The Efficiency of Biobased Carbonization Agent and Intumescent Flame Retardant on Flame Retardancy of Biopolymer Composites and Investigation of Their Melt-Spinnability

Abstract

:1. Introduction

2. Results

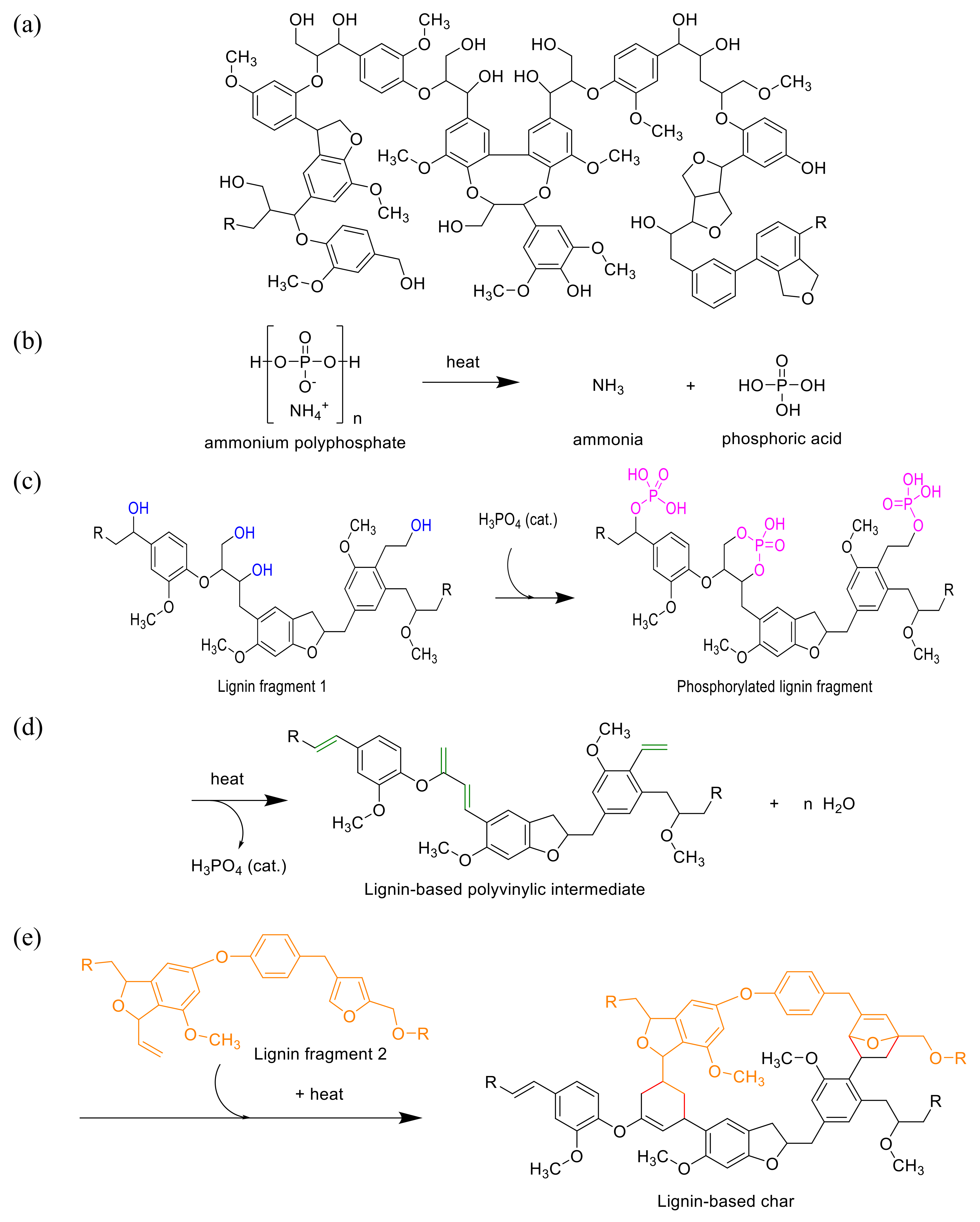

2.1. Mechanism of Intumescence

2.2. Limiting Oxygen Index and UL-94 Vertical Burning Test

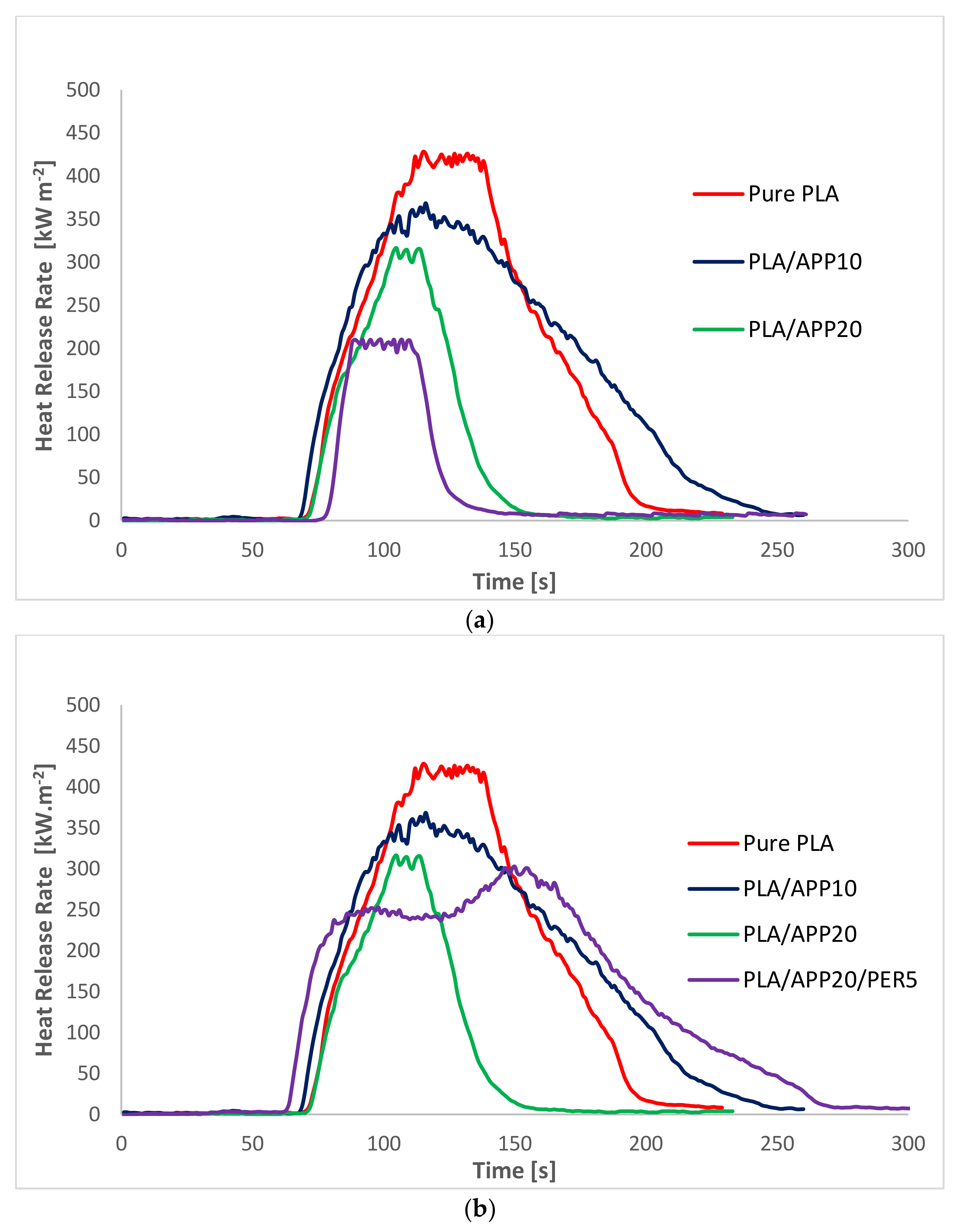

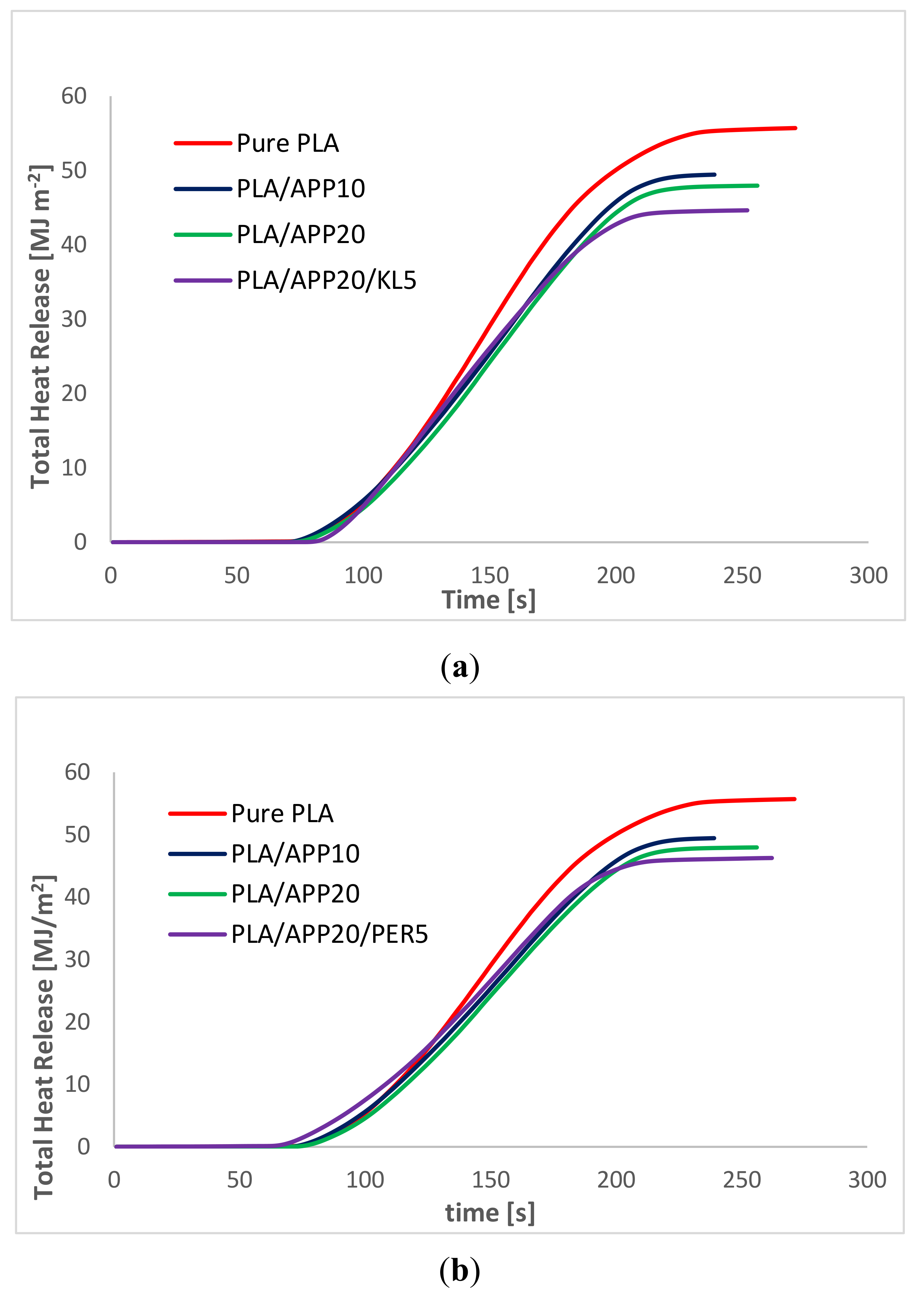

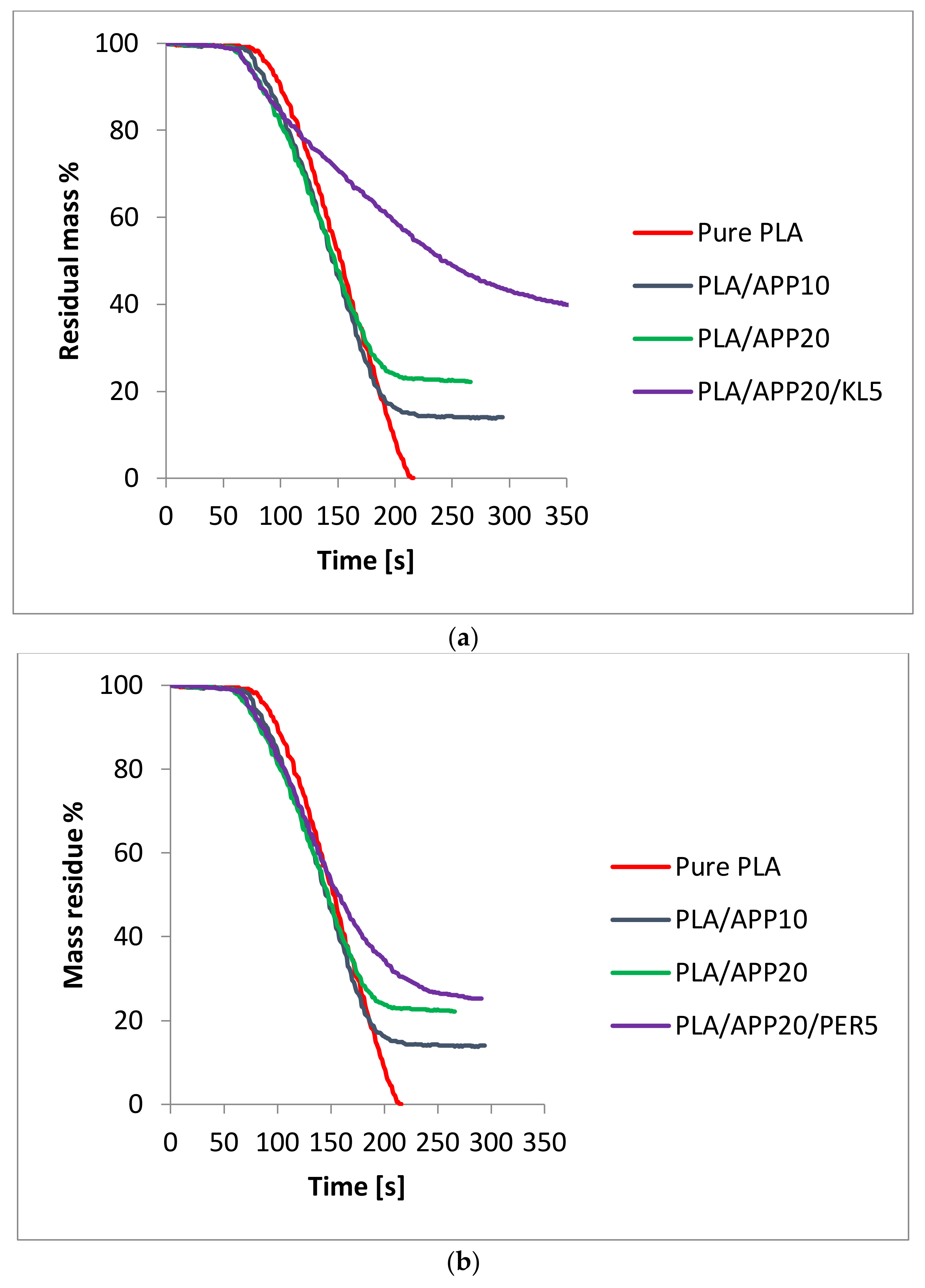

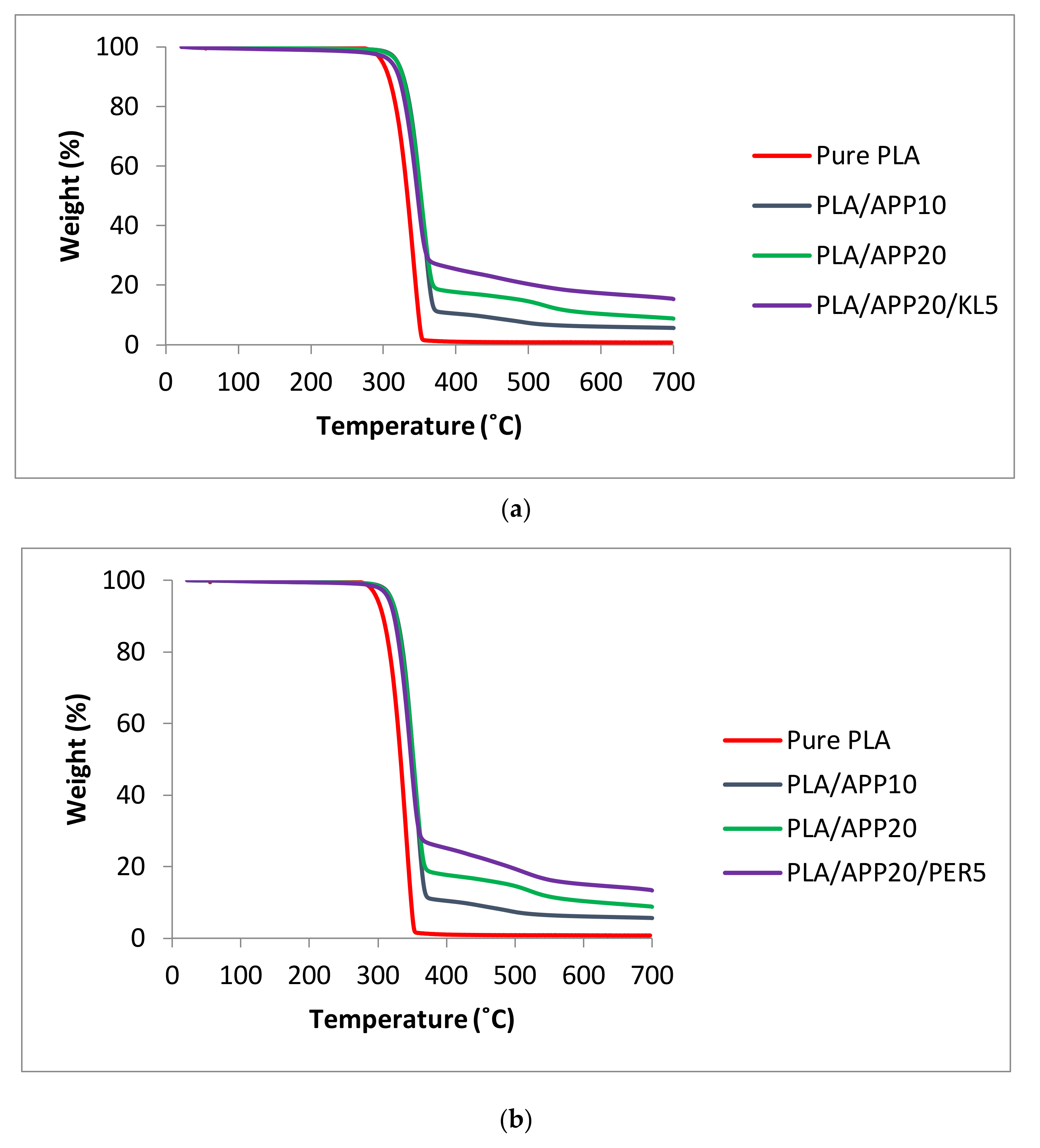

2.3. Cone Calorimetry

2.4. Energy Dispersive X-ray Spectrometry

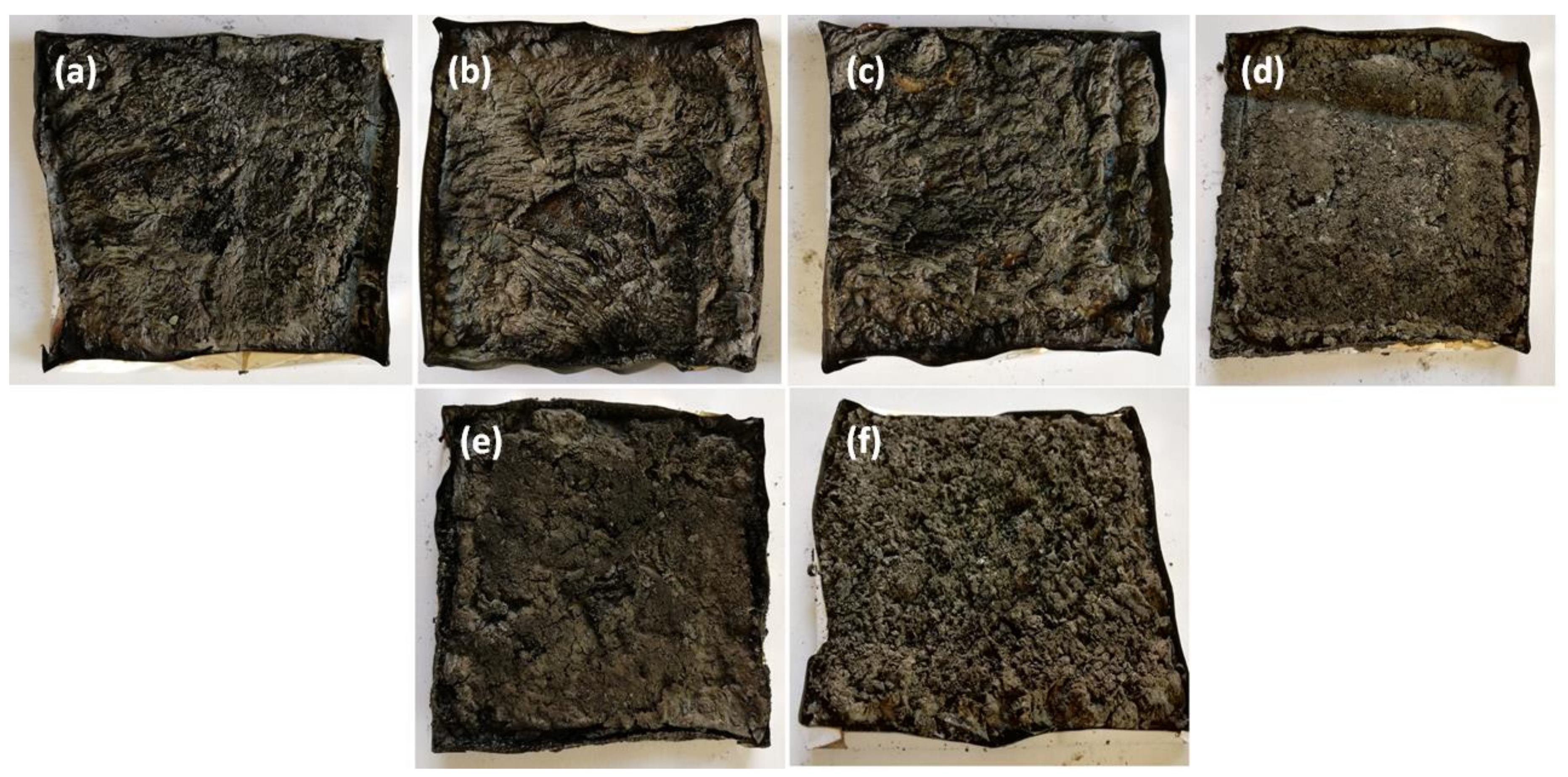

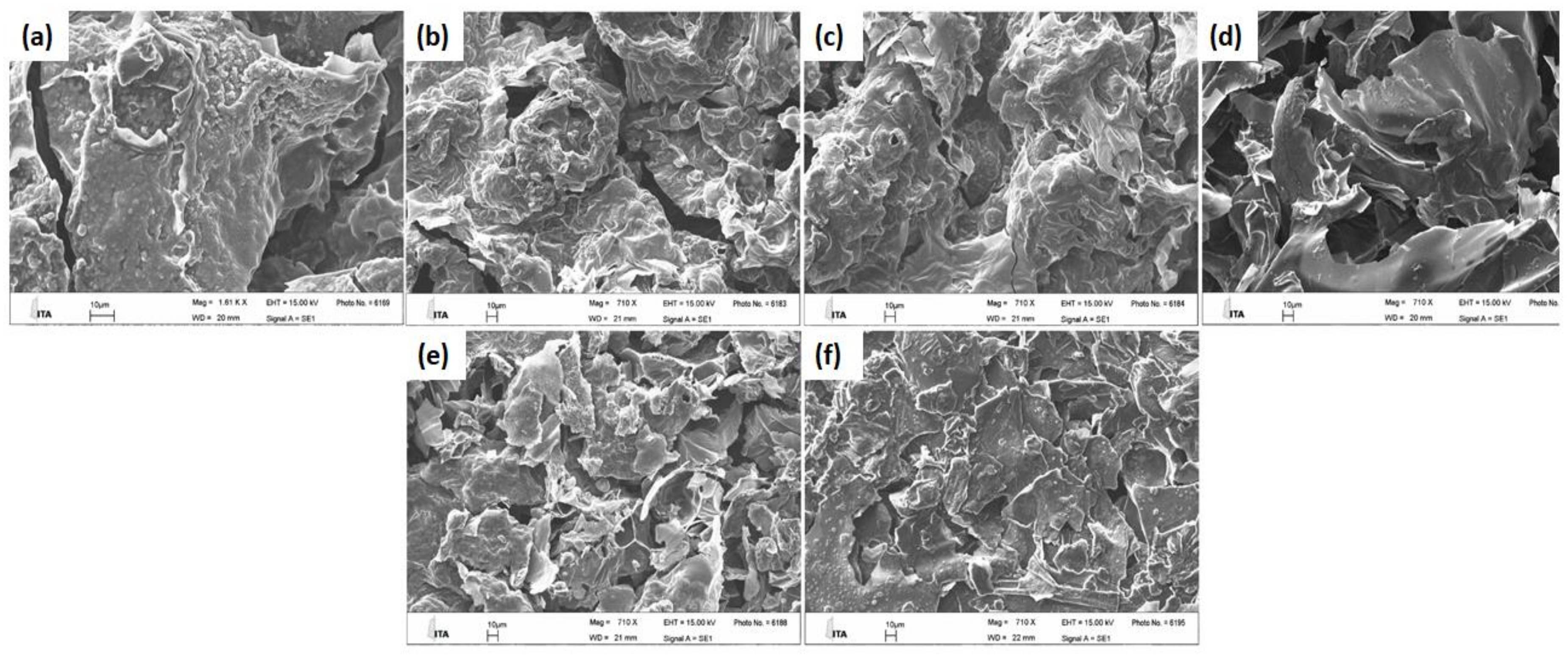

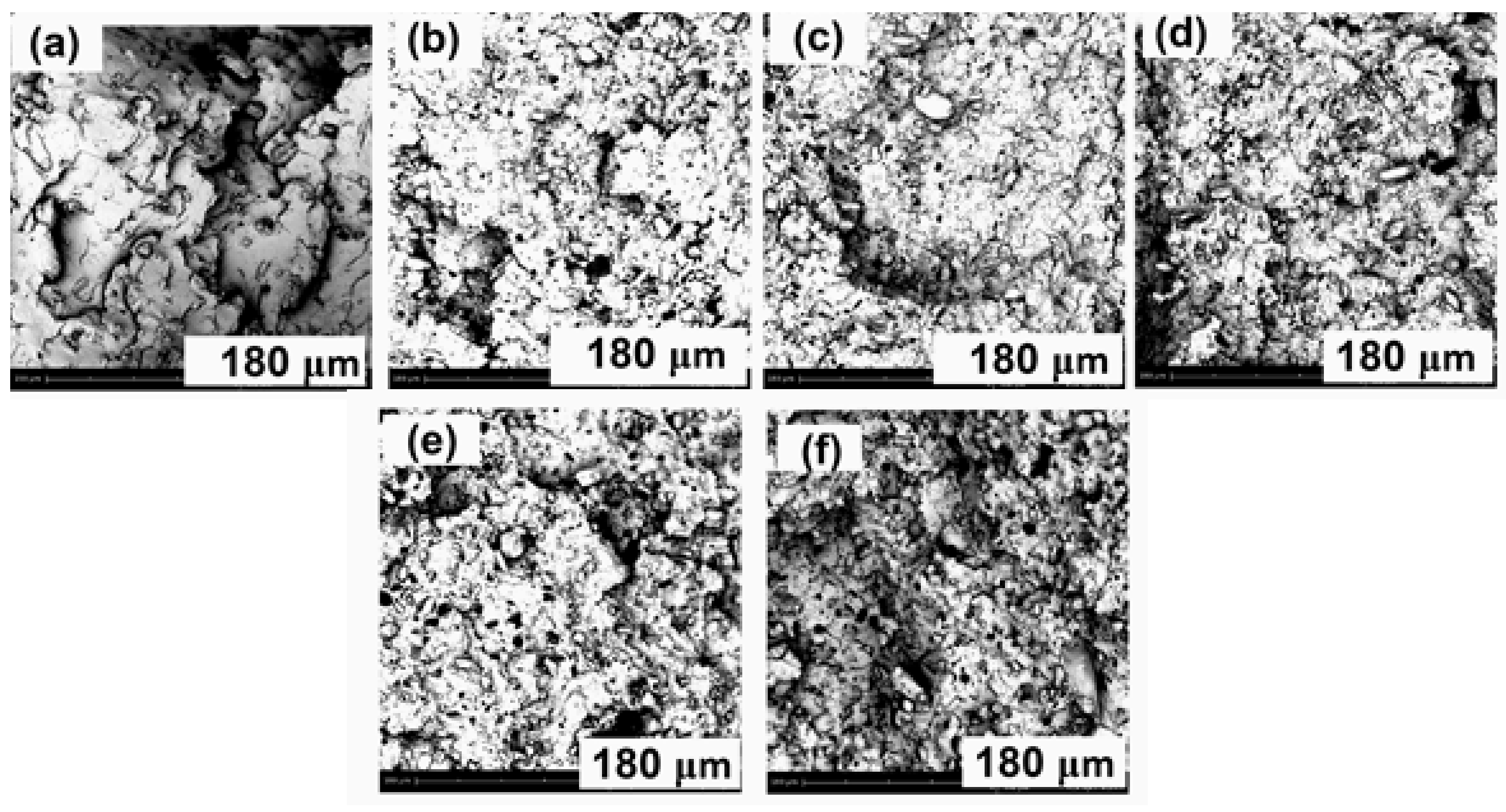

2.5. Scanning Electron Microscopy

2.6. Thermogravimetric Analysis

3. Discussion

4. Materials and Methods

4.1. Materials

4.2. Preparation of PLA/IFR Composites

4.3. Thermogravimetric Analysis

4.4. Scanning Electron Microscopy

4.5. Limiting Oxygen Index and UL-94 Vertical Burning Tests

4.6. Cone Calorimetry Test

4.7. Mechanical Testing of Multifilament Yarns

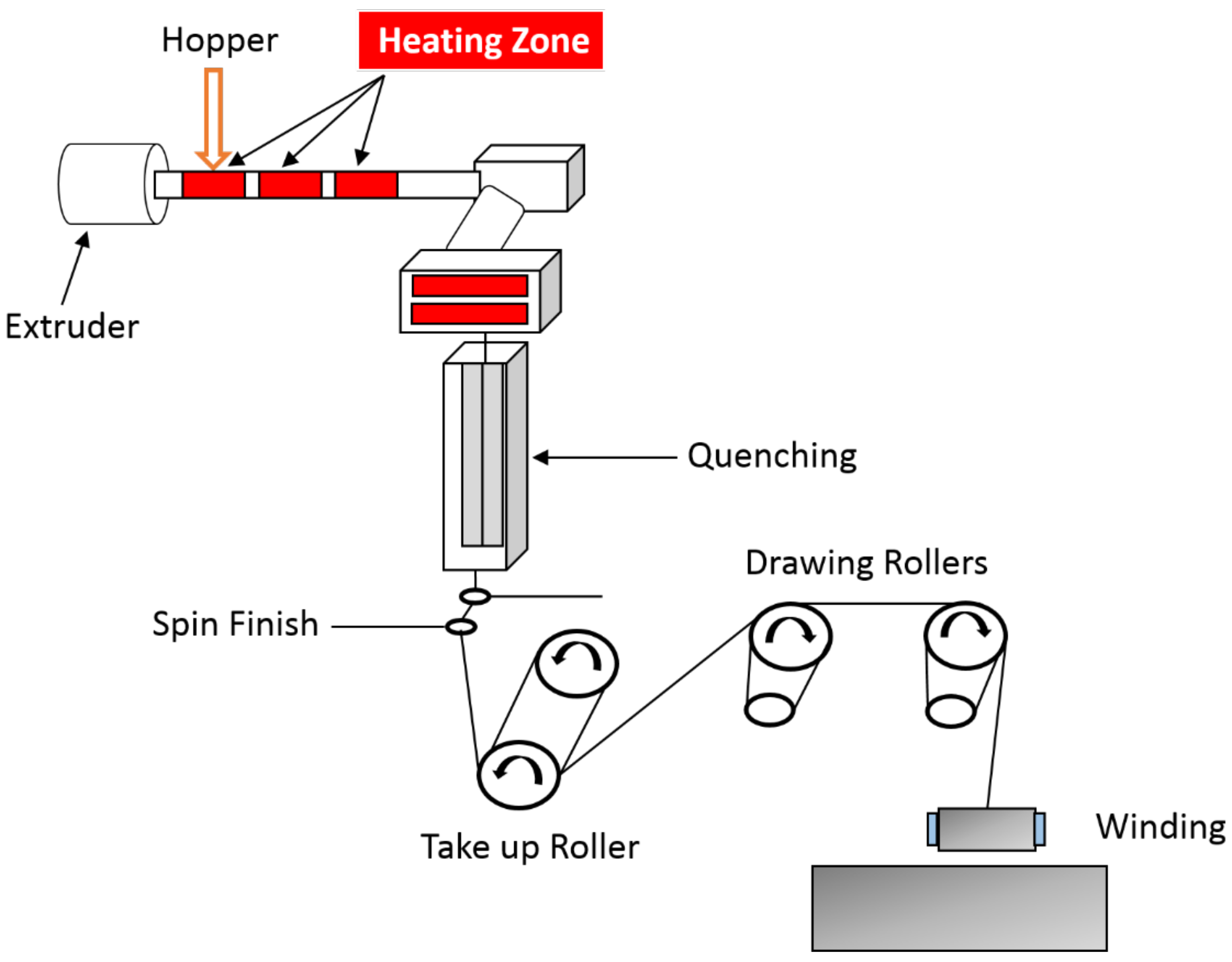

4.8. Melt Spinning of IFR Composites

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Al-itry, R.; Lamnawar, K.; Maazouz, A. Improvement of thermal stability, rheological and mechanical properties of PLA, PBAT and their blends by reactive extrusion with functionalized epoxy. Polym. Degrad. Stab. 2012, 97, 1898–1914. [Google Scholar] [CrossRef]

- Hussain, T.; Tausif, M.; Ashraf, M. A review of progress in the dyeing of eco-friendly aliphatic polyester- based polylactic acid fabrics. J. Clean. Prod. 2015, 108, 476–483. [Google Scholar] [CrossRef]

- Armentano, I.; Bitinis, N.; Fortunati, E.; Mattioli, S.; Rescignano, N.; Verdejo, R.; Lopez-manchado, M.A.; Kenny, J.M. Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog. Polym. Sci. 2013, 38, 1720–1747. [Google Scholar] [CrossRef]

- Martin, J.A. An effect of lactic acid oligomers on the barrier properties of polylactide. J. Mater. Sci. 2014, 49, 2975–2986. [Google Scholar] [CrossRef]

- Cheng, K.C. Flammability and tensile properties of polylactide nanocomposites with short carbon fibers. J. Mater. Sci. 2015, 50, 1605–1612. [Google Scholar] [CrossRef]

- Nofar, M.; Park, C.B. Poly (lactic acid) foaming. Prog. Polym. Sci. 2014, 39, 1721–1741. [Google Scholar] [CrossRef]

- Cheng, X.; Guan, J.; Tang, R.; Liu, K. Improvement of flame retardancy of poly (lactic acid) nonwoven fabric with a phosphorus- containing flame retardant. J. Ind. Text. 2015, 1–12. [Google Scholar] [CrossRef]

- Rhim, J.; Park, H.; Ha, C. Bio-nanocomposites for food packaging applications. Prog. Polym. Sci. 2013, 38, 1629–1652. [Google Scholar] [CrossRef]

- Fukushima, K.; Murariu, M.; Camino, G.; Dubois, P. Effect of expanded graphite/layered-silicate clay on thermal, mechanical and fire retardant properties of poly(lactic acid). Polym. Degrad. Stab. 2010, 95, 1063–1076. [Google Scholar] [CrossRef]

- Uddin, F. Flame-retardant fibrous materials in an aircraft. J. Ind. Text. 2016, 45, 1128–1169. [Google Scholar] [CrossRef]

- Lin, H.J.; Liu, S.R.; Han, L.J.; Wang, X.M.; Bian, Y.J.; Dong, L.S. Effect of a phosphorus-containing oligomer on flame-retardant, rheological and mechanical properties of poly (lactic acid). Polym. Degrad. Stab. 2013, 98, 1389–1396. [Google Scholar] [CrossRef]

- Lin, H.; Han, L.; Dong, L. Thermal degradation behavior and gas phase flame-retardant mechanism of polylactide/PCPP blends. J. Appl. Polym. Sci. 2014, 131, 1–11. [Google Scholar] [CrossRef]

- Mngomezulu, M.E.; Luyt, A.S.; John, M.J. Morphology, thermal and dynamic mechanical properties of poly(lactic acid)/expandable graphite (PLA/EG) flame retardant composites. J. Thermoplast. Compos. Mater. 2017, 1–19. [Google Scholar] [CrossRef]

- Murariu, M.; Bonnaud, L.; Yoann, P.; Fontaine, G.; Bourbigot, S.; Dubois, P. New trends in polylactide (PLA)-based materials: “Green” PLA-Calcium sulfate (nano)composites tailored with flame retardant properties. Polym. Degrad. Stab. 2010, 95, 374–381. [Google Scholar] [CrossRef]

- Atabek Savas, L.; Mutlu, A.; Dike, A.S.; Tayfun, U.; Dogan, M. Effect of carbon fiber amount and length on flame retardant and mechanical properties of intumescent polypropylene composites. J. Compos. Mater. 2017, 1–12. [Google Scholar] [CrossRef]

- Depeng, L.; Chixiang, L.; Xiulei, J.; Tao, L.; Ling, Z. Synergistic effects of intumescent flame retardant and nano-CaCO 3 on foamability and flame-retardant property of polypropylene composites foams. J. Cell. Plast. 2017, 1–17. [Google Scholar] [CrossRef]

- Duquesne, S.; Samyn, F.; Ouagne, P.; Bourbigot, S. Flame retardancy and mechanical properties of flax reinforced woven for composite applications. J. Ind. Text. 2015, 44, 665–681. [Google Scholar] [CrossRef]

- Wang, D.Y.; Leuteritz, A.; Wang, Y.Z.; Wagenknecht, U.; Heinrich, G. Preparation and burning behaviors of flame retarding biodegradable poly(lactic acid) nanocomposite based on zinc aluminum layered double hydroxide. Polym. Degrad. Stab. 2010, 95, 2474–2480. [Google Scholar] [CrossRef]

- Wang, J.; Ren, Q.; Zheng, W.; Zhai, W. Improved flame-retardant properties of poly(lactic acid) foams using starch as a natural charring agent. Ind. Eng. Chem. Res. 2014, 53, 1422–1430. [Google Scholar] [CrossRef]

- Wang, K.; Wang, J.; Zhao, D.; Zhai, W. Preparation of microcellular poly(lactic acid) composites foams with improved flame retardancy. J. Cell. Plast. 2017, 53, 45–63. [Google Scholar] [CrossRef]

- Qian, Y.; Wei, P.; Jiang, P.; Li, Z.; Yan, Y.; Ji, K. Aluminated mesoporous silica as novel high-effective flame retardant in polylactide. Compos. Sci. Technol. 2013, 82, 1–7. [Google Scholar] [CrossRef]

- Zhan, J.; Song, L.; Nie, S.; Hu, Y. Combustion properties and thermal degradation behavior of polylactide with an effective intumescent flame retardant. Polym. Degrad. Stab. 2009, 94, 291–296. [Google Scholar] [CrossRef]

- Wang, D.Y.; Song, Y.P.; Lin, L.; Wang, X.L.; Wang, Y.Z. A novel phosphorus-containing poly(lactic acid) toward its flame retardation. Polymer 2011, 52, 233–238. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Yang, J.; Hu, Y. Preparation of lignin–silica hybrids and its application in intumescent flame-retardant poly(lactic acid) system. High Perform. Polym. 2012, 24, 738–746. [Google Scholar] [CrossRef]

- Bourbigot, S.; Duquesne, S.; Fontaine, G.; Bellayer, S.; Turf, T.; Samyn, F. Characterization and Reaction to Fire of Polymer Nanocomposites with and without Conventional Flame Retardants. Mol. Cryst. Liq. Cryst. 2008, 486, 37–41. [Google Scholar] [CrossRef]

- Reti, C.; Casetta, M.; Duquesne, S.; Bourbigot, S.; Delobel, R. Flammability properties of intumescent PLA including starch and lignin. Polym. Adv. Technol. 2006, 17, 395–418. [Google Scholar] [CrossRef]

- Zhang, R.; Xiao, X.; Tai, Q.; Huang, H.; Hu, Y. Modification of lignin and its applications as a char agent in intumescent flame retardant polylactic acid. Polym. Eng. Sci. 2012, 2620–2626. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Aguedo, M.; Richel, A.; Brohez, S.; Delvosalle, C.; Dubois, P. Phosphorus and nitrogen derivatization as efficient route for improvement of lignin flame retardant action in PLA. Eur. Polym. J. 2016, 84, 652–667. [Google Scholar] [CrossRef]

- Costes, L.; Laoutid, F.; Brohez, S.; Delvosalle, C.; Dubois, P. Phytic acid – lignin combination : A simple and e ffi cient route for enhancing thermal and fl ame retardant properties of polylactide. Eur. Polym. J. 2017, 94, 270–285. [Google Scholar] [CrossRef]

- Gordobil, O.; Delucis, R.; Egüés, I.; Labidi, J. Kraft lignin as filler in PLA to improve ductility and thermal properties. Ind. Crop. Prod. 2015, 72, 46–54. [Google Scholar] [CrossRef]

- Cayla, A.; Rault, F.; Giraud, S.; Salaün, F.; Fierro, V.; Celzard, A. PLA with intumescent system containing lignin and ammonium polyphosphate for flame retardant textile. Polymers 2016, 8. [Google Scholar] [CrossRef] [PubMed]

- Maqsood, M.; Seide, G. Investigation of the Flammability and Thermal Stability of Halogen-Free Intumescent System in Biopolymer Composites Containing Biobased Carbonization Agent and Mechanism of Their Char Formation. Polymers 2018, 11, 48. [Google Scholar] [CrossRef] [PubMed]

- Teoh, E.L.; Mariatti, M.; Chow, W.S. Thermal and Flame Resistant Properties of Poly (Lactic Acid)/Poly (Methyl Methacrylate) Blends Containing Halogen-free Flame Retardant. Procedia Chem. 2016, 19, 795–802. [Google Scholar] [CrossRef]

- Wei, L.L.; Wang, D.Y.; Chen, H.B.; Chen, L.; Wang, X.L.; Wang, Y.Z. Effect of a phosphorus-containing flame retardant on the thermal properties and ease of ignition of poly(lactic acid). Polym. Degrad. Stab. 2011, 96, 1557–1561. [Google Scholar] [CrossRef]

- Fox, D.M.; Lee, J.; Citro, C.J.; Novy, M. Flame retarded poly(lactic acid) using POSS-modified cellulose. 1. Thermal and combustion properties of intumescing composites. Polym. Degrad. Stab. 2013, 98, 590–596. [Google Scholar] [CrossRef]

- Shabanian, M.; Kang, N.J.; Wang, D.Y.; Wagenknecht, U.; Heinrich, G. Synthesis of aromatic-aliphatic polyamide acting as adjuvant in polylactic acid (PLA)/ammonium polyphosphate (APP) system. Polym. Degrad. Stab. 2013, 98, 1036–1042. [Google Scholar] [CrossRef]

Sample Availability: Samples of the compounds containing PLA/APP/KL are available from the authors. |

| No | Formulations | PLA % (w/w) | APP % (w/w) | KL % (w/w) | LOI% | UL-94 | Dripping |

|---|---|---|---|---|---|---|---|

| 1 | PLA | 100 | 0 | 0 | 20.1 | Failed | Y/Y |

| 2 | PLA/APP5 | 95 | 5 | 0 | 23.2 | V-2 | Y/Y |

| 3 | PLA/APP10 | 90 | 10 | 0 | 25.7 | V-1 | Y/Y |

| 4 | PLA/APP15 | 85 | 15 | 0 | 29.4 | V-1 | N/Y |

| 5 | PLA/APP20 | 80 | 20 | 0 | 33.5 | V-1 | N/Y |

| 6 | PLA/APP20/PER3 | 77 | 20 | 3 | 33.9 | V-1 | N/Y |

| 7 | PLA/APP20/PER5 | 75 | 20 | 5 | 34.4 | V-1 | N/Y |

| 8 | PLA/APP20/KL3 | 77 | 20 | 3 | 36.6 | V-0 | N/N |

| 9 | PLA/APP20/KL5 | 75 | 20 | 5 | 37.8 | V-0 | N/N |

| Formulation | TTI (s) | PHRR (kW m−2) | THR (MJ·m−2) | Residual Mass (%) | TSP (m2·m−2) | EHC (kJ·g−1) |

|---|---|---|---|---|---|---|

| PLA | 63 ± 1.1 | 428 ± 7 | 55.7 ± 0.27 | 0 ± 0.00 | 43 ± 2 | 17.33 ± 1.60 |

| PLA/APP5 | 66 ± 1.4 | 382 ± 6 | 52.1 ± 0.16 | 9 ± 0.03 | 274 ± 13 | 16.10 ± 0.90 |

| PLA/APP10 | 69 ± 2.3 | 361 ± 3 | 49.7 ± 0.22 | 14 ± 0.01 | 230 ± 17 | 16.05 ± 1.22 |

| PLA/APP15 | 72 ± 1.8 | 336 ± 2 | 49.1 ± 0.17 | 17 ± 0.09 | 190 ± 19 | 15.93 ± 1.13 |

| PLA/APP20 | 76 ± 2.8 | 316 ± 8 | 47.9 ± 0.31 | 22 ± 0.04 | 164 ± 9 | 15.46 ± 0.86 |

| PLA/APP20/PER3 | 78 ± 3.4 | 310 ± 9 | 47.5 ± 0.41 | 23 ± 0.05 | 221 ± 23 | 15.13 ± 1.56 |

| PLA/APP20/PER5 | 80 ± 2.9 | 300 ± 7 | 46.4 ± 0.29 | 25 ± 0.07 | 209 ± 17 | 14.62 ± 1.34 |

| PLA/APP20/KL3 | 79 ± 1.1 | 250 ± 4 | 45.0 ± 0.29 | 25 ± 0.05 | 155 ± 21 | 12.68 ± 1.43 |

| PLA/APP20/KL5 | 81 ± 1.4 | 210 ± 6 | 44.6 ± 0.12 | 40 ± 0.03 | 103 ± 14 | 11.72 ± 1.18 |

| No. | Samples | C (wt %) | O (wt %) | P (wt %) | Al (wt %) |

|---|---|---|---|---|---|

| 1 | PLA/APP20 | 21.2 | 40.9 | 34.6 | 3.3 |

| 2 | PLA/APP20/KL3 | 34.9 | 38.0 | 26.6 | 0.5 |

| 3 | PLA/APP20/KL5 | 37.7 | 34.2 | 26.4 | 1.7 |

| No | Formulations | T5 (°C) | T50 (°C) | Residue at 700 °C (%, w/w) |

|---|---|---|---|---|

| 1 | PLA | 298 | 333 | 0 |

| 2 | PLA/APP5 | 310 | 343 | 3.54 |

| 3 | PLA/APP10 | 318 | 351 | 5.63 |

| 4 | PLA/APP15 | 320 | 355 | 8.16 |

| 5 | PLA/APP20 | 328 | 358 | 8.78 |

| 6 | PLA/APP20/PER3 | 329 | 360 | 10.63 |

| 7 | PLA/APP20/PER5 | 328 | 365 | 13.20 |

| 8 | PLA/APP20/KL3 | 330 | 362 | 13.34 |

| 9 | PLA/APP20/KL5 | 330 | 365 | 15.32 |

| Formulations | Tenacity ± (cN/tex) | Elongation at Break ± (%) |

|---|---|---|

| PLA | 17.88 ± 6 | 123.11 ± 23 |

| PLA/APP5 | 14.44 ± 4 | 94.73 ± 21 |

| PLA/APP10 | 13.19 ± 7 | 80.66 ± 14 |

| PLA/APP15 | 10.37 ± 8 | 64.97 ± 13 |

| PLA/APP20 | 9.81 ± 6 | 58.16 ± 24 |

| PLA/APP20/PER3 | 9.33 ± 7 | 55.43 ± 12 |

| PLA/APP20/PER5 | 8.10 ± 5 | 49.56 ± 17 |

| PLA/APP20/KL3 | 8.76 ± 3 | 50.12 ± 11 |

| PLA/APP20/KL5 | 7.43 ± 4 | 45.25 ± 19 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maqsood, M.; Langensiepen, F.; Seide, G. The Efficiency of Biobased Carbonization Agent and Intumescent Flame Retardant on Flame Retardancy of Biopolymer Composites and Investigation of Their Melt-Spinnability. Molecules 2019, 24, 1513. https://doi.org/10.3390/molecules24081513

Maqsood M, Langensiepen F, Seide G. The Efficiency of Biobased Carbonization Agent and Intumescent Flame Retardant on Flame Retardancy of Biopolymer Composites and Investigation of Their Melt-Spinnability. Molecules. 2019; 24(8):1513. https://doi.org/10.3390/molecules24081513

Chicago/Turabian StyleMaqsood, Muhammad, Fabian Langensiepen, and Gunnar Seide. 2019. "The Efficiency of Biobased Carbonization Agent and Intumescent Flame Retardant on Flame Retardancy of Biopolymer Composites and Investigation of Their Melt-Spinnability" Molecules 24, no. 8: 1513. https://doi.org/10.3390/molecules24081513

APA StyleMaqsood, M., Langensiepen, F., & Seide, G. (2019). The Efficiency of Biobased Carbonization Agent and Intumescent Flame Retardant on Flame Retardancy of Biopolymer Composites and Investigation of Their Melt-Spinnability. Molecules, 24(8), 1513. https://doi.org/10.3390/molecules24081513