A Comparative Study on Cu2+, Zn2+, Ni2+, Fe3+, and Cr3+ Metal Ions Removal from Industrial Wastewaters by Chitosan-Based Composite Cryogels

Abstract

1. Introduction

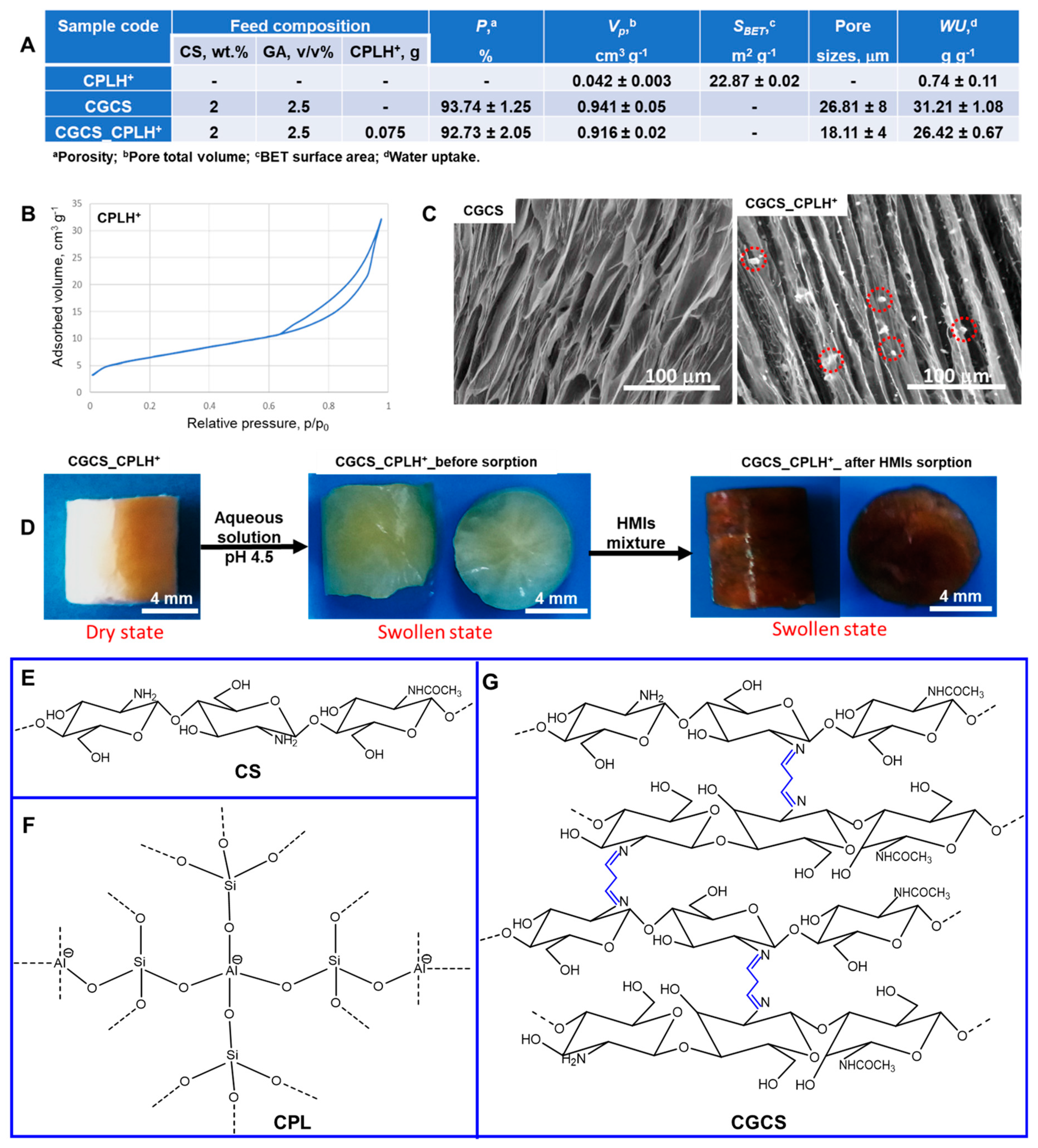

2. Results and Discussion

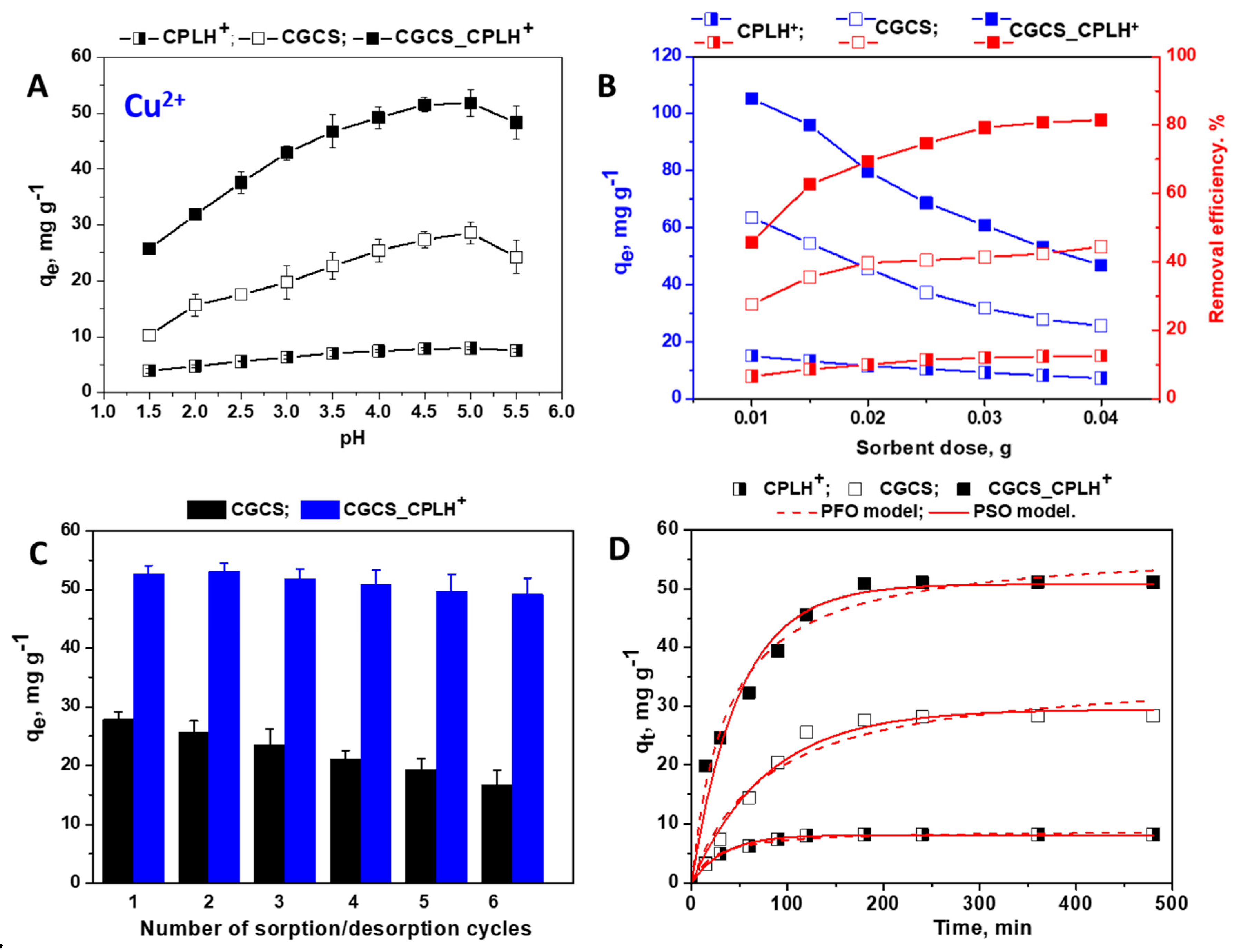

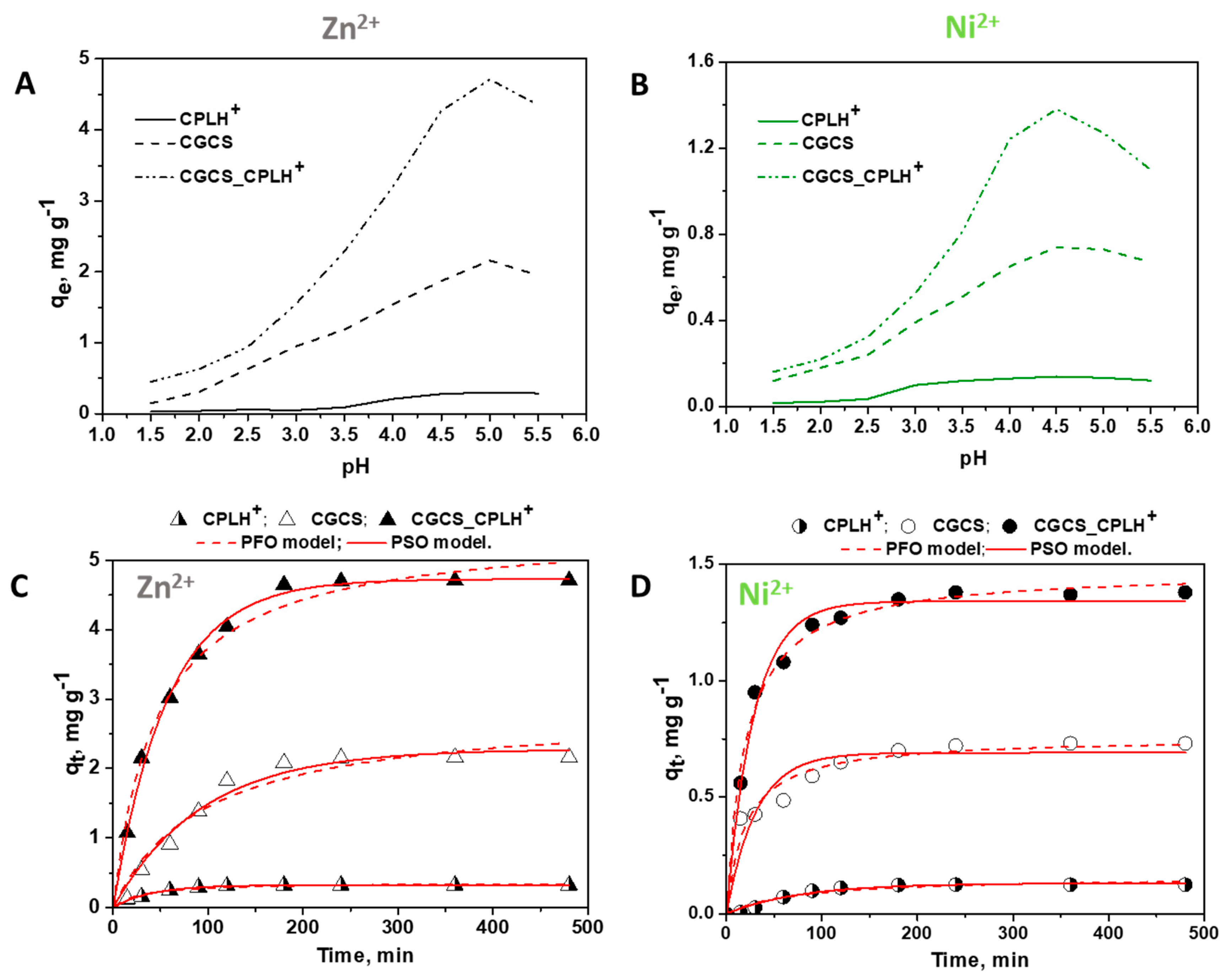

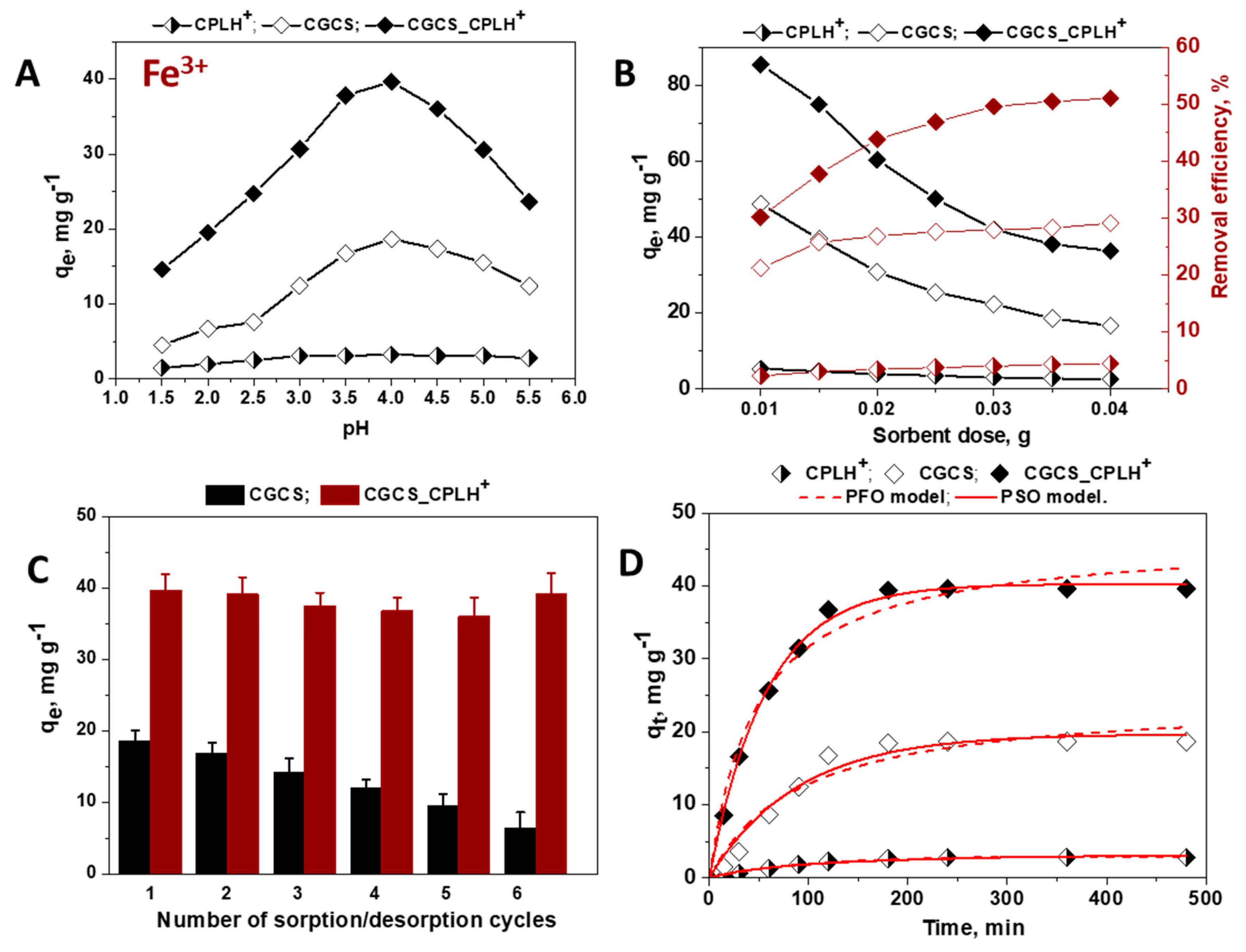

2.1. Sorption Properties of Cryogel-Based Sorbents in Bach Mode

2.1.1. Removal of Divalent Cations (Cu2+, Zn2+, and Ni2+) under Competitive Conditions

2.1.2. Removal of Trivalent Cations (Fe3+ and Cr3+) under Competitive Conditions

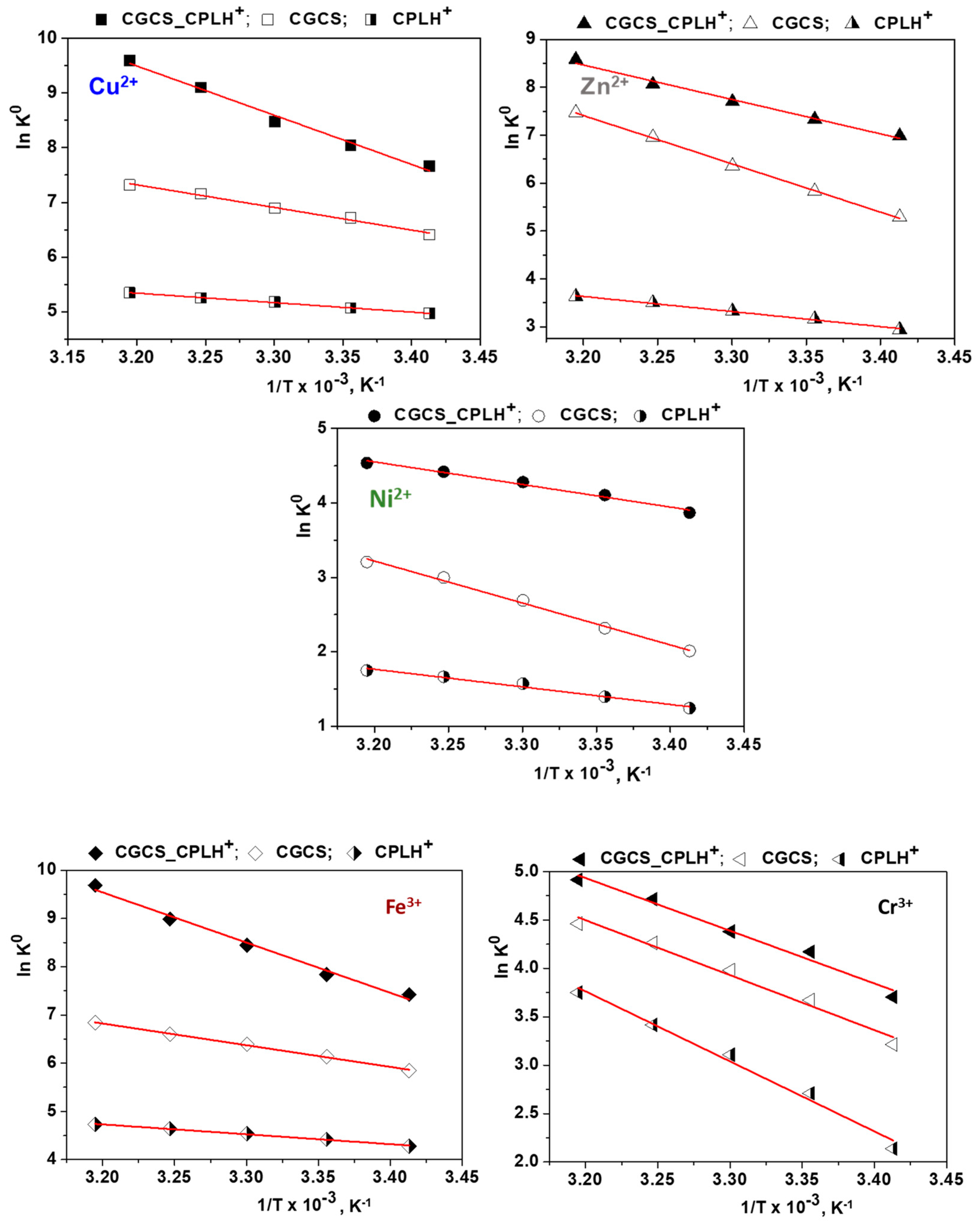

2.1.3. Thermodynamic Studies

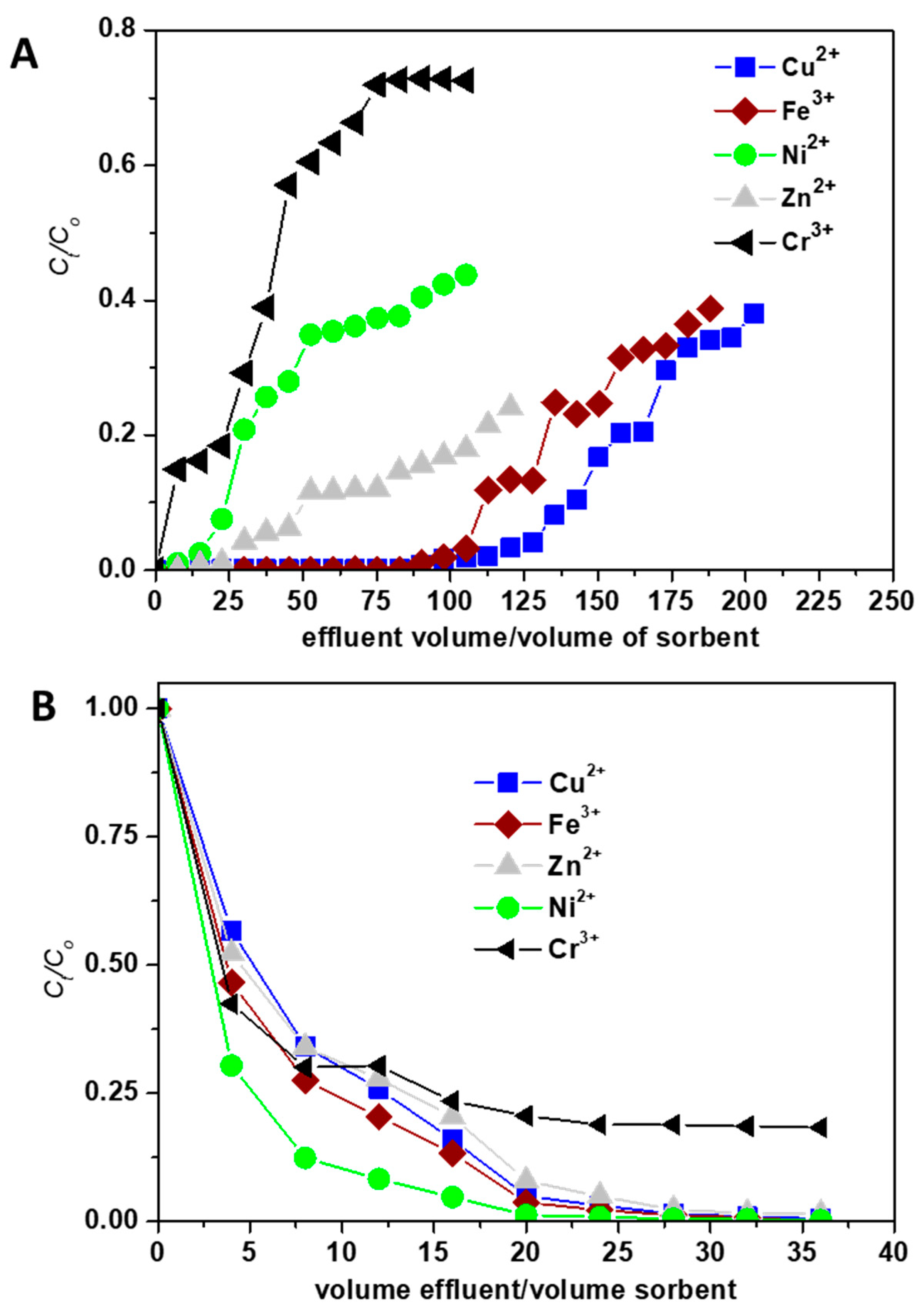

2.2. Sorption Properties of Cryogel-Based Sorbents in Dynamic Mode

3. Materials and Methods

3.1. Materials

3.2. Methods

3.3. Batch Sorption Studies

3.4. Dynamic Sorption Studies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Carolin, C.F.; Kumar, P.S.; Saravanan, A.; Joshib, G.J.; Naushad, M. Efficient techniques for the removal of toxic heavy metals from aquatic environment: A review. J. Environ. Chem. Eng. 2017, 5, 2782–2799. [Google Scholar] [CrossRef]

- Giwa, A.; Dindi, A.; Kujawa, J. Membrane bioreactors and electrochemical processes for treatment of wastewaters containing heavy metal ions, organics, micropollutants and dyes: Recent developments. J. Hazard. Mater. 2019, 370, 172–195. [Google Scholar] [CrossRef] [PubMed]

- Tounsadi, H.; Khalidi, A.; Machrouhi, A.; Farnane, M.; Elmoubarki, R.; Elhalil, A.; Sadiq, M.; Barka, N. Highly efficient activated carbon from Glebionis coronaria L. biomass: Optimization of preparation conditions and heavy metals removal using experimental design approach. J. Environ. Chem. Eng. 2016, 4, 4549–4564. [Google Scholar] [CrossRef]

- Bassyouni, M.; Mansi, A.E.; Elgabry, A.; Ibrahim, B.A.; Kassem, O.A.; Alhebeshy, R. Utilization of carbon nanotubes in removal of heavy metals from wastewater: A review of the CNTs’ potential and current challenges. Appl. Phys. A Mater. 2020, 126, 38. [Google Scholar] [CrossRef]

- Dragan, E.S.; Humelnicu, D.; Dinu, M.V. Design of porous strong base anion exchangers bearing N,N-dialkyl 2–hydroxyethyl ammonium groups with enhanced retention of Cr(VI) ions from aqueous solution. React. Funct. Polym. 2018, 124, 55–63. [Google Scholar] [CrossRef]

- Mihaly–Cozmuta, L.; Mihaly–Cozmuta, A.; Peter, A.; Nicula, C.; Tutu, H.; Silipas, D.; Indrea, E. Adsorption of heavy metal cations by Na-clinoptilolite: Equilibrium and selectivity studies. J. Environ. Manag. 2014, 137, 69–80. [Google Scholar] [CrossRef] [PubMed]

- Irannajad, M.; Haghighi, H.K. Removal of Co2+, Ni2+, and Pb2+ by manganese oxide-coated zeolite: Equilibrium, thermodynamics, and kinetics studies. Clays Clay Miner. 2017, 65, 52–62. [Google Scholar] [CrossRef]

- Rajic, N.; Stojakovic, D.; Jovanovic, M.; Zabukovec Logar, N.; Mazaj, M.; Kaucic, V. Removal of nickel (II) ions from aqueous solutions using the natural clinoptilolite and preparation of nano-NiO on the exhausted clinoptilolite. Appl. Surf. Sci. 2010, 257, 1524–1532. [Google Scholar] [CrossRef]

- Sprynskyy, M.; Buszewski, B.; Terzyk, A.P.; Namiesnik, J. Study of the selection mechanism of heavy metal (Pb2+, Cu2+, Ni2+, and Cd2+) adsorption on clinoptilolite. J. Colloid Interf. Sci. 2006, 304, 21–28. [Google Scholar] [CrossRef]

- Guibal, E.; Vincent, T.; Navarro, R. Metal ion biosorption on chitosan for the synthesis of advanced materials. J. Mater. Sci. 2014, 49, 5505–5518. [Google Scholar] [CrossRef]

- Zhang, L.; Zeng, Y.; Cheng, Z. Removal of heavy metal ions using chitosan and modified chitosan: A review. J. Mol. Liq. 2016, 214, 175–191. [Google Scholar] [CrossRef]

- Pietrelli, L.; Francolini, I.; Piozzi, A.; Sighicelli, M.; Silvestro, I.; Vocciante, M. Chromium (III) removal from wastewater by chitosan flakes. Appl. Sci. 2020, 10, 1925. [Google Scholar] [CrossRef]

- Qi, X.; Liu, R.; Chen, M.; Li, Z.; Qin, T.; Qian, Y.; Zhao, S.; Liu, M.; Zeng, Q.; Shen, J. Removal of copper ions from water using polysaccharide-constructed hydrogels. Carbohydr. Polym. 2019, 209, 101–110. [Google Scholar] [CrossRef] [PubMed]

- Zeng, Q.; Qi, X.; Zhang, M.; Tong, X.; Jiang, N.; Pan, W.; Xiong, W.; Li, Y.; Xu, J.; Shen, J.; et al. Efficient decontamination of heavy metals from aqueous solution using pullulan/polydopamine hydrogels. Int. J. Biol. Macromol. 2020, 145, 1049–1058. [Google Scholar] [CrossRef]

- Torres–Caban, R.; Vega–Olivencia, C.A.; Mina–Camilde, N. Adsorption of Ni2+ and Cd2+ from water by calcium alginate/spent coffee grounds composite beads. Appl. Sci. 2019, 9, 4531. [Google Scholar] [CrossRef]

- Jakóbik–Kolon, A.; Mitko, K.; Bok-Badura, J. Zinc sorption studies on pectin-based biosorbents. Materials 2017, 10, 844. [Google Scholar] [CrossRef]

- Elsayed, N.; Alatawi, A.; Monier, M. Diacetylmonoxine modified chitosan derived ion-imprinted polymer for selective solid-phase extraction of nickel (II) ions. React. Funct. Polym. 2020, 151, 104570. [Google Scholar] [CrossRef]

- Chen, S.; Li, C.; Hou, T.; Cai, Y.; Liang, L.; Chen, L.; Li, M. Polyhexamethyleneguanidine functionalized chitosan nanofiber membrane with superior adsorption and antibacterial performances. React. Funct. Polym. 2019, 145, 104379. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, S.; Qiao, J.; Kołodyńska, D.; Ju, Y.; Zhang, M.; Cai, M.; Deng, D.; Dionysiou, D.D. Malic acid-enhanced chitosan hydrogel beads (mCHBs) for the removal of Cr(VI) and Cu(II) from aqueous solution. Chem. Eng. J. 2018, 353, 225–236. [Google Scholar] [CrossRef]

- Abdelwahab, H.E.; Hassan, S.Y.; Mostafa, M.A.; El Sadek, M.M. Synthesis and characterization of glutamic-chitosan hydrogel for copper and nickel removal from wastewater. Molecules 2016, 21, 684. [Google Scholar] [CrossRef]

- Yang, Z.; Chai, Y.; Zeng, L.; Gao, Z.; Zhang, J.; Ji, H. Efficient removal of copper ion from wastewater using a stable chitosan gel material. Molecules 2019, 24, 4205. [Google Scholar] [CrossRef] [PubMed]

- Dragan, E.S.; Dinu, M.V. Advances in porous chitosan-based composite hydrogels: Synthesis and applications. React. Funct. Polym. 2020, 146, 104372. [Google Scholar] [CrossRef]

- Dragan, E.S.; Apopei Loghin, D.F. Fabrication and characterization of composite cryobeads based on chitosan and starches-g-PAN as efficient and reusable biosorbents for removal of Cu2+, Ni2+, and Co2+ ions. Int. J. Biol. Macromol. 2018, 120, 1883–1972. [Google Scholar] [CrossRef] [PubMed]

- Trikkaliotis, D.G.; Christoforidis, A.K.; Mitropoulos, A.C.; Kyzas, G.Z. Adsorption of copper ions onto chitosan/poly(vinyl alcohol) beads functionalized with poly(ethylene glycol). Carbohydr. Polym. 2020, 234, 115890. [Google Scholar] [CrossRef]

- Contreras-Cortés, A.G.; Almendariz-Tapia, F.J.; Gómez-Álvarez, A.; Burgos-Hernández, A.; Luque-Alcaraz, A.G.; Rodríguez-Félix, F.; Quevedo-López, M.Á.; Plascencia-Jatomea, M. Toxicological assessment of cross-linked beads of chitosan-alginate and Aspergillus australensis biomass, with efficiency as biosorbent for copper removal. Polymers 2019, 11, 222–238. [Google Scholar]

- Dinu, M.V.; Dinu, I.A.; Lazar, M.M.; Dragan, E.S. Chitosan-based ion-imprinted cryo-composites with excellent selectivity for copper ions. Carbohydr. Polym. 2018, 186, 140–149. [Google Scholar] [CrossRef]

- Monier, M.; Bukhari, A.A.H.; Elsayed, N.H. Designing and characterization of copper (II) ion-imprinted adsorbent based on isatin functionalized chitosan. Int. J. Biol. Macromol. 2020, 155, 795–804. [Google Scholar] [CrossRef]

- Rafiee, F.; Karder, R. Synthesis and characterization of magnetic glycocyamine-modified chitosan as a biosupport for the copper immobilization and its catalytic activity investigation. React. Funct. Polym. 2020, 146, 104434. [Google Scholar] [CrossRef]

- Hamza, M.F.; Aly, M.M.; Abdel-Rahman, A.A.H.; Ramadan, S.; Raslan, H.; Wang, S.; Vincent, T.; Guibal, E. Functionalization of magnetic chitosan particles for the sorption of U(VI), Cu(II) and Zn(II)—Hydrazide derivative of glycine-grafted chitosan. Materials 2017, 10, 539. [Google Scholar] [CrossRef]

- Dragan, E.S.; Dinu, M.V.; Timpu, D. Preparation and characterization of novel composites based on chitosan and clinoptilolite with enhanced adsorption properties for Cu2+. Bioresour. Technol. 2010, 101, 812–817. [Google Scholar] [CrossRef]

- Djelad, A.; Morsli, A.; Robitzer, M.; Bengueddach, A.; di Renzo, F.; Quignard, F. Sorption of Cu(II) ions on chitosan-zeolite X composites: Impact of gelling and drying conditions. Molecules 2016, 21, 109. [Google Scholar] [CrossRef] [PubMed]

- Bandura, L.; Franus, M.; Madej, J.; Kołodynska, D.; Hubicki, Z. Zeolites in phenol removal in the presence of Cu(II) ions—Comparison of sorption properties after chitosan modification. Materials 2020, 13, 643. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Tian, X.; Wang, Z.; Guan, Z.; Li, X.; Qiao, H.; Ke, H.; Luo, L.; Wei, Q. Multifunctional adsorbent based on metal-organic framework modified bacterial cellulose/chitosan composite aerogel for high efficient removal of heavy metal ion and organic pollutant. Chem. Eng. J. 2020, 383, 123127. [Google Scholar] [CrossRef]

- ALOthmanA, Z.A. Review: Fundamental aspects of silicate mesoporous materials. Materials 2012, 5, 2874–2902. [Google Scholar] [CrossRef]

- Humelnicu, D.; Lazar, M.M.; Ignat, M.; Dinu, I.A.; Dragan, E.S.; Dinu, M.V. Removal of heavy metal ions from multi-component aqueous solutions by eco-friendly and low-cost composite sorbents with anisotropic pores. J. Hazard. Mater. 2020, 381, 120980. [Google Scholar] [CrossRef]

- Dinu, M.V.; Dinu, I.A.; Lazar, M.M.; Dragan, E.S. Insights into the mechanism of Cu2+ binding onto chitosan-based cryogel composites: Equilibrium, kinetics and thermodynamics studies. Cellulose Chem. Technol. 2018, 52, 181–192. [Google Scholar]

- Fan, L.; Luo, C.; Lv, Z.; Lu, F.; Qiu, H. Preparation of magnetic modified chitosan and adsorption of Zn2+ from aqueous solutions. Colloid Surf. B 2011, 88, 574–581. [Google Scholar] [CrossRef]

- Cocarta, A.I.; Gutanu, V.; Dragan, E.S. Comparative sorption of Co2+, Ni2+ and Cr3+ onto chitosan/poly(vinyl amine) composite beads. Cellulose Chem. Technol. 2015, 49, 775–782. [Google Scholar]

- Jamnongkan, T.; Singcharoen, K. Towards novel adsorbents: The ratio of PVA/chitosan blended hydrogels on the copper (II) ion adsorption. Energy Procedia 2016, 89, 299–306. [Google Scholar] [CrossRef]

- Yu, R.; Shi, Y.; Yang, D.; Liu, Y.; Qu, J.; Yu, Z.Z. Graphene oxide/chitosan aerogel microspheres with honeycomb-cobweb and radially oriented microchannel structures for broad-spectrum and rapid adsorption of water contaminants. ACS Appl. Mater. Inter. 2017, 9, 21809–21819. [Google Scholar] [CrossRef]

- Zarghami, S.; Mohammadi, T.; Kazemimoghadam, M. Adsorption behavior of Cu(II) ions on crosslinked chitosan/polyvinyl alcohol ion imprinted membrane. J. Disper. Sci. Technol. 2015, 36, 190–195. [Google Scholar] [CrossRef]

- Wan Ngah, W.S.; Ab Ghani, S.; Kamari, A. Adsorption behaviour of Fe(II) and Fe(III) ions in aqueous solution on chitosan and cross-linked chitosan beads. Bioresour. Technol. 2005, 96, 443–450. [Google Scholar] [CrossRef] [PubMed]

- Tran, H.N.; Jou, S.J.; Bandegharaei, A.H.; Chao, H.P. Mistakes and inconsistencies regarding adsorption of contaminants from aqueous solutions: A critical review. Water Res. 2017, 120, 88–116. [Google Scholar] [CrossRef] [PubMed]

- Lujaniene, G.; Semcuk, S.; Lecinskyte, A.; Kulakauskaite, I.; Mazeika, K.; Valiulis, D.; Pakstas, V.; Skapas, M.; Tumenas, S. Magnetic graphene oxide based nano-composites for removal of radionuclides and metals from contaminated solutions. J. Environ. Radioact. 2017, 166, 166–174. [Google Scholar] [CrossRef] [PubMed]

- Pomazkina, O.I.; Filatova, E.G.; Pozhidaev, Y.N. Adsorption of Ni(II), Cu(II), and Zn(II) ions by natural alumosilicate modified with N,N′-bis(3-triethoxysilylpropyl)thiocarbamide. Prot. Met. Phys. Chem. Surf. 2017, 53, 416–421. [Google Scholar] [CrossRef]

- Zhou, X.; Zhou, X. The unit problem in the thermodynamic calculation of adsorption using the Langmuir equation. Chem. Eng. Comm. 2014, 201, 1459–1467. [Google Scholar] [CrossRef]

- Li, L.; Wang, Z.; Ma, P.; Bai, H.; Dong, W.; Chen, M. Preparation of polyvinyl alcohol/chitosan hydrogel compounded with graphene oxide to enhance the adsorption properties for Cu(II) in aqueous solution. J. Polym. Res. 2015, 22, 150. [Google Scholar] [CrossRef]

- Vatanpour, V.; Salehi, E.; Sahebjamee, N.; Ashrafi, M. Novel chitosan/polyvinyl alcohol thin membrane adsorbents modified with detonation nanodiamonds: Preparation, characterization, and adsorption performance. Arab. J. Chem. 2020, 13, 1731–1740. [Google Scholar] [CrossRef]

- Lazar, M.M.; Dinu, I.A.; Silion, M.; Dragan, E.S.; Dinu, M.V. Could the porous chitosan based composite materials have a chance to a “NEW LIFE” after Cu(II) ion binding. Int. J. Biol. Macromol. 2019, 131, 134–146. [Google Scholar] [CrossRef]

- Kaczmarek, B.; Sionkowska, A.; Osyczka, A.M. The comparison of physic-chemical properties of chitosan/collagen/hyaluronic acid composites with nano-hydroxyapatite cross-linked by dialdehyde starch and tannic acid. Polym. Test. 2017, 62, 171–176. [Google Scholar] [CrossRef]

- Dinu, M.V.; Přádný, M.; Dragan, E.S.; Michálek, J. Morphogical and swelling properties of porous hydrogels based on poly(hydroxyethyl methacrylate) and chitosan modulated by ice-templating process and porogen leaching. J. Polym. Res. 2013, 20, 285. [Google Scholar] [CrossRef]

- Dinu, M.V.; Lazar, M.M.; Dragan, E.S. Dual ionic cross-linked alginate/clinoptilolite composite microbeads with improved stability and enhanced sorption properties for methylene blue. React. Funct. Polym. 2017, 116, 31–40. [Google Scholar] [CrossRef]

Sample Availability: The CPLH+, CGCS, and CGCS_CPLH+ sorbents are available from the authors. |

| Kinetic Modelsa | ; k1—Rate Constant of the PFO Kinetic Model, min−1 | ; k2—Rate Constant of the PSO Kinetic Model, g mg–1 × min–1 | ||||||

|---|---|---|---|---|---|---|---|---|

| Sorbents | Sorbents | |||||||

| Metal Ions | CPLH+ | CGCS | CGCS_ CPLH+ | CPLH+ | CGCS | CGCS_ CPLH+ | ||

| Cu2+ | qe,calc | 8.97 | 35.80 | 57.15 | qe,calc | 8.14 | 29.42 | 50.77 |

| k1 | 0.03 | 0.01 | 0.02 | k2 | 0.005 | 0.0004 | 0.0005 | |

| R2 | 0.99 | 0.96 | 0.97 | R2 | 0.99 | 0.98 | 0.98 | |

| χ2 | 0.08 | 5.79 | 8.71 | χ2 | 0.08 | 2.36 | 5.49 | |

| Zn2+ | qe,calc | 0.36 | 2.84 | 5.46 | qe,calc | 0.32 | 2.27 | 4.73 |

| k1 | 0.02 | 0.01 | 0.02 | k2 | 0.09 | 0.004 | 0.004 | |

| R2 | 0.94 | 0.96 | 0.99 | R2 | 0.98 | 0.98 | 0.99 | |

| χ2 | 0.0008 | 0.04 | 0.03 | χ2 | 0.0002 | 0.02 | 0.01 | |

| Ni2+ | qe,calc | 0.16 | 0.75 | 1.47 | qe,calc | 0.13 | 0.69 | 1.34 |

| k1 | 0.01 | 0.03 | 0.04 | k2 | 0.08 | 0.07 | 0.03 | |

| R2 | 0.94 | 0.91 | 0.98 | R2 | 0.97 | 0.96 | 0.99 | |

| χ2 | 0.0009 | 0.005 | 0.003 | χ2 | 0.002 | 0.002 | 0.001 | |

| Kinetic Models | ; k1—Rate Constant of the PFO Kinetic Model, min−1. | ; k2—Rate Constant of the PSO Kinetic Model, g mg–1 × min−1. | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Sorbents | Sorbents | ||||||||

| Metal Ions | CPLH+ | CGCS | CGCS_ CPLH+ | CPLH+ | CGCS | CGCS_ CPLH+ | |||

| Fe3+ | qe,calc | 3.72 | 24.51 | 46.63 | qe,calc | 2.95 | 19.68 | 40.27 | |

| k1 | 0.01 | 0.01 | 0.02 | k2 | 0.003 | 0.0005 | 0.0004 | ||

| R2 | 0.96 | 0.95 | 0.98 | R2 | 0.98 | 0.97 | 0.99 | ||

| χ2 | 0.03 | 1.95 | 0.57 | χ2 | 0.06 | 3.65 | 4.81 | ||

| Cr3+ | qe,calc | 0.02 | 0.05 | 0.07 | qe,calc | 0.02 | 0.03 | 0.06 | |

| k1 | 0.03 | 0.01 | 0.01 | k2 | 2.08 | 0.2 | 0.17 | ||

| R2 | 0.98 | 0.94 | 0.92 | R2 | 0.99 | 0.96 | 0.95 | ||

| χ2 | 0.0002 | 0.0006 | 0.0003 | χ2 | 0.006 | 0.0002 | 0.0005 | ||

| Metal Ions | CGCS_CPLH+ | ||||||

|---|---|---|---|---|---|---|---|

| ΔH°, J mol−1 | ΔS°, kJ mol−1 K−1 | ΔG°, kJ·mol−1 | |||||

| 293 | 298 | 303 | 308 | 313 | |||

| Cu2+ | 74.79 | 0.318 | −18.67 | −19.93 | −21.34 | −23.31 | −24.97 |

| Zn2+ | 59.74 | 0.261 | −17.02 | −18.16 | −19.40 | −20.64 | −22.34 |

| Ni2+ | 25.22 | 0.047 | −9.42 | −10.17 | −10.78 | −11.32 | −11.81 |

| Fe3+ | 86.42 | 0.356 | −18.08 | −19.42 | −21.27 | −23.02 | −25.21 |

| Cr3+ | 45.29 | 0.185 | −9.02 | −10.34 | −11.03 | −12.07 | −12.80 |

| CGCS | |||||||

| ΔH°, J·mol−1 | ΔS°, kJ mol−1 K−1 | ΔG°, kJ·mol−1 | |||||

| 293 | 298 | 303 | 308 | 313 | |||

| Cu2+ | 34.42 | 0.171 | −15.61 | −16.65 | −17.37 | −18.33 | −19.04 |

| Zn2+ | 83.76 | 0.329 | −12.88 | −14.44 | −16.03 | −17.82 | −19.45 |

| Ni2+ | 46.86 | 0.176 | −4.89 | −5.74 | −6.78 | −7.67 | −8.34 |

| Fe3+ | 37.31 | 0.476 | −14.24 | −15.19 | −16.10 | −16.90 | −17.80 |

| Cr3+ | 104.93 | 0.188 | −7.83 | −9.09 | −10.03 | −10.91 | −11.61 |

| CPLH+ | |||||||

| ΔH°, J·mol−1 | ΔS°, kJ mol−1 K−1 | ΔG°, kJ·mol−1 | |||||

| 293 | 298 | 303 | 308 | 313 | |||

| Cu2+ | 14.38 | 0.090 | −12.12 | −12.55 | −13.04 | −13.46 | −13.92 |

| Zn2+ | 26.17 | 0.114 | −7.16 | −7.83 | −8.37 | −8.96 | −9.45 |

| Ni2+ | 19.61 | 0.077 | −3.02 | −3.45 | −3.95 | −4.26 | −4.55 |

| Fe3+ | 17.03 | 0.093 | −10.43 | −10.95 | −11.43 | −11.88 | −12.30 |

| Cr3+ | 60.08 | 0.223 | −5.21 | −6.71 | −7.83 | −8.75 | −9.76 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Humelnicu, D.; Dragan, E.S.; Ignat, M.; Dinu, M.V. A Comparative Study on Cu2+, Zn2+, Ni2+, Fe3+, and Cr3+ Metal Ions Removal from Industrial Wastewaters by Chitosan-Based Composite Cryogels. Molecules 2020, 25, 2664. https://doi.org/10.3390/molecules25112664

Humelnicu D, Dragan ES, Ignat M, Dinu MV. A Comparative Study on Cu2+, Zn2+, Ni2+, Fe3+, and Cr3+ Metal Ions Removal from Industrial Wastewaters by Chitosan-Based Composite Cryogels. Molecules. 2020; 25(11):2664. https://doi.org/10.3390/molecules25112664

Chicago/Turabian StyleHumelnicu, Doina, Ecaterina Stela Dragan, Maria Ignat, and Maria Valentina Dinu. 2020. "A Comparative Study on Cu2+, Zn2+, Ni2+, Fe3+, and Cr3+ Metal Ions Removal from Industrial Wastewaters by Chitosan-Based Composite Cryogels" Molecules 25, no. 11: 2664. https://doi.org/10.3390/molecules25112664

APA StyleHumelnicu, D., Dragan, E. S., Ignat, M., & Dinu, M. V. (2020). A Comparative Study on Cu2+, Zn2+, Ni2+, Fe3+, and Cr3+ Metal Ions Removal from Industrial Wastewaters by Chitosan-Based Composite Cryogels. Molecules, 25(11), 2664. https://doi.org/10.3390/molecules25112664