Highly Loaded Cellulose/Poly (butylene succinate) Sustainable Composites for Woody-Like Advanced Materials Application

Abstract

1. Introduction

2. Results and Discussion

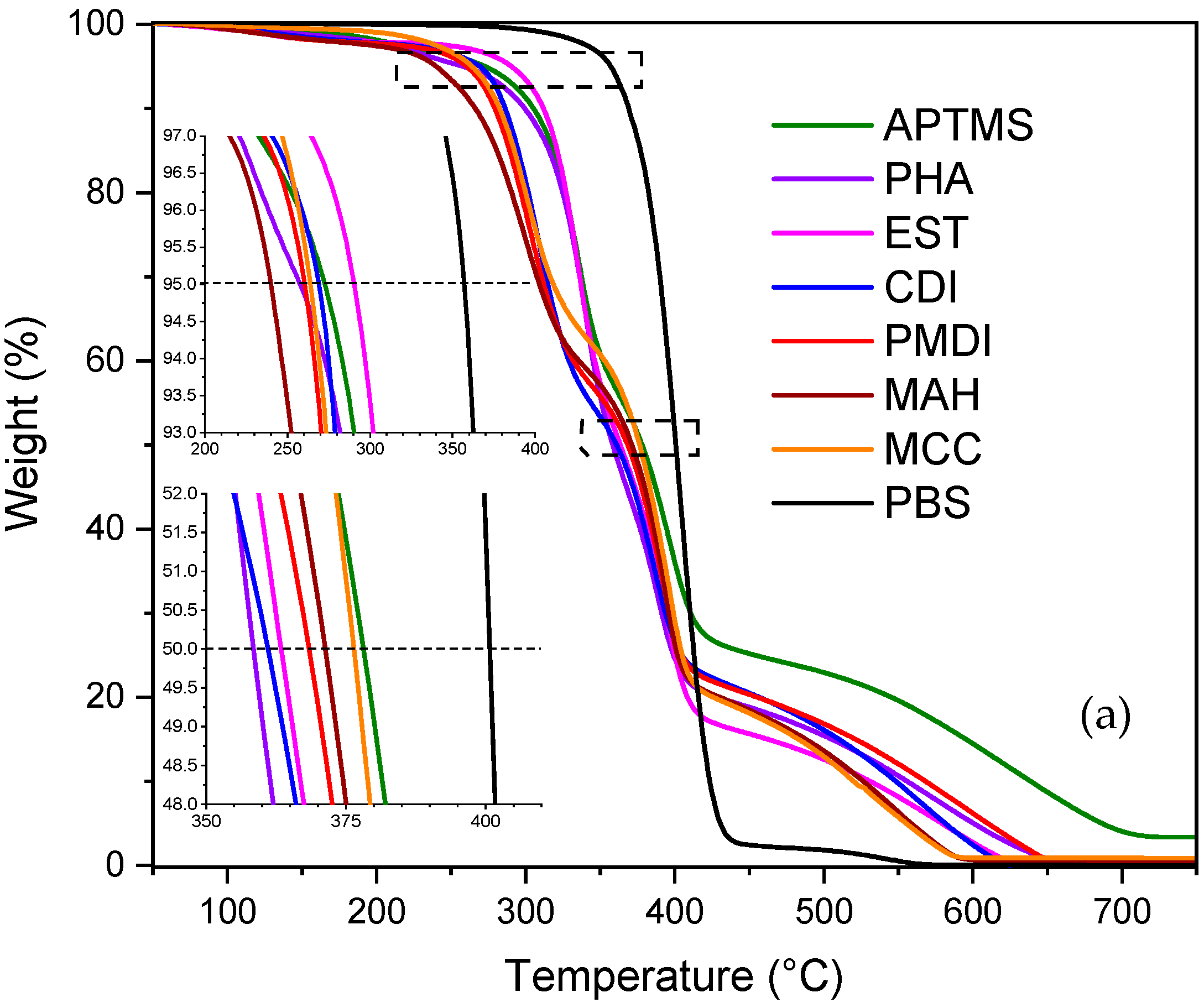

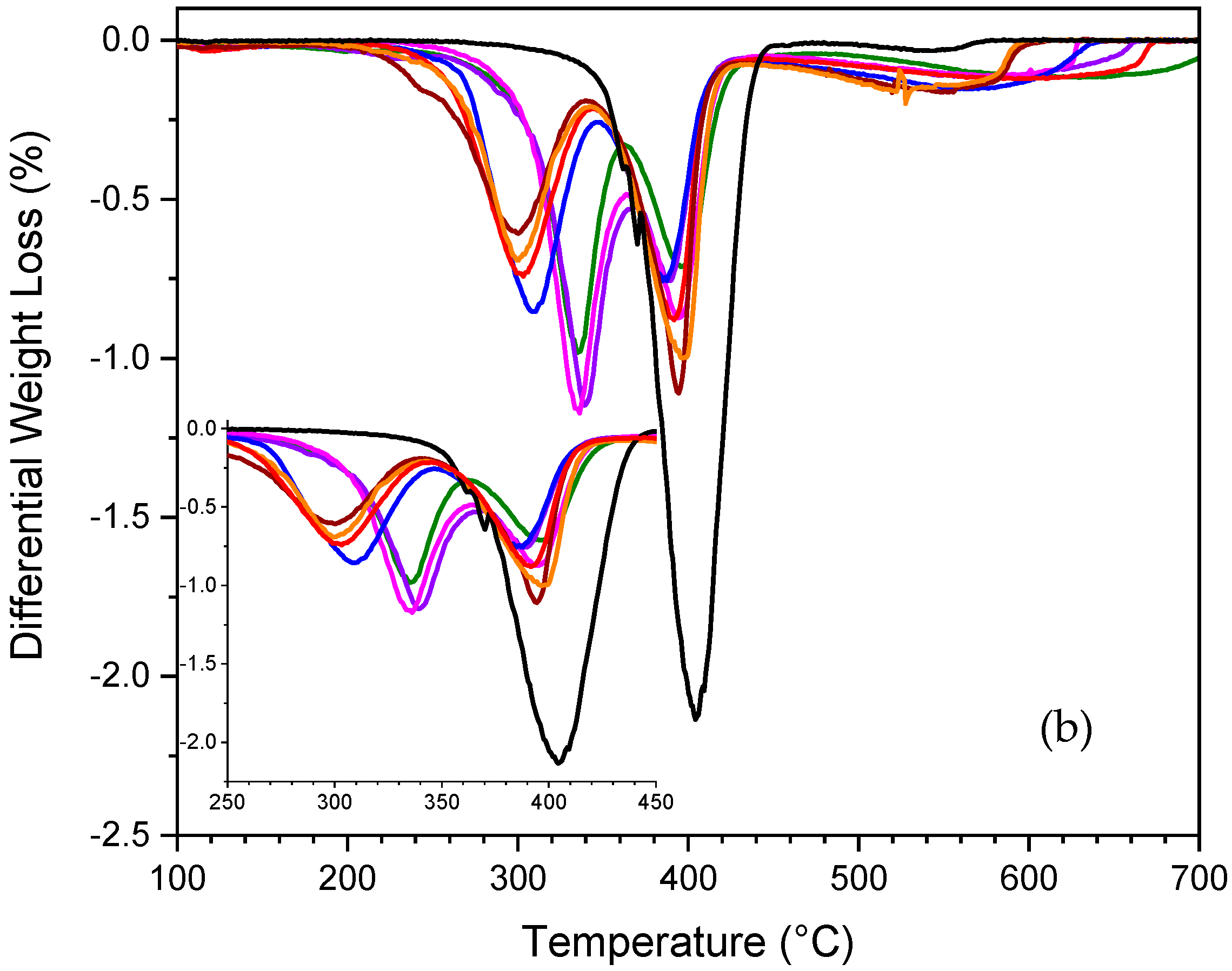

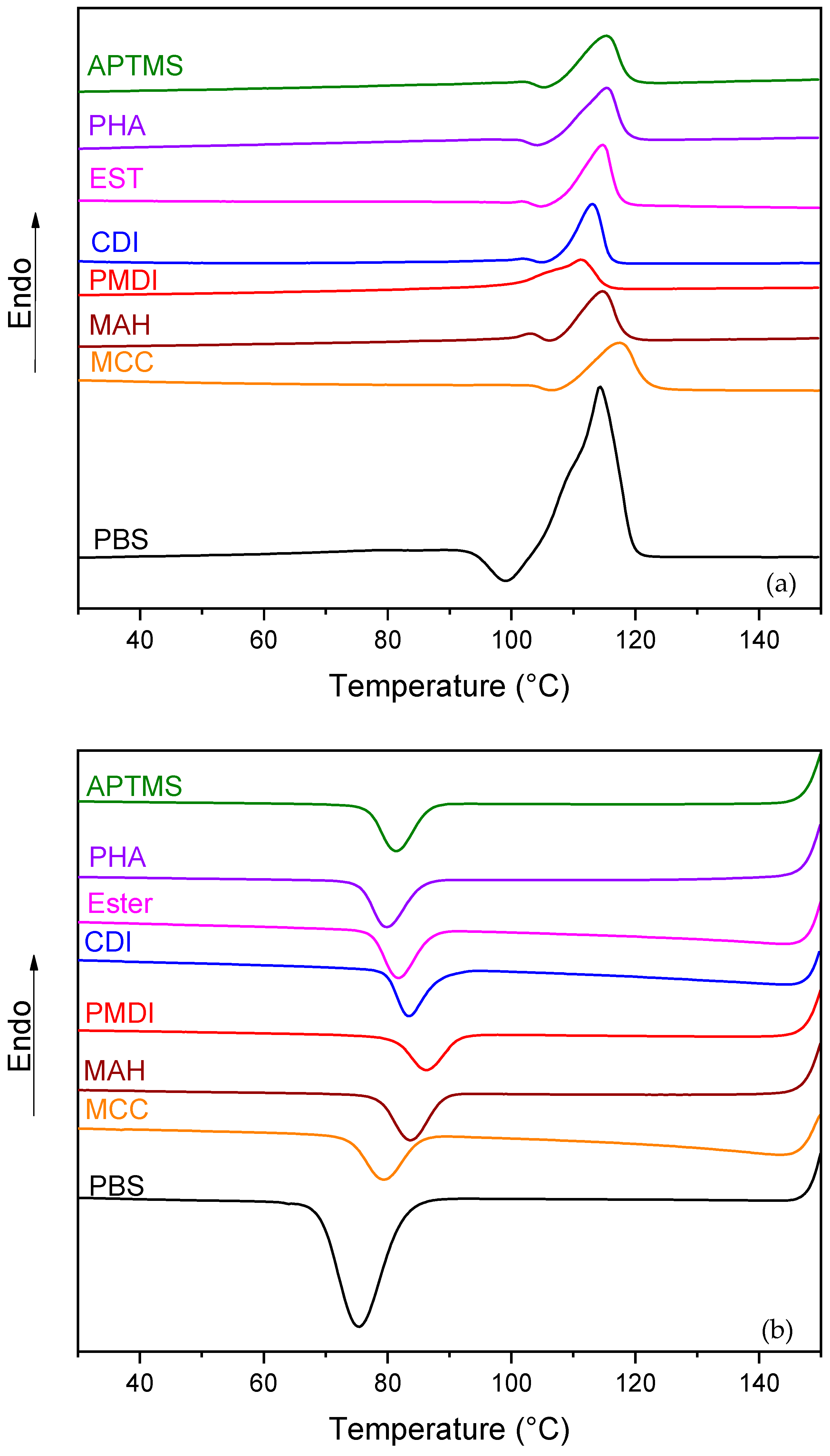

2.1. Thermal Properties

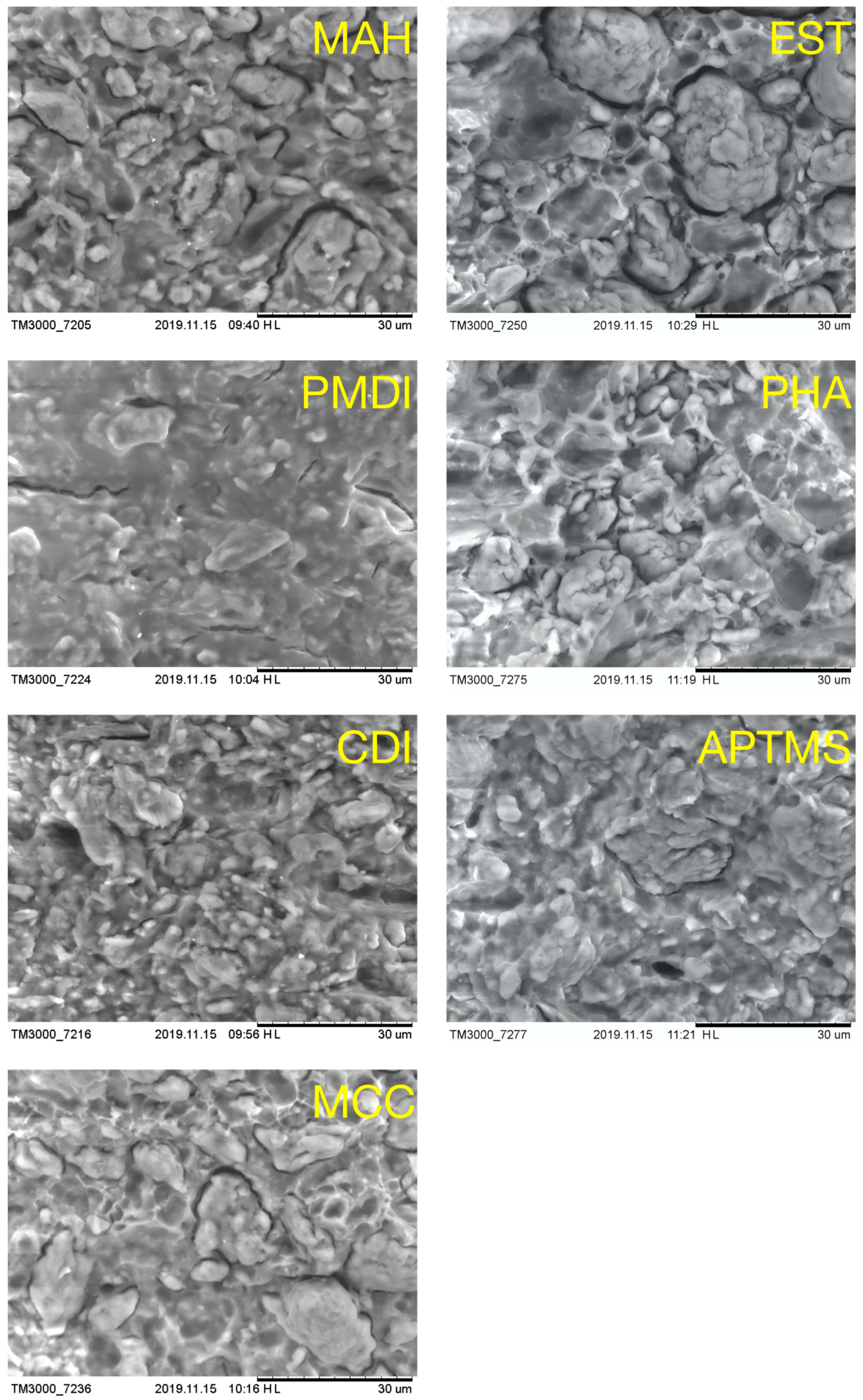

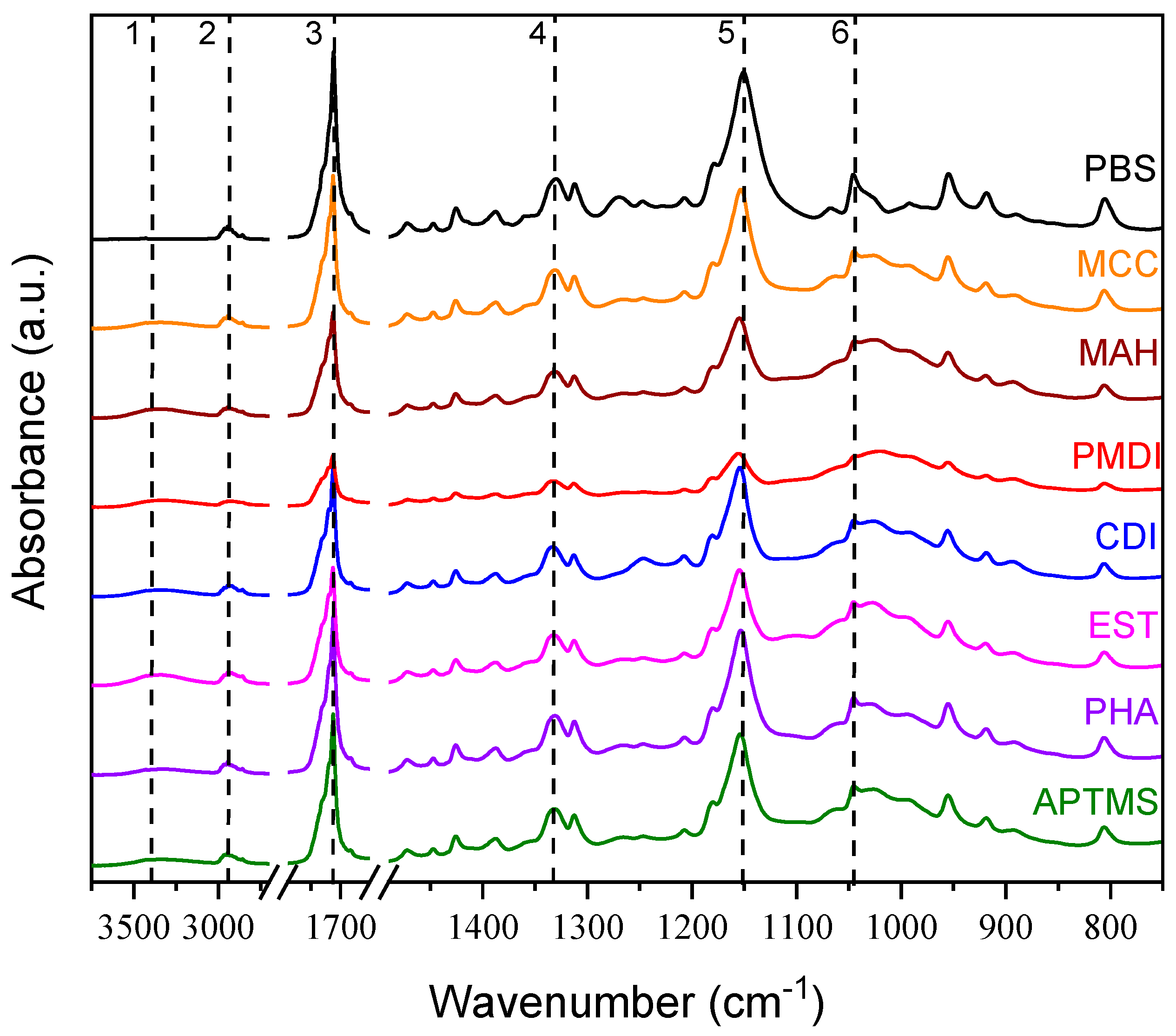

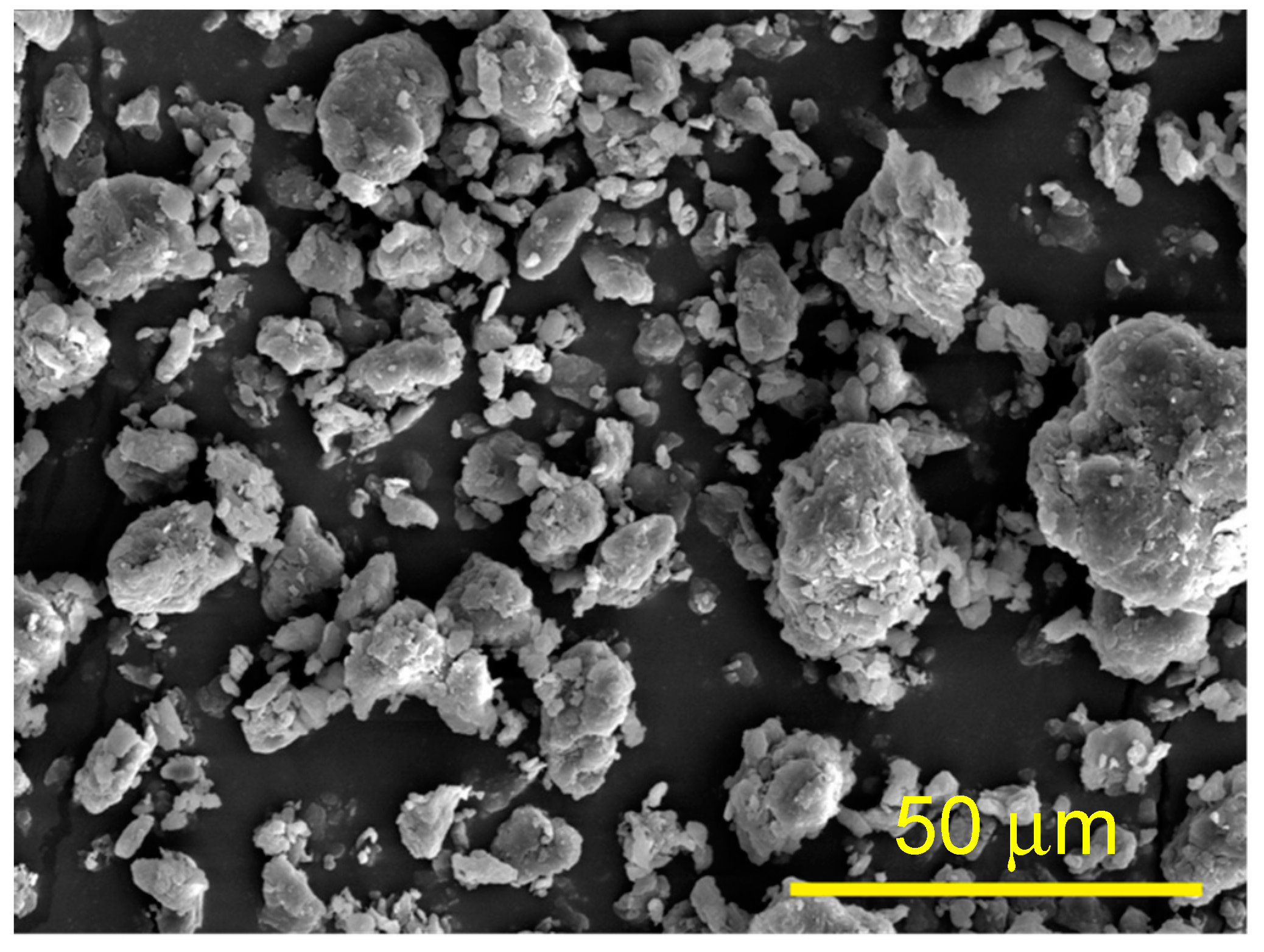

2.2. Structure and Morphology Characterization

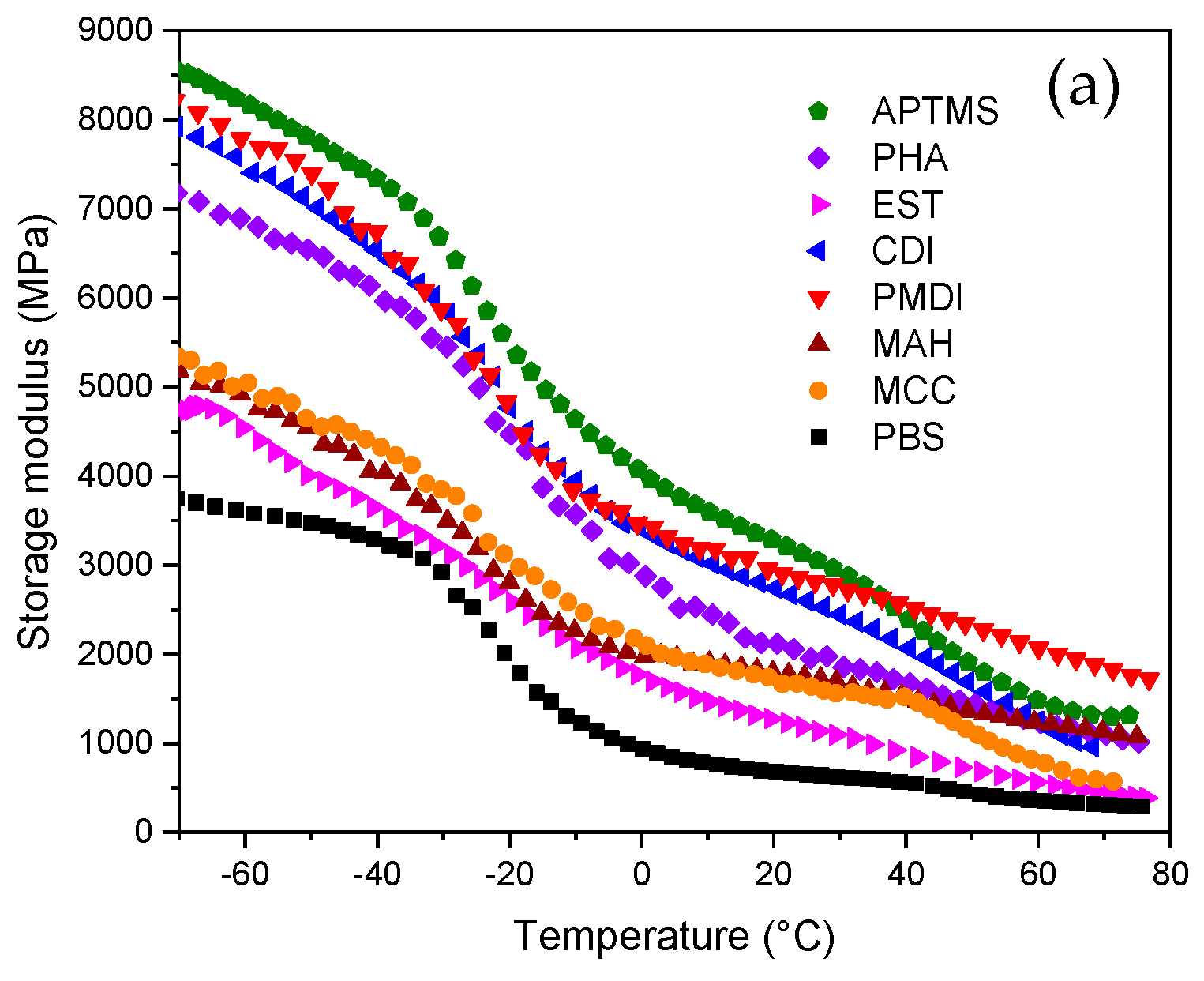

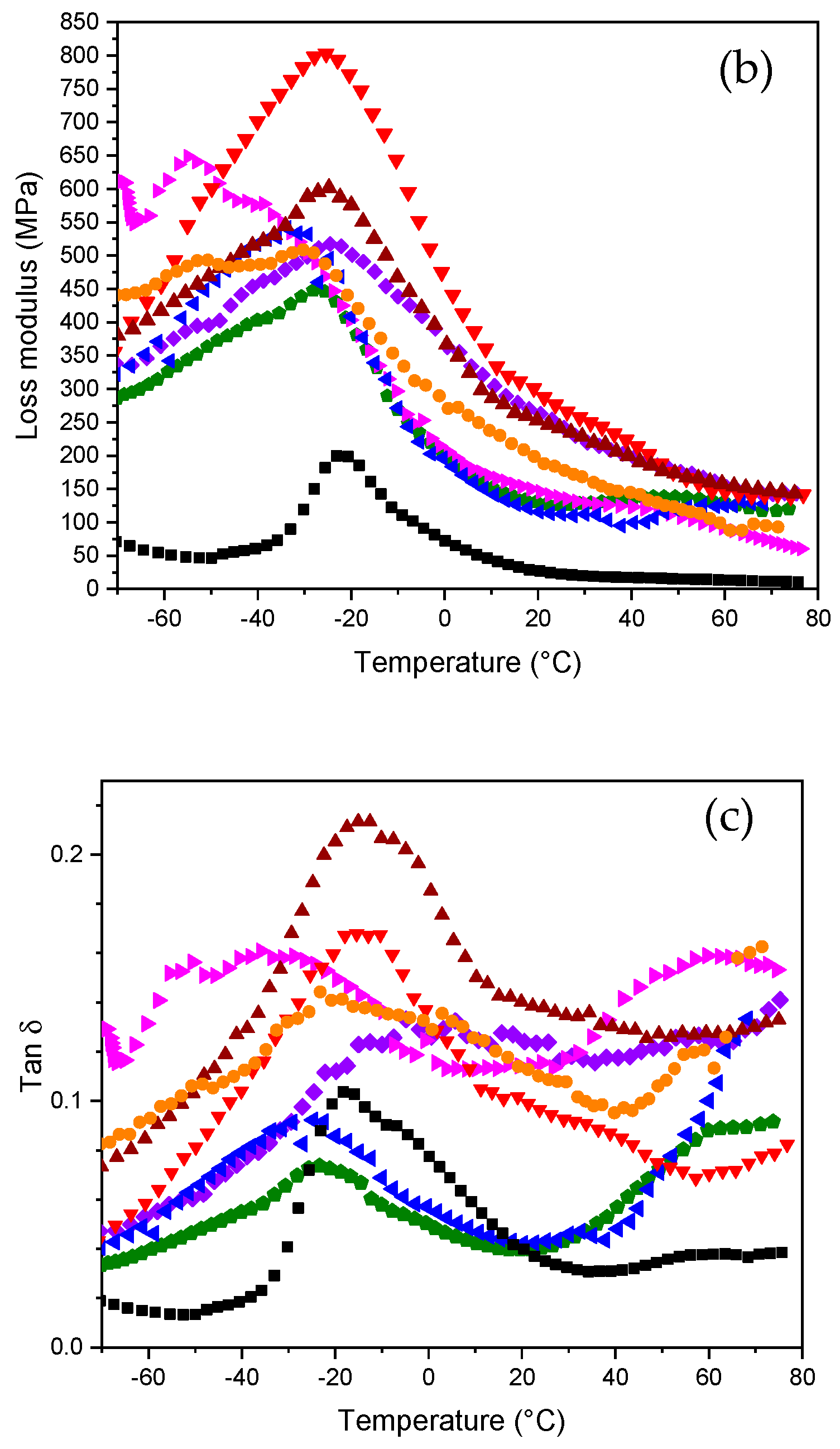

2.3. Thermomechanical Properties

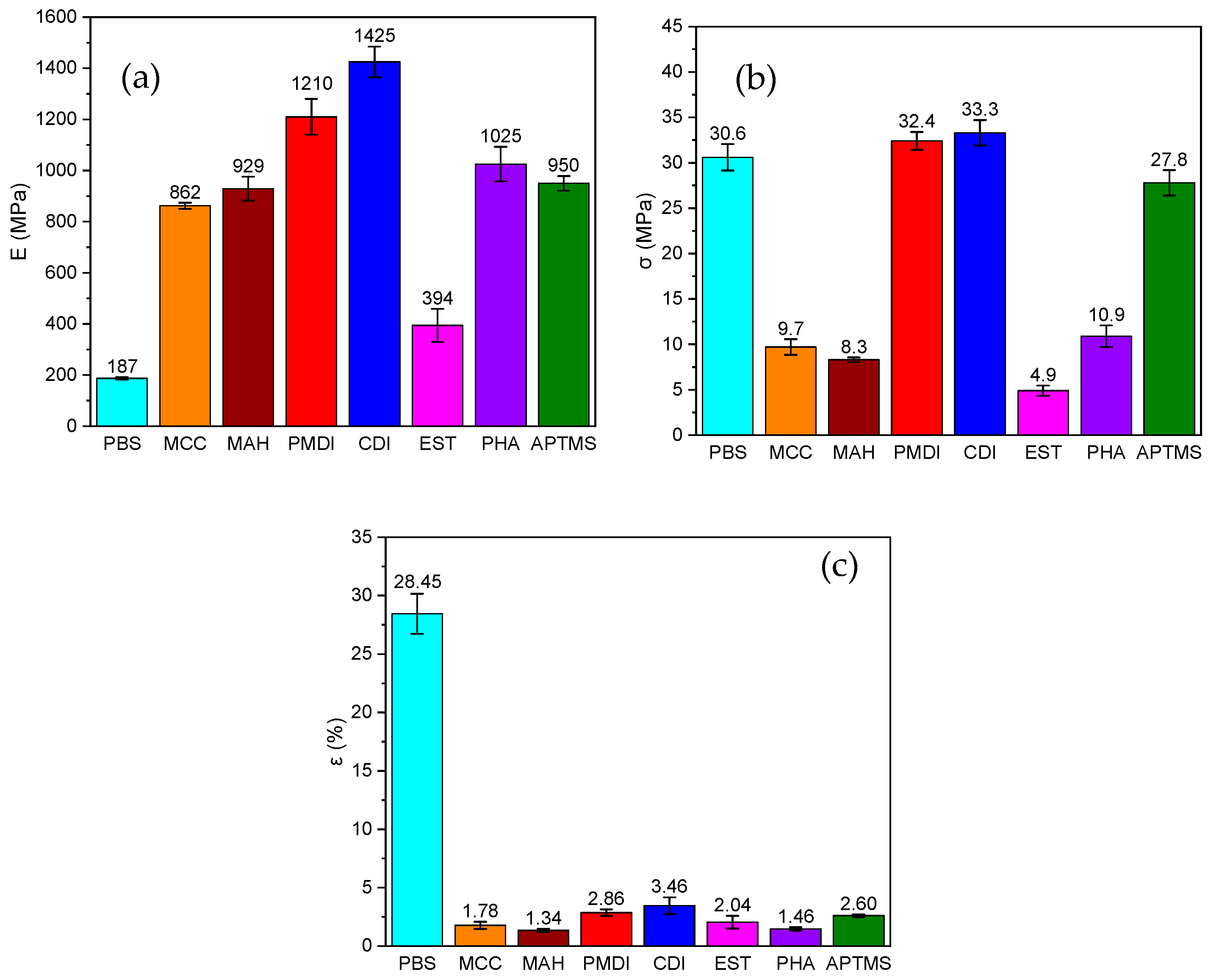

2.4. Mechanical Properties

3. Materials and Methods

3.1. Raw Materials

3.2. Preparation of Microcrystalline Cellulose

3.3. Processing of PBS/MCC Composites

3.4. Chemical Modification of PBS/MCC Composites

3.5. Testing Methods

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Dormer, A.S.; Finn, D. Carbon Footprint Analysis of a Polymer Manufacturing Process. In Proceedings of the 28th International Manufacturing Conference, Dublin, Ireland, 1 August 2011. [Google Scholar]

- Jambunathan, P.; Zhang, K. Engineered biosynthesis of biodegradable polymers. J. Ind. Microbiol. Biotechnol. 2016, 43, 1037–1058. [Google Scholar] [CrossRef] [PubMed]

- Chen, G.-Q.; Patel, M.K. Plastics derived from biological sources: Present and future: A technical and environmental review. Chem. Rev. 2012, 112, 2082–2099. [Google Scholar] [CrossRef]

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Ashby, M. Materials and the Environment: Eco-informed Material Choice, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Bayer, J.; Granda, L.A.; Méndez, J.A.; Pèlach, M.A.; Vilaseca, F.; Mutjé, P. 5-Cellulose Polymer Composites (WPC); Fan, M., Fu, F.B.T., Eds.; Woodhead Publishing: Cambridge, UK, 2017; pp. 115–139. ISBN 978-0-08-100411-1. [Google Scholar]

- Spear, M.J.; Eder, A.; Carus, M. 10-Wood Polymer Composites; Ansell, M.P.B.T.-W.C., Ed.; Woodhead Publishing: Cambridge, UK, 2015; pp. 195–249. ISBN 978-1-78242-454-3. [Google Scholar]

- Väisänen, T.; Das, O.; Tomppo, L. A review on new bio-based constituents for natural fiber-polymer composites. J. Clean. Prod. 2017, 149, 582–596. [Google Scholar] [CrossRef]

- Satyanarayana, K.G.; Arizaga, G.G.C.; Wypych, F. Biodegradable composites based on lignocellulosic fibers-An overview. Prog. Polym. Sci. 2009, 34, 982–1021. [Google Scholar] [CrossRef]

- Trache, D.; Hussin, M.H.; Hui Chuin, C.T.; Sabar, S.; Fazita, M.R.N.; Taiwo, O.F.A.; Hassan, T.M.; Haafiz, M.K.M. Microcrystalline cellulose: Isolation, characterization and bio-composites application—A review. Int. J. Biol. Macromol. 2016, 93, 789–804. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Mariano, M.; Huang, J.; Lin, N.; Ahmad, I.; Dufresne, A.; Thomas, S. Recent developments on nanocellulose reinforced polymer nanocomposites: A review. Polymer (Guildf.) 2017, 132, 368–393. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Azizi Samir, M.A.S.; Alloin, F.; Dufresne, A. Review of Recent Research into Cellulosic Whiskers, Their Properties and Their Application in Nanocomposite Field. Biomacromolecules 2005, 6, 612–626. [Google Scholar] [CrossRef]

- Rafiee, Z.; Keshavarz, V. Synthesis and characterization of polyurethane/microcrystalline cellulose bionanocomposites. Prog. Org. Coat. 2015, 86, 190–193. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Dufresne, A.; Pinheiro, I.F.; Souza, D.H.S.; Gouveia, R.F.; Mei, L.H.I.; Lona, L.M.F. How do cellulose nanocrystals affect the overall properties of biodegradable polymer nanocomposites: A comprehensive review. Eur. Polym. J. 2018, 108, 274–285. [Google Scholar] [CrossRef]

- Kargarzadeh, H.; Huang, J.; Lin, N.; Ahmad, I.; Mariano, M.; Dufresne, A.; Thomas, S.; Gałęski, A. Recent developments in nanocellulose-based biodegradable polymers, thermoplastic polymers, and porous nanocomposites. Prog. Polym. Sci. 2018, 87, 197–227. [Google Scholar] [CrossRef]

- Miao, C.; Hamad, W.Y. Cellulose reinforced polymer composites and nanocomposites: A critical review. Cellulose 2013, 20, 2221–2262. [Google Scholar] [CrossRef]

- Missoum, K.; Belgacem, M.N.; Bras, J. Nanofibrillated cellulose surface modification: A review. Materials 2013, 6, 1745–1766. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Ashori, A.; Nourbakhsh, A. Performance properties of microcrystalline cellulose as a reinforcing agent in wood plastic composites. Compos. Part B Eng. 2010, 41, 578–581. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites reinforced with cellulose based fibres. Prog. Polym. Sci. 1999, 24, 221–274. [Google Scholar] [CrossRef]

- Siqueira, G.; Bras, J.; Dufresne, A. New process of chemical grafting of cellulose nanoparticles with a long chain isocyanate. Langmuir 2010, 26, 402–411. [Google Scholar] [CrossRef]

- Wu, Q.; Henriksson, M.; Liu, X.; Berglund, L.A. A high strength nanocomposite based on microcrystalline cellulose and polyurethane. Biomacromolecules 2007, 8, 3687–3692. [Google Scholar] [CrossRef]

- Zaman, M.; Xiao, H.; Chibante, F.; Ni, Y. Synthesis and characterization of cationically modified nanocrystalline cellulose. Carbohydr. Polym. 2012, 89, 163–170. [Google Scholar] [CrossRef]

- Putro, J.N.; Ismadji, S.; Gunarto, C.; Yuliana, M.; Santoso, S.P.; Soetaredjo, F.E.; Ju, Y.H. The effect of surfactants modification on nanocrystalline cellulose for paclitaxel loading and release study. J. Mol. Liq. 2019, 282, 407–414. [Google Scholar] [CrossRef]

- Pukánszky, B.; Fekete, E. Adhesion and Surface Modification BT - Mineral Fillers in Thermoplastics I: Raw Materials and Processing; Jancar, J., Fekete, E., Hornsby, P.R., Jancar, J., Pukánszky, B., Rothon, R.N., Eds.; Springer: Berlin/Heidelberg, Germany, 1999; pp. 109–153. ISBN 978-3-540-69220-1. [Google Scholar]

- Ma, X.; Chang, P.R.; Yu, J. Properties of biodegradable thermoplastic pea starch/carboxymethyl cellulose and pea starch/microcrystalline cellulose composites. Carbohydr. Polym. 2008, 72, 369–375. [Google Scholar] [CrossRef]

- Chaiwutthinan, P.; Chuayjuljit, S.; Leejarkpai, T. Use of microcrystalline cellulose prepared from cotton fabric waste to prepare poly(butylene succinate) composites. Adv. Mater. Res. 2012, 356–360, 430–434. [Google Scholar] [CrossRef]

- Shen, D.K.; Gu, S. The mechanism for thermal decomposition of cellulose and its main products. Bioresour. Technol. 2009, 100, 6496–6504. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.M.; Mohd Ishak, Z.A.; Mat Taib, R.; Law, T.T.; Ahmad Thirmizir, M.Z. Mechanical, Thermal and Water Absorption Properties of Kenaf-Fiber-Based Polypropylene and Poly(Butylene Succinate) Composites. J. Polym. Environ. 2013, 21, 293–302. [Google Scholar] [CrossRef]

- Roman, M.; Winter, W.T. Effect of Sulfate Groups from Sulfuric Acid Hydrolysis on the Thermal Degradation Behavior of Bacterial Cellulose. Biomacromolecules 2004, 5, 1671–1677. [Google Scholar] [CrossRef]

- Ahmad, E.E.M.; Luyt, A.S. Polyvinyl Alcohol-Modified Pithecellobium Clypearia Benth Herbal Residue FiberPolypropylene Composites. Polym. Compos. 2016, 37, 915–924. [Google Scholar]

- Tang, T.; Zhu, J.; Wang, W.; Ni, H. Morphology, thermal, and crystallization properties of poly(butylene succinate)-grafted Nanocrystalline Cellulose by polymerization in situ. Polym. Eng. Sci. 2019, 59, 928–934. [Google Scholar] [CrossRef]

- Cao, Z.; Lu, Y.; Zhang, C.; Zhang, Q.; Zhou, A.; Hu, Y.; Wu, D.; Tao, G.; Gong, F.; Ma, W.; et al. Effects of the chain-extender content on the structure and performance of poly(lactic acid)–poly(butylene succinate)–microcrystalline cellulose composites. J. Appl. Polym. Sci. 2017, 134, 1–8. [Google Scholar] [CrossRef]

- Bhasney, S.M.; Bhagabati, P.; Kumar, A.; Katiyar, V. Morphology and crystalline characteristics of polylactic acid [PLA]/linear low density polyethylene [LLDPE]/microcrystalline cellulose [MCC] fiber composite. Compos. Sci. Technol. 2019, 171, 54–61. [Google Scholar] [CrossRef]

- Dufresne, A.; Kellerhals, M.B.; Witholt, B. Transcrystallization in Mcl-PHAs/cellulose whiskers composites. Macromolecules 1999, 32, 7396–7401. [Google Scholar] [CrossRef]

- Bin, T.; Qu, J.P.; Liu, L.M.; Feng, Y.H.; Hu, S.X.; Yin, X.C. Non-isothermal crystallization kinetics and dynamic mechanical thermal properties of poly(butylene succinate) composites reinforced with cotton stalk bast fibers. Thermochim. Acta 2011, 525, 141–149. [Google Scholar] [CrossRef]

- Grunert, M.; Winter, W.T. Nanocomposites of cellulose acetate butyrate reinforced with cellulose nanocrystals. J. Polym. Environ. 2002, 10, 27–30. [Google Scholar] [CrossRef]

- Gaidukov, S.; Cabulis, U.; Gromilova, K.; Tupureina, V.; Grigalovica, A. Preparation and structural properties of free films from rapeseed oil-based rigid polyurethane-montmorillonite nanocomposites. Int. J. Polym. Sci. 2013, 2013, 1–8. [Google Scholar] [CrossRef][Green Version]

- Gaidukovs, S.; Zukulis, E.; Bochkov, I.; Vaivodiss, R.; Gaidukova, G. Enhanced mechanical, conductivity, and dielectric characteristics of ethylene vinyl acetate copolymer composite filled with carbon nanotubes. J. Thermoplast. Compos. Mater. 2017, 31, 1161–1180. [Google Scholar] [CrossRef]

- Mukherjee, T.; Kao, N.; Gupta, R.K.; Quazi, N.; Bhattacharya, S. Evaluating the state of dispersion on cellulosic biopolymer by rheology. J. Appl. Polym. Sci. 2016, 133, 43200. [Google Scholar] [CrossRef]

- Kale, R.D.; Gorade, V.G.; Madye, N.; Chaudhary, B.; Bangde, P.S.; Dandekar, P.P. Preparation and characterization of biocomposite packaging film from poly(lactic acid) and acylated microcrystalline cellulose using rice bran oil. Int. J. Biol. Macromol. 2018, 118, 1090–1102. [Google Scholar] [CrossRef]

- Maldas, D.; Kokta, B.V. Role of coupling agents on the performance of woodflour-filled polypropylene composites. Int. J. Polym. Mater. Polym. Biomater. 1994, 27, 77–88. [Google Scholar] [CrossRef]

- Espino-Pérez, E.; Bras, J.; Ducruet, V.; Guinault, A.; Dufresne, A.; Domenek, S. Influence of chemical surface modification of cellulose nanowhiskers on thermal, mechanical, and barrier properties of poly(lactide) based bionanocomposites. Eur. Polym. J. 2013, 49, 3144–3154. [Google Scholar] [CrossRef]

- Gregorova, A.; Hrabalova, M.; Kovalcik, R.; Wimmer, R. Surface modification of spruce wood flour and effects on the dynamic fragility of PLA/wood composites. Polym. Eng. Sci. 2011, 51, 143–150. [Google Scholar] [CrossRef]

- Gowman, A.; Wang, T.; Rodriguez-Uribe, A.; Mohanty, A.K.; Misra, M. Bio-poly(butylene succinate) and Its Composites with Grape Pomace: Mechanical Performance and Thermal Properties. ACS Omega 2018, 3, 15205–15216. [Google Scholar] [CrossRef] [PubMed]

- Suardana, N.P.G.; Piao, Y.; Lim, J.K. Mechanical properties of HEMP fibers and HEMP/PP composites: Effects of chemical surface treatment. Mater. Phys. Mech. 2011, 11, 1–8. [Google Scholar]

- Eyley, S.; Thielemans, W. Surface modification of cellulose nanocrystals. Nanoscale 2014, 6, 7764–7779. [Google Scholar] [CrossRef] [PubMed]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Duarte, A.P.; Ben Salah, A.; Gandini, A. Modification of cellulosic fibres with functionalised silanes: Development of surface properties. Int. J. Adhes. Adhes. 2004, 24, 43–54. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Dufresne, A.; Gandini, A. Modification of cellulose fibers with functionalized silanes: Effect of the fiber treatment on the mechanical performances of cellulose-thermoset composites. J. Appl. Polym. Sci. 2005, 98, 974–984. [Google Scholar] [CrossRef]

- Robles, E.; Urruzola, I.; Labidi, J.; Serrano, L. Surface-modified nano-cellulose as reinforcement in poly(lactic acid) to conform new composites. Ind. Crops Prod. 2015, 71, 44–53. [Google Scholar] [CrossRef]

- Posthumus, W.; Derksen, A.J.; van den Goorbergh, J.A.M.; Hesselmans, L.C.J. Crosslinking by polycarbodiimides. Prog. Org. Coatings 2007, 58, 231–236. [Google Scholar] [CrossRef]

- Badri, K.B.H.; Sien, W.C.; Shahrom, M.S.B.R.; Hao, L.C.; Baderuliksan, N.Y.; Norzali, N.R. Ftir Spectroscopy Analysis of the Prepolymerization of Palm-Based Polyurethane. Solid State Sci. Technol. 2010, 18, 1–8. [Google Scholar]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Mittal, M.; Chaudhary, R. Effect of fiber content on thermal behavior and viscoelastic properties of PALF/Epoxy and COIR/Epoxy composites. Mater. Res. Express 2018, 5, 125305. [Google Scholar] [CrossRef]

- Gaidukovs, S.; Kampars, V.; Bitenieks, J.; Bochkov, I.; Gaidukova, G.; Cabulis, U. Thermo-mechanical properties of polyurethane modified with graphite oxide and carbon nanotube particles. Integr. Ferroelectr. 2016, 173, 1–11. [Google Scholar] [CrossRef]

- Deng, S.; Binauld, S.; Mangiante, G.; Frances, J.M.; Charlot, A.; Bernard, J.; Zhou, X.; Fleury, E. Microcrystalline cellulose as reinforcing agent in silicone elastomers. Carbohydr. Polym. 2016, 151, 899–906. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Zhou, J.; Zhang, H.; Luo, Z.; Yao, J. Microcrystalline cellulose as reactive reinforcing fillers for epoxidized soybean oil polymer composites. J. Appl. Polym. Sci. 2015, 132, 42488. [Google Scholar] [CrossRef]

- Miao, C.; Hamad, W.Y. Critical insights into the reinforcement potential of cellulose nanocrystals in polymer nanocomposites. Curr. Opin. Solid State Mater. Sci. 2019, 23, 100761. [Google Scholar] [CrossRef]

- Bandzierz, K.; Reuvekamp, L.; Dryzek, J.; Dierkes, W.; Blume, A.; Bielinski, D. Influence of network structure on glass transition temperature of elastomers. Materials 2016, 9, 607. [Google Scholar] [CrossRef]

- Kiziltas, A.; Gardner, D.J.; Han, Y.; Yang, H.-S. Dynamic mechanical behavior and thermal properties of microcrystalline cellulose (MCC)-filled nylon 6 composites. Thermochim. Acta 2011, 519, 38–43. [Google Scholar] [CrossRef]

- Mathew, A.P.; Oksman, K.; Sain, M. Mechanical properties of biodegradable composites from poly lactic acid (PLA) and microcrystalline cellulose (MCC). J. Appl. Polym. Sci. 2005, 97, 2014–2025. [Google Scholar] [CrossRef]

- Sun, C. (Calvin). True Density of Microcrystalline Cellulose. J. Pharm. Sci. 2005, 94, 2132–2134. [Google Scholar] [CrossRef]

- Kajaks, J.; Kalnins, K.; Naburgs, R. Wood plastic composites (WPC) based on high-density polyethylene and birch wood plywood production residues. Int. Wood Prod. J. 2018, 9, 15–21. [Google Scholar] [CrossRef]

- Kajaks, J.; Kalnins, K.; Kalnina, I.; Matvejs, J. Some exploitation properties of wood plastic composites based on polypropylene and birch plywood sanding dust. Proc. Est. Acad. Sci. 2018, 67, 117–123. [Google Scholar] [CrossRef]

- Niska, K.O.; Sanadi, A.R. 3 - Interactions between wood and synthetic polymers. In Woodhead Publishing Series in Composites Science and Engineering; Niska, K.O., Sain, M.B.T.-W.C., Eds.; Woodhead Publishing: Cambridge, UK, 2008; pp. 41–71. ISBN 978-1-84569-272-8. [Google Scholar]

- Ghorbani, M.; Aghmashhadi, Z.A.; Amininasab, S.M.; Abedini, R. Effect of different coupling agents on the thermal, mechanical and biological behavior of vinyl acetate-wood polymer composite. Holzforschung 2019, 73, 967–973. [Google Scholar] [CrossRef]

- Adebayo, G.O.; Hassan, A.; Yahya, R.; Rahman, N.A.; Lafia-Araga, R. Influence of wood surface chemistry on the tensile and flexural properties of heat-treated mangrove/high-density polyethylene composites. Polym. Bull. 2019, 76, 6467–6486. [Google Scholar] [CrossRef]

- Klyosov, A.A. Wood-Plastic Composites; John Wiley & Sons: Hoboken, NJ, USA, 2007; pp. 1–698. [Google Scholar]

- Goussé, C.; Chanzy, H.; Cerrada, M.L.; Fleury, E. Surface silylation of cellulose microfibrils: Preparation and rheological properties. Polymer (Guildf). 2004, 45, 1569–1575. [Google Scholar] [CrossRef]

- Bai, C.; Huang, X.; Xie, F.; Xiong, X. Microcrystalline Cellulose Surface-Modified with Acrylamide for Reinforcement of Hydrogels. ACS Sustain. Chem. Eng. 2018, 6, 12320–12327. [Google Scholar] [CrossRef]

- Lee, J.S.; Ryu, Y.S.; Kim, I.-S.; Kim, S.H. Effect of interface affinity on the performance of a composite of microcrystalline cellulose and polypropylene/polylactide blends. Polym. Int. 2019, 68, 1402–1410. [Google Scholar] [CrossRef]

- Çetin, N.S.; Özmen Çetin, N.; Harper, D.P. Vinyl acetate-modified microcrystalline cellulose-reinforced HDPE composites prepared by twin-screw extrusion. Turkish J. Agric. For. 2015, 39, 39–47. [Google Scholar] [CrossRef]

- Pichandi, S.; Rana, S.; Parveen, S.; Fangueiro, R. A green approach of improving interface and performance of plant fibre composites using microcrystalline cellulose. Carbohydr. Polym. 2018, 197, 137–146. [Google Scholar] [CrossRef]

- Laka, M.; Chernyavskaya, S. Method of Obtaining Microcrystalline Cellulose. Latvian Republic Patent 11184, 1996. [Google Scholar]

- Laka, M.; Chernyavskaya, S.; Treimanis, A.; Faitelson, L. Preparation and properties of microcrystalline cellulose gels. Cellul. Chem. Technol. 2000, 34, 217–227. [Google Scholar]

- Satov, D. V 2 - Additives for wood–polymer composites. In Woodhead Publishing Series in Composites Science and Engineering; Niska, K.O., Sain, M.B.T.-W.C., Eds.; Woodhead Publishing: Cambridge, UK, 2008; pp. 23–40. ISBN 978-1-84569-272-8. [Google Scholar]

- Chan, C.M.; Vandi, L.J.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B. Composites of Wood and Biodegradable Thermoplastics: A Review. Polym. Rev. 2018, 58, 444–494. [Google Scholar] [CrossRef]

- Hubbe, M.A.; Rojas, O.J.; Lucia, L.A. Green modification of surface characteristics of cellulosic materials at the molecular or nano scale: A review. BioResources 2015, 10, 6095–6206. [Google Scholar] [CrossRef]

- An, S.; Ma, X. Properties and structure of poly(3-hydroxybutyrate-co-4-hydroxybutyrate)/wood fiber biodegradable composites modified with maleic anhydride. Ind. Crops Prod. 2017, 109, 882–888. [Google Scholar] [CrossRef]

- Holcapkova, P.; Stloukal, P.; Kucharczyk, P.; Omastova, M.; Kovalcik, A. Anti-hydrolysis effect of aromatic carbodiimide in poly(lactic acid)/wood flour composites. Compos. Part A Appl. Sci. Manuf. 2017, 103, 283–291. [Google Scholar] [CrossRef]

- Gregorova, A.; Sedlarik, V.; Pastorek, M.; Jachandra, H.; Stelzer, F. Effect of Compatibilizing Agent on the Properties of Highly Crystalline Composites Based on Poly(lactic acid) and Wood Flour and/or Mica. J. Polym. Environ. 2011, 19, 372–381. [Google Scholar] [CrossRef]

- Lv, S.; Gu, J.; Tan, H.; Zhang, Y. Modification of wood flour/PLA composites by reactive extrusion with maleic anhydride. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Takatani, M.; Ikeda, K.; Sakamoto, K.; Okamoto, T. Cellulose esters as compatibilizers in wood/poly(lactic acid) composite. J. Wood Sci. 2008, 54, 54–61. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds are not available from the authors. |

| Sample | Tm (°C) | Tc (°C) | Hm (J/g) | Hc (J/g) | χc (%) | ρ (g/cm3) | ρ * (g/cm3) |

|---|---|---|---|---|---|---|---|

| PBS | 114.2 | 75.3 | 75.1 | 72.9 | 68.0 | 1.365 | - |

| MCC | 117.5 | 79.4 | 21.4 | 19.8 | 64.6 | 1.370 | 0.947 |

| MAH | 114.7 | 83.6 | 16.9 | 20.4 | 51.0 | 1.362 | 0.925 |

| PMDI | 111.3 | 86.2 | 15.8 | 16.0 | 47.6 | 1.336 | 0.851 |

| CDI | 113.1 | 83.4 | 15.6 | 16.8 | 47.1 | 1.315 | 0.791 |

| EST | 114.8 | 81.8 | 19.2 | 18.2 | 57.9 | 1.385 | 0.990 |

| PHA | 115.3 | 80.0 | 18.5 | 20.3 | 55.8 | 1.402 | 1.038 |

| APTMS | 115.2 | 81.3 | 17.3 | 20.2 | 52.2 | 1.385 | 0.990 |

| Sample | Description |

|---|---|

| PBS | Neat polymer |

| MCC | Microcrystalline cellulose |

| MAH | Maleic acid anhydride |

| PMDI | Polymeric diphenylmethane diisocyanate |

| CDI | Carbodiimide |

| EST | Aliphatic ester |

| PHA | Polyhydroxyamide |

| APTMS | (3-Aminopropyl) trimethoxysilane |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Platnieks, O.; Gaidukovs, S.; Barkane, A.; Gaidukova, G.; Grase, L.; Thakur, V.K.; Filipova, I.; Fridrihsone, V.; Skute, M.; Laka, M. Highly Loaded Cellulose/Poly (butylene succinate) Sustainable Composites for Woody-Like Advanced Materials Application. Molecules 2020, 25, 121. https://doi.org/10.3390/molecules25010121

Platnieks O, Gaidukovs S, Barkane A, Gaidukova G, Grase L, Thakur VK, Filipova I, Fridrihsone V, Skute M, Laka M. Highly Loaded Cellulose/Poly (butylene succinate) Sustainable Composites for Woody-Like Advanced Materials Application. Molecules. 2020; 25(1):121. https://doi.org/10.3390/molecules25010121

Chicago/Turabian StylePlatnieks, Oskars, Sergejs Gaidukovs, Anda Barkane, Gerda Gaidukova, Liga Grase, Vijay Kumar Thakur, Inese Filipova, Velta Fridrihsone, Marite Skute, and Marianna Laka. 2020. "Highly Loaded Cellulose/Poly (butylene succinate) Sustainable Composites for Woody-Like Advanced Materials Application" Molecules 25, no. 1: 121. https://doi.org/10.3390/molecules25010121

APA StylePlatnieks, O., Gaidukovs, S., Barkane, A., Gaidukova, G., Grase, L., Thakur, V. K., Filipova, I., Fridrihsone, V., Skute, M., & Laka, M. (2020). Highly Loaded Cellulose/Poly (butylene succinate) Sustainable Composites for Woody-Like Advanced Materials Application. Molecules, 25(1), 121. https://doi.org/10.3390/molecules25010121