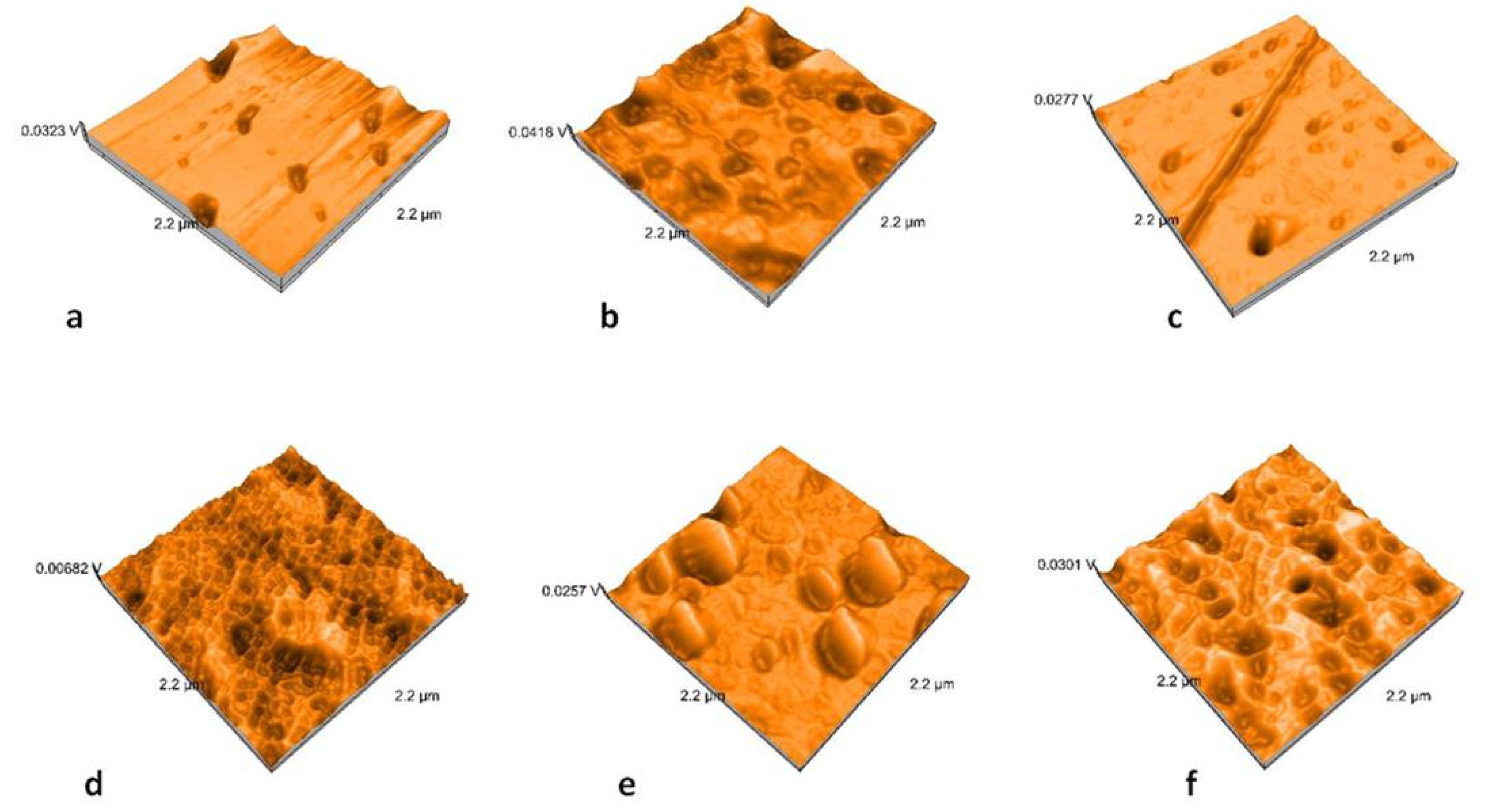

2.3. Nanosurface Topographic Characterization by AFM

3. Discussion

4. Materials and Methods

4.1. Sample Preparation

4.2. Surface Roughness Measurements

4.3. Optical Properties Measurements

4.4. Microstructure Analysis by Scanning Electron Microscopy (SEM)

4.5. Nanosurface Topographic Characterization Using Atomic Force Microscopy (AFM)

4.6. In Vitro Artificial Aging Using Thermal Cycling

4.7. Statistical Analysis

5. Conclusions

- The differences recorded between translucency and opalescence of ZLS and LDS ceramics are not significant. Regarding processing technologies, milling and polishing are associated with significantly higher translucencies.

- Thermal cycling has a significant influence on the translucency of ZLS and LDS glass-ceramic materials. The most harmful effect is on the pressed and polished samples, the consequences being the decrease in translucency.

- The surface roughness values of all samples are under an acceptable limit of 0.2 µm. Among the processing procedures, glazing increases the microroughness significantly, and milling leads only to an insignificant increase.

- In terms of nanoroughness, ZLS samples are significantly influenced due to the size of the crystals.

- A negative correlation was recorded for micro- and nano roughness parameters. Ra and Sa’s values are significantly influenced by in vitro aging.

Author Contributions

Funding

Conflicts of Interest

References

- Silva, L.H.; De Lima, E.; Miranda, R.B.D.P. Dental ceramics: A review of new materials and processing methods. Braz. Oral Res. 2017, 31 (Suppl. 1), 58. [Google Scholar] [CrossRef] [PubMed]

- Massera, J. Bioactive glass-ceramics: From macro to nano. In Nanostructured Biomaterials for Regenerative Medicine; Woodhead Publishing Series in Biomaterials; Woodhead Publishing: Cambridge, UK, 2020; pp. 275–292. [Google Scholar]

- Lohbauer, U.; Belli, R. Effect of sintering parameters on phase evolution and strength of dental lithium silicate glass-ceramics. Dent. Mater. 2019, 35, 1360–1369. [Google Scholar] [CrossRef]

- Crovace, M.C.; Souza, M.T. Biosilicate®—A multipurpose, highly bioactive glass-ceramic. In vitro, in vivo and clinical trials. J. Non-Cryst. Solids 2016, 432, 90. [Google Scholar] [CrossRef]

- Rampf, M.; Höland, W. Glass-ceramics for dental restoration. In Woodhead Publishing Series in Biomaterials, Bone Repair Biomaterials, 2nd ed.; Pawelec, K.M., Planell, J.A., Eds.; Woodhead Publishing: Cambridge, UK, 2019; pp. 329–340. [Google Scholar]

- Porojan, L.; Topală, F. Failure analysis of various monolithic posterior aesthetic dental crowns using finite element method. J. Phys. Conf. Ser. 2017, 885, 012003. [Google Scholar] [CrossRef]

- Porojan, L.; Porojan, S.; Rusu, L.; Boloş, A.; Savencu, C. Experimental Analyses for The Mechanical Behavior of Pressed All-Ceramic Molar Crowns with Anatomical Design. MATEC Web Conf. 2017, 108, 02001. [Google Scholar] [CrossRef]

- Porojan, L.; Savencu, C.; Porojan, S. Applications of Heat-pressed Ceramics for Single Tooth Restorations. Rev. Chim. 2016, 67, 123–126. [Google Scholar]

- Höland, W.; Schweiger, M.; Rheinberger, V.M.; Kappert, H. Bioceramics and their application for dental restoration. Adv. Appl. Ceram. 2009, 108, 373–380. [Google Scholar] [CrossRef]

- Ritzberger, C.; Schweiger, M.; Höland, W. Principles of crystal phase formation in Ivoclar Vivadent glass-ceramics for dental restorations. J. Non Cryst. Solids 2016, 432, 137–142. [Google Scholar] [CrossRef]

- Kang, S.H.; Chang, J.; Son, H.H. Flexural strength and microstructure of two lithium disilicate glass ceramics for CAD/CAM restoration in the dental clinic. Restor. Dent. Endod. 2013, 38, 134–140. [Google Scholar] [CrossRef]

- Wendler, M.; Belli, R.; Petschelt, A.; Mevec, D.; Harrer, W.; Lube, T.; Danzer, R.; Lohbauer, U. Chairside CAD/CAM materials. Part 2: Flexural strength testing. Dent. Mater. 2017, 33, 99–109. [Google Scholar] [CrossRef]

- Rinke, S.; Pabel, A.-K.; diger, M.; Ziebolz, D. Chairside Fabrication of an all-ceramic partial crown using a zirconia-reinforced lithium silicate ceramic. Case Rep. Dent. 2016, 2016, 1354186. [Google Scholar] [CrossRef] [PubMed]

- Belli, R.; Wendler, M.; de Ligny, D.; Cicconi, M.R.; Petschelt, A.; Peterlik, H.; Lohbauer, U. Chairside CAD/CAM materials. Part 1: Measurement of elastic constants and microstructural characterization. Dent. Mater. 2017, 33, 84–98. [Google Scholar] [CrossRef]

- Traini, T.; Sinjari, B.; Pascetta, R. The zirconia-reinforced lithium silicate ceramic: Lights and shadows of a new material. Dent. Mater. J. 2016, 35, 748–755. [Google Scholar] [CrossRef] [PubMed]

- Kurt, M.; Güngör, M.B.; Nemli, S.K.; Bal, B.T. Effects of glazing methods on the optical and surface properties of silicate ceramics. J. Prosthodont. Res. 2019. [Google Scholar] [CrossRef] [PubMed]

- Sen, N.; Us, Y.O. Mechanical and optical properties of monolithic CAD-CAM restorative materials. J. Prosthet. Dent. 2018, 119, 593–599. [Google Scholar] [CrossRef]

- Della Bona, A.; Nogueira, A.D.; Pecho, O.E. Optical properties of CAD-CAM ceramic systems. J. Dent. 2014, 42, 1202–1209. [Google Scholar] [CrossRef]

- Akar, G.C.; Pekkan, G.; Çal, E.; Eskitaşçıoglu, G.; Özcan, M. Effects of surface-finishing protocols on the roughness, color change, and translucency of different ceramic systems. J. Prosthet. Dent. 2014, 112, 314–321. [Google Scholar] [CrossRef]

- Kilinc, H.; Turgut, S. Optical behaviors of esthetic cad-cam restorations after different surface finishing and polishing procedures and uv aging: An in vitro study. J. Prosthet. Dent. 2018, 120, 107–113. [Google Scholar] [CrossRef]

- Vichi, A.; Carrabba, M.; Paravina, R.; Ferrari, M. Translucency of ceramic materials for CEREC CAD/CAM system. J. Esthet. Restor. Dent. 2014, 26, 224–231. [Google Scholar] [CrossRef]

- Paravina, R.D.; Ontiveros, J.C.; Powers, J.M. Curing-dependent changes in color and translucency parameter of composite bleach shades. J. Esthet. Restor. Dent. 2002, 14, 158–166. [Google Scholar] [CrossRef]

- Lee, Y.K.; Lu, H.; Powers, J.M. Measurement of opalescence of resin composites. Dent. Mater. 2005, 21, 1068–1074. [Google Scholar] [CrossRef] [PubMed]

- Cho, M.S.; Yu, B.; Lee, Y.K. Opalescence of all-ceramic core and veneer materials. Dent. Mater. 2009, 25, 695–702. [Google Scholar] [CrossRef] [PubMed]

- Hampe, R.; Lümkemann, N.; Sener, B.; Stawarczyk, B. The effect of artificial aging on Martens hardness and indentation modulus of different dental CAD/CAM restorative materials. J. Mech. Behav. Biomed. Mater. 2018, 86, 191–198. [Google Scholar] [CrossRef]

- Kelly, J.R.; Cesar, P.F.; Scherrer, S.S.; Della Bona, A.; van Noort, R.; Tholey, M.; Vichi, A.; Lohbauer, U. ADM guidance-ceramics: Fatigue principles and testing. Dent. Mater. 2017, 33, 1192–1204. [Google Scholar] [CrossRef] [PubMed]

- Gerogianni, P.; Lien, W.; Bompolaki, D.; Verrett, R.; Haney, S.; Mattie, P.; Johnson, R. Fracture Resistance of Pressed and Milled Lithium Disilicate Anterior Complete Coverage Restorations Following Endodontic Access Preparation. J. Prosthodont. 2019, 28, 163–170. [Google Scholar] [CrossRef]

- Swain, M.V. Impact of oral fluids on dental ceramics: What is the clinical relevance? Dent. Mater. 2014, 30, 33–42. [Google Scholar] [CrossRef]

- Du, J.; Niu, X.; Soboyejo, W. Creep-assisted slow crack growth in bio-inspired dental multilayers. J. Mech. Behav. Biomed. Mater. 2015, 46, 41–48. [Google Scholar] [CrossRef]

- Dal Piva, A.M.O.; Tribst, J.P.M.; Borges, A.L.S.; Souza, R.O.A.E.; Bottino, M.A. CAD-FEA modeling and analysis of different full crown monolithic restorations. Dent. Mater. 2018, 34, 1342–1350. [Google Scholar] [CrossRef]

- Archangelo, K.C.; Guilardi, L.F.; Campanelli, D.; Valandro, L.F.; Borges, A.L.S. Fatigue failure load and finite element analysis of multilayer ceramic restorations. Dent. Mater. 2019, 35, 64–73. [Google Scholar] [CrossRef]

- Pereira, G.K.R.; Venturini, A.B.; Silvestri, T.; Dapieve, K.S.; Montagner, A.F.; Soares, F.Z.M.; Valandro, L.F. Low-temperature degradation of Y-TZP ceramics: A systematic review and meta-analysis. J. Mech. Behav. Biomed. Mater. 2015, 55, 151–163. [Google Scholar] [CrossRef]

- Pereira, G.K.; Silvestri, T.; Camargo, R.; Rippe, M.P.; Amaral, M.; Kleverlaan, C.J.; Valandro, L.F. Mechanical behavior of a Y-TZP ceramic for monolithic restorations: Effect of grinding and low-temperature aging. Mater. Sci. Eng. C Mater. Biol. Appl. 2016, 63, 70–77. [Google Scholar] [CrossRef] [PubMed]

- Lai, X.; Si, W.; Jiang, D.; Sun, T.; Shao, L.; Deng, B. Effects of small-grit grinding and glazing on mechanical behaviors and ageing resistance of a super-translucent dental zirconia. J. Dent. 2017, 66, 23–31. [Google Scholar] [CrossRef]

- Li, D.; Guo, J.W.; Wang, X.S. Effects of crystal size on the mechanical properties of a lithium disilicate glass-ceramic. Mater. Sci. Eng. 2016, 669, 332–339. [Google Scholar] [CrossRef]

- Hallmann, L.; Ulmer, P.; Lehmann, F.; Wille, S.; Polonskyi, O.; Johannes, M.; Köbel, S.; Trottenberg, T.; Bornholdt, S.; Haase, F.; et al. Effect of surface modifications on the bond strength of zirconia ceramic with resin cement. Dent. Mater. 2016, 16, 631–639. [Google Scholar] [CrossRef] [PubMed]

- Paravina, R.; Powers, J. Esthetic Color Training in Dentistry; Elsevier Mosby: St. Louis, MO, USA, 2004; pp. 51–78. [Google Scholar]

- Kim, J.B.; Paravina, R.; Chen, J.W. In Vivo evaluation of color ofprimary teeth. Peadr. Dent. 2007, 29, 383–386. [Google Scholar]

- Harianawala, H.H.; Kheur, M.G.; Aple, S.K.; Kale, B.B.; Sethi, T.S.; Kheur, S.M. Comparative analysis of transmittance for different types of commercially available zirconia and lithium disilicate materials. J. Adv. Prosthodont. 2014, 6, 456–461. [Google Scholar] [CrossRef]

- Elsaka, S.E.; Elnaghy, A.M. Mechanical properties of zirconia reinforced lithium silicate glass-ceramic. Dent. Mater. 2016, 32, 908–914. [Google Scholar] [CrossRef]

- Awad, D.; Stawarczyk, B.; Liebermann, A.; Ilie, N. Translucency of esthetic dental restorative CAD/CAM materials and composite resins with respect to thickness and surface roughness. J. Prosthet. Dent. 2015, 113, 534–540. [Google Scholar] [CrossRef]

- Wang, F.; Yu, T.; Chen, J. Biaxial flexural strength and translucent characteristics of dental lithium disilicate glass ceramics with different translucencies. J. Prosthodont. Res. 2019. [Google Scholar] [CrossRef]

- Wang, F.; Takahashi, H.; Iwasaki, N. Translucency of dental ceramics with different thicknesses. J. Prosthet. Dent. 2013, 110, 14–20. [Google Scholar] [CrossRef]

- Yu, B.; Ahn, J.S.; Lee, Y.K. Measurement of translucency of tooth enamel and dentin. Acta Odontol. Scand. 2009, 67, 57–64. [Google Scholar] [CrossRef] [PubMed]

- Vasiliu, R.-D.; Porojan, S.D.; Bîrdeanu, M.I.; Porojan, L. Effect of Thermocycling, Surface Treatments and Microstructure on the Optical Properties and Roughness of CAD-CAM and Heat-Pressed Glass Ceramics. Materials 2020, 13, 381. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.K.; Kim, S.H.; Lee, J.B.; Ha, S.R. Effects of surface treatments on the translucency, opalescence, and surface texture of dental monolithic zirconia ceramics. J. Prosthet. Dent. 2016, 115, 773–779. [Google Scholar] [CrossRef]

- Vasiliu, R.-D.; Porojan, S.-D.; Bîrdeanu, M.-I.; Uțu, I.-D.; Porojan, L. The Effect of Thermocycling and Surface Treatments on the Surface Roughness and Microhardness of Three Heat-Pressed Ceramics Systems. Crystals 2020, 10, 160. [Google Scholar] [CrossRef]

- Vasiliu, R.-D.; Porojan, S.; Porojan, L. The Influence of Oral Environment on the Optical Properties of Heat- pressed Ceramics. Mater. Plast. 2019, 56, 271–276. [Google Scholar] [CrossRef]

- Bollen, C.M.; Lambrechts, P.; Quirynen, M. Comparison of surface roughness of oral hard materials to the threshold surface roughness for bacterial plaque retention: A review of the literature. Dent. Mater. J. 1997, 13, 258–269. [Google Scholar] [CrossRef]

- Incesu, E.; Yanikoglu, N. Evaluation of the effect of different polishing systems on the surface roughness of dental ceramics. J. Prosthet. Dent. 2020, 124, 100–109. [Google Scholar] [CrossRef]

- Sarac, D.; Sarac, Y.S.; Yuzbasioglu, E.; Bal, S. The effects of porcelain polishing systems on the color and surface texture of feldspathic porcelain. J. Prosthet. Dent. 2006, 96, 122–128. [Google Scholar] [CrossRef]

- Demirel, F.; Yuksel, G.; Muhtarogullari, M.; Cekic, C. Effect of topical fluorides and citric acid on heat-pressed all-ceramic material. Int. J. Periodontics Restor. Dent. 2005, 25, 277–281. [Google Scholar]

- Sasahara, R.M.; Ribeiro Fda, C.; Cesar, P.F.; Yoshimura, H.N. Influence of the finishing technique on surface roughness of dental porcelains with different microstructures. Oper. Dent. 2006, 31, 577–583. [Google Scholar] [CrossRef]

- Hallmann, L.; Ulmer, P.; Gerngross, M.D.; Jetter, J.; Mintrone, M.; Lehmann, F.; Kern, M. Properties of hot-pressed lithium silicate glass-ceramics. Dent. Mater. 2019, 35, 713–729. [Google Scholar] [CrossRef] [PubMed]

- Mota, E.G.; Smidt, L.N.; Fracasso, L.M.; Burnett, L.H.; Spohr, A.M. The effect of milling and post milling procedures on the surface roughness of CAD/CAM materials. J. Esthet. Restor. Dent. 2017, 29, 450–458. [Google Scholar] [CrossRef] [PubMed]

- Vichi, A.; Fonzar, R.F.; Goracci, C.; Carrabba, M.; Ferrari, M. Effect of finishing and polishing on roughness and gloss of lithium disilicate and lithium silicate zirconia reinforced glass-ceramic for CAD/CAM systems. Oper. Dent. 2018, 43, 90–100. [Google Scholar] [CrossRef] [PubMed]

- Karpukhina, N.; Hilla, R.G. Crystallisation in oxide glasses – a tutorial review. Chem. Soc. Rev. 2014, 43, 2174–2186. [Google Scholar] [CrossRef] [PubMed]

- Riquieri, H.; Monteiro, J.B. Impact of crystallization firing process on the microstructure and flexural strength of zirconia-reinforced lithium silicate glass-ceramics. Dent. Mater. 2018, 34, 1483–1491. [Google Scholar] [CrossRef] [PubMed]

Sample Availability: Samples of the compounds are not available from the authors. |

| Type of Tested Samples | p-Value |

|---|---|

| dry-wet | 0.1157 |

| ZLS-LDS | 0.7228 |

| G-P | <0.0001 |

| P-M | 0.1376 |

| dry tc-wet tc | 0.0005 |

| ZLS tc-LDS tc | 0.2344 |

| G tc-P tc | 0.0018 |

| P tc-M tc | 0.0593 |

| all-all tc | <0.0001 |

| Tye of Tested Samples | p-Value |

|---|---|

| dry-wet | 0.0102 |

| ZLS-LDS | 0.0117 |

| G-P | 0.0228 |

| P-M | 0.0030 |

| dry tc-wet tc | 0.0035 |

| ZLS tc-LDS tc | 0.0065 |

| G tc-P tc | 0.4460 |

| P tc-M tc | 0.2511 |

| all-all tc | <0.0001 |

| Restoration Material | Manufacturer | Class of Ceramic | Processing | Composition | Translucency/Shade |

|---|---|---|---|---|---|

| IPS e.max CAD | Ivoclar Vivadent, Schaan, Liechtenstein | lithium disilicate glass-ceramic (LDS) | CAD/CAM milled | 70 vol% of the crystalline phase (average particle size 0.2–1.0 µm) incorporated in a glassy matrix | MT/A2 |

| IPS e.max Press | Ivoclar Vivadent, Schaan, Liechtenstein | lithium disilicate glass-ceramic (LDS) | hot-pressed | lithium disilicate crystals (approx. 70%), Li2Si2O5 crystals (3–6 µm length) | MT/A2 |

| HT/A2 | |||||

| Vita Suprinity | Vita Zahnfabrik, Bad Säckingen, Germany | zirconia-reinforced lithium silicate ceramic (ZLS) | CAD/CAM milled | silica (55–65 wt.%), lithia (15–21 wt.%), zirconia (8–12 wt.%) particle size 0.5–0.7 µm | MT/A2 |

| Celtra Press | Degudent, Hanau, Germany | zirconia-reinforced lithium silicate ceramic (ZLS) | hot-pressed | a glass matrix and lithium disilicate crystals 1.5 µm plus nanoscale lithium phosphate, 10% zirconia (ZrO2) | MT/A2 |

| HT/A2 |

| Pressing Parameters for Hot-Pressed Ceramics | Starting Temperature | Hold Time | Vacuum Level | Press Time | Heat Rate | Press Temperature | Press Pressure |

|---|---|---|---|---|---|---|---|

| IPS e.max Press | 700 °C | 29 min | 47 hPa | 1 min | 60 °C/min | 915 °C | 3 bar |

| Celtra Press | 700 °C | 30 min | 45 hPa | 3 min | 40 °C/min | 860 °C | 3 bar |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Porojan, L.; Vasiliu, R.-D.; Bîrdeanu, M.-I.; Porojan, S.-D. Surface Characterization and Optical Properties of Reinforced Dental Glass-Ceramics Related to Artificial Aging. Molecules 2020, 25, 3407. https://doi.org/10.3390/molecules25153407

Porojan L, Vasiliu R-D, Bîrdeanu M-I, Porojan S-D. Surface Characterization and Optical Properties of Reinforced Dental Glass-Ceramics Related to Artificial Aging. Molecules. 2020; 25(15):3407. https://doi.org/10.3390/molecules25153407

Chicago/Turabian StylePorojan, Liliana, Roxana-Diana Vasiliu, Mihaela-Ionela Bîrdeanu, and Sorin-Daniel Porojan. 2020. "Surface Characterization and Optical Properties of Reinforced Dental Glass-Ceramics Related to Artificial Aging" Molecules 25, no. 15: 3407. https://doi.org/10.3390/molecules25153407

APA StylePorojan, L., Vasiliu, R.-D., Bîrdeanu, M.-I., & Porojan, S.-D. (2020). Surface Characterization and Optical Properties of Reinforced Dental Glass-Ceramics Related to Artificial Aging. Molecules, 25(15), 3407. https://doi.org/10.3390/molecules25153407